- Features of ventilation in the kitchen

- Requirements for a basement room with a boiler room

- Additional elements

- Ventilation

- Chimney

- doors

- REQUIREMENTS FOR PLANNING AND DESIGN SOLUTIONS OF A GAS BOILER IN A PRIVATE HOUSE

- Features of installing gas equipment in the basement

- Requirements and rules for installing a gas boiler house in a country house

- Norms of ventilation of a gas boiler room according to SNiP

- What should be the doors in the boiler room

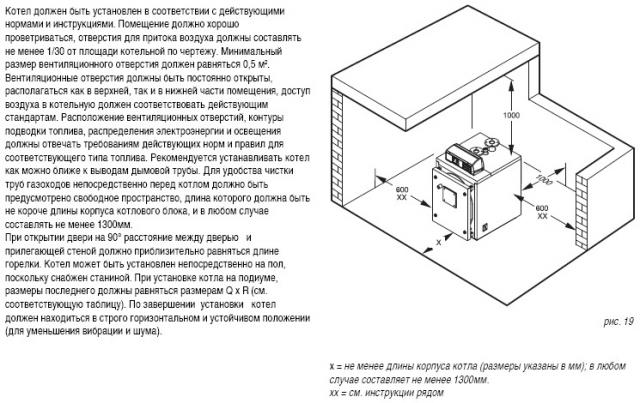

- Boiler installation

- Norms and documents

- Ventilation device

- Glazing material

- Freestanding firebox

- Ventilation for the boiler: its parameters and scheme

- Do I need a window in the boiler room of a private house according to the norms of the Republic of Belarus?

- Ventilation device for a gas boiler house in a private house

- natural ventilation

- Forced

- Conclusions and useful video on the topic

Features of ventilation in the kitchen

Separate requirements apply to air exchange systems in the kitchen. First of all, for rooms where there is a gas stove, it is possible to provide a supply valve with the ability to adjust the volume of passing flows. If the kitchen has a gas boiler, then you can limit yourself to the same valve, but without the ability to adjust the throughput. The same recommendation applies to rooms in which there is a coal stove.It is worth noting that the ventilation of a kitchen with a gas stove is largely determined by the area of \u200b\u200bthe room, as well as the connection with other rooms. For example, under the condition of effective interaction of natural kitchen ventilation with other channels, the need for supply valves may disappear altogether.

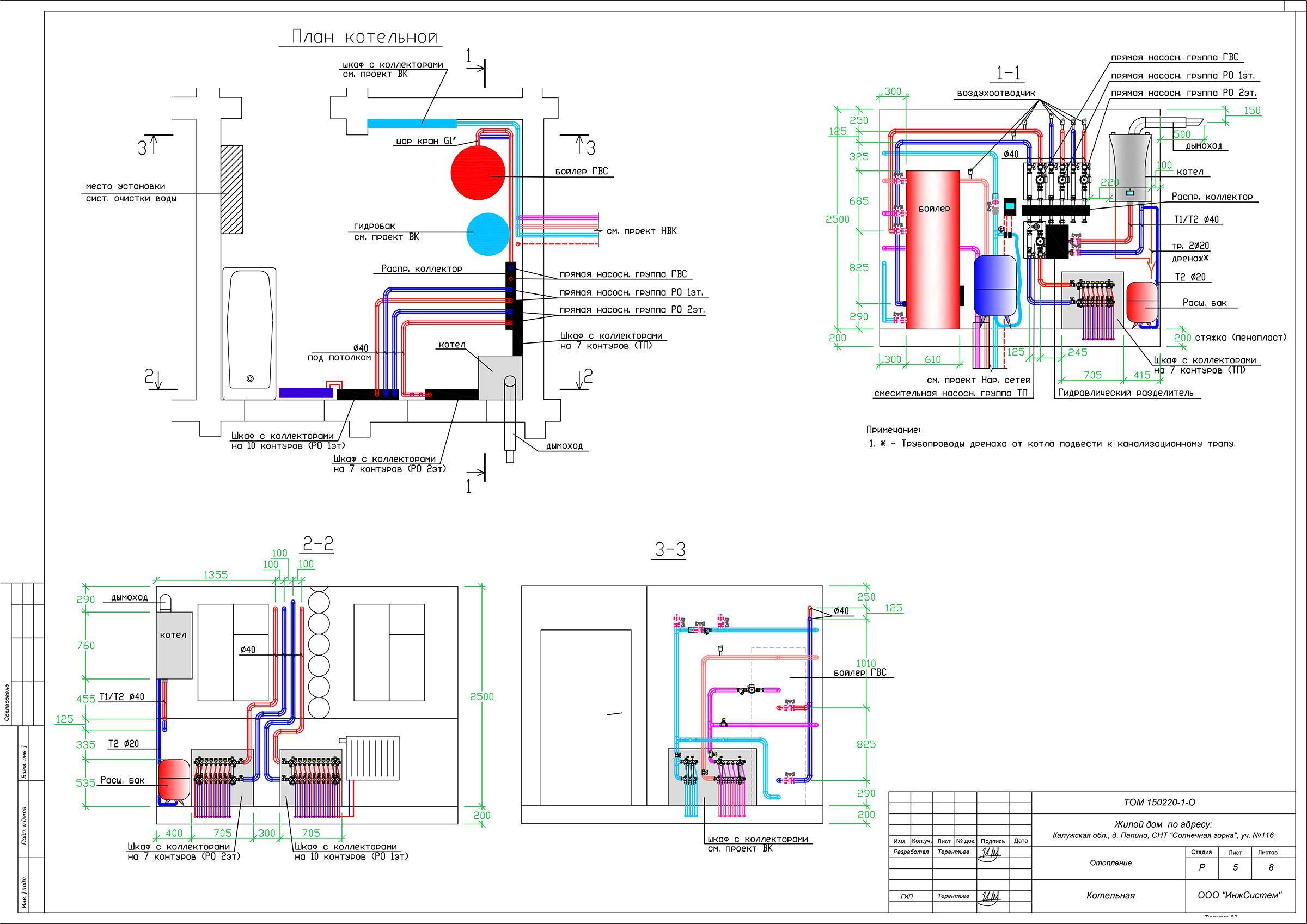

Requirements for a basement room with a boiler room

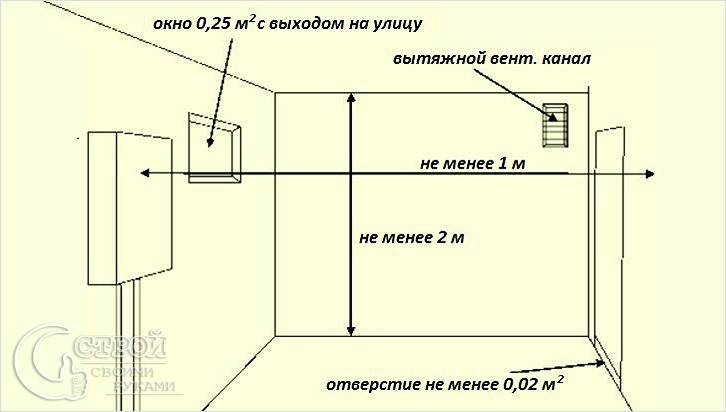

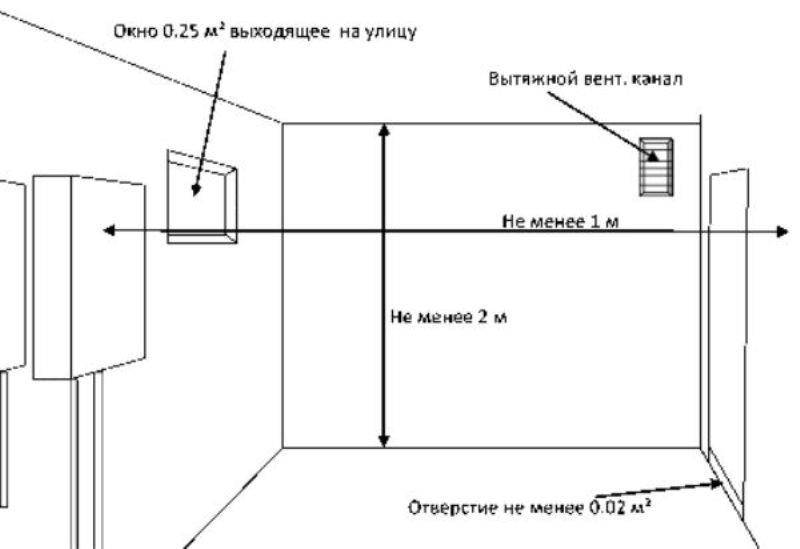

Boiler rooms in the basement of a residential building are subject to certain requirements for arrangement, in accordance with which the following requirements must be met:

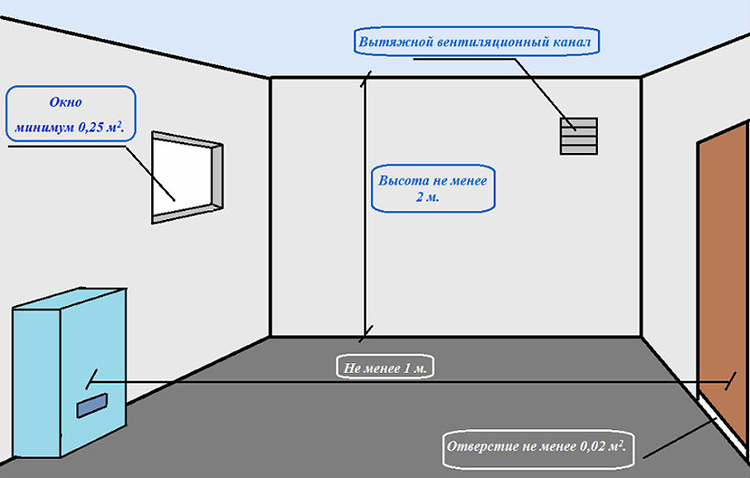

- The room must be more than two meters high. Optimal is 2.5m;

- The boiler room must be isolated from the living rooms of the house, in which the installation of gas equipment is strictly prohibited;

- The placement of one boiler must account for at least 4 square meters of the room, moreover, the system must be located at a distance of one meter from the wall of the building;

- Access to the boiler must be free from any side, so that it can be quickly turned off or repaired;

- The boiler room must have a window with an opening of at least a quarter of a square meter. The recommended size is 0.03 sq.m. per cubic meter of basement;

- The door to the basement should be comfortable and safe, with an opening width of at least 0.8 meters;

- The floor covering can be a cement screed, but not linoleum or laminate. All combustible materials are strictly prohibited. It is recommended to finish the floor with tiles or tiles made of refractory materials;

- All wall and ceiling surfaces must be treated with fire-resistant materials and sheathed with tiles or tiles. If there are things around the boiler room that are vulnerable to burning, they must be covered with special shields with insulation;

- At the entrance to the boiler room, it is necessary to make ventilation ducts, as a rule, pierced at the bottom of the door;

- A boiler room with a gas unit requires the arrangement of a supply and exhaust air exchange system;

- Access to the premises is restricted to unauthorized persons, except for repair teams or maintenance personnel. Children and animals are strictly prohibited from entering the boiler room.

These requirements are dictated for the safety of people living in the house. In addition, this allows you to use the equipment in the most optimal mode. Failure to comply with these requirements leads to fires and accidents, since the small size of the room with a gas boiler is very favorable for the emergence of a fire source and its subsequent spread.

All restrictions on room volumes apply to boilers with an open combustion system. Almost all modern models are equipped with a sealed firebox, but if old equipment is in operation, then the dimensions of the room can be 7.5 cubic meters, 13.5 or 15 cubic meters for boilers with a capacity of 30.30-60 and 60-200 kW, respectively.

All modern models can be located on any volume of the basement, but in the case of location in the basement, it is necessary to equip a separate exit to the street. All outlets are immediately made of refractory materials.

After the building is put into operation, and the boiler room is not equipped, living spaces should not be allocated for these purposes. It is recommended to build a separate building, an extension to a residential building, but in this case it is necessary to provide for all the requirements for the arrangement of the boiler room.

Additional elements

At this point, we stop considering the boiler itself - the main reason for the conversion of the building

But there are some related factors that need to be taken into account. They also have a number of conditions that must be observed.

The main mistake many cottage owners often make is that they focus on the dimensions of the premises and forget that the check may well issue a fine for more prosaic reasons. Next, we will focus on the details that must be taken into account without fail.

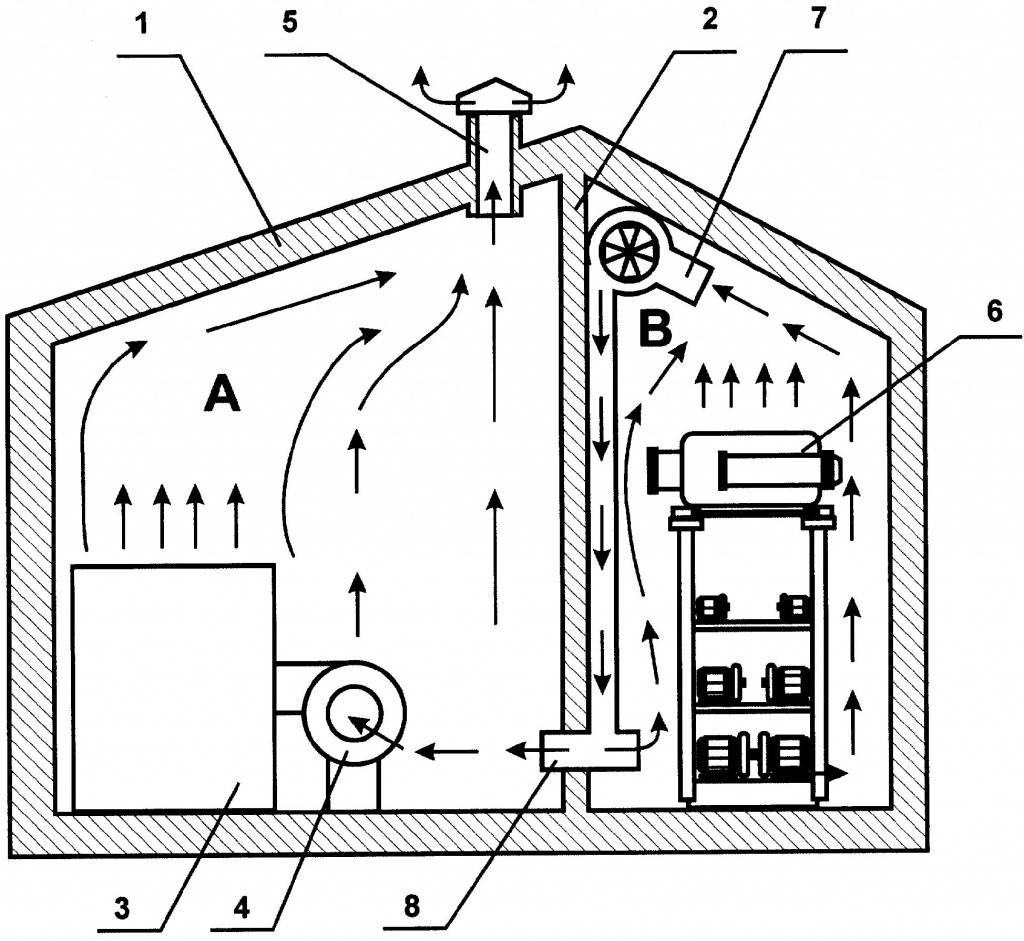

Ventilation

The ventilation system is connected to the smoke outlet. This saves space and resources during construction.

The boiler room must be ventilated, even if the dimensions gas boiler for private house minimum. The limit of up to three complete indoor air cycles every hour must still be reached. That is, a complete air exchange should take place in the time range of 20 minutes.

The only way to avoid such a need is to install electrical equipment.

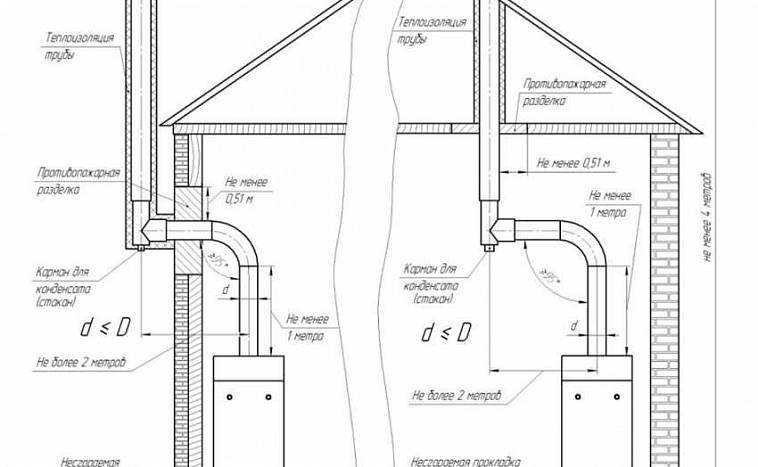

Chimney

Installed if combustion products are present. All rules are quite standard. The diameter of the chimney itself must exceed the pipe

It is important that the chimney outlet is above the roof. That is, it is the highest point

The internal structure does not matter: brick, metal or modular pipe.

doors

As already noted, there should be two of them. One leads to a residential building, the second to the street. Street can be almost anyone. There are requirements only in terms of dimensions, but this already depends on the opening. A tenant can even make it out of wood.

But a fireproof door should lead to the residential part, which can withstand a direct flame for at least 10-20 minutes without any problems. Therefore, only one material is suitable for such a task - metal.

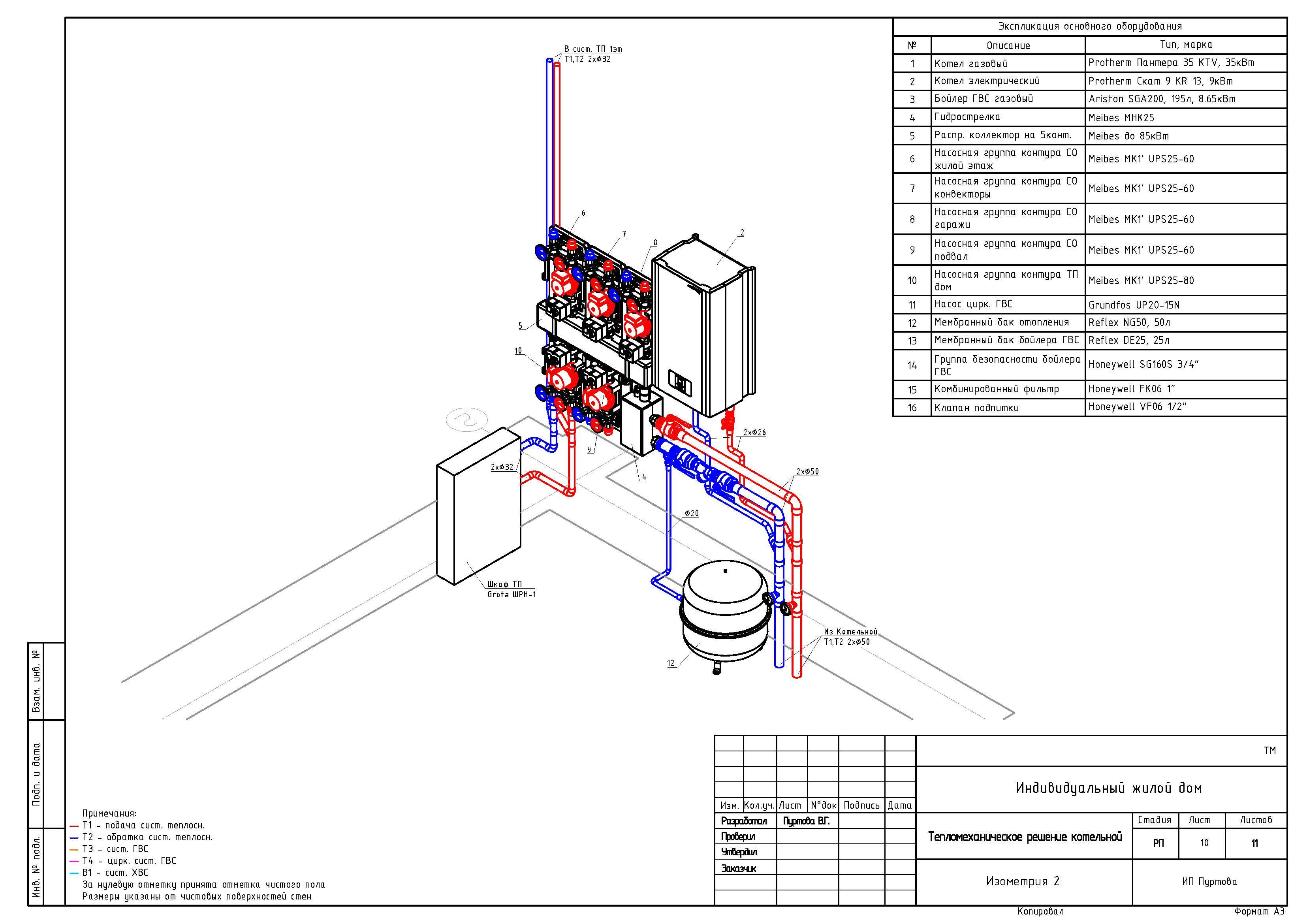

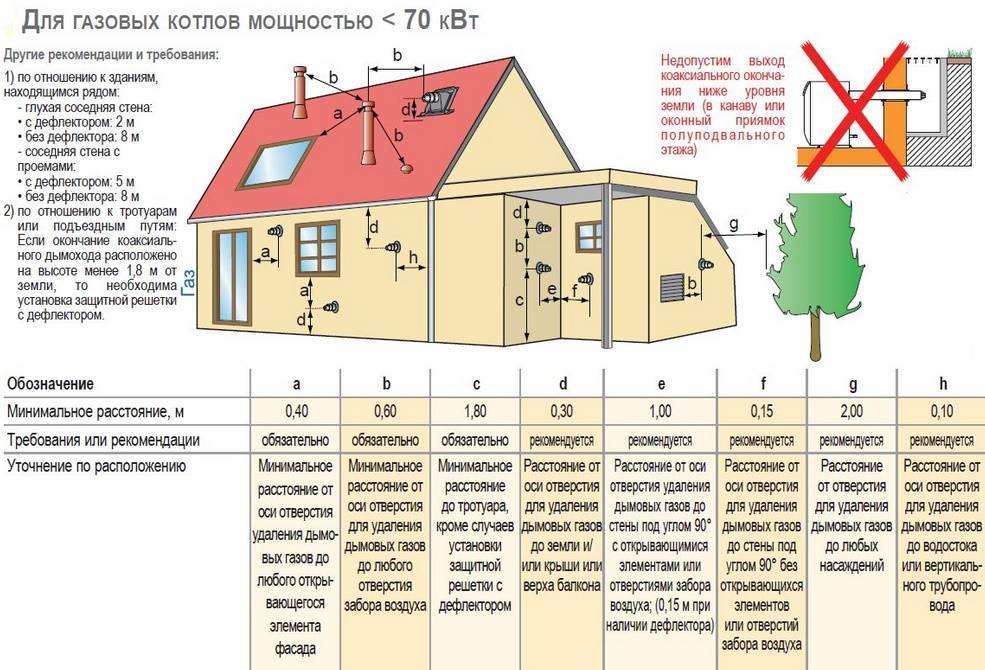

REQUIREMENTS FOR PLANNING AND DESIGN SOLUTIONS OF A GAS BOILER IN A PRIVATE HOUSE

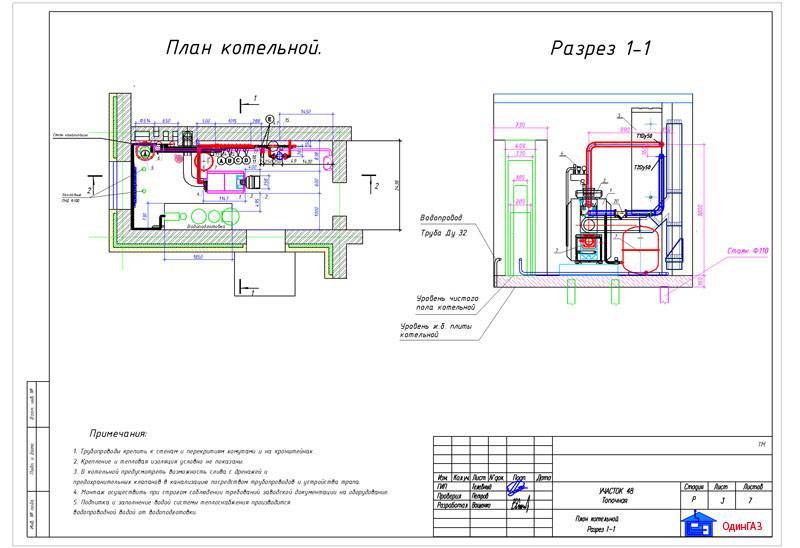

General requirements for gas boiler rooms in private houses, the following conditions are met:

- the height of the room is not less than 2.5 m;

- the premises are designed from the conditions of convenient maintenance of thermal units and auxiliary equipment, but with a volume of at least 15 cubic meters;

- supply and exhaust ventilation is designed on the basis of: exhaust in the volume of 3-fold air exchange of the room per hour, inflow in the exhaust volume plus the amount of air for gas combustion (plus - for boilers with an open combustion chamber);

- the room must be separated from adjacent rooms by enclosing walls with a fire resistance limit of 0.75 h (REI 45), and the limit of fire propagation along the structure must be equal to zero;

- for natural lighting of the room, a window (s) with a total glazing area at the rate of 0.03 sq.m per 1 cubic meter of room volume is required;

- Window openings may be used as easy-to-reset enclosing structures, the glazing of which must be carried out according to the following conditions: the area of an individual glass must be at least 0.8 sq.m with a glass thickness of 3 mm, 1.0 sq.m - with a thickness of 4 mm and 1 .5 sq.m - with a thickness of 5 mm.

In addition to the above requirements for gas boilers located in the premises of the lower floors and in annexes, there are additional requirements:

- Boiler room in a separate room on the first, basement or basement floor should have an exit directly outside.It is allowed to provide a second exit to the utility room, while the door must be a type 3 fireproof door.

- Boiler room in extension to residential building must meet the following requirements:

- the extension should be located at the blind part of the wall of the building with a horizontal distance from the window and door openings of the house at least 1 m;

- the wall of the extension must not be connected to the wall of the residential building.

Features of installing gas equipment in the basement

Placing a gas boiler in the basement is convenient for people living in a private house, but this is not always allowed. The exceptions for a long time were liquefied hydrocarbon gas systems, which were used everywhere for a long time.

Boilers of such a system operate on fuel extracted from oil. As soon as natural gas became widespread and special equipment for residential buildings was produced for it, restrictions on installation in basements were completely removed.

Now the requirements of SNIP allow up to 4 gas units of any type located in the basement, the total power of which should not exceed 200 kW. The degree of security is so high that their location is possible even in the attic.

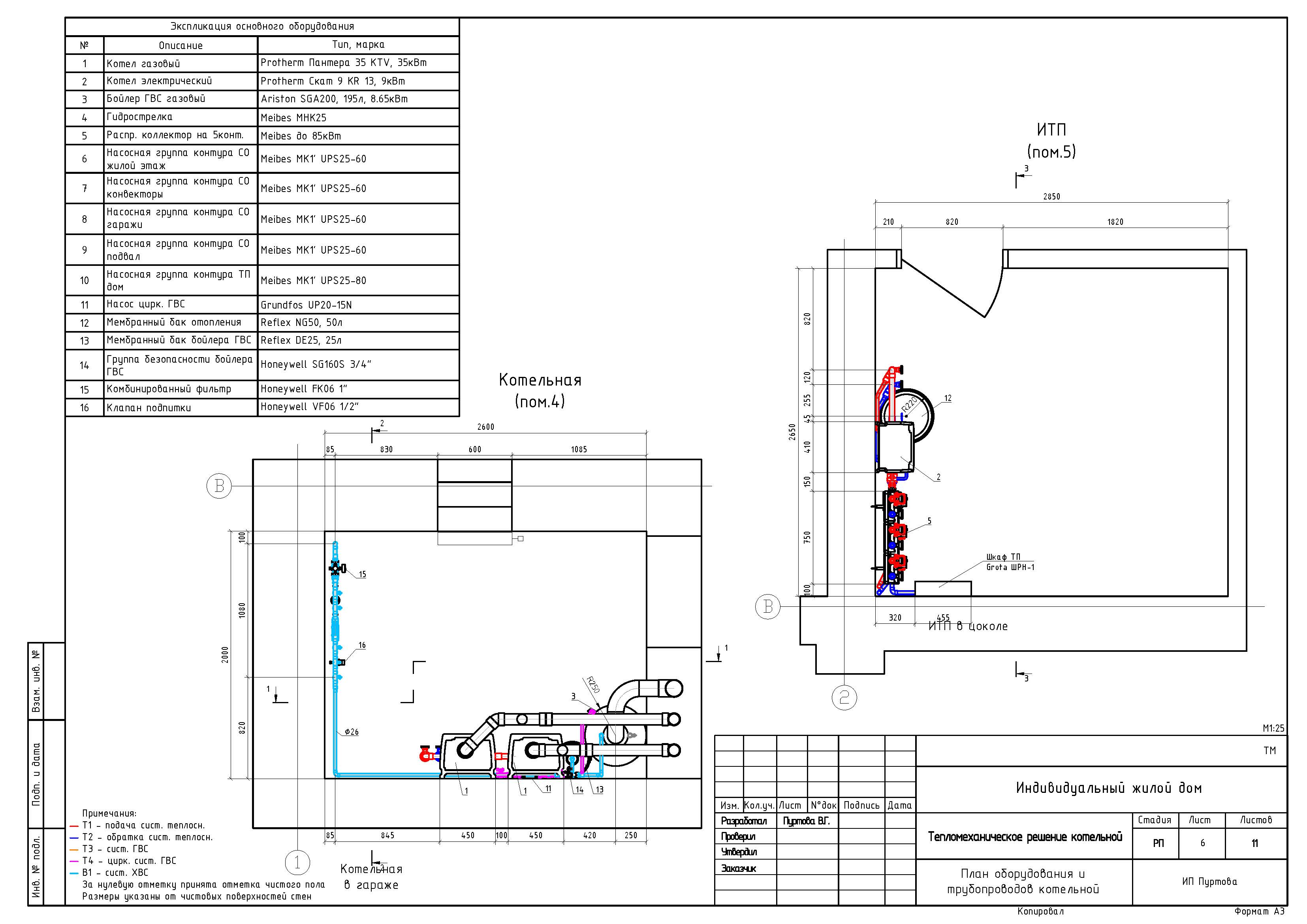

One of the main requirements before starting installation work on the installation of gas equipment is an approved boiler room design. This must be done before starting the system, since its operation is a factor of increased fire hazard, as a result of which it may be prohibited by the fire inspection. In this case, it comes even to the dismantling of the boiler room or the restructuring of the system.

Requirements and rules for installing a gas boiler house in a country house

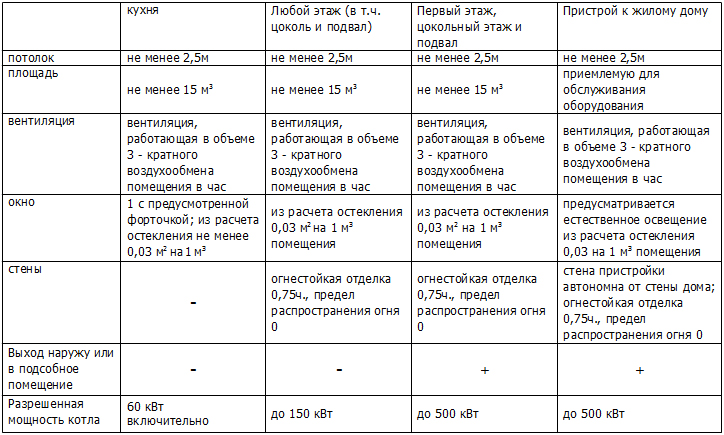

Let's start with the fact that the requirements for the premises of a gas boiler room are distributed by type of premises. So, if the heat output of the boiler is ≤ 30 kW, then it can be installed directly in the house - in the kitchen, for example, in the basement or in the annex. With a heat generator power ≥ 30 kW, it will be necessary to allocate a separate room for it, equipped in accordance with all fire safety rules.

There are separate requirements for boilers installed in kitchens and the main points are listed below:

- If the kitchen is gasified, then its minimum area should not be less than 15 m2, while the ceiling height should not be less than 2.5 meters;

- The kitchen ventilation system or exhaust hood should provide hourly air exchange in the amount of 3-5 kitchen volumes. So, if the room has a volume of 15 m2 x 2.5 m = 37.5 m3, the minimum volume of air moved per hour should be 113 m3;

- Glazing to the kitchen should be such that the proportions of 0.3 m2: 1 m3 are observed, while the window (or windows) must have a window or a swivel frame. To ensure air flow from the street and between rooms, a grate or a gap of any shape with a cross section of ≥ 0.025 m2 is arranged in the lower part of the door leaf.

Additional requirements for a kitchen with gas heating installed in them in terms of fire safety are as follows:

- Under the front door to the kitchen, it is necessary to equip a narrow opening for air exchange with the rest of the rooms in the house;

- The distance from objects made of flammable materials to gas equipment must be at least 10 cm;

- If the load-bearing wall or interior partition is too close to gas appliances, then a metal or other sheet of non-combustible material is mounted between them.

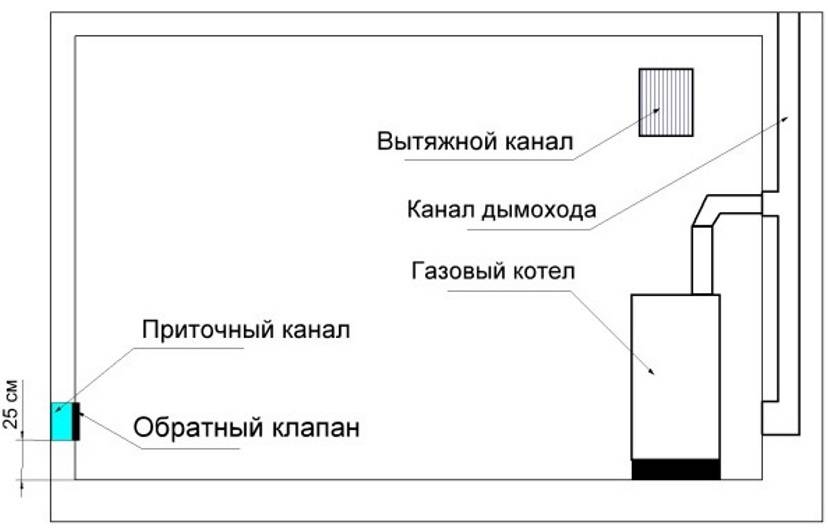

Norms of ventilation of a gas boiler room according to SNiP

All requirements for ventilation of a gas boiler house are set out in SNiP 2.04.05, II-35.

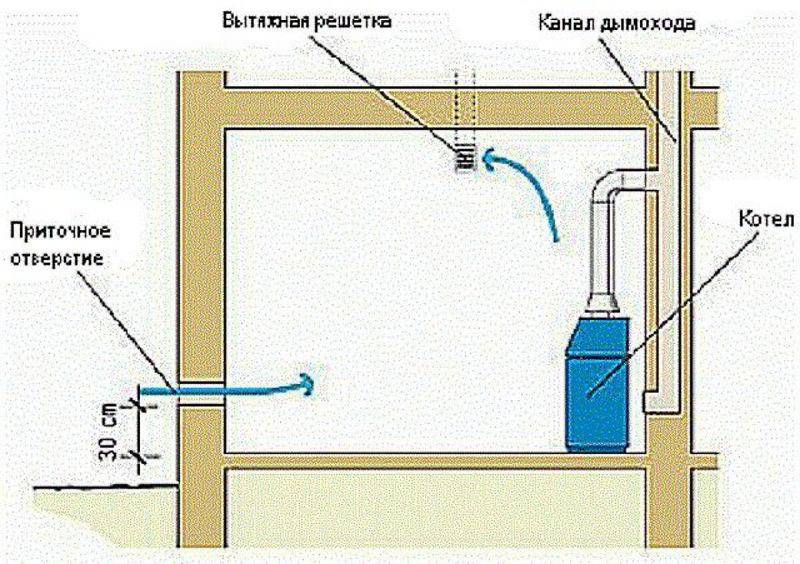

- There must be ventilation in the gas boiler room, the duct outlet is located on the ceiling;

- Near the chimney channel, another one breaks through, 30 cm lower. It serves to clean the chimney;

- The air flow is provided from the street through the ventilation duct or from the adjacent premises through the holes in the lower part of the door;

- The air flow for ventilation is calculated based on the boiler power:

- inflow from the street: for 1 kilowatt of power - from 8 sq. centimeters of products;

- inflow from an adjacent room: for 1 kilowatt of power - from 30 sq. centimeters of products.

The rest of the rules for equipping a boiler room in a private house can be found in the relevant regulatory documents.

What should be the doors in the boiler room

If this is a separate room in a residential building, then the doors leading from the furnace must be fireproof. This means that they must contain the fire for 15 minutes. These requirements are only suitable for those made of metal.

Factory or homemade - not so important, as long as the parameters fit

If there is an exit to the street in the furnace room, there should be unfortified doors. Moreover, in the SNiP it is written "weakly fortified." This is necessary so that during the explosion the box is simply squeezed out by the blast wave. Then the energy of the explosion will be directed to the street, and not to the walls of the house. The second plus of easily “carried out” doors is that gas can freely escape.

Doors to the boiler room are sold immediately with a grate at the bottom

Often, an additional requirement is put in the project - the presence of a hole in the lower part of the door taken by the grate. It is necessary to ensure the flow of air into the room.

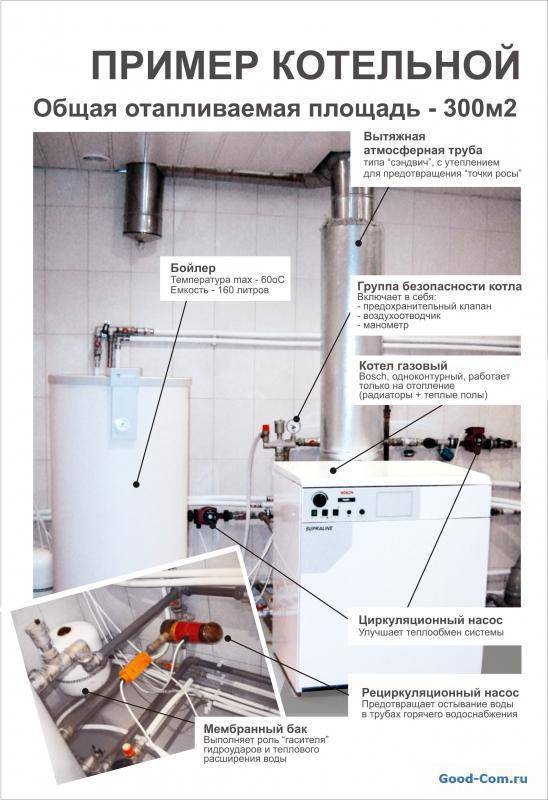

Boiler installation

Installation of any gas equipment is carried out by a gas master, its independent installation is strictly prohibited. The manufacturer attaches the boiler installation diagram to the documentation of the heater, and it will be useful to the installation master.

The equipment of the boiler house will require the intervention of experienced professionals

- When installing the unit in the boiler room, the floors must be properly arranged. They must be made of non-combustible material and have a drain for water. It is necessary for the selection of the coolant from the heating circuit in case of an emergency.

- Installation of gas equipment is not carried out at sub-zero temperatures, it must be at least five degrees Celsius. But even at too high a temperature, it is unsafe to install equipment, so it should not exceed 35 degrees.

- A mark is made on the wall according to the level for the bracket, on which the boiler will then be hung.

- If a double-circuit gas appliance is installed, then a strainer is placed on the return pipe. It is necessary to keep the heat exchanger clean for a long time. Ball valves are placed on both sides of the filter and on the boiler nozzles.

- When connecting the boiler to the gas supply line, a gas meter, a special gas valve, a gas alarm and a thermal shut-off valve are installed in front of it.

- The socket into which the boiler will be connected, if it is volatile, must be grounded.

- When the boiler pipes are connected to the water supply and gas supply, the system must be filled with water. This is done slowly so that air does not stagnate in the future coolant - it will have the opportunity to leave the circuit through the air vents. For the period of filling the system, the boiler must be disconnected from the power supply.

- Before starting the boiler, it is imperative to check the gas pipe connections for gas leaks. This is very simple to do - you need to knock down a thick foam from any detergent and apply it to the connecting elements with a sponge. If there is a leak, then a soap bubble will surely inflate, and if the pipe is tightly connected, the foam will gradually settle. Only after all these manipulations can the system be started by connecting it to the power supply.

Norms and documents

All the above standards are established throughout the Russian Federation, with minor exceptions that depend on the regions. The main documentation is fixed in the joint venture, SNiP and MDS. All instructions are binding. Deviations, especially when there is intent, are administrative in nature. This is not just some kind of oversight, it is an offense, because such a negligent attitude may well endanger the lives of households or neighbors. Therefore, they monitor their performance very responsibly.

When creating a project, as well as when performing specific installation, commissioning and other work, you need to get the help of real professionals. Not local brigades, but licensed companies capable of performing work in accordance with the current requirements of the current legislation.

Ventilation device

Let's ask ourselves, what elements does ventilation for a gas-fired heating boiler consist of? The installation of a ventilation system for a boiler is labor-intensive and complex work and requires strict adherence to the technology of the selected scheme. Only a properly calculated and mounted circuit will function effectively.

Here are the basic requirements for installing ventilation for. It is carried out in this order:

- First of all, all elements of the ventilation system are assembled.

- In places where pipes pass through the building structure, special access elements are equipped to avoid damage.

- Installed thermal insulation. Its presence is mandatory at the joints of chimneys with combustible material of house structures.

Ventilation for a gas boiler in a private house consists of a fairly large number of elements. We list the main ones:

- An adapter connecting the chimney pipe to the outlet pipe of the heating boiler;

- Revision tee fitting to help remove condensate;

- Mounting clamp for walls;

- Pass pipe;

- Channel pipes (telescopic);

- Bends installed near the beginning of the chimney in order to prevent a decrease in draft;

- A conical tip used in a gas boiler chimney.

Heating gas equipment of any brand and design cannot be used without sufficient air exchange. Therefore, ventilation for a gas boiler in a private house is extremely important. There is no place for negligence, Russian “maybe”! It is about human health and life. Failure to comply with the correct selection of the ventilation scheme, its installation, may lead to the penetration of both gas fuel and carbon monoxide into residential premises.The gas is colorless and odorless, although it is deadly to all living organisms.

Moreover, its excess can lead to fire and explosion! The gas boiler room constantly needs special attention and care

The most suitable and safest option is a turbocharged boiler with a double-circuit coaxial output to the outside in any design (floor, wall, etc.). In such air is taken in from the outside and additionally warmed up along the outer radius, since at the same time exhaust is emitted from the boiler along the inner radius.

Experts recommend combining natural and forced ventilation, which, in the event of a power outage, will make it possible to partially replace the operation of the forced system. Also, power supply will not be required if the fans are switched to the energy generated by the windmill on the roof.

Comments:

- The main types of ventilation in a private house and their features

- How to check the ventilation of a gas boiler in a private house?

- Choosing a ventilation system for a private house

- Arrangement of supply ventilation in a private house with a gas boiler

Currently, a lot of homeowners use gas boilers for heating. This allows not only to create a comfortable and cozy atmosphere in the house, but also helps to save money. However, it must be remembered that when using this method of heating, ventilation is necessary in a private house for a gas boiler.

The value of ventilation systems cannot be overestimated. In the absence of adequate ventilation in homes that use natural gas for heating and cooking, occupants may suffer from health and well-being problems.

This is due to the fact that during the combustion of gas, combustion products and water vapor enter the air, and insufficient removal of combustion products leads to insufficient removal of moisture. Increased humidity levels lead to the appearance of mold, which also negatively affects the microclimate of the house and the health of residents. Mold and gas combustion products are especially dangerous for the elderly and people who suffer from lung diseases. Poor ventilation negatively affects the condition of the skin, causing a state of increased fatigue, drowsiness and headaches.

To determine the sanitary and hygienic norm, the capacity of the house, the number of people living and the type of their activity are taken into account. With insufficient air exchange, the air becomes heavy and there is a desire to open windows for ventilation. Because of this, the air temperature inside the house begins to fall and the requirements for heat consumption, which is necessary for heating, increase. From this it should be concluded that air exchange affects not only the sanitary and hygienic condition of the house, but also energy costs. In old houses, the ratio of the amount of heat that is needed for ventilation to the total cost of heating is about 15%. In new homes, this ratio is much higher.

Glazing material

When equipping a window for a gasified boiler room, special requirements are also imposed on the material of the frames. They must be resistant to high temperatures and made of environmentally friendly materials.

For the construction of the window structure, aluminum or metal-plastic is used. The aluminum profile protects the heated compartment from adverse climatic conditions.It provides a reliable seal that prevents the formation of a draft, does not allow the fire to go out in the boiler even with exile gusts of wind outside.

Metal-plastic frames are no less reliable and contribute to the preservation of heat in the furnace.

Plain sheet glass is used as a glazing material. It is also allowed to install double-glazed windows that meet the requirements of GOST and perform the role of easily dropped structures.

Freestanding firebox

Separate boiler room designed for high power units - over 200 kW. But if you need to preserve the architectural appearance of the house, then it makes sense to build such a structure for a lower power boiler.

Modern polymer materials and technologies make it possible to lay underground communications for supplying heated coolant and hot water from the boiler room - a high degree of thermal protection will minimize the loss of thermal energy during the transportation of heated liquid.

A separate boiler room is being built from:

- fire-resistant materials (building blocks of various types, bricks);

- it is allowed to use metal sandwich panels with a non-combustible thermal insulator inside;

- non-combustible roofing material is used;

- reinforced concrete flooring is used for the floor.

Room requirements:

- ceiling height in a separate building should be from 2.5 m;

- when calculating the volume of the room, 0.2 m2 is added to the minimum value (15 m3) for each kilowatt of heat generator power;

- under the boiler weighing more than 200 kg, a foundation is mounted separate from the base of the building, the height of the podium above the floor level is up to 15 cm.

Standard requirements are put forward for doors, ventilation and chimney arrangement.

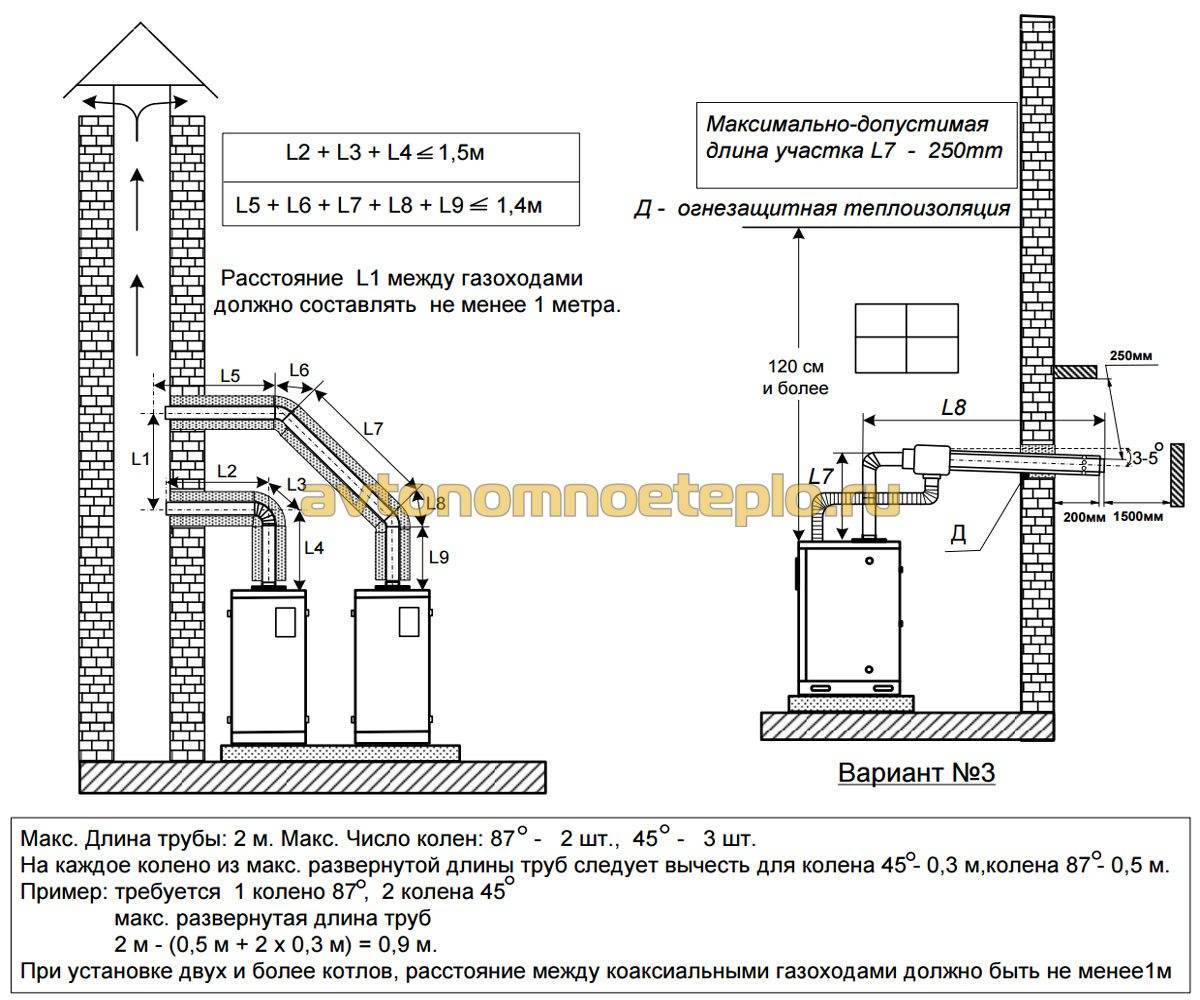

Ventilation for the boiler: its parameters and scheme

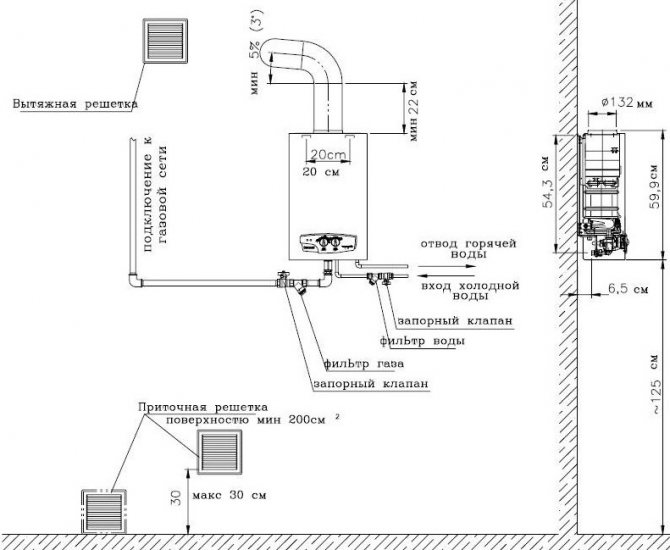

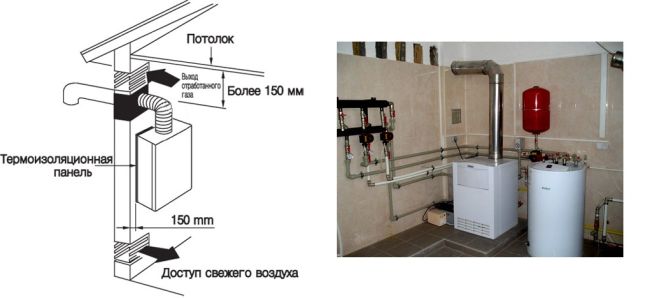

A gas boiler with an insulated combustion chamber is equipped with a coaxial duct. Such a chimney allows you to simultaneously remove smoke and deliver fresh oxygen.

The design consists of two pipes of different diameters, the smaller of which is located inside the large one. Smoke is removed through the inner pipe of a smaller diameter, and fresh oxygen enters through the space between the pipes.

Standards for installing a gas boiler and arranging ventilation:

- One or two gas appliances can be connected to the chimney, no more. This rule applies regardless of distance and location.

- The ventilation duct must be airtight.

- Seams are treated with sealants, the properties of which make it possible to provide insulation under the influence of high temperatures.

- The system must be made of non-combustible materials.

- Horizontal sections of the hood should consist of two channels: one for removing smoke, the second for cleaning.

- The channel intended for cleaning is located below the main one by 25-35 cm.

There are strict requirements for ventilation in terms of dimensions and distances:

- The space from the horizontal pipe to the ceiling is at least 20 cm.

- The walls, floor and ceiling of the room must be made of non-combustible materials.

- At the outlet of the pipe, all combustible materials must be sheathed with a layer of non-combustible insulation.

- The distance from the outer wall, from where the pipe exits, to the end of the chimney should not be less than 30 cm.

- If there is another wall opposite the horizontal pipe, the distance to it should not be less than 60 cm.

- The distance from the ground to the pipe is at least 20 cm.

Ventilation requirements for an open combustion boiler:

- Equipped with a channel for removing smoke.

- A common system is being set up with an efficient supply of the required volumes of oxygen.

Exhaust and supply ventilation for a gas boiler is located in opposite corners, equipped with a check valve. It will provide protection in the event of a violation of the direction of movement of flows, when combustion products will be drawn into the building, and fresh air will go outside.

Dimensional parameters of ventilation are calculated based on the required volumes of gas removal and oxygen supply. The output volumes are equal to three units of the air exchange rate in the room. The air exchange rate is the amount of air passing through the room per unit of time (one hour). The oxygen supply is equal to three units of multiplicity plus the volume absorbed by combustion.

The diameter of the air duct is calculated based on the power of the boiler

An example of calculating the parameters of air exchange:

- Room dimensions: length (i) 3 meters, width (b) 4 meters, height (h) 3 meters. The volume (v) of the room is 36 cubic meters and is calculated by the formula (v = I * b * h).

- The air exchange rate (k) is calculated by the formula k \u003d (6-h) * 0.25 + 3. We consider - k \u003d (6-3) * 0.25 + 3 \u003d 3.75.

- The volume that passes in an hour (V). V = v * k = 36 * 3.75 = 135 cubic meters.

- Cross-sectional area of the hood (S). S = V/(v x t), where t (time) = 1 hour. S \u003d 135 / (3600 x 1) \u003d 0.037 sq. m. The inlet should be of the same size.

The chimney can be equipped in various ways:

- Exit horizontally to the wall.

- Exit to the wall with a bend and rise.

- Vertical exit to the ceiling with a bend.

- Direct vertical exit through the roof.

The ventilation scheme in a private house with a coaxial chimney is as follows:

- gas boiler;

- angular coaxial outlet;

- coaxial pipe;

- condensate drain;

- filter;

- protective grille;

- horizontal and vertical tips;

- roof lining.

Do I need a window in the boiler room of a private house according to the norms of the Republic of Belarus?

The need and size of the window in the boiler room of a private house is regulated by paragraph 21.12 of amendment No. 7 to the above sanitary norms and rules (SNiP) of the Republic of Belarus.

In a room with installed gas boilers for ventilation, it is imperative to provide an opening window that goes outside (to the street) with a minimum area of 0.25 m2.

Important! For heating boilers with a coaxial chimney and a closed combustion chamber, the presence of a window in the furnace room is not necessary. The coaxial chimney for a gas boiler is made according to the "pipe in pipe" principle

The double-circuit design allows you to forcefully remove combustion products and suck in the right amount of atmospheric air into the closed combustion chamber of the heater from the street

The coaxial chimney for a gas boiler is made according to the "pipe in pipe" principle. The double-circuit design allows you to forcefully remove combustion products and suck in the right amount of atmospheric air into the closed combustion chamber of the heating apparatus from the street.

You will learn more about how to properly design the entrances to a private boiler room.

Ventilation device for a gas boiler house in a private house

natural ventilation

This type of ventilation does not involve the use of fans. The exhaust draft is formed by a chimney, which they try to install as high as possible above the roof.

Natural ventilation is most appropriate provided that:

- the heated building is located on a hill;

- there are no taller buildings or tall trees along the perimeter of the building;

- the heat output of the equipment is low and the building of the boiler house is small, i.e. there is no need for a large amount of air.

- The supply channel is located opposite the exhaust. Structurally, it can be a wall valve to the street, window ventilation, door ventilation through slots or a grill in the sash. Depending on the location of the boiler, the appropriate option is selected.

- The air is removed through the intake pipe. The outlet of the pipe is placed on the ceiling of the boiler house building, and the pipe itself must be higher than the roof ridge for full wind blowing and good traction. Sometimes ventilation ducts in private dwellings are placed in the wall. To do this, you need to place the outlet of the pipe as high as possible.

Forced

This type of ventilation is carried out with the help of fans. If the house is small, then only an exhaust fan is allowed, and the inflow can be natural.

The use of a forced ventilation system is necessary in the following cases:

- there is no possibility of summing up the exhaust duct;

- insufficient natural ventilation or poor location of the house (standing in a low area, surrounded by multi-storey buildings or trees);

- use of equipment with high heating capacity, where natural ventilation will not ensure proper operation.

So, supply air can flow naturally, and exhaust ventilation must be mechanical.

Its location may be as follows:

- The pipe is connected to a fan and the air is blown out through the roof or wall.

- The air duct is connected to the ventilation shaft, if any.

The exhaust fan is recommended to be used continuously during high season.

Conclusions and useful video on the topic

For information on how to combine the ventilation system and the hood, see the following video:

The main mistakes in the installation of natural ventilation:

The most difficult stage in the ventilation device is its design. The design of the system must be developed taking into account all the listed norms and requirements determined by the gas services. This will ensure safety for human life and high-performance operation of the equipment.

Have questions, found shortcomings, or can you add valuable information to our material? Please leave your comments, share your experience, ask questions in the block below.