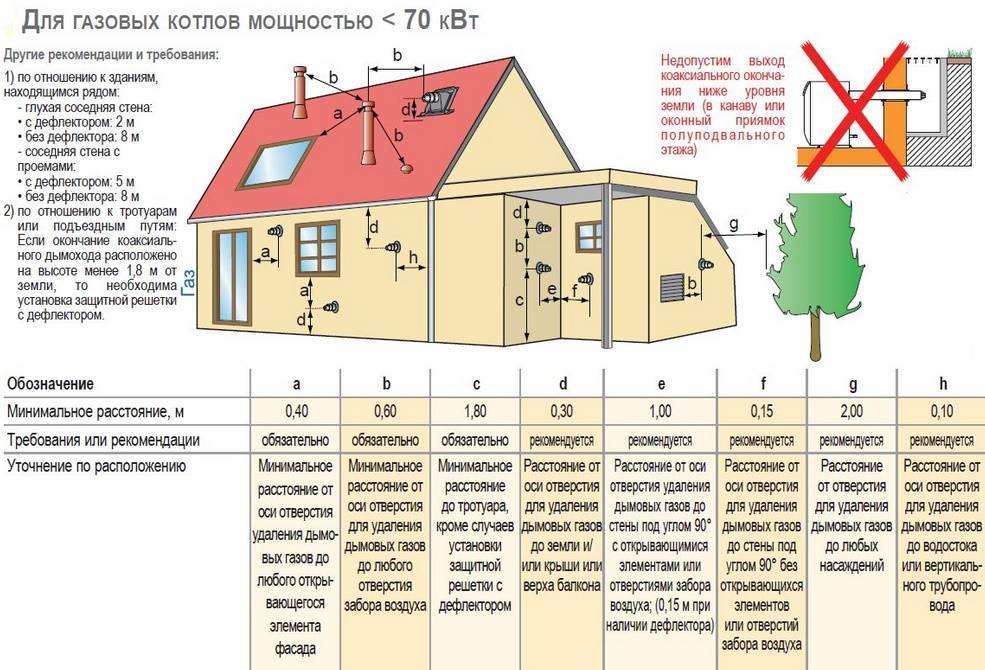

- Installation of exhaust and ventilation

- Norms for private houses

- Conducting a trial run

- Rules and regulations for the installation of gas-fired boilers

- wall

- Outdoor

- Requirements for installing a boiler in an apartment

- Required documents

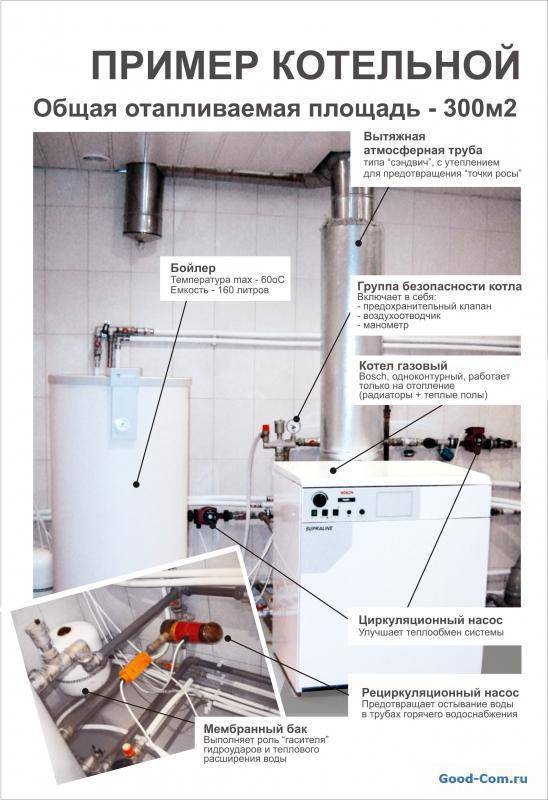

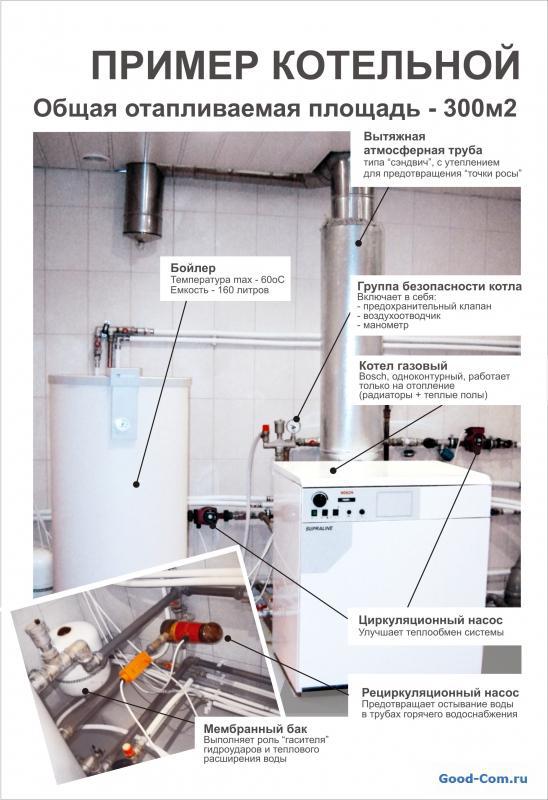

- boiler room requirements

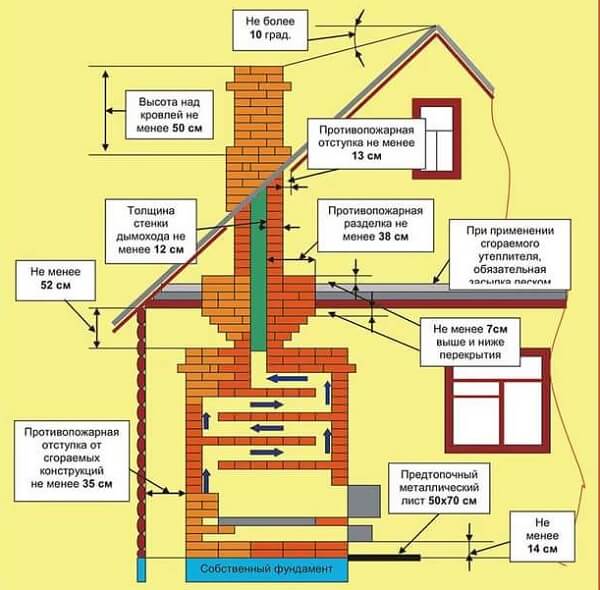

- Chimney installation

- Switching to individual heating: advantages and disadvantages

- Conducting a trial run

- Procedure for replacing an obsolete boiler

- What documents are needed when replacing a gas boiler

- Do I need a new project when replacing a gas boiler

- Features of replacing a boiler of the same power

- Is it possible to replace a gas boiler with an electric one

- Requirements for boiler rooms for the installation of solid and liquid fuel boilers

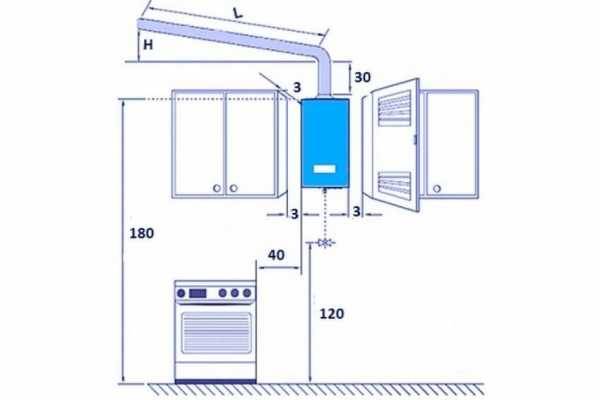

- How to install a wall-mounted boiler

- Where it is possible and where it is impossible to put a gas boiler

- Timing

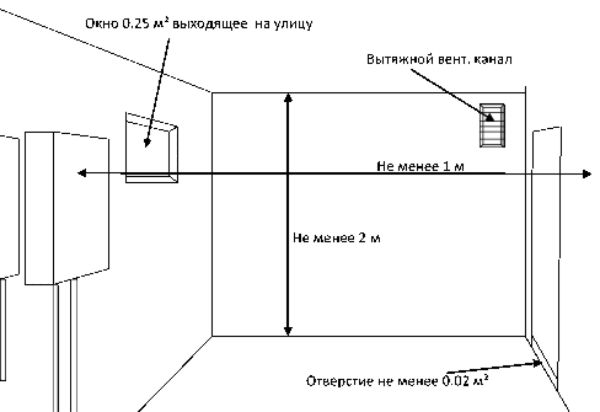

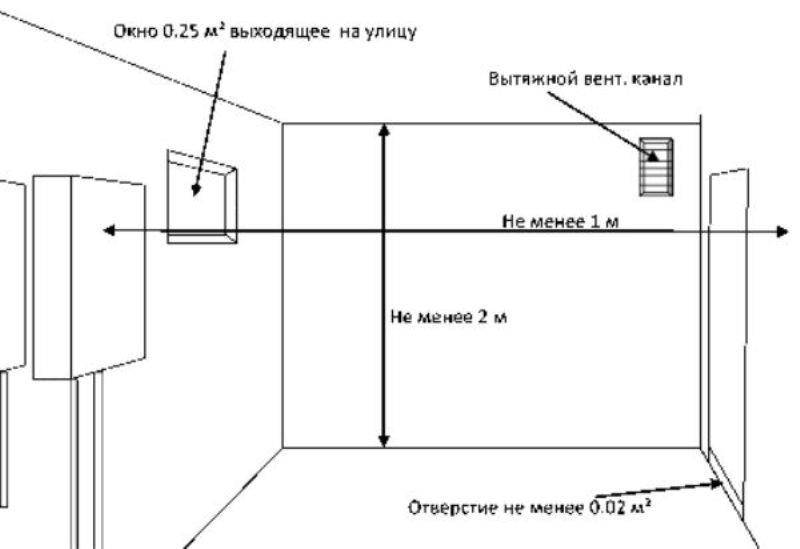

- Ventilation

- boiler room requirements

- Conclusions and useful video on the topic

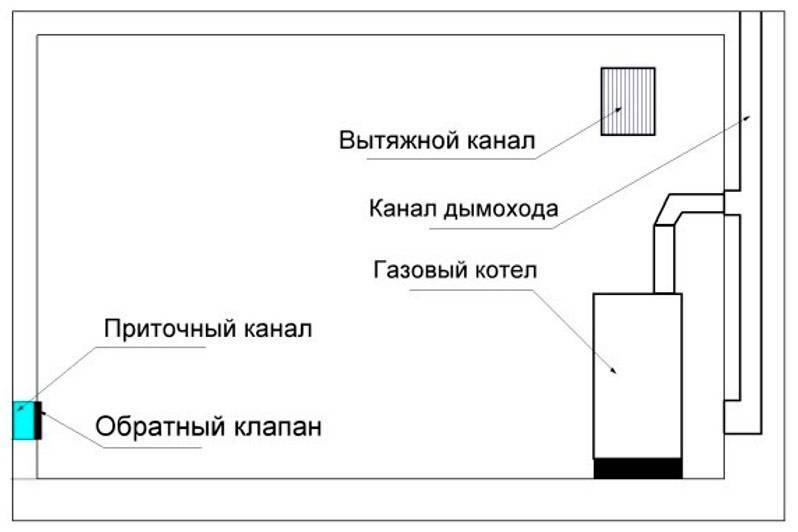

Installation of exhaust and ventilation

Safety measures require that forced ventilation be made in the room where the boiler is installed.

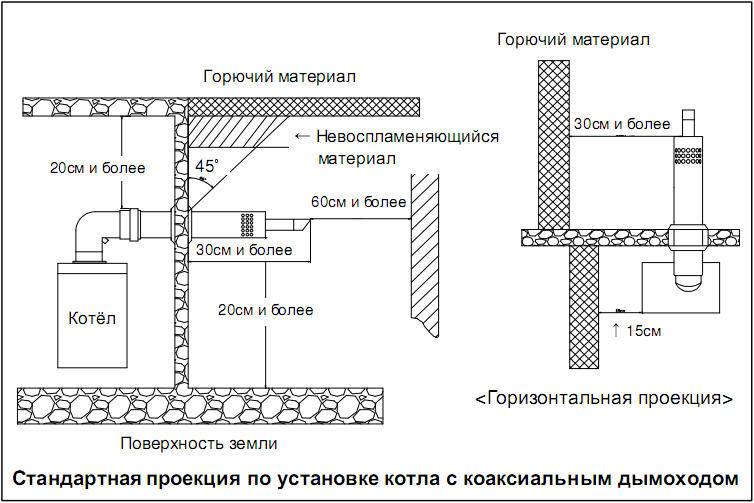

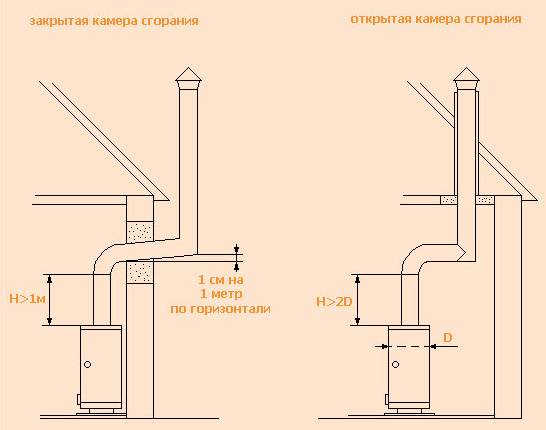

Everything is quite easy if we are talking about a device with a closed combustion chamber (and these are now the majority). By installing a coaxial chimney pipe, the owner gets two in one: both the inflow of fresh air directly into the boiler and the removal of exhaust gases.

If the hood is mounted on the roof, it is usually made in the same block as the flue, but the latter must be a meter higher.

Gas workers will periodically check the pipeline for its cleanliness and draft. Cleaning hatches and condensate collectors should be arranged.

Norms for private houses

According to the regulations, it is possible to place gas heating equipment only in rooms with good ventilation, which are located:

- On the ground floor of the building;

- At the basement level or in the basement;

- In the attic;

- In the kitchen (only boilers with a power of no more than 35 kW are suitable for installation in kitchens).

In the latter case, it is necessary to take into account not one standard, but two at once. The first of them allows you to install units with a power of up to 35 kW, and the second - up to 60 kW. These standards are only about heating equipment - no requirements are imposed on any other devices using gas.

In order to know exactly which standard must be followed in a particular situation, you need to contact the local gas service - it is its employees who will put the equipment into operation after installation. Information about the current standards can also be obtained from the designer - in the end, the source of information does not really matter, only the result is important.

The result in this case is an understanding of the rules for installing gas boilers. In addition, you need to have an idea of what kind of room is needed for a gas boiler so that it can be installed and put into operation, having gone through the coordination stage with the relevant services.

The placement of a gas boiler in a private house, depending on its total capacity, should be carried out as follows:

- Power up to 150 kW - installation is possible on any floor where there is a free separate room;

- Power from 150 to 350 kW - the equipment can be installed in a separate room no higher than the first floor, as well as in outbuildings.

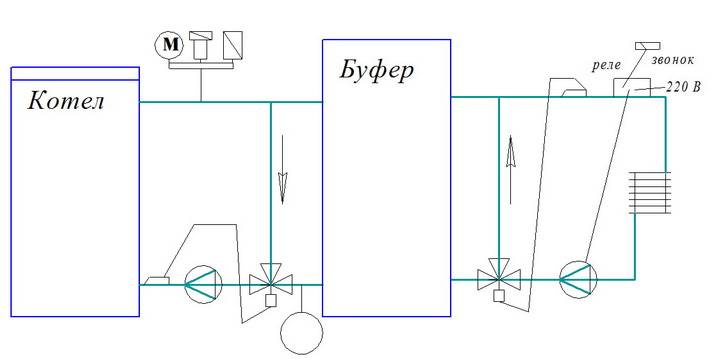

Conducting a trial run

This completes the main work on connecting the gas boiler. The exception is devices with a closed firebox. They need to be connected to the electrical network. It is better to do it through the stabilizer.

After that, the system can be filled with coolant. This is done as slowly as possible in order to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After the representative of the gas service has inspected the connection made and allowed the gas supply, you should also carefully examine all the connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start of the equipment.

Rules and regulations for the installation of gas-fired boilers

Such boilers are installed according to the project, which reflects all safety standards, the installation site and fireproof distances to the structural elements of the building are determined.

Prior to the start of construction and installation works, project documentation is coordinated with the relevant regulatory agencies, which also check it for compliance with state standards.

The installation of the boiler is carried out only by a specialized organization licensed to carry out such work.After the completion of the installation work, the boiler is put into operation on a commission basis consisting of representatives of the customer, the design organization of the installation company, city gas, architecture, capital construction, SES and the fire department. Thus, the owner must also know the requirements for the location of gas boiler equipment in order to properly prepare the terms of reference for the design.

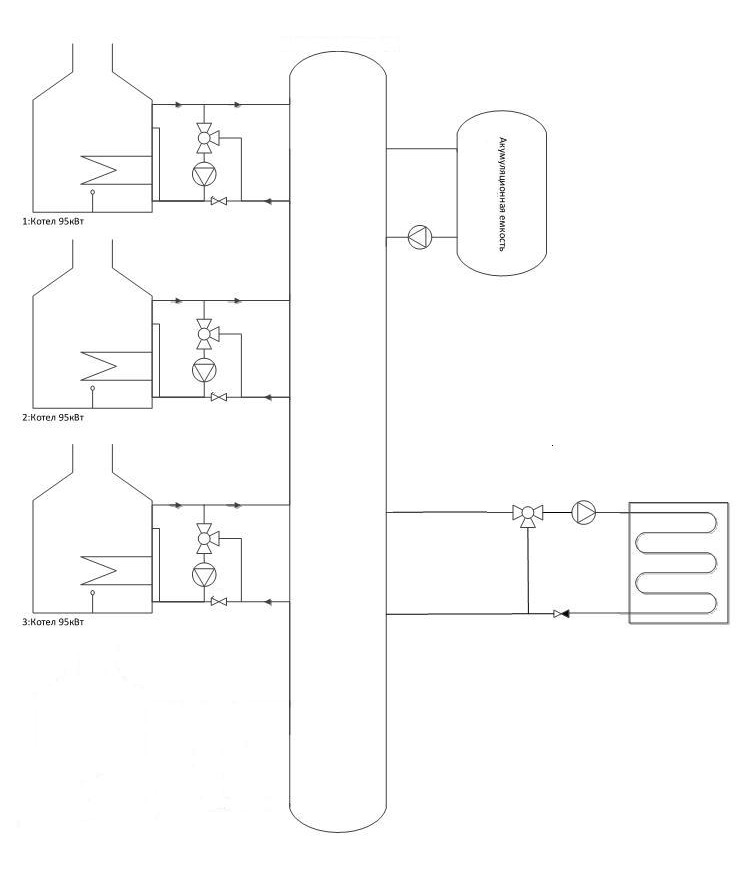

wall

Boiler diagram on the wall

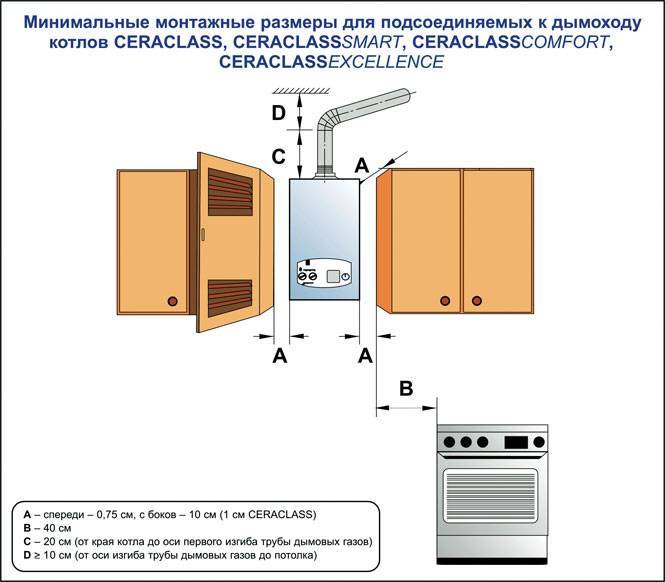

The requirements for the premises where it is planned to install a wall-mounted heating unit are primarily aimed at protecting building structures from fire

In this option, the owner will have to pay special attention to the wall on which they plan to fix the device, it must be able to withstand the weight of the structure and fire resistant

Basic room requirements for wall-mounted units:

- The volume of the room for the gas boiler is over 7.51 m3.

- The presence of powerful natural ventilation, a window block with a window and a door with an opening for air intake - 0.02 m2 should be placed in the room.

- The maximum distances to the enclosing elements of the building: floor - 80 cm, ceiling - 45 cm, walls on the sides - 20 cm, from the body to the rear wall - 40 mm, from the front of the unit to the door - 100 cm.

- The placement wall is covered with a fire-resistant material made of steel sheet with a thickness of more than 3 mm.

- Thermally insulate the side adjoining surfaces of walls and furniture.

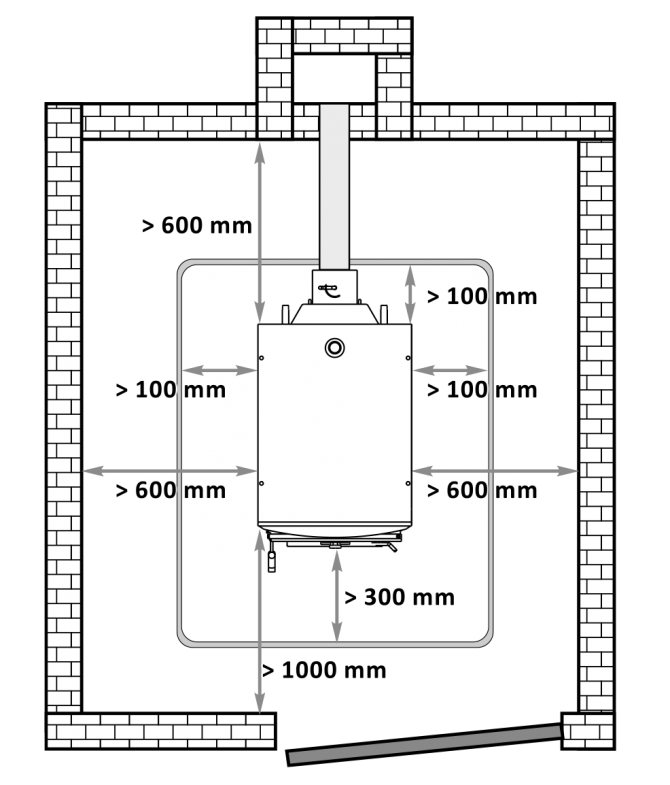

Outdoor

For these models, more attention should be paid to the floor structure, since such structures are heavy, and heat losses from the body mainly go to the flooring underneath.

Therefore, in the area of the boiler unit, a base is made of non-combustible material, with reinforcement capable of withstanding the entire design of the heat supply system, with a boiler and an indirect heating boiler.

Room norms for installing a gas boiler with floor installation:

- Free access to the working elements of the boiler unit.

- The minimum area for placing one unit is at least 4m2, while no more than 2 devices are allowed in the room.

- The height of the room is 2.20 m.

- Supply and exhaust ventilation, windows at the rate of 0.3 m2 per 10.0 m3 of room volume, a door with an opening of 0.8 m.

- The gap between the door and the front of the unit is -1 m.

- The walls and floor are made of non-combustible materials.

Requirements for installing a boiler in an apartment

How to install a double-circuit gas boiler in an apartment? Often the installation of such equipment is difficult for a number of reasons (lack of a central gas pipeline, difficulties in obtaining permission, lack of conditions, etc.). To register, knowledge of the laws and basic rules is required. In case of unauthorized installation of a gas heating boiler, you will have to pay a large fine and dismantle the boiler. You need to start by getting permission.

Required documents

To mount the boiler in an apartment with existing central heating, you need to collect a package of documents and go through several authorities in stages:

- After submitting an application to the state supervision authorities, if the conditions for installation and maintenance of the heating device are met, technical specifications are issued, which are a permit for the installation of equipment.

- After receiving the conditions, a project is created. It can be performed by an organization that has a license for this type of activity. The best choice would be a gas company.

- Obtaining permission to enter the boiler. It is issued by inspectors of companies that check ventilation. During the inspection, an act will be drawn up with instructions that need to be eliminated.

- After collecting all the documents, the design documentation for the installation of the boiler in a separate apartment is coordinated. Within 1-3 months, employees of state supervision must complete the coordination of installation. If no violations are found during the collection and preparation of documents, the consumer receives a final license for the installation.

- Documents for refusal of service are submitted to the company providing heat supply services.

You can't break the rules. Only the fulfillment of all conditions will allow obtaining permission to install gas equipment.

boiler room requirements

The room in which the boiler is installed must meet the following requirements:

- Gas equipment can only be installed in non-residential premises with tightly closed doors. For installation, do not use the bedroom, utility rooms, kitchens and toilets.

- It is best to install a gas meter in the kitchen. In this case, an additional pipe is introduced into the room.

- All surfaces (walls and ceiling) in the room must be lined with refractory materials. It is advisable to use ceramic tiles or gypsum fiber sheets.

- The area of the room for installation must be at least 4 m2. It is required to provide access to all nodes of the gas boiler for high-quality maintenance of the system.

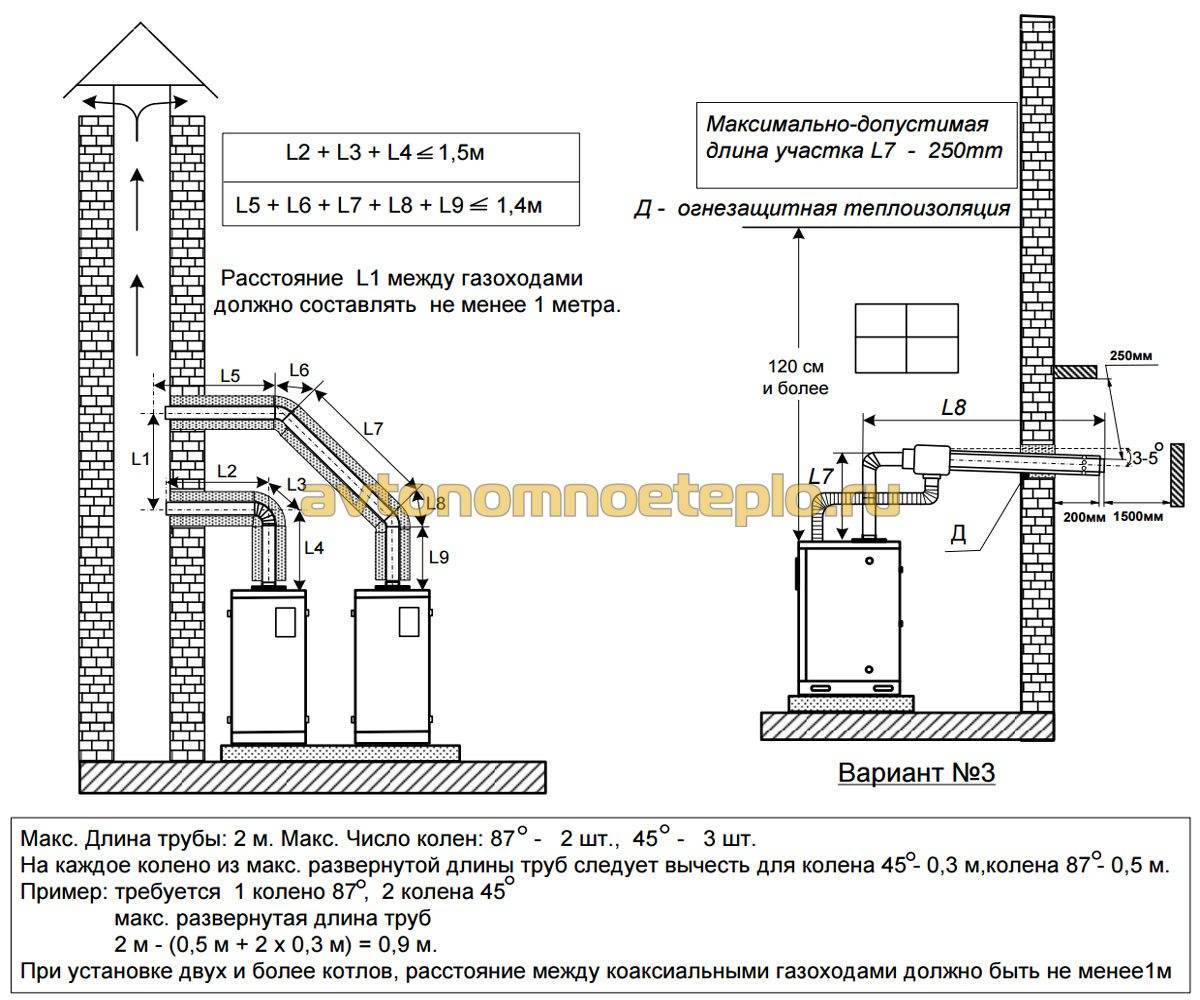

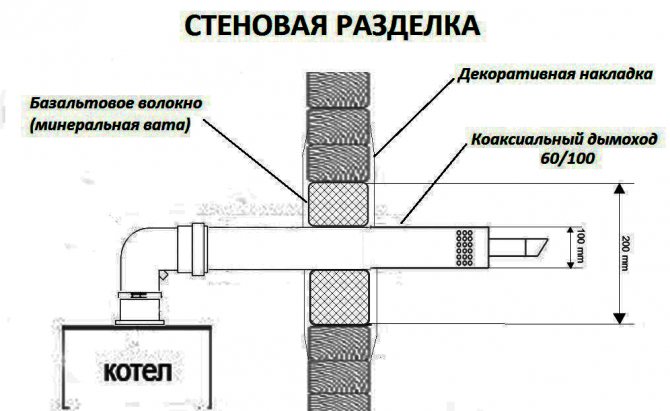

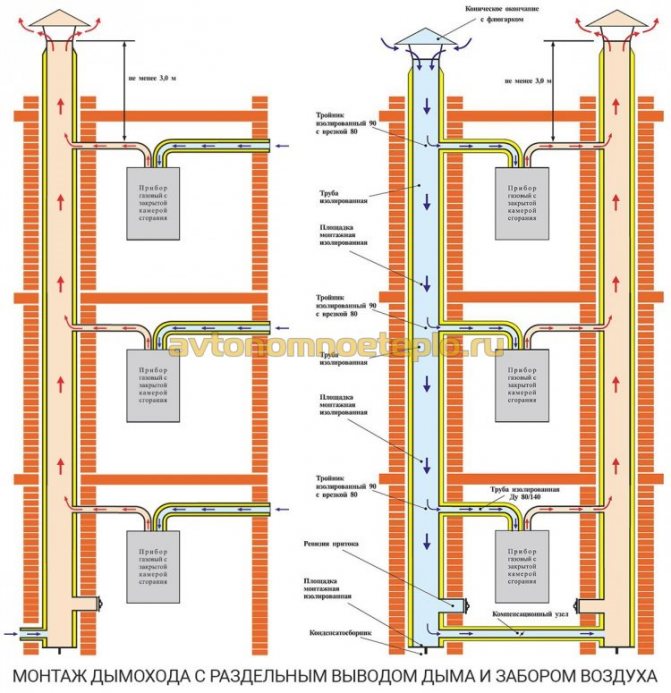

Chimney installation

Installation of heating on gas in apartments is allowed only with normally functioning ventilation and a system for removing combustion products. Therefore, it would be optimal to use a boiler with a closed combustion chamber, which is connected to a horizontal pipe for smoke removal. In this case, it will not be necessary to carry out several pipes for ventilation and smoke removal.

If several owners in the house want to switch to individual heating at the same time, the chimneys are combined into a single cluster. One vertical pipe is attached outside, to which the horizontal pipes coming from the apartments are connected.

For normal operation of the system, it is necessary to install devices for air circulation with high throughput in the boiler room. Such ventilation should be installed separately, without contact with the general one.

Switching to individual heating: advantages and disadvantages

Switching from central heating to gas requires a lot of money and labor. It takes a lot of time to issue permits, so you need to plan and start collecting the necessary papers long before the proposed installation.

Most representatives of state structures will prevent disconnection from the central heating system. Permits are issued reluctantly. Therefore, problems with paperwork are the main drawback in the transition to gas heating.

Switching cons:

- Unsuitability of the apartment for the installation of individual heating systems. To obtain a permit, a number of steps must be completed. Partial reconstruction costs a lot.

- Heating appliances require grounding.It is difficult to do this in an apartment, since according to SNiP it is impossible to use water pipes or an electrical network for this.

The main advantage of such heating is efficiency and profitability. The cost of re-equipment pays off in a few years, and the consumer receives energy independence.

Finished construction

Conducting a trial run

This completes the main work on connecting the gas boiler. The exception is devices with a closed firebox. They need to be connected to the electrical network. It is better to do it through the stabilizer.

After that, the system can be filled with coolant. This is done as slowly as possible in order to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After the representative of the gas service has inspected the connection made and allowed the gas supply, you should also carefully examine all the connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start of the equipment.

Procedure for replacing an obsolete boiler

Gas equipment is considered a device of increased danger.

Therefore, all work on the installation and maintenance of gas appliances is also classified as work with increased danger. The existing rules unequivocally answer the question - how to replace a gas boiler in a private house - it is forbidden to install or replace boiler equipment on your own. Installation of boilers can only be carried out by special authorities (gorgaz, rygaz, oblgaz) through enterprises that have a license for such work.

To start replacing the boiler, you need to do the following:

- Write an application to the gas service for permission to replace the boiler. You need to know that when replacing an old boiler with a similar one, you do not need to create a new project, but if changes have occurred - a boiler of a different type, the location or gas supply scheme changes, then a new project is created.

- After receiving a response, you need to hand over a construction passport to the gas service. Collect and submit DVK inspection certificates, and if an imported boiler is installed, a certificate of conformity.

What documents are needed when replacing a gas boiler

Before replacing a gas boiler, it is necessary to collect a lot of documents and obtain permits for such work.

You will need the following documents:

- If the equipment is from foreign manufacturers, then you need to provide a certificate in accordance with our safety standards;

- If the boiler is double-circuit, then it is necessary to have a sanitary and hygienic certificate for supplying hot water for domestic needs. Usually such a document is provided immediately with the warranty card;

- Document on checking ventilation and smoke ducts;

- Warranty contract for at least 1 year, which is concluded with a service company;

- A document with the results of connecting equipment to engineering networks.

- Act on hidden work when installing a coaxial chimney through the wall;

- Project with changes. The main condition: the new boiler must be legalized.

You must collect all the documents yourself. If you do not have such an opportunity, then you can contact a special installation company. But in this case, additional costs must be calculated.

Do I need a new project when replacing a gas boiler

The project specifies the model, type and power of the heating unit. In addition, each boiler has its own serial number, indicated in the data sheet and included in the project documentation. Therefore, when replacing, you will need to make a new project with new data.

You need to go through the following steps again:

- Obtain specifications for the replacement of a gas boiler. At this stage, the gas distribution company can change the capacity of the unit based on the actual living area of the house.

- Make a new project.

- Obtain approval by submitting a gas distribution project, specifications, and the results of checking the chimney channel.

- Replace the old unit with a new one.

When replacing an old gas boiler with a new one, the following documents are needed:

- The passport.

- Documents of the owner of the dwelling.

- Technical passport for gas equipment.

- Specifications.

Standard prices for the replacement of already installed gas equipment are 1000-1500 rubles, depending on the region.

Features of replacing a boiler of the same power

If the gas consumption per hour of the new boiler is similar to the gas consumption of the old one, then this greatly simplifies the task. Since all that is needed from the owner is to submit a notification of the replacement to Gorgaz.

And to it should be attached:

- Boiler connection certificate.

- The act of inspection of ventilation, chimney.

- Contract for at least one year maintenance of gas equipment.

After consideration, the application is granted permission. After that, the equipment is replaced, tested and its operation begins. Thus, the RF GD No. 1203 p. 61(1) allows to operate.

Is it possible to replace a gas boiler with an electric one

Replacement is quite possible, but for this you will have to obtain permission from another organization involved in power supply. Documents are needed only if the electric boiler has a power of more than 8 kW. Up to this performance limit, the unit belongs to ordinary household water heaters by the type of boiler, therefore, it is installed without permits and approvals.

For productive electric boilers, a separate power supply line will be required. You will need to make a project and obtain permission to increase the amount of electricity generated. Separately, it is necessary to write a statement about disconnecting the gas boiler from the main.

Requirements for boiler rooms for the installation of solid and liquid fuel boilers

The requirements for volume, dimensions and materials for the boiler room are the same. However, there are several specific ones that are associated with the need to organize a chimney and a place to store fuel. Here are the basic requirements (mostly they are written in the boiler passport):

- The cross section of the chimney must not be less than the diameter of the boiler outlet pipe. It is not allowed to reduce the diameter along the entire length of the chimney.

- It is necessary to design a chimney with the least number of elbows. Ideally, it should be straight.

- At the bottom of the wall there should be an inlet (window) for air to enter. Its area is calculated from the power of the boiler: 8 sq. see per kilowatt.

- The outlet of the chimney is possible through the roof or into the wall.

- Below the chimney inlet there should be a cleaning hole - for revision and maintenance.

- The chimney material and its connections must be gas-tight.

- The boiler is installed on a non-combustible base.If the floors in the boiler room are wooden, a sheet of asbestos or mineral wool cardboard is laid, on top - a sheet of metal. The second option is a brick podium, plastered or tiled.

- When using a coal-fired boiler, the wiring is only hidden; laying in metal pipes is possible. Sockets must be powered by a reduced voltage of 42 V, and switches must be sealed. All these requirements are a consequence of the explosiveness of coal dust.

Please note that the passage of the chimney through the roof or wall must be made through a special non-combustible passage

Oil fired boilers are usually noisy

It is worth saying a few words about liquid fuel boilers. Their work is usually accompanied by a fairly high level of noise, as well as a characteristic smell. So the idea of putting such a unit in the kitchen is not the best idea. When allocating a separate room, you should make sure that the walls give good sound insulation, and the smell does not penetrate through the doors. Since the internal doors will still be metal, take care of the presence of a high-quality seal around the perimeter. Perhaps the noise and smells will not interfere. The same recommendations apply to attached boiler houses, although they are less critical.

How to install a wall-mounted boiler

Before installation, unpack the heat generator and check that the appliance is complete. Make sure the stock fasteners fit your walls. For example, special fasteners are required for aerated concrete, ordinary dowels are not suitable.

We follow the following work order:

- Mark the contour of the heating unit on the wall. Make sure that technological indents from building structures or other surfaces are observed: 0.5 m from the ceiling, from below - 0.3 m, on the sides - 0.2 m.Typically, the manufacturer provides a diagram with dimensions in the instruction manual.

- For a turbo boiler with a closed chamber, we prepare a hole for a coaxial chimney. We drill it at a slope of 2–3 ° towards the street so that the resulting condensate flows out. The process of installing such a pipe is described in detail by us separately.

- The heat generator comes with a paper installation template with pre-drilled holes. Attach the sketch to the wall, align with the building level, fix the diagram with tape.

- Drilling points should be punched right away. Remove the template and make holes 50–80 mm deep. Make sure that the drill does not go to the side, this happens on brick partitions.

- Install plastic plugs in the holes, screw the hanging hooks to the maximum depth using pliers. With the help of a second person, carefully hang the machine.

When marking holes in a wooden log wall, make sure that the fastener is on the crest of the log. Hooks screw directly into the tree, without plastic plugs.

Where it is possible and where it is impossible to put a gas boiler

The rules for installing a gas boiler provide for the following requirements for installing a HEATING boiler, regardless of whether it also provides domestic hot water or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications of the admissibility of a ceiling of 2 m. This is not true. 8 cubes is the minimum free volume.

- The furnace must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with combustible materials, the presence of a false ceiling or raised floor in it is unacceptable.

- Air must be supplied to the furnace through a through, non-closable vent with a cross section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly referred to as a chimney); the use of ventilation ducts for this is unacceptable - life-threatening combustion products can get to neighbors or other rooms.

- The length of the horizontal part of the flue must not exceed 3 m within the furnace and have no more than 3 angles of rotation.

- The outlet of the flue must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since the products of combustion form chemically aggressive substances during cooling, the chimney must be made of heat- and chemical-resistant solid materials. The use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

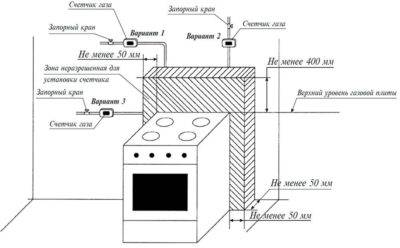

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest branch pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A strong fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- The room should not have cavities in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment / house:

- The slope of the horizontal pipe sections must be positive, but not more than 5 mm per linear meter in terms of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler in which everything is provided for: rules are rules.

- The condition of the heating system must allow it to be pressure tested at a pressure of 1.8 atm.

The requirements, as we see, are tough, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a hot water boiler, if:

- You live in a block Khrushchev or other apartment building without a main flue.

- If you have a false ceiling in your kitchen, which you do not want to clean, or a capital mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which, in principle, can be removed, and then there will be no mezzanine, gas workers look through their fingers.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment that only the owner can do.

In all other cases, you can put a hot water boiler in the apartment; heating wall is possible, and floor - very problematic.

In a private house, any boiler can be installed: the rules do not require that the furnace be located directly in the house.If you make an extension to the house from the outside under the furnace, then the authorities will only have fewer reasons for nit-picking. In it, you can put a floor gas boiler of high power for heating not only the mansion, but also office space.

For private housing of the middle class, the optimal solution is a wall-mounted boiler; under it is not required, as for the floor, to arrange a brick or concrete pallet with sides of half a meter. Installing a wall-mounted gas boiler in a private house also does without technical and organizational difficulties: a fireproof closet for a furnace can always be shielded, at least in the attic.

Timing

Connecting to the gas network is a rather long process. And most of the time is occupied not by the installation itself, but by issues related to the documentation.

Specifications are issued within 14 days after receipt of the application. Development takes 1-3 weeks. Negotiation takes longer.

You have to wait an average of 3 weeks to 3 months for a response. If the project is not accepted, you have to correct it and submit it again.

When all work is completed, they conclude an agreement for connection to the gas pipeline. This has to wait up to 30 days.

The longest time is to wait for approval. Therefore, it is advisable to immediately draw up the documentation correctly, in accordance with the conditions and SNiPs. That is, you need to choose the right company that has experience in developing and coordinating in this particular area.

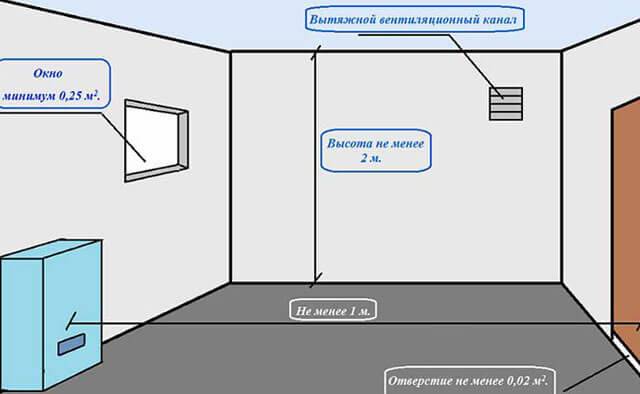

Ventilation

High-quality and well-thought-out ventilation of a room where there is no process of accumulation of an increased concentration of gas - these are the standards that are one of the fundamental ones during the installation of a gas boiler.

The requirement for installing a wall-mounted gas boiler directly relates to the design of ventilation.The standards here are very high. Important here are the requirements that relate to the safety itself, as well as to the physical characteristics of the installed gas boiler. Uniform and full-fledged air flow ensures long-term and uninterrupted operation of the entire system.

Organization of high-quality ventilation:

- Make a ventilation shaft or hood at a height of 25 cm from the ceiling of the room. The hole must be round, and its diameter is at least one decimeter.

- The open view of the hood is closed with a special grate or valve. If finances allow, you can use different weather vanes, which make it possible to adjust the air flow and protect the fire from unwanted attenuation.

- It will be better if you install a small fan on the hood, which will improve all ventilation indicators.

Ventilation

boiler room requirements

To use gas equipment with a power of 30 kW or more, you will need a separate room that complies with all applicable rules and regulations.

Most often, one of the rooms in the basement or basement is equipped as a boiler room. True, such an installation of a heating unit is allowed only for single-family residential buildings.

In private households, the rules for installing a gas boiler allow the use of equipment of any power, since most often it is placed in a separate room attached to the house, which allows you to provide heat not only for living rooms, but also for utility rooms.

Important requirements that the boiler room must meet are as follows:

- The area of the minimum room for a gas boiler based on one unit is 4 m². At the same time, more than two devices cannot be placed in one room.This size of the boiler room in a private house is required.

- Ceiling height should be at least 2.0-2.5 meters.

- To ensure natural light, it is necessary to have a window, the size of which is determined at the rate of 0.3 m² per 10 m³ of the volume of the room for a gas boiler, but not less than 0.5 m². A certain distance from the gas boiler to the window is also provided, in terms of safety.

- The width of the doorway cannot be less than 80 centimeters.

- The minimum distance from the front door to the unit is -100 centimeters, but it is better if it is 130–150 centimeters.

- In order to create conditions for the implementation of repair or preventive measures, a free space of at least 130 centimeters should be provided in front of the boiler.

- Proper installation of a gas boiler in a private house means that it is located in a horizontal position and is stable. This minimizes the level of possible noise resulting from vibration.

- The floor and walls must be made of non-combustible materials, in addition, the floor covering must be absolutely even.

- Cold water must be brought into the boiler room, and a sewer drain for the coolant must be equipped in the floor.

- For electrical outlets, a ground loop is required, since the ignition or pump is connected to the power supply.

- Easy access to the chimney, or rather to the inspection window, should be provided in order to control the patency of the channels and clean them.

Conclusions and useful video on the topic

The video discusses in detail the regulatory requirements for the installation of wall-mounted gas boilers:

The video tells about the connection scheme of the wall-mounted boiler:

The video demonstrates the process of installing a wall-mounted boiler:

p> Installing a gas heating unit is a responsible and rather complicated operation, the quality of which depends on the safety of everyone who lives in the house. Therefore, representatives of gas services strongly do not recommend doing it on their own.

Yes, and manufacturers of heating appliances insist on this. Therefore, even experienced home craftsmen are better off seeking help from professionals, which guarantees long-term, and most importantly, safe operation of the device.

Please leave your comments if you have any questions about the topic of the article. Or maybe you yourself had to deal with the installation of gas wall-mounted equipment and do you have something to advise our readers?