- Procedure for replacing gas appliances

- Glazing material

- Maintenance nuances

- Recommendations for the installation of gas equipment

- Boiler room in a private house in a separate room (built-in or attached)

- Special requirements for attached boiler rooms

- The size of the window in the boiler room for a gas boiler

- Preparatory activities

- Requirements for a basement room with a boiler room

- Extension of boiler rooms

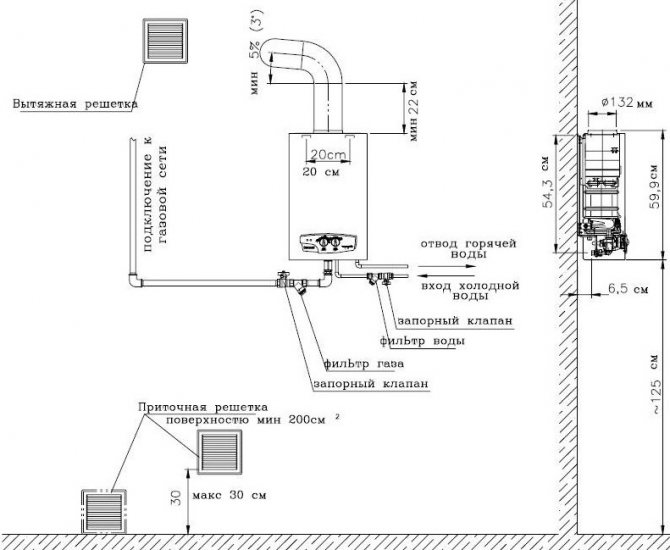

- How to install the boiler correctly?

- Room for the installation of a gas boiler

- boiler room requirements

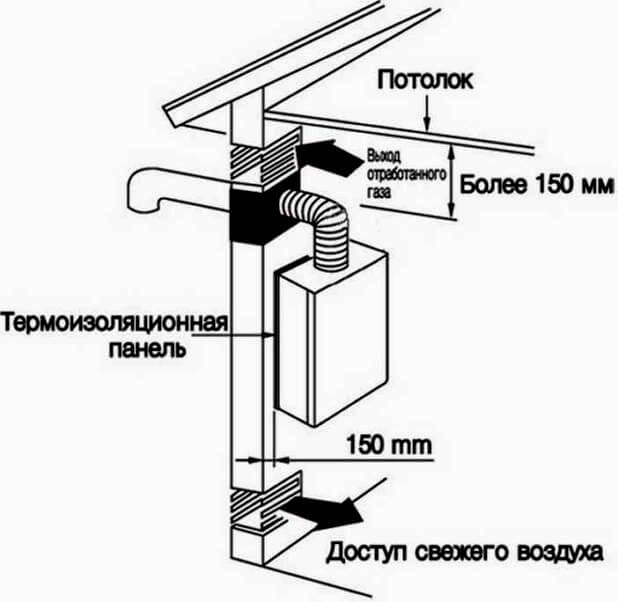

- Requirements for the room for the installation of a turbocharged unit

- 2 Design documentation for a gas boiler house

- Conclusions and useful video on the topic

Procedure for replacing gas appliances

The legislation provides for certain rules for replacing a gas boiler in a private house. This procedure should be carried out in the following steps:

- With a technical passport for a new gas boiler, they contact the gas supply company to obtain technical conditions.

- After considering the application, the organization issues technical specifications: if the characteristics of the new boiler are similar to the old one, then you only need to obtain a chimney pipe inspection certificate; if the location of any element of the system changes, then it is necessary to order a new project in a specialized organization; if the unit will have a large capacity, then it may be necessary to renegotiate the contract for the supply of gas.

- Now you can conclude an agreement to replace the gas boiler with a specialized organization. You need to get a building permit from them.

- All collected documents are submitted to the gas service for a permit.

- Obtaining permits.

It happens that the gas service does not give permission for a replacement, but the reasons for the refusal are always indicated. In this case, you should correct the comments identified by the gas service and submit the documents again.

…

When replacing one model of a gas boiler with another, keep in mind the following:

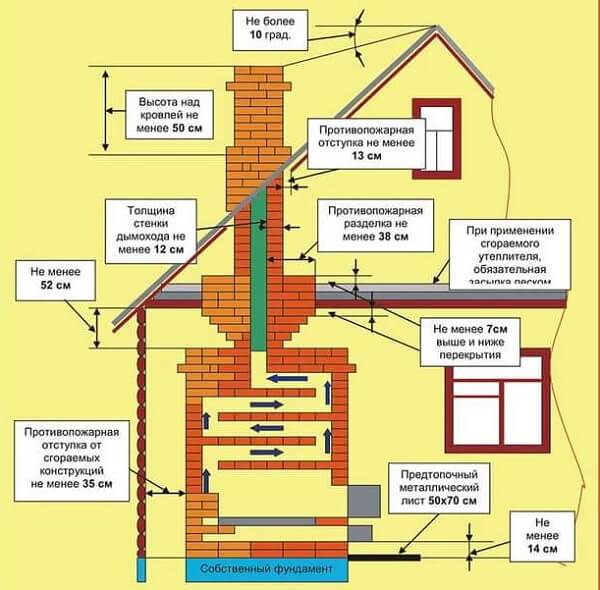

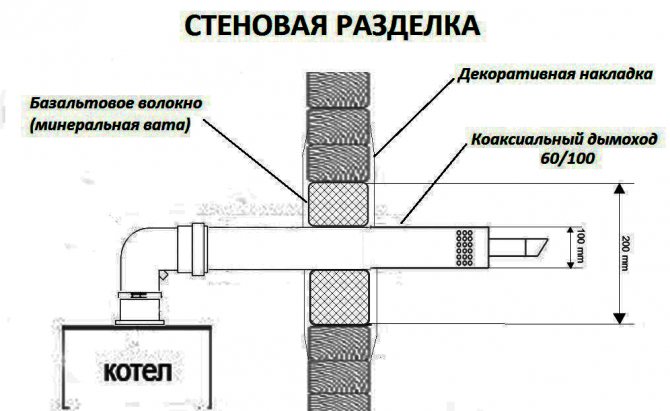

- models with an open combustion chamber can only be placed in specially equipped boiler rooms; to remove smoke, a classic chimney is required;

- boilers with a closed combustion chamber with a power of up to 60 kW can be placed in any non-residential premises (kitchen, bathroom, hallway) with an area of at least 7 m²;

- the room where the unit will be located should be well ventilated and have an opening window.

Glazing material

When equipping a window for a gasified boiler room, special requirements are also imposed on the material of the frames. They must be resistant to high temperatures and made of environmentally friendly materials.

For the construction of the window structure, aluminum or metal-plastic is used.The aluminum profile protects the heated compartment from adverse climatic conditions. It provides a reliable seal that prevents the formation of a draft, does not allow the fire to go out in the boiler even with exile gusts of wind outside.

Metal-plastic frames are no less reliable and contribute to the preservation of heat in the furnace.

Plain sheet glass is used as a glazing material. It is also allowed to install double-glazed windows that meet the requirements of GOST and perform the role of easily dropped structures.

Maintenance nuances

Maintenance of gas boilers is carried out to extend the life of the equipment. The schedule and frequency of work are determined by the manufacturer and should not contradict state regulatory requirements for the operation of gas equipment.

Main maintenance activities:

- Burner device - cleaning the retaining washer, igniter electrodes, flame sensor.

- Purging the sensor by air pressure to create a gas-air mixture.

- Flushing or replacement of cleaning filters on the gas line.

- Cleaning of all parts of the boiler exposed to open fire.

- Cleaning of gas channels and gas ducts.

- Chimney cleaning.

- Checking and repairing electrical circuits and the boiler operating panel.

- Adjustment of all units of the unit.

Maintenance of the boiler unit should begin with a thorough inspection of the units of the thermal circuit and a description of the defects of the detected violations. It is completed after all faults have been eliminated. Replacing defective or defective parts and performing adjustment work of the entire heating system.

As is obvious, the maintenance work package covers all the main elements of the unit, and its implementation will require not only experience and knowledge, but also instruments and devices. For most users of boiler equipment, these conditions are not feasible, so it is better to contact the service department for outdoor gas boilers, which are available in all regional centers, for example, in Moscow. For people living in the suburbs, it is enough to make an application by phone or on the website, the specialists themselves will come to the house to carry out the work.

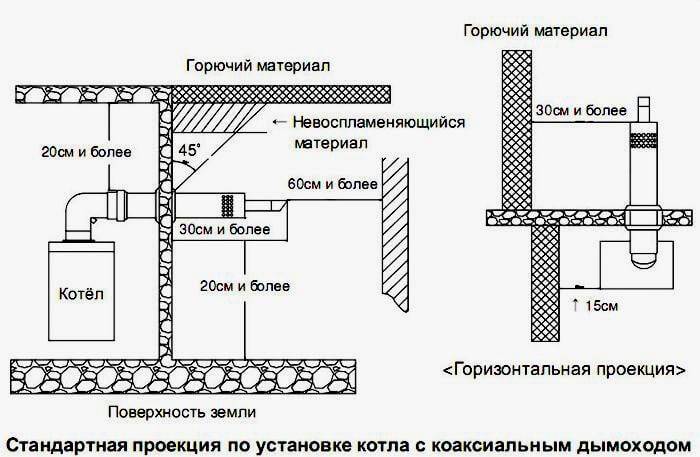

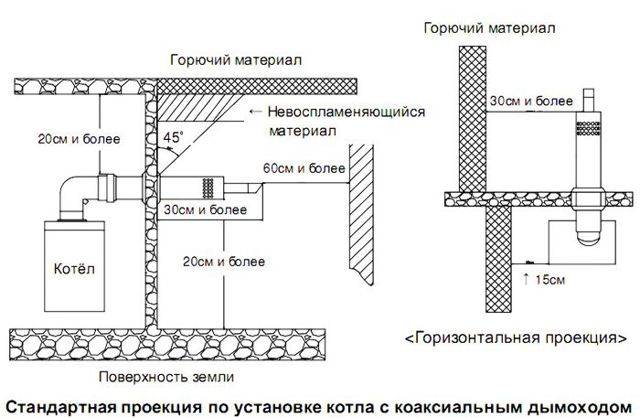

Recommendations for the installation of gas equipment

In the documents attached to the product, each manufacturer describes the requirements for installing a gas boiler in an apartment. For the manufacturer's warranty to be valid, the unit must be installed in accordance with their recommendations.

The list of requirements is as follows:

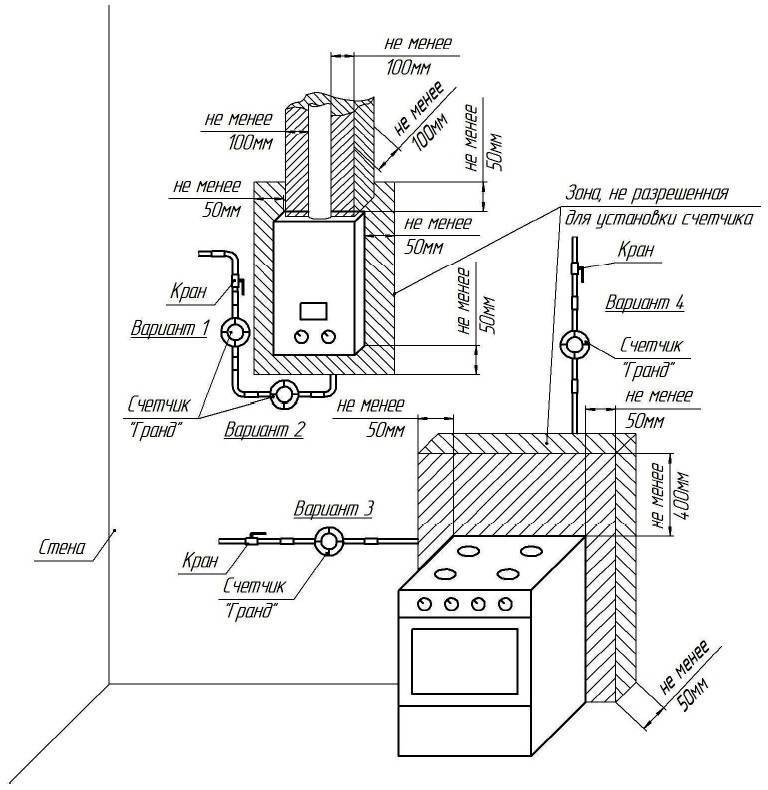

- The wall-mounted boiler is separated from the walls with non-combustible material. When they are tiled or covered with a layer of plaster, this will be enough. Do not hang the appliance directly on a surface lined with wood.

- The floor unit is placed on a non-combustible base. If the floor has ceramic tiles or it is concrete, nothing needs to be done. A sheet of heat-insulating material should be placed on a wooden floor covering, and a metal sheet should be fixed on top of it, the size of which exceeds the dimensions of the boiler by 30 centimeters.

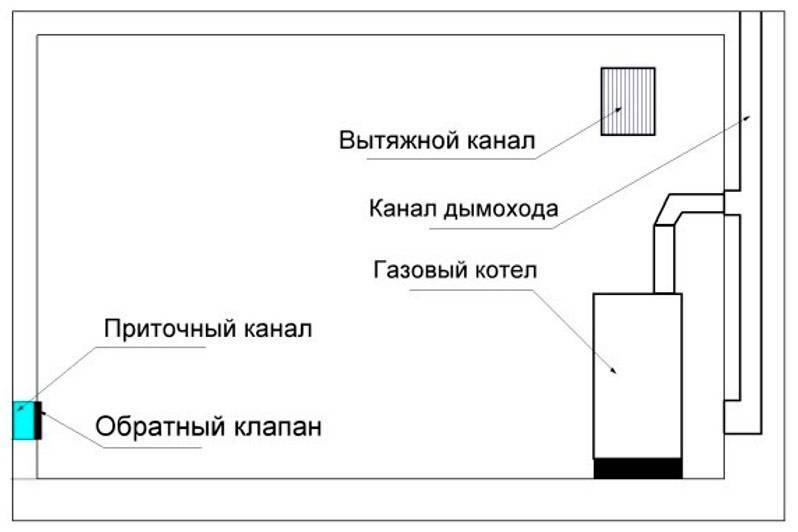

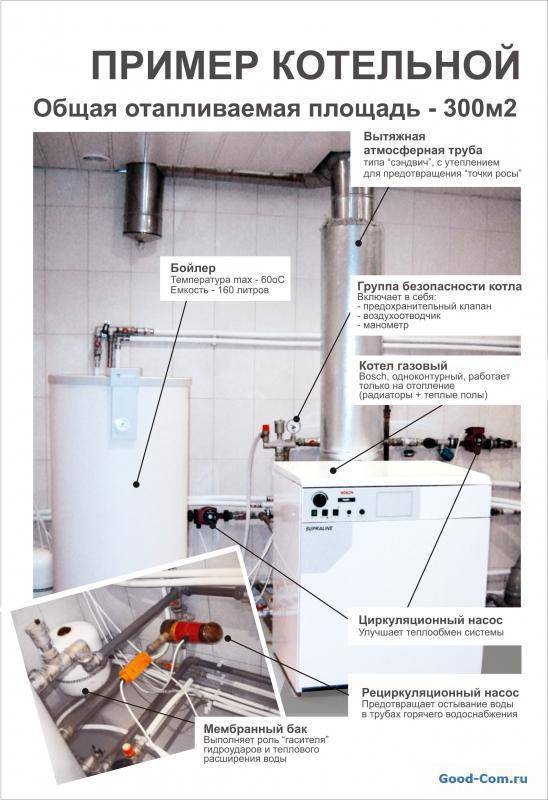

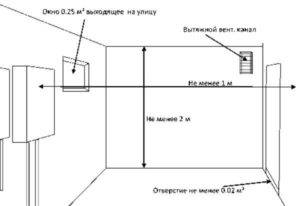

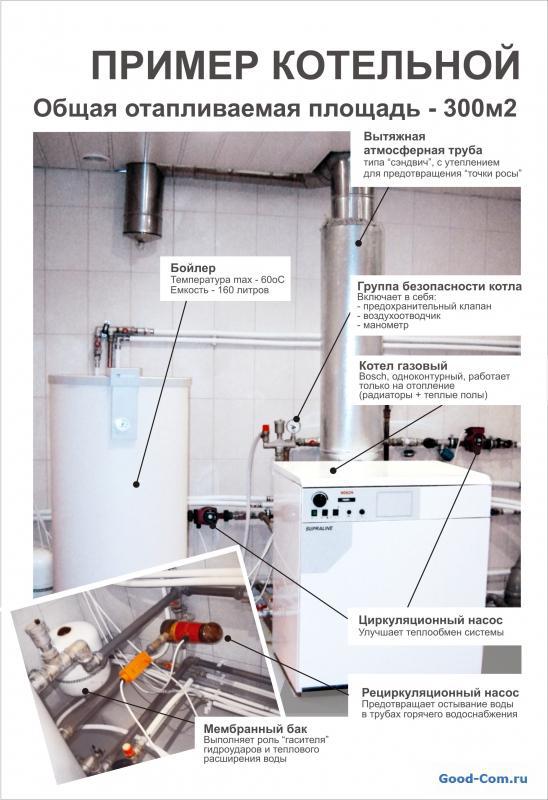

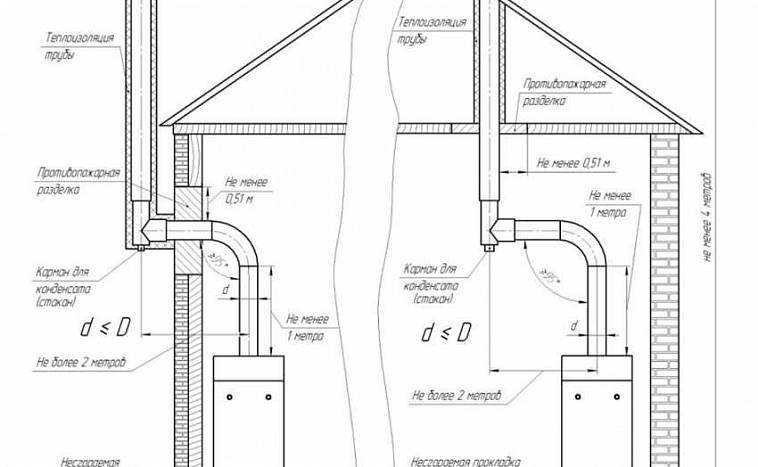

Boiler room in a private house in a separate room (built-in or attached)

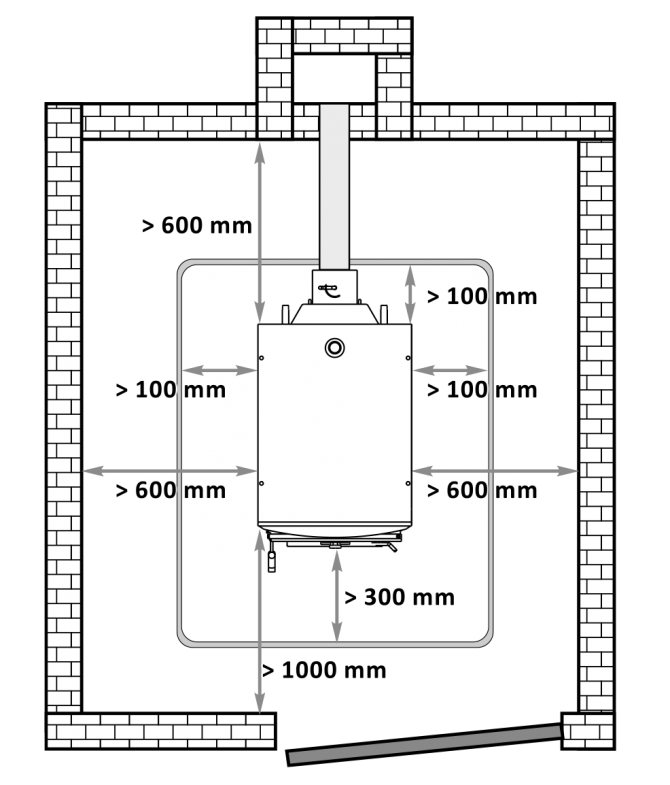

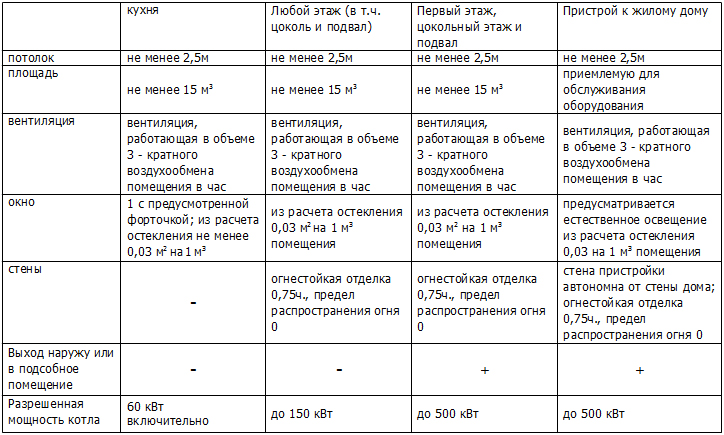

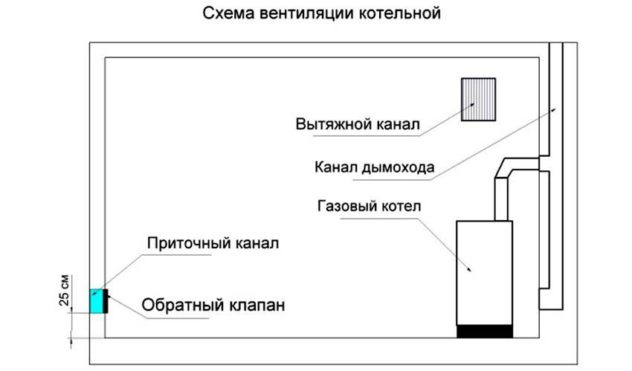

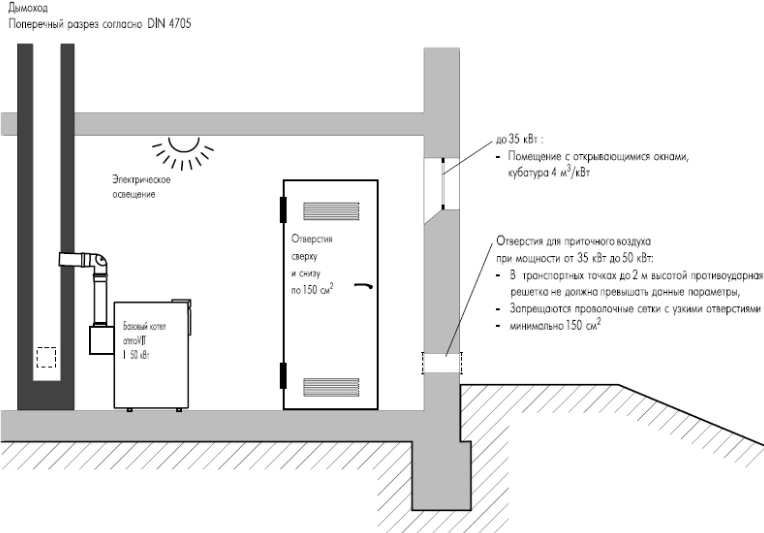

Separate boiler rooms for the installation of gas boilers with a power of up to 200 kW must be separated from the rest of the rooms by a non-combustible wall with a fire resistance limit of at least 0.75 hours.These requirements are met by brick, cinder block, concrete (light and heavy). The requirements for separate furnaces in a built-in or attached room are as follows:

- The minimum volume is 15 cubic meters.

- Ceiling height :

- with power from 30 kW - 2.5 m;

- up to 30 kW - from 2.2 m.

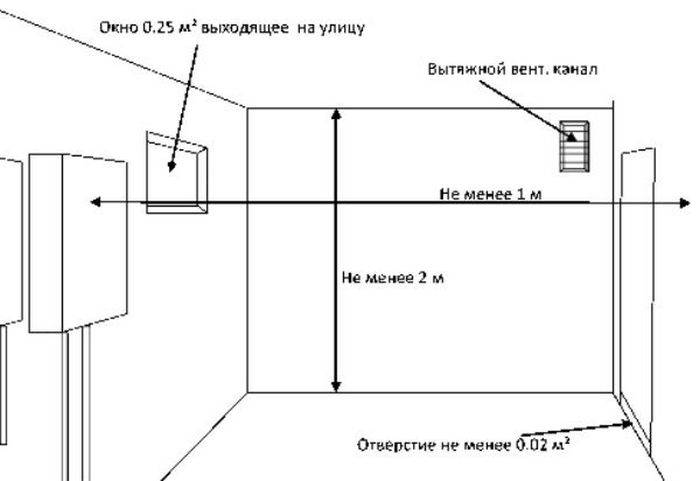

- There must be a window with a transom or window, the glass area is not less than 0.03 square meters per cubic meter of volume.

- Ventilation should provide at least three air exchanges in one hour.

If the boiler room is organized in the basement or basement, the minimum size of the boiler room will be larger: 0.2 m2 is added to the required 15 cubic meters for each kilowatt of power that goes to heating. A requirement is also added to walls and ceilings adjacent to other rooms: they must be vapor-gas-tight. And one more feature: when installing equipment with a capacity of 150 kW to 350 kW, a furnace in the basement or basement must have a separate exit to the street. Access to the corridor leading to the street is allowed.

It is not the area of \u200b\u200bthe boiler room that is normalized, but its volume, the minimum height of the ceilings is also set

In general, it is advisable to choose the size of a boiler room in a private house based on the convenience of maintenance, which, as a rule, far exceeds the standards.

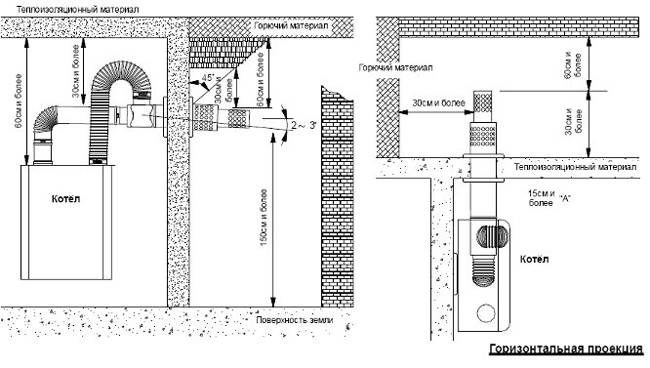

Special requirements for attached boiler rooms

There are not very many of them. Three new requirements are added to the points above:

- The extension should be located on a solid section of the wall, the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-combustible material with a fire resistance of at least 0.75 hours (concrete, brick, cinder block).

-

The walls of the extension must not be connected to the walls of the main building. This means that the foundation must be made separate, incoherent and not three walls should be built, but all four.

What to keep in mind. If you are going to arrange a boiler room in a private house, but there is no room of a suitable volume or the ceiling height is slightly lower than the requirements, you may be met and demanded in return to increase the glazing area. If you are planning to build a house, then you must meet all the requirements, otherwise the project will never be approved for you. They are also tough on the construction of attached boiler houses: everything must comply with the standards and nothing else.

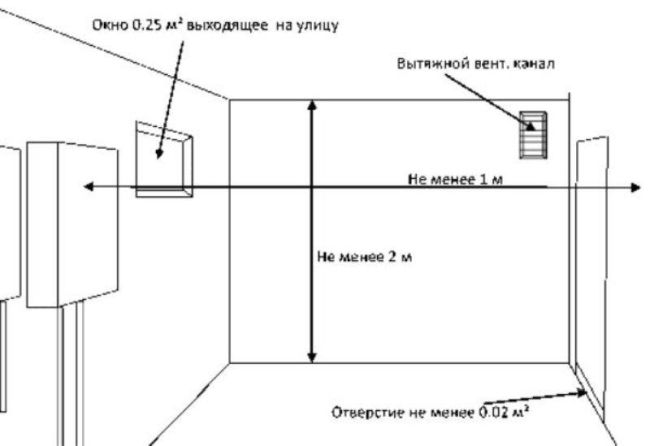

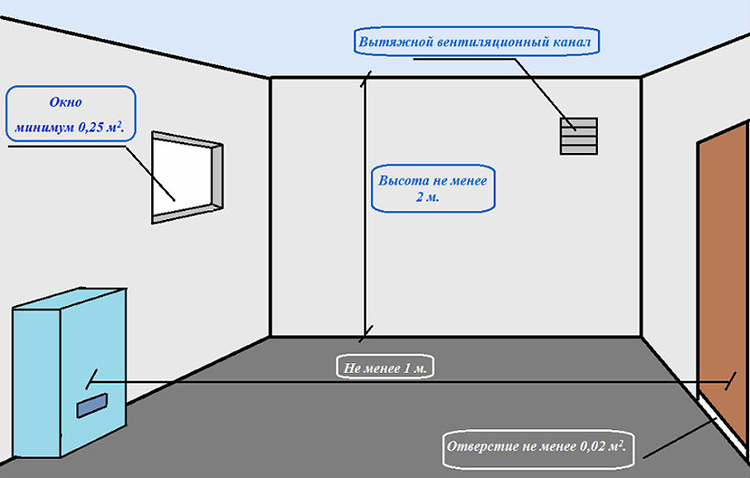

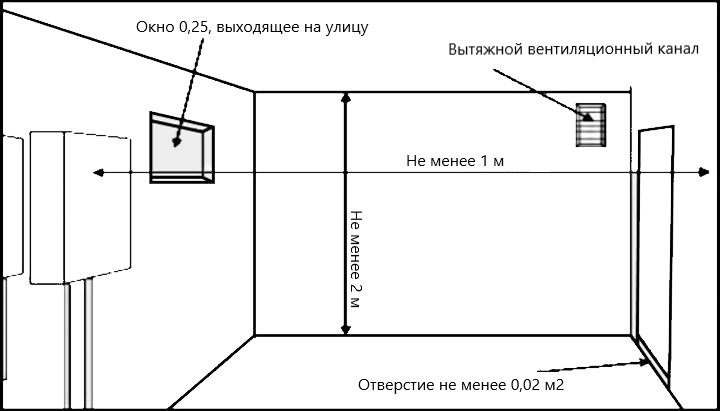

The size of the window in the boiler room for a gas boiler

A boiler room with a gas-powered unit installed in it must reach a height of up to 2.2 m. In addition, the boiler room must be equipped with a window, the size of which is at least 0.5 sq.m.

In case of fire and fire, the light is often turned off, it can be difficult to find a way out of a smoky building. In such extreme situations, safety is ensured by natural light coming through a hole in the wall.

The window structure is equipped with a window that allows ventilation in the event of a gas leak. One of the conditions is opening windows to the street.

Thus, it is used not only for natural lighting, but also as an important element of the ventilation system.

Preparatory activities

Before you install the heating system, you will have to collect a considerable amount of permits, prepare a project, go around a number of instances.Strict requirements for a room for a gas boiler are due to the dangerous properties of gas, which is an explosive substance.

The owner of the premises must independently study the regulations and SNiPs, which describe all the rules and standards for placing equipment in residential premises. Issues of gas supply to suburban households and the rules for using gas-powered equipment are regulated by SNiP 31-02-2001. After that, the owner of the house needs to contact the appropriate design service, which will draw up technical conditions. The finished project documentation will become the basis and a clear plan for further installation.

In this video you can see how to properly and safely place the boiler room in your home:

>When submitting an application to the gas supply service, you must provide the following data:

- estimated volume of blue fuel consumption;

- the presence of gas appliances in the room (gas stove or instantaneous water heaters);

- heated area.

A gas boiler makes it possible to set the microclimate that suits you without being tied to central heating and water supply

A gas boiler makes it possible to set the microclimate that suits you without being tied to central heating and water supply

Specialists consider the application, decide whether it is possible to install the boiler in this room. If the conditions for installing a gas boiler in a private house do not meet the safety requirements, the applicant will receive a justified refusal. The possibility of installing a heating system is considered in each individual case, there are no standard projects.

2 id="trebovaniya-k-tsokolnomu-pomescheniyu-s-kotelnoy">Requirements for a basement room with a boiler room

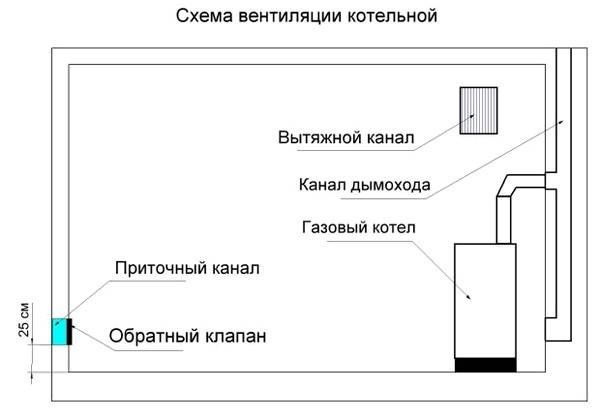

Boiler rooms in the basement of a residential building are subject to certain requirements for arrangement, in accordance with which the following requirements must be met:

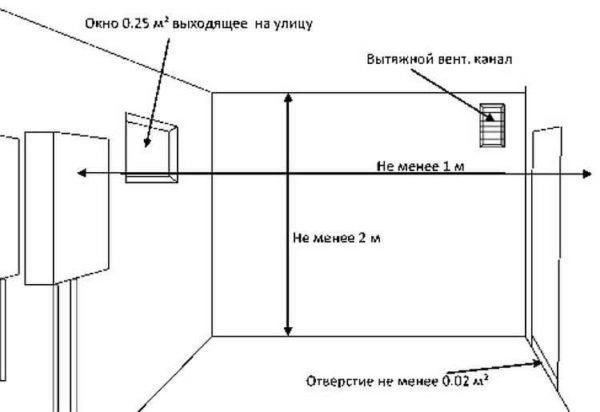

- The room must be more than two meters high. Optimal is 2.5m;

- The boiler room must be isolated from the living rooms of the house, in which the installation of gas equipment is strictly prohibited;

- The placement of one boiler must account for at least 4 square meters of the room, moreover, the system must be located at a distance of one meter from the wall of the building;

- Access to the boiler must be free from any side, so that it can be quickly turned off or repaired;

- The boiler room must have a window with an opening of at least a quarter of a square meter. The recommended size is 0.03 sq.m. per cubic meter of basement;

- The door to the basement should be comfortable and safe, with an opening width of at least 0.8 meters;

- The floor covering can be a cement screed, but not linoleum or laminate. All combustible materials are strictly prohibited. It is recommended to finish the floor with tiles or tiles made of refractory materials;

- All wall and ceiling surfaces must be treated with fire-resistant materials and sheathed with tiles or tiles. If there are things around the boiler room that are vulnerable to burning, they must be covered with special shields with insulation;

- At the entrance to the boiler room, it is necessary to make ventilation ducts, as a rule, pierced at the bottom of the door;

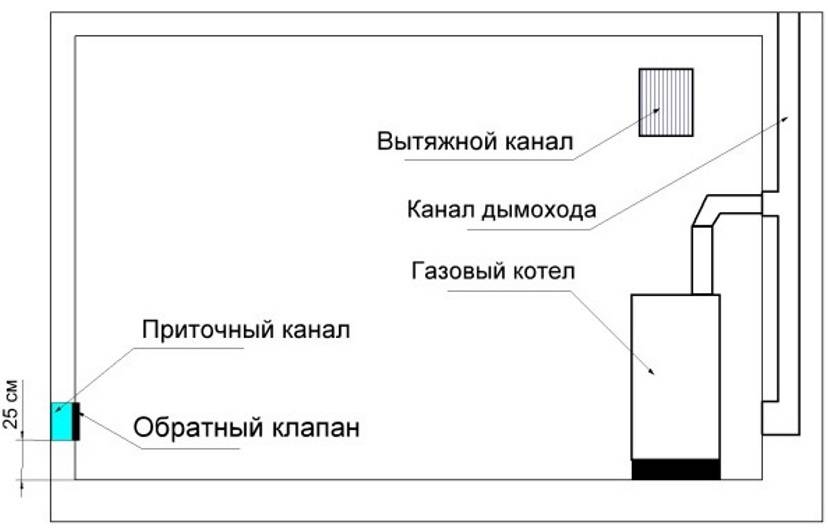

- A boiler room with a gas unit requires the arrangement of a supply and exhaust air exchange system;

- Access to the premises is restricted to unauthorized persons, except for repair teams or maintenance personnel. Children and animals are strictly prohibited from entering the boiler room.

These requirements are dictated for the safety of people living in the house. In addition, this allows you to use the equipment in the most optimal mode. Failure to comply with these requirements leads to fires and accidents, since the small size of the room with a gas boiler is very favorable for the emergence of a fire source and its subsequent spread.

All restrictions on room volumes apply to boilers with an open combustion system. Almost all modern models are equipped with a sealed firebox, but if old equipment is in operation, then the dimensions of the room can be 7.5 cubic meters, 13.5 or 15 cubic meters for boilers with a capacity of 30.30-60 and 60-200 kW, respectively.

All modern models can be located on any volume of the basement, but in the case of location in the basement, it is necessary to equip a separate exit to the street. All outlets are immediately made of refractory materials.

After the building is put into operation, and the boiler room is not equipped, living spaces should not be allocated for these purposes. It is recommended to build a separate building, an extension to a residential building, but in this case it is necessary to provide for all the requirements for the arrangement of the boiler room.

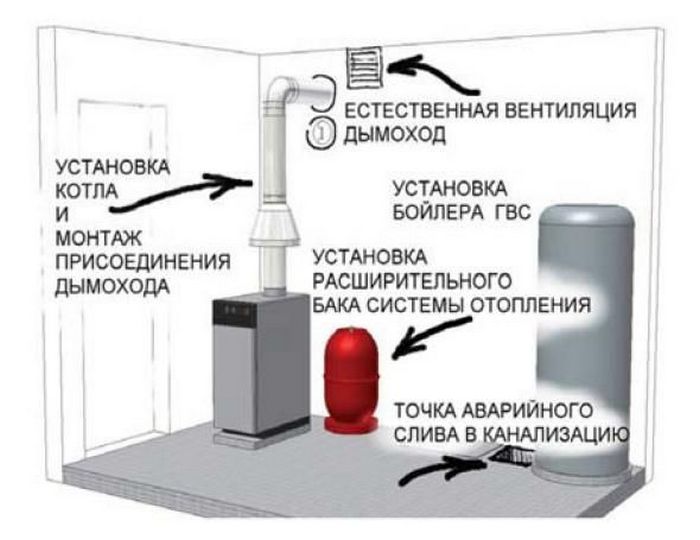

Extension of boiler rooms

Of course, it is very convenient to have a separate room for gas equipment, but such an opportunity is far from always available, and you have to think about where to place a gas boiler in a private house under such conditions. The solution to the problem is the extension of the boiler room.

The standards in this case are the same as those described above, but there are a number of additional requirements:

- The boiler room can only be attached to a solid wall;

- The distance between the nearest window or door should be more than one meter;

- The boiler room can only be laid out using non-combustible materials that can last at least 0.75 hours before igniting;

- The walls of the boiler room itself should be built separately from the main building - i.e. you will need your own foundation and four new walls.

In order to be able to run a gas main into the equipped boiler room, the building must be registered without fail. In the absence of relevant documents, representatives of the gas service will simply refuse to approve the equipment, even if all the standards are met.

How to install the boiler correctly?

It is not worth starting work on installing a gas boiler with the equipment of the boiler room. And not even from determining the model of the boiler, but from finding out whether it is possible to do this at all.

Why should you contact Gorgaz (Raygaz) in order to obtain technical conditions, and at the same time permission to design a boiler house.

Appeal to Gorgaz is made in writing. It is necessary to submit an application, to which, and without fail, are attached:

- copies of documents confirming that the applicant is the owner of the building and adjacent land;

- put on a situational plan. This item is relevant only if the boiler room will be located in a separate building, which does not yet exist.

Applicants will also need to verify their identity.

The procedure for installing a gas boiler should be initiated by submitting an application - and this is also an established rule. Like all other steps in this procedure

The procedure for installing a gas boiler should be initiated by submitting an application - and this is also an established rule. Like all other steps in this procedure

The submitted document should state the request for the provision of technical conditions and indicate the planned gas consumption.If its exact value is not known, and the property owner himself does not have the necessary knowledge to perform the calculation, then this service can be negotiated with representatives of Gorgaz. But for this you will have to submit a separate application.

Gas workers are required to issue technical conditions within the established 10 days. But the reality is that the terms depend on the workload of the specialists of one or another city gas company.

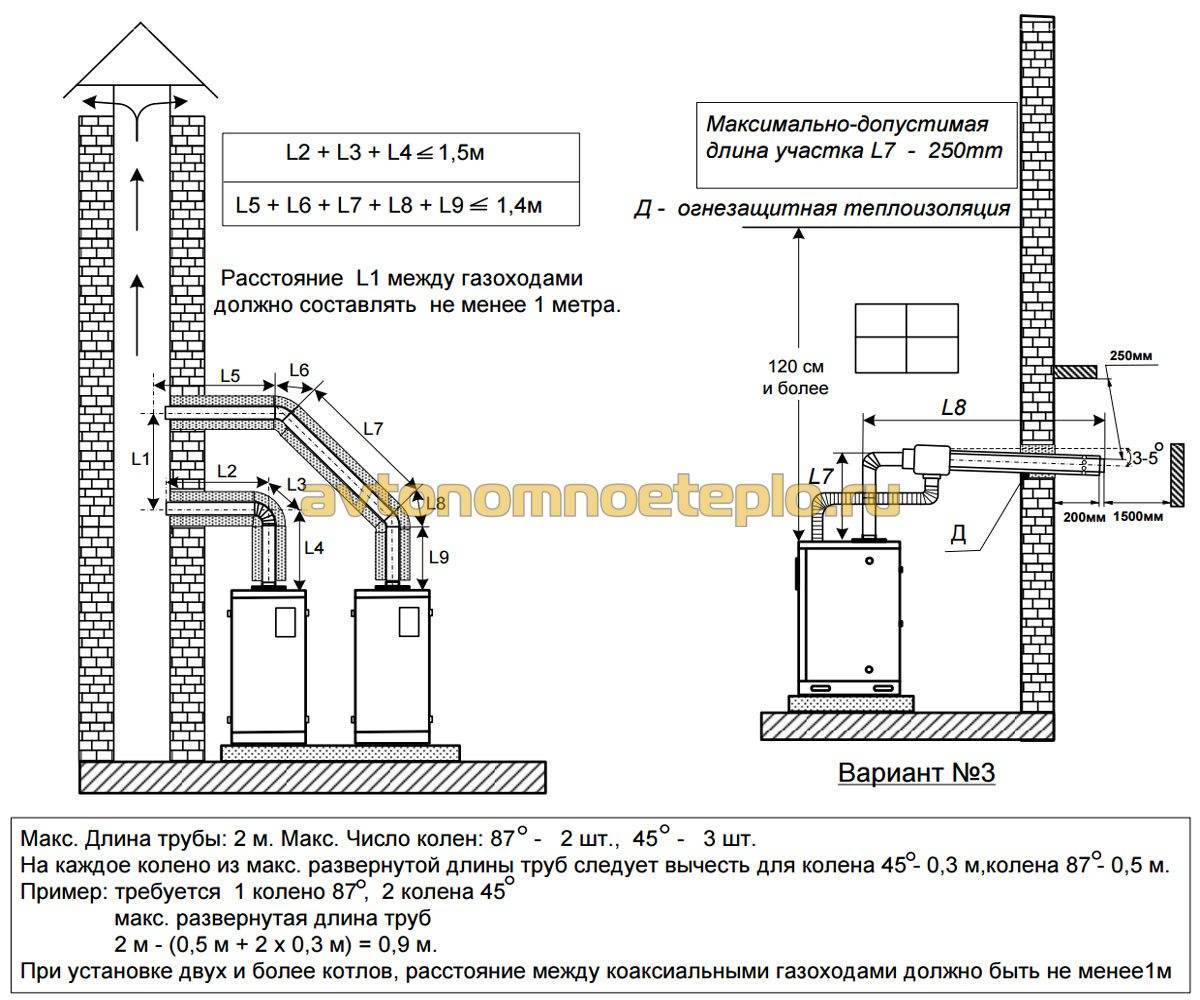

Room for the installation of a gas boiler

The volume of the room for a gas boiler depends on the type of unit and its power. All requirements for the boiler room or other place where the device is located are prescribed in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

Gas boilers differ in the type of combustion chamber:

…

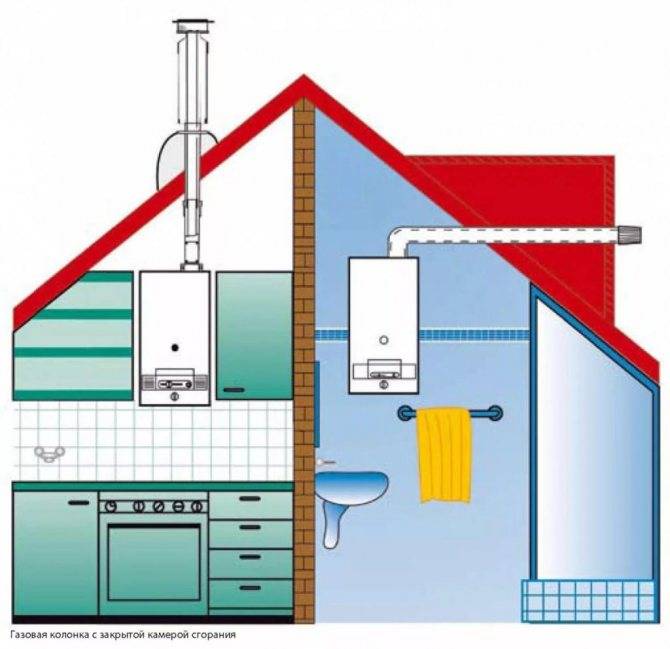

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full-fledged chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require a device for a gas boiler in a separate room - a boiler room.

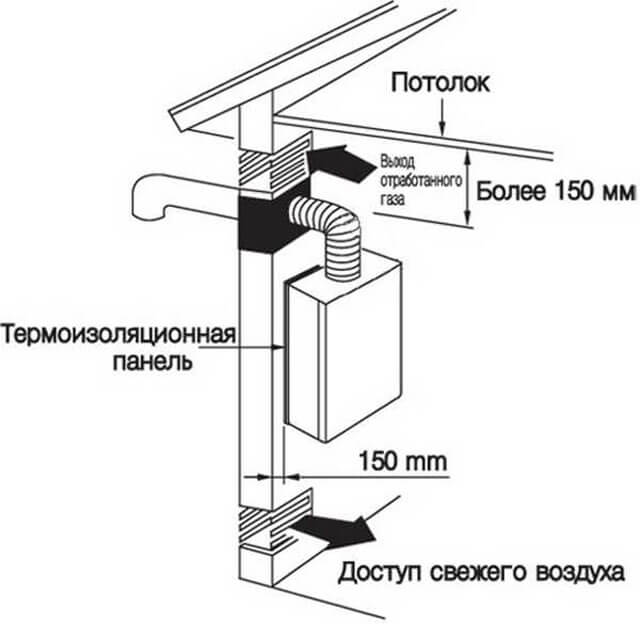

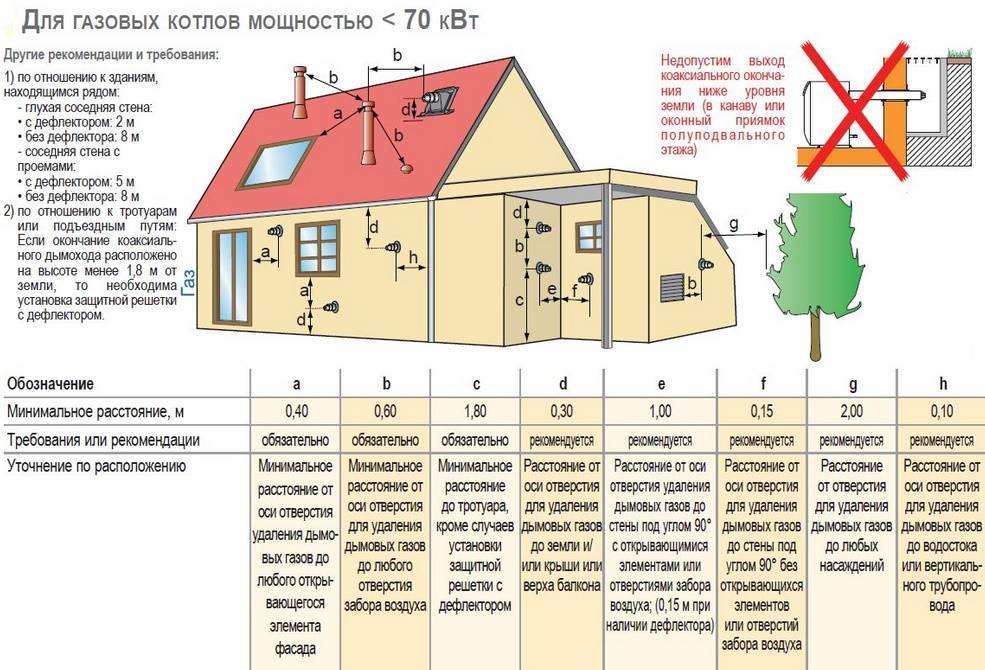

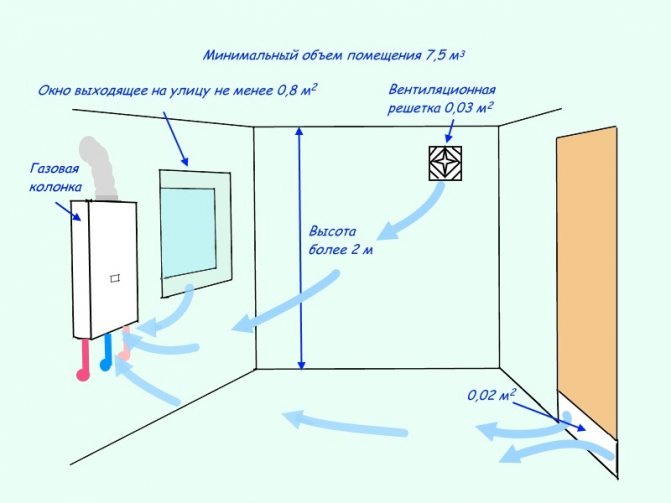

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-storey building. The removal of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

boiler room requirements

The minimum volume of the room for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum volume of the boiler room, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also, a boiler room for placing an atmospheric gas boiler must meet the following requirements:

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m. They must open towards the street.

- The door to the boiler room must not be hermetically sealed. It is required to leave a gap between it and the floor 2.5 cm wide or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3 × 0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of the volume of the furnace, 0.03 m2 of the area of the window opening should be added.

- The presence of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electric light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not a mandatory, but recommended condition. It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

The boiler must be freely accessible from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

…

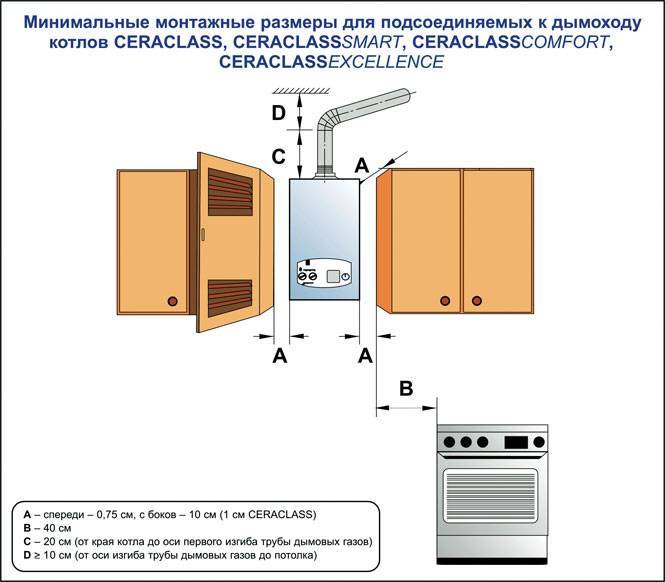

Requirements for the room for the installation of a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate furnace. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height over 2m.

- Volume - not less than 7.5 m³.

- Has natural ventilation.

- Closer than 30 cm next to the boiler there should not be other appliances and easily combustible elements: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact hinged gas boilers are even placed between cabinets in the kitchen, built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before it reaches the consumer.

In addition to generally accepted standards, each region also has its own requirements for a room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the nuances of placement operating in a given city.

2 Design documentation for a gas boiler house

Design documentation is developed by design specialists, whose right to this activity is confirmed by the relevant papers. The project reflects the scheme of laying gas communications along the personal plot to the entrance to the boiler room. This point must be reflected in the sketch.

Project documentation for a gas boiler house should be handled by specialists

The prepared project must be submitted to the service that controls the gas supply at home. Other documents to be submitted along with the application:

- Technical passport of the gas heating boiler;

- Operating Instructions;

- Certificates of conformity of the boiler to SES standards and documentary evidence of its safety for people and the environment.

All these documents are drawn up by the boiler manufacturer and given to the buyer upon sale. Consideration of an application for gasification of a house can take up to three months. Depends on the complexity of the project. The minimum period is one week.

Based on the results of verification of the submitted documents, the commission issues a positive verdict or a justified refusal. In the latter case, the applicant is invited to eliminate the identified shortcomings and resubmit the documents.

Conclusions and useful video on the topic

Rules for the use of gas in everyday life:

Requirements for the operation of gas appliances:

About the safety of use gas powered equipment:

Even to the slightest extent, neglect building codes, operating rules and fire safety requirements when using a gas boiler it is forbidden.

To avoid emergency situations, it is necessary to constantly monitor both the technical condition of the column, and the tightness of the gas pipeline connections and the absence of blockage in the chimney. Only if all the above recommendations are followed, it will be possible to talk about the safe operation of the gas heating system.

Please write comments, ask questions, post photos on the topic of the article in the block form below. Tell us about how you comply with the requirements for the safe and trouble-free operation of a gas boiler. Share useful information.