- Pipe connections

- Is it possible to connect 2 boilers or more to one chimney

- More air requirements

- Main regulatory documents

- According to SP62.13330.2011:

- Requirements for chimneys for gas boilers

- Height norms

- Ventilation of a gas boiler room requires special attention.

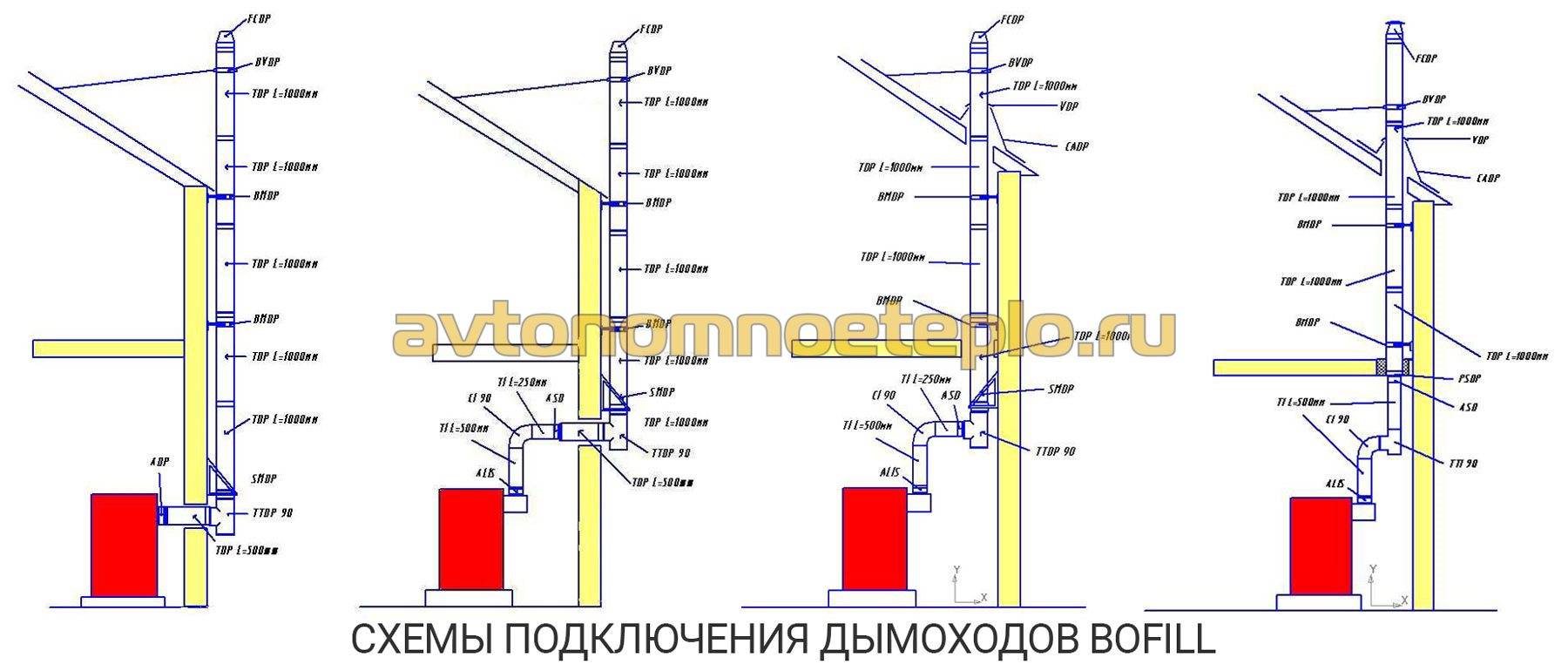

- The installation of a chimney can be considered using the example of a double-circuit design

- Room for the installation of a gas boiler

- boiler room requirements

- Requirements for the room for the installation of a turbocharged unit

- Ventilation for a boiler room in a private house

- Basic requirements for the premises for the placement of gas boilers

- To the kitchen

- To the apartment

- To a private house

- To the boiler room

- Conclusions and useful video on the topic

Pipe connections

Installation requires welding. Quality control of welding work is regulated in SNiP 3.05. 03.85 5.

Heating pipe welding

- It is required to connect gas water heaters and other gas appliances to the chimney with pipes that are made using roofing steel.

- The length of the connected pipes should not exceed 3 meters in new buildings and more than 6 meters in existing ones.

- The slope of the pipe in relation to the device must be at least 0.01.

- On pipes that remove smoke, no more than 3 bends are allowed, the radius should not be less than the diameter of the pipe.

- The connection of pipes must be tight, the entry of one pipe into another must be at least half the diameter of the pipe.

- If the pipes are made of black iron, they must be painted with a fire-resistant varnish.

Is it possible to connect 2 boilers or more to one chimney

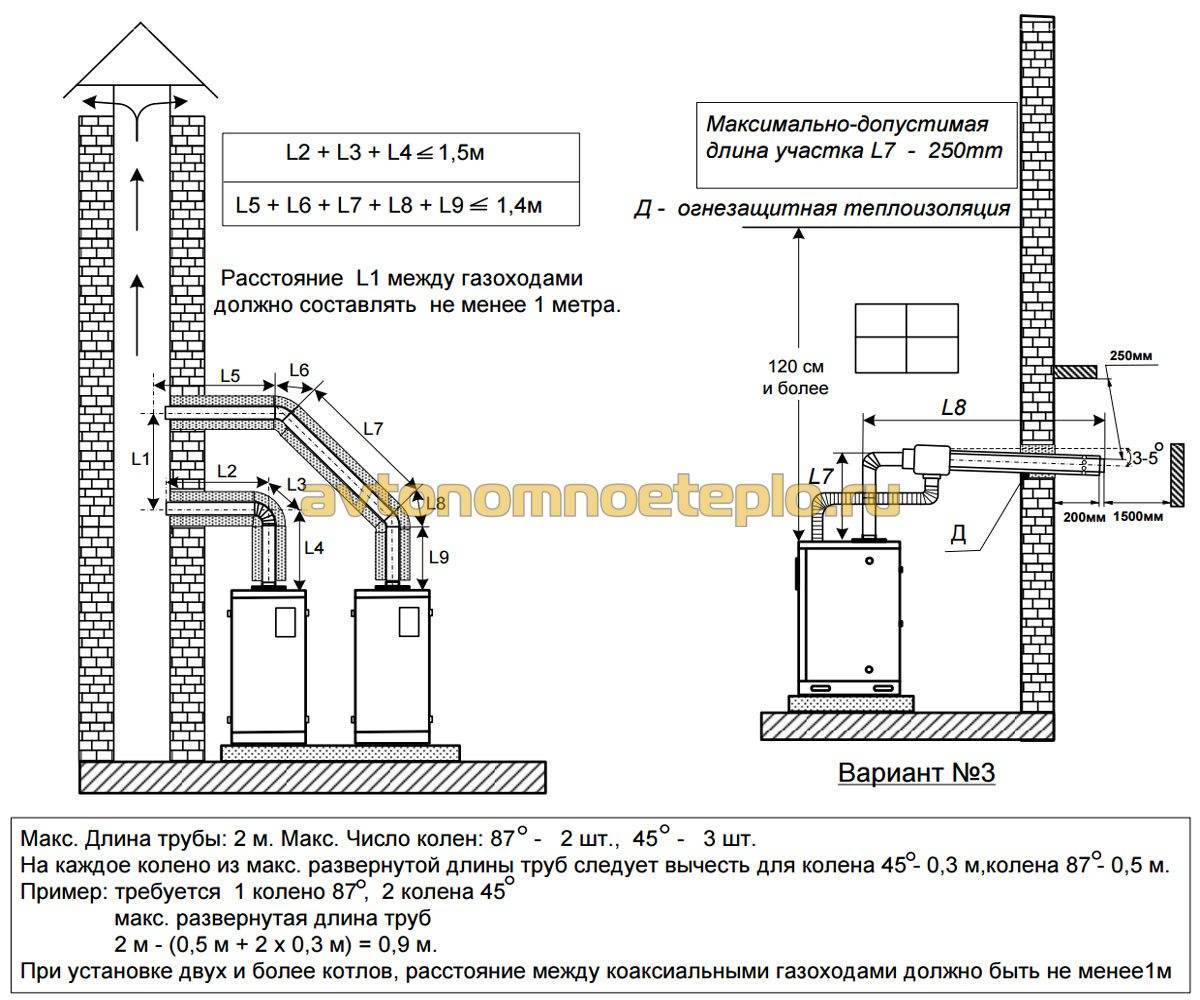

No more than 2 boilers (heaters, stoves ...) can be connected to one chimney, but only in existing houses. In others, each gas boiler must be equipped with its own chimney.

In existing houses, the cross section of the chimney must correspond to the performance of the two boilers that are connected. Also, the connections must be at different levels, and the distance between them is not less 0.75 meters. Or, the connection can be made at the same level, but from this place and 0.75 m higher, a cut must be made in the chimney while ensuring the proper section (which is rare in practice).

Or, no more than 2 boilers (water heaters, stoves) can be connected, but they must work in turn, their simultaneous operation is not allowed, which must be provided with appropriate electrical (mechanical) protection, while the cross section must correspond to the unit with high requirements.

Thus, it is possible to include the main and backup heat generators, or a boiler and a water heater in one chimney, for example, if there is a blockage from their simultaneous operation.

More air requirements

But the operation of an atmospheric boiler must be ensured by a sufficient amount of air entering the room, unless the unit itself takes this air from the street through a separate pipe. Also, the air supply to the room and exhaust ventilation should also provide a three-time air exchange within an hour.As for the inflow, it is allowed to flow from other rooms of the building, for which an inlet opening with an area of at least 200 cm2 is created in the door (structure) of the boiler room.

Or such a supply hole is made for air to enter from the street. But in order to prevent icing, which will inevitably occur, it is possible to make an oblong box inside the room along the wall descending from top to bottom, through which the supply air, entering the room, would be heated with heat, and the condensate would flow into a container and drain into the sewer ...

Main regulatory documents

Requirements for gas boilers are given in the following regulatory documents in force in 2020:

- SP 62.13330.2011 Gas distribution systems. (Updated version of SNiP 42-01-2002)

- SP 402.1325800.2018 Residential buildings. Rules for the design of gas consumption systems (acting on a voluntary basis by order 687)

- SP 42-101-2003 General provisions for the design and construction of gas distribution systems from metal and polyethylene pipes (it is advisory in nature)

- Instructions for the placement of thermal units intended for heating and hot water supply of single-family or detached residential buildings (MDS 41-2.2000) (it is advisory in nature)

We highlight the most important requirements (point by point) that must be met when design and construction of a gas boiler house in the house, as well as when designing the path of laying a gas pipeline:

According to SP62.13330.2011:

pp.5.1.6* Gas pipelines should be introduced into buildings directly into the room in which gas-using equipment is installed, or into a room adjacent to it, connected by an open opening.

It is allowed to provide for the entry of gas pipelines into the kitchens of apartments through loggias and balconies, provided that there are no detachable connections on the gas pipelines and access is provided for their inspection.

It is not allowed to introduce gas pipelines into the premises of the basement and basement floors of buildings, except for the inputs of natural gas pipelines into single-family and block houses and industrial buildings, in which the input is due to production technology.

pp. 5.2.1 Laying of gas pipelines should be carried out at a depth of at least 0.8 m to the top of the gas pipeline, case or ballasting device, except as otherwise specified. In those places where the movement of vehicles and agricultural machines is not provided, the depth of laying steel gas pipelines should not be less than 0.6 m.

pp. 5.2.2 Vertical distance (in the light) between the gas pipeline (case) and underground networks engineering and technical support and structures at their intersections are recommended to be taken in accordance with Appendix B * SP62.13330.2011.

According to Appendix B * for underground laying of a gas pipeline (gas pressure up to 0.005 MPa) and the most common communications on the land plot of a private house:

- Vertically (when crossing) with water supply and sewerage - at least 0.2 m clear (between pipe walls)

- Horizontally (in parallel) with water supply and sewerage - at least 1 m

- Horizontally (in parallel) with power cables up to 35 kV - at least 1 m (with a protective wall, it can be reduced to 0.5 m)

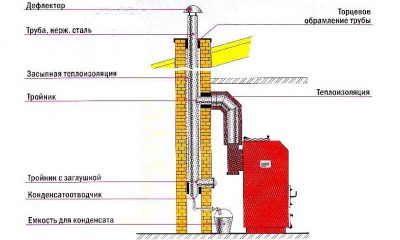

Requirements for chimneys for gas boilers

The chimney for the boiler must comply with certain characteristics and standards, otherwise, most likely there will be problems later when using it. For example, here are the basic rules for a chimney:

The slope that is allowed to be allowed, in no case, should not exceed 30 degrees, regardless of location.

The length for the lateral "processes" should not exceed the allowable values, namely 100 cm.

It is forbidden to intentionally or arbitrarily make ledges, ledges in the channel.

Cross-sections located across are prohibited due to a violation of the drainage system and the passage of thrust.

The number of "tees" is not more than three.

It is allowed to make roundings, but remember that their radius should not be lower than the diameter of the chimneys.

In corners, it is better to foresee the installation of special "containers" for collecting condensate, as well as hatches for prevention.

In the event that it was preferred to use a channel not of a round shape for the chimney, but, say, an oval or even an elongated rectangular one, then the width of one of the sides should not exceed the width of the other side twice.

At the very bottom of the channel, a “drip” and a moisture collector are equipped.

Even minimal deflections of the system are prohibited.

Consider the fact that when mounting several segments, they must be inserted into each other by at least 0.5 integers from the original diameter.

Any gaps between are prohibited.

Please note that in places where it is required to install a ceiling or in walls, it is forbidden to skip non-solid segments. The connection is made either before or after the passage.

The connection must be tight, use additional special tools.

Remember another important factor, the slope of the chimney towards the heat source cannot be more than 0.01 degrees.

Do not forget that the inner walls should be as smooth as possible.

Even small roughness creates an obstacle to the passage of soot, which subsequently accumulates there.

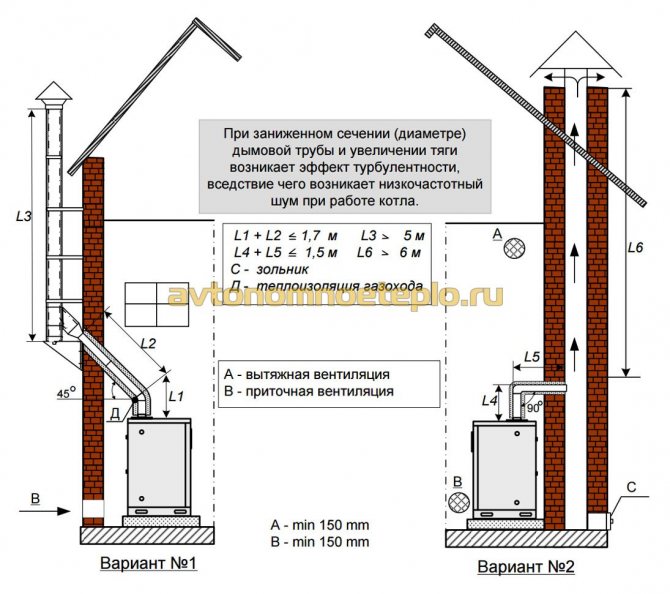

Consider two rules: the length of the horizontal section for buildings that are still at the construction stage should be no more than 300 cm, for houses already built no more than 600 cm.

Also remember that the distance between the pipe and the finishing material, the ceiling, if it is combustible, should not be more than 250 mm. or 50 mm. if the material is fire resistant.

In places where the smoke duct needs to be drawn through the ceiling, high-quality thermal insulation is made.

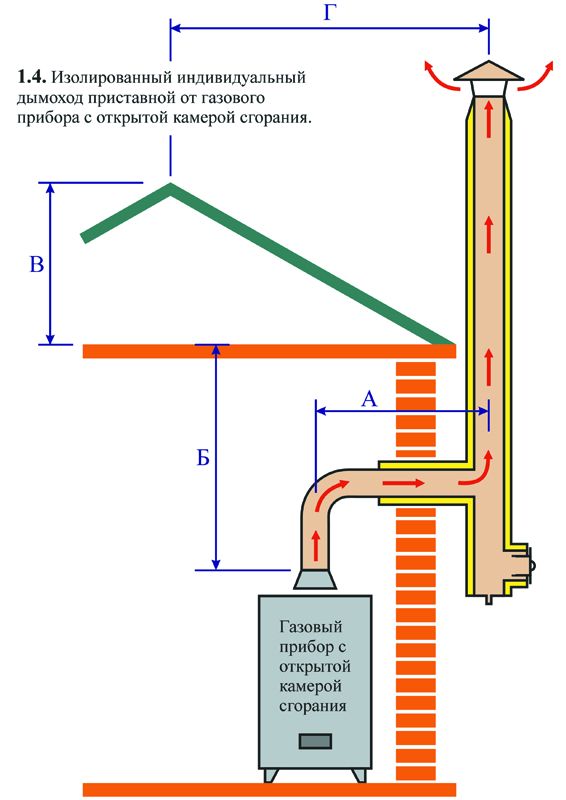

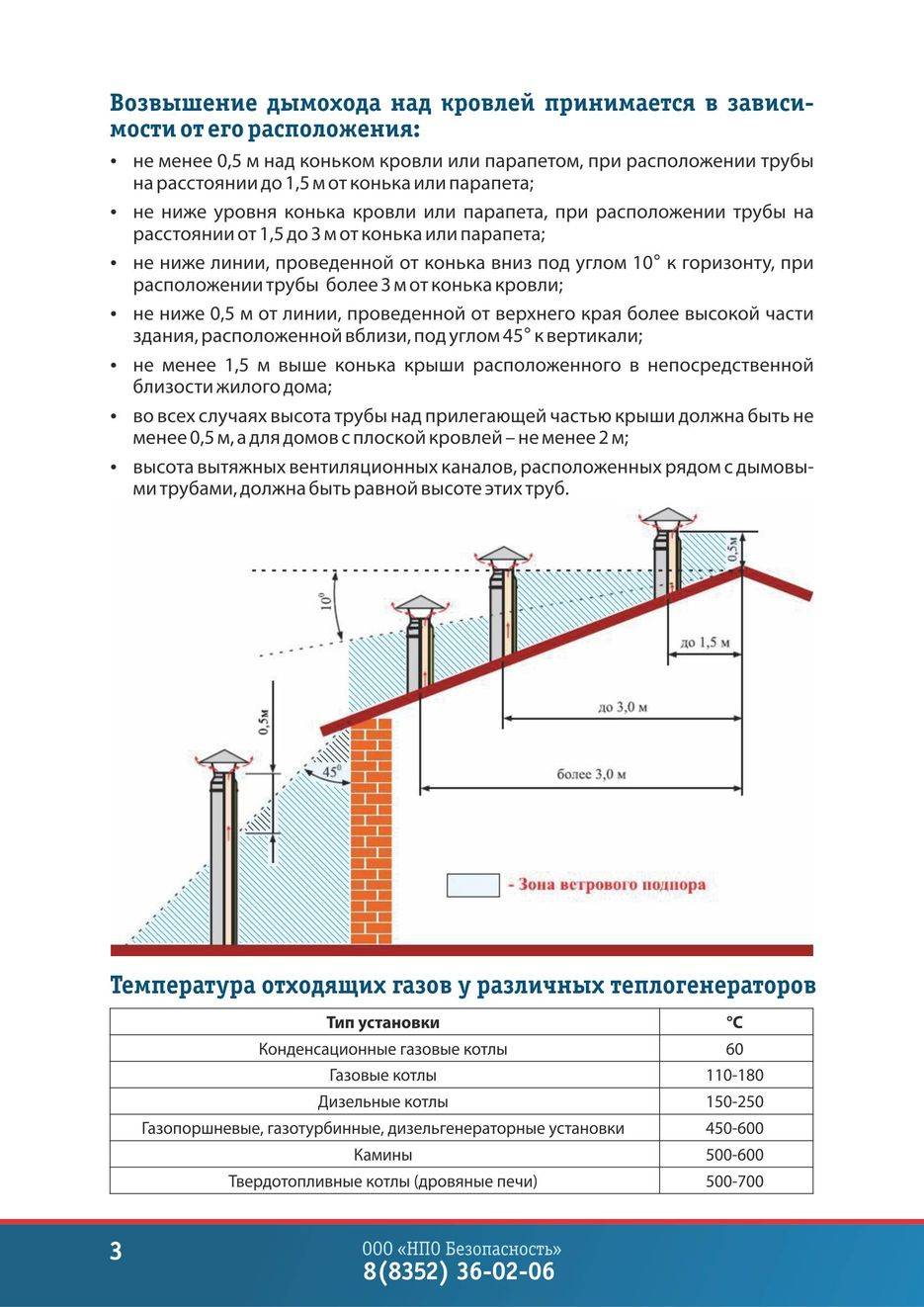

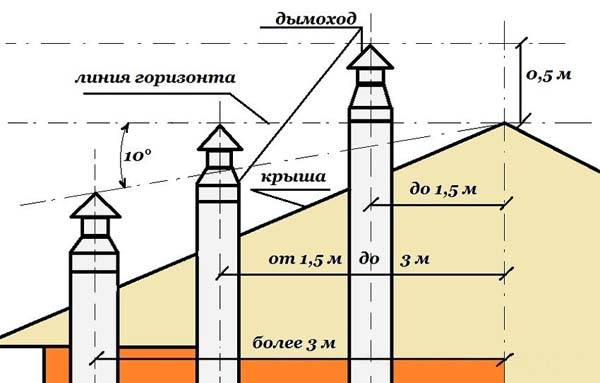

Height norms

Requirements for the chimney when installing a gas boiler

Requirements for the chimney when installing a gas boiler

As you can see, the requirements for chimney channels for gas boilers serious enough and should not be neglected. In addition to the points listed, there are also special rules for the device regarding height. So:

- If the distance from the pipe to the roof to the ridge is more than 300 cm, then you have complied with the standard values. This arrangement is allowed without increasing the height of the chimney.

- At the same level with the ridge, you need to install pipes that are at a distance of more than 150 cm.

- If the distance is less than 150 cm, it rises to a height of up to 50 cm from the ridge.

In addition, remember the rule, if the roof has a common roof and is flat, the head rises at least 50 cm.

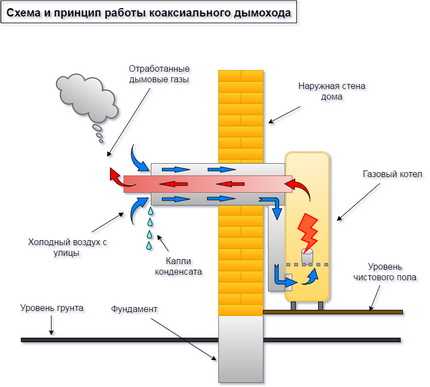

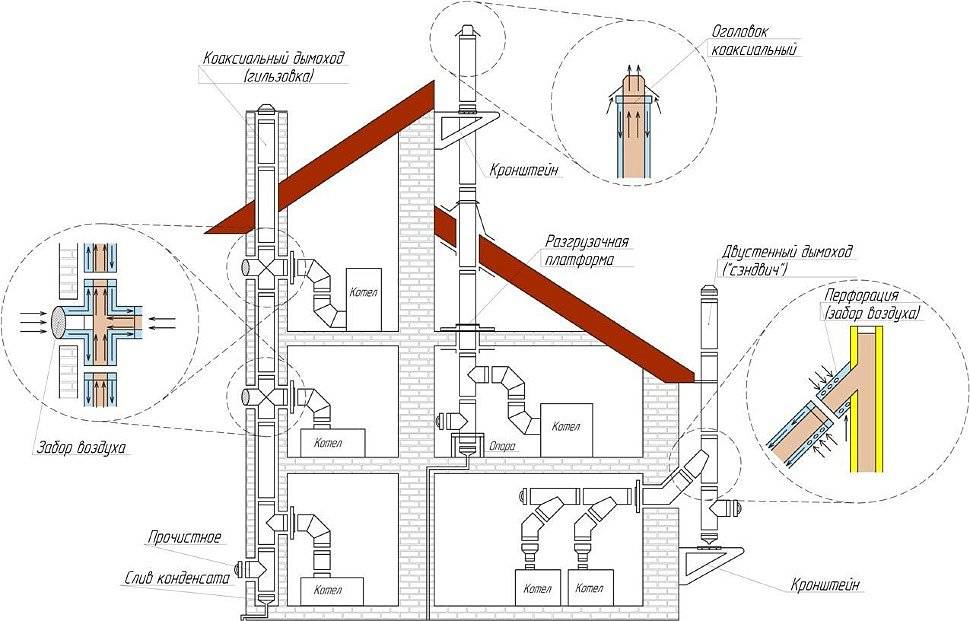

Ventilation of a gas boiler room requires special attention.

Ventilation in a boiler room with a gas boiler is a different story, because wherever there is gas, there is an increased fire hazard. The best and safest option is a turbocharged boiler with a double-circuit coaxial output. In such a chimney, air from the street is taken in along the outer radius, and exhaust from the boiler occurs through the inner radius. Among other things, such a conclusion increases the efficiency of the boiler, because when air is taken in, it is already warming up due to the fact that hot air is ejected along the inner radius.

Ventilation systems are a very important part of any boiler house, because, first of all, it ensures the safety of people living in the house, by releasing harmful combustion products from the house to the outside. Ventilation in the boiler room is also the provision of the boiler for its normal operation.

We all know from school that combustion is a special case of an oxidative reaction. In this case, the more intense the reaction, the more oxygen is consumed. Atmospheric oxygen is required to maintain an open flame. And gas boilers are no exception. For the normal operation of a combustion heating system gas or liquid fuel, requires a constant supply of fresh air in a certain volume and the disposal of combustion products, that is, there must be exhaust and supply ventilation of the boiler room.

Ventilation of autonomous heat supply sources is regulated by state regulations SP-41-104-2000, SNiP 2.04.05 and SNiP II-35. However, in private construction, the norms are often not respected. Insufficient supply ventilation leads to incomplete combustion of the gas (the oxidation process loses intensity), as a result of which the efficiency of the heating installation decreases.The absence or poor operation of the exhaust ventilation system leads to indoor air pollution by combustion products (oxides) and gas residues. As a result, poor health, a threat to health and even life, soot on the ceiling and walls.

A working gas boiler, like a powerful pump, draws air from the room, passing it through the combustion zone. If the house has old windows and doors, then, as a rule, unsealed cracks are usually enough for fresh air to enter through natural infiltration. But in the era of modern building materials, sealed double-glazed windows and doors with an automatic porch, the boiler room is isolated from the external environment. As a result, the performance of the boiler drops due to the lack of atmospheric oxygen for the normal course of combustion, and in addition, a vacuum is created in the room, which can cause the thrust to overturn. In this case, all combustion products will go straight into the room.

The optimal solution for the normal operation of the boiler room is the supply and exhaust ventilation device.

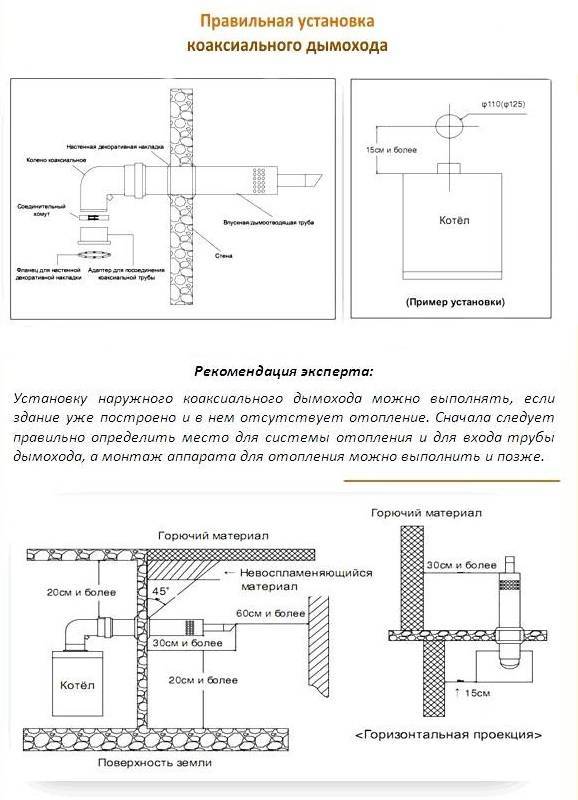

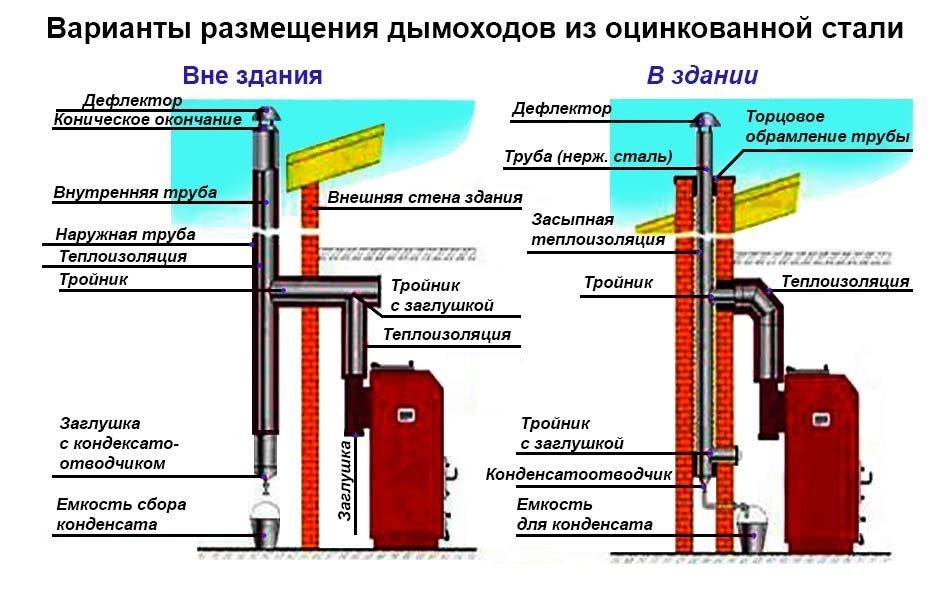

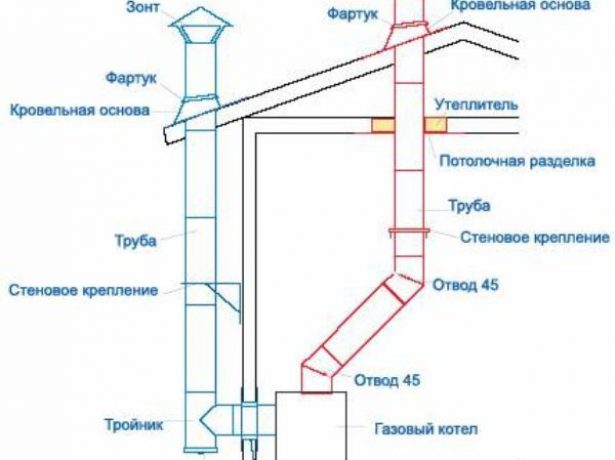

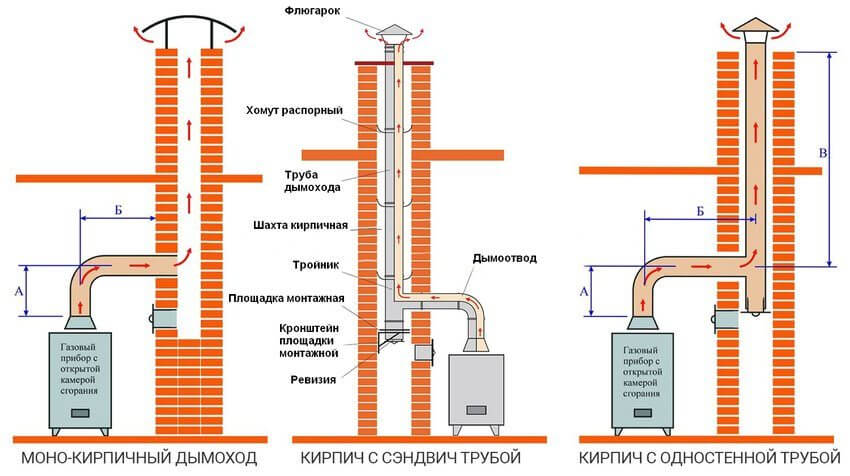

The installation of a chimney can be considered using the example of a double-circuit design

Chimneys for a gas boiler are being installed in the direction of the structure from the bottom up, that is, from the heating objects of the room towards the chimney. With this installation, the inner tube is put on the previous one, and the outer tube is inserted on the previous one.

All pipes are fastened to each other with clamps, and along the entire laying line, every 1.5–2 meters, brackets are installed to fix the pipe to a wall or other building element.A clamp is a special fastening element, with the help of which not only the parts are connected to each other, but also the tightness of the joints is ensured.

The laid sections of the structure in the horizontal direction up to 1 meter should not come into contact with elements that pass close to the communications. The working channels of the chimney are placed along the walls of buildings.

Be sure to install a bracket on the wall every 2 meters of the chimney, and the tee is attached using a support bracket. If it is necessary to fix the channel on a wooden wall, then the pipe is lined with non-combustible material, for example, asbestos.

When attaching to a concrete or brick wall, special aprons are used. Then we bring the end of the horizontal pipe through the wall and mount the tee necessary for the vertical pipe there. It is necessary to install the brackets on the wall after 2.5 m.

The next step is to mount, lift the vertical pipe and bring it out through the roof. The pipe is usually assembled on the ground and the mount for the brackets is prepared. The fully assembled volumetric pipe is difficult to install on the elbow.

To simplify, a hinge is used, which is made by welding pieces of sheet iron or cutting a pin. Typically, the vertical pipe is inserted into the tee pipe and secured with a pipe clamp. The hinge is attached to the knee in a similar way.

After raising the pipe in a vertical position, the pipe joints should be bolted where possible. Then you should unscrew the nuts of the bolts on which the hinge was fastened. Then we cut or knock out the bolts themselves.

Having selected the hinge, we attach the remaining bolts in the connection.After that, we stretch the remaining brackets. We first adjust the tension manually, then we fix the cable and adjust it with screws.

Necessary distances to be observed when the chimney is located outside

The installation is completed by checking the chimney draft. To do this, bring a burning piece of paper to the fireplace or stove. Draft is present when the flame is deflected towards the chimney.

The figure below shows the distances that must be observed in various options for the location of the chimney from the outside:

- when installed on a flat roof, the distance must not be less than 500 mm;

- if the pipe is removed from the roof ridge to a distance that is less than 1.5 meters, the height of the pipe must be at least 500 mm in relation to the ridge;

- if the chimney outlet installation is located at a distance of more than 3 meters from the roof ridge, then the height should not be more than the expected straight line.

The setting depends on the type of duct directions required for the combustion of the fuel. In the interior of the room, there are several types of directions for the chimney channel:

Support bracket for chimney

- direction with a rotation of 90 or 45 degrees;

- vertical direction;

- horizontal direction;

- direction with a slope (at an angle).

It is necessary to install support brackets for fixing the tees every 2 meters of the smoke channel, it is necessary to provide additional wall mounting. In no case, when installing a chimney, horizontal sections higher than 1 meter should not be created.

When installing chimneys, consider:

- the distance from metal and reinforced concrete beams to the inner surface of the chimney walls, which should not exceed 130 mm;

- the distance to many flammable structures is at least 380 mm;

- cuttings for non-combustible metals are made for the passage of smoke channels through the ceiling to the roof or through the wall;

- the distance from combustible structures to an uninsulated metal chimney must be at least 1 meter.

The connection of the chimney of a gas boiler is carried out on the basis of building codes and the manufacturer's instructions. The chimney requires cleaning up to four times a year (see How to Clean a Chimney).

In order to optimally calculate the height of the chimney, it is necessary to take into account the type of roof and the height of the building:

- the elevation of the chimney pipe must be at least 1 meter when installed on a flat roof and at least 0.5 meters above a non-flat one;

- the location of the chimney on the roof must be made at a distance of 1.5 meters from the ridge;

- the height of an ideal chimney has a height of at least 5 meters.

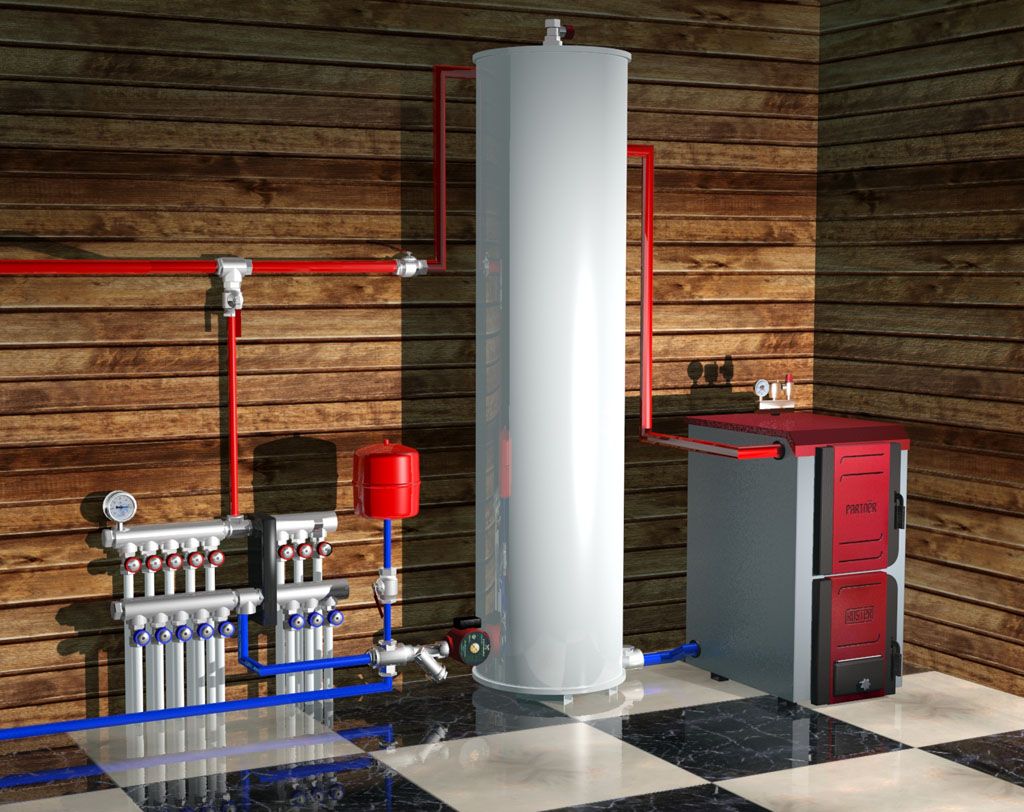

Room for the installation of a gas boiler

The volume of the room for a gas boiler depends on the type of unit and its power. All requirements for the boiler room or other place where the device is located are prescribed in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

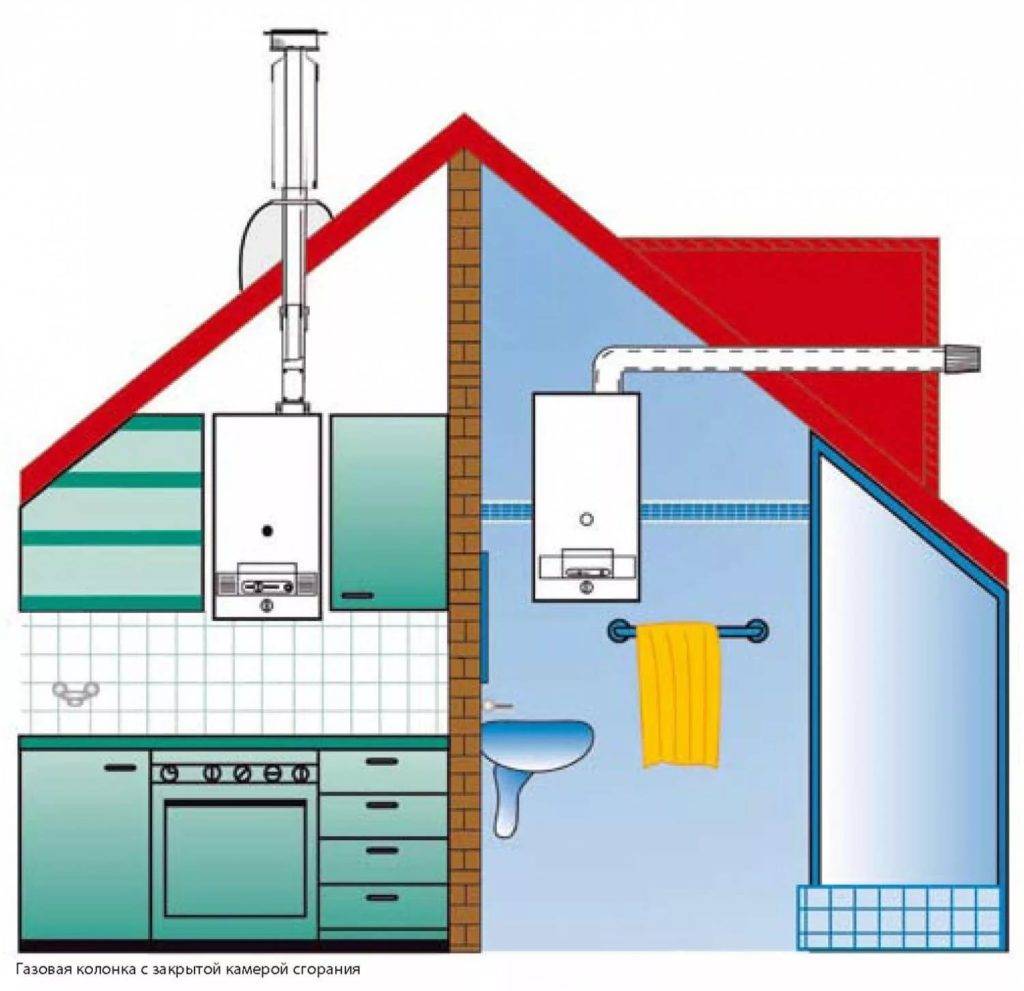

Gas boilers differ in the type of combustion chamber:

…

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full-fledged chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require gas boiler device separate room - boiler room.

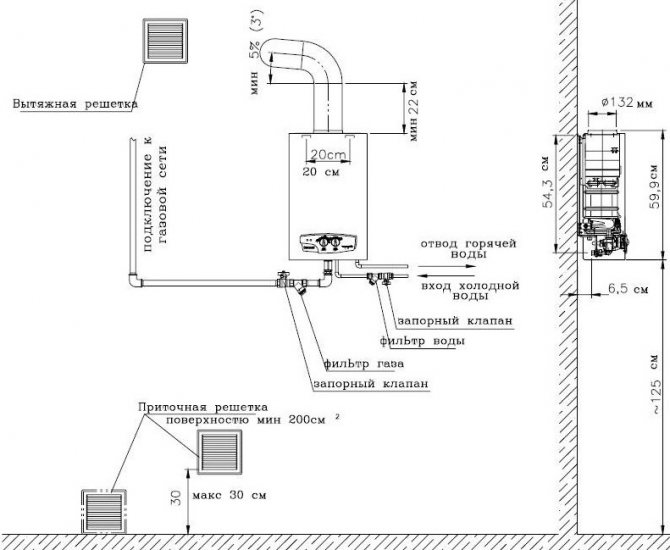

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-storey building.The removal of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

boiler room requirements

Minimum room volume for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum volume of the boiler room, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also a boiler room for placement of an atmospheric gas boiler must meet the following requirements:

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m. They must open towards the street.

- The door to the boiler room must not be hermetically sealed. It is required to leave a gap between it and the floor 2.5 cm wide or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3 × 0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of the volume of the furnace, 0.03 m2 of the area of the window opening should be added.

- The presence of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electric light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not a mandatory, but recommended condition. It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

The boiler must be freely accessible from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

…

Requirements for the room for the installation of a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate furnace. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height over 2m.

- Volume - not less than 7.5 m³.

- Has natural ventilation.

- Closer than 30 cm next to the boiler there should not be other appliances and easily combustible elements: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact hinged gas boilers are even placed between cabinets in the kitchen, built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before it reaches the consumer.

In addition to generally accepted standards, each region also has its own requirements for a room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the nuances of placement operating in a given city.

Ventilation for a boiler room in a private house

As already mentioned, the calculation of ventilation performance is calculated from the volume of the room. It must be multiplied by 3, add about 30% to the reserve. We get the volume that needs to be “pumped” per hour.

For example, a room 3 * 3 m with a ceiling height of 2.5 m. Volume 3 * 3 * 2.5 \u003d 22.5 m3. Three exchanges are required: 22.5 m3 * 3 = 67.5 m3. We add a margin of 30% and get 87.75 m3.

To ensure natural ventilation in the lower part of the wall, there should be an inlet, covered with a grate. The exhaust pipe must exit through the roof, it is possible to exit through the wall in its upper part.It is necessary to bring the ventilation pipe to the same height as the chimney.

Basic requirements for the premises for the placement of gas boilers

The fire safety of the premises is ensured by the fire resistance of the walls and floor, as well as by reliable triple natural air circulation.

Minimum Volumes rooms depend on the heat output units:

- Up to 30.0 kW - 7.5 m3;

- from 30.0 to 60.0 kW - 13.5 m3;

- over 60 kW - 15 m3.

For units with a power of more than 60 kW, 0.2 m3 of volume is added for each additional kW, for example, for a gas boiler with a power of 150 kW, the volume of the furnace room should be equal to:

150-60 = 90 x 0.2 + 15 = 33 m2.

To the kitchen

This room today is the most applicable for arranging gas boilers, especially the wall-mounted version. Many users try to close the boiler from public view, so they install it either in a special box or cover it with a decorative panel.

The boiler in the kitchen can also be beautifully placed

The boiler in the kitchen can also be beautifully placed

In order for the gas service not to impose a ban on such an installation, it is necessary to know and comply with the rules for placing boilers in the kitchen.

In terms of the main parameters: the height of the ceilings, the minimum area and the presence of three times the air circulation, the requirements for kitchens are similar to other furnace rooms.

To the apartment

Installing a gas heating boiler in an apartment is much more difficult, especially in a multi-storey building with access to central heating. The owner needs to be very reasoned in order to obtain permission from the local administration for such an installation.

Next, you will need to obtain technical specifications from all engineering services: city gas, heating network and balance holder of the house.Further, according to the general scheme, the project is carried out, coordinated with the architectural department of the local administration, and the boiler is installed by a specialized organization.

The rules allow the installation of boilers in multi-apartment residential buildings no higher than 3 floors and with a power of up to 30 kW. In kitchens integrated into the living room, installation of closed-type units is allowed.

All these actions will become impossible if the room for installing a gas boiler in an apartment does not meet the general requirements. The most difficult will be to make a through hole in the wall to connect the chimney pipe.

To a private house

In a private house, there are more opportunities for the safe installation of gas heating equipment. In accordance with current regulations, gas equipment is allowed only in rooms with good natural ventilation.

They may be located:

- On the 1st floor.

- In basements or basements.

- In the attic.

- In the kitchen units up to 35 kW.

- Thermal power up to 150 kW - on any floor, in an individual building.

- Thermal power from 150 to 350 kW - in extensions.

To the boiler room

The boiler room attached or equipped inside the house is built from fire-resistant building materials. The interior finish is also heat resistant.

The gas boiler room must have:

- Individual foundation and concrete floor covered with ceramic tiles.

- Adjacency to a blank solid wall of an object.

- Be at a distance of 1 m from the window and door.

- Have natural ventilation with three air changes per hour.

- Have an opening window with a glazing area of 0.03 m2 per 1 m3 of the furnace volume.

- Ceiling height over 2.2 meters.

- Have a separate power supply with devices: sockets, switches, machines.

- For power below 30 kW, the volume of the furnace should be more than 7.5 m3, and for 30-60 kW - more than 13.5 m3.

- Air intake for the gas combustion process must be carried out through a coaxial chimney, a window, ventilation holes.

Conclusions and useful video on the topic

Video #1 The device of a coaxial chimney, the principle of its operation and installation features are presented in the following video:

Video #2 The complete set of a coaxial chimney of industrial production is shown here in detail:

Video #3 Overview of coaxial anti-icing kit:

A coaxial chimney is a convenient and easy-to-install device that can significantly improve life in the house.

But in order for such a chimney to function effectively, it is important to comply with the norms and requirements when installing it.

Did you have any questions while reading the material, did you find any shortcomings or would you like to tell us about your own experience in assembling and using a coaxial chimney? Please post your comments in the block below the article. Leave posts with your opinion and photos on the topic.