- Composition and features of biofuels

- Bioreactor

- What materials can be made

- Reactor sizing

- Pros and cons of biofuels

- How to make a biofireplace with your own hands?

- Types of environmentally friendly biofuels

- Fireplace in the interior of different rooms

- Living room

- Bedroom

- Kitchen

- Features of biofireplaces

- Advantages

- Flaws

- Summing up

Composition and features of biofuels

The “bio” part of the word “biofuel” explains that only natural, renewable raw materials are used to make this substance. Therefore, it is completely environmentally friendly and biodegradable.

The main components used for the production of such fuels are herbaceous and grain crops containing large amounts of starch and sugar. Thus, corn and cane are considered the best raw materials.

On sale you can find biofuels of various brands. Preference should be given to certified products, otherwise you may face serious troubles

They produce bioethanol or a kind of alcohol. It is a colorless liquid and has no odor. If necessary, they can replace gasoline, however, the cost of such a substitute is much higher. When burning, pure bioethanol decomposes into water in the form of vapors and carbon dioxide.

Thus, it is even possible to humidify the air in the room where the biofireplace is installed.The substance burns with the formation of a blue "gas" flame.

This is a purely aesthetic flaw, which still prevents you from enjoying the view of an open fire. A traditional fireplace gives a yellow-orange flame, which is a kind of standard. To eliminate this shortcoming, additives are introduced into biofuels that change the color of the flame.

Thus, the traditional composition of a combustible liquid is as follows:

- bioethanol - about 95%;

- methyl ethyl ketone, denaturant - about 1%;

- distilled water - about 4%.

In addition, crystalline bitrex is added to the fuel composition. This powder has an extremely bitter taste and is designed to prevent alcohol biofuels from being consumed as alcohol. Biofuels of different grades are produced, its composition may vary somewhat, but in general it does not change. It is clear that the cost of such fuel is quite high.

It is not recommended to use home-made fuel for bio-fireplaces, but if you still decide to try it, you need to take only high-purity gasoline “Kalosha” for its manufacture

Fuel consumption depends on the number of burners and the power of the biofireplace. On average, for 2-3 hour operation of a heating unit with a power of about 4 kW per hour, about a liter of combustible liquid is consumed. In general, the operation of a biofireplace turns out to be quite expensive, so home craftsmen are trying to find a cheaper analogue of fuel. There is such an option and it is viable.

To avoid trouble, you need to purchase only high-quality components for home-made fuel. Do not forget that the biofireplace does not have a chimney, and all combustion products immediately enter the room directly.

If toxic substances are present in the fuel, and this is not uncommon for low-quality alcohol-containing compounds, they will end up in the room. This threatens with the most unpleasant consequences. We recommend that you familiarize yourself with the best brands of biofuels.

Therefore, it is not recommended to make fuel for a biofireplace on your own. However, if you really want to experiment, this is the safest recipe. Pure medical alcohol is taken. It must be purchased at the pharmacy.

To color the flame, gasoline of the highest degree of purification is added to it, which is used to refuel lighters ("Kalosha").

Filling the fuel tank must be done very carefully. If liquid is spilled, it must be wiped up immediately with a dry cloth, otherwise arbitrary fire may occur. Liquids are measured and mixed

Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline may account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the manufacture and use of biofuels can be found here

Liquids are measured and mixed. Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline may account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the manufacture and use of biofuels can be found here.

It is important to remember that the resulting fuel cannot be stored, as the mixture of gasoline and alcohol will delaminate. It should be prepared before use and shaken well for better mixing.

Bioreactor

Quite stringent requirements are imposed on the manure processing tank:

It must be impervious to water and gases. Water tightness must work both ways: the liquid from the bioreactor must not contaminate the soil, and groundwater must not change the state of the fermented mass.

The bioreactor must have high strength. It must withstand the mass of a semi-liquid substrate, the gas pressure inside the tank, the soil pressure acting from the outside

In general, when building a bioreactor, special attention must be paid to its strength.

Serviceability. More user-friendly cylindrical containers - horizontal or vertical

In them, mixing can be organized throughout the volume; stagnant zones do not form in them. Rectangular containers are easier to implement when building with your own hands, but cracks often form in their corners, and the substrate stagnates there. It is very problematic to mix it in the corners.

All these requirements for the construction of a biogas plant must be met, as they ensure safety and create normal conditions for the processing of manure into biogas.

What materials can be made

Resistance to aggressive environments is the main requirement for materials from which containers can be made. The substrate in the bioreactor may be acidic or alkaline. Accordingly, the material from which the container is made must be well tolerated by various media.

Not many materials answer these requests. The first thing that comes to mind is metal. It is durable, it can be used to make a container of any shape. What's good is that you can use a ready-made container - some kind of old tank.In this case, the construction of a biogas plant will take very little time. The lack of metal is that it reacts with chemically active substances and begins to break down. To neutralize this minus, the metal is covered with a protective coating.

An excellent option is the capacity of a polymer bioreactor. Plastic is chemically neutral, does not rot, does not rust. Only it is necessary to choose from such materials that endure freezing and heating to sufficiently high temperatures. The walls of the reactor should be thick, preferably reinforced with fiberglass. Such containers are not cheap, but they last a long time.

It is also possible to build a bioreactor for biogas production from bricks, but it must be well plastered using additives that provide water and gas impermeability.

A cheaper option is a biogas plant with a tank made of bricks, concrete blocks, stone. In order for the masonry to withstand high loads, it is necessary to reinforce the masonry (in each 3-5 row, depending on the wall thickness and material). After completion of the wall erection process, to ensure water and gas tightness, subsequent multi-layer treatment of the walls, both inside and out, is necessary. The walls are plastered with a cement-sand composition with additives (additives) that provide the required properties.

Reactor sizing

The volume of the reactor depends on the selected temperature for processing manure into biogas. Most often, mesophilic is chosen - it is easier to maintain and it implies the possibility of daily additional loading of the reactor.Biogas production after reaching the normal mode (about 2 days) is stable, without bursts and dips (when normal conditions are created). In this case, it makes sense to calculate the volume of the biogas plant depending on the amount of manure generated on the farm per day. Everything is easily calculated based on the average data.

| animal breed | Excrement volume per day | Initial humidity |

|---|---|---|

| cattle | 55 kg | 86% |

| Pig | 4.5 kg | 86% |

| chickens | 0.17 kg | 75% |

Decomposition of manure at mesophilic temperatures takes from 10 to 20 days. Accordingly, the volume is calculated by multiplying by 10 or 20. When calculating, it is necessary to take into account the amount of water that is necessary to bring the substrate to an ideal state - its humidity should be 85-90%. The found volume is increased by 50%, since the maximum load should not exceed 2/3 of the volume of the tank - gas should accumulate under the ceiling.

For example, the farm has 5 cows, 10 pigs and 40 chickens. As a matter of fact, 5 * 55 kg + 10 * 4.5 kg + 40 * 0.17 kg = 275 kg + 45 kg + 6.8 kg = 326.8 kg are formed. To bring chicken manure to a moisture content of 85%, you need to add a little more than 5 liters of water (that's another 5 kg). The total mass is 331.8 kg. For processing in 20 days it is necessary: 331.8 kg * 20 \u003d 6636 kg - about 7 cubes only for the substrate. We multiply the found figure by 1.5 (increase by 50%), we get 10.5 cubic meters. This will be the calculated value of the volume of the biogas plant reactor.

Pros and cons of biofuels

Consumption and efficiency of biofuels are of primary concern to consumers. Most modern bio-fireplaces burn no more than 500 ml of fuel per hour of burning. At the same time, the amount of heat generated is 6.58 kWh of energy per liter of biofuel.In terms of its efficiency, the operation of a biofireplace is equivalent to a three-kilowatt electric heater, but at the same time, the air in the room does not dry out, but, on the contrary, is moistened.

The advantages of biofuels include the following factors:

- Biofuel is an environmentally friendly product. In the process of its combustion, soot, soot, smoke and harmful gases are not emitted;

- the saturation of biofuel combustion can be adjusted;

- the use of biofuels does not require the installation of special hoods and other similar equipment;

- after combustion of biofuel, the burners are fairly easy to clean;

- biofireplaces due to thermal insulation of the body are reliable and fireproof;

- bioethanol is easy to transport;

- if necessary, biofireplaces are quickly dismantled and just as quickly assembled;

- due to the absence of heat loss through the chimney, the heat transfer is 100%;

- there is no need to harvest firewood, in addition, there is no garbage and dirt in the house;

- during the combustion of bioethanol, the air is moistened due to the release of water vapor into the surrounding atmosphere;

- biofuel combustion excludes flame return;

- biofuel has a fairly low cost, which is very significant for the family budget.

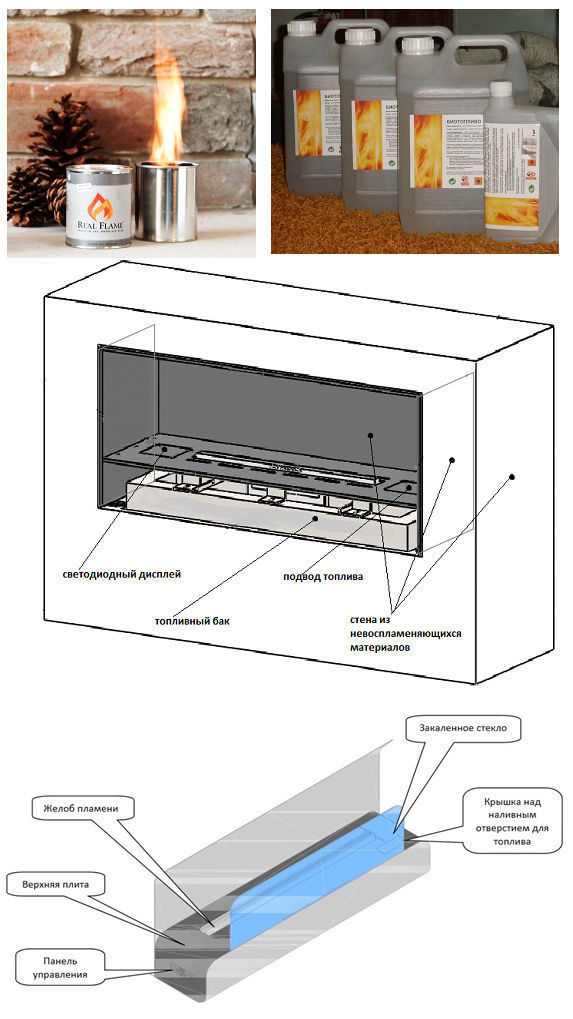

Applying biofuels is very easy and simple. If gel fuel is used, then all you need to do is open the lid of the jar, hide the container in an armful of decorative firewood or among stones and set it on fire. One can of gel fuel is enough for 2.5 - 3 hours of continuous burning. To obtain a volumetric flame, you can ignite several jars of gel at the same time. Putting out the fire is quite simple, just wrap the lids on the cans and thereby block the access of oxygen to the fire.

When using liquid biofuel, you just need to pour it into a special biofireplace heating block and set it on fire. It is almost impossible to use more fuel than necessary, since this type of fuel is produced in special containers - five-liter canisters with a consumption scale. One canister is designed for 18 - 20 hours of burning.

Among the disadvantages of using ecological fuel, only minor details can be distinguished:

- do not add fuel during combustion, it is necessary to put out the fireplace and wait for it to cool completely;

- do not store biofuels near an open flame;

- It is strictly not recommended to kindle biofuels with paper and logs; for this, special iron lighters are used.

How to make a biofireplace with your own hands?

This is where we come to the most interesting part, practical and to some extent creative. If you try, then such a unit can be made independently. A small bio-fireplace for an apartment, a summer residence does not require any special knowledge from you, and the result will certainly please you. The main thing is to think over its design in advance, observe the required distances between the walls, the top and the fire source, select the appropriate materials and work out all the steps.

How to make a biofireplace:

To get started, stock up on the necessary materials and tools: glass (approximate size of an A4 paper sheet), glass cutter, silicone sealant (for gluing glass). You will also need a piece of metal mesh (fine-mesh building mesh or even a steel grate from an oven will do), an iron box (it will act as a fuel compartment, so it is better to choose a steel box)

You will also need heat-resistant stones, it can even be pebbles, lace (future wick for a biofireplace), biofuel.

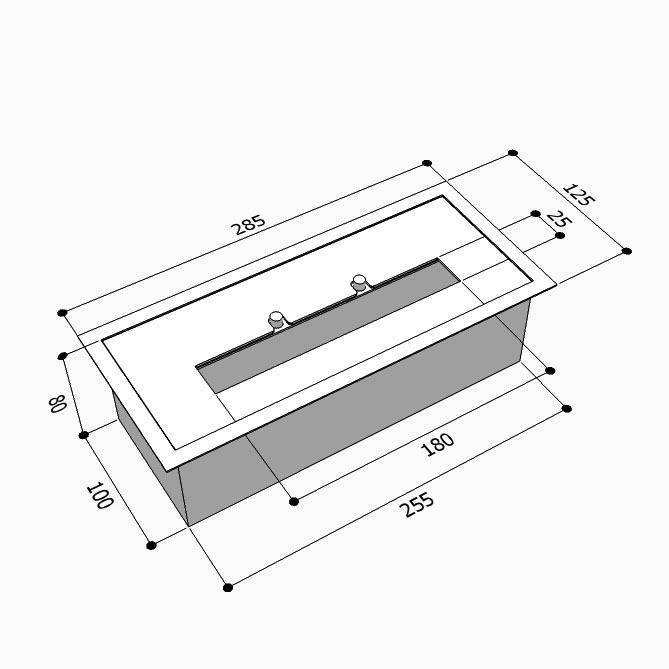

It is important to make correct calculations, for example, the distance from the fire source (burner) to the glass must be at least 17 cm (so that the glass does not burst from overheating). The number of burners is determined by the size of the room in which the eco-fireplace will be installed.

If the room is small (15 or 17 m²), then one burner will be enough for such an area.

The fuel compartment is a square metal box, keep in mind that the larger its dimensions, the further the fire source will be located from the glass. This box can be painted with paint of a suitable shade, but only on the outside! Inside, it must be “clean” so that the paint does not catch fire and does not begin to release toxic substances.

We take 4 glass fragments (their dimensions must correspond to the dimensions of the metal box) and glue them with silicone sealant. We should get something like an aquarium, only without a bottom. During the drying of the sealant, all sides of the “aquarium” can be supported with stable objects and left in this state until the binder mass has completely solidified (this is about 24 hours).

After the specified time, excess sealant can be carefully removed using a construction knife with a thin blade.

We take an iron can (you can use a container from under some canned product), fill it with biofuel and install it in a metal box. It is important that it has thick walls! But the best option is a stainless steel container.

Further, according to the dimensions of the fuel box, we cut out the metal mesh and install it on top of it. The net can be fixed for safety, but keep in mind that you will periodically lift it up to fill the iron can with biofuel.

We lay the pebbles or stones that you have chosen on top of the grate - they are not only a decor, but also help to evenly distribute heat.

We take a string and form a wick for a biofireplace out of it, lower one end into a jar of biofuel.

The wick impregnated with a combustible mixture can be set on fire with a thin wooden stick or a long fireplace match, or a splinter.

This is the simplest model for creating a biofireplace with your own hands, more complex analogues are made using guide profiles, drywall, tiles and other materials. The principle of creating a "burner", a casing and a fuel compartment is similar. To replenish the fuel reserves, you will need to remove the stones and raise the metal grate, but you can use a large syringe and direct a stream of flammable liquid between the cells of the grate, directly into the iron jar.

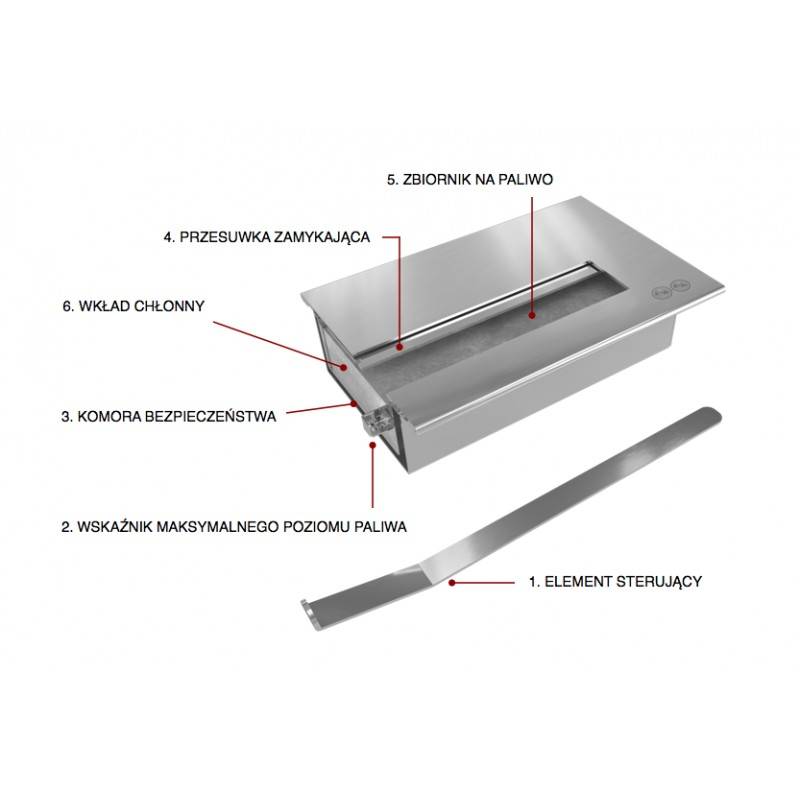

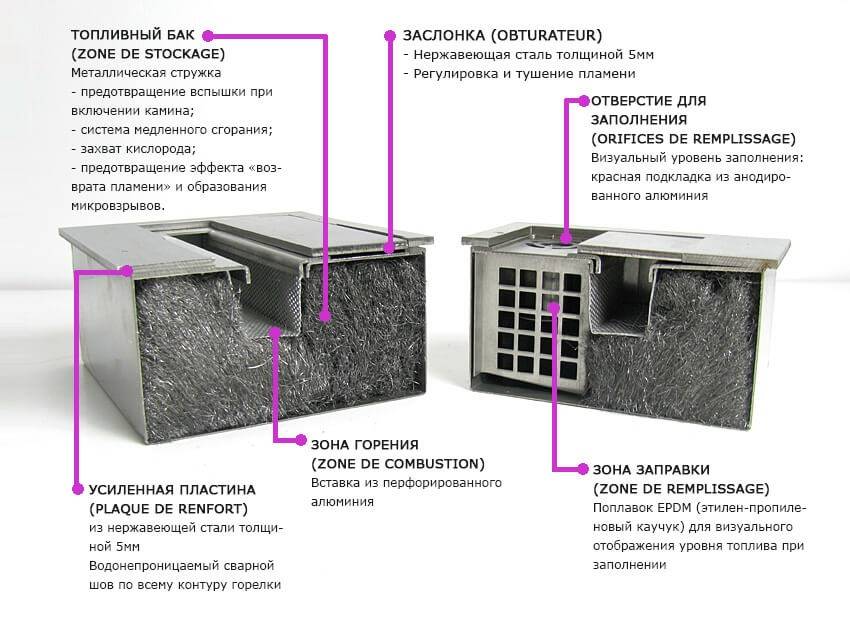

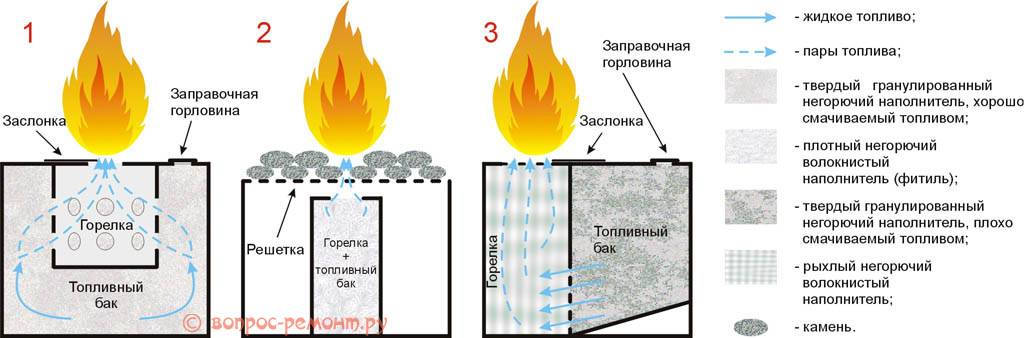

I want to pay special attention to the "heart" of the whole structure - the burner. A burner for a biofireplace is, in other words, a container for fuel

Factory burners are already manufactured according to all required standards, the most reliable material is stainless steel, such a burner will last a very long time without deformation, oxidation and corrosion. A good burner should be thick-walled so that it does not deform when heated. Also pay attention to the integrity of the burner - it should not have any cracks or any other damage! Under the influence of high temperatures, any crack increases in size.To avoid spillage of fuel and subsequent ignition, treat this nuance especially meticulously.

By the way, if you make a biofireplace yourself, you can make another version of the burner. To do this, do not fill the steel container too tightly with white glass wool, cover it from above with a grate (or mesh) cut to the size of the container. Then just pour alcohol and light the burner.

Types of environmentally friendly biofuels

The prefix "BIO" is now often added to labels based on the rules of successful marketing. The issues of preserving ecology and cleanliness are in vogue all over the planet today. Bioproducts, biocosmetics, biodetergents, biological treatment and energy stations, and even dry closets. It came to fireplaces and fuel for them.

If it is completely closed, then the fire in the bio-hearth simply goes out by itself. In general, a bio-fireplace is a great way to heat a room and bring a touch of coziness into it from the reflections of a “bonfire”.

The biofireplace differs from its wood-burning progenitor in the fuel used to produce the flame - the logs in it are replaced with smokeless fuel in the form of a liquid

Obtaining biofuel for such a fireplace involves the use of renewable natural resources, environmentally friendly technologies and raw materials in production. Plus, burning it should not produce harmful emissions into the atmosphere. Mankind cannot do without combustible fuel. But we can make it less harmful.

There are three types of biofuels:

- Biogas.

- Biodiesel.

- Bioethanol.

The first option is a direct analogue of natural gas, only it is not extracted from the bowels of the planet, but is produced from organic waste.The second is made by processing various oils obtained as a result of the pomace of oilseed plants.

As such, the fuel for biofireplaces is the third option - bioethanol. Biogas is mainly used to generate heat and electricity on an industrial scale, while biodiesel is more intended for automotive internal combustion engines.

When burning, pure ethanol gives a blue, not too beautiful flame, so additives are added to the fireplace biofuel to obtain a red-yellow hue

Home fireplaces are most often filled with bioethanol based on denatured alcohol. The latter is made from sugar (cane or beet), corn or starch. Ethanol is ethyl alcohol, which is a colorless and flammable liquid.

Fireplace in the interior of different rooms

As we have already understood, the possibility of airing the room is the main criterion for the possibility of installing a biological fireplace. Biofireplaces for an apartment can be installed in any room, the main thing is to choose the optimal form factor that will suit you and fit into the interior of the room. Let's look at the main rooms of the house for the installation of such a device.

Living room

For the living room, the fireplace has always been and remains the best accent solution. The use of bio-fireplaces gives us a free hand, since we can use them at our discretion.The eco-fireplace can be built into the main wall of the living room, it can take its place in the center of the room or on the coffee table, it can be in classic forms or in a modern futuristic design, in any case it will become the main star of your interior.

Bio-fireplace neatly built into the wall

By placing a biological fireplace without a chimney in the living room, you can enjoy the view of live fire at home at any time of the year. It is noteworthy that biofuel does not particularly emit heat, so it is hardly possible to warm up from such a fireplace, but in this case its decorative component is important.

Bedroom

Imagine, a biofireplace can be placed in the bedroom to further emphasize the comfort and warmth of the interior of this room. Was it possible before, well, of course not.

At the same time, the biofireplace in the bedroom should be placed correctly, carefully choosing a place for it. The presence of a large number of flammable items should alert you. Yes, the fireplace flame is protected by a portal, but it should still be placed away from textile curtains, silk bedspreads or other synthetic materials.

Placement of a biofireplace in the bedroom

To put a biofireplace in the bedroom or not, of course, you decide. If there is a suitable place, then why not dilute the standard interior with an original thing.

Kitchen

Modern kitchens often have modest dimensions, so extra household appliances, decor items and accessories are useless here. At the same time, it is quite possible to place a mobile fireplace in this room if you prefer the desktop version. A small live fire on the table will be the key to a great dinner with the family, it can bring with it a festive mood or romance.In addition, there is a fireplace with a live fire without a chimney in a desktop version is inexpensive, many of us can easily afford it.

Option for the location of a small bio-fireplace in the kitchen

You can define the device in other rooms, for example, a desktop device would be an excellent option for installing it on a desktop in a home office. Live fire on the table will allow you to focus on tasks, calmly find a solution to various issues. Working in such an environment will be indescribably comfortable.

If possible, you can put a bio-fireplace in the bathroom, and enjoy taking baths under the crackling firewood with a view of a real fire.

Features of biofireplaces

What are the features of a biofuel fireplace? What are its advantages, does it have significant disadvantages?

Advantages

- The fact that the fireplace does not require a chimney is a huge advantage. No modification of the ventilation duct or numerous approvals are needed if you live in an apartment building.

- Most industrial fireplaces are mobile. The weight of the heaviest models does not exceed one hundred kilograms.

- Fire safety is not affected. No, our fireplace may well be the cause of the fire; but this requires quite specific conditions. The fireplace is, in essence, an ordinary large spirit lamp; it can only be knocked over, but with its solid weight, it is accidentally difficult to do this.

Flaws

Biofireplace performs purely aesthetic functions. As a heating tool, it is practically useless: its thermal power is insufficient to warm even a small room.

The fireplace performs only aesthetic functions. It is useless for home heating.

- No matter how the sellers assure that the combustion of alcohol does not affect the composition of the atmosphere, the requirements for ventilation due to the absence of a chimney are quite stringent. In an enclosed space, the drop in oxygen levels and excess moisture will quickly make the air unbreathable.

- The cost of operating the device can not be called symbolic. Biofuel for biofireplaces is sold far from every corner, and the price of a liter starts from two hundred rubles from the most modest sellers.

Summing up

It is easy to figure out which biofireplace is better to choose. To do this, it is enough to take into account the features of its location and the premises itself. The device is easy to use, creating a cozy atmosphere of home warmth, comfort and well-being in the room. The device increases the level of comfort and can perform many useful functions. All this is possible if you understand the operation of the equipment, its principles and operating parameters. You can’t do it yourself - seek the advice of an expert to get detailed answers to all your questions.

Article author An expert in the field of fire and comfort. Store Manager Biokamin.rf

Vladimir Molchanov

I see my main task in a simple, non-technical language with the help of articles, reviews and consultations to tell about the difference between some products from others, which I hope will allow you to make the right choice.

About myself:

More than 10 years in the theme of fire and comfort. He was trained by most of the leading manufacturers of fireplaces and biofireplaces. I do my own training. I prepare technically complex projects for customers for our production.