- What types of biofuels are used for the fireplace

- Composition and features of biofuels

- How to make a big biofireplace?

- Biofuel use

- Burning charcoal - is it difficult?

- Method for making coal in a pit

- The method of making coal in a barrel on its own territory

- Main manufacturers, brands and price overview

- Kratki (Poland)

- InterFlame (Russia)

- Planika Fanola (Germany)

- Vegeflame

- Do-it-yourself biofireplace assembly options

- Option number 1: stationary corner fireplace

- No. 1. How does a biofireplace work?

- Types of environmentally friendly biofuels

- Features of manufacturing various designs

What types of biofuels are used for the fireplace

Large heating bills force you to look for other sources of heat. Now there are several alternative heating options. Often, thermal energy is produced by the wind or the sun. But biofuels have become very popular. It is made from various priceless raw materials.

Biofuel is made on the basis of biological and thermal processing. Biological treatment involves the work of different bacteria. So the materials for production are leaves, manure and other organic matter.

Types of biofuels:

- Liquid is represented by bioethanol, biodiesel and biobutanol;

- Solid is used in the form of briquettes and wood, coal, peat are used for production;

- Gaseous - biogas, biohydrogen.

Any kind of fuel can be made independently from biomass. But each option has its own characteristics of production. Liquid diesel fuel is made from vegetable oil. Such production requires a lot of vegetables, so it is not always profitable.

Often, products for manufacturing are toxic, so you should be more careful when working. With independent production, it should be remembered that the higher the ambient temperature, the faster the decomposition of organic matter will take place.

Composition and features of biofuels

The “bio” part of the word “biofuel” explains that only natural, renewable raw materials are used to make this substance. Therefore, it is completely environmentally friendly and biodegradable.

The main components used for the production of such fuels are herbaceous and grain crops containing large amounts of starch and sugar. Thus, corn and cane are considered the best raw materials.

On sale you can find biofuels of various brands. Preference should be given to certified products, otherwise you may face serious troubles

They produce bioethanol or a kind of alcohol. It is a colorless liquid and has no odor. If necessary, they can replace gasoline, however, the cost of such a substitute is much higher. When burning, pure bioethanol decomposes into water in the form of vapors and carbon dioxide.

Thus, it is even possible to humidify the air in the room where the biofireplace is installed. The substance burns with the formation of a blue "gas" flame.

This is a purely aesthetic flaw, which still prevents you from enjoying the view of an open fire.A traditional fireplace gives a yellow-orange flame, which is a kind of standard. To eliminate this shortcoming, additives are introduced into biofuels that change the color of the flame.

Thus, the traditional composition of a combustible liquid is as follows:

- bioethanol - about 95%;

- methyl ethyl ketone, denaturant - about 1%;

- distilled water - about 4%.

In addition, crystalline bitrex is added to the fuel composition. This powder has an extremely bitter taste and is designed to prevent alcohol biofuels from being consumed as alcohol. Biofuels of different grades are produced, its composition may vary somewhat, but in general it does not change. It is clear that the cost of such fuel is quite high.

It is not recommended to use home-made fuel for bio-fireplaces, but if you still decide to try it, you need to take only high-purity gasoline “Kalosha” for its manufacture

Fuel consumption depends on the number of burners and the power of the biofireplace. On average, for 2-3 hour operation of a heating unit with a power of about 4 kW per hour, about a liter of combustible liquid is consumed. In general, the operation of a biofireplace turns out to be quite expensive, so home craftsmen are trying to find a cheaper analogue of fuel. There is such an option and it is viable.

To avoid trouble, you need to purchase only high-quality components for home-made fuel. Do not forget that the biofireplace does not have a chimney, and all combustion products immediately enter the room directly.

If toxic substances are present in the fuel, and this is not uncommon for low-quality alcohol-containing compounds, they will end up in the room. This threatens with the most unpleasant consequences.We recommend that you familiarize yourself with the best brands of biofuels.

Therefore, it is not recommended to make fuel for a biofireplace on your own. However, if you really want to experiment, this is the safest recipe. Pure medical alcohol is taken. It must be purchased at the pharmacy.

To color the flame, gasoline of the highest degree of purification is added to it, which is used to refuel lighters ("Kalosha").

Filling the fuel tank must be done very carefully. If liquid is spilled, it must be wiped up immediately with a dry cloth, otherwise arbitrary fire may occur. Liquids are measured and mixed

Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline may account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the manufacture and use of biofuels can be found here

Liquids are measured and mixed. Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline may account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the manufacture and use of biofuels can be found here.

It is important to remember that the resulting fuel cannot be stored, as the mixture of gasoline and alcohol will delaminate. It should be prepared before use and shaken well for better mixing.

How to make a big biofireplace?

A large floor and stationary biofireplace has its own characteristics in manufacturing. Let's consider the process in more detail.

Drawing of a drywall biofireplace

The frame of a large biofireplace is constructed from drywall.To do this, proceed in the following sequence:

- Wall marking and preparation of suitable drywall elements.

- Formation of the base - coasters made of non-combustible material (withstanding +150 degrees).

- Fastening drywall with self-tapping screws.

- Installation of the interior of refractory materials. You can buy a special box for a biofireplace in a store and install it in a drywall construction.

- Installation of the fuel tank, in the center of the structure. For a stationary large bio-fireplace, this is the best option, it is much more reliable and practical than a fuel tank, or a do-it-yourself burner.

- Facing biofireplace. Use heat-resistant materials - tiles or natural stone.

- Mounting a glass screen or forged grille - for the safe operation of the device.

- Decorating a large bio-fireplace, possibly with the help of refractory elements in the form of firewood, which give the effect of a real hearth.

Biofuel use

If you have a bio-fireplace, you can not do without special fuel for it, it should be bought regularly. Here, the owner of the device must understand that replacing it with another liquid can harm human health.

Bio-fireplaces use specialized mixtures with the prefix "bio"

What is important is the main component of plant or animal origin. Biofuels are produced by various technologies, the base can be beetroot, potatoes or wood. The main advantage of biofuel is that when burning it emits harmful fumes, it is completely safe for use in a residential area.

In addition, the flame comes out even and looks very nice.

The main advantage of biofuels is that when burned, it emits harmful fumes, which is completely safe for use in a residential area. In addition, the flame comes out even and looks very nice.

There are several important rules for using fuel:

- Choose high-quality, certified fuel from well-known manufacturers.

- Before pouring fuel, the burner or tank must be completely extinguished and cool.

- To ignite the biofireplace, you should use a special lighter, with a long nose, made of metal.

- Keep fuel away from flammable objects, hot surfaces and of course the fire itself.

The biofireplace will become a beautiful element of any house or apartment. Build do-it-yourself biofireplace easy - if you follow our recommendations. Carefully consider the choice of basic materials and remember the rules of fire safety. The device itself will not bring much trouble, on the contrary, its installation will bring zest to the house, fill it with light and warmth.

Burning charcoal - is it difficult?

When we say - charcoal, we immediately imagine outdoor recreation, barbecue, barbecue. Pleasant smoke, flickering lights in the barbecue! However, the use of charcoal is not limited to cooking meat, it is necessary in blacksmithing, foundry work, medicine, for filtering drinking water, and even for making gunpowder and for household needs.

Those who have had to deal with charcoal know that buying it costs a lot of money, and they often think about how they can get it on their own at home or in the field, with their own hands - with their very skillful hands.Indeed, it is possible! Moreover, there are two most common methods - the production of this biofuel in a pit or in a metal barrel.

Method for making coal in a pit

Usually burning coal is carried out in the forest, which is more convenient than at home, but due to the widespread fires in the forests, you need to think carefully about the place and time of the work.

A place is chosen next to a large supply of dried wood or a fallen tree, and such that it does not damage the surrounding vegetation. In order to get two bags of coal, it is enough to dig a hole 50 cm deep and 75-80 cm in diameter with slightly sloping walls. It is also easy to do it yourself.

On the compacted bottom of the pit, a small fire made of dry birch bark and small branches is made by hand, and when the fire flares up well, prepared small firewood, up to about 30 cm long, is placed on it. If you choose branches with a diameter of about 7 cm, then you can completely cope with the cut on your own, without an assistant. Firewood is stacked tightly and gradually, as each layer is fired. Well-burnt firewood can be straightened with a long stick.

For complete burning in such conditions, 3 hours is enough. Then the coals are covered with moss, dry leaves or grass and covered with earth, which is tightly packed. In order for the coal to cool sufficiently, it will take another two days, after which the solid biofuel will be ready. After this time, a layer of earth is removed from the pit, the coal is raked out, sieved and packed in bags.

If a new laying of firewood is not done, then the pit is filled up in such a way that the fertile layer of the earth is on the surface, everything is also covered with foliage.Of course, such production of coal requires some material and physical costs, but it is much cheaper than the cost of buying it, and there is also a moral aspect - everything is achieved by one's own efforts and done by one's own hands.

The method of making coal in a barrel on its own territory

In order to get solid biofuel at home, namely charcoal, a thick-walled metal barrel with a capacity of 200 liters is used. At the bottom, it is necessary to make a fitting for forced air injection with a household vacuum cleaner.

In the same way as in the pit, a small fire is made at the bottom of the barrel, and then small chocks are gradually added. For a denser stacking of firewood, the barrel can be periodically shaken. After the air is supplied, the firewood will smoke less and will be well enveloped in flames. The air supply from below should be started only after filling the barrel with firewood about half. Also, periodically you need to correct the coals with a pole and do not forget about safety precautions when working in "hot" conditions.

To continue the process of burning coal without access to air, cover the barrel with a lid and cover all the cracks with a solution of earth and water. If there is no “native” cover, then it should be made from some piece of iron.

It should be taken into account that with this method of working at home, often in unsuitable conditions, a certain amount of waste and ash is formed, but within reasonable limits. After the final cooling of the barrel, it is turned over, and the finished coal is sifted and packaged. Here is a production that you can master with your own hands.

The first time you may not get high-quality coal, but patience and work will grind everything! The main thing is not to quarrel with the neighbors because of the strong smoke.

Main manufacturers, brands and price overview

Kratki (Poland)

Sold in 1 liter bottles. There are varieties with a flavored component: coffee, forest, etc., as well as with different flame colors (ripe cherries). Ethanol is used for production of high quality. The operating time on one bottle is from 2 to 5 hours. The price for 1 liter of Kratki is 580–1500 rubles.

InterFlame (Russia)

Sold in plastic bottles with a capacity of 1 liter. There are varieties with different flame colors. When burning 1 liter of fuel, 3 kW of thermal energy is released.

The price of 1 liter of InterFlame is from 350 rubles.

Planika Fanola (Germany)

High quality biofuel for fireplaces. Burning 1 liter of fuel produces 5.6 kW of energy. Burning time from 2.5 to 5 hours. Tested for safety and has a number of certificates. The price is in the range of 300-400 rubles per 1 liter.

Vegeflame

Ecological fuel. Produced in containers of large volumes of 5 and 20 liters. The average fuel consumption is 0.3 l/h. 20 liters of biofuel is enough for 68-72 hours of continuous burning.

The price for 20 liters of fuel is about 5200 rubles.

The price for 5 liters is 1400 rubles.

Do-it-yourself biofireplace assembly options

Biofuel fireplaces are a simple design, with shapes and finishes that can be endlessly experimented with. The article discusses two options for devices: with a fixed installation and a mobile glass box that can be used indoors, as well as on a terrace or in a gazebo.

Option number 1: stationary corner fireplace

This design can be mounted both indoors and in a gazebo with blank walls. The corner arrangement has a number of advantages, the main of which is the economical consumption of free space. From the aesthetic side, the fireplace brings coziness to the atmosphere, which makes the rest comfortable and enjoyable.

To get started, prepare the necessary materials:

• metal profiles (guide and rack) - 9 m;

• drywall non-combustible type - 1 sheet;

• metal sheet - 1 m2;

• basalt wool - 2 m2;

• artificial stone or ceramic tiles - 2.5 m2;

• plaster putty for finishing works;

• adhesive mixture for tiles;

• grout;

• hardware (dowels, self-tapping screws);

• cylindrical fuel tank (several cans can be used);

• natural stones, pebbles and other non-combustible decor.

Installation begins with determining the angle and markings. The old finish must be dismantled. Identified cracks and holes must be repaired with putty (or plaster). For convenience, it is recommended to first draw up a drawing indicating the parameters of the fireplace. So it is easier to calculate the amount of materials, and plan the sequence of work.

According to the applied markup, a frame is assembled from profiles. Each element is checked by level and plumb to avoid distortions. The racks of the structure are fastened with jumpers for reliability. The bottom of the fireplace should be made with a recess so that a container with a flammable liquid can be masked inside. For safety reasons, the bottom is lined with a sheet of metal, so you don’t have to worry about the floor during the operation of the fireplace.

The upper part of the frame and the sides are filled with basalt wool.The heat insulator will ensure long-term preservation of heat on the surface of the structure. Further, all surfaces are sheathed with non-combustible drywall.

The installation is completed by decorating the surface. To do this, you need to treat the working area with a primer, and then putty it. After drying, the surfaces are primed again and lined with decorative stone or ceramic tiles. After the adhesive mixture has hardened, the seams are sealed with grout.

Burners with fuel are installed in the portal of the finished structure, closed from above with a metal mesh and covered with non-combustible stones. Through the stone embankment, after the burner is set on fire, playful flames will break through, which you can look at endlessly.

No. 1. How does a biofireplace work?

Biofireplace is a relatively new invention. Its author is the Italian Giuseppe Lucifora, who designed the first biofireplace in 1977. Did he then think that his invention would become so popular! Today, biofireplaces are actively used in the interior design of city apartments and country houses. Often they are installed outdoors, in a summer cottage, for example. What caused such a widespread use of the device? To answer this question, it is necessary to understand the principle of operation of a biofireplace and its main components.

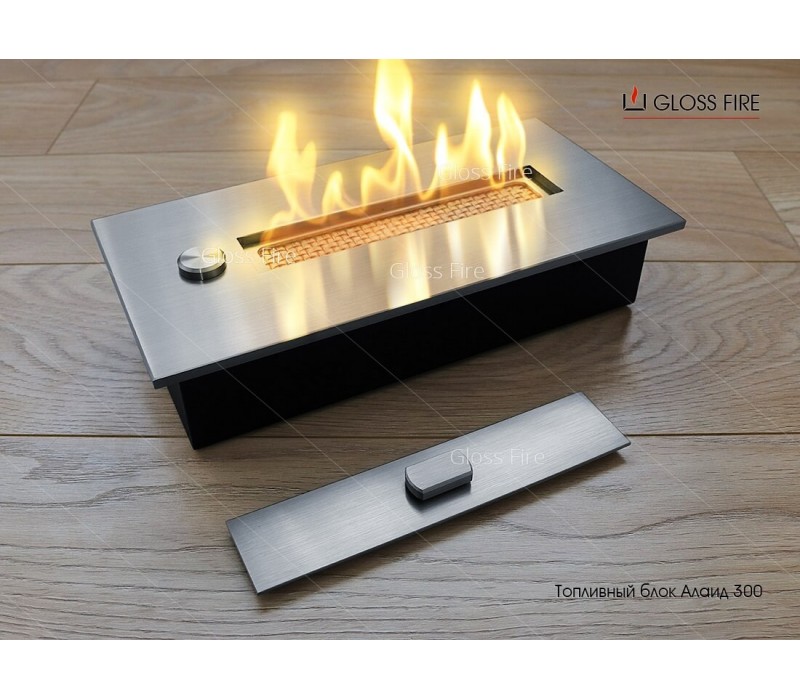

A biofireplace is completely different from a conventional wood-burning fireplace. To obtain a flame, a special fuel (bioethanol) is used, which is poured into the tank and ignited. Fuel burns without emitting carbon monoxide and other harmful products. This is in short. To delve into the process of biofireplace operation, it is necessary to study its structure:

- the burner is made of non-combustible materials (steel, ceramics, stone) and is decorated with sand, real stone, or imitation of firewood and coal. All elements that cover the burner must be non-combustible;

- the fuel tank, where bioethanol is poured, has a volume of 0.7 liters to 3 liters, in rare cases more. The larger the tank and the more fuel you can pour into it, the longer the process of continuous burning will be. On average, 1 liter of fuel is enough for 2-3 hours of fireplace operation. It is possible to add a new portion of fuel only after the device has cooled down. A fire is kindled by bringing a special long lighter. You can use fireplace matches, but it is dangerous to use folded pieces of paper. In automatic biofireplaces, the ignition process is easier - at the touch of a button;

- biofireplace fuel is obtained from vegetable crops rich in sugar. On combustion, it breaks down into carbon dioxide and water vapor. There is no soot, soot and smoke, so it is unnecessary to equip the chimney, but good ventilation will not hurt. Experts compare a biofireplace with a conventional candle in terms of the level and nature of emissions. Some biofireplaces burn bioethanol vapors;

- the portal is usually made of tempered glass. This material withstands heat and provides you with unhindered admiration of fire from different angles. The power and height of the flame can be adjusted thanks to a special damper, but the flames will never be higher than the glass barrier;

- the frame is the skeleton of the biofireplace. All functional parts of the product, as well as decor, are attached to it. The frame ensures the stability of the location on the floor, fastening to the wall (for wall models).The decor can be different, it completes the appearance of the fireplace and makes it a bright interior detail;

- there may be some additional components that significantly expand the functionality of the biofireplace. For example, a system of sensors that monitor work, sound design, buttons that turn on automatic fireplaces. Some appliances can be controlled with a remote control or even with a smartphone.

The intensity of the flame is regulated by flaps. When you move it, the flow of oxygen to the burner decreases or increases, which determines how large and powerful the flames will be. By blocking access to oxygen, you can completely extinguish the fireplace.

Biofireplace is bought and installed, first of all, for the beauty and feeling of comfort of the hearth. However, its benefits are not limited to this. Since there is a real fire in the fireplace, heat comes from it. A biofireplace can be compared with a heater with a power of up to 3 kW, it can easily heat the air in a relatively small room (about 30 m2), but it is not considered as a replacement for a heater, and tempered glass is not able to retain the accumulated heat for a long time.

If in a traditional fireplace heat loss due to the exhaust system reaches 60%, then in a biofireplace only 10% is lost - the remaining 90% go to space heating.

As for ventilation. A chimney for a biofireplace is not needed, but high-quality ventilation must be equipped. However, this requirement also applies to apartments where there is no biofireplace.If you feel that home ventilation is not coping, you will sometimes have to open windows and ventilate.

Biofireplaces can be very different in form, so this detail will perfectly fit into any style of interior, from classic to hi-tech.

Types of environmentally friendly biofuels

The prefix "BIO" is now often added to labels based on the rules of successful marketing. The issues of preserving ecology and cleanliness are in vogue all over the planet today. Bioproducts, biocosmetics, biodetergents, biological treatment and energy stations, and even dry closets. It came to fireplaces and fuel for them.

If it is completely closed, then the fire in the bio-hearth simply goes out by itself. In general, a bio-fireplace is a great way to heat a room and bring a touch of coziness into it from the reflections of a “bonfire”.

Obtaining biofuel for such a fireplace involves the use of renewable natural resources, environmentally friendly technologies and raw materials in production. Plus, burning it should not produce harmful emissions into the atmosphere. Mankind cannot do without combustible fuel. But we can make it less harmful.

There are three types of biofuels:

- Biogas.

- Biodiesel.

- Bioethanol.

The first option is a direct analogue of natural gas, only it is not extracted from the bowels of the planet, but is produced from organic waste. The second is made by processing various oils obtained as a result of the pomace of oilseed plants.

As such, the fuel for biofireplaces is the third option - bioethanol. Biogas is mainly used to generate heat and electricity on an industrial scale, while biodiesel is more intended for automotive internal combustion engines.

Home fireplaces are most often filled with bioethanol based on denatured alcohol. The latter is made from sugar (cane or beet), corn or starch. Ethanol is ethyl alcohol, which is a colorless and flammable liquid.

Features of manufacturing various designs

There are a lot of ways to create and design biofireplaces. They can be assembled using available equipment at home or in the country. Step-by-step instructions for making the simplest and most common designs are as follows:

Desktop:

- The base is being made. It should be a refractory stable container with a bottom. On the inside of the sides, it is necessary to fix the strips for installing the grid. The upper surface of the sides should be convenient for placing a protective screen.

- A fuel tank is inserted inside the tank, which should be 30 mm lower in height and located at a sufficient distance from the walls.

- Then a grate is installed on top. The wick is immersed in the tank and fixed on the grate. Stones are laid out around, through which the flame will beautifully break through. At this stage, the fireplace is almost ready. It remains only to create a protective screen.

- The walls are glued from refractory glass with silicone sealant, repeating the perimeter of the base, on which they are then glued.

Floor:

- Mark the wall, prepare the drywall of the desired size and fix it with self-tapping screws.

- Make the base of non-combustible material (for example, brick).

- The interior must also be fireproof. You can buy a ready-made box and place it inside a drywall frame, laying insulating material between them.

- For such a design, it is better to buy a ready-made fuel tank manufactured at the enterprise. It is installed in the center of the fireplace.

- Then facing with heat-resistant tiles or similar materials is carried out.

- For safety, a glass screen or forged grate is installed in front of the hearth.

To make such an eco-device is quite simple. With patience and diligence, you can create a quality product that will not differ from professional interior work.

Good thing, but fuel is expensive

Alexander

You can save on fuel if you cook it yourself. In general, this is a purely decorative thing, you can’t call it a heating device.

Victor

Bribes the opportunity to create an almost real fireplace in the house without installing a chimney

Paul