- Homemade granulators

- Homemade screw granulator

- How to make a flat die granulator

- medium quality pellets

- Comparison with firewood and benefits in front of them.

- Classification and scope

- Application

- Production technology

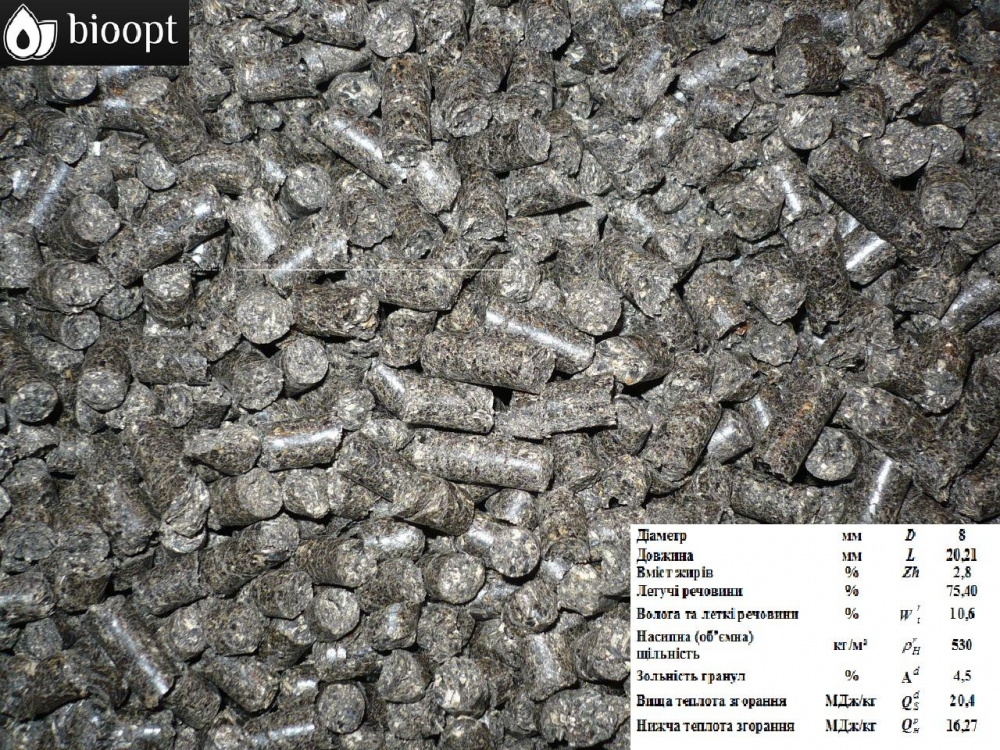

- Torrefied (fired without oxygen) pellets

- Pellets for boilers: advantages and disadvantages

- Main advantages

- Why are pellets good?

- Comparison with other solid fuels

- Pellet classification

- Do-it-yourself pellets: from theory to practice

- Equipment for the production of pellets

- Afterword

- Advantages of heating with peat briquettes

- Pellets what is it

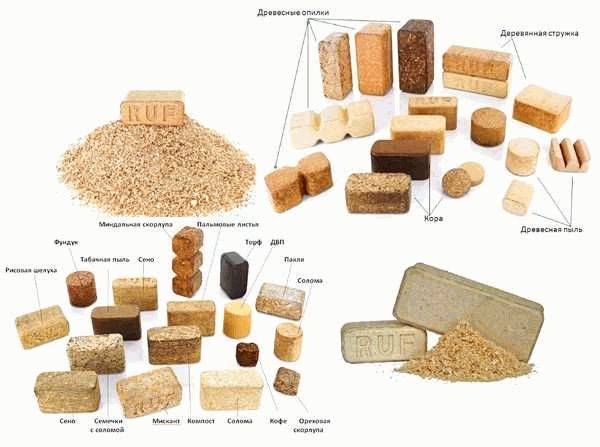

- Types of waste for the production of pellets

Homemade granulators

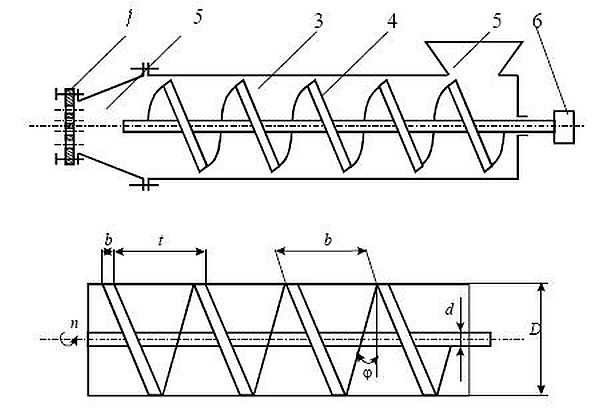

Although a lot of equipment is required for the production of pellets, the main device is a granulator. With its help, pellets are formed from raw materials. There are several models of granulators:

- Screw. The structure is similar to a household meat grinder. The same screw shaft and matrix - a grate through which the raw material is forced. They can be used for soft raw materials such as straw. Wood, even well chopped, he "does not pull" - there is not enough effort. In principle, with sufficient strength of the parts, you can put a more powerful motor.

Schematic diagram of a screw extruder (granulator)

The device of the main node of the granulator with a flat matrix

The device of the granulator with a cylindrical matrix

The simplest screw extruder. It is often made for pressing compound feed, but can also be used to make fuel pellets from soft raw materials. If you need to make equipment for the production of pellets, this is the easiest option. Provided that you know how to handle a lathe and a welding machine.

Homemade screw granulator

As in any equipment of this type, the screw granulator has a matrix. In this case, it looks like a meat grinder mesh, only it is made of a much thicker plate. The second important node is the screw shaft. All these details can be done by hand. How - it is useless to describe in words, see the video.

Making a matrix for the finished screw.

The screw and the matrix are "packed" into a housing or sleeve. How to do it, see the next video.

After assembling the main assembly, it is necessary to install a motor with a gearbox, a hopper into which chopped straw will be fed. You can run.

How to make a flat die granulator

First you need to figure out how it works. Everything is well shown in the video.

Flat die pelletizer device

In the next video, quite detailed explanations on the manufacturing process of the matrix and rollers.

The cost of traditional energy carriers is rising, and more and more owners of private houses are choosing to use various types of biomass for heating. One such type of fuel is pellet. It is a pressed granules, and small sawdust, peat, straw, etc. can be used as materials. Since the production of this type of fuel in the CIS countries is poorly developed, many people decide to make pellets with their own hands.

medium quality pellets

In the above calculations, the calorific value characteristic of high quality white granules, the so-called elite ones, was used. They are made from the waste of good wood and practically do not have foreign inclusions, such as tree bark. Meanwhile, various impurities increase the ash content of the fuel and reduce its calorific value, but the price per ton of such wood pellets is much lower than elite ones. By reducing the cost, many homeowners are trying to make their pellet heating more economical.

In addition to elite fuel pellets, cheaper pellets are produced from agricultural waste (usually from straw), whose color is somewhat darker. Their ash content is low, but the calorific value is reduced to 4 kW / kg, which will ultimately affect the amount consumed. In this case, the consumption per day for a house of 100 m2 will be 35 kg, and per month - as much as 1050 kg. The exception is pellets made from rapeseed straw, their calorific value is not worse than that of birch or coniferous pellets.

There are other pellets that are made from a wide variety of waste from woodworking enterprises. They contain all sorts of impurities, including bark, from which in modern pellet boilers faults and even malfunctions occur. Naturally, the unstable operation of the equipment always causes increased fuel consumption. Especially often heat generators with retort burners in the form of a bowl facing upwards are capricious from low-quality granules. There, the auger supplies fuel to the lower part of the "bowl", and around there are holes for the passage of air. Soot gets into them, due to which the intensity of combustion decreases.

In order to avoid such situations and the efficiency of the boiler does not decrease, it is advisable to choose fuel with a low ash content and in no case wet. Otherwise, problems with the screw feed will begin because the wet granules crumble and turn into dust that clogs the mechanism. It is possible to use cheaper fuel for heating a house with pellets when the boiler is equipped with a torch-type burner. Then the ash covers the walls of the furnace and falls down without falling back into the burner. The only condition is that the combustion chamber and burner elements will have to be serviced and cleaned more often, as they get dirty.

Comparison with firewood and benefits in front of them.

The main area of application for pellets is heating boilers, but pellets are also successfully used in grill ovens. In rural areas, heating with firewood still prevails, because they can be stored simply under a shed in a woodpile, and a rural resident is not embarrassed by the laborious process of preparing firewood, laying it in a woodpile, and then daily carrying raw firewood directly to a heating boiler or stove. However, many owners of dachas and country cottages are not attracted by the prospect of such unpleasant exercises.

In the Russian Federation, there are many companies that deliver packaged pellets to the door in small towns. All that is required is to place an order, accept and pay for shipping.

Classification and scope

Peat briquettes for heating are classified according to the type of mechanisms by which they are produced. The type of finished products depends on this, which includes several different forms:

- Rectangles or bricks with rounded corners. They were first made in Germany. Produced by shock-mechanical or hydraulic presses.

- Cylinders come in different lengths and diameters, and can be provided with a round bore. They have an affordable cost, but are not very resistant to moisture.

- Hexagons with a radial hole in the central part. The technology of their production involves the use of thermal firing. Thanks to this, the products are not damaged during transportation and are resistant to a humid environment. Produced using extruder technology.

Given the ease of use, ease of storage and safety, briquettes are ideal for space heating in country houses, saunas and baths. They are indispensable in hiking and for cooking in barbecues and grills. When used in boiler rooms, it should be borne in mind that briquettes are used only in solid fuel boilers.

Application

High quality wood pellets (white and gray) are used for heating residential buildings by burning in pellet boilers, stoves and fireplaces. They are usually 6-8 mm in diameter and less than 50 mm long. In Europe, they are often sold in 15-20 kg bags. In addition to heating, modern small steam power plants with pellet boilers can also produce electricity together with heat. For example, in Russia, the production of such systems with small steam axial piston engines with a power of 6 to 60 kW has been established.

Demand for wood briquettes and pellets, equipment for their combustion and production is growing in proportion to the prices of traditional fuels such as oil and gas. In some European countries, where the market for alternative energy sources is most developed, up to 2/3 of residential premises are heated with pellets.This widespread use is also explained by the environmental friendliness of this type of fuel - during combustion, emissions of CO2 are equal to the absorption of this gas during the growth of the tree, and the emissions of NO2 and volatile organic components are significantly reduced due to the use of modern combustion technologies.

Dark pellets with a high content of bark are burned in larger boilers to produce heat and electricity for settlements and industrial enterprises. Dark granules may be larger in diameter. They are sold in bulk in batches of two to three thousand tons or more.

In addition to being used for its intended purpose, fuel pellets (their light, unburned variety), due to their hygroscopicity, good odor retention and ability to greatly expand when wet (a couple of handfuls of pellets gives a layer of sawdust with a volume of several tens of cubic centimeters) are widely used as a filler for cat litter.

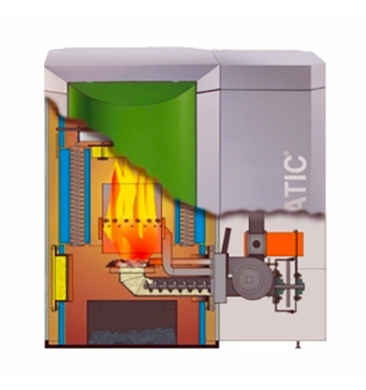

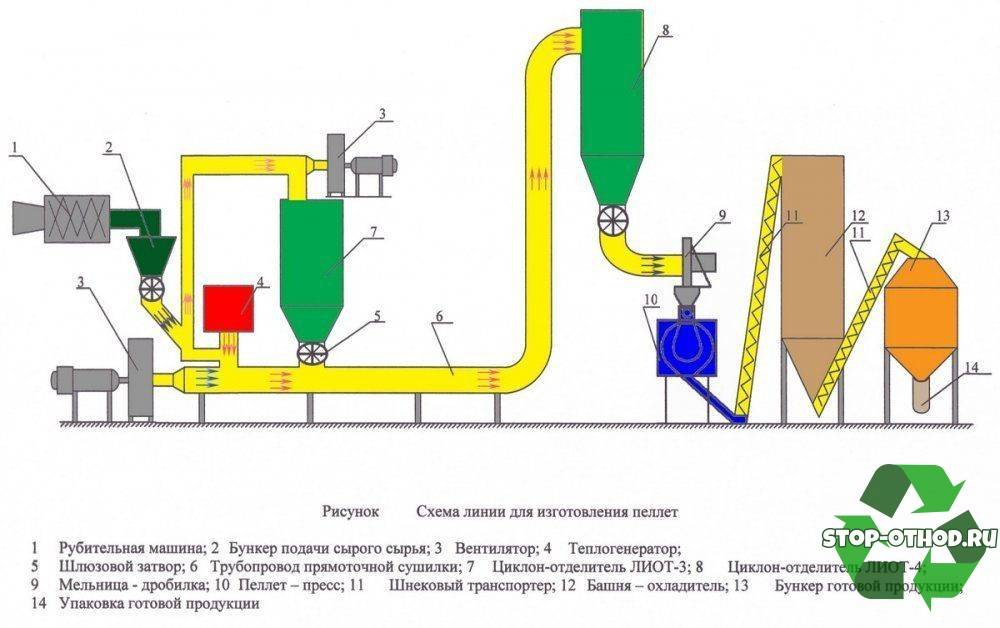

Production technology

Pellet press

Raw materials (sawdust, bark, etc.) enter the crusher, where they are crushed to the state of flour. The resulting mass enters the dryer, from it - to the press granulator, where the wood flour is compressed into granules. Compression during pressing increases the temperature of the material, the lignin contained in the wood softens and sticks the particles together into dense cylinders. The production of one ton of pellets takes about 2.3-2.6 dense cubic meters of wood waste, plus 0.6 dense cubic meters of sawdust for each ton of product produced is burned.

The finished granules are cooled, packed in various packages - from small bags (2-20 kg) to big bags (large industrial packaging) weighing 1 ton - or delivered to the consumer in bulk.

Torrefied (fired without oxygen) pellets

During torrefaction, solid biomass is burned without access to oxygen at a temperature of 200–330 ºC. Torrefied, or bio-coal (black), pellets have a number of advantages compared to conventional, otherwise called white:

- Repel moisture, can be stored outdoors, i.e. do not require covered storage

- Do not rot, mold, swell or crumble

- They have the best combustion performance (close to coal. Hence the name - biochar)

Pellets for boilers: advantages and disadvantages

The main advantages of fuel pellets include:

- efficient heat generation at more than a small consumption (1 ton of pellets gives as much heat energy as 1.5 tons of firewood or 500 m 3 of gas);

- minimum waste (ash is 1% of the initial volume of fuel);

- the rarity of cleaning the boiler (no more than 1-2 times a month);

- uniform combustion and temperature constancy;

- lack of spark;

- ease of transportation (pellets are delivered in packages);

- absence of unpleasant odors;

- environmental friendliness (only 0.03% sulfur is produced during combustion);

- ash can be used as fertilizer;

- acceptable cost of fuel;

- permits are not required to equip the boiler with a pellet burner.

Solid fuel has such an indicator as calorific value - the amount of energy obtained by burning 1 kg of material. For pellets, it is 4500-5300 kcal / kg, which is comparable to the calorific value of black coal and dry firewood.

This fuel has only one drawback: before using pellets, you will have to buy a special burner.

The use of pressed pellets sometimes requires the purchase of a new boiler, although more often you can get by with retrofitting an existing one. Pellet boilers are special devices that work only on this fuel. The devices organize a full-fledged heating circuit inside the house, and also provide the owners with hot water.

Before using pellet fuel, you will have to buy a special burner.

Main advantages

Pellets are cylindrical granules with a diameter of 4–10 mm and a length of 15–50 mm. Various natural materials can be used as raw materials for their manufacture. Most often, do-it-yourself pellets at home are made from the following raw materials:

- Waste from woodworking enterprises - sawdust pellets are of the highest quality.

- Bark, twigs, as well as dry needles and foliage.

- Waste of the agro-industrial complex.

- Peat - the use of this type of fuel allows you to achieve maximum heat transfer.

In this video you will learn how to make a briquette press:

The quality of the pellets largely depends on the raw materials used. It is best to use fuel made from sawdust. Since the wood waste in premium fuels has a high degree of purification, it is quite difficult to make it yourself.

Also, industrial varieties may contain a certain amount of impurities - bark, needles, leaves. They have a higher ash content, but the energy intensity remains high. For the production of pellets at home, various types of woodworking and agricultural waste are most often used.

Among the main advantages of this type of fuel are:

- The content of harmful substances is minimal, and during its combustion, carbon dioxide with water vapor is mainly released.

- Can be used in long burning boilers.

- Doesn't require a lot of storage space.

- Since there is no need to use chemical ingredients in the production process, the risks of developing allergic reactions are minimal.

- Has a high rate of heat transfer.

- Pellet fuel is not subject to internal decay processes, which excludes spontaneous combustion.

This type of fuel has many advantages.

Why are pellets good?

Comparison with other solid fuels

The strength of pellets is their progressiveness compared to wood, coal and even briquettes. Imagine a solid fuel boiler operating in the same mode as a gas boiler. Only even safer because pellets don't explode like natural gas.

The difference between gas and pellet heating is expressed in several points:

- the supply of pellets must be replenished;

- once a week the boiler stops for cleaning;

- during the operation of the pellet heat generator, the noise of pellets pouring down the plastic pipe is heard;

- the use of this fuel is not related to the work of utilities and various inspections;

- heating equipment that burns pellets is automated no worse than gas.

If we compare granulated waste with firewood or coal, then the latter win only in terms of cost.

In return, they take away comfort and time from the homeowner, as wood or coal heating requires constant attention. Even a long-burning boiler needs to be “feeded” 2 times a day and constantly cleaned, while a pellet one works non-stop weeks.

The results of comparison according to other criteria also speak in favor of heating with pellets:

- Burning pellets is safer than wood and coal. Boilers equipped with pellet burners practically do not suffer from inertia, like conventional solid fuel ones. When the required coolant temperature is reached, the burner turns off and the fuel supply stops. Only a small handful of pellets burn out.

- The room with the pellet boiler is clean, there is no smell of smoke, which is present when the furnace is loaded with coal and firewood. Installation of a buffer tank is at the request of the owner. Pellet heat generators can do without a battery to dump excess heat.

Comparison in terms of technical characteristics and cost of different types of biomass fuel is presented in the table:

| Fuel | Heat output 1 kg, kW | kW Thermal plant efficiency, % | Real heat dissipation 1 kg | kW Price of 1 kg in Russia, rub | The price of 1 kg in Ukraine, UAH | Cost of 1 kW of heat in Russia, rub | Cost of 1 kW of heat in Ukraine, UAH | Ash content of fuel, % |

| Firewood freshly cut | 2 | 75 | 1,50 | 2,25 | 0,75 | 1,50 | 0,50 | 3 to 10 |

| Firewood dry moisture | 4,10 | 75 | 3,08 | 3,00 | 1,00 | 0,98 | 0,33 | up to 2 |

| Briquettes | 5,00 | 75 | 3,75 | 5,50 | 2,00 | 1,47 | 0,53 | until 3 |

| Agropellets | 5,00 | 80 | 4,00 | 7,00 | 2,00 | 1,75 | 0,50 | until 3 |

| Anthracite coal | 7,65 | 75 | 5,74 | 10,00 | 3,80 | 1,74 | 0,66 | from 15 to 25 |

The actual heat transfer of energy carriers may differ from the theoretical one and depends on the efficiency of your heating equipment and the moisture content of the raw materials you purchased.

Comparing the cost of a unit of heat on pellets, wood and coal, it is easy to conclude that pellet heating is not much more expensive than wood or coal heating.

It should be borne in mind that not the highest quality granules - agropellets - take part in the comparison. Pellets from wood waste show themselves even better.

Fuel briquettes have excellent performance in all criteria, but they lose to pellets in terms of the degree of automation of heating equipment.

Briquettes, like firewood, must be put into the firebox by the owner of the house. There are very few disadvantages of granular fuel:

- The high cost of boiler equipment and automation. The price of a medium quality pellet burner is comparable to a conventional solid fuel boiler with a power of up to 15 kW.

- Granules must be stored under certain conditions so that they do not become saturated with moisture and do not crumble. The method of storing a pile under a canopy is categorically not suitable, you will need a closed room or a container like a silo.

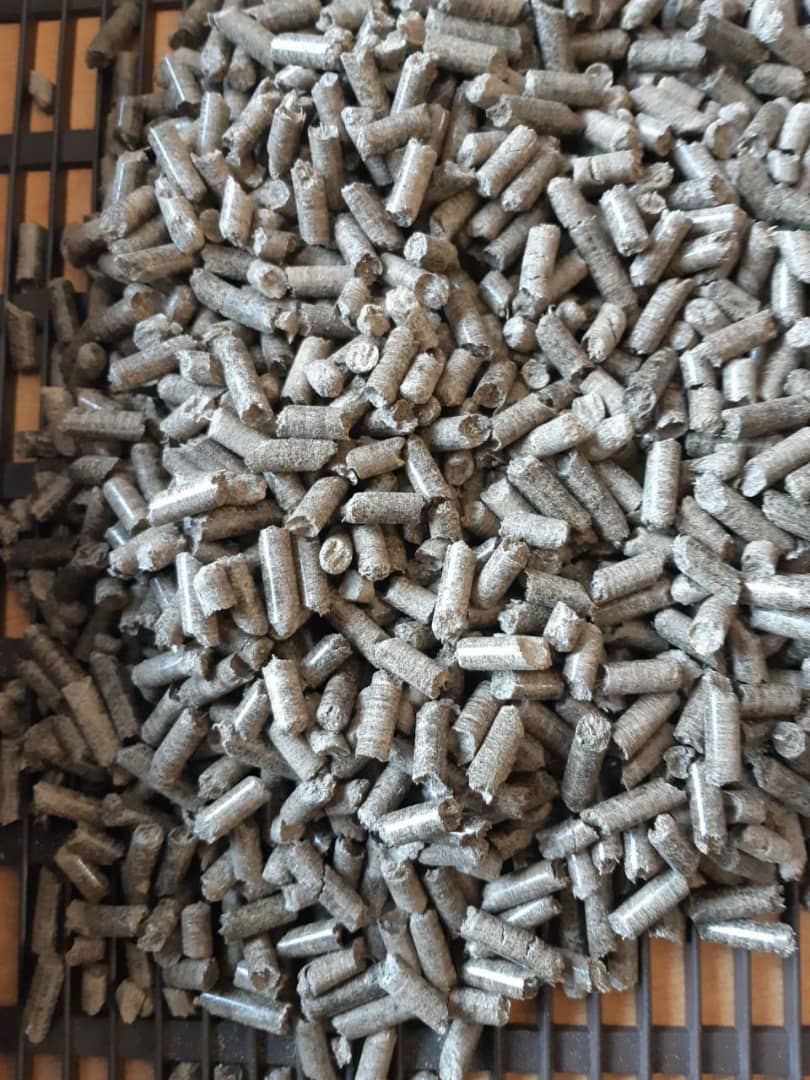

Pellet classification

According to their grade, pellets are divided into 3 types:

- Industrial pellets. Gray-brown granules. They contain approximately 0.7 mass fraction of ash due to the fact that the wood, which is the material for the manufacture of this type of pellet, has not been debarked. In other words, these wood pellets contain a large amount of bark. Due to the high content of bark, not all boilers can work with such fuel, this leads to their breakdown. But their advantage lies in the cost: industrial pellets cost less than premium quality pellets by about half the amount. And if a person has a boiler that can handle this type of pellets, then you can use them without any problems. However, cleaning the boiler due to this fuel will take place more often.

- Agropellets. The color of such fuel varies from gray to dark gray. The color depends on the material from which the pellets are made. You can often find sawdust pellets. This type is usually obtained from crop waste, such as straw, hay, leaves and others.Therefore, sometimes this kind of fuel is called straw pellets or leaf pellets. This type of fuel is the cheapest, since a huge amount of ash falls out during combustion, even more than during the combustion of industrial pellets. They are usually used at large thermal power plants; regular cleaning of slags is required. However, this type of fuel causes a number of problems: the highest ash content and the problem of transportation, because of this, agro-pellets are cheaper than other pellets. During transportation, half of the granules crumble into dust due to their softness. And, as you know, such dust will no longer serve as material for boilers - the boilers will become clogged even more. Therefore, in order to use this type of fuel, the best option would be to be close to the very place where agro-pellets are produced.

- White pellets. By name it is clear that the granules of this class are distinguished by their slightly gray, yellowish white or completely white color. They have their own pleasant smell - the smell of fresh wood. Such pellets are expensive, as their ash content is the lowest and is approximately 0.5%. If you use such fuel for heating, you can forget about cleaning the boiler for the next couple of months. When using them, the equipment will serve for a long time, and little ash will be released from them.

There is also a separate type of pellet that is not included in this classification:

Peat pellets - such fuel is characterized by high ash content. Such material is ecological and eco-friendly. Due to the ash content, these pellets are used only in industry. And most often - in improving fertilizers.

Do-it-yourself pellets: from theory to practice

Since pellets appeared on the market, amateur optimizers have begun to puzzle over how to independently solve the issue of producing such fuel, at least for their own needs. It is obvious that manufacturers do not just process free raw materials into such a valuable product. But the whole secret is that an obvious profit is possible only on the condition that production is put on stream, and the volumes transship not tens, but hundreds of tons per season. We suggest you watch an entertaining video on this topic. The author of this article does not agree with all the statements, but most of them look very convincing.

Equipment for the production of pellets

The forming element in any granulator is the matrix. It is made of hard grades of steel and is a unit with many holes through which the mass is pressed, which serves as a raw material for the production of granules. The most popular type of such dies is a flat plate, on one side of which the rollers fit tightly, the rotation of which ensures the pressing out of the raw material and its subsequent molding. There is no point in detailing construction instructions such devices - if you wish, you can easily find them on requests like "flat die granulator" or similar. Below, to mournful music, one of the options for pellet production equipment is demonstrated.

And a little lower is a visual device of a granulator with a flat matrix.

Afterword

Summarizing all of the above, you involuntarily come to the only logical conclusion: either you start production on an industrial scale (and at the same time for yourself), or you buy pellets from third-party manufacturers. There is no third!

To ensure the operation of pellet boilers heating, installed in autonomously operating boiler houses, pellets are needed. This word, borrowed from the English language, refers to cylindrical fuel pellets obtained from wood flour by pressing. Sanded and non-sanded wood, waste from sawmills, woodworking and furniture industries are used as raw materials for the manufacture of pellets. Manufacturers of an alternative type of solid fuel have also mastered the production of agro-pellets from straw, corn, sunflower husks, buckwheat husks, etc. When transporting and storing pellets, it is necessary to comply with a number of requirements that are much softer than the rules for diesel and gaseous fuels. Therefore, the popularity of pellet heating boilers is growing among owners of suburban housing. When buying granulated fuel, consumers are interested in its quality, since the performance of boiler equipment and the percentage of efficiency depend on it. The quality level of pellets is affected by raw materials, the organization of the production process, the storage conditions for finished products and delivery to the end consumer.

Fuel pellets are formed under pressure equal to 300 atm and under the influence of high temperature. At the same time, a special substance called lignin is released from the crushed mass, which ensures the gluing of individual fragments into granules.

The length of an individual pellet can vary between 10-30 mm.The diameter of the thinnest granule is 6 mm, and the largest is 10 mm. Pellets are classified as environmentally friendly fuels, since only natural materials are used in their production. When burning granular fuel in pellet boilers, the amount of carbon dioxide released into the atmosphere is negligible. The natural decomposition of wood is accompanied by the release of approximately the same amount of carbon dioxide.

Pellets are an environmentally friendly and very economical fuel used for heating residential premises with fireplaces, stoves, solid fuel boilers

Advantages of heating with peat briquettes

As buyers who have already used this fuel to heat their homes have noticed, with the right air supply, such briquettes maintain heat for about ten hours. This is very convenient because at night it will not be necessary to throw additional raw materials. It is estimated that one ton of peat briquettes emits as much heat as four cubic meters of good quality wood.

You can also emphasize a number of other advantages that show good performance, thereby allowing this type of fuel to conquer new markets.

- Peat briquettes can be used for heating all types of furnace equipment.

- After burning, only one percent of the ash from the total mass of raw materials remains from the peat briquette.

- When heating, little soot and smoke are emitted, so the chimney is not prone to clogging.

- Heat transfer during heating comes out from 5500 to 5700 kcal / kg.

- Affordable price.

- This fuel is easy to transport.

- Peat bars do not lose their combustible qualities for several years.

- Natural product with minimal impurities.

Gardeners and gardeners have found another use for the waste that remains after burning peat briquettes. It turned out that the ash left after the heating process is a good phosphorus and lime fertilizer.

Pellets what is it

These are solid cylindrical granules 6-10 mm in diameter, obtained by pressing (granulating) waste from various industries - woodworking and agricultural. Their use in the field of heat supply is very different from the combustion of other types of biomass - firewood, coal, sawdust and straw in its pure form.

The advantages of fuel pellets have made them one of the widely used energy carriers in Western Europe:

- high bulk density - 550-600 kg/m3, which saves space for fuel storage;

- low relative humidity, permissible maximum - 12%;

- due to the high degree of compaction and low humidity, the pellets are characterized by an increased calorific value - from 5 to 5.4 kW / kg;

- low ash content - from 0.5 to 3%, depending on the raw material.

The pellets have the size and solid structure to automate the combustion process, while the low ash content makes it last longer without intervention for maintenance.

Thermal equipment that burns pellets is stopped for cleaning from soot on average 1 time per week.

The fuel perfectly tolerates transportation and bulk storage, without collapsing or turning into dust. This allows you to arrange the supply of fuel to high-capacity industrial boilers from special storage facilities - silos, where a monthly supply of pellets is placed.

Fuel pellets are a convenient and environmentally friendly energy source that does not form a private house dirt and dust, so it gradually conquers the market of Ukraine and the Russian Federation.

Types of waste for the production of pellets

The raw materials for the manufacture of pellets are the following types of waste from various industries:

- wood chips, sawdust, slabs, wood chips and other substandard wood;

- husks remaining from the processing of sunflower or buckwheat seeds;

- stems of various agricultural crops in the form of straw;

- peat.