- For reference

- Benefits of using

- Equipment and raw materials

- General information

- eurofirewood

- Pellets ↑

- Fuel briquettes or ordinary firewood: what to choose?

- Algorithm for the production of fuel briquettes

- Heating with conventional wood

- Why compare cheap firewood with expensive briquettes

- What are briquettes and pellets

- reference Information

- Time to think

- common data

For reference

It is impractical and even pointless to send wood waste in its natural form to a furnace or boiler. Their friability leads to the fact that burnout occurs in the shortest possible time and is accompanied by poor heat transfer. In addition, a significant part of sawdust spills from the grate into the ash pan, which reduces efficiency and increases consumption. All these shortcomings are deprived of fuel briquettes from sawdust. From an economic point of view, it is unreasonable not to use for your own purposes the waste that is available in abundance in the country.

As raw materials, you can use shavings, and straw, and hay, and dry foliage.

Benefits of using

- in the process of burning, the briquettes do not have a characteristic crackle, and also do not sparkle;

- have a high degree of heat transfer during prolonged combustion;

- excellent resistance to moisture;

- practicality in use;

- with a uniform investment in the furnace of briquettes and firewood, the heat transfer of the boiler is significantly increased, and the consumption of fuel materials is reduced by 2-4 times;

- briquettes, which contain birch wood, do not leave carbon deposits and tar scale on the walls of the fuel chamber of the boiler, which greatly facilitates the maintenance of this boiler unit;

- occupy a small amount of space during storage, while the cleanliness in the warehouse will be guaranteed.

The above advantages of Ruf fuel briquettes can only say that this is the best type of fuel for a heating boiler in a country house. And in conclusion of the article I would like to dwell on one more aspect.

As you know, transportation costs for the delivery of fuel are logically included in its cost. And now let's give an example: a truck with a body volume of 80 m3 at a time can transport 7-8 tons of firewood with dense packing, at the same time, it can deliver 20-24 tons of Ruf fuel briquettes! Draw your own conclusions!

Thus, in this article we have indicated all the important aspects of using fuel briquettes of the Ruf brand. We hope that our strong arguments will cause you to use only Ruf fuel briquettes to heat your home.

How to choose a quality RUF briquette, see the following video:

Equipment and raw materials

You can create fuel briquettes with your own hands from various types of human waste. In principle, any substance that can burn normally can be used. What household waste can become a full-fledged raw material:

- First of all, wood, sawdust and shavings, wood dust, leaves and tree branches.The type of wood does not play a primary role, but it is better that the sawdust be birch, oak, alder or aspen.

- Straw left over from harvesting wheat or corn.

- Cardboard and paper. It is much easier to make fuel briquettes from paper with your own hands than from wood, only the paper version will burn out faster.

- Good, but rare raw materials can be the remains and husks of seeds, nut shells.

Good to know: How to kindle a stove with raw wood, effective techniques

The composition of the briquettes can be different, and hence the different adhesive capabilities of the mixture. Depending on the raw materials used, clay is added to some briquettes to help bind the elements, usually in a ratio of 10 to 1.

Wood sawdust can be the best raw material

To create homemade fuel briquettes, you need special equipment. You can immediately order a whole line for home production by contacting a specific company, or you can assemble the equipment in parts, because the technology for making fuel briquettes is essentially simple.

The whole technology is based on three stages of production:

- The first stage involves the initial preparation of raw materials. The existing waste should be crushed, crushed to the required consistency so that the composition of the mixture is homogeneous.

- The second stage involves bringing the mixture to the finished state by drying. On the drying machine, the raw material gets rid of moisture.

- The third stage involves the manufacture of products, here the pressing of fuel briquettes takes place on a special machine under high pressure and temperature.

Screw press for working with raw materials

Accordingly, for each stage, you will need to choose a machine suitable for your raw materials: crusher, dryer and press.

Another difference in home production is that, in principle, you can exclude the dryer from the line. You can dry raw materials and briquettes naturally under the sun. By the way, if the raw materials are ready-made sawdust or seed husks, then you may not need a crusher.

Particularly skilled craftsmen make the press themselves, based on their needs and capabilities. Nowadays, access to information is not limited, therefore, drawings of a device of any type can be found freely available on the net. Having assembled your press according to the drawings, you can make a unique briquetted product that will burn perfectly in furnaces.

Good to know: How to make a firewood rack for firewood on the street and at home with your own hands

How to make a press machine can be suggested by friends who are already dealing with similar handicraft or factory-made equipment. You can choose screw, hydraulic or shock-mechanical option.

Machine for the production of fuel briquettes

You will need a decent amount of space to install the equipment. It will have to place all the machines, raw materials and resulting products. It is desirable to provide comfortable conditions for drying so that the humidity of the briquettes is minimal, so take care of ventilation. Electricity is required to connect the machines, but since we produce fuel, we should not forget about fire safety measures.

General information

Let's first understand what fuel briquettes are and how they are made in order to understand the essence of this alternative fuel.

Fuel briquettes are known to most people under the name "euro firewood". Like ordinary firewood, briquettes are considered solid fuel and are used to kindle stoves and fireplaces.They are made from various natural materials, worn down to sawdust and pressed on a machine under high pressure to a given shape. Usually, either a rectangular shape or log imitation is used.

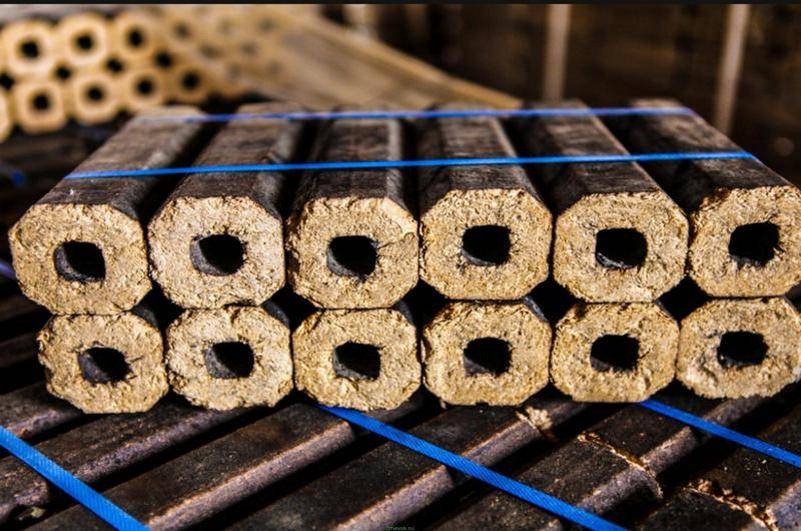

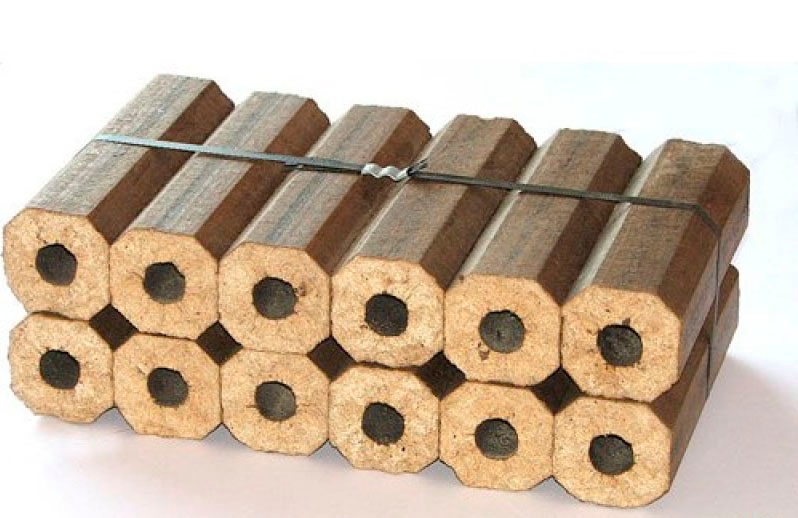

Currently, all fuel briquettes, eurofirewood, can be divided into three types that do not differ too much from each other:

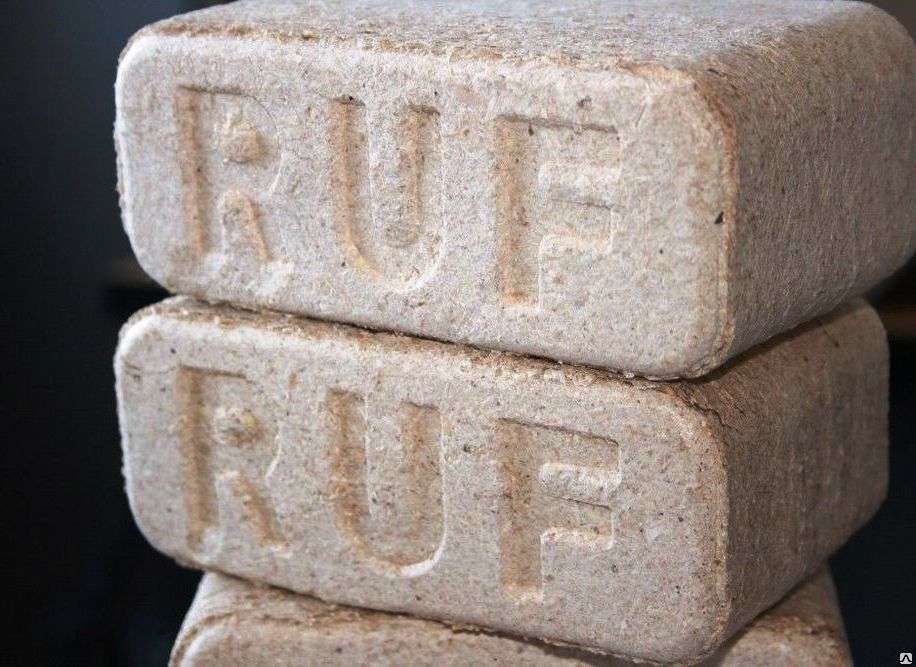

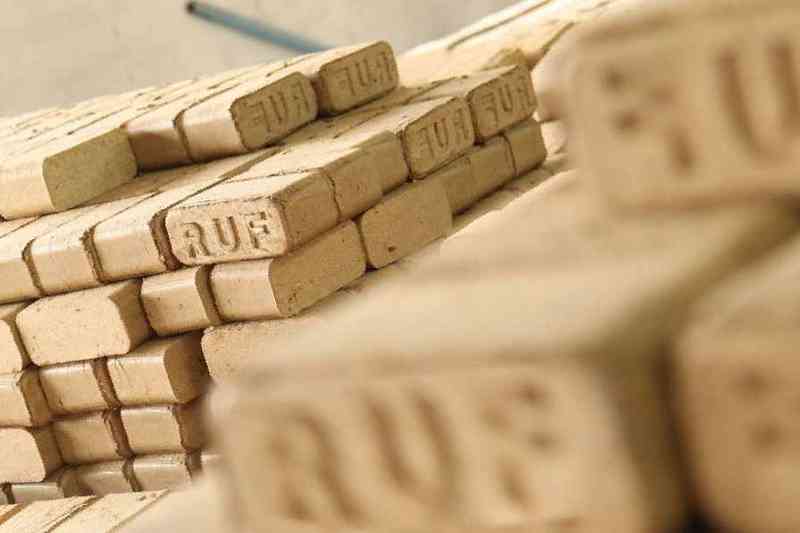

- Eurobriquettes RUF (Ruf);

- Eurobriquettes Pini Kay;

- Eurobriquettes Nestro.

Warehouse for RUF euro briquettes

The first option can be considered classic eurofirewood. They are created according to the technology described above from sawdust, which are compressed into pretty rectangles, like small bricks. Fuel briquettes for the stove in this design are inexpensive, so this type can be considered optimal in terms of price and quality.

The second option is not much different from the first, just here, at the last stages of production, the firing of eurobriquettes is added, which is necessary to create the possibility of increasing the shelf life of sawdust products. Roasting allows you to create some kind of shell, protection from moisture and other unpleasant influences, which ensures long-term preservation, and most importantly, the integrity of the briquette.

The third option is a kind of hybrid of the first and second species. These briquettes have a regular cylindrical shape, similar to poles, but they are not fired on the outside.

Like all fuel briquettes, Pini-kei products are created in a rectangular shape, similar to firewood. However, unlike ordinary firewood, they have a through hole in the center.

Warehouse of eurobriquettes Pini-Key

Another procedure with raw materials affects the price, which for Pini-Key euro briquettes is slightly higher than the RUF analogue.However, no matter what options you choose for a fireplace or stove, they will still cost inexpensively, cheaper than ordinary firewood.

How much do fuel briquettes cost, approximately a couple of thousand rubles per ton, which is quite comparable to the cost of several tons of ordinary wood, and we will consider what is better to choose next.

eurofirewood

The composition of the briquette is subjected to strong pressing and drying. Burning fuel briquettes does not harm human health, as they do not contain chemicals. There are three main forms of fuel briquettes: ruf, pini-kay and nestro.

They differ from each other only in the maximum density, which directly depends on the shape, but there are no fundamental differences in the composition and calorific value of the material. Advantages of fuel briquettes:

- Low humidity and high density of the material, which provides high heat transfer and long burning time (up to 4 hours).

- Compared to firewood, they are more compact in storage due to their regular geometric shape.

- They do not spark or shoot when burned, emitting a minimum amount of smoke.

Flaws:

- Briquettes warm up for a long time due to the high density of the material and leave a fairly large amount of ash.

- In the room where the stove is heated with briquettes, there is a pungent specific smell of burning.

- Fuel briquettes have a very low moisture resistance, crumble under improper storage conditions.

- Very unstable to mechanical damage, which leads to the impossibility of their further operation.

- The absence of an aesthetic component when lighting a fireplace. Fuel briquettes are able to burn with a barely smoldering flame.

Pellets ↑

Although these fuels are very similar in composition, they look different.Briquettes are larger and resemble bricks, and pellets are cylinder-shaped granules, 0.4–1 cm in diameter and 5 cm long. Pellets appeared in the 80s of the 20th century, in Europe, or rather, an environmentalist, Sweden . Within a few years, residents of Finland, France, Norway, Denmark, Italy, and England began to use pellets. Pellets are made from the remains of wood, without any additives. Like fuel briquettes, this is an environmentally friendly raw material; when burned, it almost does not give off smoke, and the one that even exists is practically considered harmless to humans. But on the other hand, heat is released from such fuel (what else is needed for heating? ;)) But there is a nuance - the fuel must be dry without fail. If the pellets are made in a room with high humidity, they absorb it and after a couple of days they themselves become wet, therefore, there will be less heat from them. Yes, and after the purchase, they must be stored in a room well protected from moisture, otherwise they will begin to soak, rot, and instead of economical fuel, a bunch of wet wood will turn out. By the way, pellets are usually sold in bags of 15-50 kg, or 600-700 kg. For heating with pellets, a system for supplying pellets to a fuel boiler is required, so such heating is not very popular in Russia so far. But at the same time, it cannot be said that pellets have not taken root in our country at all. No, they are very popular, though not as a fuel. They are used as a filler for cat litter, as well as for rodent pets.

Fuel briquettes or ordinary firewood: what to choose?

What to give preference to: ordinary firewood or fuel briquettes? To answer this question, it is necessary to study the advantages and disadvantages of both.

We list the most important advantages of fuel briquettes:

- A fuel briquette, when compared with ordinary firewood, burns 4 times longer than the latter, which contributes to the economical consumption of such fuel.

- After the combustion of pellets, very little ash remains - about 1% of the total mass of used fuel. When using conventional firewood, this figure can reach up to 20% of the total mass of fuel used. The ash left after the combustion of wood briquettes or any other type can be used as a fertilizer containing a large amount of potassium.

- The amount of thermal energy released during the combustion of eurofirewood is almost twice as much as when using ordinary firewood.

- During combustion, fuel briquettes emit heat almost all the time, which cannot be said about ordinary firewood, the heat output of which decreases rapidly as it burns.

- During combustion, fuel briquettes practically do not spark, emit a minimum amount of smoke and smell. Thus, this type of fuel does not create discomfort and does not harm the environment. In addition, when burning firewood infected with mold or fungus, toxic smoke is formed, which is excluded when using eurofirewood, for the production of which carefully dried sawdust or shavings are used.

- When using wood briquettes as fuel, much less soot is deposited on the walls of chimneys than when using conventional firewood.

- The compact dimensions that distinguish eurofirewood allow more economical use of the area for storing such fuel.Moreover, when storing fuel briquettes, usually placed in a neat package, there is no garbage and wood dust, which are necessarily present in places where ordinary firewood is stored.

Compact storage is an indisputable advantage of fuel briquettes

Naturally, this type of fuel has certain disadvantages:

- Due to the high density of the internal structure, fuel briquettes flare up for a long time, it will not be possible to quickly warm up the room with the help of such fuel.

- The low moisture resistance of eurofirewood can cause them to simply deteriorate if the required storage conditions are not provided.

- Fuel briquettes, which are compressed sawdust, are characterized by a rather low resistance to mechanical damage.

- When burning fuel briquettes, there is no such beautiful flame as when using ordinary firewood, which somewhat limits the use of pellets as fuel for fireplaces, where the aesthetic component of the combustion process is also very important.

Comparison of the main parameters of various types of solid fuels

To make a choice between fuel briquettes and ordinary firewood, the advantages of the latter should also be taken into account.

- When burning ordinary firewood, as mentioned above, more heat is generated, respectively, with the help of such fuel it is possible to quickly warm up the heated room.

- The cost of ordinary firewood in comparison with fuel briquettes is much lower.

- Firewood is more resistant to mechanical damage.

- When burning firewood, a beautiful flame is formed, which is an especially important quality for fireplace fuel.In addition, when burning firewood, essential oils contained in wood are released into the surrounding air, which has a beneficial effect on the nervous and respiratory systems of a person who is in a heated room.

- The characteristic crackle that firewood emits during combustion also has a beneficial effect on the nervous system.

- The ash left after burning ordinary firewood does not have such a tart smell as the product of burning pellets.

Algorithm for the production of fuel briquettes

Do-it-yourself briquetting is carried out differently than in production. The initial stage is similar: wood waste is being shredded. But then there is not drying, but, on the contrary, soaking in water. Or at least good hydration so you don't have to decant excess moisture afterwards.

Next, a binder is introduced. There are three options here:

- Clay. The cheapest and most widely available filler. Proportions with the main material 1:10. Perfectly binds the original wood raw materials, however, after using ready-made briquettes, a significant amount of ash waste is obtained: clay practically does not burn.

- Wallpaper glue. Deprived of the disadvantages of the previous additive, introduced in smaller quantities, but makes production noticeably more expensive.

- Any waste paper, including cardboard, pre-shredded and soaked. No waste, virtually no cost, proportions just like with clay. Drawback two. The finer the sawdust fraction, the more paper filler is required - this time. Second: it will take much longer to dry the finished briquettes.

The next step will be mixing - manual or mechanized. To make a truly high-quality briquette, you need to bring the mass to the maximum available uniformity.

The press can also be wall-mounted

Next, the raw material is put into a mold for briquetting, and a press is used. At the output, briquettes of a given shape are obtained, which are sent for drying. They should be laid out freely enough so that there is room for ventilation. To speed up the drying process, it is recommended to periodically turn the fuel over. And also - to shift the elements with paper or dry rags - these materials quickly draw out excess moisture from the briquettes.

Drying fuel briquettes should be until their humidity reaches at least the indicators of raw firewood, that is, 25%. In fact, it is desirable to achieve even lower humidity - the heat transfer will then be higher. You are not in a hurry, so in hot weather you can afford to keep the fuel briquettes in the sun for a week longer. The warmer it will be in the home in winter. Please note that it is harmful to rush: solid fuel boilers, like hydrolysis boilers, operate only on fuel whose humidity is not higher than 30%. Hurry up - you will pay for expensive repairs or even have to buy new heating equipment.

Well-dried fuel is removed for storage. You can keep the briquettes in an unheated and rather damp place if you pack them in plastic bags, tighten the neck tightly and seal it with several overlapping layers of adhesive tape.

There are reasons for doubt

Heating with conventional wood

Firewood has been used for heating for a very long time; it is a high-quality fuel for home and baths, barbecues and barbecues. The environmental friendliness of firewood will always be at the level of 100%, and this fuel has plenty of other advantages. We note the main advantages of firewood, without deeply delving into this topic:

- First of all, I would like to say that the process of harvesting, drying and storing firewood is understandable to everyone. From an early age, we know how to look for firewood, collect and kindle it.

- Kindling wood is not difficult, even damp. Some varieties of trees can burn at high humidity, giving off heat.

- The cost of firewood is small, even if you do not go through the entire harvesting cycle, but buy ready-made poles or logs. (However, until the time of comparing the prices of various types of fuel, it will not be argued which is more profitable.)

- Firewood is not afraid of mechanical damage and can be stored in a woodpile in completely different ways.

- From an aesthetic point of view, firewood burns perfectly. They create a beautiful fire and soulful crackling, and when burned, some varieties produce a characteristic pleasant aroma. For open fireplaces, where the appearance of what is happening is important, such fuel is considered optimal.

- The substances released during the combustion of firewood have a beneficial effect on a person, they calm the nervous system, and heal the respiratory organs.

Strategic forest reserve for the winter

We will also highlight the disadvantages of natural fuel:

- In order to obtain a high heat output, the firewood must be well dried under natural conditions, which requires an extremely long time, for example, 1 or 2 years. The best firewood is considered to be wood that has lain in a dry barn for a couple of years.

- With long-term storage, wood loses some of its qualities, especially fragrant varieties of trees.

- Firewood takes up a lot of space; for their normal storage in the proper amount, it is necessary to build an appropriate structure.

- When using firewood, there is always a lot of garbage (wood chips, bark, wood dust, sawdust).

Having got acquainted with the main features of the two types of fuel, let's make a comparison.

Why compare cheap firewood with expensive briquettes

For residents of regions rich in forests, where woodworking enterprises are located, such a comparison is irrelevant. Firewood and sawdust in those parts are inexpensive or donated. But we decided to compare them with briquettes for the following reasons:

- There are practically no forests in the southern and desert regions. Hence the higher price of firewood bought by the owners of country houses and summer cottages.

- In these areas, it is advantageous to press any kind of combustible mass - coal dust, agricultural waste and peat. Thanks to the development of such industries, the cost of briquettes is reduced and they become an alternative to firewood.

- It is more comfortable to heat with pressed products than with wood raw materials, which our experiment will show.

The last reason is the conflicting reviews of homeowners about various fuels on thematic forums. A user who does not understand this issue is hardly able to figure out which types of briquettes are best used for a stove, fireplace or boiler. We will present the conclusions and opinion of the expert on this matter.

What are briquettes and pellets

Briquettes are a pressed mass based on waste from the agricultural, woodworking, and logging industries. They do not contain harmful binders, since the fractions are held together by lignin, a natural compound found in "dead" plant residues.

In fact, there are no differences between fuel briquettes and pellets, the whole difference lies in the production method and the possibility of use.In the case of the second type, it is more complicated and expensive, since the raw materials must first be crushed, then heated, compressed and granulated. Eurowood can be used in all solid fuel appliances, but for pellets you need to buy special equipment. There is also an unprincipled external difference, briquettes are bars, and pellets look like granules, they are made from the waste of such raw materials:

- peat;

- coal;

- sawdust and wood chips;

- chicken manure;

- husks;

- straw;

- municipal solid waste and others.

On a note! The calorific value depends on the material from which the fuel is made. Pine will have a value of 4500 kcal, and beech or oak will reach 6000 kcal. The raw material used also determines the ash content.

reference Information

DocumentsLawsNotificationsApproval of documentsContractsRequests for proposalsTerms of referenceDevelopment plansDocumentationAnalyticsEventsCompetitionsResultsCity administrationsOrdersContractsExecution of worksProtocols of consideration of applicationsAuctionsProjectsProtocolsBudget organizationsMunicipalitiesRegionsEducationProgramsReportsby referencesDocument baseSecuritiesRegulationsFinancial documentsDecreesCategories by topicsFinancecities of the Russian Federationregionsby exact datesRegulationsTermsScientific terminologyFinancialEconomicTimeDates20152016Documents in the financial sectorin the investment

Time to think

Before you get enthusiastic about sawdust briquetting, decide for yourself how interested you are in it. Despite the outward simplicity of the process, it also has significant drawbacks.

- Preparing raw materials and pressing them into molds takes a lot of time and requires serious physical exertion.

- If you want the weather to not affect the drying of the finished briquettes, you will have to allocate a spacious, ventilated, dry room for them, which obviously can be used differently.

- Modernization with the introduction of electrical equipment affects the cost of production. As a result, making briquettes with your own hands is not a way to save money, but a hobby, and not cheap.

- And most importantly: a home-made sawdust briquette still loses in quality to factory eurofuel.

If you are serious about using the waste at your disposal rationally, think about making money on it. That is - about the production of fuel briquettes from sawdust in a larger quantity. It could be a good business!

And how to make a press, watch the video:

common data

Fuel briquettes, or as they are also called eurofirewood, appeared on the construction market relatively recently. However, due to their quality characteristics, they quickly became popular. Now we can say with confidence that this advanced fuel for fireplaces and stoves has appealed to many people.

How did specialists achieve such quality from wood, it turns out everything is very simple. There are two main reasons for this increased performance:

- The high density of wood, achieved in the process of thermal pressing of sawdust, shavings and wood dust.

- The minimum moisture content, again resulting from pressing and heat treatment. Humidity of fuel briquettes is 7-9%, while the driest firewood, for example, from birch, has a moisture content of about 20%. The absence of moisture allows more heat to escape from the briquettes, because there is no need to heat and evaporate water.

Due to such density and humidity, fuel briquettes are able to give off heat in the range from 4000 to 4500 kcal/kg. Such heat transfer is enough to warm the house well, to heat the bath. In addition, there are no restrictions on the use of eurobriquettes, they can be placed in any oven, even the simplest heater, in which there are restrictions on the amount of heat, approximately 4900-5000 kcal / kg. The stove is heated with fuel briquettes like ordinary firewood, except that they need to be thrown up less often.

Loading fuel briquettes into the furnace

The environmental friendliness of fuel briquettes is undeniable, since they are made exclusively from sawdust of natural wood, which are pressed together. In this case, it is not necessary to add an adhesive composition, since the wood contains a suitable lingin component, which holds the sawdust together.

A distinctive feature of fuel briquettes is the small amount of ash remaining after their combustion. Approximately ash is obtained up to 1% of the total volume of the briquette. This burnout is again due to the high density of the material.

At the same time, sawdust, from which fuel briquettes are produced, is practically devoid of resins, which means that during combustion there is no smoke and soot. You can use such fuel even in black baths, to say nothing of the fact that it is practically not necessary to clean the chimney after using such firewood.

Modern packing of pressed firewood

The long burning time and high heat transfer of eurobriquettes indicate that the reserves of this fuel can be several times less than the volumes of ordinary firewood. In addition, packed in moisture-proof bags that are convenient for storage and have the same shape and size, fuel briquettes can be successfully stored almost anywhere.Good packaging will reduce the amount of waste both during storage and further use.