- Pros and cons of fuel briquettes

- Fuel briquettes Nielsen

- Advantages of fuel briquettes

- Fuel briquettes or ordinary firewood: what to choose?

- Types of eurobriquettes

- Eurobriquettes RUF

- Eurobriquettes Pini-Key

- What are Pini-Key briquettes

- House heating

- Disadvantages of traditional solid fuel

- What is Eurowood and can it be an efficient fuel?

- Fuel briquettes Nestro

- What are fuel briquettes

- Differences in form

- Differences in material

- Table comments

- What are briquettes and pellets

- How and where to buy Pini-Key briquettes

- Fuel briquettes Pini Kay

Pros and cons of fuel briquettes

Now consider eurofirewood. Fuel briquettes are made from woodworking and furniture waste. Chips or sawdust are usually crushed. Then the resulting wood flour is pressed under high pressure and the output is "bricks", "cylinders", "tablets", glued together with lignin - a natural polymer.

Fuel briquettes are also made from agro-industrial waste - sunflower husks and straw. From peat and coal.

Advantages of wood fuel briquettes:

- High specific heat of combustion - 4500 - 5000 kcal (5.2 - 5.8 kWh per 1 kg)

- A small percentage of humidity - 8 - 10%.

- Low ash content - 1%.

Coal fuel briquettes give a higher specific heat during combustion than eurofirewood, but they have a higher ash content.

Practice shows that fuel briquettes with a higher density (about 1000 kg/m3) and lower humidity burn longer and better than firewood.

vita01User

I will share my experience. There is no gas. The allocated electric power is not enough. I do not want to be heated by diesel fuel or coal. He heated a solid fuel boiler with dry firewood and briquettes. It is more convenient for me to heat with fuel briquettes, and not to harvest firewood for future use. Dry them. Briquettes take up three times less storage space than firewood. They burn longer. One bookmark is enough for a day. I want to properly insulate the house and then, I think, the briquettes will be enough for 2 days.

But, briquettes are different. The quality is highly dependent on the manufacturer and raw materials. Negligent manufacturers use waste from plywood production with phenol-formaldehyde glue. Waste from sawmills - bark, slab. This affects the quality of eurofirewood and their calorific value.

XUWHUKUser

I bought myself a sample of briquettes in the form of "bricks". Didn't like it. They burn for a long time. There is little heat from them. The boiler does not reach maximum power. Before them I tried fuel briquettes in the form of "cylinders" with a hole in the middle. They burn much better. And give a lot more heat. But they cost more. By the way, even those briquettes in the form of "bricks" still burned better than firewood. Maybe I just got raw briquettes?

Unlike firewood, fuel briquettes are not bought with a margin of 2-3 years in advance. The fresher the product, i.e. just arrived from production, the better. During long-term storage, even eurofirewood packed in a protective film gains excess moisture, which worsens their calorific value.

According to Andreyraduga, when buying fuel briquettes, pay attention not to the name, but to what they are made of.The user, for the fireplace, bought different briquettes

For example, brown "cylinders" with a hole in the middle, although the most expensive, burned out very quickly. “Bricks”, made not from shavings (this can be seen by eye), but from wood flour and tightly pressed, burn for a long time and hot and give a little ash.

Ham59User

He heated a house with an area of 210 sq. m birch firewood, but there is a lot of tar about them. I bought fuel briquettes "bricks". For a month, one pallet with euro firewood left + bought 20 packs. Total spent 6100 rubles. If it is 10 - -15 ° C outside, then one pallet of eurowood is enough for heating. Well, once a week, I burn 2-3 aspen logs to clean the boiler and chimney. Used briquettes from coniferous breeds. Fraction - almost sawdust. They burn very quickly. Unsuitable. Birch briquettes in Perm cost 55 rubles. for 1 pack of 12 pcs. There are 96 packs on a pallet. Total - 5280 rubles. Coniferous briquettes - 86 rubles. for 1 pack. The pallet costs 8256 rubles. Not beneficial. For comparison: when heating with electricity, 2 heating elements of 3 kW, it took 10,000 - 12,000 rubles per month.

Fuel briquettes Nielsen

Briquettes fuel Nielsen are made in Denmark. The pressing technology is different from the Ruf technology. On Nielsen machines, pressing is carried out using an impact press. Since the pressure exerted on the material is high, the calorific value of these products is also higher.

A briquette comes out of the pressing machine in a continuous cylinder, after which it is cut into bars by an automatic machine. Packaging is made with shrink film, which provides additional protection from the external environment.

Fuel briquettes Nielsen

Due to various forms, it is possible to produce several types of fuel on these machines:

- Round cylinders without a hole in the middle.

- Round cylinders with a hole in the middle (suitable for fireplaces, baths, saunas), in addition to the natural increased heat transfer, due to additional traction due to the hole, create a uniform and beautiful fire, which also increases heat production in a special way.

Perforated Nielsen wood firewood has the disadvantage of having a shorter burn time than non-perforated fuel.

Two types of products are fired around the perimeter, this does not allow moisture to be absorbed.

Advantages of fuel briquettes

Fuel briquettes are distinguished by the ability of high heat transfer. Their calorific value is 4600-4900 kcal/kg. For comparison, dry birch firewood has a calorific value of about 2200 kcal/kg. And birch wood of all types of wood has the highest heat transfer rates. Therefore, as we see, fuel briquettes give 2 times more heat than firewood. In addition, throughout the combustion, they maintain a constant temperature.

Long burning time

Briquettes are also characterized by a rather high density, which is 1000-1200 kg/m3. Oak is considered the most dense wood applicable for heating. Its density is 690 kg/cu.m. Again, we see a big difference in favor of fuel briquettes. Good density just contributes to the long-term burning of fuel briquettes. They are able to give a steady flame from laying to complete combustion within 2.5-3 hours. With the supported smoldering mode, one portion of high-quality briquettes is enough for 5-7 hours. This means that you will need to add them to the stove 2-3 times less than if you fired wood.

Low humidity

Humidity of fuel briquettes is no more than 4-8%, while the minimum moisture content of wood is 20%.The briquettes have such a low moisture content due to the drying process, which is an essential step in the production.

Due to their low humidity, briquettes reach a high temperature during combustion, which contributes to their high heat transfer.

Minimum ash content

Compared to wood and coal, the ash content of briquettes is much less. After burning, they leave only 1% ash. Burning coal leaves up to 40% ash. Moreover, the ashes of the briquettes can still be used as fertilizer, and the ashes of coal will still have to be disposed of.

The advantage of heating with briquettes is that the cost of cleaning and maintaining the fireplace or stove is much reduced.

Environmental friendliness

The choice of fuel briquettes for heating in the house is a great option for people who care about their health. Briquettes practically do not emit smoke and other harmful volatile substances, so you can fire the stove without charcoal even with a low chimney draft.

Unlike coal, the combustion of briquettes does not form dust that settles in the room. Also, since briquettes are fuel produced from waste, there is less damage to the environment.

Ease of storage

Fuel briquettes are convenient both to use and store. Unlike shapeless firewood, briquettes have a fairly regular and compact shape. Therefore, even if you try to put firewood as carefully as possible into a compact woodpile, they will still take up 2-3 times more space than briquettes.

No condensation on chimneys

Since firewood has a higher moisture content, during combustion, it forms condensate on the walls of the chimney.Depending on the moisture content of the wood, there will be more or less condensation, respectively. What is bad about condensate in a chimney is that it narrows its working section over time. With heavy condensate, after one season you will notice a strong drop in draft in the chimney.

8% humidity of the briquettes practically does not form condensate, consequently, the chimney's working capacity is maintained longer.

Fuel briquettes or ordinary firewood: what to choose?

What to give preference to: ordinary firewood or fuel briquettes? To answer this question, it is necessary to study the advantages and disadvantages of both.

We list the most important advantages of fuel briquettes:

- A fuel briquette, when compared with ordinary firewood, burns 4 times longer than the latter, which contributes to the economical consumption of such fuel.

- After the combustion of pellets, very little ash remains - about 1% of the total mass of used fuel. When using conventional firewood, this figure can reach up to 20% of the total mass of fuel used. The ash left after the combustion of wood briquettes or any other type can be used as a fertilizer containing a large amount of potassium.

- The amount of thermal energy released during the combustion of eurofirewood is almost twice as much as when using ordinary firewood.

- During combustion, fuel briquettes emit heat almost all the time, which cannot be said about ordinary firewood, the heat output of which decreases rapidly as it burns.

- During combustion, fuel briquettes practically do not spark, emit a minimum amount of smoke and smell. Thus, this type of fuel does not create discomfort and does not harm the environment.In addition, when burning firewood infected with mold or fungus, toxic smoke is formed, which is excluded when using eurofirewood, for the production of which carefully dried sawdust or shavings are used.

- When using wood briquettes as fuel, much less soot is deposited on the walls of chimneys than when using conventional firewood.

- The compact dimensions that distinguish eurofirewood allow more economical use of the area for storing such fuel. Moreover, when storing fuel briquettes, usually placed in a neat package, there is no garbage and wood dust, which are necessarily present in places where ordinary firewood is stored.

Compact storage is an indisputable advantage of fuel briquettes

Naturally, this type of fuel has certain disadvantages:

- Due to the high density of the internal structure, fuel briquettes flare up for a long time, it will not be possible to quickly warm up the room with the help of such fuel.

- The low moisture resistance of eurofirewood can cause them to simply deteriorate if the required storage conditions are not provided.

- Fuel briquettes, which are compressed sawdust, are characterized by a rather low resistance to mechanical damage.

- When burning fuel briquettes, there is no such beautiful flame as when using ordinary firewood, which somewhat limits the use of pellets as fuel for fireplaces, where the aesthetic component of the combustion process is also very important.

Comparison of the main parameters of various types of solid fuels

To make a choice between fuel briquettes and ordinary firewood, the advantages of the latter should also be taken into account.

- When burning ordinary firewood, as mentioned above, more heat is generated, respectively, with the help of such fuel it is possible to quickly warm up the heated room.

- The cost of ordinary firewood in comparison with fuel briquettes is much lower.

- Firewood is more resistant to mechanical damage.

- When burning firewood, a beautiful flame is formed, which is an especially important quality for fireplace fuel. In addition, when burning firewood, essential oils contained in wood are released into the surrounding air, which has a beneficial effect on the nervous and respiratory systems of a person who is in a heated room.

- The characteristic crackle that firewood emits during combustion also has a beneficial effect on the nervous system.

- The ash left after burning ordinary firewood does not have such a tart smell as the product of burning pellets.

Types of eurobriquettes

Fuel briquettes are of two types, but the difference between them is not too great:

Eurobriquettes RUF

Fuel briquettes from wood waste Kuf

They are made according to the technology described above: chips and sawdust are pressed together, fastened together with a natural adhesive. They have the shape of a rectangle. The most optimal option, since they are inexpensive, but the price does not affect the quality.

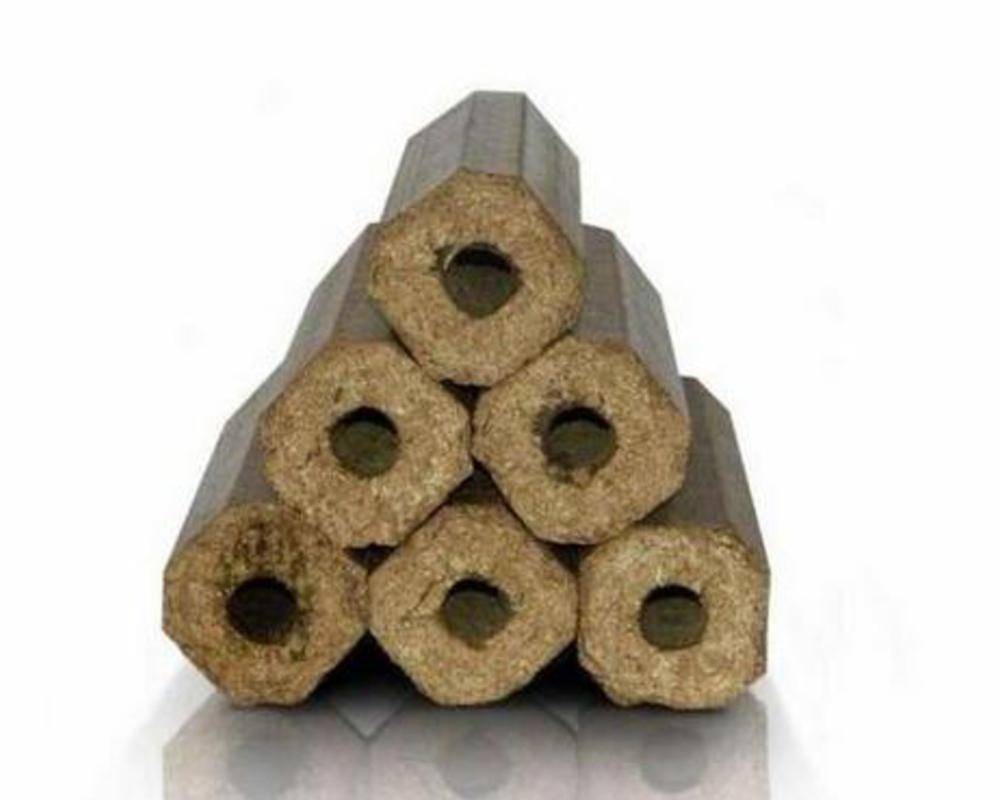

Eurobriquettes Pini-Key

Fuel briquettes Pini-Key

They are made according to the same principle, but at the final stage they also go through the firing process. As a result, eurobriquettes of this type acquire natural protection against moisture, which guarantees their longer storage.

Due to this, the price of such firewood is higher: the markup is about two thousand rubles per ton.Outwardly, they also do not look like RUF: these firewood have a shape close to an ordinary log, with a through hole.

DIY briquette press

What are Pini-Key briquettes

Briquettes are delivered on pallets, any suitable place can be used for storage - a neat rectangular shape does not create problems when storing fuel.

Pini-Key wood briquettes are a product of wood waste processing. Here dust and shavings are used. They are compressed under great pressure, turning into small logs with a hole in the middle. This hole is necessary to improve the combustion of Pini-Key in the bowels of boilers and furnaces.

In their structure, Pini-Key wood briquettes resemble enlarged pencil stubs - as if the stylus was taken out of them. This form was not created by chance, it facilitates the ignition of the fuel and its further active combustion.

Let's present the other advantages of Pini-Key in the form of a list:

- Excellent characteristics - judge for yourself, the calorific value reaches 5000-5200 kcal, which is 20-25% higher than that of ordinary pieces of wood.

- Ecological cleanliness - in the production of briquettes, adhesive bases and chemical additives are not used.

- Almost complete combustion - Pini Kay fuel briquettes form a minimum amount of ash. It should also be noted that the minimum amount of tar released, which reduces the frequency of cleaning stoves, fireplaces and boilers.

- Even burning - Pini-Key briquettes do not "shoot", do not scatter burning coals, provide a uniform flame.

- Ability to process - if necessary, briquetted fuel can be sawn (if not placed in the furnace).

The internal humidity is about 4%.

There are also disadvantages:

For pre-ignition, you will need some firewood - eurofirewood (they are Pini-Key briquettes) are well ignited only if there is kindling.

When storing eurofirewood, it is necessary to pay attention to the humidity indicator - it is recommended to store them in a heated room (placement on the street is not allowed).

Higher cost compared to traditional firewood - it all depends on the manufacturer of Pini-Key fuel briquettes and the manufacturer's pricing policy.

Nevertheless, this fuel is popular among consumers.

House heating

For home heating, fuel briquettes are probably ideal. The ability to light the stove once and keep the fire and heat for a long time without additional tossing, allows us to talk about the good characteristics of eurobriquettes. Consider how to heat a brick stove with fuel briquettes within the house.

Of course, pressed bricks will not immediately burn, so let's figure out how to ignite fuel briquettes. To do this is quite simple, you should first put wood bark, wood chips, some dry newspapers into the oven, and put alternative firewood on top. During kindling, while the chips are actively lit, we adjust the blowing. As soon as the fire on the first briquettes began to play, you can report the rest.

Another option is to heat the stove with fuel briquettes after the first batch of firewood has burned down and decent coals have appeared. In such a firebox, fire is quickly caught on eurobriquettes.

Preparing to kindle the stove

Depending on the needs, we choose the tactics of filling the furnace with fuel:

- If you fold the fuel briquettes loosely, at a short distance from each other, then the fire in the furnace will be quite intense, there will be a lot of heat, which will allow you to quickly heat the house.

- If you stack alternative firewood tightly to each other and cover the blower, the firewood will smolder for a longer time, which is perfect for heating a house at night. At the same time, the consumption of fuel briquettes per day will be several times less than firewood.

In order to roughly understand how much eurobriquettes will require for heating a house, several experiments should be carried out, each time finding out this parameter in practice. There are too many nuances in this case.

It is worth noting that fuel briquettes have a specific purpose - to create warmth, while firewood can be considered in order to create a comfortable and cozy environment. For example, is it possible to heat a fireplace with fuel briquettes - well, of course, yes, but they will not create such an atmosphere as firewood with its pleasant crackle and uneven fire. By the way, the smell of burning wood is stronger and more pleasant.

In conclusion, I would like to say a little about the storage of eurobriquettes and compare it with the preparation and storage of firewood. Fuel briquettes are sold in individual packages wrapped in cellophane. In this state, they are not afraid of moisture, which means they can be put in the back room, in the attic, in the basement or in the shed. Eurobriquettes look like bricks or tubes, all of the same shape, which is very convenient for storage. In addition, they take up much less space, since for the winter they will need several times less than firewood.

If we remember what difficulties await us when harvesting firewood, there is ground for reflection when choosing the right fuel.Eurobriquettes do not need to be sawn, split, stored and dried throughout the year, they are ready for use.

Disadvantages of traditional solid fuel

Pini Kay fuel briquettes were developed in Germany, but today they are supplied by many manufacturers. They are nothing more than compressed wood waste. This fuel comes in the form of neat bars with an internal hole. In this form, it is sent to the furnaces of solid fuel boilers and wood-burning stoves.

Traditional firewood has a number of disadvantages. To begin with, we note their imperfect shape - this creates problems in fuel storage. Individual bars differ in size from other bars, some of them contain knots, which prevents them from being neatly stored. Thus, when using firewood in a boiler or stove, care must be taken to purchase neat logs - they usually cost more.

We also note the low calorific value of wood - this indicator depends both on the type of wood and on the level of humidity. And the higher the humidity level, the worse the firewood burns and the less the amount of heat generated. The approximate calorific value at a humidity of about 10-15% is 3800-4000 kcal. In the case of Pin-Key briquettes, this figure is much higher.

What is Eurowood and can it be an efficient fuel?

Most summer residents attended to the preparation of firewood back in June-September. But what if there is not enough fuel? Or was it not purchased on time for one reason or another? Or is it necessary to kindle a fireplace on rare trips to the country? The way out of the situation can be the so-called eurofirewood

Eurowood is compressed briquettes made from sawdust, husks, straw, grass or peat, which can be used in stoves, fireplaces and even solid fuel boilers. Natural raw materials are pressed under pressure without using toxic binders, so eurofirewood can be called an environmentally friendly product. But our consumer is not primarily interested in this. Much more important is the effectiveness of "alternative logs".

As practice shows, this fuel burns surprisingly hot. If ordinary firewood gives 2500-2700 kcal / kg of heat, then briquettes from compressed sawdust - 4500-4900 kcal / kg. That is almost twice as much.

Such high rates are explained by the fact that compressed briquettes undergo efficient drying during the production process, and the heat transfer during combustion directly depends on the moisture content in the fuel. For European firewood, this figure is about 8%, while, as for ordinary wooden logs, it is about 17%.

Eurowood is destroyed by moisture, so they need to be stored in a dry place.

Of course, above we have given average figures. The calorific value of eurofirewood depends on several factors. First of all, from raw materials. Best of all shows itself ... the husk of seeds and cereals. The vegetable oils contained in them provide the maximum calorific value - 5151 kcal / kg. True, when they burn, they create a rather thick smoke that settles on the walls of the chimney in the form of a black coating.

Compressed sawdust is almost as good as husk. They form up to 5043 kcal / kg, while there is significantly less ash and soot from them.

Straw also gives off heat well (4740 kcal / kg), but at the same time it smokes. Oddly enough, pressed grass burns quite cleanly and efficiently - 4400 kcal / kg. Rice closes the rating - it produces a lot of ash and little heat - 3458 kcal / kg.

In addition to raw materials, there is another important factor - density, more precisely, the amount of combustible substance per cubic centimeter of volume. For oak firewood, which is rightfully considered the best, this figure reaches 0.71 g / cm³. But high-quality fuel briquettes are even denser - up to 1.40 g/cm³. However, options are possible.

There are three main types of eurofirewood, depending on the density and shape.

Pini-kay

— fuel of maximum density (1.08–1.40 g/cm³). Made in the form of square/hexagonal briquettes. To ensure efficient air circulation in the furnace, manufacturers make a through hole in each such "log".

Nestro

- firewood of medium density (1–1.15 g / cm³) and cylindrical shape.

Ruf

- small bricks of the lowest density 0.75–0.8 g / cm³. The least efficient fuel of all listed.

Eurowood made from peat cannot be used to heat boilers, fireplaces and stoves. They are intended only for industrial needs, as they contain unsafe volatile substances.

So, given the wide range, it will not be difficult to choose the best eurofirewood in all respects. What limits their distribution? The answer is simple - the price. As of December 2020, this fuel costs from 5,500–9,500 rubles. per ton. This is two to three times more expensive than regular logs. Therefore, eurofirewood is usually used as an "ambulance" in case traditional fuel is not at hand.

The high price obliges to be vigilant when buying. An unscrupulous manufacturer may neglect the cleaning of raw materials or deliberately add leaves and other debris to it in order to reduce the cost of production. Also, mistakes or deliberate negligence during drying are not ruled out, due to which the briquettes will turn out to be too wet.

It is impossible to determine the quality of the product by eye, it is also impossible to check it on the spot. To protect yourself from an unsuccessful purchase, you should first of all check the documentation. It should contain detailed characteristics of the product and information about the tests carried out.

Also, given the high cost of Eurowood, it is advisable to take a couple of kilograms for testing before purchasing a large batch. Only by testing the fuel on site, you can be sure of its effectiveness.

Fuel briquettes Nestro

The production of Nestro fuel briquettes is carried out on hydraulic presses with the creation of back pressure with a collet. These products can be in diameter from 50 to 90 mm, and in length - from 50 to 100 mm. Packed in bags.

Since the Nestro fuel briquette is a compressed fuel, it needs little storage space. In addition, the high density prevents the penetration of moisture inside and subsequent decay, so they can be stored for a long time.

Very little torch or liquid is required to ignite Eurowood. A couple of briquettes are usually enough for a fireplace. After ignition, they burn with an even flame and spread a woody smell, and after combustion, beautiful coals remain, maintaining a high temperature for a long time.

Fuel briquettes Nestro

What are fuel briquettes

Briquettes differ in shape and material of manufacture.

Differences in form

There are three main forms of fuel briquettes: pini-cay, ruf and nestro. Their difference is only in the maximum density that can be achieved in each of the forms. In terms of chemical composition or mass calorific value, there are no differences between European firewood.

Fuel briquettes pini-kay

The highest density is from 1.08 to 1.40g/cm3. Section shape - square or hexagon. There is a through hole in the center, which provides better air movement and combustion of the briquette.

Fuel briquettes RUF

Fuel briquettes from sawdust ruf, in the form of a brick. They have a small size and the lowest density - 0.75-0.8 g / cm3.

Briquettes Nestro

Nestro fuel briquettes have a cylinder shape and an average density of 1-1.15 g/cm3.

Peat briquettes

Peat fuel briquettes have a special shape, unlike the others. And because of the high ash content and the presence of other harmful impurities in the composition, they are not recommended for use at home. Such briquettes are suitable for industrial furnaces or boilers that can run on low-quality fuel.

Fuel briquette from peat

Differences in material

Eurowood is made from sawdust, seed husks, rice and buckwheat, straw, tyrsa, peat and other materials. The material affects the calorie content of the fuel briquette, ash content, the amount of soot emitted, the quality and completeness of combustion.

Below in the table is a comparison of the characteristics of briquettes from different materials - seed husks, rice, straw, tyrsa and sawdust. Such an analysis shows not only that briquettes made of different materials differ from each other. But also the fact that even briquettes from the same material differ in quality and properties.

All data are taken from real test reports of fuel briquettes.

Calorie content, humidity, ash content and density of fuel briquettes from different materials.

Table comments

Seed. The highest calorific value of seed husk briquettes is 5151kcal/kg. This is due to their low ash content (2.9-3.6%) and the presence of oil in the briquette, which burns and is of energy value.On the other hand, due to oil, such briquettes more intensively pollute the chimney with soot, and it has to be cleaned more often.

Wood. Wood sawdust briquettes are in second place in terms of calorific value - 5043kcal/kg at 4% humidity and 4341kcal/kg at 10.3% humidity. The ash content of wood briquettes is the same as that of a whole tree - 0.5-2.5%.

Straw. Straw briquettes are not much inferior to seed husks or sawdust and have a good potential for use. They have a slightly lower calorie content - 4740 kcal / kg and 4097 kcal / kg, and a relatively high ash content - 4.8-7.3%.

Tyrsa. Tyrsa is a perennial herb. Such briquettes have a fairly low ash content - 0.7% and good heat transfer of 4400 kcal / kg.

Rice. Rice husk briquettes have the highest ash content - 20% and low calorific value - 3458 kcal / kg. This is even less than that of wood, at 20% humidity.

What are briquettes and pellets

Briquettes are a pressed mass based on waste from the agricultural, woodworking, and logging industries. They do not contain harmful binders, since the fractions are held together by lignin, a natural compound found in "dead" plant residues.

In fact, there are no differences between fuel briquettes and pellets, the whole difference lies in the production method and the possibility of use. In the case of the second type, it is more complicated and expensive, since the raw materials must first be crushed, then heated, compressed and granulated. Eurowood can be used in all solid fuel appliances, but for pellets you need to buy special equipment. There is also an unprincipled external difference, briquettes are bars, and pellets look like granules, they are made from the waste of such raw materials:

- peat;

- coal;

- sawdust and wood chips;

- chicken manure;

- husks;

- straw;

- municipal solid waste and others.

On a note! The calorific value depends on the material from which the fuel is made. Pine will have a value of 4500 kcal, and beech or oak will reach 6000 kcal. The raw material used also determines the ash content.

How and where to buy Pini-Key briquettes

What is not in the briquettes is artificial additives. They are not needed here, so the output is clean and safe fuel for any need - you can heat a house or heat a bathhouse.

We have already said that the basis for this fuel is environmentally friendly wood waste. Often, sunflower and rice husks, straw, a herbaceous perennial plant called tyrsa and many other components are used here.

The production of Pini-Key briquettes is carried out by compressing the feedstock under high pressure and high temperature. As a result, all plant and wood components are combined into small logs. The link here is not glue, but lignin, a natural component found in vegetation. It is released from plant cells during heating and pressure.

You can buy Pini-Key briquettes from specialized suppliers. The price of one package of wood products is from 80-90 rubles (the weight of the package is approximately 10-11 kg). Briquettes from sunflower husks and other plant components cost 15-20% cheaper. We recommend finding a regional supplier of briquetted fuel.

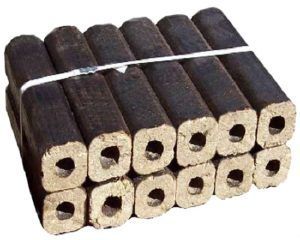

Fuel briquettes Pini Kay

Fuel briquettes of this manufacturer are popular due to their unique characteristics, and have many positive user reviews.

It is worth saying that Pini Kay fuel briquettes should be stored separately from other materials and substances.If the following conditions are met, products can lie for a very long time:

- it is required to store briquettes in a covered warehouse at a temperature from plus 5 to plus 40 °C;

- relative humidity should vary between 30-80%;

- briquettes should not come into contact with water and aggressive media;

- to prolong their shelf life, it is better to remove products from the sun.

Fuel briquettes Pini Kay

| Parameter | Meaning |

|---|---|

| Density | 1200 kg/m³ |

| Bulk density | 1000 kg/m³ |

| Ash content | 3 % |