- Firebox features

- Preliminary calculations

- How to grind wood at home

- How to make sawdust concrete with your own hands

- “Dung Economy”

- Biodiesel at home

- What are fuel briquettes

- Differences in form

- Differences in material

- Table comments

- Homemade briquettes - pros and cons

- Methodology for calculating the amount of fuel per season

- Raw materials for the production of fuel briquettes.

- How and where to buy Pini-Key briquettes

- Price

- Fuel briquettes not from sawdust

- Firebox features

- Block building technology

- sawdust as a substrate

- Advantages of fuel briquettes

- Features and types of peat

- The nuances of biogas production

- How are peat briquettes superior to firewood?

- What is Eurowood and can it be an efficient fuel?

Firebox features

As we have already said, ease of use and availability are the main indicators that distinguish briquettes for heating.

Reviews about them focus on the high quality of combustion. The heating process is also simple, especially if wood briquettes are used - they are simply placed in the oven

When creating peat products, they first get rid of moisture, after which they are crushed.

During briquetting, the material is subjected to compression, as a result of which the substances contained in the wood are released, binding the material into a single piece.Under high temperature, moisture is evaporated from the wood, however, if this is carried out too intensively, so-called steam pockets may form. That is, the material will expand, which means that the briquette will collapse.

Preliminary calculations

Before starting the construction of a biogas plant, it is necessary to perform accurate calculations in order to assess its future performance.

Calculate all possible consumers of gas (stove, water heater, etc.), and how much fuel they will need. If biogas is needed to heat a barn or garage, you need to take into account their volume.

What you need to get biogas at home:

- A metal sealed container is buried in the ground. Its volume depends on how much raw material will be used, taking into account the fact that the capacity is loaded by 2/3.

If there is no suitable container, you can pour it on the spot from concrete, always with reinforcement for structural strength. The concrete reactor should be carefully waterproofed. If water seeps in, it will stop the gas production process.

- On top of the reactor, a bunker device is constructed for loading raw materials.

- The processed manure is removed through a pipe at the bottom of the tank.

- The biogas obtained by decomposition of organic matter has a complex composition, 60-70% of which is methane, 25-35% carbon dioxide and impurities. You can clean the gas with a water seal. CO2 and impurities are dissolved in water, and purified methane is collected in a gas tank.

- The resulting biomethane is similar to natural gas.

- Production waste is an excellent organic fertilizer.

The amount of biogas produced differs when using different raw materials. For example, a ton of cow manure yields 30-50 m3 of biogas (60% methane) at the output.Vegetable raw materials of different types will give 150-500 m3 of biogas (70% methane). The largest amount of biogas is obtained from fat - 1300 m3 (up to 87% methane).

- LiveJournal

- Blogger

Biofuel boilers take up more space than any other

How to grind wood at home

Wood chips can be made by hand or with the help of various mechanisms. For manual chopping, you will need a knife or an ax with which the wood is cut / chopped into chips of the desired size.

The disadvantage of this method is the extremely low productivity, as well as a rather high injury risk.

The only plus is the ability to give each chip the right size and shape. In addition, this method allows you to create chopped wood with a stable percentage of bark.

In the same way, you can make oak chips with your own hands - for example, for infusing drinks. Since it is required in a small amount, the manual method is quite suitable.

The second way is grinding with the help of any:

- wood chips;

- branch cutters;

- chipping machines;

- shredders;

- grinders.

More information about these devices, as well as the differences between them, can be found here:

- Additional equipment for chips.

- Machines for wood chips with their own hands.

- Chip cutter.

- Garden shredder.

How to make sawdust concrete with your own hands

Initially, the so-called dough is kneaded from:

-

sawdust;

- cement;

- clay;

- lime;

- sand;

- water.

It is best to carry out the mixing process in a concrete mixer. Gradually add all the ingredients. The consistency of the mass should be homogeneous. This will have a favorable effect on the structure of houses, since the surface of the material will be even.

After that, a solution is poured into pre-made wooden forms of any size, upholstered with linoleum or a special polyethylene tape. It dries pretty quickly. Only in order for the material to get stronger, it will take more than 3 months. Ready blocks of sawdust concrete are laid out under a canopy on the street. Moisture will come out of it gradually, which avoids the appearance of internal deformations.

“Dung Economy”

The concept, derogatoryly called the “dung economy” in India today, is in fact a direct path to the progress and prosperity of society.

It is no coincidence that even ancient scientists considered manure a treasure, the basis of the wealth and prosperity of the country and its economy.

Judge for yourself. It is enough to accept the fact that manure is the most important product, the basis of our well-being, a product to which there is no alternative, and begin to act correctly in accordance with this, as the following prospects immediately open before us:

How much we humans owe to these peaceful ruminants! Yes, with age, animals may stop producing milk, they will no longer be able to work in the fields and bear offspring ... But they will never stop supplying us with this most valuable resource - manure!

When the breeding of cows and bulls was forcibly made the prerogative of a few large livestock enterprises, this led to sad consequences.

This unique product - manure - became inaccessible to many farmers, and the main part of the population was captured by poverty, hunger, soil impoverishment, and degradation in all spheres of life.

I appeal to the most active compatriots in India: demand from the government that the destructive agricultural policy be corrected, that common sense return to agriculture, and manure to the fields!

At present, the traditions of using manure have been destroyed due to its inaccessibility, and the sad consequences were not long in coming:

Biodiesel at home

Biodiesel is a fuel obtained from any vegetable oil (sunflower, rapeseed, palm).

Brief description of the biodiesel production process:

- Vegetable oil is mixed with methanol and a catalyst.

- The mixture is heated for several hours (up to 50-60 degrees).

- During the esterification process, the mixture separates into glycerol, which settles down and biodiesel.

- Glycerin is drained.

- Diesel is cleaned (evaporated, settled and filtered).

The finished product is of suitable quality and is clear and pH neutral.

The yield of biodiesel from vegetable oil is approximately 95%.

The disadvantage of home-made biological diesel is the high cost of vegetable oil. It makes sense to produce biodiesel with your own hands only if you have your own fields for growing rapeseed or sunflower. Or having a constant source of cheap processed vegetable oil.

What are fuel briquettes

Briquettes differ in shape and material of manufacture.

Differences in form

There are three main forms of fuel briquettes: pini-cay, ruf and nestro. Their difference is only in the maximum density that can be achieved in each of the forms. In terms of chemical composition or mass calorific value, there are no differences between European firewood.

Fuel briquettes pini-kay

The highest density is from 1.08 to 1.40g/cm3.Section shape - square or hexagon. There is a through hole in the center, which provides better air movement and combustion of the briquette.

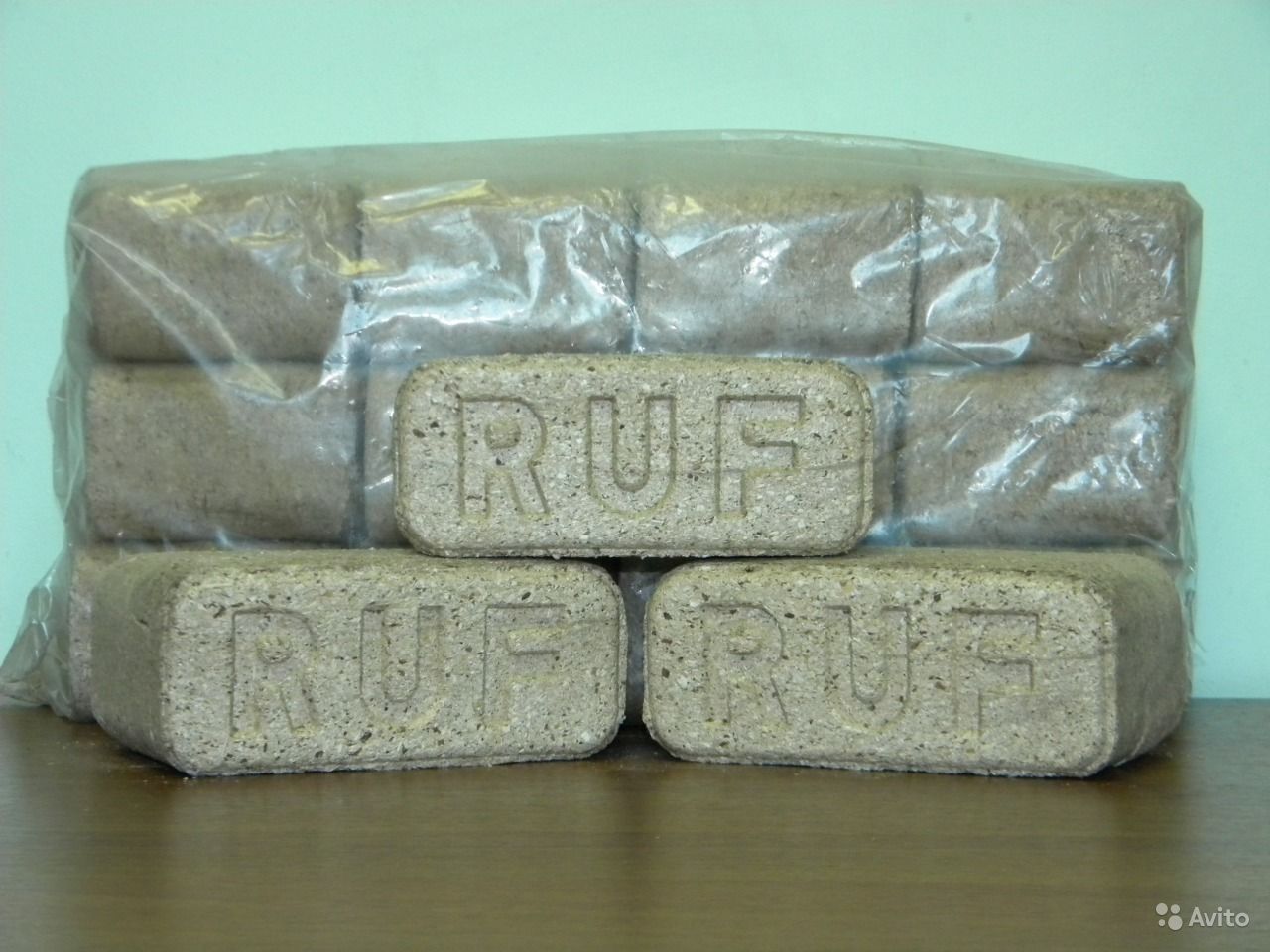

Fuel briquettes RUF

Fuel briquettes from sawdust ruf, in the form of a brick. They have a small size and the lowest density - 0.75-0.8 g / cm3.

Briquettes Nestro

Nestro fuel briquettes have a cylinder shape and an average density of 1-1.15 g/cm3.

Peat briquettes

Peat fuel briquettes have a special shape, unlike the others. And because of the high ash content and the presence of other harmful impurities in the composition, they are not recommended for use at home. Such briquettes are suitable for industrial furnaces or boilers that can run on low-quality fuel.

Fuel briquette from peat

Differences in material

Eurowood is made from sawdust, seed husks, rice and buckwheat, straw, tyrsa, peat and other materials. The material affects the calorie content of the fuel briquette, ash content, the amount of soot emitted, the quality and completeness of combustion.

Below in the table is a comparison of the characteristics of briquettes from different materials - seed husks, rice, straw, tyrsa and sawdust. Such an analysis shows not only that briquettes made of different materials differ from each other. But also the fact that even briquettes from the same material differ in quality and properties.

All data are taken from real test reports of fuel briquettes.

Calorie content, humidity, ash content and density of fuel briquettes from different materials.

Table comments

Seed. The highest calorific value of seed husk briquettes is 5151kcal/kg.This is due to their low ash content (2.9-3.6%) and the presence of oil in the briquette, which burns and is of energy value. On the other hand, due to oil, such briquettes more intensively pollute the chimney with soot, and it has to be cleaned more often.

Wood. Wood sawdust briquettes are in second place in terms of calorific value - 5043kcal/kg at 4% humidity and 4341kcal/kg at 10.3% humidity. The ash content of wood briquettes is the same as that of a whole tree - 0.5-2.5%.

Straw. Straw briquettes are not much inferior to seed husks or sawdust and have a good potential for use. They have a slightly lower calorie content - 4740 kcal / kg and 4097 kcal / kg, and a relatively high ash content - 4.8-7.3%.

Tyrsa. Tyrsa is a perennial herb. Such briquettes have a fairly low ash content - 0.7% and good heat transfer of 4400 kcal / kg.

Rice. Rice husk briquettes have the highest ash content - 20% and low calorific value - 3458 kcal / kg. This is even less than that of wood, at 20% humidity.

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are understandable. When a person has his own wood production or the ability to buy sawdust for a briquette cheaply, then thoughts about making them at home are quite natural. The fact is that not all heating equipment is suitable for burning sawdust. As a rule, wood chips in an ordinary stove or boiler burn out quickly and give off little heat, and even half will spill into the ash pan.

It turns out that everything is not so simple here either, and here's why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to buy ready-made eurofirewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of poor quality and will give little heat, and take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light. The second point requires clarification. Due to the inability to comply with the technology, the “bricks” after drying are light due to their low density. Their specific heat of combustion is three times lower than that of wood, which means that they will need three times more for heating. The whole process will take a lot of time and take a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Informative video for enthusiasts who want to put pressure on manual briquetting of various household waste:

Methodology for calculating the amount of fuel per season

We will figure out how to calculate the consumption of any type of fuel for a room. First, we calculate how much heat is needed to heat the entire house per hour. Multiplying by 24, we get the daily value, then multiplying by 30 and 111 days, what is the consumption per month and for the entire heating period.

After that, we calculate the heat transfer of the accepted unit of measurement for each type of solid fuel. Dividing the amount of heat required for a month and a season by heat transfer, we will see how much is needed per month and for the whole year of this type of combustible materials. This will show us how much fuel we need to stock up for the winter and allow us to compare the efficiency of different devices.

Raw materials for the production of fuel briquettes.

Fuel briquettes can be made from the following materials:

- Sawdust, branches, bark and other woodworking waste.

- Straw.

- Reeds.

- Husk of grain crops.

- Waste from flax processing.

- Plant waste.

- Peat.

- Screenings in the production of charcoal.

Woodworking waste (sawdust, shavings) in itself does not represent any value, and in order not to dispose of them on their own, they are often given away at sawmills for free, subject to self-delivery or at a minimum price. With the availability of any type of raw material, it is possible to organize a promising business for the production of fuel briquettes.

How and where to buy Pini-Key briquettes

What is not in the briquettes is artificial additives. They are not needed here, so the output is clean and safe fuel for any need - you can heat a house or heat a bathhouse.

We have already said that the basis for this fuel is environmentally friendly wood waste. Often, sunflower and rice husks, straw, a herbaceous perennial plant called tyrsa and many other components are used here.

Production briquettes Pini Kay It is carried out by compressing raw materials under high pressure and high temperature. As a result, all plant and wood components are combined into small logs. The link here is not glue, but lignin, a natural component found in vegetation. It is released from plant cells during heating and pressure.

You can buy Pini-Key briquettes from specialized suppliers. The price of one package of wood products is from 80-90 rubles (the weight of the package is approximately 10-11 kg). Husk briquettes sunflower and other plant components are 15-20% cheaper. We recommend finding a regional supplier of briquetted fuel.

Price

The cost of this product depends on:

- types of wood;

- volume;

- purity;

- the ratio of supply and demand.

An equally important factor is the volume, so the price per 1 kg when sold in bags will always be higher than when sold by trucks.

Another factor that affects the cost of the product is purity, that is, the absence of parts of the bark and leaves.

The ratio of supply and demand is very important, therefore, in cities and regions with a developed forestry and woodworking industry, the cost of shavings is always lower than where the supply of this product is minimal. We have prepared a table in which we included the average cost of shavings in different cities of Russia: We have prepared a table that includes the average cost of shavings in different cities of Russia:

We have prepared a table that includes the average cost of shavings in different cities of Russia:

| City | Volume | Price in rubles | Minimum lot |

| Tyumen | Bag (50 l) | 40 | Bag |

| Krasnodar | Bag (50 l) | 100 | Bag |

| Moscow | 1 m3 | 1100 | 1 m3 |

| Moscow | Bag (240 l) | 379 | Bag |

| Tver | 1 m3 | 400 | Car |

| St. Petersburg | Bag (14 kg) | 105 | Bag |

| Yekaterinburg | 1 m3 | 350 | Car |

Fuel briquettes not from sawdust

In addition to sawdust, the raw material for the manufacture of fuel cells can be seed husks, coal dust, paper, etc. If there is a large amount of paper available, then the production of eurofirewood can be established from it. The technological process will be as follows:

- paper is cut into small pieces;

- raw materials are soaked in warm water to the state of liquid porridge, you can add a little starch to the solution;

- excess moisture is removed from the resulting mass;

- paper dough is stuffed into molds;

- after evaporation of almost all the remaining moisture, the briquettes are removed and sent to dry.

Pressed paper blocks emit more heat when burned and leave less ash behind. Pressed seed husk has the following features:

Pressed seed husk has the following features:

- heat release is slightly higher than sawdust logs;

- have a low ash content;

- the ashes smell bad.

When creating fuel cylinders from coal dust, two methods are used, with and without the addition of binders. It makes no sense to consider the first production method when creating fuel for a home stove, since the finished product will emit toxic substances, which is unacceptable when heating a home. The second method is similar in technology to the production of sawdust. The sequence of actions is as follows:

- coal particles are crushed so that the largest of them is not more than 6 mm;

- in dryers of steam or gas type, the moisture level of the raw material is reduced to 15%;

- the resulting mass is cooled and transported to the press;

- in a special stamp-type press, the fraction is subjected to pressure up to 150 MPa.

Firebox features

As we have already said, ease of use and availability are the main indicators that distinguish briquettes for heating.

Reviews about them focus on the high quality of combustion. The heating process is also simple, especially if wood briquettes are used - they are simply placed in the oven

When creating peat products, they first get rid of moisture, after which they are crushed.

During briquetting, the material is subjected to compression, as a result of which the substances contained in the wood are released, binding the material into a single piece. Under high temperature, moisture is evaporated from the wood, however, if this is carried out too intensively, so-called steam pockets may form.That is, the material will expand, which means that the briquette will collapse.

Block building technology

To build a house from sawdust concrete with your own hands, you need to take into account a lot of nuances. The first of these is that the thickness of the walls depends on the average winter temperature outside. If it is necessary to make the walls more durable, then the thickness of the seams can be reinforced with a special mesh. The durability of the walls of houses can be increased by finishing with clinker or plaster.

Before you start building a house, you should take care of the installation of communications and openings for them. In advance, you need to make holes for chimneys and ventilation. It is impossible to mount walls made of damp material, the products must be dry. The technology of mounting walls with sawdust concrete is absolute, identical to installation technologies from similar materials.

sawdust as a substrate

Sawdust will make the soil looser, which means that more oxygen will flow to the roots of the plant. For the substrate, you need to take stale sawdust or add urea to fresh (40 g of fertilizer per 1 bucket). This will prevent the sawdust from taking nitrogen from the plants. To prepare the substrate for seedlings, mix the following ingredients:

Mix 1: sawdust, lowland peat, river sand (1:2:1 ratio).

Mix 2: sawdust, garden soil, lowland peat (1:1:2).

To the finished mixture (based on 10 liters of substrate), add 40 g of double superphosphate, 1/2 cup of ash, 15 g of ammonium nitrate and 40 g of potassium sulfate.

Advantages of fuel briquettes

Fuel briquettes are distinguished by the ability of high heat transfer. Their calorific value is 4600-4900 kcal/kg. For comparison, dry birch firewood has a calorific value of about 2200 kcal/kg.And birch wood of all types of wood has the highest heat transfer rates. Therefore, as we see, fuel briquettes give 2 times more heat than firewood. In addition, throughout the combustion, they maintain a constant temperature.

Long burning time

Briquettes are also characterized by a rather high density, which is 1000-1200 kg/m3. Oak is considered the most dense wood applicable for heating. Its density is 690 kg/cu.m. Again, we see a big difference in favor of fuel briquettes. Good density just contributes to the long-term burning of fuel briquettes. They are able to give a steady flame from laying to complete combustion within 2.5-3 hours. With the supported smoldering mode, one portion of high-quality briquettes is enough for 5-7 hours. This means that you will need to add them to the stove 2-3 times less than if you fired wood.

Low humidity

Humidity of fuel briquettes is no more than 4-8%, while the minimum moisture content of wood is 20%. The briquettes have such a low moisture content due to the drying process, which is an essential step in the production.

Due to their low humidity, briquettes reach a high temperature during combustion, which contributes to their high heat transfer.

Minimum ash content

Compared to wood and coal, the ash content of briquettes is much less. After burning, they leave only 1% ash. Burning coal leaves up to 40% ash. Moreover, the ashes of the briquettes can still be used as fertilizer, and the ashes of coal will still have to be disposed of.

The advantage of heating with briquettes is that the cost of cleaning and maintaining the fireplace or stove is much reduced.

Environmental friendliness

The choice of fuel briquettes for heating in the house is a great option for people who care about their health. Briquettes practically do not emit smoke and other harmful volatile substances, so you can fire the stove without charcoal even with a low chimney draft.

Unlike coal, the combustion of briquettes does not form dust that settles in the room. Also, since briquettes are fuel produced from waste, there is less damage to the environment.

Ease of storage

Fuel briquettes are convenient both to use and store. Unlike shapeless firewood, briquettes have a fairly regular and compact shape. Therefore, even if you try to put firewood as carefully as possible into a compact woodpile, they will still take up 2-3 times more space than briquettes.

No condensation on chimneys

Since firewood has a higher moisture content, during combustion, it forms condensate on the walls of the chimney. Depending on the moisture content of the wood, there will be more or less condensation, respectively. What is bad about condensate in a chimney is that it narrows its working section over time. With heavy condensate, after one season you will notice a strong drop in draft in the chimney.

8% humidity of the briquettes practically does not form condensate, consequently, the chimney's working capacity is maintained longer.

Features and types of peat

Peat is an organic rock, which is the result of the biochemical process of decay of marsh plants with excessive moisture and oxygen deficiency. Peat includes vegetable fibers, humic acids and various trace elements.

If you look at peat as a fuel, given its main characteristics, then it can be safely called young coal.In terms of basic parameters, they are similar, but at the same time, peat extraction does not imply the creation of a complex developed infrastructure, because of this, its cost is much lower compared to coal.

The main feature of peat is the ash content. It refers to the amount of combustible products that remain after burning a kilogram of fuel. This parameter is measured in percentage.

The ash content of peat also depends on the origin. Based on this, three types of this breed can be named.

| Type of peat | Peculiarities |

| Lowland | Consists of a large amount of rotted wood residues. It has a very high ash content (for some species it can reach 50%) and a low thermal capacity. Because of these characteristics, it is often used in the preparation of natural fertilizers for clay soils. |

| Horse | At the base are the remains of marsh vegetation and sphang mosses. It has a low ash content of 1-5%. This peat is most often used for domestic purposes, it is he who is most often used as the main raw material in the production of fuel. |

| Transition | This is something between lowland and highland peat. |

Of course, peat as a fuel is not used in its pure form. After extraction, the natural material is subjected to a special treatment that allows rational and efficient use of all its properties.

Therefore, the following types of peat can be distinguished depending on the characteristics of its processing.

| Type of peat | Peculiarities |

| Chopped / milled peat | This is a placer that is intended for combustion in a suspended state. |

| Semi-briquette / lump peat | Characterized by a low degree of pressing, this fuel product is manufactured directly on the site of the developed deposit. |

| Peat briquette | This is a high-calorie product with a significant degree of pressing. Due to the characteristics obtained as a result of processing, it is able to replace coal. A ton of peat briquettes is equal to 1.6 tons of brown coal and 4 m³ of firewood in terms of the volume of heat generated. Peat briquettes are stable in their thermal characteristics, this makes it possible to make accurate calculations of the need for a certain object in fuel. |

About the manufacturers of fuel briquettes Ruf, Pini Kay, Nestro and Nilson can be found in detail on this page.

The nuances of biogas production

For safety during the operation of a home-made biogas plant, a pressure gauge is installed on the reactor to monitor the pressure level. A relief valve is required to release excess gas.

To speed up the processing of raw materials by bacteria, it must be periodically mixed. To do this, a shaft with blades is installed inside the reactor. Just do not forget about the tightness of the installation.

A prerequisite for the fermentation of the mass and the release of gas is a temperature of at least 38 degrees. In the warm season, the fermentation process itself will provide the desired temperature. But in winter, it will be necessary to provide heating of the reactor with the help of electric heating elements or a pipeline with hot water.

The production of biomethane at home is profitable only if the required volume of manure or other organic raw materials is constantly available.

How are peat briquettes superior to firewood?

- High density in a small volume. Due to the high density, 1 peat briquette replaces almost a whole small log.At the same time, the briquette burns out for a long time, which allows you not to throw new ones into the oven for 5-6 hours.

- Convenient form. A ton of briquettes takes 1.5-2 times less than the volume of firewood.

- Quality. Firewood can often bring low-quality firewood with a huge water content (40-50%), while this is not always noticeable. As a result, the useful return from such firewood remains much less than planned. Poor-quality briquettes are immediately visible - if the briquettes are damp, they literally crumble in your hands. Thus, a ton of briquettes will be much more efficient than a ton of firewood.

- No need to dry. Firewood, as a rule, needs to be dried for 6 months. Briquettes (including peat briquettes) are produced under high pressure from highly dried material and immediately have an amount of water of 8-9% (standard humidity up to 18%). They can be thrown into the furnace immediately after purchase.

- Less than a quarter to a third of ash and soot compared to burning wood.

What is Eurowood and can it be an efficient fuel?

Most summer residents attended to the preparation of firewood back in June-September. But what if there is not enough fuel? Or was it not purchased on time for one reason or another? Or is it necessary to kindle a fireplace on rare trips to the country? The way out of the situation can be the so-called eurofirewood

Eurowood is compressed briquettes made from sawdust, husks, straw, grass or peat, which can be used in stoves, fireplaces and even solid fuel boilers. Natural raw materials are pressed under pressure without using toxic binders, so eurofirewood can be called an environmentally friendly product. But our consumer is not primarily interested in this. Much more important is the effectiveness of "alternative logs".

As practice shows, this fuel burns surprisingly hot. If ordinary firewood gives 2500-2700 kcal/kg heat, then briquettes from compressed sawdust - 4500-4900 kcal / kg. That is almost twice as much.

Such high rates are explained by the fact that compressed briquettes undergo efficient drying during the production process, and the heat transfer during combustion directly depends on the moisture content in the fuel. For European firewood, this figure is about 8%, while, as for ordinary wooden logs, it is about 17%.

Eurowood is destroyed by moisture, so they need to be stored in a dry place.

Of course, above we have given average figures. The calorific value of eurofirewood depends on several factors. First of all, from raw materials. Best of all shows itself ... the husk of seeds and cereals. The vegetable oils contained in them provide the maximum calorific value - 5151 kcal / kg. True, when they burn, they create a rather thick smoke that settles on the walls of the chimney in the form of a black coating.

Compressed sawdust is almost as good as husk. They form up to 5043 kcal / kg, while there is significantly less ash and soot from them.

Straw also gives off heat well (4740 kcal / kg), but at the same time it smokes. Oddly enough, pressed grass burns quite cleanly and efficiently - 4400 kcal / kg. Rice closes the rating - it produces a lot of ash and little heat - 3458 kcal / kg.

In addition to raw materials, there is another important factor - density, more precisely, the amount of combustible substance per cubic centimeter of volume. For oak firewood, which is rightfully considered the best, this figure reaches 0.71 g / cm³. But high-quality fuel briquettes are even denser - up to 1.40 g/cm³. However, options are possible.

There are three main types of eurofirewood, depending on the density and shape.

Pini-kay

— fuel of maximum density (1.08–1.40 g/cm³). Made in the form of square/hexagonal briquettes. To ensure efficient air circulation in the furnace, manufacturers make a through hole in each such "log".

Nestro

- firewood of medium density (1–1.15 g / cm³) and cylindrical shape.

Ruf

- small bricks of the lowest density 0.75–0.8 g / cm³. The least efficient fuel of all listed.

Eurowood made from peat cannot be used to heat boilers, fireplaces and stoves. They are intended only for industrial needs, as they contain unsafe volatile substances.

So, given the wide range, it will not be difficult to choose the best eurofirewood in all respects. What limits their distribution? The answer is simple - the price. As of December 2020, this fuel costs from 5,500–9,500 rubles. per ton. This is two to three times more expensive than regular logs. Therefore, eurofirewood is usually used as an "ambulance" in case traditional fuel is not at hand.

The high price obliges to be vigilant when buying. An unscrupulous manufacturer may neglect the cleaning of raw materials or deliberately add leaves and other debris to it in order to reduce the cost of production. Also, mistakes or deliberate negligence during drying are not ruled out, due to which the briquettes will turn out to be too wet.

It is impossible to determine the quality of the product by eye, it is also impossible to check it on the spot. To protect yourself from an unsuccessful purchase, you should first of all check the documentation. It should contain detailed characteristics of the product and information about the tests carried out.

Also, given the high cost of Eurowood, it is advisable to take a couple of kilograms for testing before purchasing a large batch.Only by testing the fuel on site, you can be sure of its effectiveness.