- Classification of solenoid valves depending on the features of the device

- Solenoid gas valves

- Functions of devices integrated in multivalves

- Filtration properties of the multivalve

- How to choose a reliable valve

- Features of the choice of fittings and equipment

- Principle of operation

- Why are thermal shut-off valves needed?

- Purpose of the thermal shut-off valve

- Where is a thermostatic valve used?

- Why are thermal shut-off valves needed?

- Purpose of the thermal shut-off valve

- Where is a thermostatic valve used?

- Conclusion

- Classification

- Conclusions and useful video on the topic

Classification of solenoid valves depending on the features of the device

Solenoid valves are distinguished by a significant variety of design features, and therefore there is an extensive field for classification.

They differ in the operating environment used on the systems where the devices are installed:

- water;

- air;

- gas;

- couple;

- fuel, such as gasoline.

In difficult conditions, where there is a possibility of an emergency, explosion-proof valve models are used

In difficult conditions, where there is a possibility of an emergency, explosion-proof valve models are used

The composition of the working environment and the features of the room determine the features of the performance:

- ordinary;

- explosion-proof.It is customary to install devices of this kind at objects that are classified as explosive and fire hazardous.

According to the control features, there is a division of solenoid valves into devices:

- direct action. This is the simplest design, which is characterized by reliability and speed. It does not have a pilot channel. With an instantaneous rise of the membrane, the device opens. In the absence of a magnetic field, a spring-loaded plunger is lowered, pressing the membrane. The direct acting valve does not require a minimum pressure drop, it creates the necessary action on the spool stem due to the pulling force of the coil located at the top of the device;

- having membrane (piston) strengthening. Unlike direct action devices, they use the transported medium itself to function as an additional energy supplier. These valves have two spools. The purpose of the main spool is to directly cover the hole for which the seat of the body is allocated. The control spool closes the relief hole(s), through which the pressure is released from the cavity above the membrane (piston). This causes the main spool to rise and open the main passage.

According to the location of the locking mechanism at the moment when the coil is in a de-energized state, it is customary to separate the so-called pilot devices as belonging to a certain type:

- normally closed (NC). For NC valves, when the solenoid is de-energized, the passage for the working medium is closed. That is, the static position implies the absence of voltage on the solenoid, the closed state of the device.Due to the difference in diameter between the pilot and bypass channels, the pressure above the membrane decreases in favor of the first one. The pressure difference ensures that the membrane (piston) rises and the valve opens, remaining in this position as long as voltage is applied to the coil;

- normally open (NO). On the contrary, in normally open valves, when the coil is in a de-energized state, the working medium can move along the passage in a given direction. By keeping the NO valve closed, a constant voltage supply to the coil must be ensured.

Normally closed valve shuts off the flow of the working medium in a de-energized state

Normally closed valve shuts off the flow of the working medium in a de-energized state

There are also models of the device in which, when a control pulse is applied to the coil, switching from the open position to the closed position and in the opposite direction is provided. Such an electrovalve is called bistable. Such a solenoid device requires a differential pressure and a constant current source to function. Depending on the number of pipe connections, it is customary to name solenoid valves:

- two-way. Such devices have one inlet and outlet pipe connection. Two-way devices are both NC and NO;

- three-way. Equipped with three connections and two flow sections. They can be produced as NC, NO or universal. Three-way valves are used to alternately supply pressure / vacuum to control valves, single-acting cylinders, automatic actuators;

- four-way.Four or five pipe connections (one for pressure, one or two for vacuum, two for the cylinder) ensure the operation of double-acting cylinders, automatic drives.

Solenoid gas valves

Devices of this type belong to pipeline fittings and are used to distribute the gas flow and cut it off if necessary. They are widely used both in individual gas equipment and in industrial ones. The device is controlled automatically under the action of voltage.

Solenoid gas valves are placed at the inlet of the gas pipeline in front of such consumers:

- boilers;

- geysers;

- gas ovens;

- automotive gas equipment;

- pipe entry into a multi-storey building.

Most gas valves have a closed design, that is, in the absence of voltage, the valve closes the pipe.

Functions of devices integrated in multivalves

At the moment of refueling with 80% liquefied gas, the filling valve shuts off the fuel supply. Full filling of the actual volume of the cylinder is unacceptable according to safety requirements - under the influence of some external factors, for example, a sharp change in ambient temperature, the gas can expand dramatically, which can be fraught with dangerous consequences when fully loaded (the container may even explode), that is, when the pressure reaches the indicator at 25 atmospheres (standard storage device)

Adjusting the level of supply to the gas line

The gas pipeline has a special anti-cotton high-speed valve that regulates the rate of fuel supply to the gas pipeline.In addition, it performs another safety function - it prevents potential leakage if deformation or breakage of the auto line occurs.

Emergency fire protection for a car that runs on gas consists in a separate element of the multivalve: the fuse will release fuel through the ventilation unit outside the car if a sharp and strong increase in temperature (hence, excessive pressure in the system) signals a fire that has begun in the immediate vicinity of the LPG .

Measuring valve

To indicate the amount of remaining gas in the system, another separate filling valve is used, the operation of which is associated with a corresponding magnetic sensor. In injector systems of 3 or more generations, at the moment of automatic transition to gasoline in case of a shortage of alternative fuel, it is the gas measuring valve that closes the line.

check valve

The second refueling fuse works only on the gas inlet and prevents it from returning back during refueling.

Standby shut-off valves

Safety comes first: no matter how modern and computerized equipment is, failures, malfunctions, and emergencies are always possible. In a position that requires decisive action from the driver of the car, two manual valves can come in handy, which, if necessary, are always able to forcibly shut off the gas flow in the line.

Filtration properties of the multivalve

The standard HBO design implies the placement of a multivalve in a ventilation unit, which is located directly on the cylinder with a separate removable container.Special hoses go outside to separate impurities and, in case of any danger, release gas away from the car interior.

The air filter, which is equipped with a ventilation box, is recommended to be replaced every 15-20 thousand kilometers in order to avoid severe clogging.

Let's talk about what is solenoid gas valve

(EGK), gas valve or HBO solenoid valve. You will learn about what kind of valve is needed for what, as well as about malfunctions of the electromagnetic gas valve.

Solenoid gas valve

(not to be confused with) - this is a valve designed to shut off the gas line while the car is parked or while the engine is running on the main type of fuel (gasoline or diesel). The EGK is equipped with a fuel purification filter from solid impurities, and its control can be performed both in manual and automatic mode by means of a gas-gasoline switch.

How to choose a reliable valve

In the design of the heating system, it is necessary to clearly define the maximum permissible pressure values. It also takes into account the productive capacity of the boiler or pump, volume, features of the circulation of the temperature of the working medium. Based on this, the type and design features are selected. Of the previously listed types, users are recommended to use spring loaded safety valves. They are perfect for small boilers. Also use devices with low or medium rise for water heating systems.

If the working medium is discharged into the environment, then an open type device should be selected. If the discharge occurs to the drain, then the body design with a threaded outlet pipe is used.

Traditional blast valve is affordable, easy to install. This device well protects a closed heating system with a gas or electric boiler, since in the event of an accident, heating stops immediately. It is also not recommended to purchase cheap Chinese fittings. It is unreliable and leaks immediately after the first explosion.

This is interesting: The device and principle of operation of a thermostatic valve (video)

Features of the choice of fittings and equipment

When choosing fittings for gas pipelines, one should carefully consider the chemical and physical properties of the material from which it is made.

The most popular materials for the manufacture of gas fittings are cast iron and steel. This is due to the requirements for an increased level of strength and reliability. Polymer elements that are perfect for water conduits are not applicable here, in addition, they can be easily damaged.

Steel is the most popular material for the manufacture of gas fittings. Such equipment has an affordable cost and high durability.

Experts do not recommend using equipment with bronze sealing inserts on gas pipelines. This is due to the fact that LPG contains hydrogen sulfide, which can have a negative effect on bronze and copper alloys.

Principle of operation

A shut-off locking device is often called an anti-flood, meaning its main purpose is to prevent fluid from flowing out of the pipeline.

The valve is designed in such a way that upon a manual command of the personnel, a signal given by a sensor or another element, the movement of the medium in a direction not provided for by the design, the locking device quickly operates and the device cuts off the passage of the working medium. A characteristic feature of the apparatus is its rapid response, usually provided by actuation of a spring or other mechanism to close the valve.

For example, in a disposable valve, fluid entering the device impacts the silicone gasket. Under the influence of moisture, it grows in volume, lifts the shutter of the locking mechanism. It blocks the channel and stops the movement of the medium.

Why are thermal shut-off valves needed?

Thermal shut-off valves are devices that are shut-off gas fittings. They automatically shut off the gas pipeline leading to all gas-powered appliances.

All "stubs" are marked as KTZ with a certain set of numbers after the letters. The second number indicates the diameter of the gas pipe for which this mechanism may be suitable.

Purpose of the thermal shut-off valve

The main purpose of the KTZ is to shut off the gas supply to the equipment in case of fire. That helps not only to protect against an explosion, but also prevents the fire area from doubling or more.

If the shut-off valve is in the open position, then the device itself does not in any way prevent the passage of a combustible substance to the instruments and equipment.

Thermal locking mechanisms are mounted on pipelines, where the maximum pressure can be 0.6 MPa - 1.6 MPa.

Next, we denote the purpose of the valves, prescribed by the rules of fire authorities.

In the fire safety regulations, there is a regulation that implies the use of valves:

- On the equipment of all pipelines of natural gas. Any types of systems (complexity, branching), any number of consumer devices are assumed.

- To ensure the protection of various gasified objects and devices operating on gas. In this case, valves are applicable that are designed for automation (operation) when the temperature in the room reaches up to 100 ° C.

- Installation of thermal locking modules at the entrance to the room.

In accordance with PPB-01-03 (Fire Safety Rules), thermal locking devices must be installed in all rooms where there is a gas pipeline. However, this does not include buildings of the V category of fire resistance.

It is also not necessary to install a short circuit in buildings where pipelines are equipped with solenoid valves. They are usually placed outside the building, and if an ignition occurs inside the building, the gas analyzer is triggered, after which the gas supply is stopped.

It should be understood that KTZ is not just another Russian “trend”. The use of these devices at various facilities where gas equipment exists is mandatory in such countries as Germany, France, the USA, etc.

Where is a thermostatic valve used?

The field of application of thermal shut-off gas plugs is, first of all, pipelines supplying gas to devices of various purposes in which gas is burned (household and industrial devices, regardless of type).

The installation of a short circuit protection plant on any gas pipeline is not allowed outside the premises, after the installation of any other gas fittings, also on bypasses, in adjacent rooms and where the operating air temperature during the operation of gas equipment can reach more than 60 ° C.

It is important not to violate the installation rules - a shut-off valve is installed first on the gas pipeline, and only after it the rest of the gas fittings, instruments and equipment

You can place the valve in different positions, just pay attention to the arrow-pointer applied by the manufacturer on the body

In relation to the horizon, the location of the installed valve can be any. We will describe in more detail the rules for installing KTZ in more detail later.

Thermal shut-off valves have a special design that allows the device to automatically shut off the gas supply at the right time. If you get to know the design features of the valves, you can quickly understand the essence of their action. Next, we will analyze everything in more detail.

Why are thermal shut-off valves needed?

Thermal shut-off valves are devices that are shut-off gas fittings. They automatically shut off the gas pipeline leading to all gas-powered appliances.

All "stubs" are marked as KTZ with a certain set of numbers after the letters. The second number indicates the diameter of the gas pipe for which this mechanism may be suitable.

Purpose of the thermal shut-off valve

The main purpose of the KTZ is to shut off the gas supply to the equipment in case of fire. That helps not only to protect against an explosion, but also prevents the fire area from doubling or more.

If the shut-off valve is in the open position, then the device itself does not in any way prevent the passage of a combustible substance to the instruments and equipment.

Thermal locking mechanisms are mounted on pipelines, where the maximum pressure can be 0.6 MPa - 1.6 MPa.

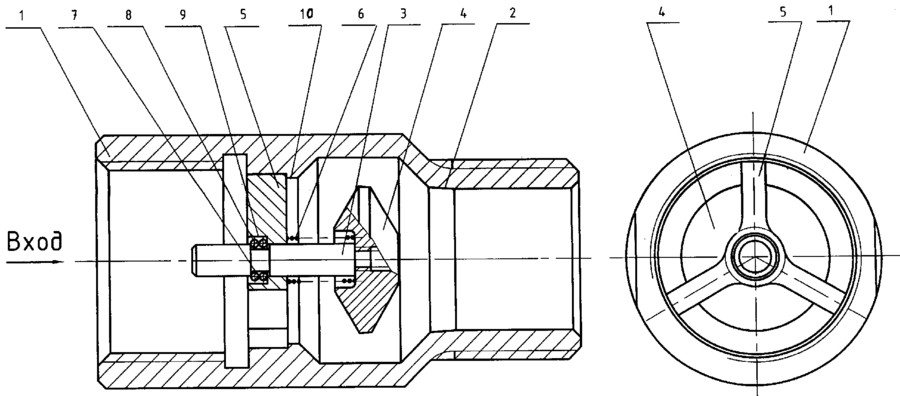

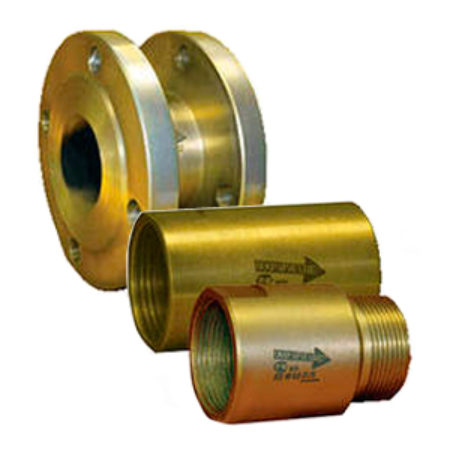

Threaded type thermal shut-off valve. It is used for equipment with lower pressure (up to 0.6 MPa). They are most often used for household needs.

Threaded type thermal shut-off valve. It is used for equipment with lower pressure (up to 0.6 MPa). They are most often used for household needs.

KTZ flange type, which is used in pipelines with high pressure (close to maximum). Most often used in industrial facilities

KTZ flange type, which is used in pipelines with high pressure (close to maximum). Most often used in industrial facilities

Next, we denote the purpose of the valves, prescribed by the rules of fire authorities.

In the fire safety regulations, there is a regulation that implies the use of valves:

- On the equipment of all pipelines of natural gas. Any types of systems (complexity, branching), any number of consumer devices are assumed.

- To ensure the protection of various gasified objects and devices operating on gas. In this case, valves are applicable that are designed for automation (operation) when the temperature in the room reaches up to 100 ° C.

- Installation of thermal locking modules at the entrance to the room.

In accordance with PPB-01-03 (Fire Safety Rules), thermal locking devices must be installed in all rooms where there is a gas pipeline. However, this does not include buildings of the V category of fire resistance.

It is also not necessary to install a short circuit in buildings where pipelines are equipped with solenoid valves. They are usually placed outside the building, and if an ignition occurs inside the building, the gas analyzer is triggered, after which the gas supply is stopped.

It should be understood that KTZ is not just another Russian “trend”. The use of these devices at various facilities where gas equipment exists is mandatory in such countries as Germany, France, the USA, etc.

Where is a thermostatic valve used?

The field of application of thermal shut-off gas plugs is, first of all, pipelines supplying gas to devices of various purposes in which gas is burned (household and industrial devices, regardless of type).

The installation of a short circuit protection plant on any gas pipeline is not allowed outside the premises, after the installation of any other gas fittings, also on bypasses, in adjacent rooms and where the operating air temperature during the operation of gas equipment can reach more than 60 ° C.

It is important not to violate the installation rules - a shut-off valve is installed first on the gas pipeline, and only after it the rest of the gas fittings, instruments and equipment

You can place the valve in different positions, just pay attention to the arrow-pointer applied by the manufacturer on the body

Thermal shut-off valve with threaded connection. The arrows on the steel element when mounting on a gas pipeline must correspond to the direction of gas flow

Thermal shut-off valve with threaded connection. The arrows on the steel element when mounting on a gas pipeline must correspond to the direction of gas flow

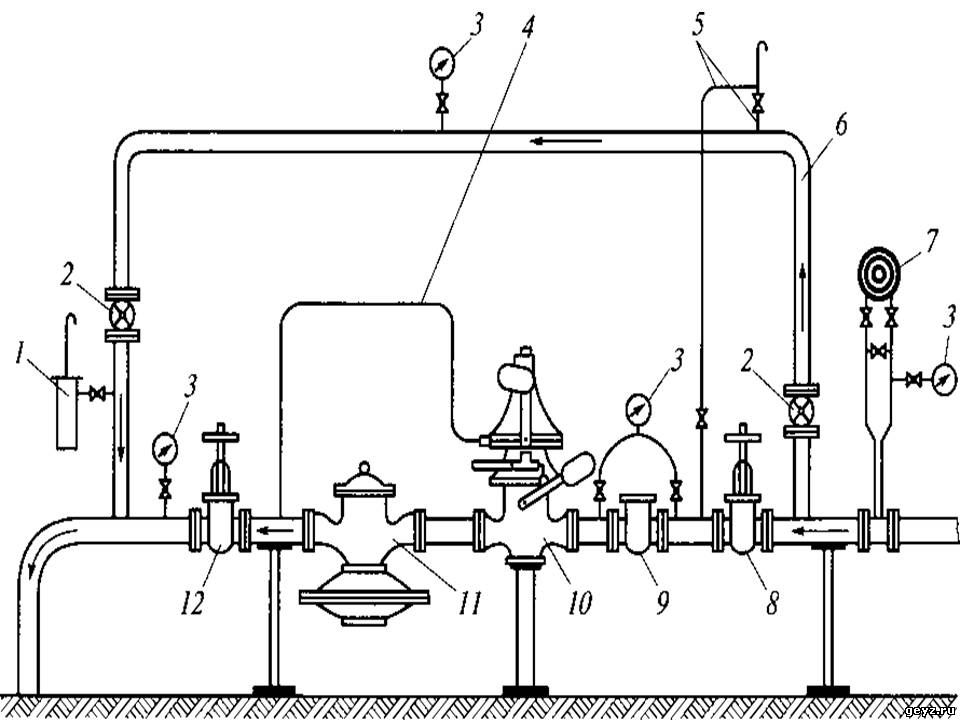

Here you can see the location of the CTP on the pipeline. The installation of the valve must be carried out first at the inlet of the gas pipeline, or at the outlet from the riser

Here you can see the location of the CTP on the pipeline. The installation of the valve must be carried out first at the inlet of the gas pipeline, or at the outlet from the riser

In relation to the horizon, the location of the installed valve can be any. We will describe in more detail the rules for installing KTZ in more detail later.

Thermal shut-off valves have a special design that allows the device to automatically shut off the gas supply at the right time. If you get to know the design features of the valves, you can quickly understand the essence of their action. Next, we will analyze everything in more detail.

Conclusion

When buying a thermal shut-off valve, you should make sure that the channel cut-off mechanism has not worked, which sometimes happens during transportation. With complex gas distribution inside the premises and the presence of several fuel consumers located in different parts of the building, it is recommended to install several shut-off valves for each branch.

LPG equipment for a car, abbreviated as HBO, is the latest, affordable and effective means of saving car fuel, increasing engine life and reducing emissions of harmful substances into the environment - all in one bottle. Every year, the unfavorable situation in the oil price market and the general deterioration in the quality of gasoline cause a steady desire of car owners to switch to more economical and harmless to the motor principles of operation. The ability to fill with liquefied propane and petroleum gas (methane) has been known since the middle of the 19th century, it appeared simultaneously with gasoline and diesel internal combustion engines and developed in parallel. But only from the end of the 70s of the XX century, gas equipment became truly in demand, and a developed infrastructure of gas stations and car service stations appeared.

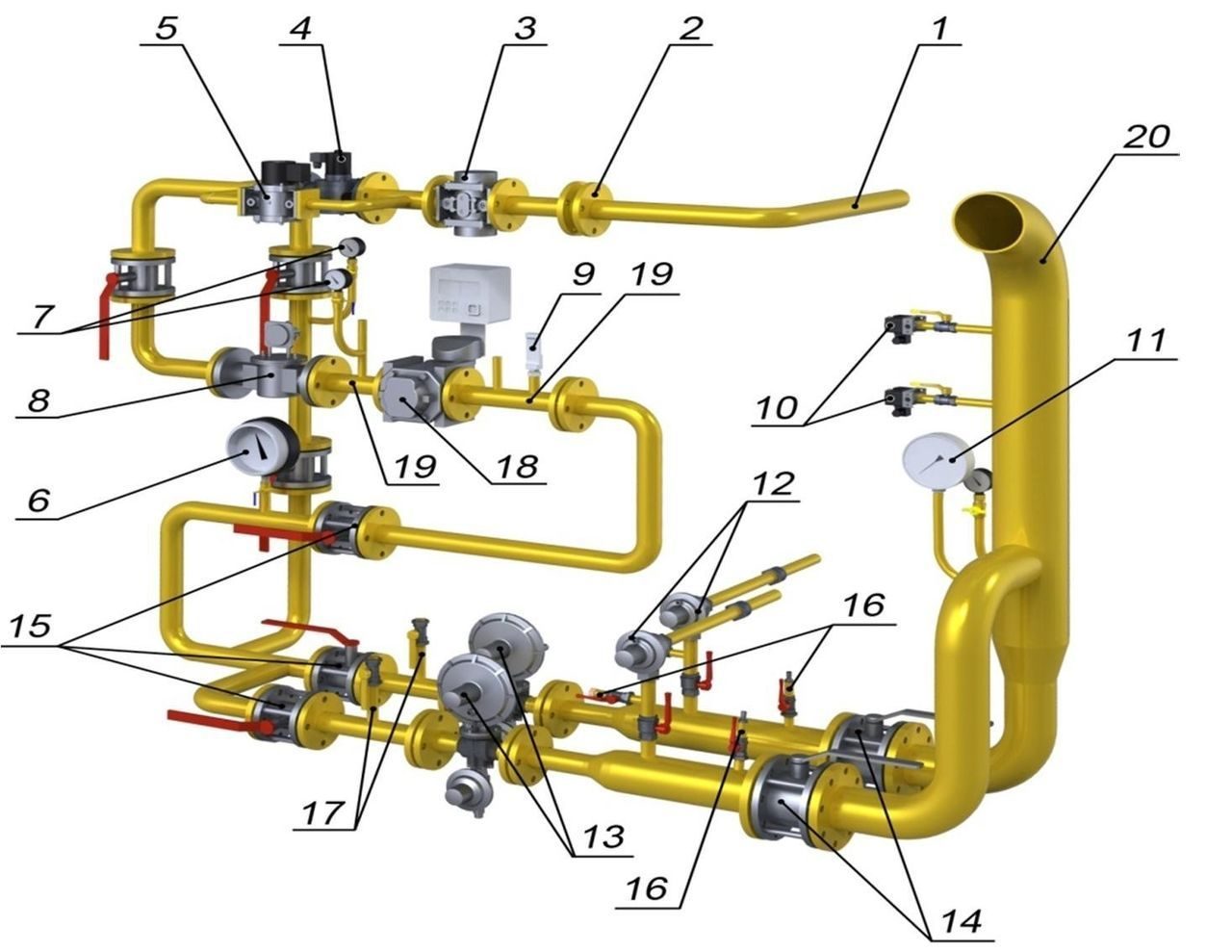

In the general case, it includes a gas cylinder, from which a gas line extends, at the end it closes the multivalve.Behind him, the gear evaporator puts the gas into working condition and accumulates in portions in the manifold and injects it into the engine through separate nozzles. The process is controlled by a control unit connected to the on-board computer (in more advanced models).

Classification

Today, a huge number of specialized manufacturers offer a wide range of both carburetor and injection types of engines of any complexity and configuration. Conventionally, all systems are divided into generations, each of which has its own work and degree of adjustment automation:

The first generation is the vacuum principle of dosage of each gas portion. A special mechanical valve reacts to the rarefaction that occurs in the car's intake manifold when the engine is running and opens the way for gas. A primitive device for simple carburetor systems has no feedback from the motor electronics, fine adjustment and other optional add-ons.

The second generation reducers are already equipped with the simplest electronic brains, which, by communicating with an internal oxygen sensor, act on a simple solenoid valve. This principle of operation already allows not just the car to drive just like it, but regulates the composition of the gas-air mixture, striving for optimal parameters. A practical and still widely used device among carbureted car owners, it has already been banned in Europe since 1996 for its high level of environmental pollution.

Demand for representatives of the transition is quite low. The work of these high-tech systems is based on stand-alone software that creates its own fuel maps.Gas is supplied by a special built-in injector to each cylinder separately. The internal software emulates the operation of petrol injectors using its own hardware. The design turned out to be not very successful, the weak processor of the block hung, causing failures in the smooth operation of the mechanism. The idea was lost when a newer and more developed class of HBO appeared.

The most common gearboxes today are with a divided injection of a gas-air mixture. This is a completed project of the 3rd generation, but using the car's standard petrol maps in the setup program, which does not burden the computing power of the control unit. Separately, there is a 4+ generation line designed for direct-flow direct fuel injection systems directly into the FSI engine.

The latest tool that is being introduced on the auto market is the 5th generation. The key feature of the principle of operation is that the gas does not evaporate in the gearbox, but is injected as liquid directly into the cylinders. Otherwise, it is in full compliance with the 4th generation: split injection, using data from the factory fuel card, automatic switching from gas to gasoline, etc. Other advantages include the fact that the equipment is fully compatible with current environmental standards and the latest on-board diagnostics .

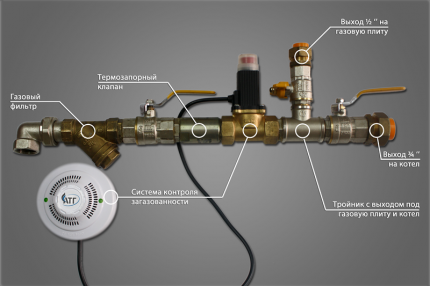

Conclusions and useful video on the topic

Overview of a household signaling device with a valve, system assembly.

Analysis of the design of the sensor and valve, its parameters, demonstration of the operation of the device.

Most fires in apartments are caused by gas leaks. Installing a sensor with a valve will help prevent serious consequences from such situations.But the safety of property and human lives is guaranteed only when the equipment is correctly selected and its installation is carried out by a qualified gas service worker.

Do you have a gas detector installed in your apartment, complete with a valve on the gas pipe, and you want to tell how this equipment protected your family and property from the negative consequences of a gas leak? Share your experience, leave recommendations on the advisability of installing such locking devices - the comment form is located below the article.