- Advantages of thermal paint

- Paint composition

- How to choose

- Rating of the best high-temperature paints for metal

- Alpina Heizkoerper

- Elcon

- Tikkurila Termal Silikonimaali

- Bosny Hi-Temp

- Tikkurila Termal Silikonialumiinimaali

- Manufacturers overview

- What are there?

- Alkyd

- Acrylic

- oily

- Molotkovaya

- Epoxy

- 5 Application features

- Training

- Tool selection

- Purpose

- The best paints for rust 3 in 1

- Novbytchim primer-enamel

- metallista

- Rules for selection and use

- Specific nuances in terminology

- Theory and practice of thermal hardening

- Features of the choice of paint for the oven

- Thermal paint terminology for metal

- Application for different surfaces

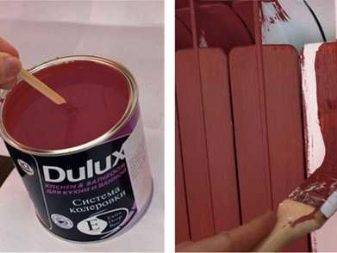

- Color selection

- Manufacturing form

- Heat-resistant paint for metal CERTA blue 25 kg

- Thermal paint for stoves, barbecues, fireplaces

- Heat resistant paint For calipers, muffler, engine

- Heat-resistant paint for metal up to 1000 degrees

- Heat resistant paint, high temperature thermal paint

- Heat resistant enamel for metal

- Thermal enamel for CERTA ovens

- Paint for metal in cans

- Conclusions and useful video on the topic

Advantages of thermal paint

The properties of high-temperature paint allow it to be used where other materials simply will not work. It is versatile and can be used anywhere.Its benefits include:

Electrical insulation. Required where there is a possibility of contact with electric current.

Adhesion strength. Perfectly lays down on the painted surface.

Corrosion protection. The paint can be used in rooms with high humidity.

Resistant to sudden temperature changes. Withstands not only high but also low temperatures.

Resists most household chemicals.

Plastic. When heated, it does not crack, but expands along with the metal, stretches.

Low toxicity

This is important when working indoors.

Ease of use. Can be applied in any convenient way.

All these qualities make it attractive to use.

Paint composition

First, let's look at the composition of heat-resistant solutions. It is different, and is selected based on the operating conditions of the painted devices. That is, the main composition depends on the height of the temperatures to which the materials will be subjected.

Composition - base:

- Acrylic and alkyd resins. Operating temperature maximum - up to +100 degrees. Are applied to metal designs of domestic use. A zinc-phosphate mixture can be added to the coloring enamel. Compatible with epoxy primer.

- Epoxy resins. Temperature maximum - up to +200 degrees.

- Ethyl silicate and epoxy resins. Enamel with such a base is used at temperatures up to +400 degrees. The admixture of metal powder is allowed.

- Silicone resins - paint heat resistance - up to +650 degrees.

- Composition with composites and heat-resistant glass - up to 1000 degrees of heating.

Additional substances give and enhance other protective properties of the coating.The composition also includes solvents, pigments, silicon organic varnishes and more.

Again, the ability to apply on various types of metal surfaces also depends on the quality of the mixture. Let's try to make this DIY enamel.

How to choose

To choose the right paint for the stove, you need to carefully consider the label, where they write what surface it can be used for, for example, heat-resistant paint for metal products. Often this information is printed in large print - it is difficult not to notice it. In cases where the scope of paint and varnish products is wide, this is also written on the packaging, but in small print. Be that as it may, such information must be indicated on the packaging, as well as the name of the manufacturer. If these data are not available, you do not need to purchase such a product. It is possible that this is a counterfeit product that may threaten your health.

For metal sauna stoves, use only moisture-resistant compounds, otherwise they will not last long on the surface.

This is interesting: What is thermochromic paint and what is it for?

Rating of the best high-temperature paints for metal

A large number of heat-resistant enamels for metal are presented on the construction market. It is difficult to choose among such a variety, but you can focus on those brands that have earned their popularity among buyers over the years.

A large number of heat-resistant enamels for metal are presented on the construction market.

Alpina Heizkoerper

It contains alkyd resin, as well as titanium dioxide. This is a high quality product that is easy to apply and gives an even coat without further scratching.The high cost is justified by the low consumption of 90 to 120 ml per square meter of surface.

The color is white enamel with a glossy effect, can withstand up to 100 degrees. Most often used for water heaters. To obtain the desired shade, mixing with pigments is used. Can be applied to cast iron, steel, aluminum and other types of metals.

White enamel with a glossy effect, can withstand up to 100 degrees.

Elcon

You can also mix with different colors, about 250 shades are presented in the coloring. However, the addition of colors leads to a decrease in temperature exposure, if the original black color is left, then the layer will be able to provide protection from +1000 degrees. The coating can have a matte or glossy effect. fireproof paint Elcon metal is sold in a standard form in cans, also in aerosols and buckets. In addition to metal products, it can be painted on brick, asbestos, concrete, only surface hardening should be carried out after painting.

In addition to metal products, it can be painted on brick, asbestos, concrete, only surface hardening should be carried out after painting.

Tikkurila Termal Silikonimaali

This paint is created from acrylic resin. Also black, sold only in cans, the coating is semi-gloss. You can use a spray gun for application. This is a quality product at a high cost. The hardening process should also be carried out after dyeing, for 60 minutes the product should be subjected to a 230-degree effect. After that, it can withstand up to four hundred degrees.

This paint is created from acrylic resin.

Bosny Hi-Temp

Sold only in cans, while the price is quite high.Colors shown are silver and black. Temperature exposure reaches up to 650 degrees, the resulting painting effect is matte.

Based on alkyd resins, not limited to metal, suitable for wood, ceramics, plastics and other materials. Aerosol spraying is convenient, but small volumes of paint do not allow large areas to be treated. It can be used without special surface preparation, it is permissible to apply directly to rusted places.

Temperature exposure reaches up to 650 degrees, the resulting painting effect is matte.

Tikkurila Termal Silikonialumiinimaali

It also belongs to the high price category. The color of the coating is aluminum (gray), the effect is semi-matt, it is available in cans, it can withstand up to 600 degrees. Based on silicone resin, low consumption.

To obtain a cured coating, heating is carried out up to 230 degrees. After 30 days after painting, it will be possible to wash the surface with detergents.

Based on silicone resin, low consumption.

Manufacturers overview

Since the actual characteristics of paint products are of the utmost importance, there are a number of leaders who best protect the load-bearing structures. The Thermal Barrier coating guarantees steel protection up to two hours, the minimum level is three quarters of an hour.

Prices and colors can vary greatly. "Nertex", for example, is created on a water basis and reliably covers the structure from high heat.

"Frizol" fully meets the standards of GOST, may have the properties of the second to sixth groups.The time of use of the coating is a quarter of a century, resistance to fire meets all the requirements.

Joker brand protection works well, but it is advisable to use it only in rooms where the security level is equal to the second, third or fourth groups.

"Avangard" is a product of the recently appeared company of the same name, but it has already managed to gain solid prestige, become famous for its excellent ratio of efficiency and price.

What are there?

Metal is actively used in all spheres and industries. Depending on the type of activity, specific formulations have been developed. It is customary to classify anti-corrosion compounds according to one element:

Alkyd

Budget option, in high demand. Alkyd enamel is made on the basis of the varnish of the same name, or synthetic resins. The main field of application is the painting of galvanized metal surfaces.

Dignity:

- does not require much time to dry;

- operation for many years;

- aggressive chemicals and temperature changes do not harm;

- easy to use and low consumption.

Flaws:

- carry out work only in a protective respirator, special clothing and a mask;

- are easily flammable, use in rooms and strongly heated metal structures is not allowed;

- high adhesive properties.

Acrylic

The basis is polyacrylates, dyes and anti-corrosion modifiers. The universal structure which is used in and outside of the room.

Advantages:

- dense inert layer is not afraid of temperature fluctuations and atmospheric phenomena;

- acrylic adapts to the tension and compression of the metal;

- incombustible;

- no odor or harmful compounds. Used inside buildings;

- does not burn out;

- colors are allowed.

Flaws:

- clean and dry surface without dust and dirt;

- humidity and air temperature must comply with the manufacturer's recommendations.

oily

In the manufacture of natural oils and drying oil were used. Educated enamel is practically unstable to negative atmospheric manifestations, ultraviolet, temperature extremes and rust. In this regard, they are painted only in buildings.

Molotkovaya

The polymeric pitches which are a part of paint provide high coupling with metal. The resulting coating is strong and will last for several years. Forms a rough layer with a characteristic sheen.

Advantages:

- not afraid of high humidity and temperature changes;

- does not burn out;

- resistance to mechanical damage;

- heat resistance.

Flaws:

- high price;

- problems with the elimination of the old layer;

- high consumption.

Epoxy

Enamel, which is highly popular and popular recognition. The composition includes epoxy resins, coloring pigments and hardeners. The main field of application, painting of external elements.

Advantages:

- dries within 4 - 10 hours;

- glossy finish;

- resistance to high temperatures;

- affordable price.

Flaws:

5 Application features

It shows its qualities most effectively at a temperature of -10 ° C. However, it should be remembered that the coating will dry for a long time and if a second layer is provided, then it must be applied after 2-3 days (according to the instructions).

Despite the fact that the paint itself does not freeze, however, at sub-zero temperatures it becomes viscous. Therefore, in order not to slow down the process, it is recommended to use two containers of paint alternately, one of which will be warm.Otherwise, it will have to be heated in a container with warm water.

The packaging must indicate the storage temperature of paintwork materials. According to the standard, it is necessary to store materials for priming and painting from -40C to +40C.

Training

Processing and painting metal in frost requires more careful preparation. The surface must be well cleaned of dirt and rust, using special brushes and abrasive compounds. Acetone and isopropanol are used for degreasing. You can paint only if the surface is dry. In the case of frost coverage, the area must be treated with a flash of a gas burner.

Tool selection

Paint with brush or roller. In frosty weather, the nozzle of the spray gun will quickly become clogged, so it should not be used.

Purpose

Heat-resistant paints are able to transform the product into any color. Compositions intended for painting furnaces have an excellent level of protection against corrosion, do not collapse under the influence of moisture. Mandatory requirements for this group of paints are reliable protection against electric shock and the ability to tolerate contact with aggressive substances.

All the desired properties of the coating must be maintained both at significant heating and at low temperatures, even if the drops are very sharp. Additionally, such a valuable parameter as plasticity should be mentioned - the decorative layer should stretch after the heating base, and not split. The absence of the necessary properties also guarantees the appearance of cracks after drying.

Heat Resistant Metalwork Paints can be applied to any type of ferrous metal or alloy. The existing classification subdivides coloring materials according to various criteria. First of all, the packaging method.Cans, cans, buckets and barrels are used as containers. Another gradation is made by staining methods, which determine the amount of paint used.

In everyday life, heat-resistant coloring compositions are applied to metal structures in baths, saunas, and to chambers for drying wood. They cover stoves and barbecues, fireplaces, radiators, mufflers and car brakes.

The best paints for rust 3 in 1

The presence of the prefix "3 in 1" indicates that the product works in several directions - priming, converting rust and decorating. Products of this type are resistant to any impact. After analyzing the reviews of consumers and experts, among the many products, two nominees with the best recommendations were selected.

Novbytchim primer-enamel

Paint "Novbytchim primer-enamel" is intended for painting any types of surfaces. It is applicable to both new and already partially or completely corroded products. The composition of the product is synthetic resins, additives, solvents (organic) and anti-corrosion components. The product combines the qualities of an anti-corrosion primer, a rust converter and a top coat. Its consumption is quite small - up to 120 ml per m² with a single layer application.

Work can be started at an air temperature of -10°C. The coating is preliminarily cleaned from existing delaminations. If it was painted with oil or alkyd compounds, then stripping to a matte state is necessary. A brush and roller are suitable for applying the composition. The paint also lays down well when applied pneumatically. For best results, apply 2 layers. Intermediate drying should last at least 60 minutes. Complete drying takes only 2 hours.

Advantages

- Fast drying;

- Resistance to different types of exposure and temperature extremes;

- High adhesion rates;

- Excellent decorative properties;

- Good hiding power.

Flaws

Not suitable for heated surfaces due to odor.

metallista

The rusty metal paint in question, from the myrrh brand Tikkurila, provides a 3-in-1 effect. Thanks to the wax included in it, it creates an increased protection of the metal from the negative effects of moisture, giving it excellent water-repellent properties. Structures coated with composition will last at least a decade without renewal. Metallista is immune to the effects of fats, lubricants, industrial alcohols and turpentine, so its scope is unusually extensive.

The manufacturer offers several base shades for tinting, but in total they can be created up to 32 thousand. The hardened layer easily withstands heating up to 80 ° C while maintaining the original color. Drying of the applied composition to sticking takes up to 2 hours. Metallista must be topped up with solvent before use. It adheres well to uncleaned surfaces without prior application of primer.

Advantages

- Creation of an insoluble base;

- Delay the formation of corrosion;

- Eliminates the need for preliminary preparation of the base;

- Double chemical formula;

- Ease of use with any tool.

Flaws

- Implementation of small volumes;

- The need for tinting;

- Not a very large number of finished colors (four).

Enamel is sold in small containers - from 400 ml to 2.5 liters.

Rules for selection and use

To choose the right paint, you need to determine the maximum temperature of the surface on which it will be applied. You also need to calculate the area and make a choice between a spray in a can and a liquid consistency in a jar. But there are some more rules to be aware of.

Specific nuances in terminology

Many sellers in their advertising campaigns are very frivolous about the terminology adopted for compounds that can be applied to surfaces with high temperatures. There is no normatively established gradation according to the name of the composition and its maximum allowable heating temperature.

However, three established terms are commonly used:

- high temperature;

- heat-resistant;

- heat-resistant.

High-temperature paints for metal include compositions that can withstand prolonged surface heating up to 2000C. They are used to process radiators and heating pipes, brick ovens and fireplaces. In addition, they will be suitable for automotive parts such as engine, muffler and exhaust system.

Water jacket of a metal furnace. Outside, it does not heat up above the coolant temperature, therefore, high-temperature paint can be used to treat its surface.

Heat-resistant compositions are used for surfaces with temperatures up to 6500C.

Such paints are used for the following metal objects:

- sidewalls and bottom of furnaces;

- barbecues;

- pipes for the removal of combustion products;

- the junction of the pipes of the water circuit to the furnace or boiler.

Heat-resistant paints and enamels often contain pigments that give them color, so they can be used to create original interior design solutions.

Heat-resistant paint is designed to cover surfaces that are heated to temperatures above 6500C. First of all, these are cooking stoves and furnace fireboxes, as well as grates for wood-burning stoves and fireplaces.

Some types of thermal paint have an additional feature - fire resistance. This means that the painted surface may be in direct contact with the flame. From household metal objects, this is true for the fireplace grate and the inside of the barbecue.

Theory and practice of thermal hardening

Heat-resistant paint is inherently heat-resistant enamel. To create an impenetrable barrier, you must perform thermal hardening process. In the process of heating the surface with the composition applied to it, the layers polymerize, after which the access of air to the dyed metal stops.

Sometimes a colorless varnish is applied to protect metal products. This type of coating also requires thermal hardening.

It is after thermal hardening that neither oxygen, which causes the rusting process, nor moisture can penetrate under the enamel. Prior to this, the paint has only a decorative and, in part, protective function from physical impact.

Moreover, after creating an impermeable layer, the evaporation of the substances contained in the paint into the room air stops. Therefore, ideally, you should wait for the specified period of complete drying, which is indicated on the label or in the instructions, and then immediately carry out the thermal hardening procedure.

Typically, the temperature at which enamel polymerizes is 200-2500C. This leads to one common mistake that is often made by people who have residue after painting the stove.

It is impossible to apply a heat-resistant composition that requires thermal hardening to radiators and heating pipes, since the degree of their heating is insufficient to complete the process. For slightly hot objects, you need to use ordinary high-temperature paint.

Theoretically, the heat hardening process should take place at a constant temperature for 30-60 minutes. However, in practice, such “laboratory” conditions are unrealistic to achieve.

Therefore, wood-burning stoves, barbecues and fireplaces are not flooded at full capacity and gradually increase their heating. Typically, a test run takes 1.5-2 hours. Another option is warming up with an industrial hair dryer.

This is interesting: Heat treatment of metals and alloys: we state in detail

Features of the choice of paint for the oven

You cannot paint a stove with simple paints: the highest temperatures that they can withstand are 45-55 ° C. During the first fire, this coating will swell, begin to change color before our eyes, go in bubbles, and also spread “aromas” and smoke. Therefore, special formulations that can withstand elevated temperatures are clearly needed.

The degree of heat resistance required will depend on the type of furnace. If this is a metal furnace, then it can heat up more than 700-900 ° C: the temperature is higher in the combustion zone, but taking into account the design, the outer walls may not heat up so much. For the outer surface of the brick, increased performance is not required - 300 ° C is enough.

An important requirement is that the refractory paint for metal for the furnace must be suitable for interior painting. For sauna stoves, it is best that it still protects from high humidity.

Thermal paint terminology for metal

For painting surfaces with elevated temperatures, refractory, heat-resistant and heat-resistant paints are suitable. Do not use flame retardants. Although the name is similar, the purpose of this paint is completely different: when heated to a certain temperature (about 150 ° C), it bubbles, blocking the access of oxygen to the structure, thus preventing its destruction. Pretty useful effect, but not in the case of the stove.

- Heat-resistant paints, as a rule, have an area of application up to 700 degrees. These compositions can be used to paint metal elements of fireplaces and brick stoves, metal heating stoves. It is undesirable to cover the body of metal sauna stoves with these paints, since in some places the temperature rises to 900 ° C. For them, there are heat-resistant enamels that can withstand temperatures up to 1000 degrees.

- Fireproof paint for metal can withstand open fire. Their operating temperature is even higher, however, for domestic use, these compositions are unprofitable, as they are quite expensive.

- There are also high-temperature paints that are used to paint the radiators of the heating system. As a rule, they behave normally if they are heated no more than 250 ° C. They can only be used for brick ovens - they are perfect for tinting the surface or painting the seams.

- There are also heat-resistant varnishes. They normally tolerate temperatures up to 300−350°C. If a brick is treated with such a varnish, the surface will become brighter, acquire color and shine.

Application for different surfaces

In order to decide which paint to paint the oven with, you need to pay attention to which surfaces this composition is intended for. Often the scope is indicated on the packaging in large letters.

For example, refractory paint for metal. If the scope of use is extensive, then it is indicated in smaller print, but it must be on the packaging, like the brand name. If these data are missing, refuse the purchase. Most likely, this is a fake, and the combination of high temperatures and questionable quality is dangerous to health.

Paint for a metal sauna stove, in addition to temperature resistance, must protect against high humidity. This way it will last longer.

Color selection

Heat-resistant paint, as a rule, is found in silver, gray and black. Other shades need to be looked for, but they also exist: red, white, blue and green. The finish is glossy or matte.

Matte black thermal paint is usually found, however, some manufacturers have different shades and colors.

Manufacturing form

Thermal paints are made in cans or cans. Accordingly, it can be applied from cans with rollers, brushes or sprayed using special equipment, and sprayed from cans.

Heat-resistant spray paint, as a rule, has a volume of approximately 500 ml. In banks, packing is usually 0.4-5 kg. There is a larger packaging in barrels and buckets.

What is more convenient? It's a matter of habit. With dexterity from the can, the layer comes out more uniform. In this case, there may be less consumption than when using a brush or roller.

Heat-resistant paint for metal CERTA blue 25 kg

Thermal paint for stoves, barbecues, fireplaces

- metal stoves, barbecues, fireplaces, accessories. The coating is retained even when heated to incandescence. Thermal paint for metal in cans will help touch up chips, scratches and restore the original look.

- brick ovens, fireplaces; RAL tinting allows you to choose your color and keep the look even after heating.

Heat resistant paint For calipers, muffler, engine

- for engine and hot parts

- thermal paint for calipers, mufflers, brake drums, heating parts of brake systems,

- thermal paint for mufflers, heated parts of exhaust systems

Defense complex, aviation

- engines, cooling and exhaust gas systems for special and combat vehicles

- heating parts of aviation and rocketry equipment, parts of jet engines

- heating surfaces of equipment and power plants of marine vessels

Food complex, household goods

- burners for gas and electric stoves, baking ovens

- heating furnaces, heating radiators and heat exchangers

- gas boiler heaters

- barbecues, barbecues, stoves for baths and saunas, fireplaces, accessories for stoves and fireplaces

Automotive

- engines, cooling systems and exhaust gases

- heating parts of brake systems, brake drums

- heated parts of exhaust systems, mufflers

Metallurgy and mining

- industrial furnaces and structures in metallurgical plants

- mining machinery and equipment

Fuel and energy complex

- heat exchange and boiler equipment of nuclear and thermal power plants, pipelines and pipeline fittings

- gas turbine engines, turbine blades, exhaust shafts of gas compressor units

- transformers

- CHP pipes, cooling towers

- ventilation equipment

- capacitive equipment and oil pipelines

- as a heat-resistant adhesive primer for fire-retardant coatings on offshore platforms, oil and chemical terminals (TsNIIMF, 2009)

- to protect polyurethane "shells" of heating mains from destruction

- waste incinerators (pyrolysis ovens)

Construction

- metal and concrete structures, building facades, reinforced concrete supports and fences of bridges, overpasses, flyovers (STO-01393674-007-2015 JSC "TsNIIS")

- for fire-prevention finishing of walls and ceilings on evacuation routes: in elevator lobbies, stairwells, vestibules, corridors, lobbies and foyers of buildings (except for high-rise buildings)

Heat-resistant paint for metal up to 1000 degrees

Tests show the resistance of CERTA heat-resistant enamel at the level of 1000 degrees. Theoretically, short-term heating of thermal paint for metal up to 1000 degrees.

Heat resistant paint, high temperature thermal paint

Our paint is also searched for by the query heat-resistant paint or high-temperature paint, meaning paint material with high temperature resistance. Thermal paint for metal CERTA is also designed for these purposes. Passed the necessary tests. Certified.

Heat resistant enamel for metal

Anti-corrosion heat-resistant enamel CERTA is designed for protective anti-corrosion painting. Withstands heating up to a metal heat temperature of 1000 degrees. Tested by research laboratories and Russian research institutes. Frost-resistant to -60 degrees.

Thermal enamel for CERTA ovens

You can buy thermal enamel for stoves in CERTA cans. Spray cans are more convenient when applied, do not require a brush or roller for application. More convenient to store. Thermal enamel withstands heating up to 1000 degrees. Repeatedly tested by laboratories and our customers.

Paint for metal in cans

Aerosol paint for metal is an easy and convenient way to paint a small product on metal, plastic, concrete, brick. Paint in cans for metal CERTA, as well as our other enamels, have good hiding power. The coating has excellent adhesion to the painted surface, high weather resistance and strength, long service life.

Conclusions and useful video on the topic

Painting the cooking surface and the firebox door. Preparatory work, paint application with a brush and thermal hardening with a hair dryer:

How to paint cast iron radiators with a roller:

Painting the brazier from a spray can:

Now it is easy to find paint that can be applied to a metal surface heated with different intensities. The choice of product must be made taking into account the temperatures reached by the object, the suitable method of application and some other features.

It is also necessary to pay attention to the nuances indicated by the manufacturer in working with the composition and precautions. Do you want to talk about how you selected paint to renew or restore the coating of a metal sauna stove or barbecue? Tell us which option you chose and why. Please write comments in the block below, ask questions, post photos on the topic of the article

Please write comments in the block below, ask questions, post photos on the topic of the article

Do you want to talk about how you selected paint to renew or restore the coating of a metal sauna stove or barbecue? Tell us which option you chose and why. Please write comments in the block below, ask questions, post photos on the topic of the article.