- Types of thermal heads

- How does a thermal valve work

- Balancing valve installation

- Benefits of using modern thermostats

- thermostatic heads

- Mechanical

- gas or liquid

- With remote sensor

- Electronic

- Choosing the optimal thermal head

- Thermal valve installation

- What are thermostatic radiator heads

- What are the criteria for choosing a thermal head?

- Advantages of the device

- Types of heat agent

- The main types of thermostats

- Balancing valve for heating system

- In a private house

- In a multi-storey building or building

- The principle of operation of a thermostatic valve

- Conclusions and useful video on the topic

- Conclusion

Types of thermal heads

All manufactured thermal heads can be divided into two types:

- mechanical, the adjustment of which is carried out manually;

- electronic, controlling the adjustment process in automatic mode.

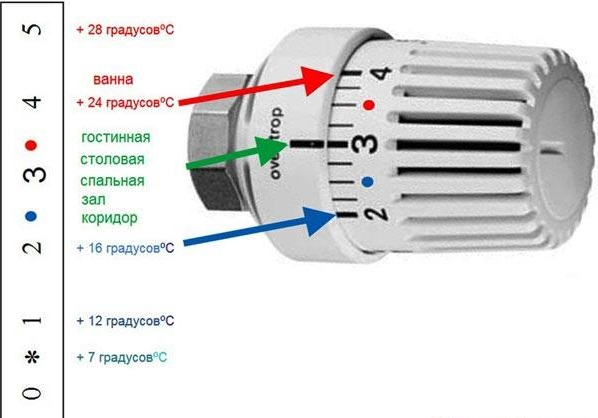

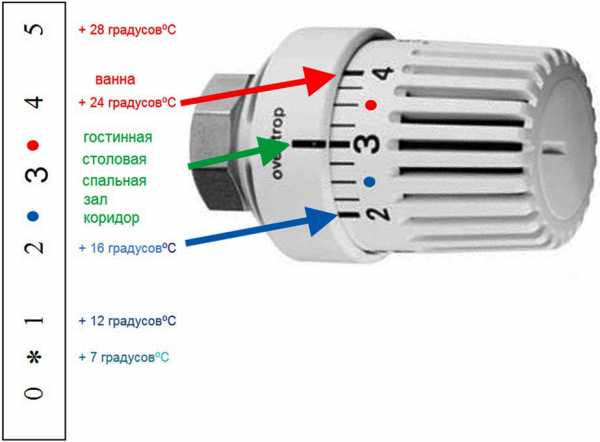

Mechanical models are a small head with a rotary knob. The temperature range that can be controlled starts at +7° and goes up to +28°. The device provides several modes of operation. Each division of the temperature scale equates to 2-5 degrees.

In electronic models, the entire adjustment process is automated.The tuning accuracy corresponds to 1-2 degrees. A flexible control system allows you to set the most suitable heating mode.

How does a thermal valve work

The thermal head is needed to regulate the temperature of the radiator.

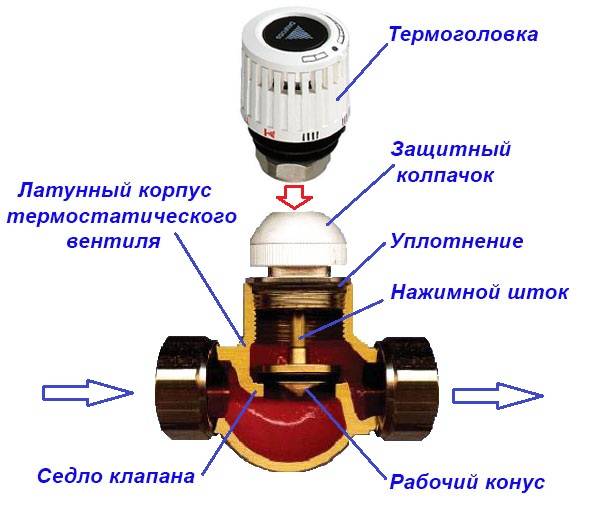

The very first versions of thermostats that were installed on heating radiators were created in 1943 by DANFOSS. Several decades later, such devices have undergone many changes, as a result of which they have become more accurate. Their design consists of several parts: a valve and a thermal head. At the same time, they are connected by a special locking mechanism. The purpose of the thermal head itself is to measure and analyze the temperature and influence it by using a valve mechanism for this mechanism that opens and closes the flow of water to the radiator.

This adjustment method is also called quantitative due to the fact that the device changes the temperature by changing the amount of coolant that passes through the heating radiator. There is also another method, which is called qualitative. Its principle is to change the temperature of the water directly in the system itself. The mixing unit, which is usually installed in the boiler room, is responsible for this.

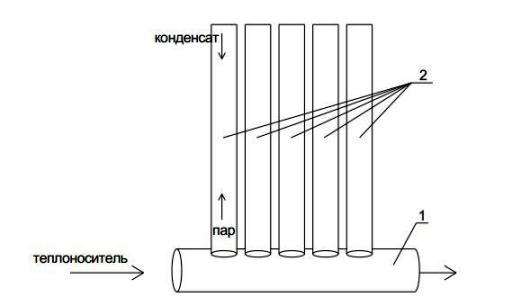

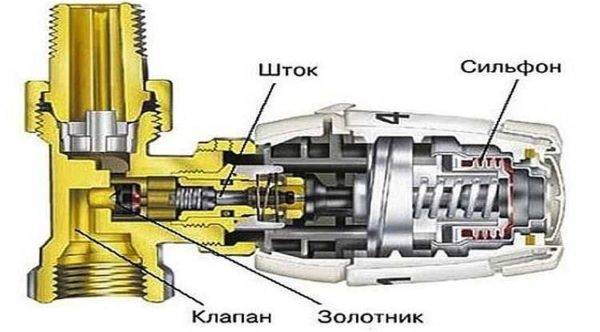

Inside such an element is a bellows, which is filled with a temperature-sensitive medium.

In this case, the latter can be of several types:

- liquid;

- gas-filled.

It should be noted that liquid versions are easier to manufacture, but their performance is lower than that of gas ones. The essence of their work is as follows: as the temperature rises, the substance inside expands according to the laws of physics, due to which the bellows stretches.Further, the latter reduces the size of the valve section by moving a special cone. Ultimately, the coolant consumption is reduced. When the air in the room cools, the process is reversed.

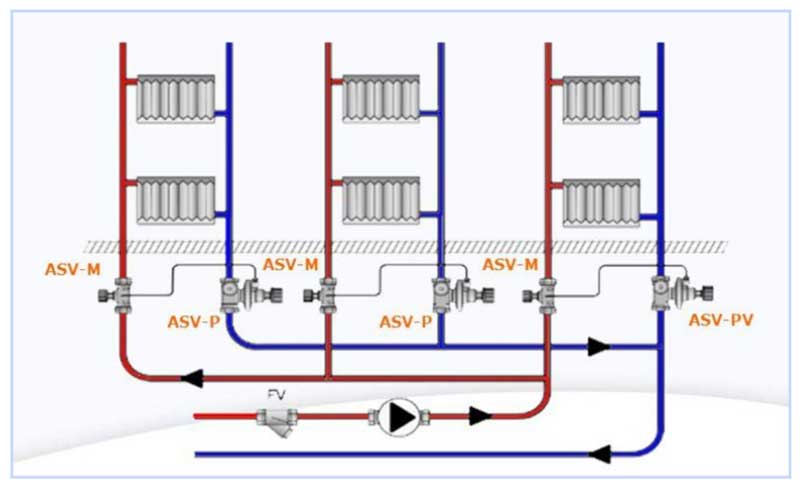

Balancing valve installation

The thermostatic balancing valve is designed for hydraulic adjustment of the heating system. It provides a uniform supply of water to all heating devices. In addition, it is arranged for a small piping loop for solid fuel boilers if it is closed to a buffer tank. With its help, the temperature in the circuit is maintained at least 60 0 C, and there is no need to arrange a mixing unit. In such a scheme, the flow rate of the small circuit must exceed the flow rate of the heating circuit. This provides a valve set to supply.

The best option would be to install a thermostatic balancing valve for each circuit, including underfloor heating and hot water supply.

Benefits of using modern thermostats

Before installing temperature controllers on the battery, it does not hurt to understand their advantages:

- The presence of an ergonomic design, so the devices will fit the interior of premises for various purposes. They make it easy to adjust the temperature.

- It is not difficult to put a temperature controller on the battery in installed or operated systems, since this heating equipment is adapted to local climatic conditions. They are operated during their entire long service life without maintenance and preventive maintenance.

- When radiators are equipped with thermostats, there is no need to open windows in the house to regulate the temperature in it.

- Devices operate in the range from 5 to 27 degrees. To properly operate them, you need to know the features of how to use the thermostat on the battery. You can set the temperature to any value within the specified range, it will be maintained with an accuracy of one degree.

- Thermostats contribute to the uniform distribution of the coolant throughout the heating system. In this case, even devices located at the end of the branch will function effectively.

- The thermometer for a heating radiator prevents excessive heating of the air in the room in case of penetration of direct sunlight into it, or when the temperature rises as a result of other factors, for example, from the operation of electrical household appliances.

- If thermostats are used in autonomous systems, then fuel consumption can be saved up to 25%, which has a positive effect on heating costs and on the amount of harmful combustion products.

Since the price of thermostats is low, the advantages of using them are significant:

- Thermal energy is economically spent.

- The microclimate in the premises of the house improves.

- Provides easier installation.

- The operation of thermostats does not require costs.

The use of thermostats proved to be especially effective in projects for the creation of autonomous heat supply systems at suburban real estate, since their installation pays off in one heating season.

With the central supply of thermal energy, thermostats are able to provide a comfortable microclimate in the rooms. In apartments of high-rise buildings, it is necessary to start mounting these devices from rooms where temperature changes reach large values - a kitchen, a living room, in which the number of people is constantly changing.This also applies to rooms located on the sunny side of the house.

The general instruction on how to put the thermostat on the battery is as follows: in their own households, they are first of all mounted on the upper floors. This is due to the fact that warm air is directed upwards and as a result there is a large temperature difference between the lower floor and the upper one.

thermostatic heads

There are three types of thermostatic elements for heating thermostats - manual, mechanical and electronic. All of them perform the same functions, but in different ways, provide different levels of comfort, and have different capabilities.

Manual thermostatic heads work like a regular tap - turn the regulator in one direction or another, passing more or less coolant. The cheapest and most reliable, but not the most convenient devices. To change the heat transfer, you must manually turn the valve.

Manual thermal head - the easiest and most reliable option

These devices are quite inexpensive, they can be installed at the inlet and outlet of the heating radiator instead of ball valves. Any of them can be adjusted.

Mechanical

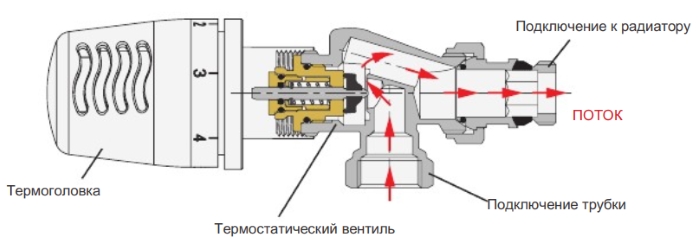

A more complex device that maintains the set temperature in automatic mode. The basis of this type of thermostatic head is a bellows. This is a small elastic cylinder that is filled with a temperature agent. A temperature agent is a gas or liquid that has a large coefficient of expansion - when heated, they greatly increase in volume.

Thermostat device for a heating radiator with a mechanical thermostatic head

The bellows supports the stem, blocking the flow area of the valve.Until the substance in the bellows is heated, the stem is raised. As the temperature rises, the cylinder begins to increase in size (gas or liquid expands), it presses on the rod, which more and more blocks the flow area. Less and less coolant passes through the radiator, it gradually cools down. The substance in the bellows also cools down, due to which the cylinder decreases in size, the rod rises, more coolant passes through the radiator, it starts to warm up a little. Then the cycle repeats.

gas or liquid

With such a device, the room temperature is fairly maintained at exactly +- 1°C, but in general the delta depends on how inert the material in the bellows is. It can be filled with some kind of gas or liquid. Gases respond faster to temperature changes, but are more difficult to produce technologically.

Liquid or gas bellows - no big difference

Liquids change volumes a little slower, but they are easier to produce. In general, the difference in the accuracy of maintaining the temperature is about half a degree, which is almost impossible to notice. As a result, most of the presented thermostats for heating radiators are equipped with thermal heads with liquid bellows.

With remote sensor

The mechanical thermostatic head must be installed so that it is directed into the room. This way the temperature is measured more accurately. Since they are quite decent in size, this installation method is not always possible. For these cases, you can put a thermostat for a heating radiator with a remote sensor.The temperature sensor is connected to the head with a capillary tube. You can place it at any point where you prefer to measure the air temperature.

With remote sensor

All changes in the heat transfer of the radiator will occur depending on the air temperature in the room. The only disadvantage of this solution is the high cost of such models. But the temperature is maintained more precisely.

Electronic

The size of the electronic thermostat for the heating radiator is even larger. The thermostatic element is even bigger. In addition to the electronic filling, two batteries are also installed in it.

Electronic thermostats for batteries are large

The movement of the stem in the valve in this case is controlled by a microprocessor. These models have a fairly large set of additional features. For example, the ability to set the temperature in the room by the hour. How is it fashionable to use? Doctors have long proven that it is better to sleep in a cool room. Therefore, at night you can program the temperature lower, and in the morning, when it's time to wake up, it can be set higher. Comfortable.

The disadvantage of these models is their large size, the need to monitor the discharge of batteries (enough for several years of operation) and the high price.

Choosing the optimal thermal head

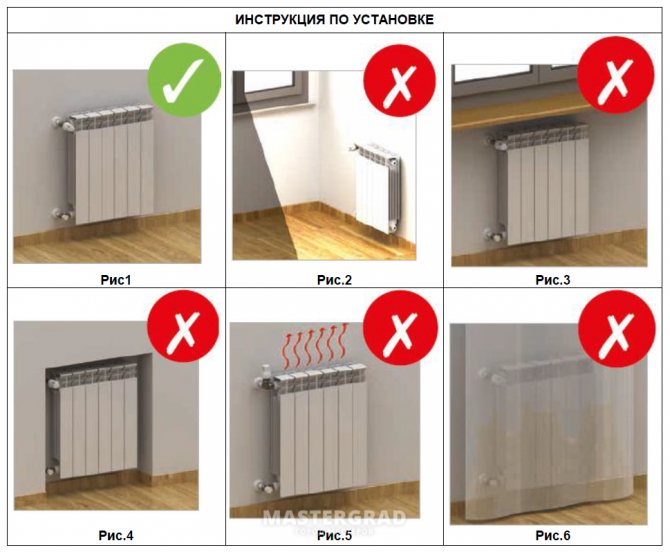

The thermostatic head for heating radiators must be correctly installed.

The first parameter on the basis of which the choice is made is the type of filler, if the regulator is automatic. According to this principle, thermostats are divided into two types: liquid and gas. Devices of the first type more accurately adjust the valve to the needs of residents, but the thermal inertia of such devices is higher than that of gas regulators.Gas-filled thermal heads balance the temperature less accurately, but faster.

The second principle of choice is the type of signal applied to the valve. Thermal heads for radiators can be actuated based on the temperature:

- water in pipes;

- air in the room;

- air outside.

Regulators of the first type are less accurate - the setting error can vary within 1 - 7 degrees. Often such a spread does not suit the consumer, therefore, regulators that receive information from the air are most often used. They sensitively react to changes in the temperature balance between the radiator and the air in the room and adjust the flow of water, maintaining the desired conditions automatically.

Control can be direct or electric. In the first case, the thermostat will receive information about the change in temperature regime from the coolant. Changing the mode is carried out by turning the valve handle, on which the scale is applied.

Electrical control is divided into two subtypes:

- control of a circulation pump or heating boiler;

- signaling to mechanical valves, which are installed next to the radiator - in this case, you can adjust all the radiators in one motion.

Thermal valve installation

The first step is to insert the element into the pipeline. To do this, it is necessary to stop the operation of the radiator and remove it, as well as turn off the circuit. Initially, fittings are installed, and later the device is equipped with an external thermostat.

The position of the valve is extremely important for its further operation. It is important to install it with the sensor in the opposite direction from the radiator and the leading pipe so that the fluid temperatures do not affect the readings.After installing the thermostat, the regulator is mounted without additional elements

Having connected the required marks, it is fixed manually. After that, the device is ready to turn on the boiler. The thermal valve starts working immediately, its additional adjustment is not required. Only the correct installation is important, which in the future will ensure the efficiency of the device.

After installing the thermostat, the regulator is mounted without additional elements. Having connected the required marks, it is fixed manually. After that, the device is ready to turn on the boiler. The thermal valve starts working immediately, its additional adjustment is not required. Only the correct installation is important, which in the future will ensure the efficiency of the device.

The three-way valve is installed in the same way. It is only necessary to supplement the system with an additional channel for hot water for its functioning and ensuring the operation of the boiler. Because of this change, it is worth carefully calculating the pressure in this area so that it is sufficient for fluid to enter the subsequent elements of the system.

What are thermostatic radiator heads

Thermostatic heads are of the following types:

- manual;

- mechanical;

- electronic.

They have the same purpose, but the custom properties are different:

- Manual devices work on the principle of conventional valves. When the regulator is turned in one direction or another, the coolant flow opens or closes. Such a system will not be expensive, it is reliable, but not very comfortable. To change the heat transfer, you must adjust the head yourself.

- Mechanical - more complex in the device, they can maintain the desired temperature in a given mode.The device is based on a bellows filled with gas or liquid. When heated, the temperature agent expands, the cylinder increases in volume and presses on the rod, blocking more and more the flow channel of the coolant. Thus, a smaller amount of coolant passes into the radiator. When the gas or liquid cools, the bellows decreases, the stem opens slightly, and a larger volume of coolant flow rushes into the radiator. A mechanical thermostat for a heating radiator is quite convenient to use and popular among consumers because of its ease of maintenance.

- Electronic thermostats are large. In addition to massive thermostatic elements, two batteries are included with them. The stem is controlled by a microprocessor. The models have quite a lot of functionality. You can set the temperature in the room for a certain time. For example, at night it will be cooler in the bedroom, warmer in the morning. During those hours when the family is at work, the temperature can be lowered and raised in the evening. Such models are large in size, they must be installed on high-quality heating devices in order to operate without problems for several years. Their cost is quite high.

Is there a difference between liquid and gas bellows? It is believed that gas responds better to temperature changes, but such devices are more complex and expensive. Liquid normally cope with their task, but a little "clumsy" in reaction. You can set the required temperature and maintain it with an accuracy of 1 degree. Therefore, a thermostat with a liquid bellows successfully solves the issues of adjusting the supply of coolant to the heater.

What are the criteria for choosing a thermal head?

Thermostats are produced by many manufacturers.

To make the right choice, you need to be guided by the following criteria:

Thermal valve to which the head will be attached

Since the connection can be clip-on or threaded, you need to pay attention to this point. If the manufacturer is the same, there will be no problems.

Type of threaded connection on the head itself

It can be in the form of a nut with curtains or just round. In the first case, during installation, an additional tool is needed to crimp the connection. In the second - everything is much simpler.

The presence of a "skirt". With her, the head looks better, because. it closes the workspace.

Manufacturing material. The cheapest are thermal heads in a plastic case. Expensive models have a metal case.

Plastic quality. Some manufacturers, in order to reduce the cost of their products, use the cheapest type of plastic. The strength of the structure suffers from this, and over time, the plastic turns yellow and loses its aesthetic appearance.

Work item type. The choice will have to be made between liquid, gas, electronic and paraffin.

Smooth rotation. The handle should rotate smoothly. This is a sign of good quality. All sorts of crackles, squeaks and jams indicate a not quite high-quality product.

Graduation and scale length. For most models, it is in the range of +5 - +30 ° C. If the graduation scale is located around the entire perimeter of the head, it can quickly be erased.

The presence of an anti-vandal casing. It protects against unauthorized access to settings.

Design.Since thermal heads are mainly located in plain sight, their appearance and color scheme are important.

It is not necessary to purchase a ready-made kit consisting of a thermal valve and a thermal head. These devices can be purchased separately.

The gas-filled bellows are not too sensitive to third-party heat sources. This is a definite plus, but its cost is much higher than that of a liquid bellows

A thermal head equipped with automation wins a lot, but it is not always effective. It makes no sense to mount it on cast iron radiators. This material is very heat-consuming, and since the mass of the battery is large, it has great inertia. Only the manual head type can work correctly here.

Advantages of the device

The use of thermostats has several benefits:

- With its help, you can maintain comfort and the required temperature conditions, significantly save thermal energy. This is noticeable in apartments with district heating, where there are heat meters. It is estimated that when using the device in an individual heating system, the savings are up to 25 percent.

- With the help of a thermostat, the microclimate in the room improves, since the air does not dry out from excessively high temperatures.

- You can set different temperature conditions for the rooms of the house or apartment.

It's never too late to embed a thermostat in radiators

The current system or just starting up - it doesn’t matter, the installation is not complicated.

When using the device, no additional maintenance costs are required.

Modern design solutions for thermostats are suitable for any room interior.

Long service life with proper installation.

The thermostat allows you to set the temperature mode with an accuracy of 1 degree.

The device helps to evenly distribute the coolant along the water circuit.

Types of heat agent

Most often, liquid and gas are used in its role. Because of this, the following types of thermal heads are distinguished:

Cheaper and simpler are the regulators of the first type. For this reason, they are represented by a very large number of models. However, they manage the battery more slowly.

Gas regulator for heating battery has a lower inertia, due to which it is able to quickly respond to changes in the temperature in the room.

In practice, the difference between the two types of reaction is very small.

Therefore, when choosing, it is better to focus on the quality of performance. It also depends on the manufacturer. Almost all types of thermostats are able to set the temperature, the range of which is +6 ... +28 ° С

Of course, there are options designed to set other temperature levels. However, as the temperature range increases, the price rises.

Almost all types of thermostats are able to set the temperature, the range of which is +6 ... +28 ° С. Of course, there are options designed to set other temperature levels. However, as the temperature range increases, the price rises.

The main types of thermostats

The main types of thermostats

Thermostats are a large group of devices designed to maintain the temperature at a certain constant level. There are several types of thermostats, classified according to the principle of operation, namely:

- passive. Such devices operate in isolated conditions.For protection from the environment, special materials are used;

- active. Automatically maintain the temperature at a given level;

- phase transition. The principle of operation of such devices is based on the property of the working substance to change its physical state, for example, from liquid to gaseous.

In everyday life, active thermostats are the most popular. They are called thermostats. Most of the existing temperature control devices are equipped with a suitable thermostat at the stage of their factory assembly. It is only necessary to carefully read the instructions for the device before using it.

There are also remote thermostats. They are made in the form of a separate block. The connection to the radiator is carried out in accordance with a certain technology, without observing the requirements of which it is impossible to count on the efficient, economical, safe and durable operation of the installation.

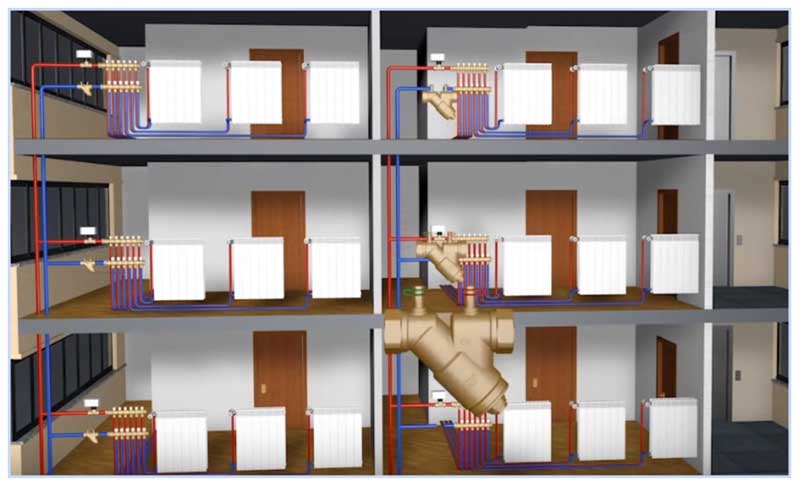

Balancing valve for heating system

Existing heating systems are conditionally divided into two types:

- Dynamic. They have conditionally constant or variable hydraulic characteristics, these include heating lines with two-way control valves. These systems are equipped with automatic balancing differential regulators.

- Static. They have constant hydraulic parameters, include lines with or without three-way control valves, the system is equipped with static manual balancing valves.

Rice. 7 Balancing valve in the line - installation diagram of automatic fittings

In a private house

A balance valve in a private house is installed on each radiator, the outlet pipes of each of them must have union nuts or another type of threaded connection. The use of automatic systems does not require adjustment - when using a two-valve design, the coolant supply to radiators installed at a great distance from the boiler is automatically increased.

This is due to the transfer of water to the actuators through the impulse tube at a lower pressure than the first batteries from the boiler. The use of another type of combined valves also does not require the calculation of heat transfer using special tables and measurements, the devices have built-in control elements, the movement of which occurs with the help of an electric drive.

If a hand balancer is used, it must be adjusted using measuring equipment.

Rice. 8 Automatic balancing valve in the heating system - connection diagram

To determine the volume of water supply to each radiator and, accordingly, balancing, an electronic contact thermometer is used, with which the temperature of all heating radiators is measured. The average feed volume per heater is determined by dividing the total value by the number of heating elements. The largest flow of hot water should flow to the farthest radiator, a smaller amount to the element closest to the boiler. When carrying out adjustment work with a manual mechanical device, proceed as follows:

- Open all the adjusting taps to the stop and turn on the water, the maximum surface temperature of the radiators is 70 - 80 degrees.

- The temperature of all batteries is measured with a contact thermometer and the readings are recorded.

- Since the most distant elements must be supplied with the maximum amount of coolant, they are not subject to further regulation. Each valve has a different number of revolutions and its own individual settings, so it is easiest to calculate the required number of revolutions using the simplest school rules based on the linear dependence of the radiator temperature on the volume of the passing heat carrier.

Rice. 9 Balancing fittings - installation examples

For example, if the operating temperature of the first radiator from the boiler is +80 C., and the last +70 C. with the same supply volumes of 0.5 cubic meters / h, on the first heater this indicator is reduced by a ratio of 80 to 70, the flow will go less, and the resulting volume will be 0.435 cubic meters / h. If all valves are set not to the maximum flow, but to set the average value, then the heaters located in the middle of the line can be taken as a guide and similarly reduce the throughput closer to the boiler and increase it at the farthest points.

In a multi-storey building or building

The installation of valves in a multi-storey building is carried out in the return line of each riser, with a large remoteness of the electric pump, the pressure in each of them should be approximately the same - in this case, the flow rate for each riser is considered equal.

For setting up in an apartment building with a large number of risers, it uses the data on the volume of water supplied by the electric pump, which is divided by the number of risers.The value obtained in cubic meters per hour (for the Danfoss LENO MSV-B valve) is set on the digital scale of the device by turning the handle.

The principle of operation of a thermostatic valve

To understand the principle of operation of the thermal head, it is proposed to study the diagram of the device shown in the section:

Inside the body of the element there is a bellows filled with a temperature-sensitive medium. It is of two types:

- liquid;

- gas.

Liquid bellows are easier to manufacture, but they lose to gas bellows in terms of speed, so the latter are very widespread. So, when the air temperature rises, the substance in the enclosed space expands, the bellows stretches and presses on the valve stem. That, in turn, moves down a special cone, which reduces the flow area of the valve. As a result, the coolant consumption is reduced. When the ambient air is cooled, everything happens in the reverse order, the amount of flowing water increases to a maximum, this is the principle of operation of the thermostat.

Conclusions and useful video on the topic

The device and purpose of the thermal head are discussed in detail in the following video:

Is it worth installing a thermal head on batteries? One of the users talks about this in detail in his video review:

Thermostatic valve and head in action:

The heating circuit with a thermal head is more convenient to use. This device increases the life of the equipment included in the heating system, increases the level of its fire safety.

Based on the usefulness of these relatively simple devices and their 20-year service life, their cost is low. To buy a product of really high quality, find out if there is a certificate for the selected device.

Do you use thermal heads for your heating equipment? If so, please share your personal experience of installation and operation, add photos, tell us if you are satisfied with these devices and how comfortable the microclimate in your house has become after installing thermal heads.

If you still have questions, then do not hesitate to ask them in the comments block - our experts and competent users will try to cover difficult points as clearly as possible.

Conclusion

Connecting the thermostat to the boiler on your own is a simple matter, there are a lot of materials on this topic on the Internet. But making it yourself from scratch is not so easy, in addition, you need a voltage and current meter to make adjustments. Buy a finished product or take on its manufacture yourself - the decision is up to you.

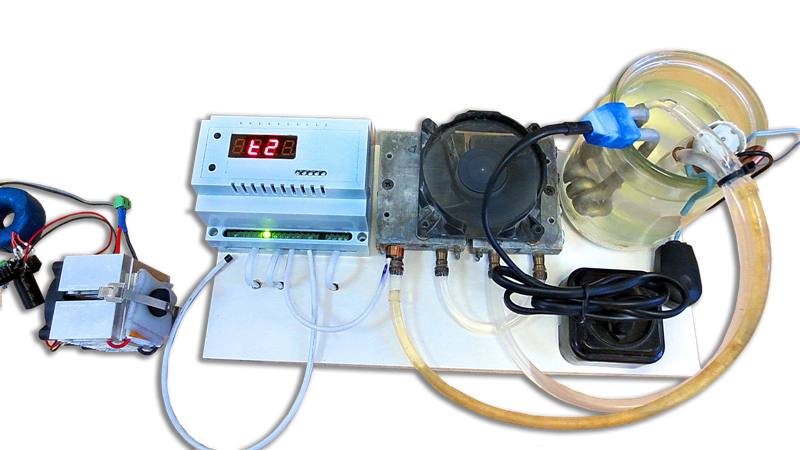

Introducing electronic development - homemade thermostat for electric heating. The temperature for the heating system is set automatically based on changes in the outside temperature. The thermostat does not need to manually enter and change readings to maintain the temperature in the heating system.

In the heating system, there are similar devices. For them, the ratio of the average daily temperature and the diameter of the heating riser is clearly spelled out. Based on these data, the temperature for the heating system is set. This heating system table was taken as a basis. Of course, some factors are unknown to me, the building may turn out to be, for example, not insulated. The heat loss of such a building will be large, heating may not be sufficient for normal space heating. The thermostat has the ability to make adjustments for tabular data.(More information can be read at this link).

I planned to show a video in the operation of the thermostat, with an eclectic boiler (25KV) connected to the heating system. But as it turned out, the building for which all this was done was not residential for a long time, during the check, almost the entire heating system fell into disrepair. When everything will be restored, it is not known, perhaps it will not be this year. Since in real conditions I cannot adjust the thermostat and observe the dynamics of changing temperature processes, both in heating and outdoors, I went the other way. For these purposes, he built a model of the heating system.

The role of an electric boiler is performed by a glass half-liter jar, the role of a heating element for water is a five-hundred-watt boiler. But with such a volume of water, this power was in abundance. Therefore, the boiler was connected through a diode, lowering the power of the heater.

Connected in series, two aluminum flow radiators take heat from the heating system, forming a kind of battery. With the help of a cooler, I create the dynamics of cooling the heating system, since the program in the thermostat monitors the rate of rise and fall of temperature in the heating system. On the return, there is a digital temperature sensor T1, based on the readings of which the set temperature in the heating system is maintained.

In order for the heating system to start working, it is necessary for the T2 (outdoor) sensor to record a decrease in temperature, below + 10C. To simulate changes in outdoor temperature, I designed a mini refrigerator on a peltier element.

It makes no sense to describe the work of the entire home-made installation, I filmed everything on video.

Some points about assembling an electronic device:

The electronics of the thermostat is located on two printed circuit boards, for viewing and printing you will need the SprintLaut program, version 6.0 or higher. The thermostat for heating is attached on DIN rail, thanks to the case of the Z101 series, but something does not prevent you from placing all the electronics in another case that is suitable in size, the main thing is that you are satisfied. The Z101 case does not have a window for the indicator, so you will have to mark and cut it yourself. The ratings of the radio components are indicated on the diagram, except for the terminal blocks. To connect the wires, I used the terminal blocks of the WJ950-9.5-02P series (9 pcs.), But they can be replaced with others, when choosing, take into account that the step between the legs matches, and the height of the terminal block does not prevent the case from closing. The thermostat uses a microcontroller that needs to be programmed, of course, I also provide the firmware in the public domain (it may have to be finalized during the work). When flashing the microcontroller, set the operation of the internal clock generator of the microcontroller to 8 MHz.

P.S. Of course, heating is a serious matter and most likely the device will have to be finalized, so it cannot yet be called a finished device. I will make all the changes that the thermostat will undergo in the future.