- Underfloor heating under tiles

- Materials and tools

- Material Quantity Calculation

- Manifold cabinet installation

- Filling the screed

- Tile selection

- How to prepare a tile for laying on a heat-insulated floor?

- Room layout

- Laying tiles

- Seam processing

- System pressure test

- Putting tiles on a warm floor

- Required tool

- Laying tiles on an electric floor

- Laying tiles on underfloor heating

- Device disadvantages

- The best heating mats

- ERGERTMAT EXTRA-150

- DEVI DEVIheat 150S (DSVF-150)

- Teplolux Mini MH200-1.4

- Electrolux EEM 2-150-0.5

- Warmstad WSM-300-2.0

- TEPLOCOM MND-5.0

- Comparison of technical characteristics, considered models of heating mats

- Thermomats

- Cable heating

- best electric tile underfloor heating

- Pros and cons of electric floors

- What types of electric underfloor heating are better

- Underfloor heating with cable

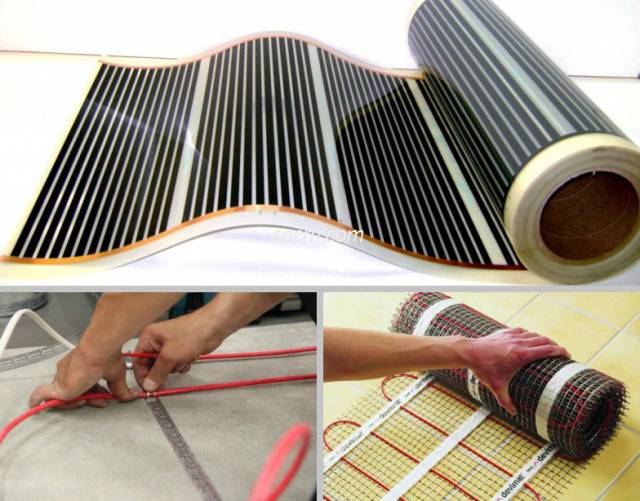

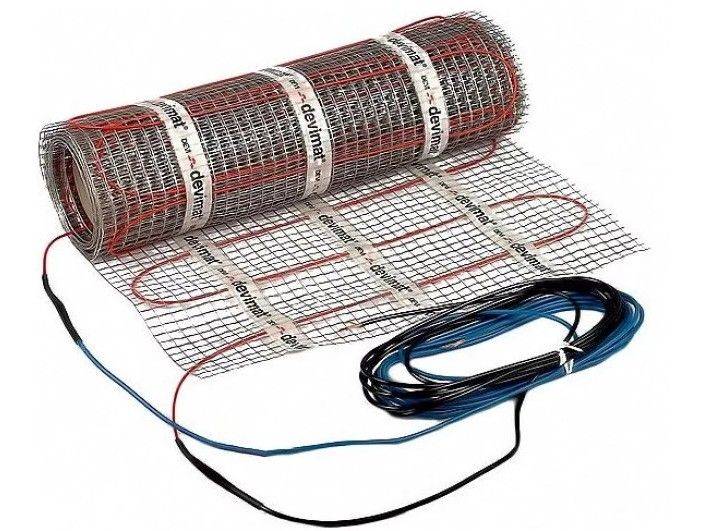

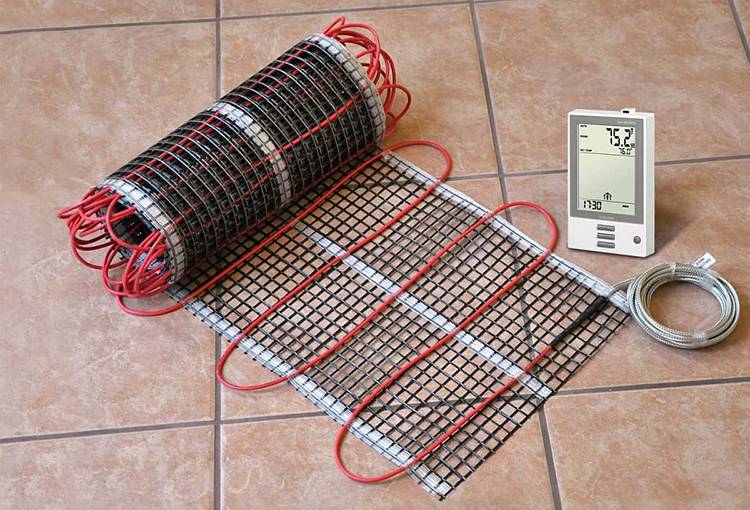

- Mesh heating mats

- Systems of rod infrared heaters “Unimat”

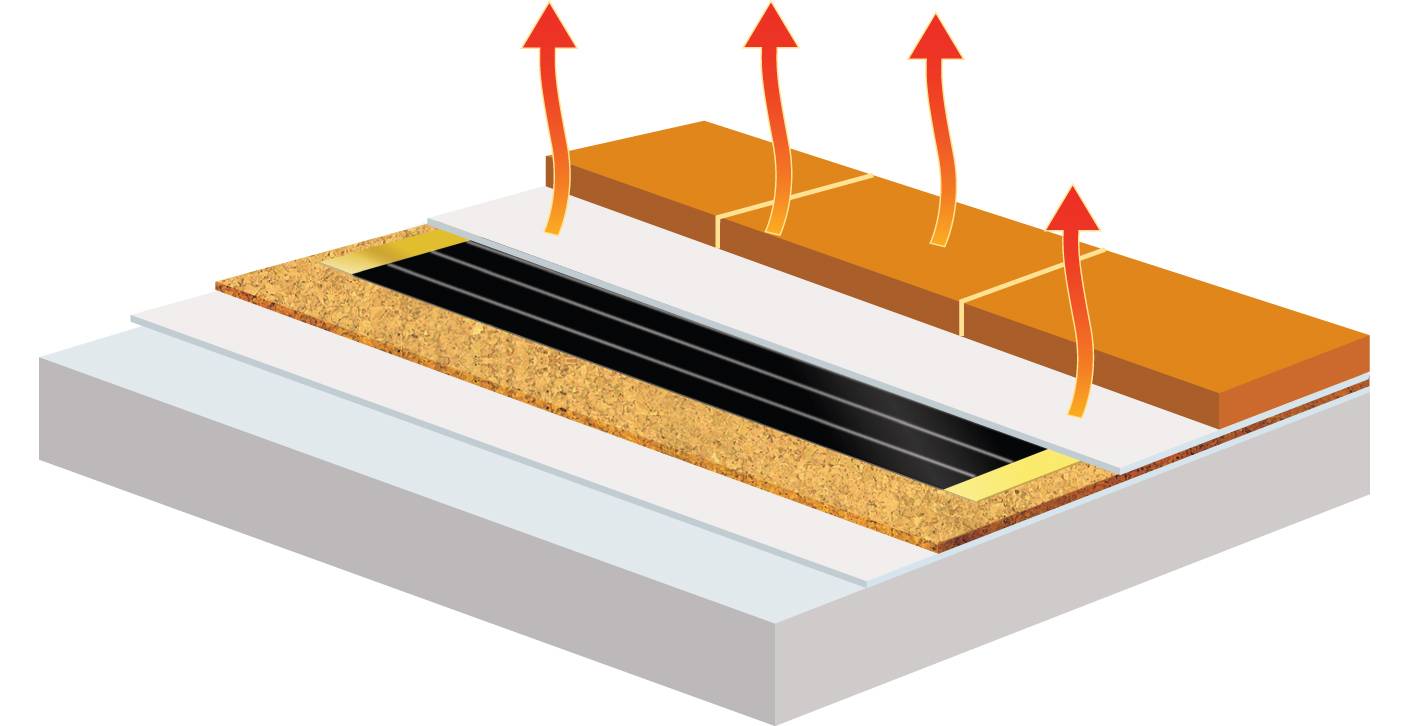

- Film Type Infrared Heaters

- The device in the steam room: pros and cons

- Laying tiles on electric underfloor heating

- Features of the water floor heating system for ceramic cladding

- Tips and tricks for choosing

- Choosing a warm floor for specific conditions

- What floor can be used if the room is supposed to fill the screed

- What to do if there is already a screed, and there is no way to increase the height of the floor

- What underfloor heating to use under laminate, linoleum and carpet

Underfloor heating under tiles

Usually, for the sake of greater efficiency, a warm floor is equipped only under a tile, because this material gives off heat very well due to its high density. And due to porosity, in addition, it also partially accumulates, which allows you to save some money on water heating.

Materials and tools

To build a warm floor on a ready-made base of concrete or reinforced concrete slabs, you will need a small set of tools: a plumbing kit, scissors for cutting metal-plastic, polypropylene, cross-linked polyethylene, a hacksaw or grinder for cutting copper.

You will also need measuring devices as part of a ruler and tape measure. Pencil for marking and marking.

From the materials you will need a film for waterproofing, a dense insulation with a lock, a mesh in cards, clamps for tying pipes, dowels for attaching the mesh. The main material is a pipe, the choice of which depends on the number of fittings and other parts.

Material Quantity Calculation

To determine the required number of pipes for underfloor heating, you will have to perform accurate measurements of the geometry of the room. Multiply each of the two adjacent sides by a step, which is usually 10-15 cm, and summarize the resulting values.

This will be the approximate length of the pipe, which is necessary for laying the underfloor heating system.

It is only important to take into account also the length of the pipe sections for supply to the manifold cabinet, which is usually located in the boiler room

Clamps are attached every 30-40 cm to prevent unwanted rise of the heating main. The grid is bought according to the square of the room.

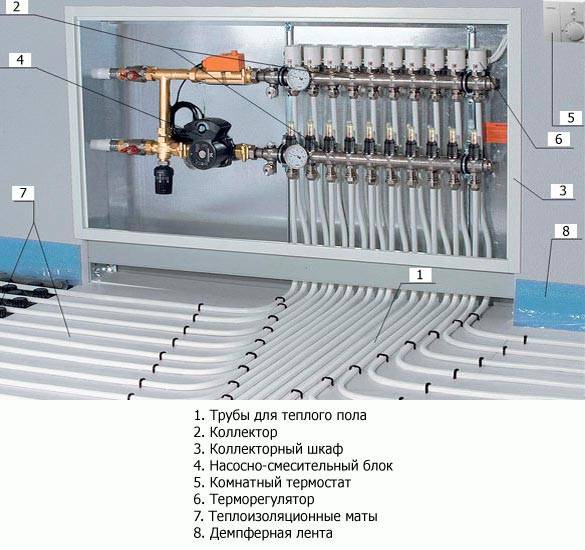

Manifold cabinet installation

Installation of the collector cabinet is carried out in the boiler room, closer to the heat source. Immediately from there it is output to all rooms by separate circuits. Immediately, a pump is mounted on the collector assembly, a safety valve for protection against overpressure. In order for the pump to turn not constantly, but to maintain the set temperature, a thermostat with an integrated timer is connected to it.

Filling the screed

After the pipe has been laid, proceed with the pouring of the screed. For this, a cement-sand mortar is prepared, which is poured indoors and leveled with a rule.

The recommended thickness of the screed should not exceed 5-6 cm.

Before pouring the solution, a damper tape must be glued around the perimeter of the room.

Tile selection

After the warm floor has been equipped, proceed to the choice of tiles. It can be any, depending on the preferences of the owner. Here the fantasy is limitless, but you should choose something suitable for the existing interior, if any.

How to prepare a tile for laying on a heat-insulated floor?

The tile does not require special preparation when laying it on a warm floor. Choose the right adhesive, which must be adapted to use on slippery surfaces.

The preparation consists in cutting, but it is better to do this after the whole tile has been laid in order to minimize losses due to incorrect cuts. The surface on which the tile will be laid must first be impregnated with a high penetration primer.

We also recommend that you see - How to cut tiles with a manual tile cutter

Room layout

To facilitate the process of marking the room for further laying tiles, you can use the laser level.This is the most convenient and technological option. But you can also use the old-fashioned way - use a lace with coloring powder.

Laying tiles

It is necessary to lay the tiles from the middle, marking the zero line with a perpendicular intersection. It will be convenient to move away from this place in different directions. Control each tile with a level at several points.

Seam processing

The next day, after the glue has dried, it is carefully removed from the seams with a spatula or other device. This is necessary for their decorative grouting.

System pressure test

After the installation of the heating system has been completed, and it is connected to the collector and the boiler, carry out pressure testing. The procedure consists in raising the pressure in it to the maximum limit and holding the system for some time. As a result, all fittings are sealed by internal pressure.

Putting tiles on a warm floor

Laying tiles on a warm floor with your own hands is within the power of any man who knows how to hold a hammer and a spatula in his hands. By and large, laying tiles on a warm floor is no different from ordinary tiling.

Required tool

For work we need:

- Rubber spatula;

- notched trowel;

- Rubber mallet;

- Level (water or laser);

- A set of crosses of the desired size;

- A skein of twine.

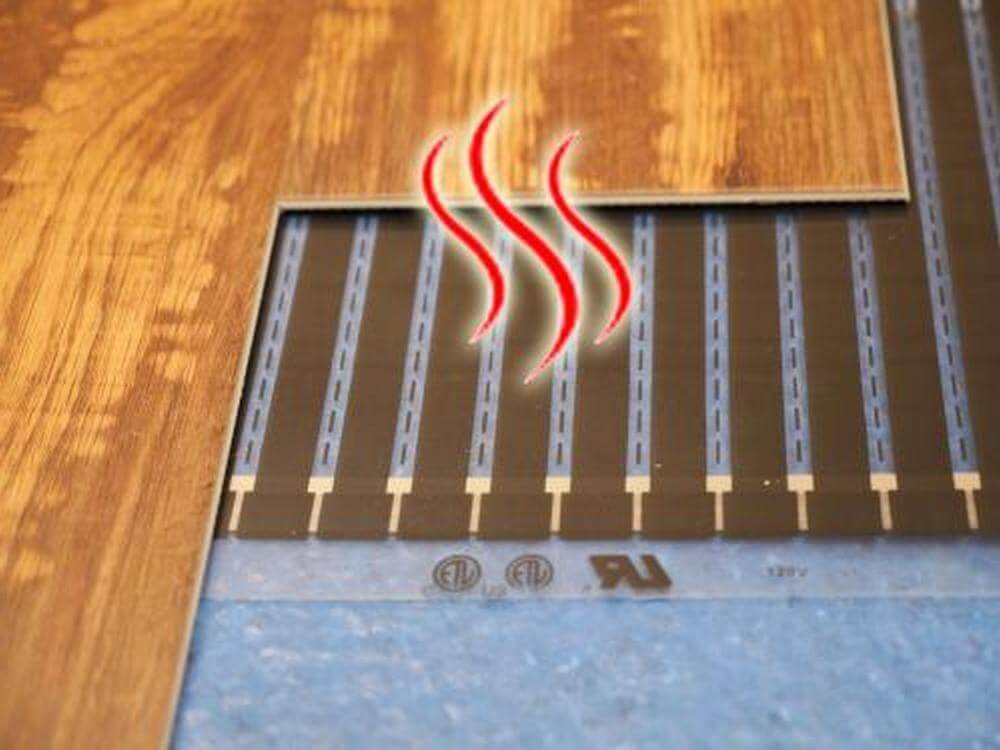

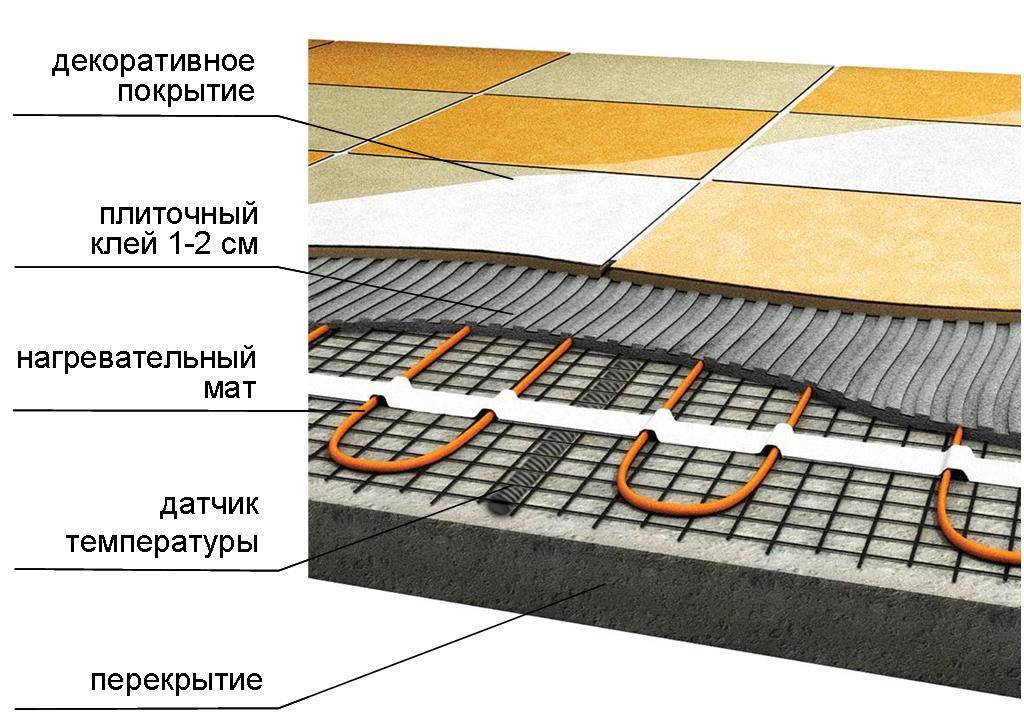

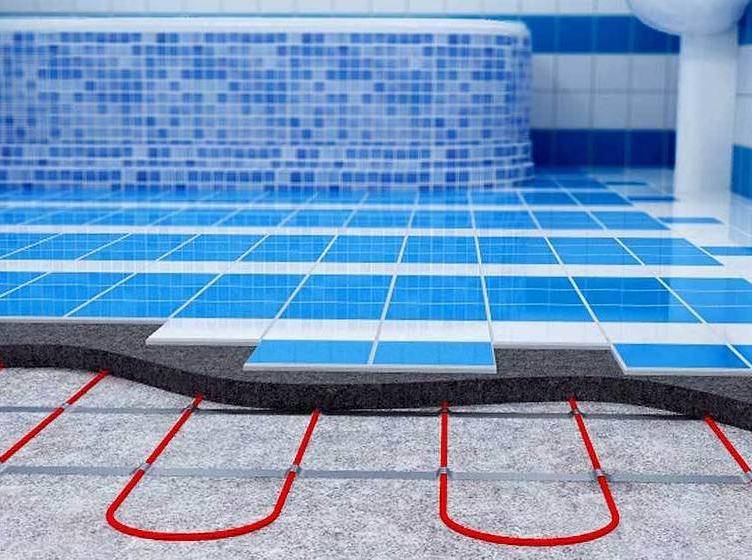

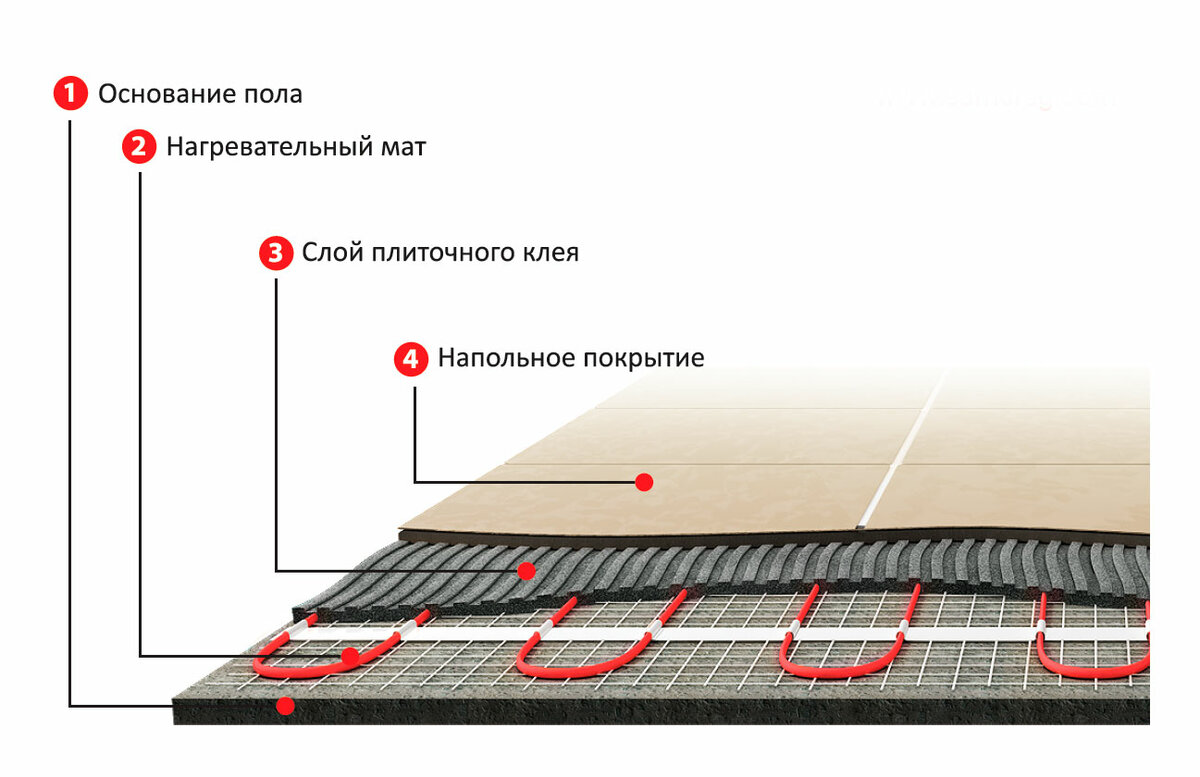

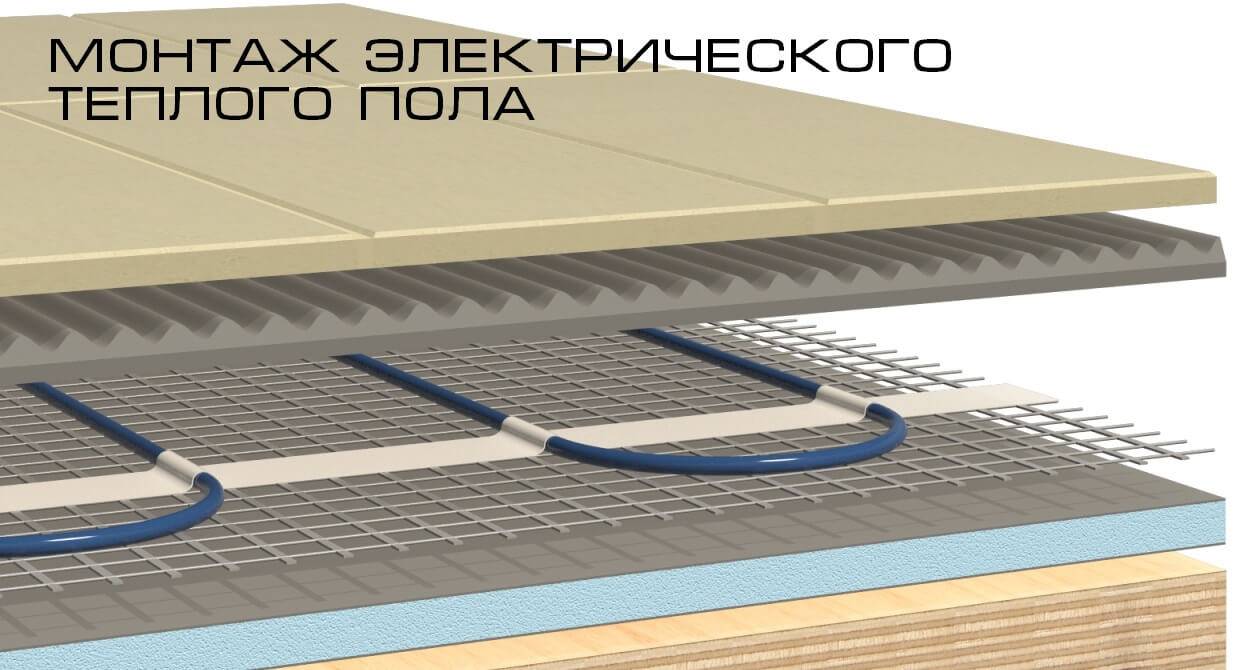

Laying tiles on an electric floor

It must be said right away that a warm floor can be made under ceramics based on a heating mat and a heating section.

In this case, the location of the materials will be as follows:

- Concrete screed;

- Thermal insulation (may not be);

- heating elements;

- Concrete screed (about 3-5 cm);

- tile adhesive;

- Ceramic tile.

Sample image of the floor

Advice! Many people are not satisfied with the second screed. However, it's better to do it. It perfectly protects the heating elements from mechanical damage due to uneven load.

I must say that it is best to level the floors with the first screed, and lay heating elements on already flat surface.

As already mentioned, there may not be a layer of insulation either. However, professionals recommend taking care of him. XPS boards can be used as insulation. In this case, it is better to take such material that has a density above 35 kg/ cubic meters.

A foil tape should be placed on top of such a heater. The seams between its individual parts are recommended to be glued with adhesive tape. The price for it is not particularly high, but the effectiveness is on the face.

Foil, the seams of which are taped

Next, a tape of underfloor heating or pipes is laid.

A layer of concrete is poured over them. It, like the first layer, is recommended to be laid using beacons. They will help to make the screed equal in height at all its points.

Foil underfloor heating

After the concrete screed dries sufficiently, which occurs approximately on the fifth day with a thickness of not more than 50 mm, you can proceed to the direct laying of ceramics.

The instruction is very simple. The adhesive is applied to the screed using a special notched trowel. The corner element is laid first. It is aligned with the walls and level.

Advice! Often the walls themselves are slightly uneven. In this case, the tiles must be laid on them, that is, also unevenly. Otherwise, it will seem that it is laid obliquely.

If there is such a situation as described above, then the ceramics are laid parallel to the longer wall, that is, along the room. On a perpendicular wall, a mark is made or a rail is nailed. Both the mark and the rail should be located strictly at right angles to the longer wall.

In this case, at the end of the small wall, there will be a gap between the tile and the wall, the size of which depends on the degree of unevenness of the walls. This gap can easily be hidden under the floor plinth. If the size of the gap is large, then pieces of tiles cut to size can be laid on it.

The photo shows how the gap increases already on the second element (leftmost row)

Between each two adjacent tiles it is recommended to put plastic crosses - seam formers. They will help to make all the seams the same thickness. A cross is placed on each corner.

It is worth noting that the glue is applied not only to the screed, but also to the ceramic itself. To make it lie flat, you need to use the level. It can be pressed by hand. If you need very minor changes, then you can knock on the surface of the tile with a trowel handle or a rubber mallet.

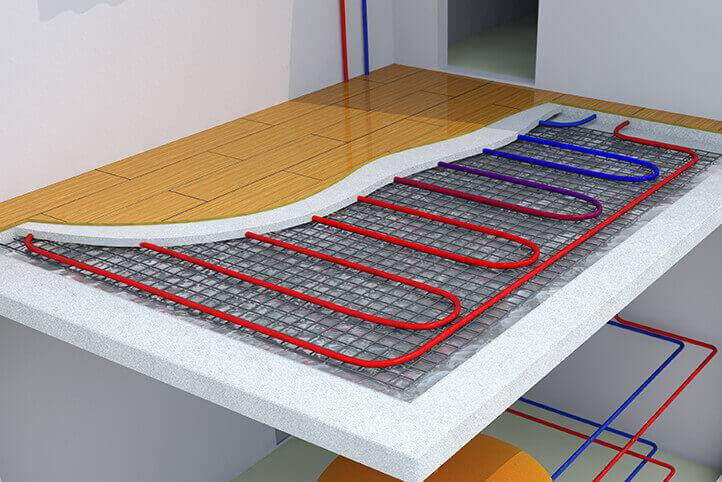

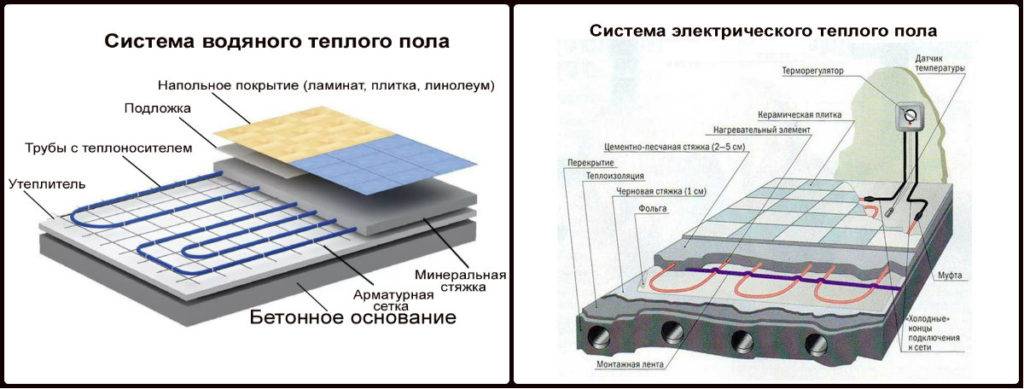

Laying tiles on underfloor heating

The sequence of work is as follows:

- Surface preparation, i.e. removal of the old floor and so on;

- Leveling concrete screed device;

- The device of a heat-insulating layer;

- Pipe installation. At the same time, all equipment connections and system checks are made immediately. If necessary, troubleshooting;

- Filling the entire floor with a layer of concrete (unlike the previous case, here the second screed is simply required, since the pipes are thick enough and it is simply unprofitable to hide them under a layer of adhesive);

- Laying ceramics or tiles.

I must say that the tiles are laid according to the same principles as in the previous case.

As you can see, the laying of tiles is carried out in the same way in all cases. The differences are only in the preparatory processes associated with the installation of the warmest floor. The video in this article will help you get visual subtleties in this matter!

Device disadvantages

In addition to the advantages, each material has its drawbacks. First of all, it is worth noting that the heat generated by the infrared floor under the tiles will not be spent on heating interior items, but on the flooring. In this case, the heating function will be assigned to convection. The heated floor material will give off heat to surrounding objects, and the walls will warm up due to the movement of warm air masses. The rate of warming up the room depends on the choice of floor surface. It is not recommended to install coverings in closed areas where furniture is located.

The material should be laid exclusively under open areas, so you should think about the layout and future location of the furniture in advance. You should also expect disconnection of the terminals that are used to connect and connect the heating mats. This will cause the device to stop functioning. It is also possible subsequent short circuit and spontaneous combustion of the infrared underfloor heating under the tile. To reduce adhesion performance, glass cloth can be used as an intermediate layer between the floor and the device.If there are no certain skills in working with such material, then it is better to shift everything onto the shoulders of a specialist. Wiring skills are required to connect the individual contacts.

The best heating mats

ERGERTMAT EXTRA-150

This heating mat differs from similar options in increased reliability, which is ensured by the use of a two-core heating cable, which, in turn, has high-temperature Teflon insulation and continuous shielding of heating and current-conducting cores.

The base in which the cable is fixed is self-adhesive and is a fiberglass mesh.

The kit comes with a corrugated tube with a plug for installing a temperature sensor.

The price depends on the coverage area. The cost for a mat measuring 0.5x1.0 m is 5410 rubles. Information about available sizes and cost can be found on the website of the official manufacturer of the product.

ERGERTMAT EXTRA-150

Advantages:

- External and internal high temperature insulation is the highest possible (fluoroplastic PTFE 270°C);

- The minimum thickness of the mat is 2.5 mm;

- Solid armored, braided screen provides protection against mechanical damage and tearing;

- The manufacturer gives a guarantee of 50 years.

Flaws:

High price.

DEVI DEVIheat 150S (DSVF-150)

The model is a synthetic mesh, on which a single-core cable is fixed with a certain step. The shielded cable has a cross section of 2.5 mm. Installation under a tile or a laminate in a layer of glue is recommended. It is used for heating passage rooms: bathrooms, hallways, balconies.

Cost: from 4570 rubles.

DEVI DEVIheat 150S (DSVF-150)

Advantages:

practically does not change the height of the floor.

Flaws:

- creates electromagnetic radiation;

- it is necessary to think over the location of the heating mat in advance, because the second end must be returned to the beginning of the installation to connect the thermostat.

Teplolux Mini MH200-1.4

Heating mat based on a single-core shielded cable. The ideal solution for laying under tiles. Made in Russia.

Cost: from 3110 rubles.

Teplolux Mini MH200-1.4

Advantages:

- installation on a various basis of a floor is possible;

- does not require grouting.

Flaws:

creates an electromagnetic field.

Electrolux EEM 2-150-0.5

Underfloor heating from Electrolux is a two-core cable fixed on a textile base. The thickness of the mat is 3.9 mm. Perfect for living rooms, bathroom. Warranty period of operation is 20 years. The brand is from Sweden.

Cost: from 1990 rubles.

Electrolux EEM 2-150-0.5

Advantages:

- can be used in wet areas;

- double insulation of cable cores withstands up to 4000 V breakdown voltage;

- electromagnetic radiation is several times lower than the minimum allowable standards;

- service life: 50 years.

Flaws:

not found.

Warmstad WSM-300-2.0

Heating mat 4 mm thick. It is based on a two-core shielded heating cable with one cold end, which greatly facilitates installation in comparison with single-core models. Suitable for laying under tiles, laminate and other flooring. Warranty period - 25 years. Manufacturer - Russia.

Cost: from 1750 rubles.

Warmstad WSM-300-2.0

Advantages:

- The optimum ratio of price and quality;

- can be used to heat any room.

Flaws:

not found.

TEPLOCOM MND-5.0

The heating mat consists of a thin two-core cable laid on a fiberglass mesh. The double shield not only protects against electric shock, but also allows electromagnetic radiation to propagate. Laying in a cement-sand screed 2 cm thick or in a layer of tile adhesive is acceptable. Warranty period of use: 16 years. Made in Russia.

Cost: from 4080 rubles.

TEPLOCOM MND-5.0

Advantages:

- recommended for use in rooms in which people are constantly;

- inexpensive.

Flaws:

the warranty period is shorter than other models.

Comparison of technical characteristics, considered models of heating mats

| Model | Size, cm | Power consumption, W | Specific power, W/sq.m | Heating area (max), sq.m | Cold cable length, m | Price for 1 sq.m, rub. |

|---|---|---|---|---|---|---|

| ERGERTMAT EXTRA-150 | Various, from 100x50 to 2400x50 | 75-1800, depending on the size | 150 | 12 | 3 | 6590 |

| DEVI DEVIheat 150S (DSVF-150) | 200x50 | 150 | 150 | 1 | 4 | 4576 |

| Teplolux Mini MH200-1.4 | 250x50 | 200 | 140 | 1,4 | 2 | 2494 |

| Electrolux EEM 2-150-0.5 | 100x50 | 82 | 150 | 0,5 | 2 | 3980 |

| Warmstad WSM-300-2.0 | 400x50 | 300 | 150 | 2 | 2 | 876 |

| TEPLOCOM MND-5.0 | 1000x50 | 874 | 160 | 5 | 2 | 816 |

Thermomats

Heating mats are a type of cable underfloor heating. The working element is also single-core or twin-core conductors, which are fixed on a fiberglass mesh with an adhesive layer. or without it.

The small thickness and the ability to glue the tiles directly onto the mat without a backing make this an optimal option.

Types of thermomats for underfloor heating

Types of thermomats for underfloor heating

The warm floor must correspond to a certain power:

- for dry rooms recommended - 100 W / sq. m.;

- for wet - 140 W / sq. m.;

- for unheated - 150-180W / sq. m.

Before buying, you need to decide only on the heated area.

Cable heating

The principle of cable-type heating is based on heating a shielded cable with a thickness of up to 8 mm. Heating occurs as a result of the resistance of the conductor when voltage is applied and electric current is passed.

Two types of cable are used: in single-core and two-core version. Installation of a single-core cable must necessarily combine the start and end points of the cable, i.e. it needs to be closed.

Recently, two-core type of cable is mainly used, for which this requirement does not apply. The heating cable is laid in parallel rows at a distance of 8-25 cm from each other under a cement screed, which is made 3 to 6 cm thick.

The tile is placed on top of the screed. The installation of a cable heating system is not difficult, except for pouring the screed, which takes a long time to dry - up to 28 days. But the cable system provides a quick warm-up of the surface after switching on.

The disadvantages are:

- Significant electricity bills.

- Increased additional load on the general energy system of the house.

- The presence of electromagnetic radiation.

- Limited load on the floor: do not put heavy objects in the form of furniture, equipment, etc.

best electric tile underfloor heating

If we talk about thermomats, then they can be laid on any rough surface, and it is not necessary to level it. After connecting the mats and connecting them to the network, tiles are laid on them using tile adhesive. This underfloor heating option is the best for laying under tiles.

Electric mat - the best option for laying under tiles

When laying film infrared floor, there are certain limitations.Some of its types cannot be mounted under the tile, so before buying, you must definitely ask the seller a question or study the instructions yourself. IR film should only be laid on a leveled surface and is rarely used under tiles.

It is recommended to lay the cable floor in a screed, which increases the efficiency of its work. First, they mount the cable and pour 4-7 cm of the screed, and after it dries, lay the tiles.

Ceramic tile has a number of advantages, the only drawback is that it is cold. Underfloor heating under electric tiles will help make your stay in the bathroom comfortable.

You can find the rules for installing underfloor heating under tiles here.

Pros and cons of electric floors

Electric underfloor heating allows you to quickly achieve uniform and highly efficient heating of the room. The heat from them rises from the floor covering immediately throughout the room where the heating system in question is laid. From the battery, heat flows still have to disperse from the window to the far corners. At the same time, a large part of the air heated by radiators will remain under the ceiling, where no one needs it.

Benefits of electric underfloor heating

The advantages of underfloor heating on electricity are as follows:

- Versatility - such systems are allowed to be laid in bedrooms, hallways, kitchens and bathrooms.

- Lack of even minimal risk of water leaks.

- Possibility of precise temperature control.

- Connection to a conventional electrical network without any tricks and installation of additional equipment such as boilers or boilers.

- The minimum period from the start of work to commissioning - the installation of a film electric floor in a small room up to 15 m2 takes a day at most.

- Uniform heating over the entire heated area above the heating system.

- The possibility of laying on top of almost any floor covering - tiles, linoleum, porcelain stoneware, laminate, etc.

- Ease of repair and high reliability - with proper installation, the risk of a short circuit is minimal.

- No need for complex maintenance and seasonal preparation on the eve of winter.

- Minimum load on the interfloor ceiling - electrical cables and mats weigh relatively little, and also do not require a heavy thick concrete screed.

With a large heating area, a warm floor powered by the mains consumes a lot of energy in kilowatts per hour. He needs about 100–200 W / m2. However, in the vast majority of cases, such a system is enough for the existing 220 V network. Connecting it to the power supply is even easier than connecting a water heater to the water supply or a dishwasher to the sewer.

Temperature distribution in the underfloor heating system

Among the disadvantages of electric floors for heating are:

- High power consumption.

- Possible problems associated with short circuits and electric shock.

It is not required to coordinate the connection of the electrical equipment in question, as is the case with a gas boiler, from public utilities and power engineers. The main thing is that the electrical network of the cottage or apartment should be designed for the connected load. If there is not enough free capacity, then another cable will have to be laid from the nearest transformer. And this can result in a lot of money.

What types of electric underfloor heating are better

Before you install electric floor heating under the tiles, you should understand its varieties and the characteristics of each of them. There are 4 types of underfloor heating with electric heating.

Underfloor heating with cable

There are such types of cable:

- single core. The heating circuit in such a system resembles an ordinary spiral, that is, the temperature of the conductor rises when an electric current passes through it. To run such a system, the cable must be looped, which requires a certain laying pattern. In addition, heating is carried out evenly over the entire area, which is not always advisable.

- two-wire. In such a heating cable for underfloor heating, there are two conductors, one of which plays the role of a heating element, and the second is designed to close the circuit through an end sleeve. It has the same drawbacks as the previous look, with the exception of simplifying styling.

- Two-core cables with self-regulating system. Between themselves, the cables are separated by a semiconductor matrix, which is heated by the passage of current. However, the higher the temperature of the matrix itself, the less current it can pass. Consequently, more intensive heating is carried out in the coldest places. This principle of self-regulation works in all parts of the chain.

Mesh heating mats

In fact, such a floor is an analogue of a two-core self-regulating cable, laid in loops and fixed on a fiberglass mesh.

Such a heated floor under a tile does not need an additional screed, since the tiles can be laid directly on top of it.Of course, this type of underfloor heating is quite expensive, but additional work can save both time and money.

Systems of rod infrared heaters “Unimat”

This heating system is very convenient for laying under tiles, because after its installation no additional screed is required. The circuit consists of two conductors connected by rod infrared heating elements.

Each of the rods is independent of the others and works on the principle of self-regulation, which allows you to significantly save energy when heating the floor. Despite the convenience, it is worth noting that such a system is quite expensive, much more than mesh mats.

Film Type Infrared Heaters

This electric underfloor heating system is the most economical in terms of energy costs, however, it is not very suitable for laying under ceramic tiles. The fact is that due to the continuous film, the tile will not be able to firmly grasp the base. And if you resort to fixing tiles on liquid clusters, you still cannot be sure of its durability and fastening strength.

Such heating systems are most preferred when it comes to floor coverings such as parquet, laminate or linoleum that do not need to be firmly attached to the base.

The device in the steam room: pros and cons

When determining whether a warm floor is needed in a steam room, you need to keep in mind that you will have to refuse a wooden covering with a drain. This is the main drawback, but there are much more positive aspects.

Information. If the steam room and the washing department in the bath are made separately, then the warm floor in the steam room can be built without much difficulty.Standard water protection methods are used.

The steam room needs to be heated much more intensively than a dressing room or a rest room. The temperature there can be 10 C higher. A warm floor, especially connected to a powerful gas boiler or sauna stove, will allow you to heat the bath well in less than an hour.

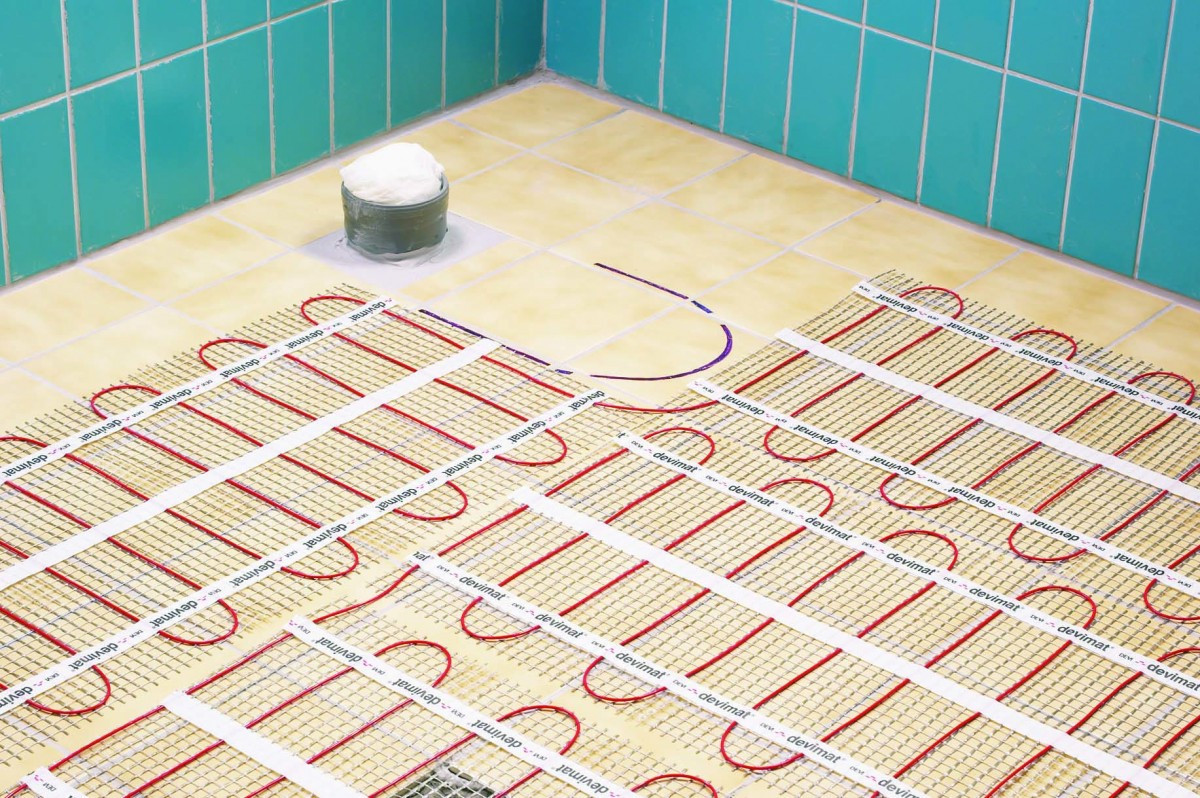

Laying tiles on electric underfloor heating

Laying the flooring is one of the final stages of repair work. Specifically, there is no clear framework in what sequence the construction process should be carried out, and whether the laying of the flooring will be the final stage or not. But, nevertheless, this moment is very important and responsible, especially if ceramic tiles act as a floor covering.

It is worth paying special attention if it is placed on an electric underfloor heating, a qualified specialist is required to perform this work. Laying tiles on cable electric underfloor heating includes a number of important steps: 1) First, you need to use a special tile adhesive for underfloor heating, which would withstand temperatures of at least 50-60 degrees. Since the first time the heating element is turned on, the temperature on the thermostat is set to the maximum, and it can be 40-50 degrees. You need to be sure that the glue will withstand it.

You need to be sure that the glue will withstand it.

2) Secondly, the floor sensor from the thermostat must be in the corrugation. A canvas is cut under the corrugation, which is smeared with glue in such a way that the level of the heating cable is the same everywhere.

3) Thirdly, if a heating mat is used as a warm floor, many experts recommend pre-tightening it with a thin layer of tile adhesive. This is done so that during the tiling process, the heating cable is not accidentally damaged, otherwise the entire floor will completely fail. And only after complete drying, you can proceed to the next stage of work.

4) Before you start working with tiles, you should calculate where to start. If there is a drawing, then it is necessary to build on it (it should be in the central part of the room), if the tile passes from one room to another, then the transition and trimming of the tile in the area of the doorway should not be visible. It is recommended to calculate in such a way that there is as little trimming as possible, and it is located in the most inconspicuous places. 5) Glue with a comb of 7-8 mm is applied to the work surface, as well as to the tile. Its inner side is pre-wiped with a damp cloth, if necessary, in order to remove dust (otherwise, it is likely that the tile can quickly move away due to lack of proper adhesion). In this case, you always need to monitor the level of the floor, removing excess glue if necessary, and also use crosses to maintain the same distance between the tiles, which in turn have a different size.

6) After the glue has dried, you can start sealing the seams. For this, special putties are used, of different colors.If this is a production facility and beauty is not so important, or there is a financial constraint, the same tile adhesive can be used as a putty. All seams are preliminarily cleaned of dust with a knife, if necessary, an industrial vacuum cleaner is used. The adhesive is applied using a special flexible (rubber) spatula. After 10-20 minutes (depending on the air temperature in the room), all excess is wiped off with a damp sponge (rag). After that, walking on the tiles is prohibited until the joints are completely dry, at least a couple of hours.

Another important point is that under no circumstances should underfloor heating be turned on until the tile adhesive has completely dried. If, when laying the tiles, the rough screed was completely dry, then the underfloor heating system can be put into operation no earlier than after 14-16 days. If before this the screed was insulated and poured, then the drying time increases to a month. When you turn on the underfloor heating earlier than the specified dates, in most cases the tile may move away from the base.

«Do it yourself - do it yourself "- a site of interesting homemade products made from improvised materials and items at home. Step-by-step master classes with photos and descriptions, technologies, examples of work - everything a real master or just a craftsman needs for needlework. Crafts of any complexity, a large selection of directions and ideas for creativity.

Features of the water floor heating system for ceramic cladding

To figure out how to properly make a warm floor under a tile, you need to study the principle of its operation and know nuances for the installation of the structure.

Features of the operation of a water-heated floor are the circulation of heated water through pipes made of metal-plastic or brass, laid under the floor finish. The system is powered by central or autonomous heating. The cost, installation and energy consumption of this type of floor heating is much cheaper when compared with electrical counterparts.

But there is an unpleasant nuance - in high-rise buildings built in the sixties, the installation of water-heated floors is not possible. Since their overlap may not withstand the additional load. In addition, get planning permission heating system in high-rise buildings is quite difficult.

Next, a metallized reflective screen is lined. This is a composite material made of polypropylene fiber and a metallized film, which has the properties of reflecting thermal radiation and waterproofing. The film must be tightly fixed on the damper tape with adhesive tape.

In the process of laying a water-heated floor, all pipes are connected to a distribution manifold

In the process of laying a water-heated floor, all pipes are connected to a distribution manifold

At the next stage, pipes are laid. It is necessary to use special tubes mounted to the grid. In this case, the distance from the walls should be at least ten centimeters.

In the process of laying pipes, you should pay attention to the fact that they are placed strictly along the guides available on a special grid. After the adjustment relay and thermometer are mounted

At the end of the installation process, the structure is covered with a layer of cement screed.

Tips and tricks for choosing

The underfloor heating system induces a different microclimate than radiators.For this reason, it is difficult to speak objectively about the usefulness of this system, it was simply not considered in SNiPs before.

If you still decide to install a warm floor, you can focus on our article:

- Heating on water looks the cheapest in material terms.

- On the other hand, the cost of installation can be quite high, since plumbing is responsible and expensive.

- At the same time, electric underfloor heating is much more expensive, but installation is very simple, and some will not require it as such (if you lay them on top of the tiles).

- Weigh everything and decide what exactly you want to receive.

- Electric floors seem to be the most logical since they can be an addition to the main heating.

- It is better to connect water heated floors if there is an AGV.

- Finally, if you have a large living area and few people, then it makes sense to purchase electric heating that can be moved, that is, one that is mounted on top of the tiles.

Choosing a warm floor for specific conditions

To finally decide for yourself which underfloor heating is better to choose, you must first of all carefully examine the base on which these floors will be laid. And then you can choose at random, and then learn with chagrin that this heating system does not fit the existing base or conditions at all. Let's take a look at some of the options ahead of time.

What floor can be used if the room is supposed to fill the screed

If you have a new apartment or house or you are doing a major overhaul, then the floor as such is not there yet. In any case, in most cases this is the case.In a private house with an autonomous heating system, you can arrange a water heated floor. In the apartment, in this case, a heating cable system is installed. After the installation of a particular system, the entire base is poured with a cement-sand screed.

What to do if there is already a screed, and there is no way to increase the height of the floor

Here it is best to use the system of mini-mats. Such a “rug” is rolled out on the old base with heating cables hidden inside. By quickly connecting it, you can start laying decorative tiling. Tiles are laid directly on mini mats.

Applying adhesive to ceramic tile mats.

It is possible in this case to mount and infrared heat-insulated floors. Having laid them on the base, you can immediately start laying the material with which it is supposed to finish the floor. But you should not mount an infrared floor under the tile, as the glue will not stick to it. However, if there is a strong desire to do this, then use only the dry method and put sheets of drywall or glass-magnesium on the carbon film, and then tiles.

What underfloor heating to use under laminate, linoleum and carpet

If you are tormented by the question of which underfloor heating is better - cable or infraredIf you are going to lay one of these coatings, but it is not supposed to fill the screed, then give preference to the second one. For carpet and laminate with linoleum, a thin carbon film is the best option. Its thickness is only 0.3 millimeters, and only it will perfectly warm up any of these materials.

When underfloor heating is installed, it is usually decided immediately whether the house will have some other source of heating besides these floors.As a rule, the main heating system is already in place (or planned), and underfloor heating is used to create additional comfort. However, more and more often underfloor heating is chosen as the main heating system. Therefore, here you need to figure out which floor heating system to use in a particular case.

#one. If a warm floor is just an addition to the main heating system.

Here you can afford almost any of the systems listed above. Naturally, given the fact that different types of underfloor heating require the presence or absence of a screed, as well as a certain floor covering. Well, let's not forget that the water system is only suitable for underfloor heating in a large private house with an autonomous heating system. Otherwise, the choice is unlimited.

#2. If a warm floor is the only source of heat in a frosty winter.

In this case, you need to remember an important thing: the heated floor surface area should be no less than seven tenths of the total area. Only then will the house be warm. When mounting the heating cable section, it is necessary to lay adjacent turns of the cable as close to each other as possible. So we will increase the specific power (calculated per square meter), respectively, and heat transfer.

It should be noted that the heating mats, which are rigidly assembled, initially do not have very high power. Nothing can be done about it, so they are not suitable as the main source of heat. And when deciding which warm floor to choose as the main one, it’s better not to even look in the direction of mini mats. But infrared film, a water floor or cables will do just fine.At the same time, in a private house with an autonomous heating system, it is best to stop on water-heated floors. Their installation is carried out during the installation of the entire heating system of the house, after which the screed is poured and further finishing is carried out.