- Installation of a warm water floor under linoleum

- Types of substrates

- Multilayer insulation

- How to make a floor finish

- Calculation of material consumption during laying

- Which IR warm floor is preferable under linoleum

- Concrete floor installation

- Features of laying linoleum

- Installation of electric floor heating

- Types of substrate for linoleum on a concrete floor: which ones are laid, which ones are better

- cork material

- jute base

- linen lining

- Combined variant

- PE foam material

- Electric floor heating device

- How to lay the substrate: step by step instructions

- Training

- Waterproofing

- Substrate

- Fixation

- Laying linoleum

- Recommendations and steps for laying linoleum on a concrete floor

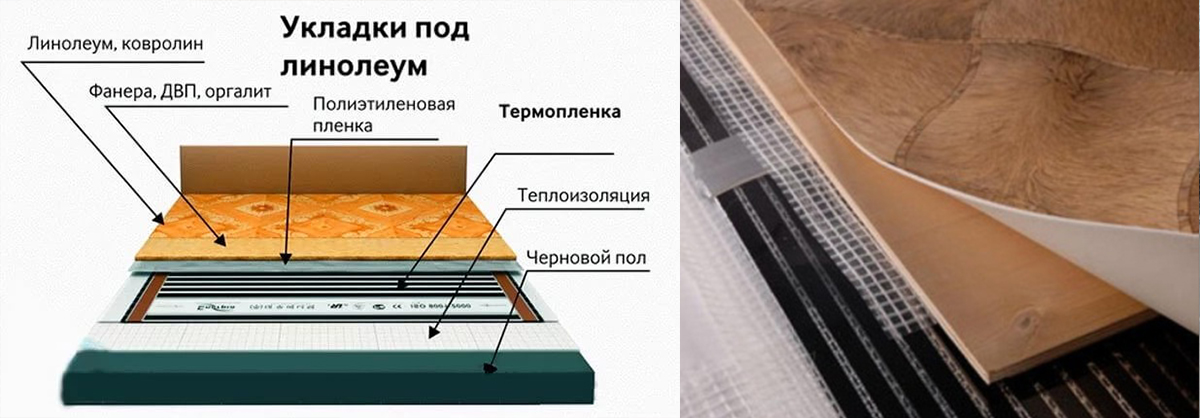

Installation of a warm water floor under linoleum

To install a warm floor, you need to purchase the following materials:

- polyethylene film, the thickness of which is 150 microns;

- polystyrene plate with a thickness of more than 20 mm (with "lugs");

- reinforcing mesh;

- damper tape;

- input and output manifolds;

- pipe for underfloor heating, made of cross-linked polyethylene.

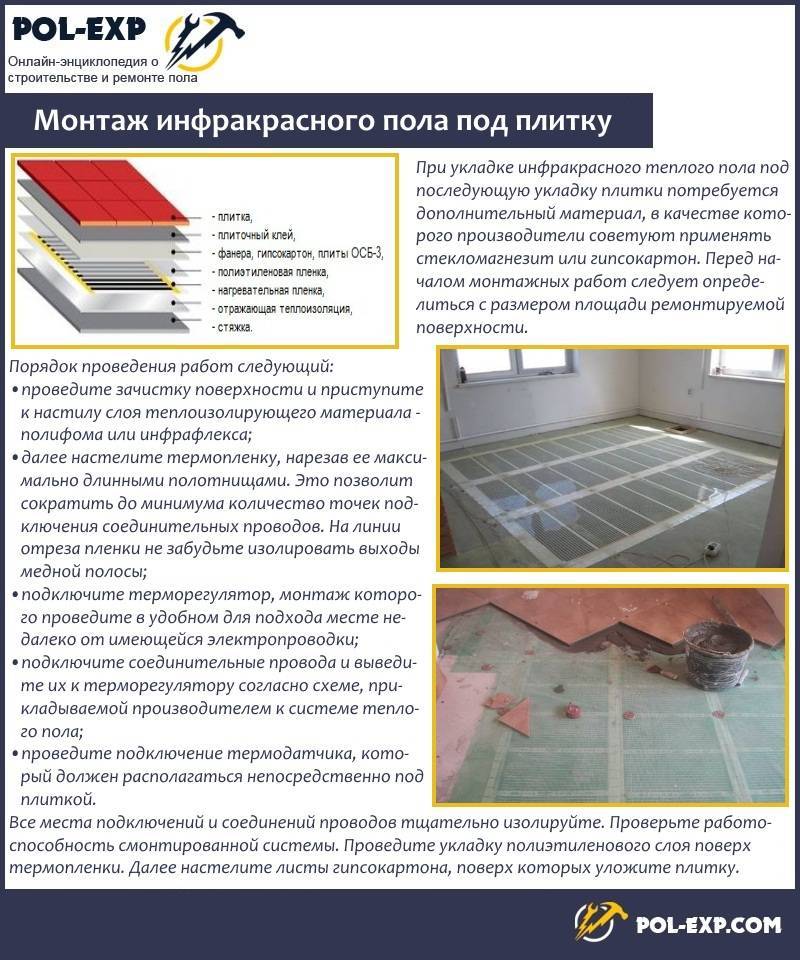

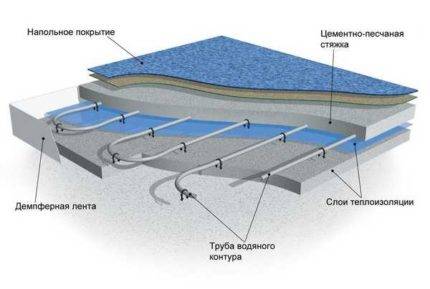

A schematic arrangement of a warm water floor clearly shows that the pipe is inside a concrete screed, so each circuit consists of a whole segment

The installation of a warm water floor begins with the provision of waterproofing and thermal insulation of the concrete base, which must be even and clean. A plastic film is laid on a thoroughly leveled screed.

Adjacent canvases are fastened with construction tape. On the film, polystyrene plates are laid, which have special elevations, which are called “bosses”.

Bosses are needed to quickly fix the flexible floor heating pipe in the desired configuration.

The location of a polyethylene or metal-plastic pipe for a water-heated floor on special mats with bosses. Additionally, the system is fixed with a reinforcing mesh

The pipe laying step is from 10 to 30 cm. choice of laying step affects the amount of heat loss in a room equipped with underfloor heating. On average, it takes about 5 linear meters of a polyethylene pipe per square meter of a heated room.

On top of the polystyrene slabs with a pipe fixed between the bosses, a reinforcing mesh is laid, which is needed to strengthen the concrete screed, in which the warm water floor system is hidden.

A damper tape is laid along the entire perimeter of the room along the walls, which can compensate for the thermal expansion of the cement screed. Then one end of the pipe is connected to the inlet manifold, and the other to the outlet. The mixing unit is fixed in a manifold cabinet screwed to the wall of the room.

On this, the installation of a pipe for a warm floor is considered completed. The screed is poured. Linoleum is not laid on the concrete screed itself, but on plywood sheets. Other floor coverings can be placed without the use of plywood in accordance with the requirements of their installation technology.

The advantages of installing a floor heating system in a house are clearly shown in the diagram. Heated floors under linoleum are used as additional heating to the existing heating system

You can use a water heated floor as additional heating to the radiator system. If desired, a warm floor can completely replace it, acting as an independent heat supplier in the house.

Water floor heating operates on any source of energy: gas, liquid fuel, electricity. It does not require heating the coolant in the system to high temperatures. At the inlet to the circuit, the temperature of the coolant is 30-40 degrees.

During the operation of the water heating system, electromagnetic radiation does not occur, the impact of which is harmful to human health. Since there are no detachable connections in the floor, the probability of leakage is zero.

The service life of the system is 50 years or more.

Types of substrates

To perform floor insulation under linoleum, you first need to choose a substrate. There are several types of such material. Here are the most popular:

- cork;

- jute;

- linen.

Let's consider each separately.

Cork underlay is made from pressed, crushed cork oak bark. Such insulation is produced in rolls. The advantages of this material include:

- environmental friendliness - made from natural cork;

- pleasant sensations when walking on this surface, as it is quite soft.

It is precisely because of the last given positive quality that a problem may arise: if a heavy object is placed on the coating, then after a while dents may form on it. To avoid this, you should choose the most rigid cork substrate.

The linen backing is 100% pure natural linen. It is made by the method of double punching with a needle, and then impregnated with means against fire and the formation of fungus. Linen substrate is a good material for thermal insulation under linoleum.

Multilayer insulation

Warm

floor - universal system with heating. It will allow you to move comfortably

the room is barefoot and will be an addition to the heating.

underfloor heating comparison

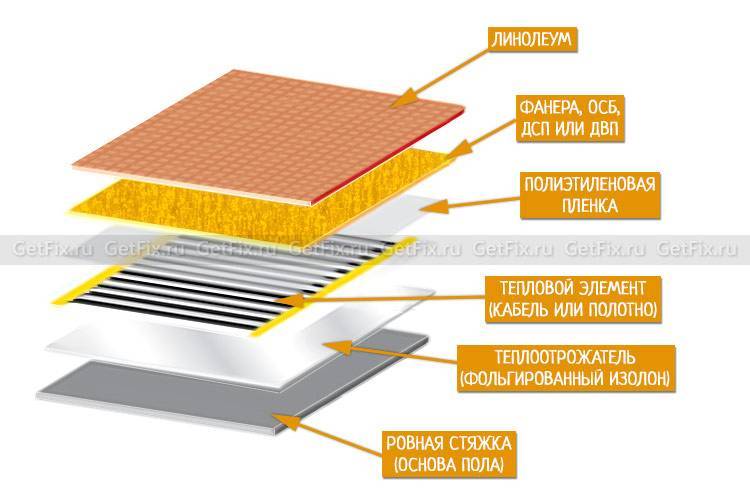

For laying under linoleum use the following types:

- Infrared. Produced in the form of an elastic coating-film. It features low power consumption, ease of installation and efficiency. To control the heating temperature, the system has a thermostat.

- Electric. Another option for underfloor heating, which is powered by the mains. It works effectively, but it’s not quite suitable for laying under linoleum, its design consists of a wire and fixation rails, and such a base cannot be called even.

- Water. It is a system of tubes through which water heated in the boiler moves. A good option, but only suitable for individual heating systems.

Mount underfloor heating on a concrete base

recommended only 3 weeks after applying the screed compositions.

How to make a floor finish

After the successful completion of testing, proceed to the finishing of the heated floor. The thermal film must have a moisture-proof coating. For this purpose, you can use either expensive modern waterproofing or a cheap ordinary polyethylene film. And in one, and in another case, the effect will be the same, and the savings in money are big.

The film should be spread with an overlap of approximately 10 centimeters, and the joints should be glued with adhesive tape.The work must be done carefully, avoiding gaps or poorly glued areas.

Since linoleum is a flexible material, it is not laid directly on the thermal film. The heating layer must be covered with plywood, the sheets of which are about one centimeter thick. They are attached to the base with small nails.

They should be hammered in carefully so that the conductive elements are not damaged.

The locations of the intended location of the nails are carefully checked before hammering. They are placed around the perimeter of the sheets, which, before installation, experts advise to dry in a warm, ventilated room. As a result, it is possible to prevent the formation of cracks during the operation of the floor covering.

Calculation of material consumption during laying

In order to calculate the cost of laying linoleum on a concrete floor, you need to sum up the cost:

- materials for leveling the concrete floor;

- insulating materials and elements of their fixation;

- linoleum;

- fixative for linoleum (glue, mounting tape);

- skirting boards.

The calculation of materials for leveling the floor must be made depending on the condition of the concrete base. The consumption of cement mixture and primer is based on the quadrature of the room. it should be remembered that the screed, if necessary, must be at least 3 cm in height. For priming the surface, one finishing layer of primer is sufficient, the materials for which can also be calculated based on the quadrature of the room.

The calculation of insulation materials is also made on the basis of the square of the room. Sheet and roll materials should be laid so that there is a minimum number of joints, especially for chipboard and plywood, which are presented in a number of standard sizes.

Particular attention should be paid to places where the material will need to be cut or cut to the shape of a protrusion or recess, while it is highly undesirable to use small fragments of material from waste - it is better to cut an unnecessary fragment from the main web. Joints are glued with masking tape

When calculating linoleum, it is necessary to take into account the standard roll width - it is optimal if the roll width is greater than the width of the room, since by minimizing the number of joints, the service life of the material increases and visually the coating looks uniform.

If joints cannot be avoided, then it is better to place the canvas so that the length of the joint is minimal (parallel to the short wall).

Great care should also be taken in the calculation of linoleum, which involves combining the pattern at the junction - the length of the cut of the coating in this case should be approximately 1.5 m longer than the length of the laying area. It should also be remembered that ornamented linoleum is laid exclusively in the longitudinal direction.

The calculation of the retainer for linoleum depends on its type:

- mounting / masking tape - cheaper, more economical, but less durable - it is easier to dismantle it if necessary. When calculating, you should take into account the length of the joints and the perimeter of the room for gluing the coating under the walls;

- linoleum glue or adhesive-like mastics are applied to the entire area of \u200b\u200bthe base of the floor, which is covered with linoleum, and are calculated based on the quadrature. When working with adhesive and mastic fixatives, you should be very careful and work in stages, carefully leveling the surface of the coating to avoid wrinkles.

When calculating the length and width of linoleum, it is also necessary to take into account a margin of 10 cm for trimming as it is laid - in this case, even some curvature of the walls can be leveled due to a small supply of material.

For example, it is necessary to level the concrete floor and lay linoleum in a room with walls of 4 and 5 meters:

- Screed mortar = 20 m2 (room area) * 0.03 m (screed height) = 0.6 m3 or 600 l.

- Self-levelling compound = 20 m2 (room area) * 0.02 m (pouring height) = 0.4 m3 or 300 l.

- Insulation materials:

- Sheet = 20 m2 (area) + 10-15%.

- Roll = 20 m2 (area) + 10-15% margin on the long side of the roll based on its width.

- Waterproofing film = 20 m2 (area) + overlapping allowances of 20 cm on the sides.

- Linoleum:

- Without the need to join the pattern, taking into account the 10 cm clearance around the perimeter = 5.1 m * 4.1 m = 20.91 m2.

- Taking into account the need to match the pattern and 10 cm of clearance around the perimeter = 26.65 m2.

- Fasteners:

- On an adhesive or mastic base - an average of 12-15 kg (more accurately, you can calculate based on the manufacturer's characteristics, which are indicated on the package).

- Mounting tape - 25-30 m.

- Consumables (average quantity, which to a large extent depends on the condition of the subfloor):

- Putty - 400-500 g.

- Rags - 100-200 g.

- Epoxy resin or cement mortar - 1-1.5 liters.

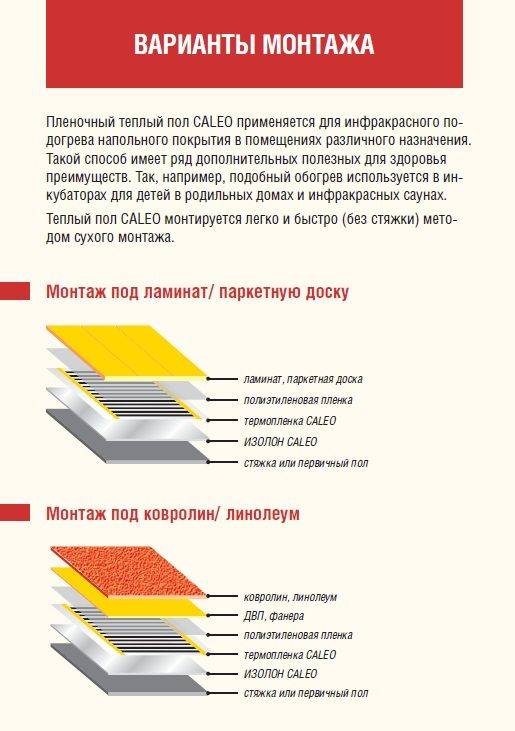

Which IR warm floor is preferable under linoleum

Manufacturers offer two type of IR systems heating. Each has its own advantages and disadvantages and when choosing a system should be done, focusing on your individual needs.

| Film floor | Rod floor |

|---|---|

| Safety and reliability of operation | Safety and reliability of operation |

| Both types work on the use of IR radiation, the warranty period is 15 years. | Both types work on the use of IR radiation, the warranty period is 15 years. |

| 1. Does not require pre-laying work, it is mounted on a flat concrete surface using the “dry installation” method. 2. Gets hot when placed on heated furniture floor. | 1. Laying in a screed of concrete or tile mixture. 2. Does not overheat when working areas are closed with furniture and household appliances. |

| Versatility | Versatility |

| Can be used to insulate floors, walls, ceilings and other flat surfaces | It is used only for floor insulation, including in rooms with high humidity. |

| energy saving | energy saving |

| Increased energy savings compared to alternative heating systems | Increased energy savings compared to alternative heating systems |

| Price | Price |

| A budget option. | High price. |

| thermoregulation | thermoregulation |

| A thermostat is required. | Independent lowering of temperature in heated areas of housing and lowering near cold zones - window and door openings. |

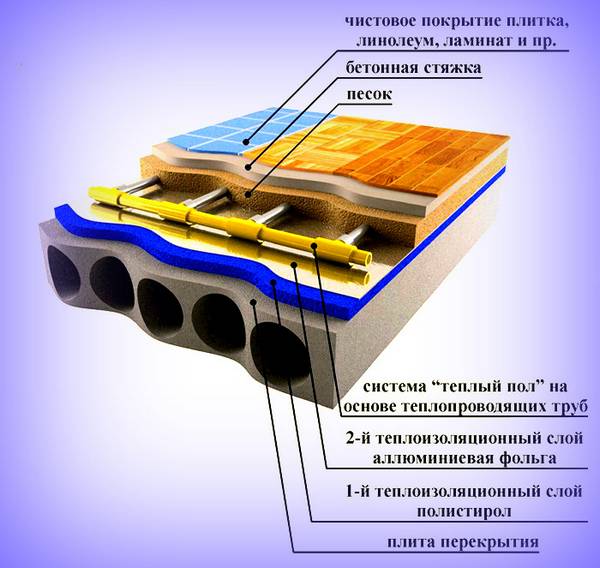

Concrete floor installation

You can immediately solve the problems associated with installing the "Warm Floor" system on a concrete base, and you can choose the appropriate type of linoleum when the subfloor already exists.If instead of it there is only an old rotten wooden base or just soil, you need to deal with the construction of the concrete floor itself.

The process consists of several stages:

- dismantling the old floor, if any;

- base alignment;

- pillow devices;

- arrangement of an insulating layer;

- preparing and pouring concrete.

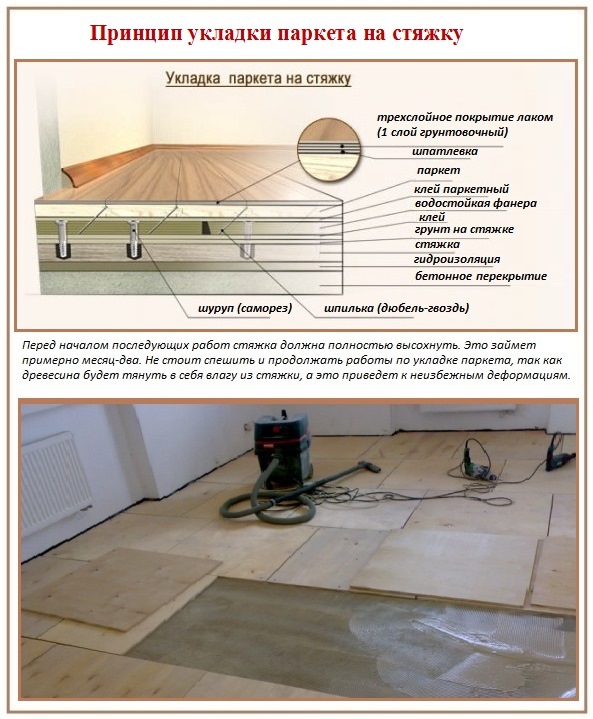

Soil leveling is carried out using a shovel. Then they begin to create a pillow. To do this, crushed stone or small pieces of brick, broken slate are poured to a height of about 50 mm. All this is slightly rammed.

The perimeter of the room is covered with sheet foam having a thickness of 20 - 50 mm. It will serve as a formwork and at the same time balance the thermal expansion of the concrete base. Pure sand is poured onto this layer - 10 centimeters.

This is followed by laying the second type of insulation. Most of all, extruded polystyrene foam is suitable for this, preferably the Penoplex brand, which is produced in the form of rigid plates with a thickness of at least 50 mm.

Expanded polystyrene or foam plastic is resistant to temperature changes, environmentally friendly, tolerates compressive loads well, moisture resistant, durable

The manufacturer has provided a lock connection on the sheets, so there are no gaps left when laying them. When installing, you need to monitor the horizontal level with a level. Waterproofing is not needed here, because. The material is extremely resistant to moisture.

The next step is the preparation of the solution. The optimal ratio of components is 1 part of cement, twice as much sand and three times as much screening. As a result, the solution should not be fluid, but not excessively thick.

In order not to heavily load the floor, light fillers and levelers are introduced into the concrete solution.Before pouring the solution, beacons are set up against the walls, a cord is pulled between them. Based on these marks, intermediate marker rails are placed.

A cement base of a traditional composition with a height of 10 mm weighs about 20 kg, so it can only be used when a warm floor is arranged on the ground floor of the house or when there is a very strong floor under it

The surface is moistened and the solution is spread on it between the beacons and leveled with the rule. As it sets, the surface is leveled. At the end, a building level is applied to check the horizontal position. After the marks are removed, the resulting voids are filled with a solution and everything is left until it dries completely.

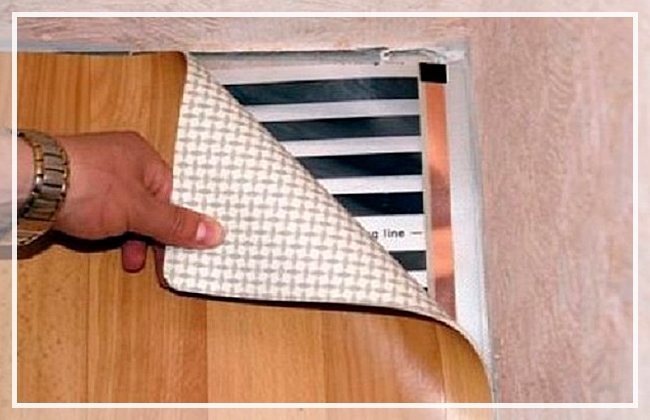

Features of laying linoleum

Separate strips are laid with an overlap of 10-20 cm and secured with tape

In this case, it is necessary to move along the surface of the infrared film very carefully so as not to violate the integrity of the graphite heaters.

Next, mount a flat surface of fiberboard. This material will reliably protect the warm floor and will become a suitable base for linoleum. This type of flooring is delivered rolled up, so it is recommended to spread it out and leave it for several days before installation.

Before laying linoleum, it is necessary to lay it out on a flat surface of a warm floor, turn on the system and wait until the coating is leveled.

In the case of underfloor heating, the process can be improved. Linoleum is laid on a fiberboard base without fixing, and then an infrared film is turned on. Under the influence of heat, the alignment process will be faster. In this case, the thermostat should be set to a level of 28 degrees or slightly less. For linoleum, this temperature is considered optimal.

After the coating becomes sufficiently even, it remains only to fix the linoleum on the base. This operation is performed using double-sided tape or glue.

The use of an adhesive is considered more suitable for use with underfloor heating, unless dismantling and relocation of equipment is planned. The adhesive provides a snug fit and uniform heating.

Before laying a heating element-based transformer substation, it is necessary to check whether there are possibilities for an internal power supply for additional load.

The screed allows you to get an even, solid base. A thermostat is a must. The exception is a self-regulating cable.

The device of a single-two-core heating cable for underfloor heating

What is the difference (other than structure) between these types? Two-wire: more expensive, installation - easier. One side connection. Single core has contact sleeves at both ends.

Mounting the heating wire under furniture is not recommended. Indent:

- from the outer walls - 25 cm;

- from internal wall fences - 5 - 10 cm;

- from furniture - 15 cm;

- from heating devices - 25 cm.

Before laying the conductor, it is necessary to calculate its length for each room.

Shk = (100×S) / L,

Where Shk is the wire pitch, cm; S is the estimated area, m2; L is the length of the wire, m.

When choosing the length of the conductor, it is necessary to take into account the value of its specific linear power.

For a room of 10m2 (with average standards of 200 W / m2 and 80% of the usable area), the power should be 1600 W. With a specific linear power of the wire of 10 W, its length is 160 m.

From the formula, SC = 5 cm is obtained.

This calculation is valid for TP as the main means of heating.If used as an additional one, then, depending on the purpose of the room, the percentage of heating is reduced from 100% to 30% - 70%.

The sequence of technological operations:

- Preparing the concrete base: leveling, applying waterproofing.

- Laying a heat-insulating substrate made of foil material with markings.

- Installation of a thermostat.

- Layout according to the scheme of the heating element. The temperature sensor is installed inside the corrugated tube.

- Screed filling.

To get a complete picture of the installation of a structure with a heating conductor, you can watch the video.

Before pouring the screed, you need to check the operation of the heating circuit. It is desirable to include for testing no earlier than 28 days, when the solution gains 100% strength.

Practical Tips:

- If the wire crosses the seam between the plates (deformation), then it should be laid

- with slack for the possibility of relative elongation;

- When crossing another heat source, it is necessary to make thermal insulation to protect against overheating;

- For accurate readings of the temperature sensor, it is placed closer to the surface, placing a gasket of the required thickness.

Pie cable underfloor heating

Installation of electric floor heating

The process of preparing the base described above is very important and mandatory. When the base is ready, you can start laying the heat-insulating material, it is laid with the heat-reflecting material up, for better reflection of heat into the interior of the room. The strips of the substrate are glued together with adhesive tape. The thickness of the underlay depends on how cool the subfloor is.

If there is a heated room under the base, then you can use a thin substrate, about 3-4 mm thick, and lay it only in places where a warm floor will be installed, otherwise, the substrate must be selected with the appropriate thickness and strength and laid out over the entire floor area .

To lay out the heating cable, we will fix the sections of the mounting tape with a distance of no more than 70 cm from each other. The tape is fastened by any means that ensure connection with the base. It can be both expansion dowels and special screws.

When the sections of the mounting tape are fixed, you can start laying out the heating cable. To do this, we calculate the layout intervals so as to effectively use the entire area. The ratio of the area to the length of the heating section will give an approximate value for the laying interval. The length of the heating sections is indicated in the passport data.

Laying starts from the thermostat, which is mounted in the wall in advance at a level of 30 cm from the floor. Let's bring the connecting end of the heating section to the location of the latter. The cold cable connector (power supply 220 V) and the heating element are first attached to the mounting tape. Further, the cable is laid evenly, without intersections and sharp kinks.

As a rule, the laying step is 10 cm. If it is less, then the heating elements may overheat. The cable is laid in a shuttle way. Swivel knees should be smooth and spaced from the wall at a distance of 10 cm around the entire perimeter of the heated area.

The connecting ends of the heating element are led to the thermostat.The temperature sensor is placed separately in a special tube, which is tightly closed with a plug on one side, and the other end is pulled to the thermostat mounting box. The reverse ends of the wire from the sensor are connected to the thermostat. The corrugated tube is mounted in the groove made in the wall and sealed with cement.

Before connecting the ends of the wires of the heating sections and the temperature sensor to the thermostat, they must be tinned. When the connections are properly made, the system can be checked by turning it on for a short period of time.

Types of substrate for linoleum on a concrete floor: which ones are laid, which ones are better

If you still need a lining for linoleum on a concrete floor, then the types, as well as features

each material will allow you to make a good choice. There are natural and

synthetic options, and you should choose among them taking into account specific

operating conditions.

cork material

The bark of the cork tree is used for production.

first crushed, and then pressed. Dense natural material

is rolled in production into special rolls, the strip width in which

is 1m. The roll version of the substrates is convenient for transportation and installation.

Until the next repair, the cork substrate will definitely survive, because

its service life reaches 30 years. Cork canvases are available for sale with

thickness from 2.5 to 9mm. Experts advise taking thin options.

The most popular option is with a thickness of 4 mm

The most popular option is with a thickness of 4 mm

Main advantages:

- Produced on the basis of natural material;

- retains heat well inside the room;

- softens the floor.

jute base

Jute is a marsh plant whose fibers are used in

production of burlap and ropes.In addition to fairly solid textiles, they are made from

him soft building pads. Contains no harmful synthetics

substrate for children's rooms.

Roll of jute bedding

Roll of jute bedding

Jute is unique in that it functions as a natural

membranes. When moisture appears, the material absorbs it into itself and removes it back,

without letting inside the house. In addition to plant fibers, they also add to the composition

special substances that can reduce flammability and resist fungus.

Main advantages:

- Removes moisture;

- easy to transport and install;

- undergoes additional protective treatment

substances.

linen lining

Another type of natural bedding. It even looks like

jute fabrics. As with other sustainable options, the material

“breathes”, so there will be no places for moisture accumulation, and, accordingly, mold.

Natural material based on flax fibers

Natural material based on flax fibers

Linen can be called the most environmentally friendly. In her

production even try to avoid the use of adhesives, material

just stitched with a needle. Hypoallergenic properties of the plant itself

better suited to the design of the floor.

Main advantages:

- Low price;

- naturalness and breathability;

- Sold in different thicknesses.

Combined variant

Due to the more complex manufacturing process, such a substrate

may cost a bit more than the pure linen option. But in herself she

combines the positive properties of the same linen, wool and jute fibers.

This lining can last up to half a century.

This lining can last up to half a century.

Lining at the same time provides ventilation properties

and keeping warm, thanks to the fibers of natural wool. Therefore suitable

for apartments and other premises located on the ground floor.

Main advantages:

- Prevents heat loss;

- serves 30-40 years;

- combines the positive properties of others

options.

PE foam material

This is a synthetic type of lining for linoleum. Simple

production and low cost of the material made it possible to create a wide range.

Polyethylene substrates are sold in different thicknesses and shapes.

(rolls or panels). Everyone will find the option he needs.

The most affordable option

The most affordable option

Perfect for second and higher floors. But for the first

floors, polyethylene is not the best option, because it does not let air through, so

mold may appear. Therefore, another drawback of synthetics is a short

service life under adverse operating conditions.

Main advantages:

- The cheapest option;

- ease of installation;

- thermal insulation properties.

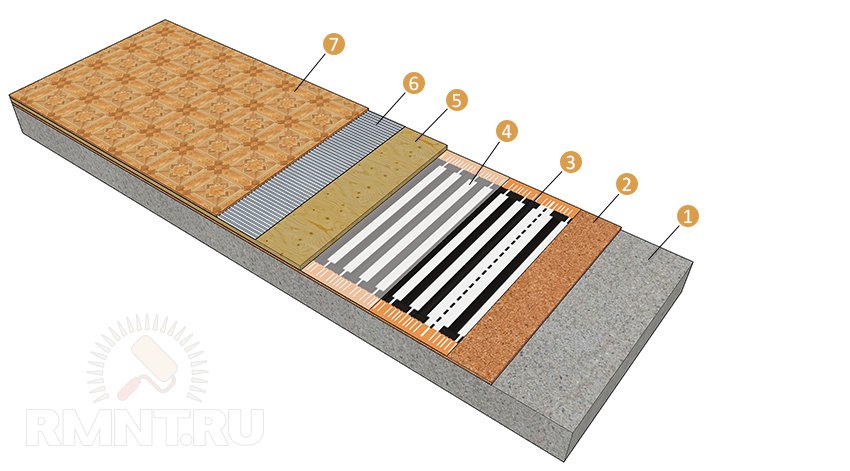

Electric floor heating device

When laying film electric heating on a concrete subfloor, it is necessary to carefully prepare the base. The screed should be completely cleaned of debris and dust and made as even as possible.

After that, a special film with heat-reflecting properties is laid. This thermal insulation is attached to the base with adhesive tape.

Next, the pre-prepared heating elements themselves are laid on top of it.

In this case, it should be ensured that the contacts of the individual strips do not come into contact with each other.

To prevent further displacement of the heating strips, they should be attached to the draft base and this can be done with adhesive tape or a stapler.

At the final stage of laying, it is necessary to carefully check the reliability of fastening of all supply wires and insulation.

After the installation of the infrared film is completed, it is necessary to install a special control relay and check the floor in operation.

Next, a polyethylene film is laid over the electric strips of the warm floor, which should completely cover the surface of the base.

Electric underfloor heating should never be filled with concrete screed.

On top of the film, it is recommended to lay sheets of plywood or chipboard, pre-treated with special protective compounds. Only after this is the laying of linoleum.

As in the case of a water floor, in order for the material substrate to take the correct shape, it is necessary to turn on the heating for two days.

Only after the linoleum substrate takes the form of a base, the material is finally fixed in place.

You can learn more about how to install an electric heated floor with your own hands by watching the video below.

Video:

Underfloor heating makes it possible to create the most optimal temperature conditions in the house. It is allowed to lay linoleum on top of it, however, for this it is necessary to take into account the specifics of this material.

In any case, subject to certain rules and technology for installing a warm floor, all the work can be done by hand in the shortest possible time.

How to lay the substrate: step by step instructions

After the lining for the new linoleum on the concrete floor is selected, it remains

just do the installation work.

The floor renovation process consists of several stages:

- Preparing the concrete base.

- Surface waterproofing.

- Lining installation.

- Fixation of the middle layer.

- Laying linoleum flooring.

Each stage has its own nuances that must be followed.

take into account when performing work independently.

Training

First you need to try so that the surface of the concrete

was as smooth as possible. All debris and tools are removed from the surface. At

With the help of a broom and a vacuum cleaner, you need to get rid of dust.

If the floor is even, you can immediately proceed to the second stage.

If not, you will have to repair it. First, concrete must be primed,

then a screed will be required to repair the damage, this will mask the defects and

level the floor.

Well prepared base

Well prepared base

If the damage is minor, patching will be required only in their

places. For this, ordinary cement mortar or laying glue is suitable.

ceramic tiles.

Waterproofing

This is an optional step, but in some cases it can

significantly extend the life of both the substrate itself and the entire

floor structures. To check for moisture problems, you need to lay

plastic film, moisture will accumulate in places of evaporation.

The film will protect against getting wet

The film will protect against getting wet

If possible, try to find a piece

waterproofing polyethylene over the area of \u200b\u200bthe room. If you couldn't find

such a large canvas, it can be glued together from several parts using

adhesive tape. All this is laid simply on top of concrete, and fixation will be provided

the next layers are the substrate and linoleum.

Substrate

The main requirement for its installation is the most solid

design. Linoleum is sensitive to various kinds of irregularities, and through

for several years, the joints of the lining tapes will be noticeable. As a result, instead of

leveling the floor litter, on the contrary, will make it crooked.

To avoid such a problem, everything must be done strictly according to

rules. Laying instructions on the example of a roll substrate:

- You need to buy a lining taking into account the area

rooms plus a small margin. - For "addiction" the material must be left in

unfolded for 24 hours. - At the joints of the rolls,

double-sided adhesive tape for fixation.

Decomposed synthetic backing

Decomposed synthetic backing

After that, you need to leave the material for a while

for adaptation and after - go to the next step.

Fixation

To ensure that the lining is securely attached to the concrete

base, you need to glue it. For thin and light synthetic substrates

use double sided tape. Suitable for heavier options

adhesive compositions based on polyurethane.

Another fixing option is self-tapping screws. It fits those

cases where waterproofing is installed under the substrate, but a strong

fixing the structure to the base.

Process video

styling will help to get acquainted with the nuances in more detail

How to lay underlayment on the floor

Laying linoleum

Before proceeding with the installation of the linoleum itself, you need

repeat part of the preparatory stage, namely cleaning the surface. Same way

as in the case of the lining, linoleum needs to “lie down” in expanded form

day in the styling room.

Stock flooring

Stock flooring

Laying process:

- Linoleum is spread in the room so that it

the edges "came" a little on the wall. - It stays in this position.

- Fixation. Adhesive or double sided applied

scotch. In this case, either the entire canvas can be processed, or only

the edges. - The room is ventilated.

- Plinths are installed.

A glueless method of coating flooring is also possible. Then linoleum

fixed only with skirting boards. The advantage of this option is the possibility

easy dismantling and maintaining the integrity of the coatings.

Recommendations and steps for laying linoleum on a concrete floor

The owners of apartments in both new buildings and old houses during the renovation process usually ask a typical question: is it possible to lay linoleum on a concrete floor. And the most popular answer both on Internet forums and from experts: linoleum is the main flooring material in modern buildings.

In order for the linoleum coating of the concrete floor to be successful, it is necessary to adhere to all the stages of laying

The process of laying linoleum includes several stages:

- selection of suitable material;

- preparation of the base and leveling the surface;

- surface waterproofing;

- calculation of material consumption for laying;

- marking and cutting linoleum;

- fixing the coating on the floor with adhesives;

- fastening mechanically using skirting boards.

Each of the stages has its own sub-stages, features and importance. The guarantee of successful work lies both in the correct choice of linoleum, glue, and in the preparation of the base.

The process is much more complicated if it also includes the installation of a warm floor under linoleum on a concrete floor.

During installation, the coating must be carefully straightened to remove air.

Experts recommend not neglecting the stage of leveling the floor under linoleum before laying, as this is a guarantee not only of the beauty of the surface, but also of the duration of the coating. The smoother the base, the longer the linoleum lasts.