- How to lay a film electric floor

- Scope of application in the house

- How to lay underfloor heating on plywood

- Plywood floor installation

- How to lay an infrared film underfloor heating under linoleum

- Cable electric floor

- The choice of linoleum

- Benefits of using infrared underfloor heating

- Installation of infrared film floor

- Types and heating device

How to lay a film electric floor

Description of technology, how to properly lay a warm floor:

Drafting

This is especially important in cases where rooms of a large area are made out. It is recommended to lay only open areas with a heating film - it is not needed under furniture

In addition, the weight of heavy objects can cause system failure. The distribution of strips is recommended to be carried out in the longitudinal direction, which will reduce the number of butt sections. If there is electrical wiring at the base of the floor, it must be indented by 5 cm. Other sources of heating (oven, fireplace, radiator, etc.) must be removed from the film at a distance of at least 20 cm.

Foundation preparation. All dirt must be removed from the rough surface, drops and defects must be eliminated. This is best done with a leveling compound.Further installation work may be continued only after the complete drying of the filling. To improve the heating efficiency, it is desirable to arrange the base with a layer of thermal insulation, gluing the joints with special adhesive tape.

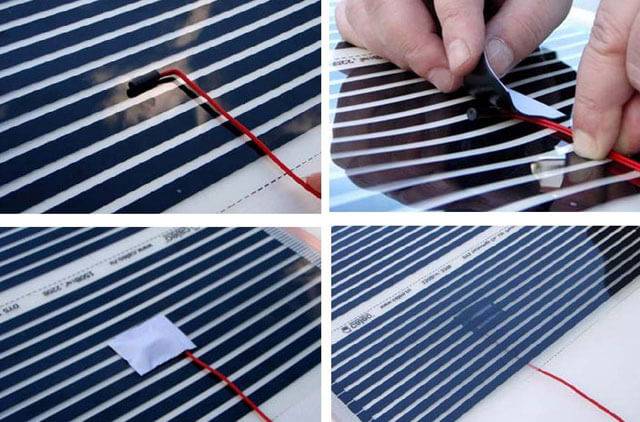

Film laying. The main task is to correctly distribute it over the entire floor area. Almost always, this requires cutting the film into separate fragments: this operation can only be carried out along special lines applied to the surface of the material. If you cut the film in any other place, it will cause serious damage to it.

Fixation. Having laid the strips of material according to a previously drawn up drawing, how to lay an electric floor heating, they must be well fixed. This can be done with adhesive tape, staples or regular furniture nails. There are special transparent areas for fasteners along the edges of the film: it is forbidden to do this in other places due to the risk of damage to the heating circuit.

Network connection. Having fixed the heating strips, they must be connected to electricity. For this, special contact clamps are included in the product kit. They are connected to the system in a special way: each element is inserted into the gap between the layers of the film and is connected to a copper wire. Strong fixation of each clamp is carried out with the help of an eyelet, which must be riveted with a special tool.

In its absence, a conventional hammer can be used for these purposes: you need to act very carefully to avoid damage to the graphite inserts. Further, the contact clamps are switched by pliers with a copper wire in a protective sheath.

Performing the installation yourself, it is recommended to arm yourself with some useful tips on how to properly lay a warm floor:

The individual parts of the film must be separated by some space. The presence of overlaps is unacceptable due to overheating of the material. This usually ends with a quick system failure and damage to the finish.

The temperature regulator during the operation of the film floor is not recommended to be set above +30 degrees. If linoleum is laid on top of the film, then the optimum temperature in this case will be +25 degrees.

Mounting temperature sensors is allowed only after a complete power outage in the house. Voltage supply is allowed after the installation and connection of the device is completed.

When starting to test the IR film, it is recommended to conduct a thorough inspection of all areas of switching contacts

It is very important that the protective insulation is not damaged.

When decorating a large area with a heating film, it is important to take into account the total power of the circuit. If this parameter exceeds 3.5 kW, it is better to equip it with a separate power cable in order to avoid network overloads.

Due to the minimum film thickness, the patch areas usually rise slightly above the surface

So that this does not lead to a deterioration in the general condition of the floor covering, the insulation in these areas needs to be cut a little, leveling the height.

The optimal place for installing the temperature sensor is those areas under the film where there are no heating elements. To fix this device, tape is usually used.

The system may only be tested after it has been connected to the thermostat.After turning on the underfloor heating, it is necessary to check the wiring connections. If defects are found, they must be corrected. A sign of high-quality work of a heat-insulated floor is uniform distribution of heat on its surface.

After the warm floor under the linoleum is correctly laid, a vapor barrier material is laid on top of the film: it is also fixed with adhesive tape. Then you can proceed to the final design of the floor.

Scope of application in the house

The underfloor heating system allows you to use it in almost any living space, while saving money on the heater and space under the batteries in the apartment.

In addition to these advantages, underfloor heating has other undoubted advantages:

- heating the room with a warm floor gives a feeling of comfort;

- heated floors prevent the appearance of mold, as the heat spreads to the entire space of the room and prevents dampness from accumulating;

- comfortable air microclimate due to individual heat regime with the help of thermoregulation;

- does not require additional cleaning, because it is enough just to wash the floor without cleaning the batteries;

- the warm floor is safe for small children, as it does not allow burns, like a conventional radiator;

- the absence of heating devices from the outside allows you to perform any layout in the room, and the interior of the apartment looks much more spacious and aesthetically pleasing;

- if desired and lack of heat, it can be combined with conventional batteries;

- With proper installation, such a heating system will last a long time.

Since modern apartments are very expensive, any person tries to appreciate every square meter of his home and tries to equip it in such a way as to use all the useful space of the apartment.This is one of the reasons why people are increasingly using underfloor heating. A very right choice in favor of heated floors is their installation on the balcony and loggia.

Firstly, it will allow you to go out to the balcony in the cold season without worrying about your health, secondly, it will make it possible to expand the space of the apartment by combining the loggia and balcony with a common room or kitchen, and thirdly, it will provide small-sized housing for additional a room that can be used, for example, as an office or recreation area.

Such a solution will not only create comfort, but also bring individuality and modern style into the familiar interior. Despite the fact that combining the space of the balcony and the room will require considerable labor, since the dismantling of the wall and window frame is inevitable, this solution will bring much more positive and functional points. Among other things, when choosing a coating for such a floor, it will take less material and time to install it, since it will not be necessary to cut out additional pieces, to make patterns for a small balcony. Having managed with a solid integral sheet of linoleum, you can solve the problem of the floor both in the common room and on the balcony, at the same time.

It will be useful for a happy pet owner to use these heating systems as local rugs so that they can comfortably warm themselves on cold winter evenings without jumping on the bed to their owners.

How to lay underfloor heating on plywood

Plywood is the most versatile material.It is used in construction everywhere, from the construction of formwork when laying foundations and ending with the production of cabinet furniture for the home.

First of all, plywood is a sheet material made from natural wood, which is obtained by cross-linking sheets of wood veneer. There are three or more such sheets. Various types of wood are used: pine, beech, oak, linden and others. Moreover, it is customary to say that plywood is made from the same wood veneer from which its front surfaces are made.

Plywood floor installation

Plywood floor in the interior

Raw plywood floor

This material is used in the construction of an intermediate base for underfloor heating. If the main floor is made of piece parquet or parquet board, which must be fixed with glue and self-tapping screws, then plywood flooring is a must. Experienced craftsmen recommend installing an intermediate plywood floor also for subsequent coating with laminate or linoleum. In this case, plywood will perform the important function of a moisture and sound insulator.

Benefits of plywood flooring material:

- material strength,

- environmental cleanliness,

- high thermal and sound insulation properties,

- resistance to excessive moisture,

- ease of installation and low labor intensity of work,

- cheap cost of material and construction work.

Types of plywood for flooring

For the renovation of apartments, plywood of various grades and varieties is used. It is classified according to the degree of moisture resistance and is divided into grades, from the first grade to the fifth. First grade plywood is made from birch, beech and oak, only wood without knots is taken. Such first-class plywood is used to make furniture.Plywood of grades 2 and 3 is just used as a secondary material for underfloor heating floor coverings, such as parquet, parquet board, laminate and linoleum.

Underfloor heating on plywood

Unlike the conventional technology of laying underfloor heating, laying on a plywood base is carried out without fixation. Floor sheets with this technology are connected using metal fastening brackets, and not with dowel screws. This technique allows the wood veneer to expand with increasing air humidity and prevents the formation of cracks and blisters. For more details on how to lay plywood, look at the photo.

There are several ways to install an intermediate plywood coating:

- laying on a concrete screed: sheets 12 mm thick are used,

- on logs made of wood: in the presence of various communications or other interference, thicker sheets are used, 20 mm or two sheets with a total thickness of about 20 mm,

- on wooden floors: you can use plywood of any thickness.

What to look for when choosing an adhesive

There are three types of adhesives used: water-based, alcohol-based and two-component adhesive. Each of them has its own advantages and disadvantages. Aqueous glue is odorless, but contains water, alcohol glue has a pungent odor and is also flammable. The two-component adhesive dries quickly and requires skill to work with it. For plywood flooring, choose alcohol-based and two-component adhesives.

When laying plywood, the sheets must be cut into four pieces each and laid in a checkerboard pattern. Such a campaign allows you to avoid excessive stress in a single sheet, the more thermal seams, the more resistant to deformation the coating. Gap between sheets - 5 mm, along walls and heaters - 1 cm.

Laying an intermediate floor under linoleum and laminate

When choosing a material, you must be guided by the following recommendations. The plywood sheet must be thicker than the face covering and sanded on one side. Plywood is laid with the treated smooth side up, and linoleum or laminate is laid on it.

For residential premises, it is better to choose an environmentally friendly brand of material with an average degree of moisture resistance - FK.

Underfloor heating under tiles

Tiled floors can be cold. To cope with this disadvantage, it is recommended to lay an intermediate plywood floor under the tiles. The surface before laying the tiles must be cleaned of saws and sanded.

How to lay an infrared film underfloor heating under linoleum

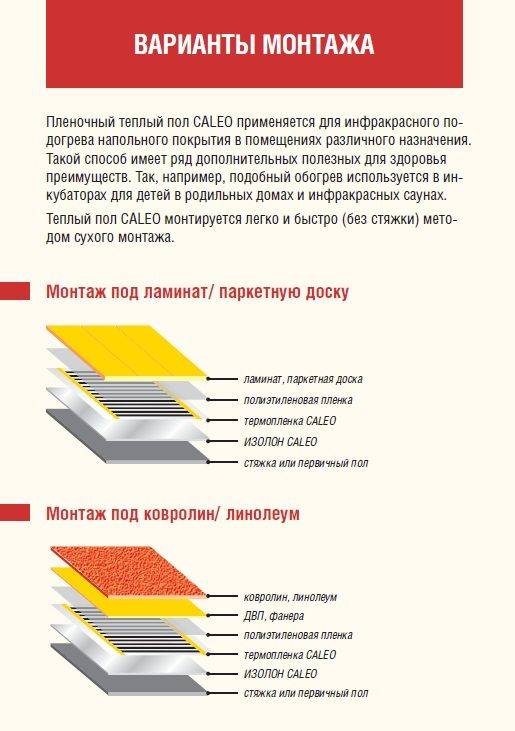

Installation of a film underfloor heating on a wooden floor can be divided into several stages:

- Installation of the insulating substrate necessary to prevent heat leakage in an undesirable direction (down). In addition, the presence of an additional substrate will hide minor irregularities and provide additional thermal insulation. For these purposes, it is expedient to use aluminum-foiled substrates made of polymeric materials.

- Carbon Film Flooring has a number of features. First of all, when laying heaters, you should retreat from the walls by about 0.5 m, and you should not lay the film in places where heavy furniture is installed. If necessary, it is allowed to cut the film heater in specially marked places. The resulting system must be connected in parallel.

- Mounting the thermostat it is advisable to carry out separately for each room.To do this, in each heated room, a temperature sensor is glued to the carbon heater, and the wire from it is led to the place of attachment of the corresponding temperature controller. Next, following the manufacturer's instructions, connect the thermostat to the mains and securely fasten it to the wall.

Since the power of such devices usually exceeds 2kV, for reliable protection of infrared heating systems for a wooden floor, it is recommended to electrically connect the system through a separate machine. After that, it is necessary to check the operability of the installed heating. To do this, set the temperature on the thermostat to 30C and after activating the carbon elements, we determine their performance, serviceable elements should heat up.

If problems are found, immediately eliminate them with the help of a special mastic included in the delivery.

The final step is laying the PVC film and attaching it to the wooden base using a stapler or self-tapping screws.

At this stage of the work, it is especially important not to damage the carbon electrodes with brackets or screws. After checking and laying the last layer of PVC film, you can start laying the finish coat on the wooden floor. Lay linoleum in such a way that the gap from the wall is at least 5-7 mm

After flooring, you need to turn on the underfloor heating and let the coating rest for 1-2 days, then fix the skirting boards

Linoleum is laid in such a way that the gap from the wall is at least 5-7 mm. After laying, you need to turn on the underfloor heating and let the coating rest for 1-2 days, then fix the skirting boards.

In our article, we examined in detail the underfloor heating under linoleum on a wooden floor using carbon heating elements. As can be seen from the above, it is quite possible for a home master to install such a system, and does not require any additional permissions.

There are alternative systems of underfloor heating for linoleum based on pipelines, however, using them in the presence of a wooden subfloor is not rational, since it requires a lot of labor with almost identical results, and in a multi-storey building this option is completely doubtful.

Cable electric floor

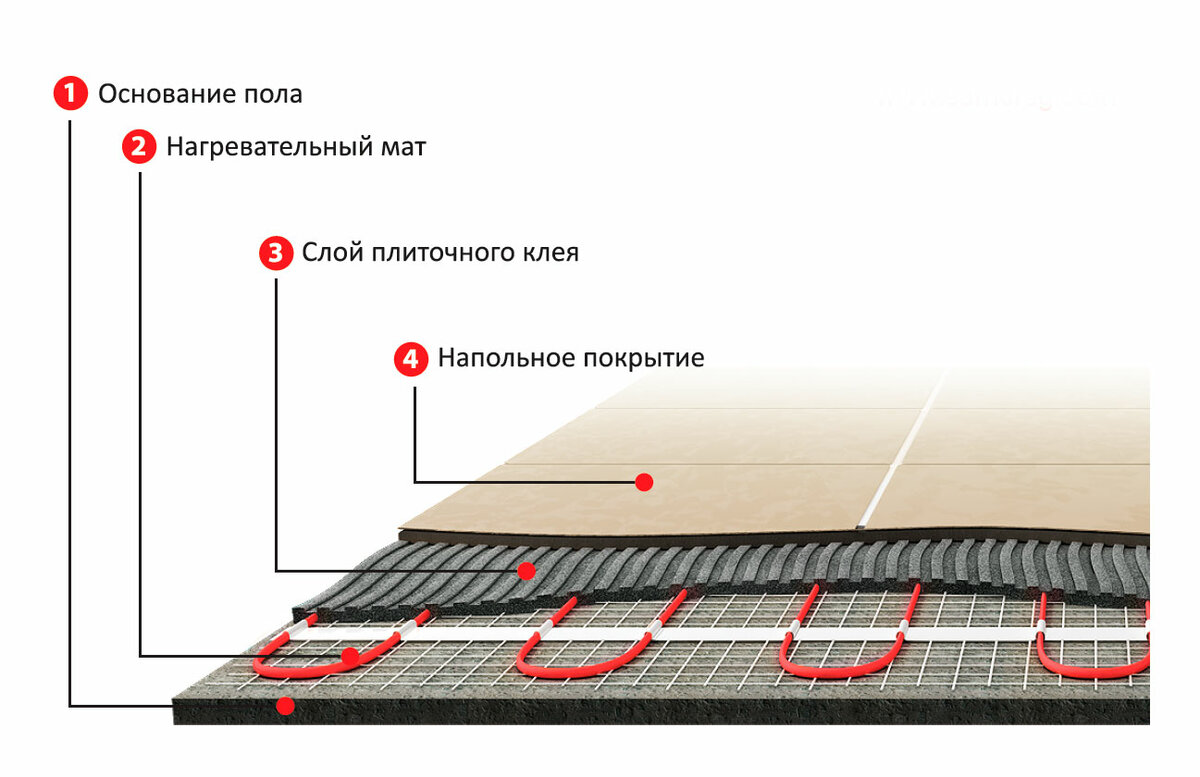

When laying the cable system, the concrete floor is first leveled, then a reinforcing layer is laid on it. mesh or special fastening tape. A cable is placed on it, fixed, then poured with a concrete mixture. When the screed is dry, lay the linoleum.

Before all these works, determine the length of the cable. If it is placed in increments of 15 cm, it will take approximately 25 cm per loop.

With a known area of \u200b\u200bthe room in which the installation of a warm floor is to be installed, the number of turns, cable branches and its length as a whole are calculated. A segment is added to the obtained value, going from the screed to the wall where the thermostat is located.

When calculating the area covered by a warm floor, a mandatory five-centimeter indent from the walls, the space occupied by furniture, is subtracted from its total value. Thermal insulation is applied to a clean concrete floor over its entire area. Seal the seams with foil tape.

In the area allotted for the installation of a warm floor, a metal tape is laid to secure the cable so that it is enough for the entire area. On the wall allocate space for the regulator.Then a hole is made for the installation of the mounting box and strobes are laid. After mounting the regulator, a temperature sensor is attached to it.

The wire coming from the heating elements is laid to the temperature controller. A temperature sensor mounted in a corrugated pipe is also brought here, a cable from the main power source

The wire coming from the heating elements is laid to the temperature controller. A temperature sensor mounted in a corrugated pipe is also brought here, a cable from the main power source

The heating cable is laid starting from the edge of the corrugated tube, on which there must be a cable end sleeve. The assembly of the electric floor is carried out, adhering to the calculated step in the form of a snake, the branches are laid evenly, excluding creases in the corners. The heating cable is fixed with hooks on the previously laid metal tape.

You should not pull it strongly, but still the cable should be as straight as possible. The pitch is calculated by multiplying the heated area by 100 and then dividing the result by the length of the cable.

After a short test of the system, a 5-cm layer of screed is poured. When it dries, mount the finish coat.

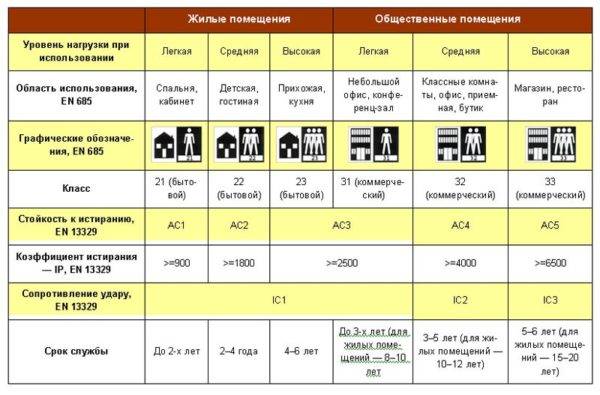

The choice of linoleum

This aspect must be taken with all due attention just because linoleum, when heated, is capable of releasing toxic substances into the environment. And then you can use the floors only at your own peril and risk to health.

How to choose the right linoleum

Table. Types of linoleum.

| View | Description |

|---|---|

| PVC | This is the cheapest, and therefore the most common option. It is based on ordinary PVC, which is sensitive to heat. This material is distinguished by a wide variety of color variations, can have different thicknesses, and also have a base in the form of a warming material.Unfortunately, it is this material that, when laid on warm floors, not only begins to release toxic substances into the air, but also shrinks, and also begins to smell unpleasant. |

| Marmoleum | This is a natural type of coating, which is of high quality and high price. It is not afraid of fire, does not electrify, and when heated, almost does not emit toxic substances into the air. It contains natural dyes, wood flour and cork flour, pine resin, linseed oil. Also, it is usually based on jute fabric. Such linoleum is easy to clean, does not fade in the sun and does not lose its appearance for many years. The only thing he does not like is washing with alkaline substances. Under the action of alkali, it will begin to collapse. |

| relin | This linoleum contains bitumen, rubber, rubber. It does not tolerate heat and therefore, in general, it rarely fits in houses and apartments, more often it can be seen in a number of industrial premises. When heated, it releases substances that are quite dangerous for humans. It is strictly forbidden to use it with a floor heating system. |

| Nitrocellulose | Such material is also called colloxylin. He is not afraid of water, elastic, thin, but does not like heat. So it cannot be used with a heating system. |

| Alkyd | Also called glyptal. Synthetic material, which is based on fabric. It’s worth saying right away that he, like the previous options, does not like heating. But it can be used in combination with underfloor heating, since it does not emit an excessive amount of hazardous substances. |

The process of laying linoleum

According to the information in the table, it is possible to mount marmoleum or PVC material on wooden floors in the presence of heating systems.However, experts note that both options can be laid on water floors, but it is better to put marmoleum on film floors.

Table with a list of characteristics of linoleum

Benefits of using infrared underfloor heating

Infrared floor heating, as the main source, has several advantages:

- Infrared floor helps to save on heating costs. The fact is that the human body also emits infrared waves, therefore, to establish a comfortable temperature in the room, less energy will be required, which leads to a reduction in costs.

- In addition to heating functions, the warm infrared floor also has healing properties. Air under the influence of infrared rays undergoes the process of ionization, thereby killing microbes and bacteria. This type of radiation is even used in medicine to combat certain diseases.

- Minimum electromagnetic radiation. Thanks to the use of advanced developments, it was possible to minimize the number of harmful electromagnetic waves to a safe level.

- Infrared heating stands out for its versatility. It does not heat the air, but the objects in the room. First, the floor covering is heated, and then the heat reaches the chairs, tables, sofas, etc. Due to convection, interior items give off the received heat, and the air temperature in the room rises. Thus, infrared floors heat the whole room.

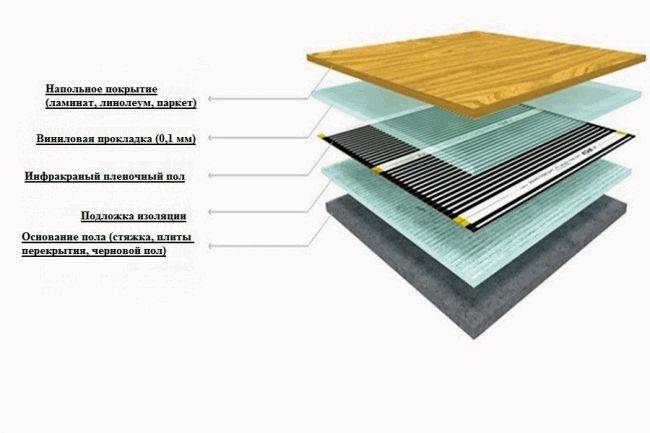

Installation of infrared film floor

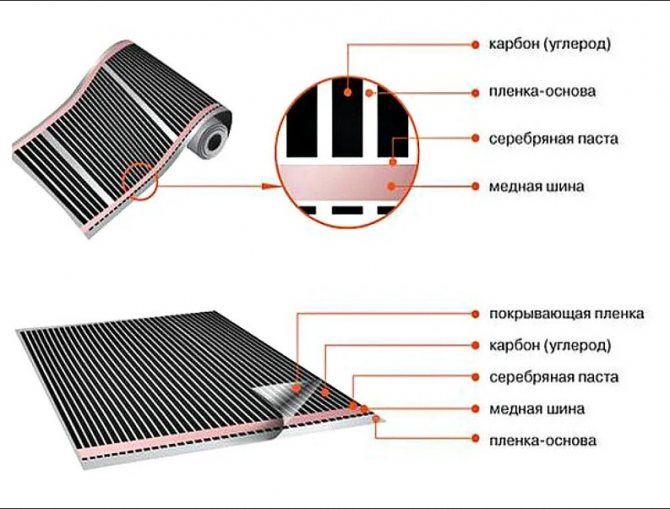

The infrared floor is designed as a film in which infrared elements are embedded. When connected to the network, they emit rays of a certain spectrum.It feels like warmth to a person. The film coating heats the linoleum, and through it the room in which it is installed.

The infrared heater does not require the stage of pouring the screed. This greatly simplifies the installation of equipment. Often, laying is done by hand, without recourse to specialists.

Features of laying a film heater:

- practically does not change the original floor height;

- when laying under linoleum, a solid layer of plywood or fiberboard sheets should be provided;

- experts consider it acceptable to drop the subfloor up to 1 cm per meter of length;

- infrared heater creates optimal heat output for linoleum;

- has increased fire safety;

- can be integrated into the “smart home” system;

- easy dismantling.

It is not necessary to fill the screed when installing an infrared floor heating

The thickness of the linoleum should not interfere with the spread of heat and at the same time not be too small. In the latter case, unevenness, floor differences will be visible.

The design of the floor relative to the room can be made according to an individual scheme. The structure of the material allows the installation of local areas. If necessary, the heating element can be mounted in another place.

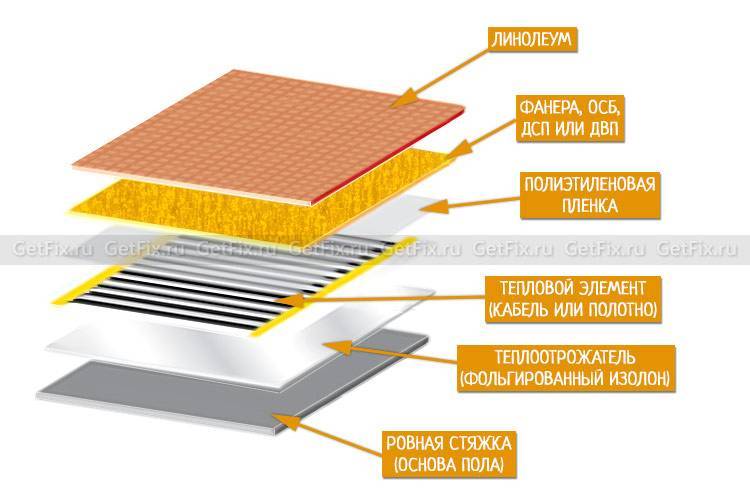

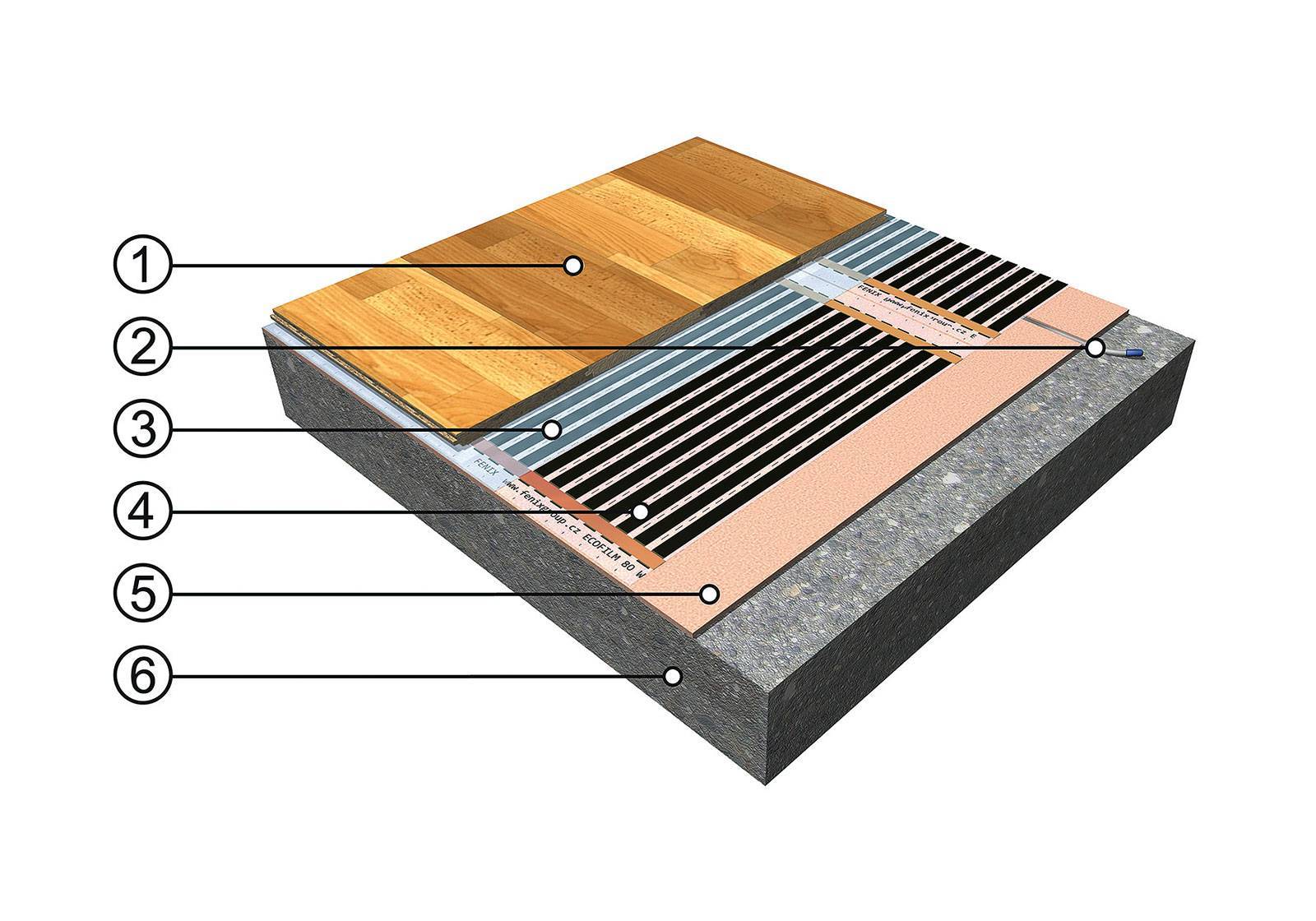

The sequence of steps:

- preparation of the concrete base;

- laying of thermal insulation material;

- fixing the thermostat on the wall, connecting it to the power cable and wires for temperature sensors;

- fixing temperature sensors;

- film cutting;

- unfolding on the floor surface and connecting wires;

- test connection;

- a layer of protective polyethylene film;

- a layer of plywood or fiberboard;

- re-testing the system;

- linoleum laying.

For thermal insulation, roll material made of polyethylene foam is used. It is resistant to moisture, is not affected by fungus, mold. An important advantage is excellent waterproofing. The material is laid on the floor tightly, without gaps, the "overlap" technology is not used. The thickness must be at least 5 mm.

Linoleum in the case of infrared underfloor heating is laid on a layer of plywood or fiberboard

The temperature sensor is attached to the carbon thermoelement. The structure itself and the wires extending from it are "drowned" in insulating material. Otherwise, the floor surface will be uneven in these places.

The film is laid strictly according to a pre-made scheme. Places where stationary furniture or household equipment is installed are not insulated. Lack of aeration can lead to overheating of the flooring material. It is necessary to take into account the distance from the source of the main heating - it must be at least 30 cm.

An important point is the connection of the infrared system and the power source. For this purpose, special rivets are used. Fastening is carried out with a tool intended for this.

The correct order of connection of an infrared heat-insulated floor is important. Despite the apparent simplicity of work, it is better to entrust the connection of the heating element to the thermostat and power source to a professional electrician. You can share the responsibilities - carry out the preparatory work and lay the flooring yourself, and entrust the installation and connection of the film itself to an experienced specialist.

Features of using linoleum with infrared underfloor heating

Types and heating device

The feeling of comfort while being in the room is the main reason for choosing a warm floor.In addition, such heating systems allow you to control the consumption of electricity in the apartment and save energy. The principle of operation of electric floor heating based on transformation electrical energy into heat. This can be achieved in two ways: using a special electric cable (this type of floor heating will be called “cable”) or using a heating film (film type floor heating):

The cable laid on the prepared floor must have a closed system (usually a zigzag with loops equal to the perimeter of the room). If it is planned to make a heated floor with heating control, then a temperature sensor is first installed in the floor, its wires are led out into the wall on which the thermostat is located.

Due to the fact that the power of this type of heating significantly exceeds the power of other types, when installing this system, it is allowed to close it with a screed or just fill the floor.

When the floor is ready, the floor has been poured and, if necessary, a screed, it is necessary to wait for some time until the floor is completely dry, sometimes it takes even a whole month. After drying the floor, proceed to its finishing coating with linoleum.

Recently, infrared (IR) film underfloor heating has become popular (some call it “tape heating”). This type of heating is perhaps the most versatile, since it can be used both under linoleum and under tiles and even under wooden parquet. However, infrared floor heating will cost a lot of money, but at the same time it will be environmentally friendly and safe, maintaining comfortable conditions in the room and not endangering the health and life of people and animals.

The infrared floor system is represented by a carbon polymer in the form of carbon rods placed on the surface of the film. These rods have the function of temperature self-regulation, so the floor will never overheat and the coating, whether it be linoleum or laminate, will not deform or dry out. Such electrical systems are mounted on glue or on a screed from above.

Another advantage of this type of heating is that its installation is available to almost anyone with basic knowledge of electrical engineering. It is not necessary to call the master to install such a heating system under linoleum, which you can also lay on your own. Accordingly, the level of costs is sharply reduced. In addition, during the next repair, this heating source can be easily dismantled and replace with another, more modern or completely removed.

And to further reduce heating costs, you can consider the option of local heating by cutting the IR tape into sections and placing them only in those parts of the floor where heat is required (for example, in the kitchen work area, in the bath or toilet area). When installing an IR tape as a floor heating, first a substrate is laid on the floor - a heat reflector. The cut strips of the heater are laid on the floor surface, after which a layer of glue is applied to them or a thin screed is made. After completing simple procedures, they proceed to finish the floor with linoleum or other selected material.

How to install a warm floor with your own hands, see the following video.