- A few tips for safe operation

- We reinforce the surface

- Step by step installation instructions

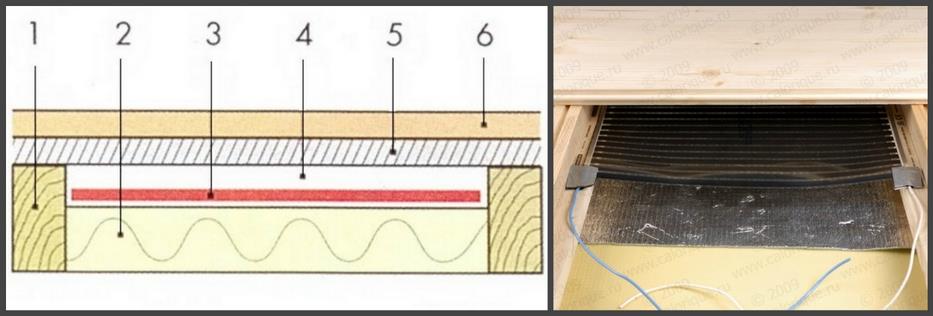

- Underfloor heating on plastic plates

- Wooden underfloor heating with water heating

- Materials and tools for carbon fiber floor heating

- Electric underfloor heating

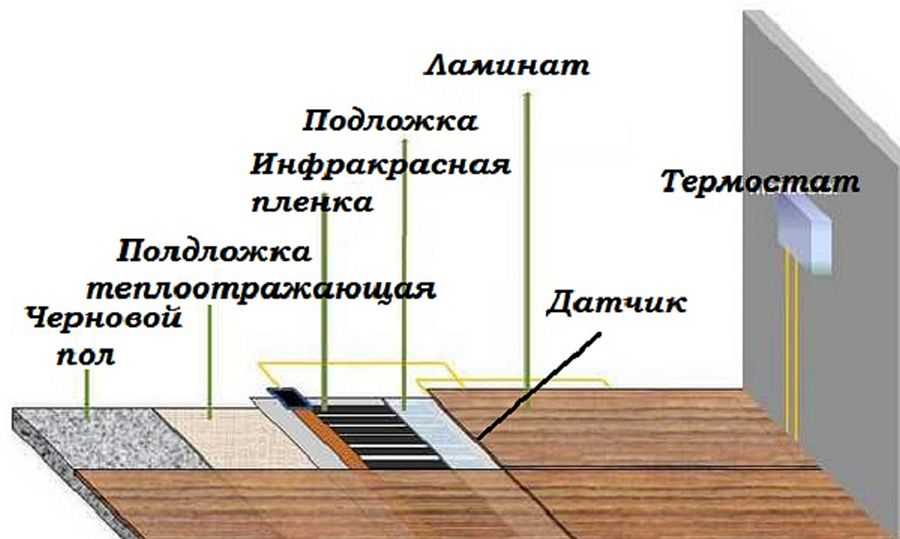

- Installation of a film underfloor heating under a laminate

- Features of the location of the IR film

- Preparing for installation

- Assembling the heating system

- How to properly heat wood floors

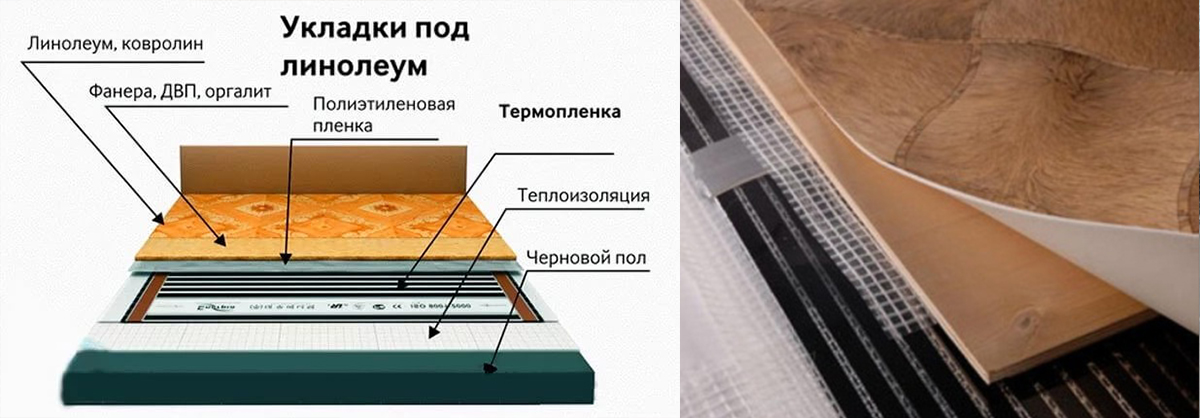

- Heating foil laying

- Laying laminate flooring

- Do-it-yourself installation of laminate on a cable floor

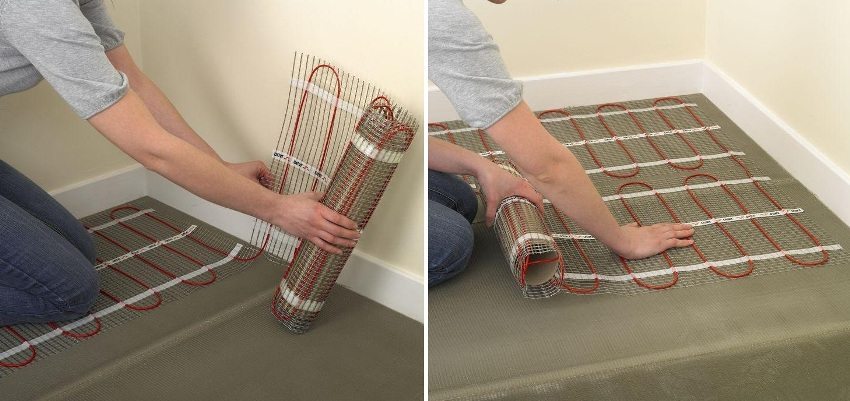

- Do-it-yourself installation of laminate on a film floor

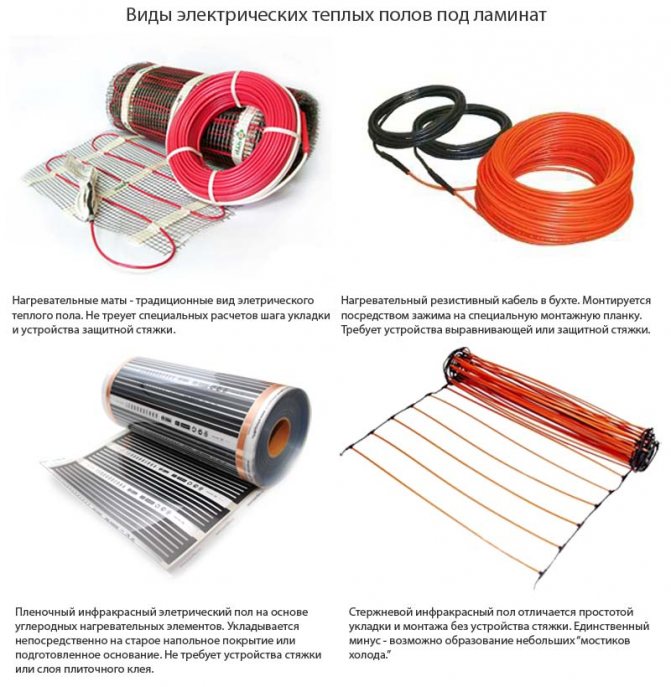

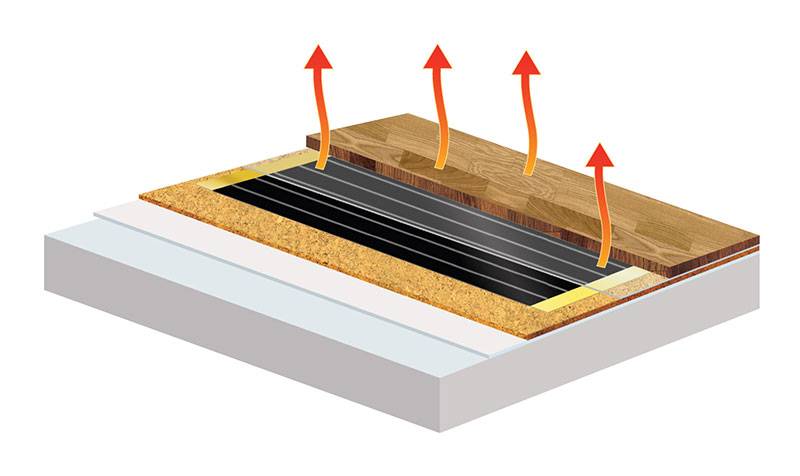

- Film (infrared)

- Tips for laying underfloor heating under laminate

- 1 Nuances when working with wooden floors

- 1.1 Features of the tree

- 1.2 Selection of the floor system

- Conclusion

A few tips for safe operation

When planning the installation of a warm floor, do not forget that neither electrical cables nor water pipes can be laid under heavy pieces of furniture. Also, do not install a warm floor in close proximity to a wood-burning, gas fireplace, stove and other heating devices.

For rooms for various purposes, you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24 ° C, and 20 ° C is enough in the kitchen and corridor

Practical nuances:

After the repair is completed, you should leave the heating system turned on, and maintain the same temperature regime for 3-5 days

This precaution will heat the entire floor pie evenly and thoroughly and ensure reliable operation of the system.

At the beginning of the heating season, you need to properly prepare the floor heating system for operation. To do this, increase the degree of heating by 5-7 units every day until the temperature reaches the required value.

This approach will avoid a sharp jump in temperature, which can damage the laminate and other materials. Similarly, heating is turned off for a warm period.

Do not forget that the film infrared floor does not tolerate moisture well. Therefore, it is not recommended to install it in rooms with a humidity level above 70%, and after wet cleaning, wipe the laminate dry.

The optimum temperature for underfloor heating is considered to be in the range of 20-30 degrees.

Lastly, do not cover a heated laminate floor with carpets or other furnishings that interfere with efficient heat distribution.

We reinforce the surface

So that the coolant pipes do not move when pouring the screed, they must be fixed. To do this, a reinforcing mesh must be placed on the heat-insulating layer. In the event that the ceiling of your premises already has good thermal insulation, the reinforcing mesh can be laid directly on the waterproofing, as shown in the figure.

Laying reinforcing mesh on the floor

Place the heating pipes

Ways of laying a water-heated floor

The figure shows the main schemes for laying coolant pipes.For cold climates, we recommend you a "snail" or its modifications, as this way the heat is distributed more evenly.

Laying pipes for underfloor heating

If your room has a complex configuration, the pipe laying pattern can be combined.

Step by step installation instructions

- We fix the heating pipes at the fittings with clamps. We leave the pipes a certain degree of freedom. We place the clamps in 1 meter increments. The distance between the coolant pipes and between them and the walls should not be less than 10 centimeters. By the way, do not forget to purchase accessories for a water-heated floor.

- Corrugations must be put on the sections of pipes that go to the collector and pass through the damping tape.

- We connect the pipes to the collector device.

- We are testing the system. We supply a coolant with a pressure one and a half times the nominal one.

-

We are testing the system daily. With quality work, we turn to the screed.

-

Using special filling mixtures, we fill the screed in the room. Its height should be about 5 centimeters. The coolant supply does not need to be interrupted during filling.

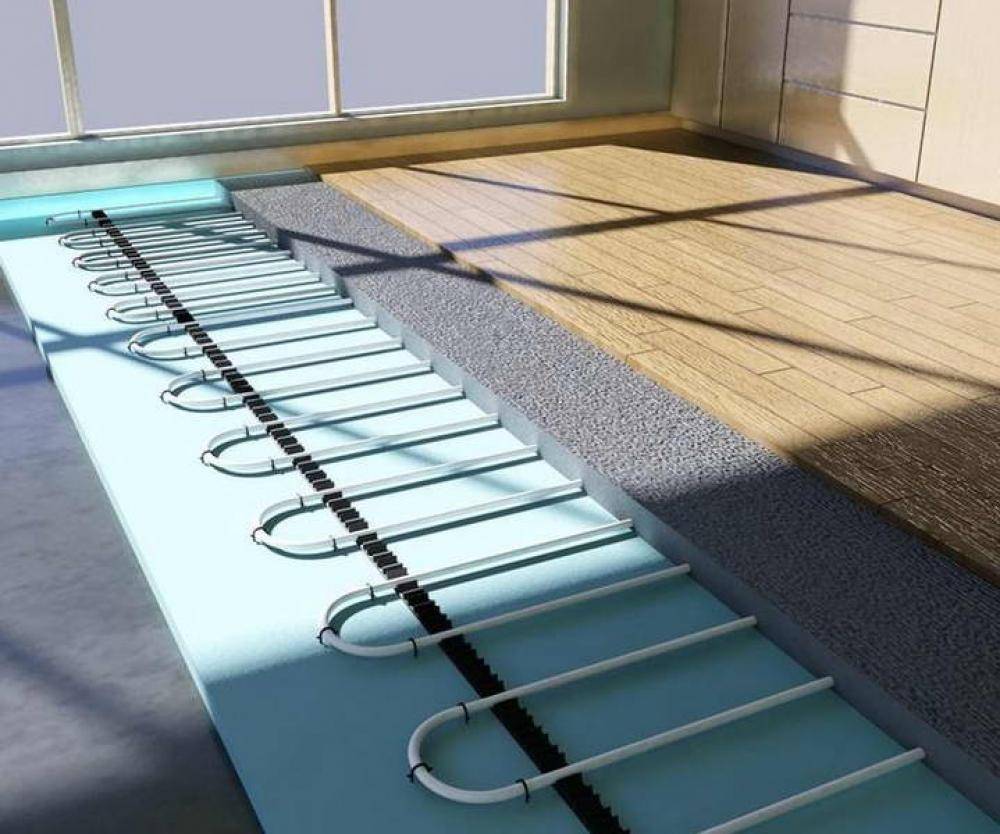

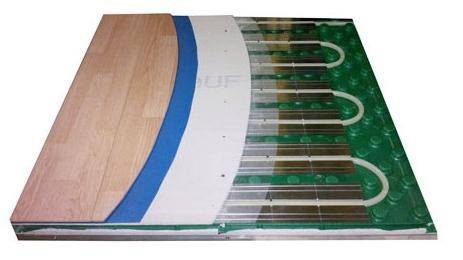

Underfloor heating on plastic plates

Instead of a cement screed, special foamed polymer slabs can be used as the base of the floor, in the grooves of which heating pipes will be placed. In addition to the grooves in such plates, there are also expansion areas that expand when heated.

Heated floor based on polystyrene

- The first layer in such a system is also a heat-insulating layer. It can be abandoned if there is high-quality insulation of the floor.

- The second layer is placed plastic plates. We lay them, starting from the corner of the room.

-

We place heating pipes in the grooves of plastic plates.

- We connect the pipes to the manifold and test the system.

- When satisfied with the results of the check, lay the subfloor.

- Place the underlayment and proceed with the installation of the laminate.

This is how a warm floor on water heating, mounted on polymer plates, looks like.

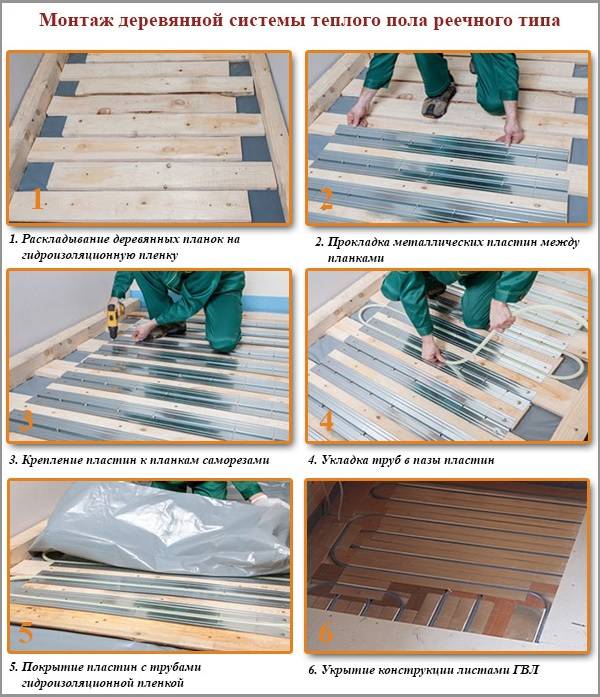

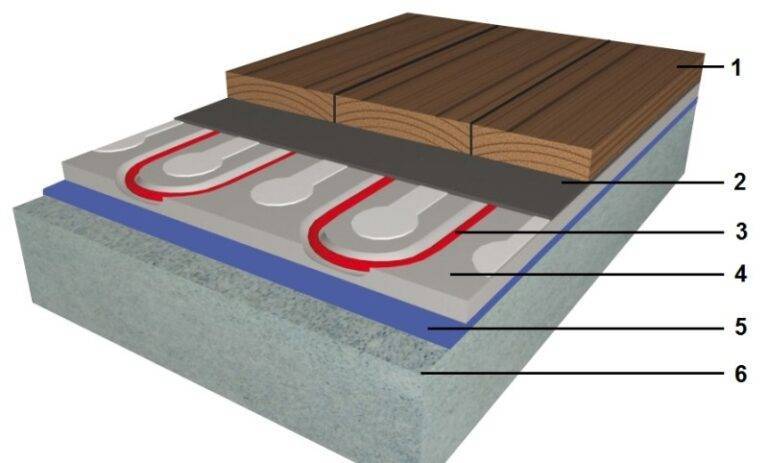

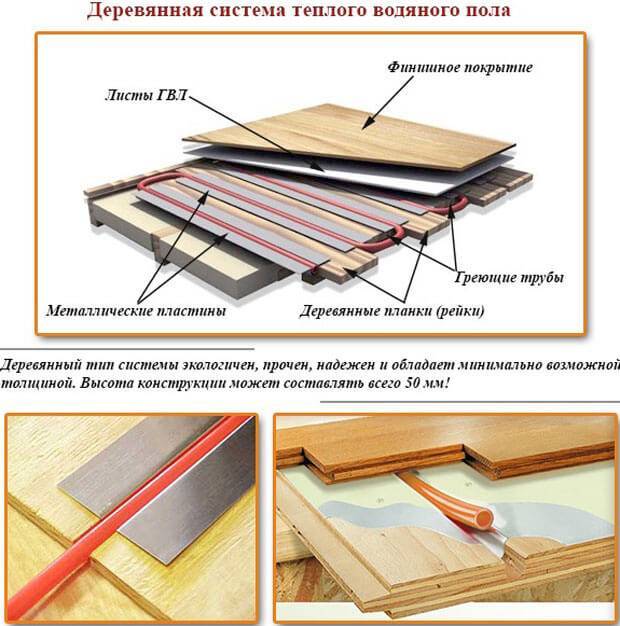

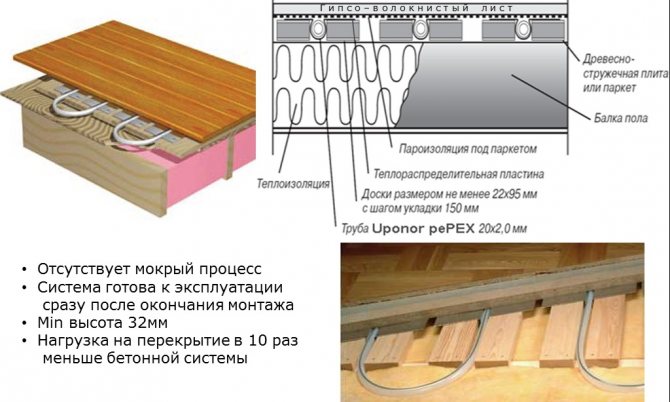

Wooden underfloor heating with water heating

In houses with wooden floors, it is recommended to use the traditional system of wooden floors. But they can also be equipped with water heating.

In wooden houses, the following modifications of the heated floor can be constructed: created from modules, slatted and traditional on logs.

A modular heated floor resembles a "puzzle" - inside the finished elements of which floors are already made to accommodate heating pipes.

Rack heated floor is mounted as follows:

- We put wood boards on the prepared and leveled floor and fix them with self-tapping screws on dowels.

- Between the plates we leave grooves for laying the pipeline system.

- In the grooves we place an aluminum profile.

- We lay heating pipes in the profile

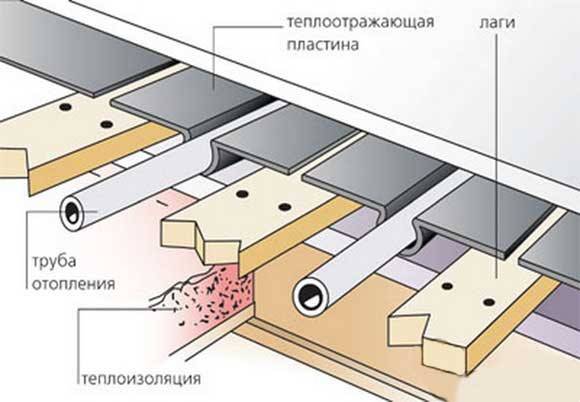

Pipes are laid in a traditional wooden floor on logs as follows:

Laying a water-heated floor on a floor on logs

- We insulate the ceiling with foam boards.

- We attach logs made of wood to the ceiling. At this stage, we level the floor.

- According to the developed scheme, we place an aluminum structure or just a profile.

- We fill the gaps between the lags and pipes with heat-insulating material.

- On top we lay a layer that absorbs moisture, for example ordinary cardboard.

- We place the draft floor. In its capacity, you can use GVL or chipboard.

- We install laminate flooring on the subfloor.

Materials and tools for carbon fiber floor heating

One of the most successful decisions during the installation of an electric floor heating will be the choice of an infrared option. If it is compared with analogues, then its advantage for laying on a wooden base is obvious. The system is suitable for a light coating, which is a laminate. Film heating is used for installation under parquet, linoleum, carpet. This is due to the ability of the infrared floor heating to warm up evenly.

For a successful installation, you will need the following materials:

- carbon film;

- clips for connecting heating blocks;

- adhesive tape, mounting tape;

- temperature sensor and regulator;

- electric cable with a cross section of 1.5 mm2;

- steam or waterproofing (if installation is planned in a room with increased moisture release or steam generation);

- insulation under the laminate on a wooden floor;

- contactors (may be needed in cases where a high-power heating system is to be installed).

Insulation should be used based on calculations. You can use universal insulation for all types of floors. The correct option for the laminate will be polyethylene foam. It is allowed to use laminated isolon.

Do not forget about the set of tools for installation:

- screwdriver;

- crimping tool (pliers);

- power indicator (tester);

- wire cutters;

- mounting knife;

- a hammer.

Using these tools, anyone who undertakes the laying of electric underfloor heating can easily carry out a successful installation of the heating system.

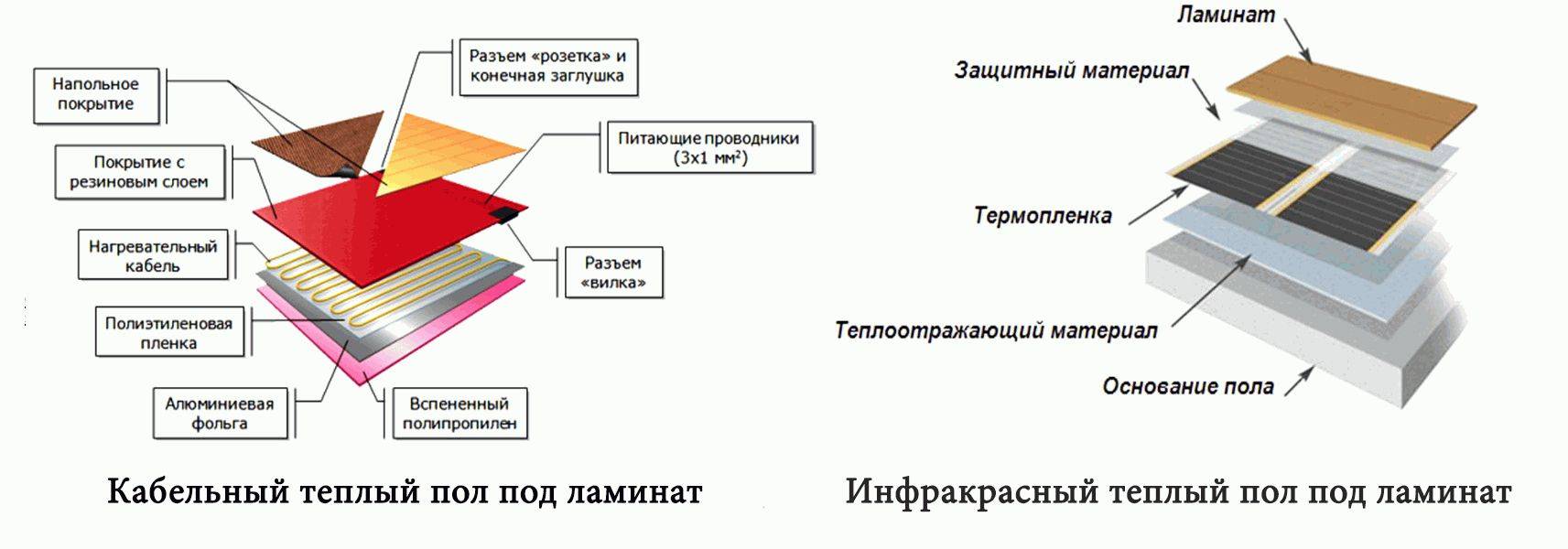

Electric underfloor heating

There are two main types

- Cable.

- Film.

Cables are divided into heating sections and mats.In the first case, a separate cable is laid, pulled along a predetermined line. In the second case, the cable is located on a special substrate. This method boils down to rolling rolls onto the floor surface, which significantly reduces installation time. As a rule, such a system implies the presence of a cement screed.

Film or infrared electric are more expensive. However, there are also advantages:

- small thickness and weight;

- simple and fast installation;

- laying without cement screed, directly under the substrate is possible.

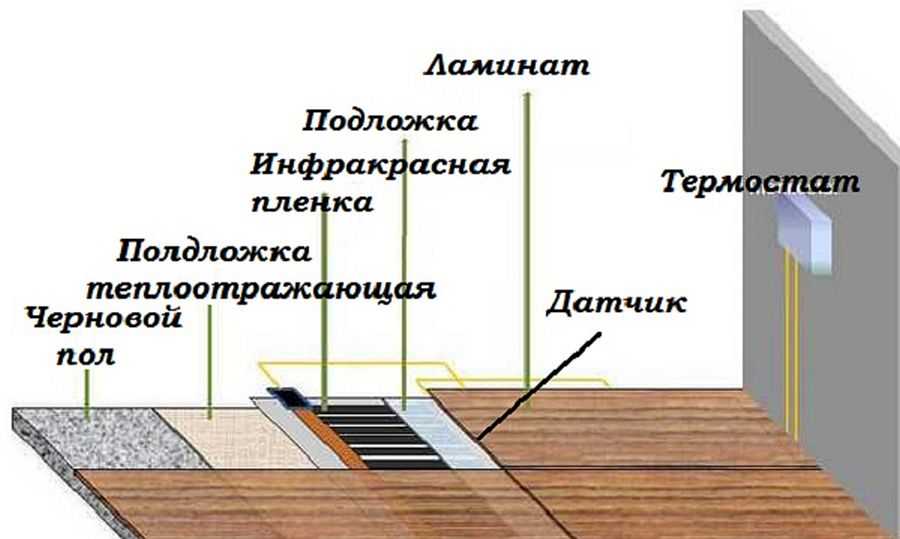

Installation of a film underfloor heating under a laminate

The assembly of the entire structure is carried out by carrying out several types of work in turn:

- Calculation of power and location of heating elements;

- Preparation of the floor for installation;

- Assembly of the heating system;

- Connection to the power grid and connection of a thermostatic device.

Features of the location of the IR film

One of the features of the underfloor heating film system is that it is mounted in the area where people are most often, while it simply does not fit under the furniture. Therefore, it is necessary to work out the layout of the furniture in the room in advance and draw the location of the underfloor heating system.

At the same time, the dimensions of the strips of the film that will cover the floor and the power of this system are calculated - it is better to contact the sellers of the system on this issue.

After the calculations are completed, you can proceed to the next stage.

Preparing for installation

The surface must be cleared of debris. It is also necessary to check the absence of condensation, since moisture is detrimental to this system. Installation is carried out on a leveled floor, on top of the laid substrate.

Assembling the heating system

This stage is the most responsible in the process. The film must be cut along the length into strips of 20-25 centimeters. After that, it is laid out on the floor in selected areas at a distance from the walls at a distance of 25-30 centimeters.

Between the rows of infrared film itself, it is necessary to leave gaps of 5 centimeters. The bands are interconnected by wires into a single network. Thermal sensors are installed in the center of the film strip, the wiring must reach the thermostat.

After that, a temperature sensor is connected, which will allow you to adjust the temperature and intensity of heating, turn off the system or make adjustments to its operation.

A laminate is laid on top of the film.

Conclusion

Warm infrared floor is an interesting solution for modern housing. However, the system requires the selection of a specific laminate. When installing under existing laminate flooring, you must ensure that it is suitable for interacting with film underfloor heating.

Infrared heating will ensure a uniform temperature throughout the room, relieve drafts. However, the cost of maintaining it is high, respectively, such a heating system is suitable for those who are ready for solid electricity bills.

How to properly heat wood floors

There are several nuances associated with the operation of heated wooden floors.

First of all, you need to understand that these will not include old Soviet floors made of boards, standing on logs, which, in turn, lie on top of concrete. There is nothing to talk about here - you need to dismantle the old floor and pour a new screed on top.Yes, you will need time and additional cash injections for this, but you will get a good even coating that will not squeak, and heating the floor will become more efficient.

Dry underfloor heating on a wooden base

- If the floor itself is made of wood, then you should not overload it. In this case, the installation of a "dry warm floor" is recommended. We are talking about modular and rack systems, with the help of which deep channels are formed on the floor for laying pipes. By the way, an electric heating cable can also be located inside such a base.

- Such systems are made from different materials. They are intended for laying on logs or a hard, even base. Furrows are cut inside, or they are formed by the material itself. The dimensions and shape of the modules are selected according to the intended pattern.

Table. Different options for bases under a water floor on a wooden floor.

| Plywood | Channels can be formed from plywood. The user has the opportunity to purchase ready-made modules or cut channels on their own with a milling cutter. The same can be done with a tree. |

| Styrofoam backing | This version of the substrate is extremely effective, since polystyrene foam is a good heat insulator. It is dense, but this is not enough for mounting on logs, so plywood or boards are laid from below. The surface of the material is divided into cells into which the pipes are simply inserted. If it is necessary to turn the route, additional cuts are made with a clerical knife. |

| PVC base | Very easy to use PVC mats. They have many protrusions, between which pipes are laid in any convenient order. This system is very strong, so that the floor coverings are laid directly on top.On top of it, you can make a thin layer of self-leveling floor. |

| OSB panels | Unlike plywood, OSB is not afraid of moisture, so the use of this material with water floors is more justified. The principle of the design device is no different. The material must be taken of such a thickness that the pipes recessed in them do not touch the floor covering. This will increase their service life. Chipboard can also be attributed here - the principle is the same, but the material is also sensitive to water, like plywood. |

| Wooden rack base | You can also form channels from wood. Whole boards or small slats are used for this, as shown in the photo. Such a solution will not cost a lot of money, it is reliably and quickly mounted. On top you will need to install durable sheet materials. |

| gypsum fiber | You can also cut channels from gypsum fiber. This material is strong enough to bear the loads of walking, is easy to process and is not afraid of water. From above, you can make both flooring and screed. |

| Extruded polystyrene foam | Modular systems made of expanded polystyrene are an excellent foundation. You can make a screed on them, or lay a laminate directly on top. The material is very rigid, so it will cope with loads without drawdowns. |

Metal roll foil for better heat transfer

Metal is a good conductor of heat. It warms up quickly and evenly, which contributes to better heating of the floor covering. If you install it on a layer of foam or other insulation, you get an effective heat-reflecting surface that will redirect all the heating energy towards the room.This will cause the substrate to gradually gain temperature and the laminate laid on it.

Heating foil laying

The most rational and economical way of laying heating films is along the length of the room. In this case, it turns out to reduce the number of connection points to a minimum. Accordingly, fewer cuts will have to be made. Film webs can be separated only along the cut lines marked on their surface.

Heating foil laying

It is possible to lay the film both closely and at some distance between the canvases. Dense laying will provide more uniform heating, however, the required power of the entire underfloor heating system should be taken into account. Depending on the characteristics of the thermal film, the power of one linear meter can reach up to 200 or more watts.

Overlapping fabrics are not allowed

| Index | Meaning | Dimension |

|---|---|---|

| Specific power consumption | 170 | W/ m2 |

| Thermal film width CALEO GOLD | 50 | cm |

| Maximum length of one strip of thermal film | 10 | linear m |

| Thermal film melting point | 130 | °C |

| IR heating wavelength | 5-20 | micron |

| Share of IR rays in the total spectrum | 9,40 | % |

| Anti-spark mesh | + | — |

| CALEO GOLD 170 W. Price | 1647-32939 (for sets from 170-0.5-1.0 to 170-0.5-20.0) | rub. |

| CALEO GOLD 230W. Price | 1729-34586 (for sets from 230-0.5-1.0 to 230-0.5-20.0) | rub. |

So that in the process of work, the previously laid strips do not move from a given position, they are attached to the thermal insulation with construction tape. You can also use a construction stapler or self-tapping screws. Staples and self-tapping screws can be used only in those places of the canvas where there is no direct heating strip.

The film is fixed with adhesive tape

The cuts are treated with non-conductive bituminous insulation.The grounding bus is bent and remains free for now.

Laying laminate flooring

Having decided to install infrared systems under the laminate, it should be borne in mind that this process has its own characteristics, which depend on the type of infrared system used.

Do-it-yourself installation of laminate on a cable floor

creating a screed

- The presence of a tie provides protection for heating cables from the aggressive effects of external factors;

- Thanks to the screed, it is possible to ensure an even distribution of the floor.

However, during the execution of this work, a problem occurs:

- Most often, when laying a laminate, a heat and sound insulating substrate is placed under it. However, remembering that the laminate will be used with underfloor heating, the underlayment will do more harm than good. The fact is that because of it, less heat generated by heating cables enters the floor surface.

- You can solve the problem if you do not use the substrate at all. However, only owners who are ready to put up with the noise that will occur while walking on the laminate can take such a step.

- But you can do otherwise, while maintaining high soundproofing properties of the flooring. To do this, after laying the heating cables, a thinner screed is created on top of them, and the substrate itself is already placed on it, the thickness of which should not exceed 3 mm. Then this will not affect the soundproofing characteristics in any way, and there will be no heat loss during its passage to the floor.

Do-it-yourself installation of laminate on a film floor

have many advantages

A thin film is used as the basis here, which does not change the height of the floor.In addition, during the installation of such infrared systems, there is no need to create a screed. Thanks to this, in most cases one day is enough to lay not only the warm floor itself, but also to install the laminate.

Those who decide to independently install the laminate on the film floor should remember a number of important nuances:

- it is not recommended to lay this floor in places where heavy furniture will subsequently stand;

- after the completion of the laying of the heating film, it is desirable to place polyethylene of a sufficiently large thickness (at least 80 microns) on it. The use of such a film will help to avoid getting liquid on the heating elements;

- in the absence of a polyethylene film, it can be replaced with a special heat-conducting substrate under the laminate. However, it should be remembered that it costs much more than ordinary polyethylene. But its high price is offset by better thermal conductivity characteristics;

- Having finished the work on laying the film, it is time for the installation of the laminate. Video instructions, of which there are many on the network, will help you do everything without errors.

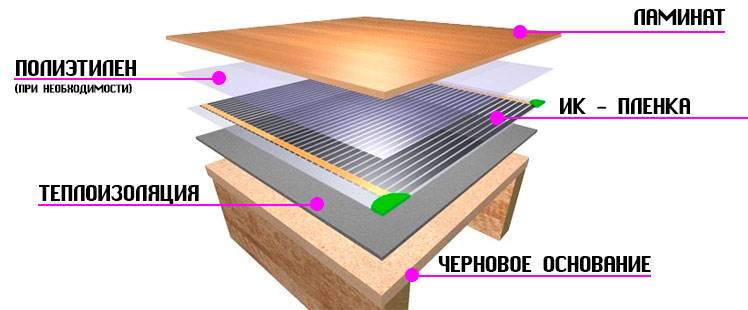

Film (infrared)

Film floor with infrared heating radiation mounted from 3 layers:

- an insulating screen made of foil with a foamed polymer coating such as penoizol or penofol;

- film generator of infrared radiation;

- final decorative laminate layer.

The entire heating structure is laminated with technical polyester, providing excellent protection and waterproofing. The thickness of the film floor does not exceed 0.5-1 cm, but the maximum efficiency reaches 90-96%.The absence of a screed allows heat to penetrate into the room directly through the laminate board.

The electricity consumption of such a design is significantly lower than that of a cable-type electric floor. But the generator film is easily damaged under the pressure of large loads during operation. It is better to install it only in places without bulky furniture or household appliances.

These floors are great for heating houses that do not have central heating. They are also indispensable in the autumn-spring period when stationary heating is turned off. The ability to install a generator film in walls and ceilings explains its demand not only in residential buildings, but also in hospitals, hotels, kindergartens.

Infrared floor heating is an excellent solution, its advantages are ease of installation, cost-effectiveness, mobility, flexibility and safety.

When purchasing such a floor, you should check the serviceability of the thermostat, the quality of the wiring, the presence of fasteners and shielding reflective material.

So, we decide on the choice of a warm floor. Of all the options, the film floor seems to be the most advantageous. It has a minimum thickness, is economical in terms of energy consumption, and is easy to install. The temperature regulator allows not to heat up a laminate more than on 26 °C.

Heating above this temperature leads to the release of formaldehyde, which adversely affects the health of the inhabitants of the house. Therefore, when choosing a warm floor in your home, first of all, stop at designs that have thermoregulation!

Tips for laying underfloor heating under laminate

Knowing all of the above, you can mount different underfloor heating systems under the laminate, and additional tips will help to work even better:

- before laying a warm floor, you need to draw up a layout plan for both wires and thermal films;

- in an apartment with low ceilings, it is better to use thermal film, as it “eats” less height;

- for self-assembly, it is better to choose a system that does not require the intervention of specialists, that is, the simplest;

- if a floor heating system is installed in a private house on the ground floor, it is recommended to lay a waterproofing layer;

- to save money on wires, the temperature sensor is installed approximately in the middle of the room;

- the structure must be mounted so that in the future it will be possible to repair it;

- in rooms with a high level of humidity, thermal film cannot be used;

- if massive furniture will be placed on infrared floors, then it is necessary to equip air pockets;

- thermal film does not fit close to heating appliances, fireplaces, stoves;

- the length of one strip of thermal film should not exceed 15 m;

- at sub-zero air temperatures, laying infrared floors is prohibited;

- the installation of the film should be carried out with the grounding of the structure.

Installation of film underfloor heating

After the underfloor heating system is laid and the laminate is laid, commissioning must be carried out no earlier than on the fourth day after completion of work. At the same time, as soon as the heating season begins, the temperature should be clearly regulated: the floors gradually warm up to the optimum temperature (the power gradually increases by 5-6 degrees). The reduction should also be gradual.

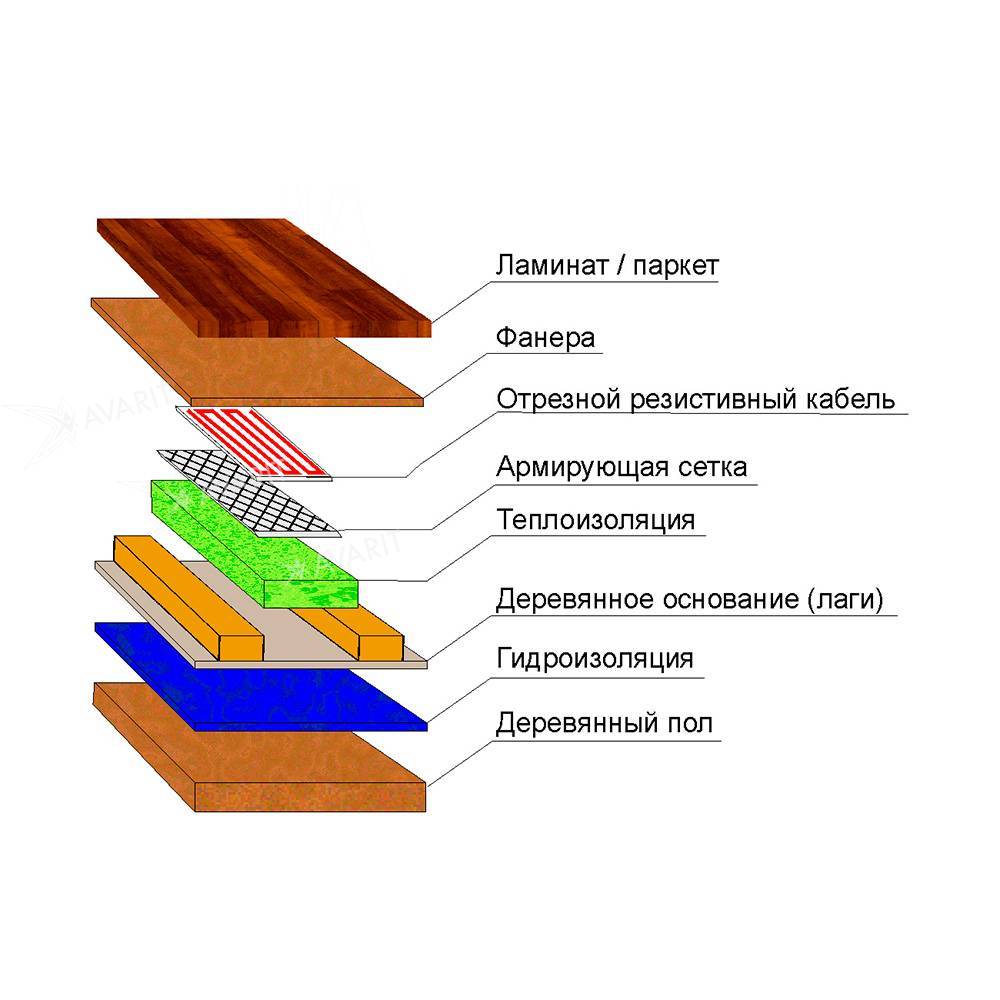

1 Nuances when working with wooden floors

A standard warm floor is a system of heating circuits that are laid under the screed. The contour can be water pipes, electrical cables or a special film called an infrared floor. In any case, the principle of action there is almost the same.

The floor is heated by the action of a circuit that releases heat. The contour is laid with a snake or a spiral. The laying principle is to cover every square decimeter of the floor so that there are no cold spots left.

Water and electric floors are laid under the screed, even if expanded clay is used to insulate the floor. The screed is made of lightweight materials with excellent thermal conductivity. That is, the screed takes on the entire temperature of the floor and fully gives its coverage. And it already, respectively, heats the room itself.

With film floors, things are different. For the most part, they are too weak to warm up the screed directly. It is rather an additional source of heating, although quite powerful. They are placed immediately under the floor covering, covering only the substrate.

1.1 Features of the tree

The complexity of the situation in which the wooden floor drives us is its poor thermal conductivity. If the screed is well gaining heat and retains it, gradually giving the coating.

It is more difficult to warm up an ordinary board, and it gives off heat very reluctantly. That is, the influence of the underfloor heating system is limited due to the poor thermal conductivity of the material.

The next obstacle is the substrate under the coating and the coating itself. A wooden floor is rarely made from ordinary boards. Most often, the boards are a rough coating, on top of which the front is laid.

As you understand, the same parquet or laminate without a substrate with a polyethylene product cannot be mounted at all. But the substrate in most cases has the properties of a heat insulator, although not very reliable.

That is, a weak heat transfer from the boards will also be extinguished by the substrate. As a result, you will get a barely warm floor, even if it works at full capacity.

Let's also not forget the fact that a water or electric sample of a heating system, and indeed, like a film one, needs efficient heat transfer.

Another scheme for arranging the heating circuit, this time the installation is carried out on plywood

That is, the pipes must be in direct contact with the elements that are heated. Or is very close to them. With wooden floors in their standard application with similar nuances, difficulties also arise.

As you can see, the usual laying technology is not suitable here. We need to act differently, improvise. Fortunately, all technologies have long been invented, you just need to consider them and apply them in your work when designing a floor heating system.

1.2 Selection of the floor system

Let's deal with one important nuance right away. Not all heating systems of this type are advantageously used when working with wooden bases. Professional builders use only underfloor heating:

- Water;

- Electric.

Moreover, samples with high power are used, since the thermal conductivity of wood still leaves much to be desired.

For the same reason, film floors are practically not used. They are too weak, and are not able to effectively give off heat in such large quantities. And those models that can, consume too much energy. Using them becomes simply unprofitable.

Water and electric samples are another story.

Water floors are quite powerful and, most importantly, stable. With proper wiring of the heating unit and the installation of three-way valves, the cost of maintaining their normal temperature can be significantly reduced. At the same time, you should not be afraid that the floors will break through, and they will spoil the wood.

As a rule, in working with them, in any case, only moisture-resistant samples are used for warming the lag floor.

At the same time, you should not be afraid that the floors will break through, and they will spoil the wood. As a rule, in working with them, in any case, only moisture-resistant samples are used for warming the lag floor.

Electric models, when finished with a wooden floor, are also good. Their maximum heating temperature is even higher than that of the previous version, but the problem here lies elsewhere.

In the event of a short circuit, there is a small chance of the coating igniting or of its thorough damage, which, of course, is completely unacceptable.

The coating on the film floor can be laid without preparation

Therefore, we still recommend using a water-heated floor as the best option.

Conclusion

Thus, the choice of underfloor heating for laminate flooring depends on several factors. The conditions of the room, its characteristics, the allowable budget and the desired heating power play a role here. Infrared underfloor heating is the best choice for laminate flooring as it comes with upgraded heating technology that not only heats the entire floor surface, but also saves energy. Installation of the floor must be done in stages, without missing a single step.If you follow all the rules, then both the warm electric floor and the laminate will last for many years.

Helpful2Useless