- A few tips for safe operation

- Laminate manufacturer's requirements

- Tarkett laminate and floor heating

- Laying QuickStep laminate on underfloor heating systems

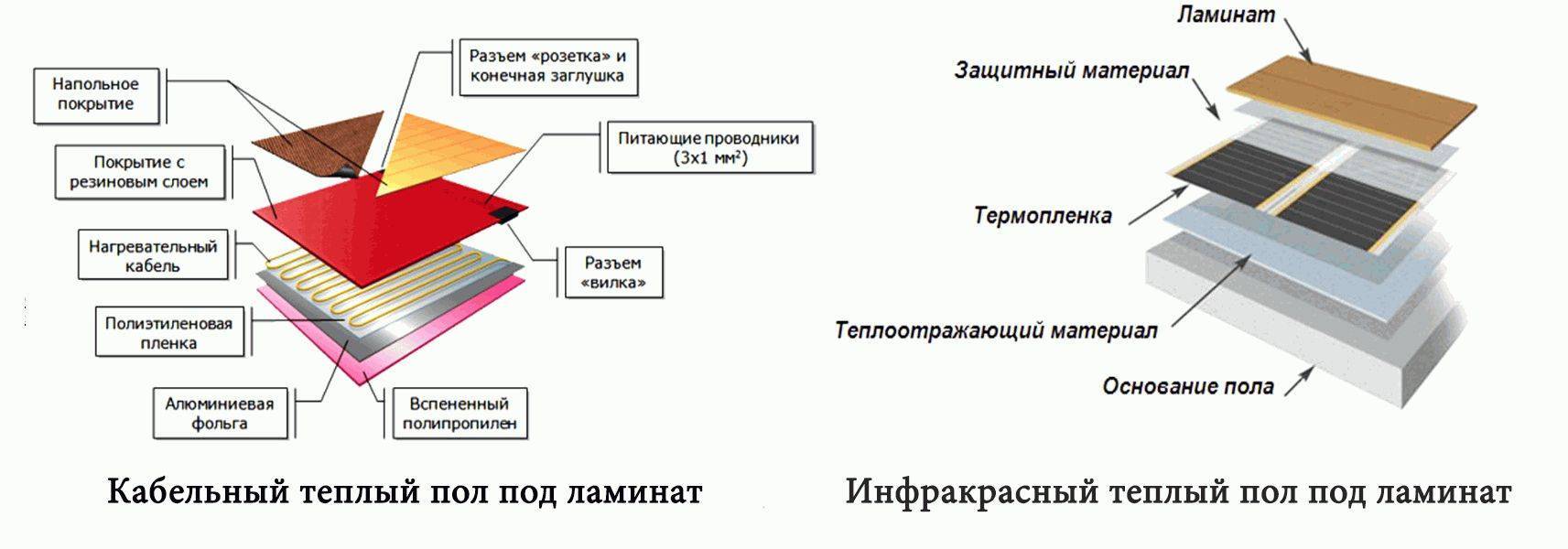

- Which electric floor is better for laminate

- Teplolux two-core cable

- Nexans Millimat

- Ensto

- Veria Quickmat

- How to properly prepare the base

- Installation of electric heating

- infrared heating

- How to choose a laminate

- Electric floor under the laminate - do it yourself

- Infrared floor installation

- Mounting technology on the example of cable systems

- Which underfloor heating is better for laminate

- Features of laminate flooring combined with underfloor heating

- Choosing a laminate on a water-heated floor

- How to install a dry floor on a wooden base?

- The right choice of laminate

- Laminate with own heating

- General tips for laying underfloor heating under laminate

A few tips for safe operation

When planning the installation of a warm floor, do not forget that neither electrical cables nor water pipes can be laid under heavy pieces of furniture. Also, do not install a warm floor in close proximity to a wood-burning, gas fireplace, stove and other heating devices.

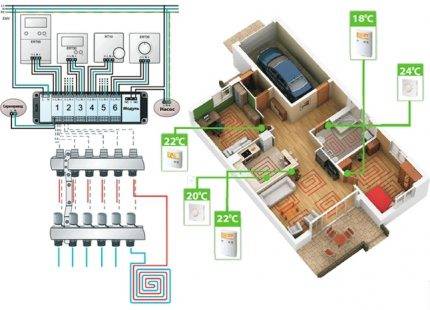

For premises for various purposes you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24 ° C, and 20 ° C is enough in the kitchen and corridor

For premises for various purposes you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24 ° C, and 20 ° C is enough in the kitchen and corridor

Practical nuances:

After the repair is completed, you should leave the heating system turned on, and maintain the same temperature regime for 3-5 days

This precaution will heat the entire floor pie evenly and thoroughly and ensure reliable operation of the system.

At the beginning of the heating season, you need to properly prepare the floor heating system for operation. To do this, increase the degree of heating by 5-7 units every day until the temperature reaches the required value.

This approach will avoid a sharp jump in temperature, which can damage the laminate and other materials. Similarly, heating is turned off for a warm period.

Do not forget that the film infrared floor does not tolerate moisture well. Therefore, it is not recommended to install it in rooms with a humidity level above 70%, and after wet cleaning, wipe the laminate dry.

The optimum temperature for underfloor heating is considered to be in the range of 20-30 degrees.

Lastly, do not cover a heated laminate floor with carpets or other furnishings that interfere with efficient heat distribution.

Laminate manufacturer's requirements

Each flooring manufacturer tests its products, knows the characteristics of the material and, based on this, puts forward its own recommendations for use on underfloor heating.

Tarkett laminate and floor heating

The manufacturer Tarkett sets the following requirements:

Heating elements (of any type) must be inside the base (concrete screed, etc.)

-

Laying on an infrared heating system is possible only if the surface temperature does not exceed 28 °C.

-

The temperature limit - no more than 28 degrees on the surface of the base applies to all heating systems.

-

If the maximum heating temperature is above 28 °C, then a temperature controller is required to ensure that the maximum is equal to this value.

-

An increase in the temperature of the base above the permissible value can cause defects in the coating, raising the laminate "house" and making it unusable.

Laying QuickStep laminate on underfloor heating systems

The Quick Step brand manufacturer gives the following instructions:

It is not recommended to use systems that include, along with the heating function, the cooling function.

Use Quick Step laminate with underfloor heating systems – water and electric. In this case:

1. Heating elements are distributed in accordance with the instructions for the heating system.

2. The screed is poured, the time required to dry the base is waited.

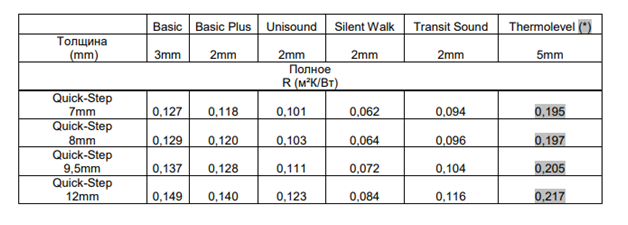

3. It is recommended to lay a Quick Step underlay with waterproofing or an underlay and a film with a thickness of at least 0.2 mm. At the same time, the indicators of the laminate and the substrate are taken into account and the total coefficient of thermal resistance is calculated, which should not exceed 0.15 m2 * K / W. You can select the substrate for the selected laminate thickness by the allowable value from the table. It can be seen that the Thermolevel underlay is not suitable for use with underfloor heating systems.

When choosing a film heating system, work is performed in the following sequence:

one. A substrate is laid on the base for leveling, floor insulation, and electrical connections can be hidden in it to prevent moisture from entering them.

2. An infrared film system is laid on the substrate with uniform heat distribution, with the heating flow directed upwards.

3. Then the laminate is laid in a floating way.

There is another novelty in the field of floor heating - frame frames with built-in water capillaries or electrical resistances. They are also acceptable when used with lamellas, installed directly under the coating in compliance with the requirements for maximum heating.

Underfloor heating is an excellent option for creating comfortable indoor conditions. There is a warm surface underfoot, and the air above is not as hot and dry as with radiator heating. The laminate itself is cold to the touch, and underfloor heating systems solve this problem.

Which electric floor is better for laminate

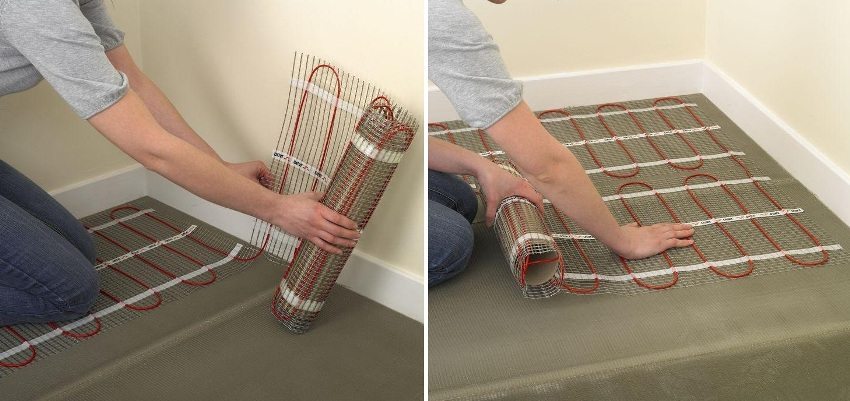

Manufacturers offer many options for electric underfloor heating, but not all of them have the desired characteristics. Consider the most basic and popular models in the building materials market. It is best to use matte underfloor heating

Teplolux two-core cable

Refers to the type of matte coolants with a power of 800 W. It consists of several sections, which are attached to each other on special mounting tapes. Installation of equipment can be done independently.

Advantages:

- easy to control the degree of heating;

- warranty period - up to 25 years;

- easy to connect to the main electrical system;

- The kit comes with a lot of useful accessories.

Flaws:

In order for the heating to be carried out properly, an additional source of electricity is needed.

Nexans Millimat

Also applies to matt underfloor heating. The whole structure consists of several sections. In each of them, a cable in a snake layout is placed on a mesh surface. Parts are fastened with an adhesive backing. The total power is 1800W.

Advantages:

- Can be used with other floor coverings more than once;

- high surface heating rate;

- easy installation and fast assembly;

- the device is fully automated.

No shortcomings of this equipment have been identified. Suitable for any coatings and premises, and also has a very budgetary cost.

Ensto

The Estonian manufacturer has taken care of those who would like to install a warm floor in a damp room. The equipment can be installed not only under a laminate, but also under a tile, concrete, brick and other materials. The floor consists of a mat on which the cable is attached, a corrugated tube and an aluminum tape. A corrugated tube is needed for the functioning of the temperature sensor.

Advantages:

- easy to install;

- is cheap;

- does not cause trouble during use;

- evenly heats the surface and protects against burns.

Flaws:

installation can only be carried out at temperatures above +5 degrees Celsius.

Veria Quickmat

This equipment is made in Poland. The cable in this device is also two-core, as in previous versions. There are 150 W per 1 square meter, which heats the room very efficiently.Also in the composition there is Teflon insulation, which allows you to maintain high temperatures. The equipment can heat up to 120 degrees.

Advantages:

- good insulation of wires, which guarantees protection against short circuits;

- operated for 30 years;

- laid in a thin layer, suitable for rooms where a strong raising of the floor level is not required;

- easy to fit.

Flaws;

high cost in the market of materials.

How to properly prepare the base

There are several ways to prepare wood flooring for underfloor heating. The best replacement for a concrete screed is the installation of chipboard slabs from 16 to 22 mm thick. It will be able to withstand a significant load, stabilize the wooden base and will not crush the heating elements. Both electric and water heating elements can be laid on it.

Flooring device in a wooden base for underfloor heating

- The plate is laid on the logs. It is better that the step size is no more than 60 cm, otherwise the installation of additional bars will be required.

- Before laying the slab, waterproofing and insulating material are laid, so that it is in the gaps between the lags.

- The next steps depend on the type of heating you have chosen. If these are electric heating elements in the form of a film or mats, then you need a soft foil substrate that will reflect heat into the room. The water and cable version of heating will require fasteners or guides, between which the heating elements will be located.

Installation of electric heating

What type of heating is better to choose for a wooden base? Installation of the cable version will require effort in the form of installing fasteners or elements between which the cable will be located. Such elements can be sawn grooves in the boards, aluminum rails or wooden plates.

Step by step installation of electric underfloor heating

Therefore, the best option for a wooden base under a laminate can be considered an electric warm mat or infrared film. Why?

-

The flat warm mat and infrared film are heavy duty and built for effortless installation.

- They can be laid under laminate flooring without an additional slab, provided that the wood flooring is sufficiently even and strong. In this case, all the cracks between the boards are foamed, the boards are leveled in height, and all irregularities are eliminated. Foil insulation is laid on the waterproofing film, and mats or infrared film are placed on top.

- Infrared warm mat or film was created specifically for laminate flooring, this is the most gentle warm floor option for such a coating.

The disadvantages of electric heating is that it will require a significant amount of electricity. With any, even the most economical option, this is a tangible amount. The most economical models of electric mats, equipped with various technical innovations, are quite expensive. Therefore, we are returning to the cable version of electric heating, which, with all the costs and labor, is more economical in the end.

Pros and cons of electric underfloor heating

infrared heating

When faced with a choice between electric mats and infrared film, do not hesitate to choose which one to choose. The most convenient and profitable option of all available is film, for several reasons.It was really conceived by the creators as an option for additional heating for such coatings as laminate, linoleum, carpet.

Connection of an infrared heat-insulated floor

Taking into account the latest achievements in this field, Kaleo infrared floors are unique in their characteristics. They can withstand significant loads, are versatile, easy to install, and can heat up to + 60 degrees. Kaleo produces several types of infrared film and mats, from budget to expensive options. They can effectively warm up the room even in the presence of a concrete screed.

Undoubted advantages:

Benefits of infrared film

What insulation is recommended to use under such a film? The manufacturer offers it as a set, as it is made using special technologies from lavsan.

How to choose a laminate

You should carefully and responsibly approach the selection of a laminate under a warm electric floor.

The main nuances that pay attention to when choosing a material are:

- Thermal resistance. It reflects the thermal insulation properties of the coating. The bigger, the better. The maximum value is 0.15 m2 K/W. It is influenced by the properties of the substrate: the higher the porosity, the worse the thermal resistance.

- Material class. This is a minor indicator. The higher the cost, the better the quality. For an expensive laminate, a minimum amount of formaldehyde is used. The material wears out more slowly.

- Maximum temperature. It is necessary to clearly know the maximum possible heating for the selected type of lamp panels so that they do not lose their properties. Usually around 30 degrees.

- Panel bonding method. Laminate, which is held together with glue, is not suitable for heated floors.When heated, the adhesive composition loses its properties. Locks will fit.

- Lamella thickness. The greater the thickness, the less heat enters the room. Thick material does not conduct heat efficiently enough. But thin types are too fragile, they are distinguished by weak fastenings. Optimal 8 mm.

Coating selection

Coating selection

Electric floor under the laminate - do it yourself

Any electrical system can be done approximately in the following sequence:

- foundation preparation;

- arrangement of waterproofing;

- arrangement of thermal insulation;

- laying heating elements;

- installation of a temperature sensor, connection of a heat regulator;

- test check of heating operation;

- screed formation - wet or dry;

- substrate installation;

- laying laminate.

Do-it-yourself installation

Do-it-yourself installation

Concrete screed is required when laying cables or thermomats. When it is impossible to pour the screed, for example, on a wooden floor, then chipboard or boards are placed on the base, leaving free space between them.

Next, the installation of metal sheets with grooves is carried out. They have a heating wire. Plywood is laid on a film system when it is planned to lay tiles or other material with a large weight on top.

Infrared floor installation

To carry out the installation of the film system, you need the following materials and tools:

- infrared film;

- thermal insulation without foil;

- clamps;

- Temperature regulator;

- pliers;

- scotch;

- scissors;

- bituminous insulation;

- wires;

- screwdriver.

- Dismantling of the old finish.

- Base leveling. If necessary, a self-levelling compound is required.

- Thorough cleaning of the subfloor from sand, dust, debris.

- Laying thermal insulation, the sheets of which are connected with adhesive tape.

- Underfloor heating installation.The thermal film is cut into segments of the desired length with scissors. The film is placed on the insulation with the copper bus down. You can cut it anywhere, the main thing is not to touch the heating elements.

- Connecting pieces of film to each other with adhesive tape.

- System connection. The opposite ends of the bus are insulated with special insulating tape. Contact clamps are attached to the film with pliers. Wires are attached to the clamps according to the scheme, they must be insulated on both sides. Recesses are formed in the thermal insulation - for clamps and wires. This allows the coating not to rear up in certain places.

- Installation of a thermostat. Wires are attached to it in accordance with the instructions and the diagram.

- After the installation of the heated floor, the laying of the laminate is realized.

Mounting technology on the example of cable systems

Before proceeding with the installation, the floor is leveled, a cement and sand screed no more than 0.3 cm thick is made for it. When necessary, thermal insulation is additionally placed. Drying of the screed will take 3 days. After that, the damper tape is fixed, then the thermostat in the selected place. The cable is laid strictly according to the instructions on the package.

After completion of the work, a screed 3–10 cm thick is formed again. It will completely dry out only after a month. Only then is the finish coat applied.

Cable structure installation

Cable structure installation

The main requirement for a laminate is the ability to conduct heat. For this purpose, the panels have special holes. The installation process includes the following steps:

- Cutting the comb on the boards in the first row.

- Laying the first panel in the corner farthest from the door.

- Formation of the first row.

- Formation of the second and subsequent rows, their connection with the previous ones.

- Wedge dismantling.

- Plinth installation.

Which underfloor heating is better for laminate

First of all, it is necessary to choose the right laminate itself, since not all of its varieties can function normally in conjunction with underfloor heating. Laminate coating must meet certain requirements and specifications. Typically, such a material has high strength, and its thickness is at least 8-10 mm.

On quality products there is a marking indicating the possibility of using laminate in conjunction with underfloor heating. For example, the designation H2O allows the use of such a coating with water floors. Markings E4-E0 correspond to the amount of free formaldehyde, which is a binder in the resins - components of the laminate. For laying on warm floors, products of the E1-E0 brand are recommended, which do not emit harmful volatile substances when heated.

The value of the thermal resistance of the material is reflected in its passport. In addition, the marking may contain the value of the maximum temperature allowed for the coating. Usually its indicator is 250 and above. The laminate is laid with glue or special locks. You can use any of the options, but it is still preferable to glue the connection.

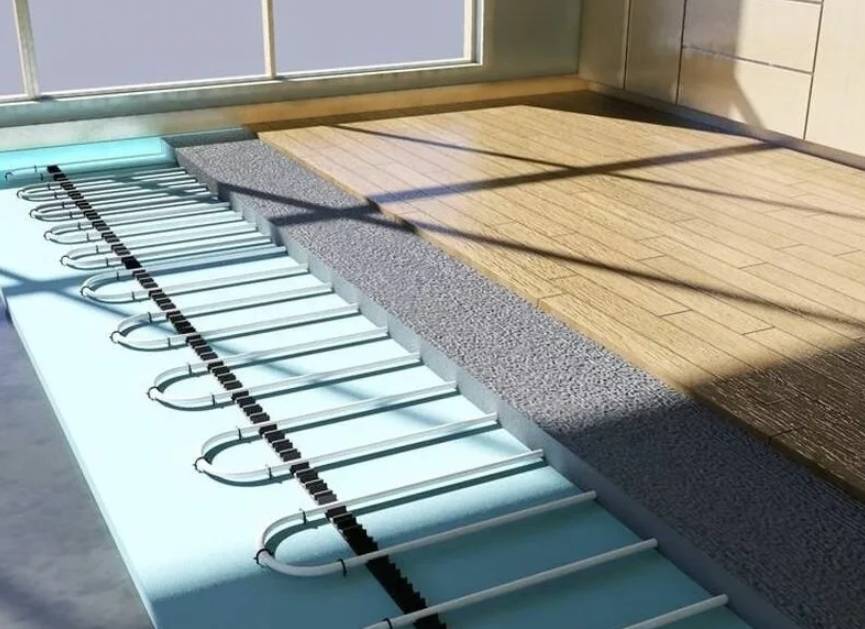

The most reliable and safe are water heated floors. After installation, they are obtained in the form of a kind of puff cake. First, a layer of waterproofing is laid on the prepared floor base. Possible expansion of the screed is prevented by the use of a damping tape covering the entire perimeter of the room. Next, a thermal insulation device is performed, pipes are installed, after which you can proceed to the screed. The floor covering is installed over the entire structure.

Heating of the room occurs due to the water circulating through the pipes and giving off heat. The total thickness of the water floors is in the range of 5-15 cm, due to which the ceiling height is noticeably reduced. In addition, significant disadvantages are considered to be difficulties in the installation of such systems and rather heavy repairs when they fail. However, the safety and cost-effectiveness of water floors allows them to be successfully used with laminate flooring.

An equally effective option for laminate flooring is the use of an electric heating cable. When deciding whether it is possible to have a warm floor under a laminate, it is recommended to use economical two-core structures in apartments, since they are easier to install. Therefore, single-core cables are best suited for private homes. In both cases, the conversion of electrical energy into thermal energy occurs. However, if at least one section is damaged, the entire system fails at once.

To avoid such situations, it is recommended to use a self-regulating cable that can independently control the temperature along its entire length. If in one of the sections the temperature becomes higher than normal, this leads to an increase in the resistance of the cable in this particular section. After that, the temperature quickly decreases to the desired level.

Heating mats are considered a type of electrical cable. This system is much easier to install because the cable attached to the mesh does not require a cable tie.Such floors are durable, have the ability to adjust the temperature to the desired level. Common disadvantages of all electric underfloor heating are the cost of electricity and a low level of electromagnetic radiation.

Most often, infrared film floors are used in conjunction with laminate flooring. They are among the latest most progressive developments among such systems. The infrared film itself is located on a heat-reflecting base, and the top coat is already laid directly on it.

These designs are reliable, durable, they are easily and quickly mounted in any conditions. They do not require additional pouring of the screed, which significantly speeds up installation. After the film floor heating is laid, you can immediately lay a laminate on it. Infrared floors are considered economical and consume a small amount of electricity.

The disadvantages that create certain difficulties include the need to prepare a perfectly even base, the absence of high humidity in the premises and the high cost of the entire system.

Features of laminate flooring combined with underfloor heating

Laminate is a popular flooring

withstand temperatures up to 40 degrees. It is durable and elastic. disadvantage

can be considered a high cost. If there is a special marking, it is allowed

proximity to heating structures, can be laid on any type of warm

floors.

Insulation should be placed between

lamellas and underfloor heating with a thickness of 2 to 5 mm. This needs to be done in order to

to separate the laminate from the concrete base. Its absence may lead to

the formation of play at the junction of the boards, which will lead to unpleasant sounds when

walking.

On a positive note, you can

consider the presence of a special property of the material from which it is made

lining - the ability not to react to an alkaline environment. They also don't like him

rodents and insects

Not unimportant is the ability of the substrate to carry out

micro-ventilation of the floor, due to which condensate does not accumulate

Choosing a laminate on a water-heated floor

Which is better to buy laminate floor heating Does this solution have significant drawbacks? Like on your own make water warm laminate floors? Many people ask these questions, and therefore, let's understand.

First, let's define terminology. What is underfloor heating system?

This is a system of pipes that, with a small step, are laid under the finish coating and warm it up. The warm-up temperature will be slightly lower than the temperature of the human body. What is the essence of such a heating scheme?

1. You can connect water heated floors to any boilers with circulation pumps, even solid fuel ones.

2. In order to create a water heated floor, there is no need to remake an existing heating system - you just update it with another circuit.

3

It is necessary to pay attention to the fact of adjusting the temperature, or adjusting the speed of water circulation, so that warm water temperature the floor was in the desired mode and did not go beyond.

4. Another plus - due to the fact that the heat source is located below, the air is heated throughout the volume.

Of course, we all know that the truth is in the details. So, what is needed in order for the underfloor heating to function normally? Yes, we are talking about the idea of good thermal conductivity of the floor covering mass surrounding the pipe. Just in order to ensure this requirement, pipes of water-heated floors are usually laid in a screed.

Otherwise, the pipe will warm up only that section of the floor that passes above it, and the main part of the floors will remain cold. Among other things, the screed also performs the function of distributing heat. But here the question arises - what is the point in heating the screed if it is isolated from the room?

So the most traditional option for laying a water-heated floor is under a tiled or porcelain stoneware coating - they have good thermal conductivity. Another good option is homogeneous linoleum.

As for the question of which laminate to choose for underfloor heating, the answer is actually quite simple. Common sense must be followed. Since the laminate is made of pressed hardboard, its thermal conductivity is quite low, it serves as a heat insulator. Accordingly, the smaller the laminate boards are in thickness, the more efficient the heating will be. Speaking of a higher grade laminate, you need to understand that its density is higher, and the protective coating is thicker.

It is on this that its thermal conductivity depends. There are other reasons why you should purchase higher grade laminate flooring for your underfloor heating. The higher the class of the laminate, the less it will be prone to drying out and changing linear dimensions depending on temperature fluctuations and humidity.The more durable and durable it will be.

In addition to the laminate you have chosen, you should not forget about the substrate, because a lot also depends on it. We recommend that you choose this type. underlays for laminate, which will be designed specifically for underfloor heating systems and have maximum thermal conductivity.

How to install a dry floor on a wooden base?

- Polystyrene boards;

- Wooden slats and modules

Polystyrene mats, smooth or with bosses, are laid on the wooden surface. If they are smooth, then you need to cut holes in them for laying pipes. This dry floor installation system is not very expensive and very convenient. Most often, ordinary foam up to 4 cm thick or polystyrene foam is used. If the plate has bosses, that is, protrusions not higher than 25 mm, then polyethylene pipes (diameter 16 mm) are placed in the grooves and secured with mounting locks.

Modules can be bought at the store and assembled at home. Pipes are laid in recesses on the surface. The rack system is made of planks 2 cm thick and 130 cm wide with a pipe pitch of 150 mm (MDF or chipboard material). Often, metal plates are also installed, which create a continuous warm field. At the end, a substrate and a laminate are laid on the surface of the underfloor heating pipes.

The right choice of laminate

An important characteristic is the indicators of the limiting heating temperature. no damage characteristics of the material its surface should be heated to at least 30 degrees. Accordingly, depending on the selected temperature class of the coating, in the future it will be necessary to configure the temperature sensors that control the operation of the electric underfloor heating

Accordingly, depending on the selected temperature class of the coating, in the future it will be necessary to configure the temperature sensors that control the operation of the electric underfloor heating.

Today, many manufacturers offer customers a special laminate designed for use with heated floor material. Such a coating will have a special marking, which greatly simplifies the choice of material.

Laminate with own heating

This is an innovation in the construction market: the heating system is already built into the panels. Each lamella has its own heating elements.

Scheme of lamella with autonomous heating

The advantage of this system is that a warm floor is mounted under the laminate without screed and separate heating elements. Thus, there is a more efficient use of the thermal floor. Energy is not wasted on heating the screed, as with a conventional underfloor heating system.

Thus, heat losses are much lower. It is also not difficult to calculate the required thermal power. Per square meter of laminated tiles, it ranges from 40 to 70 watts. You can create zones without heating.

Laminate, as in other cases, is laid on a substrate. Its use does not affect the heating of the floor surface and does not violate the temperature regime. It is desirable that it be made of environmentally friendly material, but this is a rather expensive option. Cheaper will be a synthetic underlay that has the same thermal resistance as the laminate.

General tips for laying underfloor heating under laminate

Before installing a heating floor, it is necessary to draw up a work plan in advance. For low ceilings, it is recommended to use thermal film.In the case of self-assembly, it is better to choose the most simple and understandable system:

- a waterproofing layer is required in private houses or apartments on the ground floor;

- to save on the length of the wires, the temperature sensor is built into the center of the floor;

- it is necessary to mount the structure so that in the future it can be disassembled, if repair requires it;

- it is forbidden to use thermal film in rooms with high humidity;

- lay the thermal film away from heating devices;

- length of one strip up to 15 meters;

- at temperatures below zero, infrared floors are not mounted;

- you need to ground the structure;

- if heavy furniture is planned to be placed on infrared floors, it is necessary to equip air pockets.

Thus, the system of self-heating floors is convenient and comfortable to use. She has proven herself very well. More and more people are opting for it. This is both practical and aesthetically pleasing: no radiators or other heating devices.

Underfloor heating for the whole family

Underfloor heating for the whole family

Today there are a large number of building materials. The efficiency of the “heating floor” system directly depends on the right choice of material. Linoleum, ceramic tiles and other materials are widely used. Laminate is as good as these more traditional floorings.

However, when choosing, it is very important to consider the characteristics of the coating:

- resistance to high temperatures, so that deformation does not occur during temperature changes;

- good thermal conductivity, so that there is no overheating and the entire room is heated evenly;

- low level of formaldehyde emission;

- when choosing a lock, it is better to give preference to the “click” system. The likelihood of cracks with such a lock is minimized.

Choosing the right laminate flooring, combined with the right kind of heating system, will ensure a comfortable, warm home.