- Selecting the type of heat pump

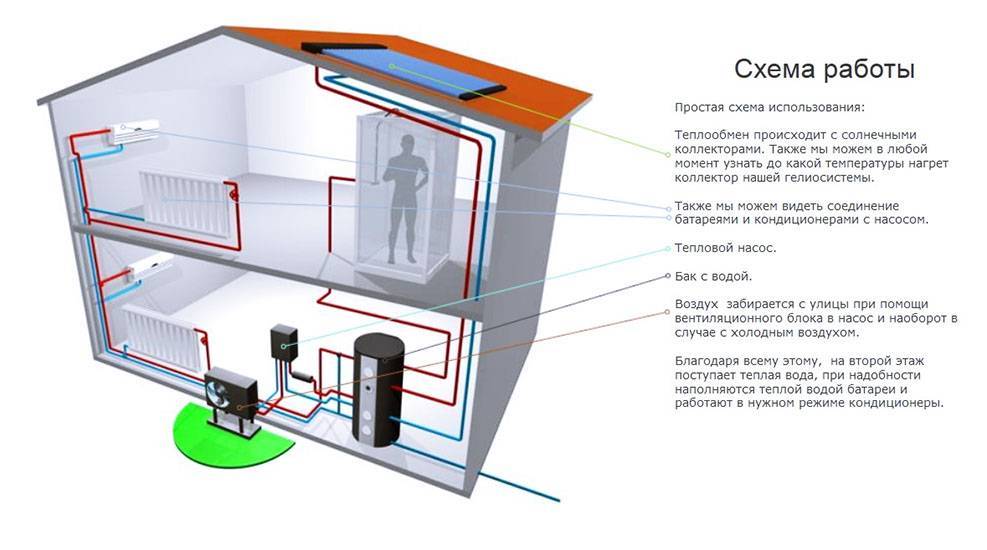

- Principle of operation

- Features of installation of HP of the air-to-air system

- Advantages and disadvantages of air-to-air heat pumps

- 3 The simplest unit

- Mounting technology

- How to make a project

- How to assemble a heat pump

- Installation of collector communications

- Equipment installation

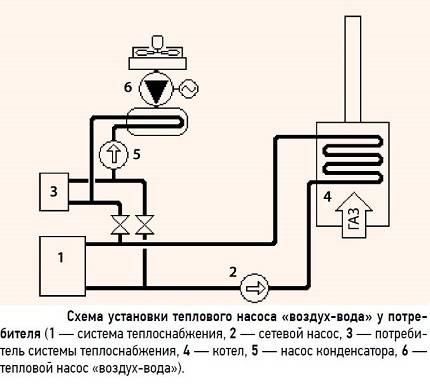

- The principle of operation of the air-to-water pump

- Video overview of the system device and its operation

- Inverter heat pumps

- How does a thermal geounit work?

- Advantages and disadvantages of technology

- Air-to-water heat pump for home

- How do air-to-water heat pumps work?

- Advantages and disadvantages

- Installation capacity calculation

- Results

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

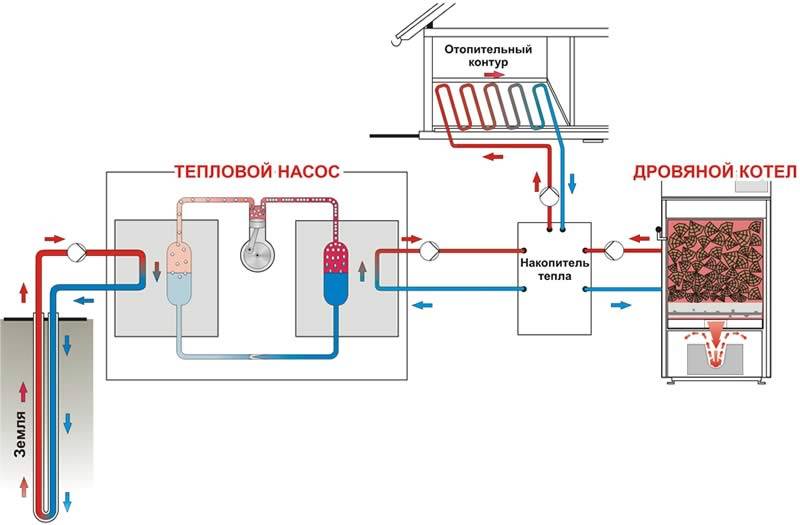

Selecting the type of heat pump

The main indicator of this heating system is power. First of all, the financial costs for the purchase of equipment and the choice of one or another source of low-temperature heat will depend on the power. The higher the power of the heat pump system, the greater the cost of components.

First of all, this refers to the compressor power, the depth of wells for geothermal probes, or the area to accommodate a horizontal collector. Correct thermodynamic calculations are a kind of guarantee that the system will work efficiently.

If there is a reservoir near the personal area, the most cost-effective and productive choice will be a water-to-water heat pump

First you need to study the area that is planned for the installation of the pump. The ideal condition would be the presence of a reservoir in this area. Using the water-to-water option will significantly reduce the amount of excavation.

The use of the heat of the earth, on the contrary, involves a large number of works associated with excavation. Systems that use water as low-grade heat are considered the most efficient.

The device of a heat pump that extracts thermal energy from the ground involves an impressive amount of earthworks. The collector is laid below the level of seasonal freezing

There are two ways to use the thermal energy of the soil. The first involves drilling wells with a diameter of 100-168 mm. The depth of such wells, depending on the parameters of the system, can reach 100 m or more.

Special probes are placed in these wells. The second method uses a collector of pipes. Such a collector is placed underground in a horizontal plane. This option requires a fairly large area.

For laying the collector, areas with wet soil are considered ideal. Naturally, drilling wells will cost more than a horizontal reservoir. However, not every site has free space. For one kW of heat pump power, you need from 30 to 50 m² of area.

The construction for the intake of thermal energy by one deep well may turn out to be a little cheaper than digging a pit

But a significant plus lies in the significant savings in space, which is important for owners of small plots.In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other

In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other.

The extraction of thermal energy in such systems by pumping groundwater in a closed circuit, parts of which are located in wells. Such a system requires the installation of a filter and periodic cleaning of the heat exchanger.

The simplest and cheapest heat pump scheme is based on extracting thermal energy from the air. Once it became the basis for the construction of refrigerators, later air conditioners were developed according to its principles.

The simplest heat pump system obtains energy from the air mass. In summer it is involved in heating, in winter in air conditioning. The disadvantage of the system is that, in an independent version, a unit with insufficient power

The effectiveness of different types of this equipment is not the same. Pumps that use air have the lowest performance. In addition, these indicators are directly dependent on weather conditions.

Ground varieties of heat pumps have stable performance. The efficiency coefficient of these systems varies within 2.8 -3.3. Water-to-water systems are the most efficient. This is primarily due to the stability of the source temperature.

It should be noted that the deeper the pump collector is located in the reservoir, the more stable the temperature will be. To obtain a system power of 10 kW, about 300 meters of pipeline are needed.

The main parameter characterizing the efficiency of a heat pump is its conversion factor. The higher the conversion factor, the more efficient the heat pump is considered.

The conversion factor of a heat pump is expressed through the ratio of the heat flow and the electrical power spent on the operation of the compressor

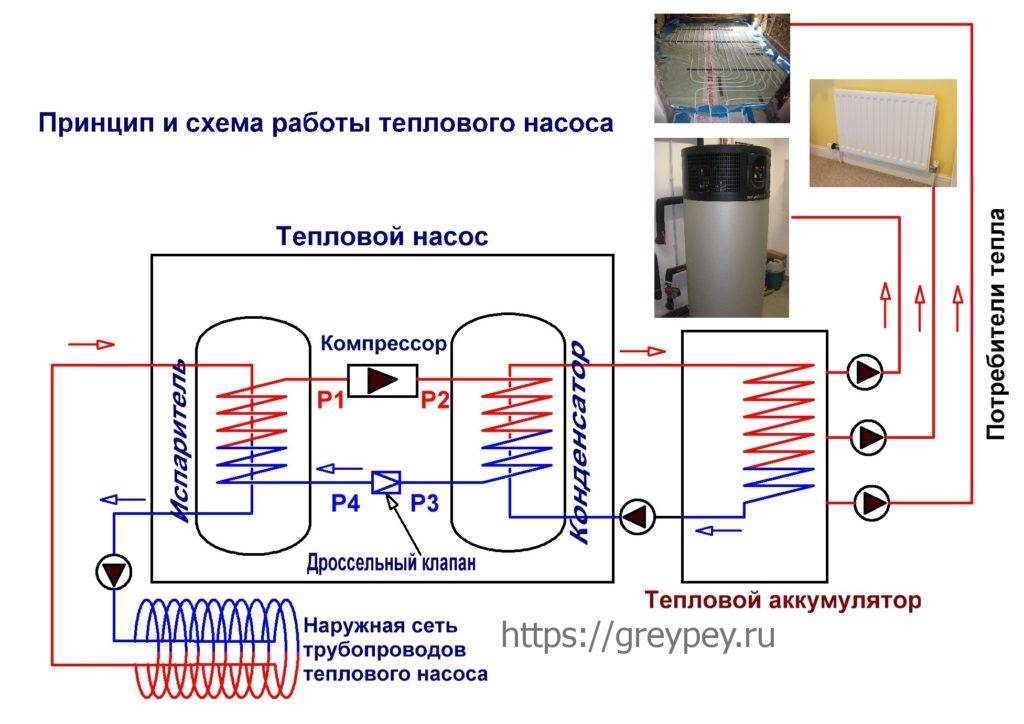

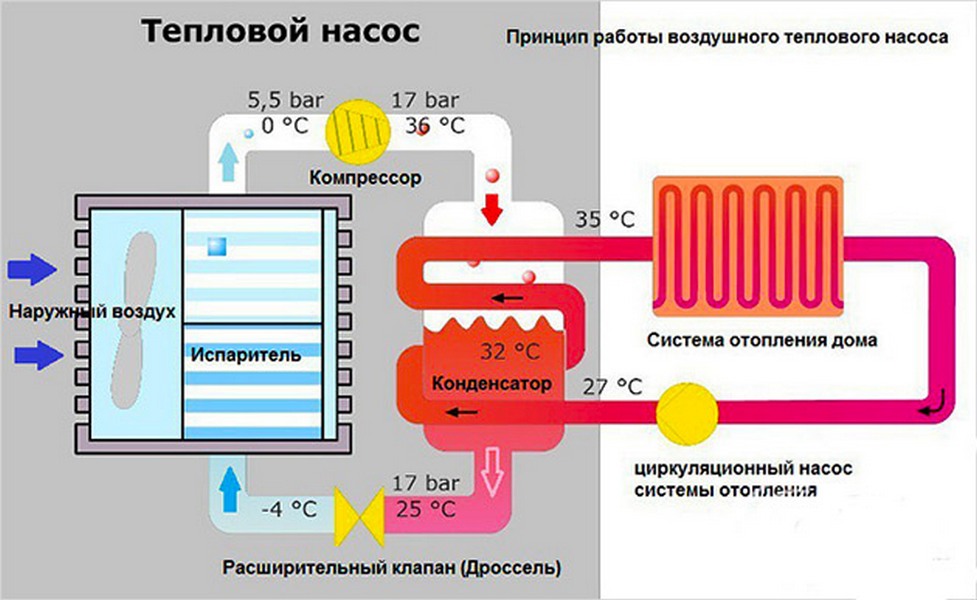

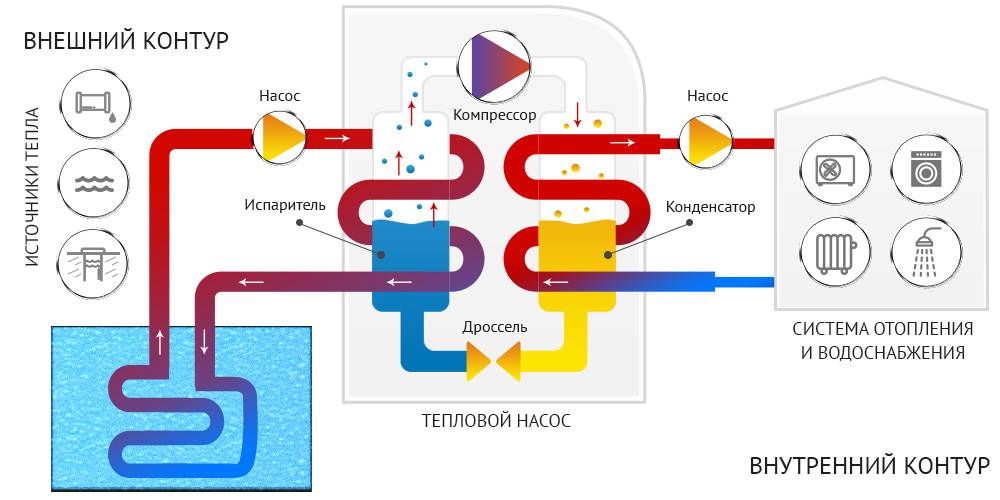

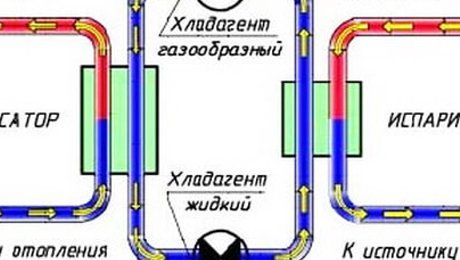

Principle of operation

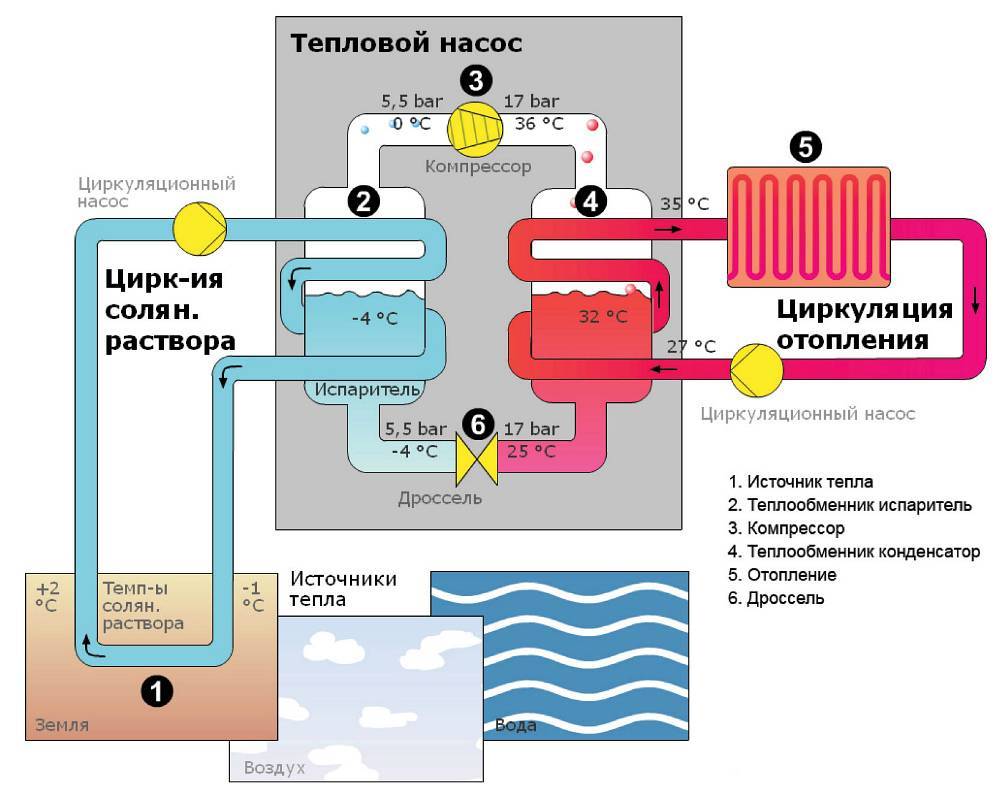

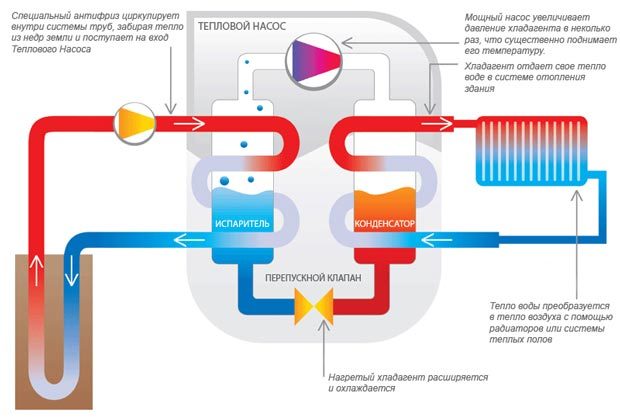

All the space around us is energy - you just need to know how to use it. For a heat pump, the ambient temperature must be greater than 1C°. Here it should be said that even the earth in winter under snow or at some depth retains heat. The work of a geothermal or any other heat pump is based on the transportation of heat from its source using a heat carrier to the heating circuit of the house.

Scheme of operation of the device by points:

- the heat carrier (water, soil, air) fills the pipeline under the soil and heats it;

- then the coolant is transported to the heat exchanger (evaporator) with subsequent heat transfer to the internal circuit;

- the external circuit contains the refrigerant, a liquid with a low boiling point under low pressure. For example, freon, water with alcohol, glycol mixture. Inside the evaporator, this substance is heated and becomes a gas;

- the gaseous refrigerant is sent to the compressor, compressed under high pressure and heated;

- hot gas enters the condenser and there its thermal energy is transferred to the house;

- the cycle ends with the conversion of the refrigerant into a liquid, and it, due to heat loss, returns back to the system.

The same principle is used for refrigerators, so home heat pumps can be used as air conditioners to cool a room.Simply put, a heat pump is a kind of refrigerator with the opposite effect: instead of cold, heat is generated.

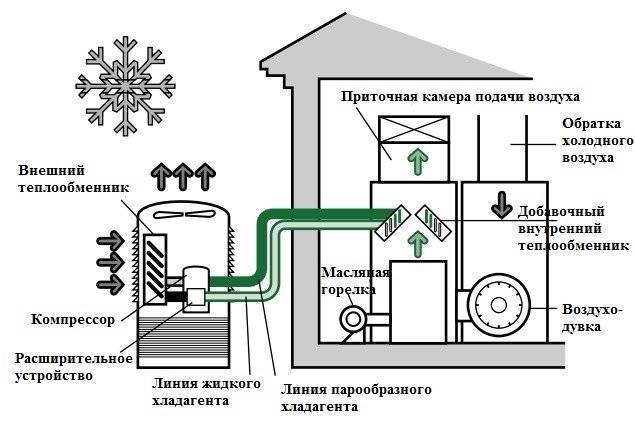

Features of installation of HP of the air-to-air system

The installation of an air-to-air heat pump is somewhat reminiscent of the installation of a split system. The device has two blocks - external and internal, interconnected by a circuit through which the refrigerant circulates.

Outdoor or outdoor heat pump unit, mounted outdoors. Some models are installed in a special protective casing. The station is so light that its installation is allowed even on the roof of a building. It is recommended that the air-to-air heat pump be installed approximately 2-3 m from the entrance to the living quarters.

The indoor unit is placed in such a way that the streams of heated air spread throughout the room as efficiently as possible. Wall and ceiling installation is allowed.

Centralized air heating of the house with an air-to-air heat pump, with permanent residence, requires the use of a forced air injection system. The length of the air channels and their location are carefully calculated during the preparation of project documentation.

Installing a heat pump is a complex technological process, therefore, the work is carried out by specialized installation teams that have the appropriate license.

Advantages and disadvantages of air-to-air heat pumps

Feedback from real owners about air-to-air heat pumps helps to get an accurate picture of the energy efficiency of using alternative heating methods, as well as to get an idea of the existing advantages and disadvantages.

Heating a house with an air-to-air heat pump has the following advantages:

- Cost savings - even with significant initial costs, the heat pump pays for itself after 3-6 years of operation. Since the equipment is designed for 30-50 years of service, the benefits are obvious. The cost of electricity, during the entire heating season, is 3-5 times less than that of an electric boiler.

Complete independence from traditional fuels. The main advantage of air-to-air heating is the production of thermal energy, without the use of gas, solid and liquid fuels, etc. With the installation of solar panels, you can refuse external electricity.

Environmental friendliness - during operation, renewable sources of thermal energy are used, there are no harmful emissions.

Of course, heat pumps have their weaknesses, which manufacturers try to correct from time to time. These include:

- The dependence of efficiency on the outside temperature - manufacturers are constantly improving systems. Modern equipment is capable of operating at -15 -25°C. Efficiency at low temperatures is noticeably reduced, which limits the use of modules for space heating in the conditions of the North.

Large material costs for the purchase and installation of a heat pump. The main disadvantage of HP air - air, due to which, the stations are not widely used in domestic conditions.

The prospects for the use of air-to-air heat pumps are quite optimistic. Relatively recently, several major manufacturers announced the development of modules capable of operating at temperatures as low as -32°C.Constant emphasis is placed on reducing the cost of products to make them affordable for middle-class consumers, improving performance (average COPs for modern models are 5-8 units).

3 The simplest unit

The cheapest homemade device will be a heat pump from an air conditioner. It is advisable to purchase a model equipped with a reversing valve. Thanks to this, the air conditioner can work for heating. Otherwise, you will have to modify the refrigerant circuit

Also, when choosing an air conditioner, you should pay attention to the performance indicator of the unit in terms of cold.

The algorithm for manufacturing the simplest heat pump has the following form:

The upper casing of the device is removed and the external heat exchange chamber is dismantled

At this stage, care must be taken not to damage the refrigerant pipes.

Then you need to remove the outer impeller from the shaft.

The tank is made of metal. Its length should correspond to the size of the heat exchange chamber, and its width will be 100-150 mm larger.

To prevent the radiator from freezing, it is necessary to increase its area. To do this, additional aluminum or copper plates are installed along the edges, depending on the material of the heat exchange chamber.

The upgraded radiator is installed in the tank, which must then be closed with a sealed lid.

At the final stage, hoses for the selection and supply of coolant are connected to the fittings, circulation pumps are connected

After that, it remains to fill the container and check it for leaks.

To do this, additional aluminum or copper plates are installed along the edges, depending on the material of the heat exchange chamber.

The upgraded radiator is installed in the tank, which must then be closed with a sealed lid.

At the final stage, hoses for the selection and supply of coolant are connected to the fittings, circulation pumps are connected. After that, it remains to fill the container and check it for leaks.

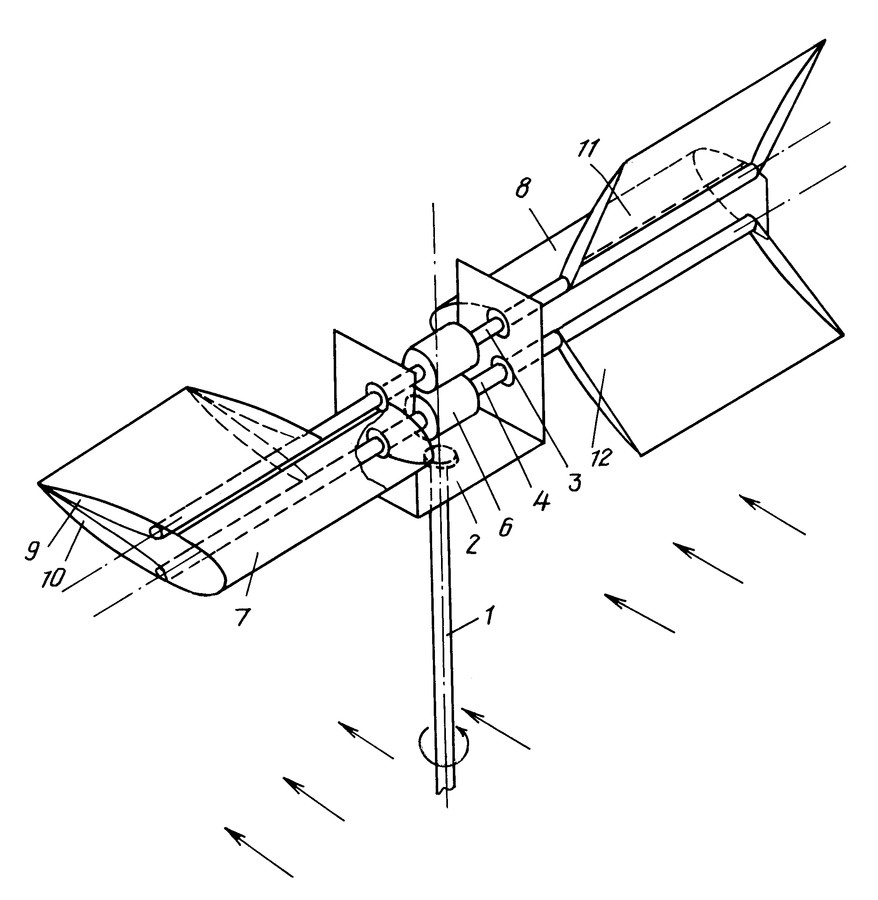

Mounting technology

The assembly of this type of equipment is carried out in several stages:

- a project is being drawn up;

- collector communications are assembled;

- a heat pump is installed in the system;

- equipment is installed inside the house;

- coolant is being filled.

Next, we will consider how to install a turnkey heat pump with your own hands step by step.

How to make a project

Before proceeding with the assembly of communications of this type, of course, all the necessary calculations should be made. The work of the external part of the system must be fully coordinated with the work of the internal. Calculations are made depending on the selected type of equipment. For horizontal collectors, they are performed as follows:

- The amount of antifreeze needed is determined. In this case, the formula Vs = Qo 3600 / (1.05 3.7 t) is used, where Qo is the thermal power of the source, t is the temperature difference between the supply and return lines. The Qo parameter is calculated as the difference between the pump power and the electric power used to heat the refrigerant.

- The required collector length is determined. The calculation formula in this case looks like this: L = Qo / q, where q is the specific heat removal. The value of the latter indicator depends on the type of soil on the site. For clay, for example, it is 20 W per rm, for sand - 10 W, etc.

- The area required for laying the collector is determined.In this case, the calculation is carried out according to the formula A = L da, where da is the pipe laying step.

The power of the heat pump is determined approximately at the rate of 70 W of heat per 1 m2 with a ceiling height of 2.7 m. The collector pipes are usually laid at a distance of 0.8 m from each other or a little more.

How to assemble a heat pump

This type of equipment is quite expensive. The design of a heat pump is relatively simple. Therefore, you can try to make it yourself. This procedure is performed like this:

- A compressor is purchased (equipment from an air conditioner is suitable).

- Capacitor housing is made. To do this, a 100-liter stainless steel tank is cut in half.

- A coil is being made. A gas or oxygen cylinder is wrapped with a copper tube from the refrigerator. The latter can be fixed with aluminum perforated corners.

- The coil is installed in the body, after which the latter is sealed.

- An evaporator is made from a plastic container of 80 liters. A coil from a ¾ inch pipe is mounted in it.

- Water pipes are connected to the evaporator to deliver and drain water.

- The system is filled with refrigerant. This operation should be entrusted to a specialist. With inept actions, you can not only ruin the assembled equipment, but also get injured.

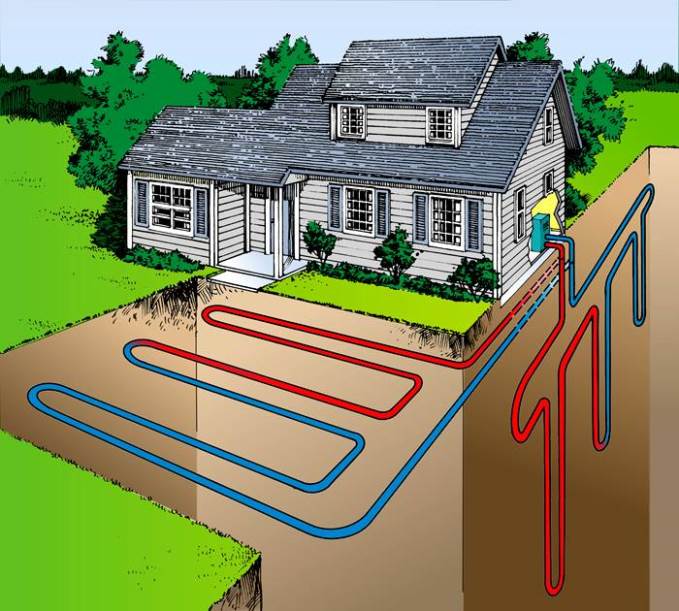

Installation of collector communications

The technology for installing the external circuit of the heating system also depends on its type. For a vertical collector, wells are drilled with a depth of 20-100 m. Under a horizontal one, trenches are broken through with a depth of 1.5 m. At the next stage, pipes are laid. Trees should not grow near the horizontal collector, as their roots can damage the mains.For the assembly of the latter, low-pressure polyethylene pipes can be used.

Equipment installation

This operation is performed in the usual way. That is, heating radiators are installed in the premises, lines are laid and they are connected to the boiler. An expansion tank, a filter and a circulation pump on the bypass are mounted on the return pipe. You can also assemble and connect a "warm floor" system to the heat pump. At the final stage, the selected type of coolant is poured into the external and internal circuits.

As you can see, you can mount the heat pump and collector yourself. Technologically, the procedure is not particularly complicated. However, unlike other types of similar equipment, the assembly of such a system, even of a horizontal type, is a physically rather laborious operation. Drilling wells for vertical drilling on your own without special equipment is practically impossible. Therefore, it is possible to perform calculations and work for system assembly it is still worth hiring professionals. Today, there are companies on the market that install equipment such as a heat pump on a turnkey basis.

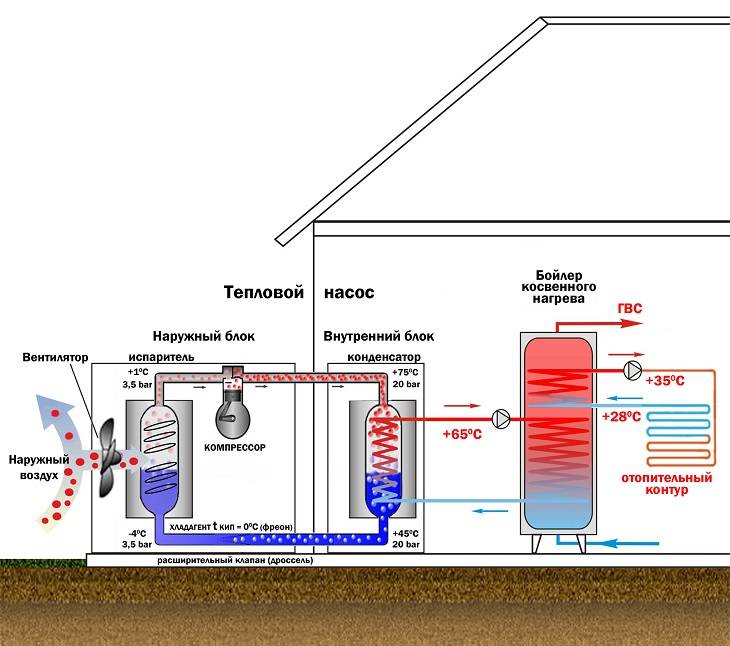

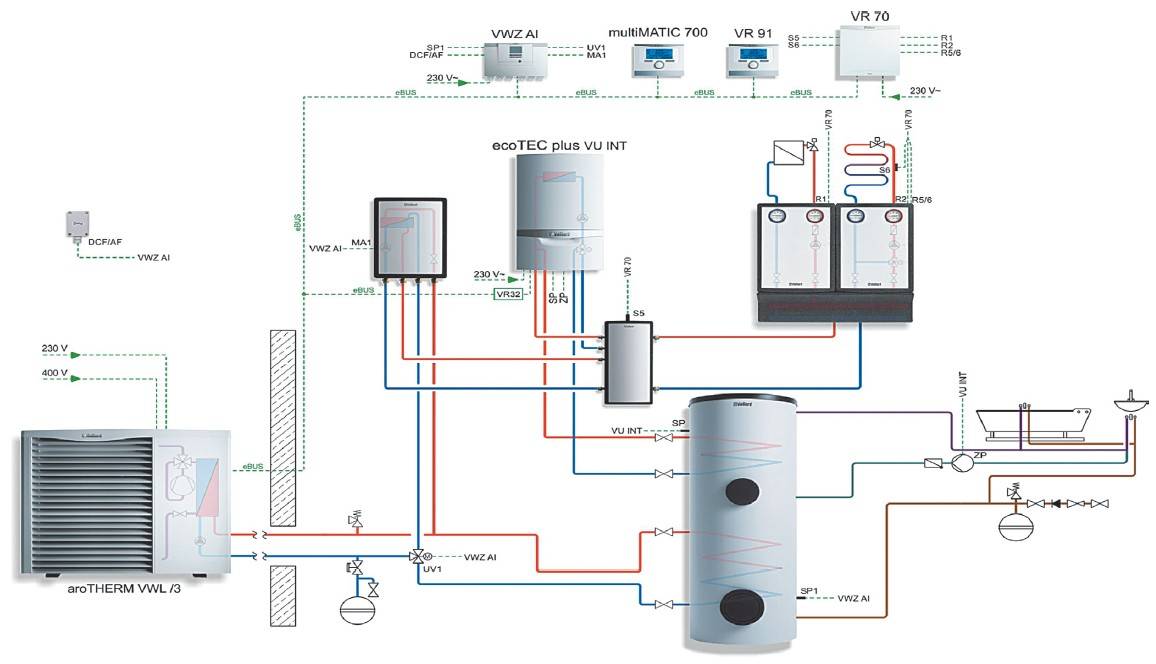

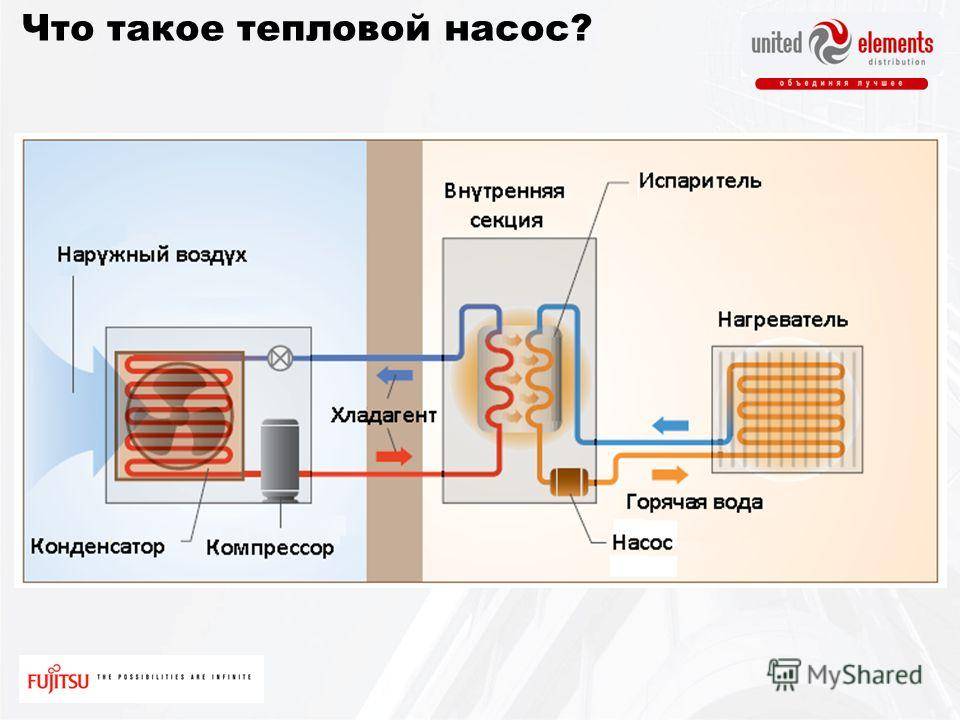

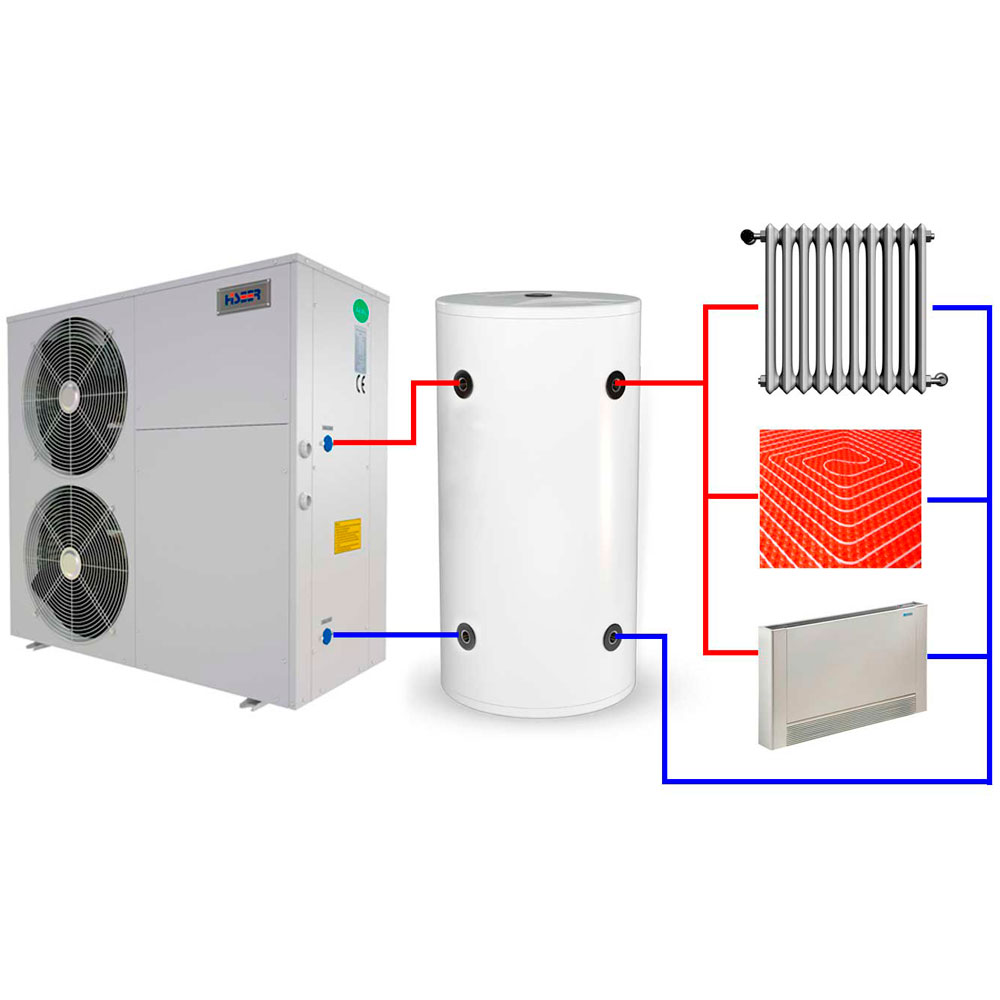

The principle of operation of the air-to-water pump

As already mentioned, the main source of thermal energy for installations of this type is atmospheric air. The fundamental basis of the operation of air pumps is the physical property of liquids to absorb and release heat during the phase transition from a liquid state to a gaseous state, and vice versa. As a result of the change of state, the temperature is released. The system works on the principle of a refrigerator in reverse.

To effectively use these properties of the liquid, a low-boiling refrigerant (freon, freon) circulates in a closed circuit, the design of which includes:

- compressor with electric drive;

- fan blown evaporator;

- throttle (expansion) valve;

- plate heat exchanger;

- copper or metal-plastic circulation tubes connecting the main elements of the circuit.

The movement of the refrigerant along the circuit is carried out due to the pressure developed by the compressor. To reduce heat losses, the pipes are covered with a heat-insulating layer of artificial rubber or polyethylene foam with a protective metallized coating. As a refrigerant, freon or freon is used, which can boil at a negative temperature and does not freeze up to -40 ° C.

The whole process of work consists of the following successive cycles:

- The evaporator radiator contains a liquid refrigerant that is cooler than the outside air. During active radiator blowing, thermal energy from low-potential air is transferred to freon, which boils and passes into a gaseous state. At the same time, its temperature rises.

- The heated gas enters the compressor, where it heats up even more during the compression process.

- In a compressed and heated state, the refrigerant vapor is fed into a plate heat exchanger, where the heat carrier of the heating system circulates through the second circuit. Since the temperature of the coolant is much lower than that of the heated gas, freon actively condenses on the heat exchanger plates, giving off heat to the heating system.

- The cooled vapor-liquid mixture enters the throttle valve, which allows only the cooled low-pressure liquid refrigerant to pass to the evaporator.Then the whole cycle is repeated.

To increase the heat transfer efficiency of the tube, spiral fins are wound on the evaporator. The calculation of the heating system, the choice of circulation pumps and other equipment must take into account the hydraulic resistance and the heat transfer coefficient of the plate heat exchanger of the installation.

Video overview of the system device and its operation

h3 id="invertornye-teplovye-nasosy">Inverter heat pumps

The presence of an inverter as part of the installation allows for a smooth start-up of the equipment and automatic regulation of modes depending on the outdoor temperature. This maximizes the efficiency of the heat pump by:

- achievement of efficiency at the level of 95-98%;

- reducing energy consumption by 20-25%;

- minimization of loads on the electrical network;

- increase the service life of the plant.

As a result, the indoor temperature is stably maintained at the same level, regardless of weather changes. At the same time, the presence of an inverter complete with an automated control unit will provide not only heating in winter, but also the supply of cooled air in summer in hot weather.

At the same time, it should be taken into account that the presence of additional equipment always entails an increase in its cost and an increase in the payback period.

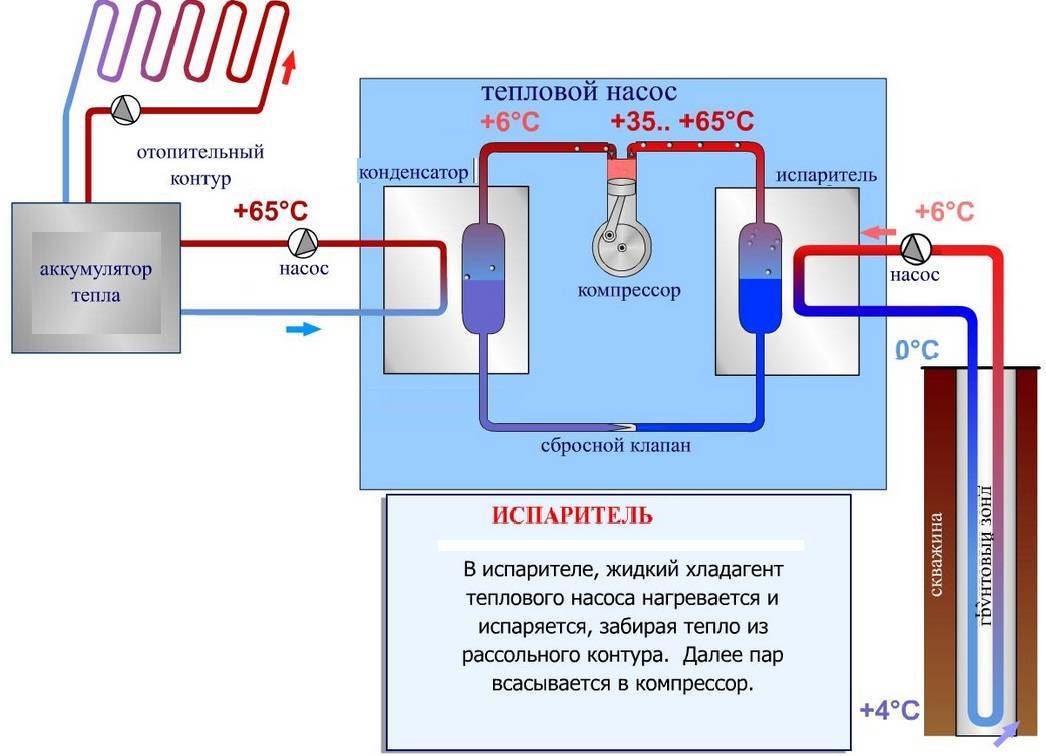

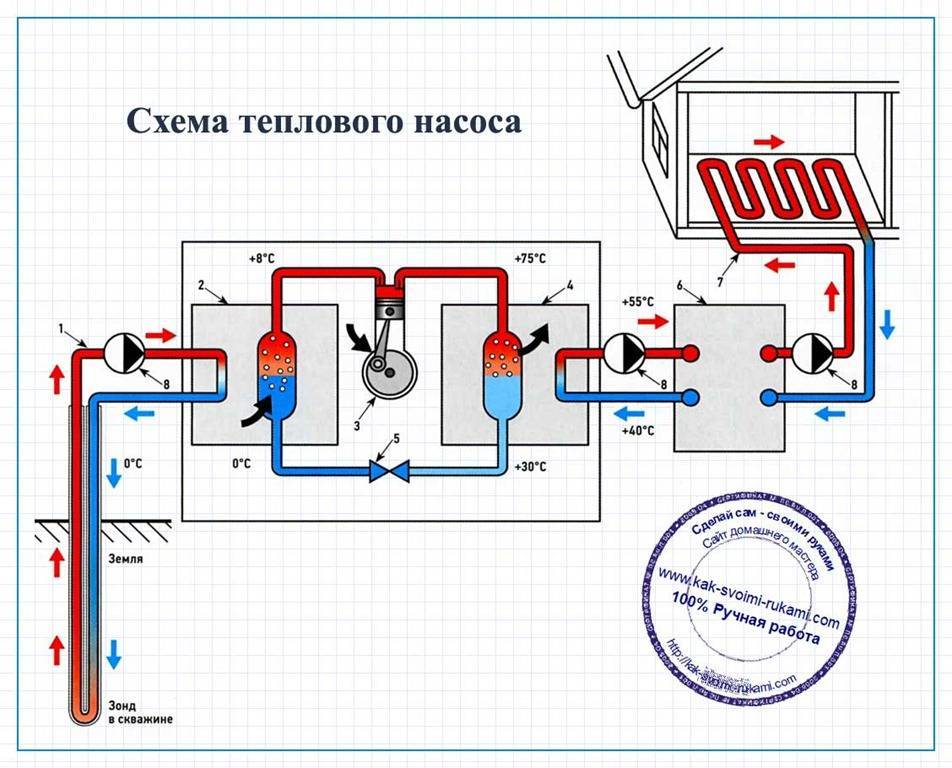

How does a thermal geounit work?

The operation algorithm of a geothermal heat pump is based on the transfer of heat from a source with a low thermal energy potential to a heat carrier. The earth here plays the role of a radiator in the summer and is an active source of heat in the winter season.

Ground temperature differences help improve overall system efficiency and help reduce actual operating costs.

The operation of a geothermal heat pump is based on such a phenomenon as thermal inertia. The temperature of the earth at a depth of 6 meters and below almost exactly corresponds to the average annual air temperature in the region and changes very little throughout the calendar year

In practice, the operating coolant enters the pipeline located in the ground and heats up there by several degrees. Then the composition passes into the heat exchange unit (or evaporator) and transfers the accumulated thermal energy to the internal system circuit.

The principle of operation of geothermal installations is similar to the functioning of refrigeration systems. That is why some types of heat pumps in the summer are successfully used as air conditioners and with their help they cool the air in residential premises.

The refrigerant operating in the external circuit is heated in the evaporator, converted into gas and enters the compressor. There it contracts under the influence of high pressure and becomes even hotter.

The hot gas passes into the condensation device and gives off thermal energy to the working coolant of the internal system responsible for heating the house. At the end of the process, the refrigerant that has lost heat returns to the starting point in a liquid state.

Advantages and disadvantages of technology

The most important advantages of TN are:

- Profitability: for every kilowatt of electricity consumed, the HP produces from 3 to 5 kW of heat. That is, we are talking about almost gratuitous heating.

- Environmental friendliness and safety: the operation of HP is not associated with the formation and release into the atmosphere of any environmentally hazardous substances, and the absence of a flame makes this technology absolutely safe.

- Ease of operation: unlike gas and solid fuel boilers, HP does not need to be cleaned of soot and soot. You also do not have to build and maintain a chimney.

A significant drawback of this technology is the high cost of equipment and installation work.

Let's do a simple calculation. For a 120 sq. m will need a HP with a capacity of 120x0.1 = 12 kW (at the rate of 100 W per 1 sq. M). The Diplomat model from Thermia with this performance costs about 6.8 thousand euros. The DUO model of the same manufacturer will cost a little less, but its cost cannot be called democratic either: about 5.9 thousand euros.

Heat pump Thermia Diplomat

Even when compared with the most expensive type of traditional heating - electric (4 rubles per 1 kWh, 3 months - work at full load, 3 months - with half), the payback will take more than 4 years, and this is without taking into account the cost installation of the outer circuit. In reality, the HP does not always work with the calculated performance, respectively, and the payback period may be longer.

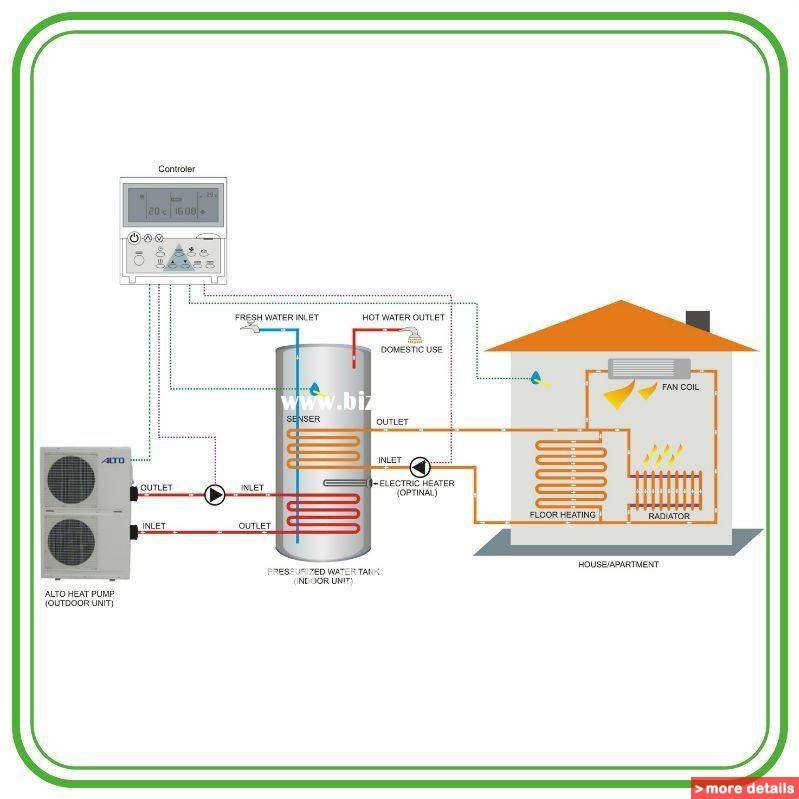

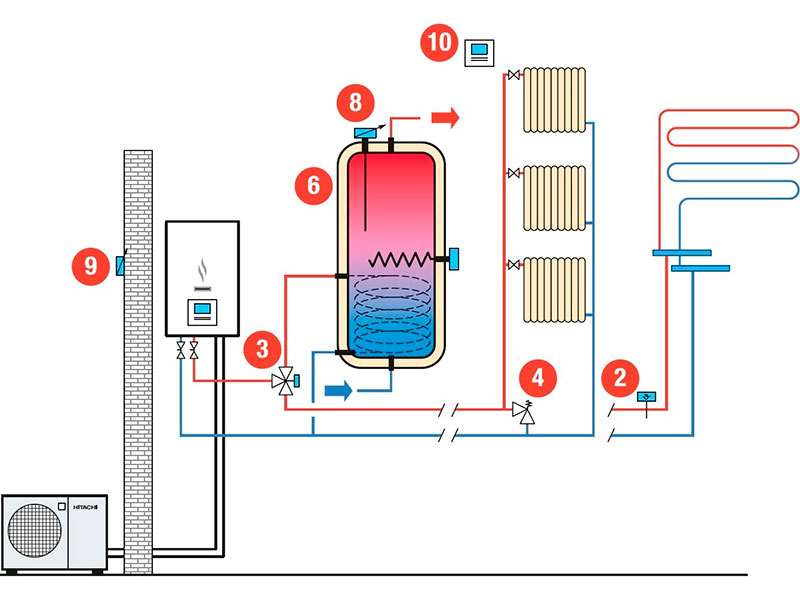

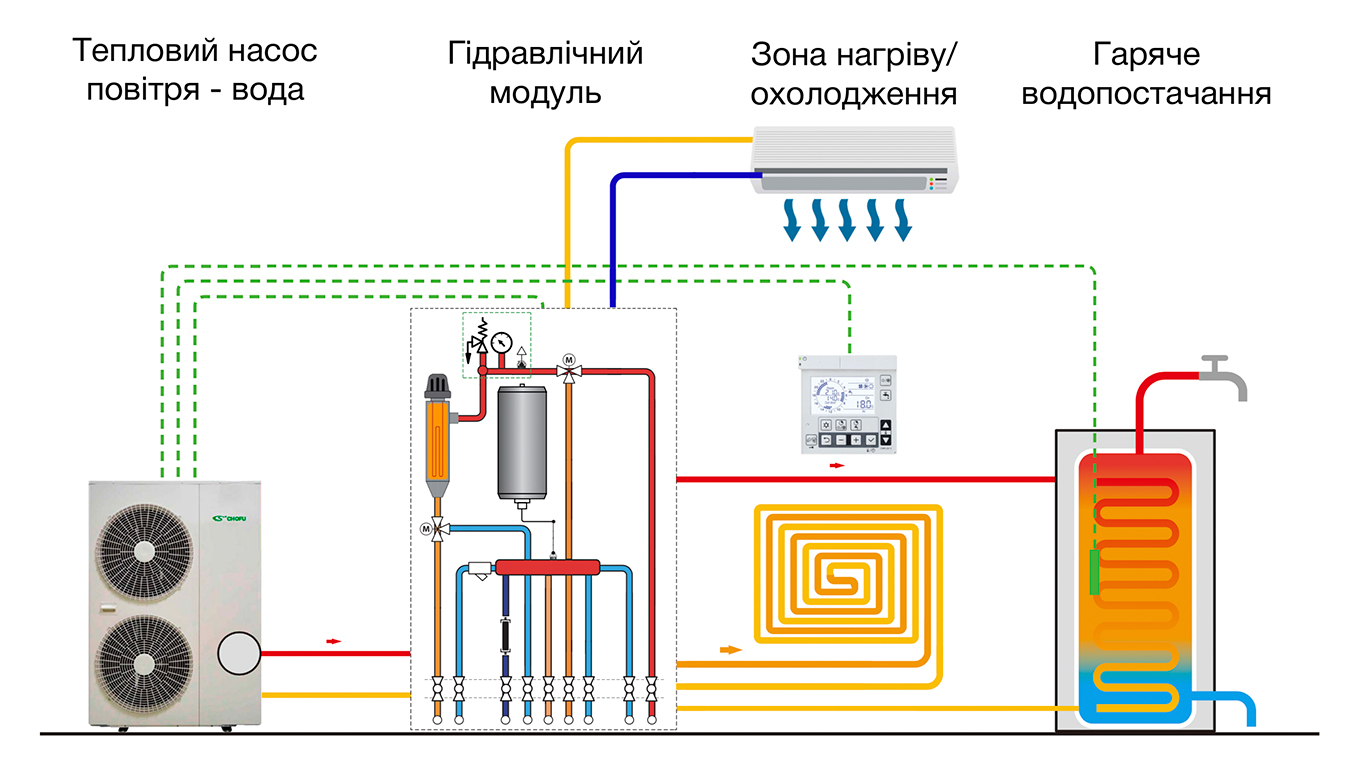

Air-to-water heat pump for home

A feature of air-to-water systems is the strong dependence of the temperatures of the coolant in the heating system on the temperature of the source - the outside air. The efficiency of such equipment is constantly changing both seasonally and in weather conditions. This shows a significant difference between aerothermal systems and geothermal complexes, whose operation is stable throughout the entire service life and does not depend on external conditions.

In addition, air-to-water heat pumps are capable of both heating and cooling indoor air, which makes them in demand in regions with relatively cold winters and hot summers. In general, the use of such systems is most effective in relatively warm areas, and for the northern regions, additional means of heating are required (usually electric heaters are used).

How do air-to-water heat pumps work?

The air-to-water heat pump is based on the Carnot principle. In a more understandable language, the design of a freon refrigerator is used. The refrigerant (freon) circulates in a closed system, passing successively through the stages:

- evaporation accompanied by strong cooling

- heating from the heat of the incoming outside air

- strong compression, at which its temperature becomes high

- liquid condensation

- passage through the throttle with a sharp drop in pressure and evaporation

For normal circulation of the refrigerant, it is necessary to have two compartments - an evaporator and a condenser. In the first, the temperature is low (negative); thermal energy from the ambient air is used for heating. The second compartment is used to condense the refrigerant and transfer thermal energy to the heat carrier of the heating system.

The role of the incoming air is to transfer heat to the evaporator, where the temperature is very low and needs to be increased for the upcoming compression. The thermal energy of the air is available even at negative temperatures and is stored until the temperature drops to absolute zero.Low-potential sources of thermal energy allow to obtain high efficiency of the system, but when the outdoor temperature drops to -20°C or -25°C, the system stops and requires the connection of an additional heating source.

Advantages and disadvantages

The advantages of air-to-water heat pumps are:

- easy installation, no excavation

- The source of thermal energy - air - is available everywhere, it is available and completely free. The system requires only power supply for the circulation equipment, compressor and fan

- the heat pump can be structurally combined with ventilation, which will significantly increase the efficiency of both systems

- the heating system is environmentally friendly and operationally safe

- the operation of the system is almost silent, it can be controlled by automation systems

The disadvantages of an air-to-water heat pump are:

- limited application. Household models of HP require connection of additional heating systems already at -7°C, industrial designs are able to keep temperatures down to -25°C, which is too low for most regions of Russia

- the dependence of the system efficiency on the outdoor temperature makes the system unstable and requires constant reconfiguration of the operating modes

- fans, compressors and other devices require a stable power supply

When planning the use of such a heating and hot water system, these features must be taken into account.

Installation capacity calculation

The procedure for calculating the power of the installation is reduced to determining the area of \u200b\u200bthe house to be heated, calculating the required amount of thermal energy and selecting equipment that corresponds to the values obtained. It makes no sense to present a detailed calculation methodology, since it is extremely complex and requires knowledge of many parameters, coefficients and other values. In addition, experience in performing such calculations is needed, otherwise the result will be completely erroneous.

To solve the problem, it is recommended to use an online calculator found on the net. Using it is easy, you just need to substitute your data in the windows and get an answer. If in doubt, the calculation can be duplicated on another resource in order to obtain balanced data.

Results

Undoubtedly, the cost of a heat pump from an air conditioner is several times lower than ready-made factory options, even those made in China. But there are a lot of nuances here: you need to take care of the source and amount of heat supplied, correctly calculate the length of heat exchangers (coils), install automation, provide guaranteed power, etc. But if you are able to solve these problems, then it is undoubtedly beneficial. Let me give you advice: in the first year it is very desirable to have backup heating, and it is better to carry out tests and trial run in the summer so that there is time to finalize the unit before the start of the heating season.

Conclusions and useful video on the topic

The video will introduce the principle of operation and features of the device:

As a result, we can conclude that a water-to-water heat pump is considered an effective environmentally friendly equipment designed to heat houses up to 150 square meters.The arrangement of a larger area may already require quite complex engineering surveys.

If you have any questions while reading the information provided, please ask them in the block below. We are waiting for your questions on the topic, stories and photos about the construction of a mini-hydroelectric power station with your own hands. We are interested in your opinion.

Conclusions and useful video on the topic

The video clearly shows how a heating system based on geothermal air-to-water heating equipment is equipped in a large house from a gas silicate block. Some interesting nuances regarding the installation of equipment are revealed and real numbers of utility bills for the month are announced.

How does land-to-water equipment work? A detailed description from a specialist in the installation of geothermal thermal boilers, recommendations and useful tips for home craftsmen from a professional in their field.

A real user of the equipment shares his impressions of the geothermal heat pump.

A professional locksmith tells how to make a heat pump at home based on a powerful compressor and tubular heat exchange parts. Detailed step by step instructions.

A geothermal pump for heating a private household is a good way to create comfortable living conditions even where centralized communication systems and more familiar sources of energy are not available.

The choice of system depends on the territorial location of the property and the financial capabilities of the owners.

Do you have experience in manufacturing a geothermal heat pump? Please share information with our readers, suggest your build option.You can leave comments and attach photos of your homemade products in the form below.