- Equipment Features

- Heat pump assembly technology

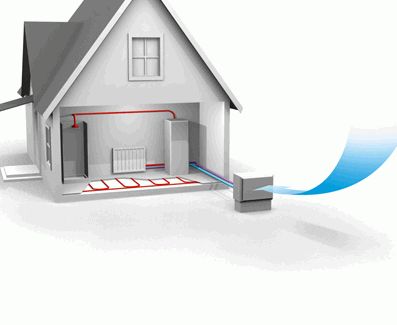

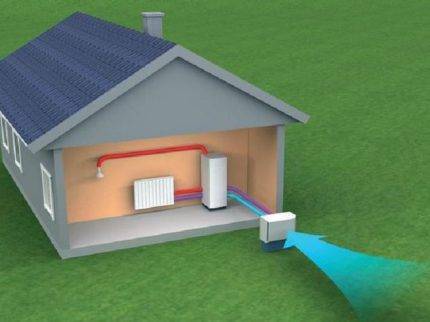

- Air-to-water heat pump

- Installation and operation of the AIR-WATER heat pump

- What is the working principle of a heat pump?

- Pros and cons

- The main types of geothermal heat pumps

- Selecting the type of heat pump

- Selecting the type of heat pump

- The use of heat pumps in the Russian climate

Equipment Features

In the seventies in America, the remarkable inventor Eugene Frenette showed the world his creation - the Frenette heat pump, named after its discoverer.

It is notable primarily for the fact that the efficiency exceeds 100%. Some believe in both 700 and 1000 percent, but skeptics who operate with physical laws do not support them - this is, after all, an exaggeration.

The scope of the Frenett pump is not limited to living quarters. It has been successfully used in production.

At one time, this device was very popular, so enthusiasts studied its circuit, more and more improving the design of the heat pump.

The basic principle still has not changed: the creator of the device offered a simple, but ingenious in its simplicity, invention. Everything is based on the release of heat due to friction.

When he first introduced the Frenette heat pump, the scheme was as follows:

- Two cylinders of excellent size: a smaller one in a larger one. Oil in between.

- A small motor is equipped on one side with a fan, on the other - with an engine (electric motor).

- The outer case implied grooves for air, and the thermostat optimized the operation of the installation.

Now let's figure out how this unit approximately functioned, which in its design differs from most of the climate devices familiar and familiar to us.

The rotation of the small cylinder heats up the oil. The fan circulates warm air in the room.

Despite the fact that this system is called a heat pump, the Frenett machine coincides with the correct representation of this term only in the role of a heater.

The heat pump must work according to the inverse Carnot principle, converting the low potential of the environment into a high potential of heat energy. Here there is no such thing.

Many tried to transform the invention, including its creator himself. Therefore, you can find different types of Frenett pump.

Structural differences from the above nuances, for example, may be as follows:

The drum with cylinders is in a horizontal position, a shaft passes through the center, the end of which protrudes outward. There is no fan, usually it is replaced by a radiator or the coolant is supplied directly to the system

It is important to ensure the tightness of the installation. View from two drums with an impeller between them. The heated oil is ejected from the impeller into the gap between the rotor and the pump housing, ensuring maximum performance.

Non-standard type of Frenett pump, developed by Khabarovsk scientists

The oil is replaced by water, the base is a mushroom element.The steam formed during heating and boiling moves through the channels at a speed of up to 135 meters per minute. This design is able to exist without the supply of energy from the outside. It is used for industrial purposes only.

The heated oil is ejected from the impeller into the gap between the rotor and the pump housing, ensuring maximum performance.

Non-standard type of Frenett pump, developed by Khabarovsk scientists. The oil is replaced by water, the base is a mushroom element. The steam formed during heating and boiling moves through the channels at a speed of up to 135 meters per minute. This design is able to exist without the supply of energy from the outside. It is used only for industrial purposes.

Heat pump assembly technology

Consider in detail the scheme of creation and assembly:

- We carry out the calculation of the pump. This can be done using a special calculator that correlates the area of \u200b\u200bheated premises with the power of the system. In general, the computational process proceeds as follows: the calculator uses the entered data (the area of the rooms and the height of the ceilings in them), converts them into volume, and at the output gives recommendations regarding the practical pump power for this case.

- Choosing the right compressor We will immediately stipulate one point (for the “home-made” masters): the compressor in the heat pump is never created manually, since the performance of the system as a whole will depend on the efficiency of its work, and even the slightest flaw will be enough for the failure of all structural elements of the pump. The best option should be selected based on the calculated pump power: the compressor power should be about 1/3 of the possible heat transfer of the pump.

- Evaporator design.This process is quite simple if you take it seriously and be careful while working. So, as this element, you can use a polymer tank with a lid. A copper coil is pulled along the inner surface of the tank, the length and diameter of which must be determined in advance. First, we calculate the pipe area using the formula P \u003d M / 0.8ΔT. M is the pump power and ΔT is the temperature difference. The resulting value is commensurate with the area of one linear meter of the pipe. We lay the properly bent pipe in the tank, bringing the ends from above and below. Then we mount two outlets (metal fittings). We attach two hoses to them: at the top - pressure, at the bottom - outlet (for draining water).

- Now you can start the process of assembling the capacitor. By the way, it is almost identical to the process of assembling the evaporator, with the only difference being that a stainless steel container is used instead of a polymer tank, and an already heated coolant will circulate through the structure itself.

- The last, but no less important stage is the assembly of all structural elements together. So, first of all, a compressor is mounted on the prepared platform / foundation. Then the upper condenser outlet is connected to its discharge branch pipe, and the lower condenser outlet is attached to the evaporator outlet. For this, a copper tube is used, the diameter of which must correspond to the diameter of the coils installed inside the structural elements of the system. It remains to connect the upper evaporator outlet with the suction compressor connection. Now you can fill in the coolant.

This concludes our consideration of the features of a water-to-water heat pump and the technology for installing it with our own hands.Be extremely careful when performing all work. Good luck!

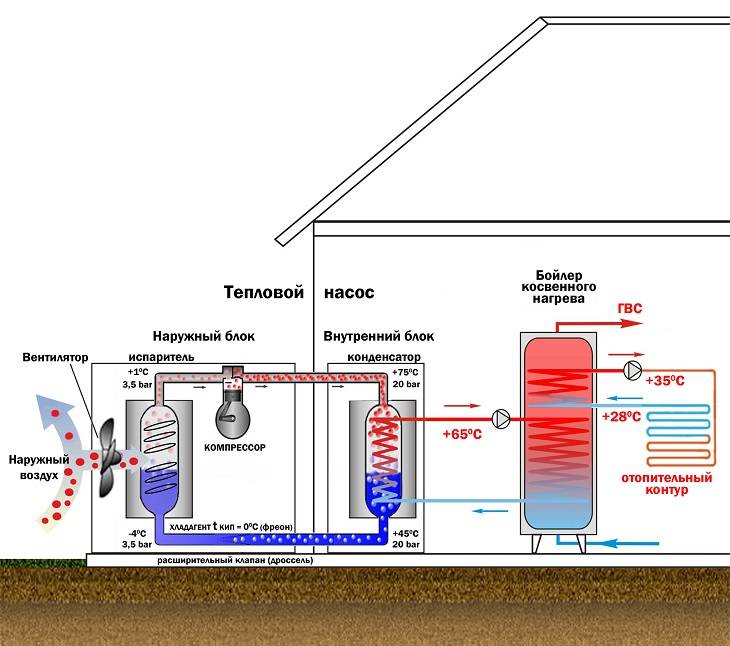

Air-to-water heat pump

Installation and operation of the AIR-WATER heat pump

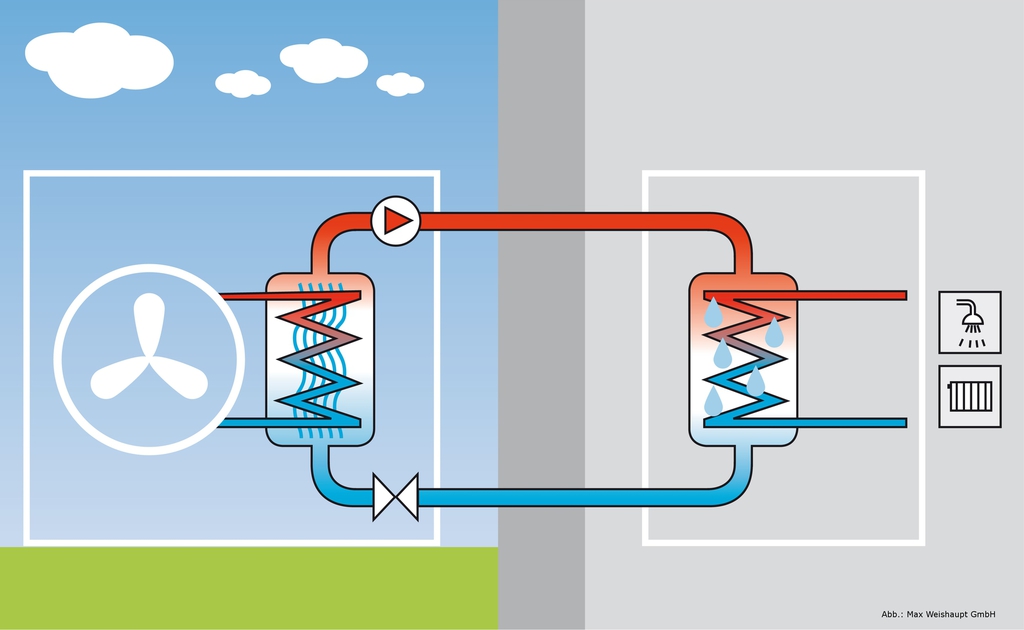

Air as a source of low-temperature thermal energy

Theoretically, air can be used as a source of low-temperature thermal energy, regardless of its temperature. In practice, air-to-water heat pumps are effective at an air temperature of at least -15 C. To date, there are already pumps on sale that operate at a temperature of -25 C, but so far their cost is too high, which makes this type of heat engineering equipment inaccessible to the general consumer.

In its most primitive form, an air-to-water heat pump can be thought of as an air conditioner used to cool the environment and dump "excess" heat into a heated room.

At the same time, an air-to-water heat pump does not require digging pits or drilling wells, laying pipelines along the bottom of reservoirs or installing vertical collectors necessary to enable water-to-water or ground-to-water heat pumps to operate. It is easy to operate and at the same time allows you to get inexpensive heat for heating your home.

As well as air conditioning systems, heat pumps of this type can be made according to 2 layout schemes:

- In the form of a split system consisting of 2 blocks connected by communications

- in the form of a monoblock

As a rule, a monoblock is a single device assembled in one housing and installed inside or outside the house. For indoor installation, it is necessary to provide a free channel for air intake.At the same time, outdoor installation is preferable: it allows you to move the compressor as a source of noise outside the room.

To date, many manufacturers produce air-to-water heat pumps in the form of monoblocks. It is convenient and practical, allows you to freely move the pump and install it without complicated installation and connection. The only drawback is the low power of pumps of this type: from 3 to 16 kW.

The split system is divided into two blocks, one of which includes a condenser and an automatic control system. It is installed indoors. The second (outdoor) unit includes a compressor. Its economic feasibility of installing air-to-water heat pumps

Air-to-water heat pumps are efficient at positive outside temperatures. They have found wide application in the southern regions of our country: in the Kuban, in the Stavropol Territory, etc. where severe frosts are rare, and in winter the temperature rarely drops below zero.

This does not mean at all that in other regions of our country, with more severe climatic conditions, heat pumps of this type cannot be used. Not at all. It's just that the efficiency of an air-to-water pump decreases as the air temperature drops, along with an increase in the cost of electricity needed to run the pump.

Therefore, the expediency of operating a heat pump at a negative air temperature, as well as the selection of equipment in accordance with the required power, should be carried out by qualified heating engineers.

To date, the best option is to use an air-to-water heat pump for heating and hot water supply at positive ambient temperatures and to turn on a boiler or other source of thermal energy when frost sets in.

Another condition for using a heat pump for heating a house is the high thermal efficiency of the building, the absence of heat losses in it associated with poor-quality thermal insulation and drafts.

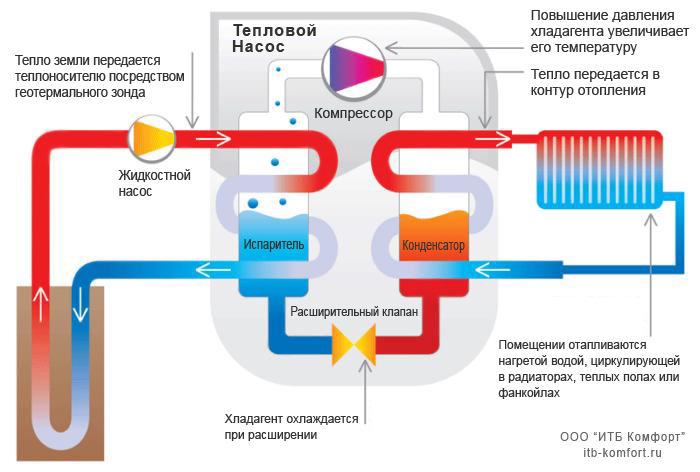

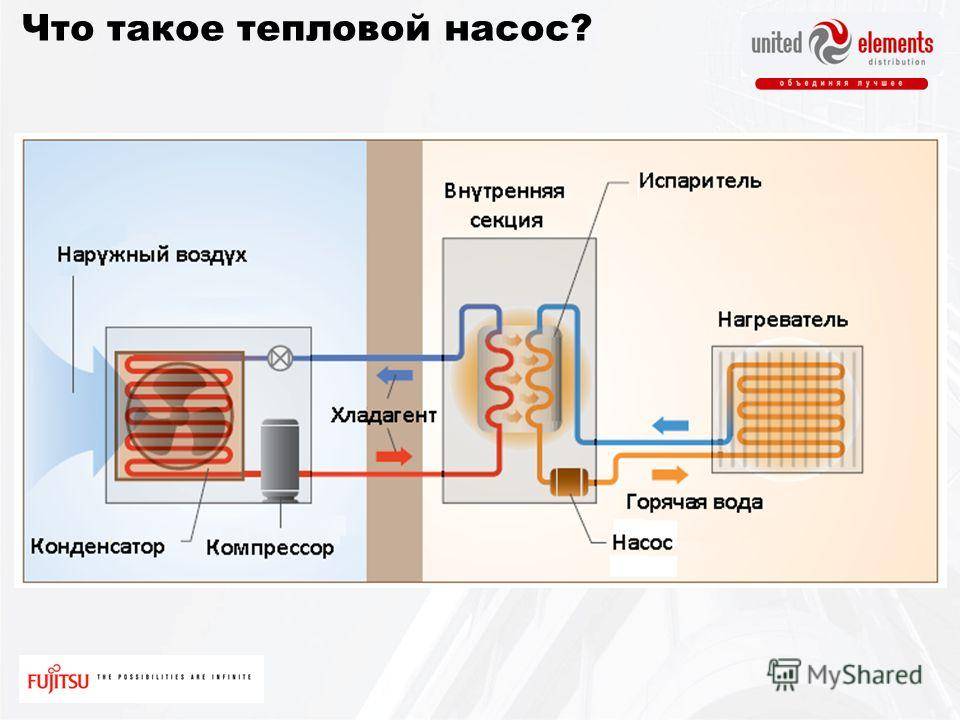

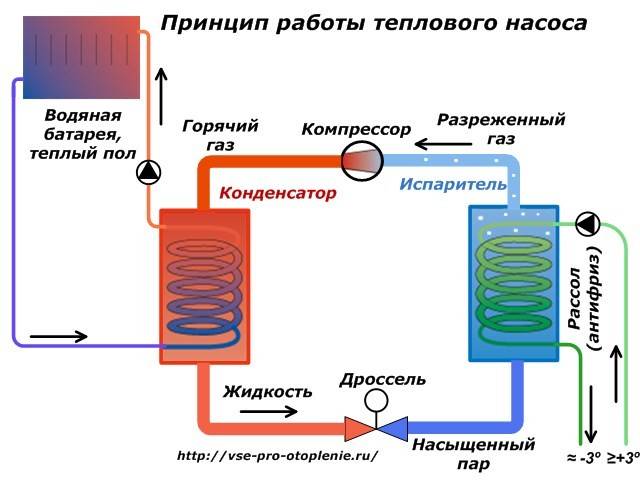

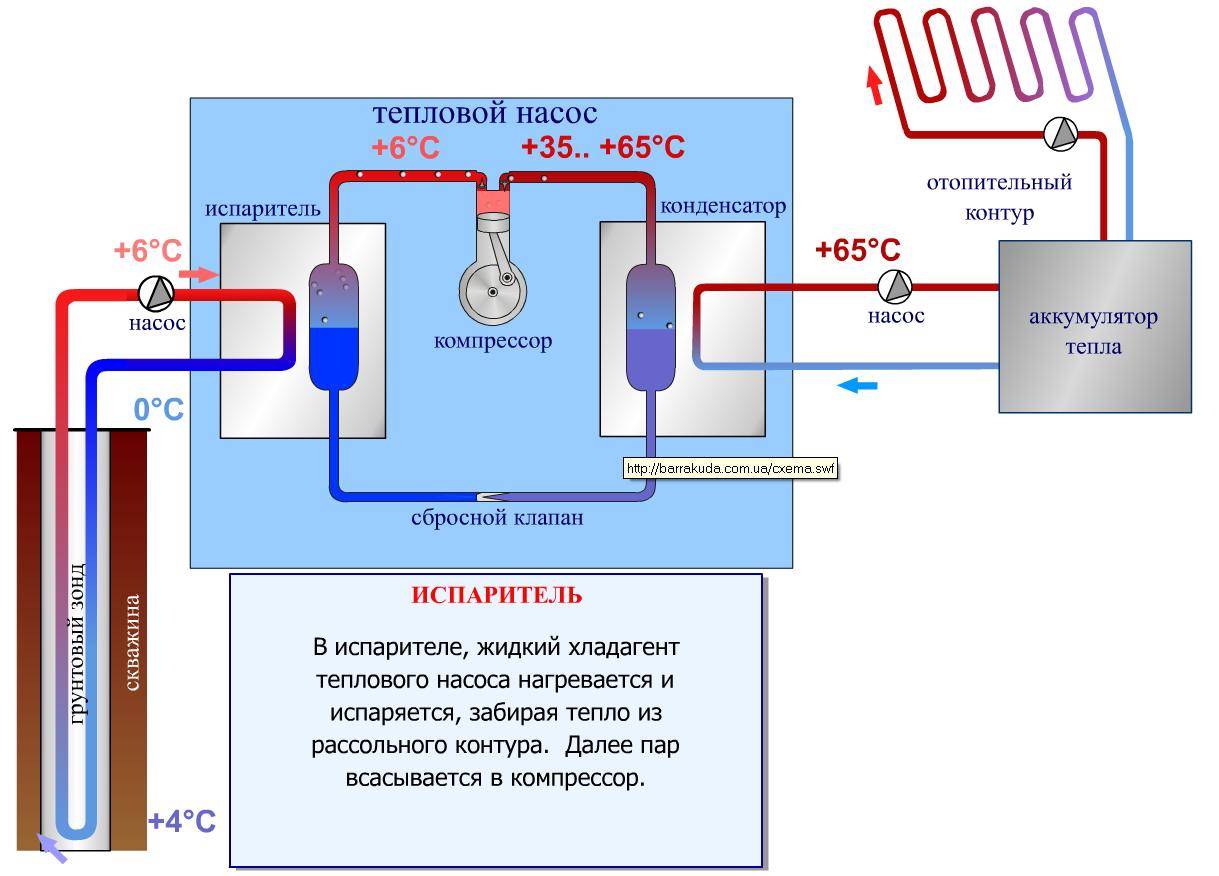

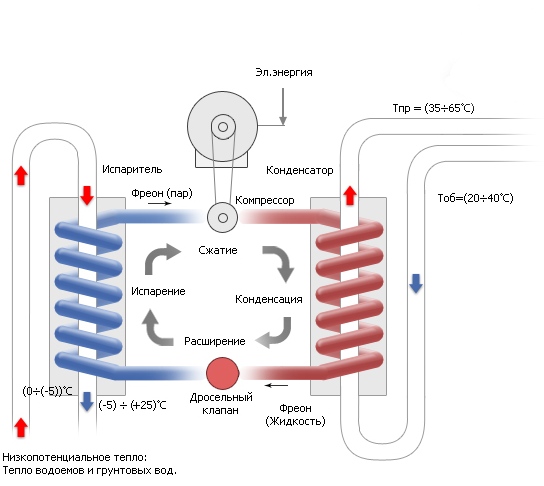

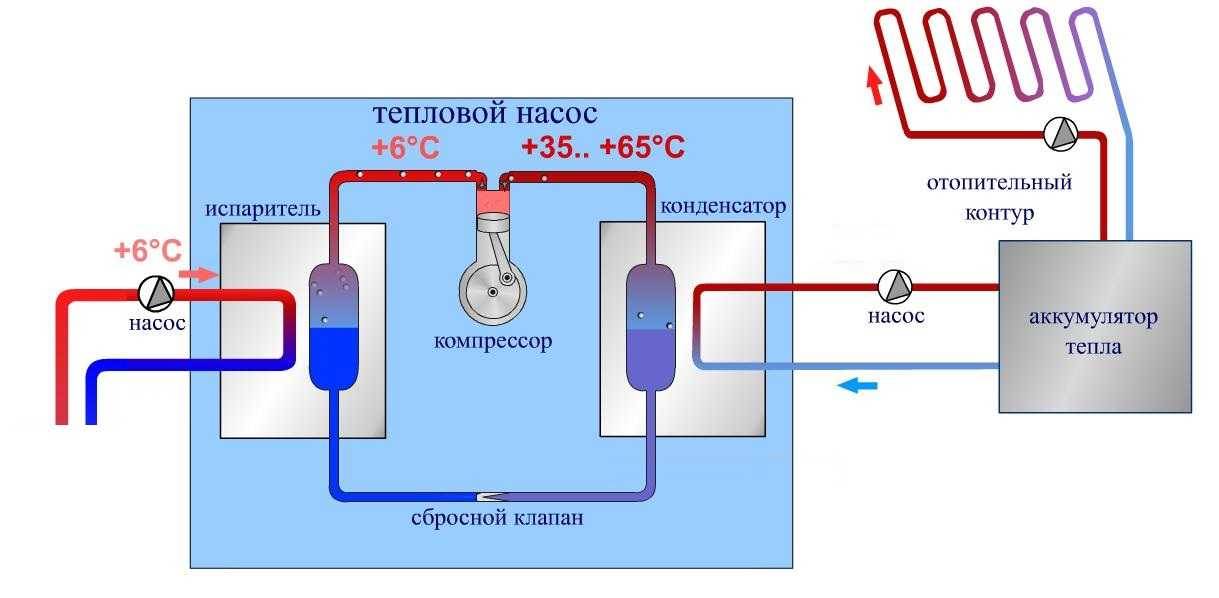

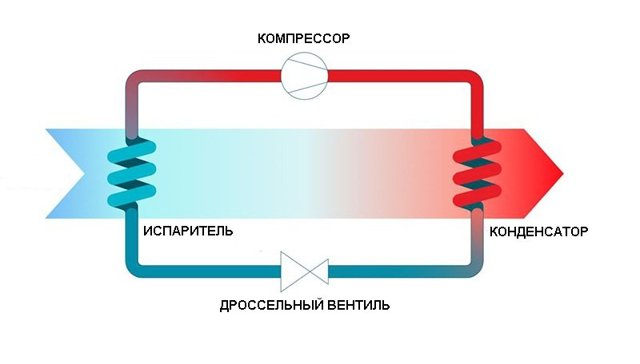

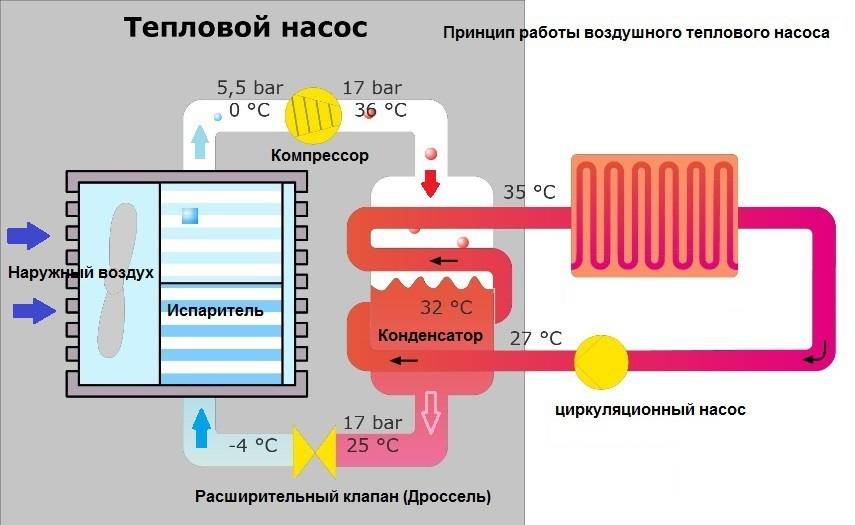

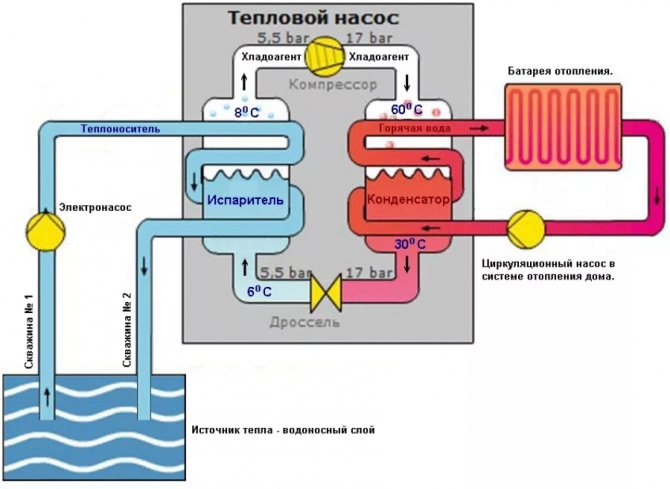

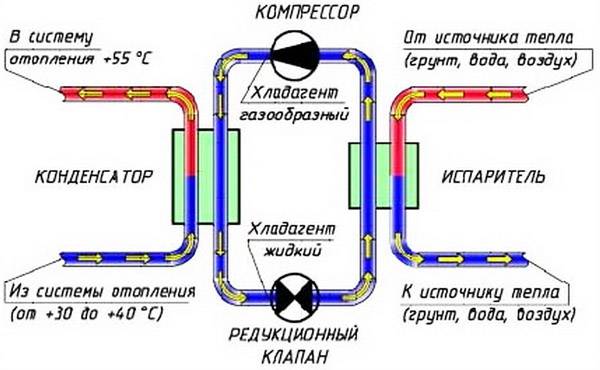

What is the working principle of a heat pump?

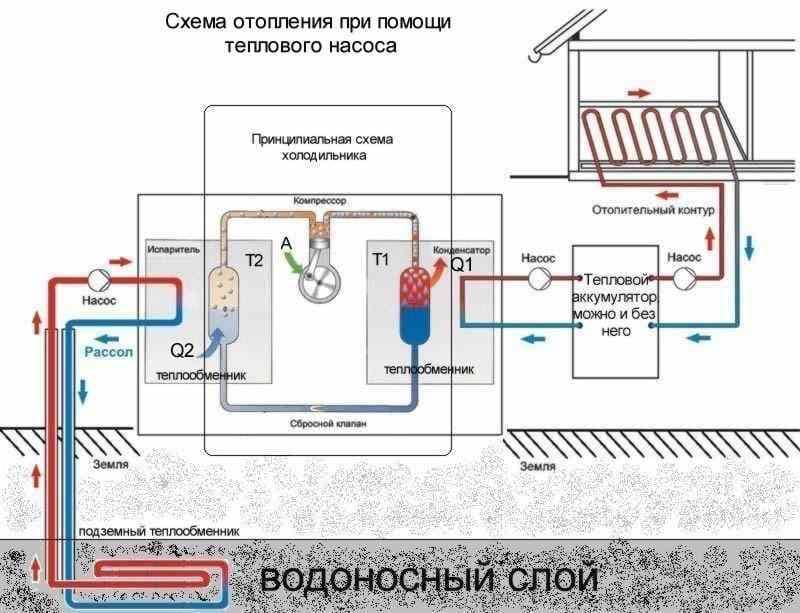

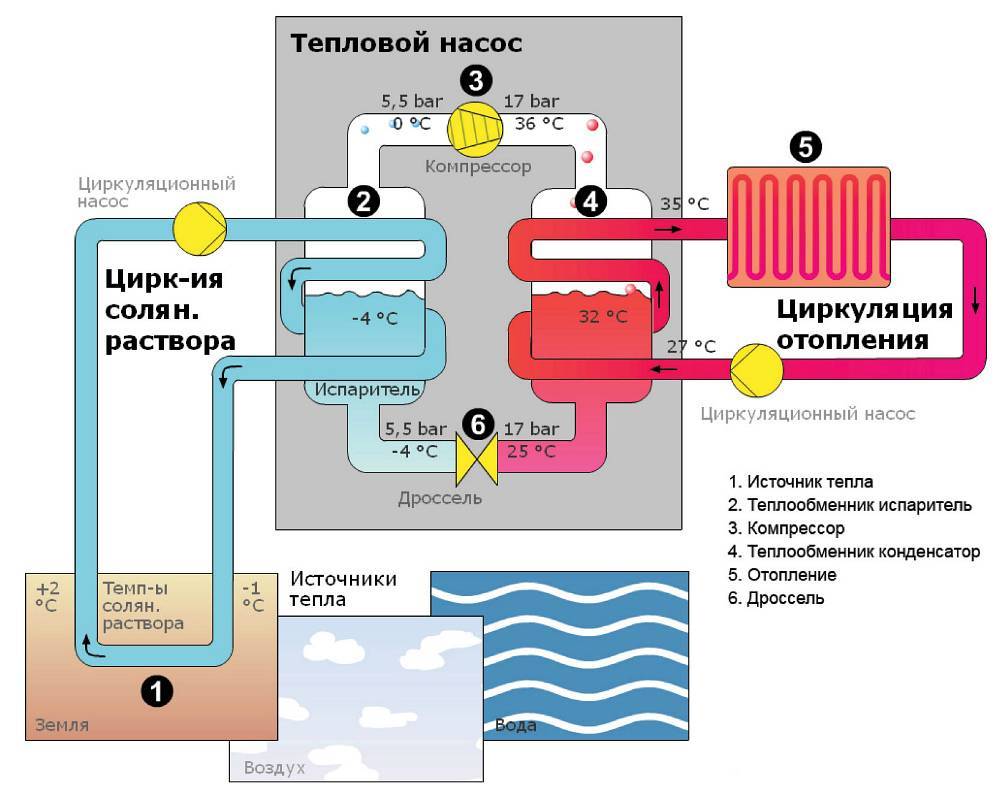

This system consists of a heat pump, a heat intake and distribution device. When creating the internal circuit of the heat pump, a compressor, an evaporator, a throttle valve and a condenser are used. Electricity is only needed to run the compressor.

The development of the principle of operation of the device was made in the 19th century. Even then it was called the "Carnot cycle". The operation of the pump is as follows:

- an anti-freeze mixture is supplied to the collector, which can be water with alcohol, brine or a glycol mixture. Its task is to absorb thermal energy with subsequent transportation to the pump;

- in the evaporator, energy passes to the refrigerant, as a result of which the latter begins to boil, turning into steam;

- as a result of the increase in compressor pressure, the temperature rises;

- through the condenser, all thermal energy is transferred to the heat carrier of the heating system located inside the house, while the refrigerant, cooling, turns into a liquid state and returns to the collector.

Pros and cons

Installing the pump and connecting it to the heating system has a number of advantages:

- Autonomy - from a centralized element, it is worth highlighting only the connection to the mains.

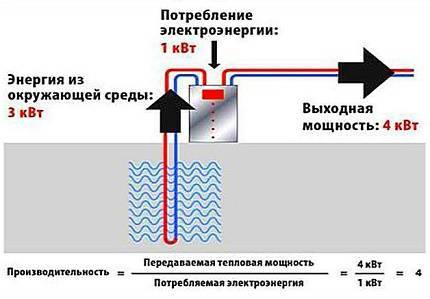

- Significant savings on expensive energy carriers, they are used for heating and can reduce financial costs for utilities. From 1 kW of electricity, the device produces from 3 to 7 kW of heat - these are the highest coefficients among boilers that operate on different types of fuel.

- Environmental safety - the equipment does not harm either the environment or the health of residents.

- Fire resistance and non-flammability of elements. Such a pump does not overheat, does not burn and does not emit carbon monoxide.

- The equipment can cool or increase the temperature in the room, creating the necessary microclimate in the room. It is suitable for use in both winter and summer.

- Long service life - on average, the system can last 40-50 years, and with proper installation and comfortable operating conditions, the service life is extended by several more years.

- Silence during operation - the system is controlled automatically, which is very convenient.

- The installation of the pump does not require a permit, as, for example, the installation of gas equipment. You can buy and install any model of the device at any time, without going to various authorities and without waiting for permission.

But like all equipment, such pumps also have disadvantages:

- The acquisition and installation of the device is quite expensive, and not everyone can afford it. The payback of the equipment depends on the intensity of its use. But even in the best case, the purchase will pay off in at least 5 years.

- For installation, you need to seek help from specialists, you need drilling and other equipment for arranging a geothermal pump with a vertical circuit with a depth of up to 200 m. You can install it yourself if you have the appropriate knowledge and tools.

- In regions where the temperature in winter is below -15 degrees, another heat source should be used. For example, a bivalent heating system, where the device heats the room while it is -20 degrees outside. When it does not perform its tasks, an electric heater or a gas boiler is turned on.

Circulation pumps are in demand among home owners and companies that are located in low-rise buildings. These devices have earned only positive reviews.

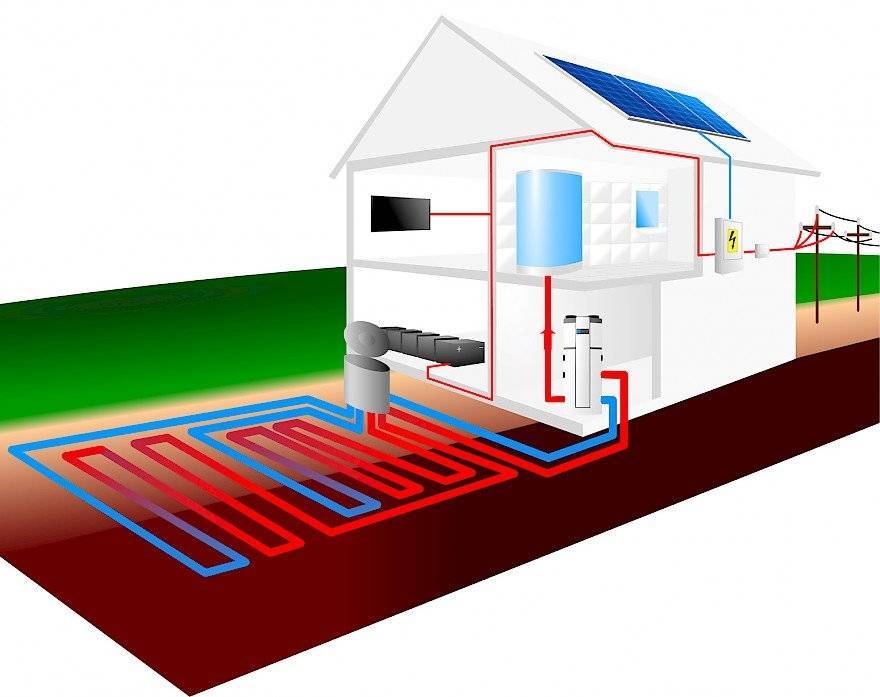

The use of heat pumps for home heating is, first of all, significant financial savings. The most efficient heating system is based on a ground source heat pump. Every month, the cost of it is much less than the cost of gas or pellet heating. By installing a heat pump, the user receives both air conditioning and efficient heating of the house in one design. Some models can be controlled from a distance, for example, using a smartphone via the Internet or using a thermostat located in the house. And by installing solar collectors or batteries, you can make the system completely autonomous, and you will not worry about the increase in energy prices at all.

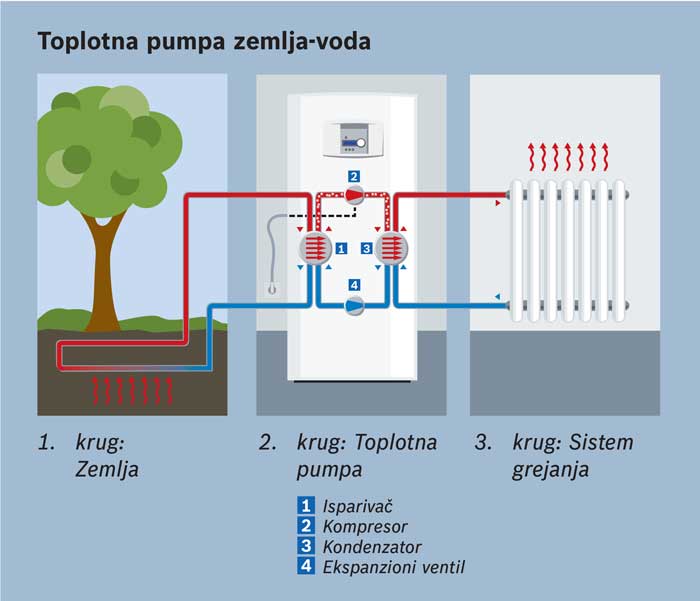

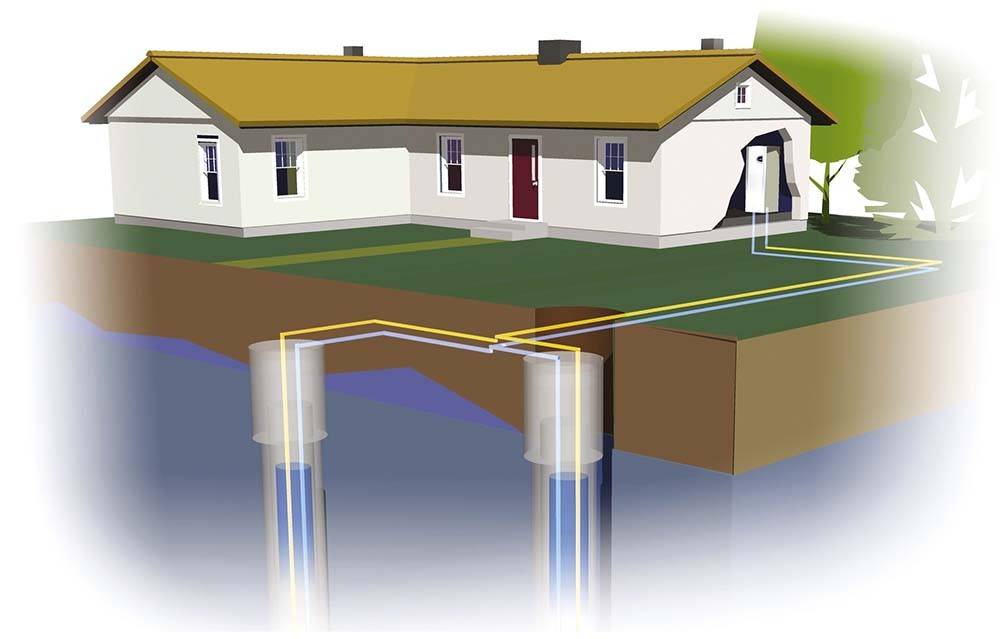

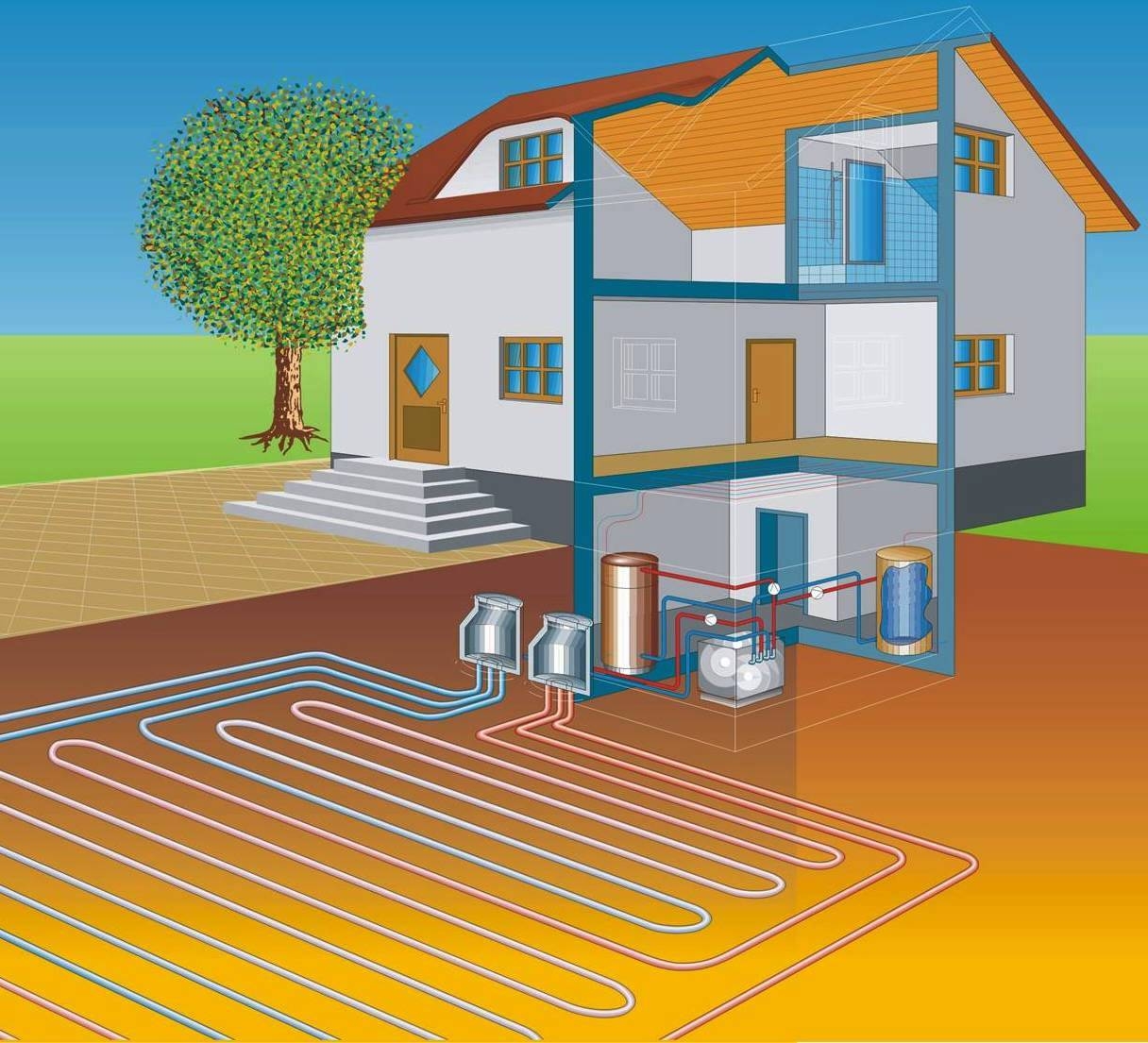

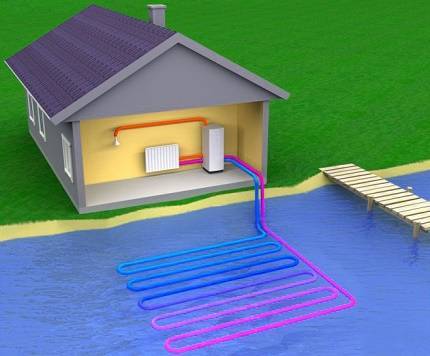

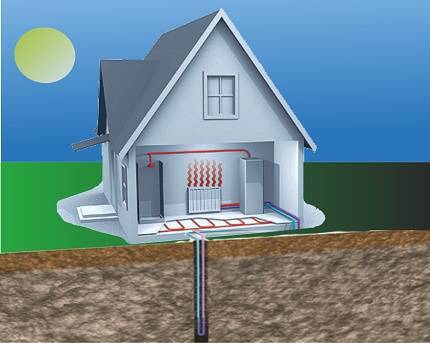

The main types of geothermal heat pumps

In total, there are four types of specialized collectors that supply thermal energy. These include:

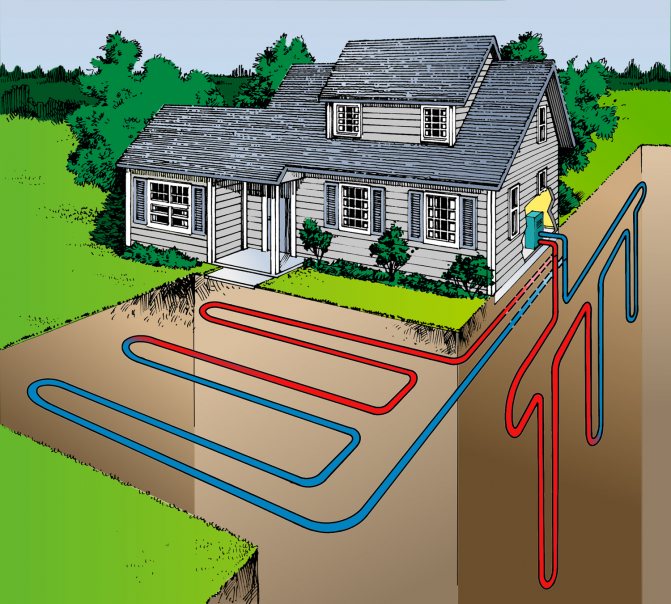

- Horizontal heat pumps located at a depth of about one and a half meters - exactly at the level that lies deeper than the freezing of the soil. This option is preferred for residential properties.

- Vertical heat pumps, located in special wells with a depth of about one and a half hundred meters. This decision becomes relevant in the case when there is simply no territory for horizontal placement of the contour.

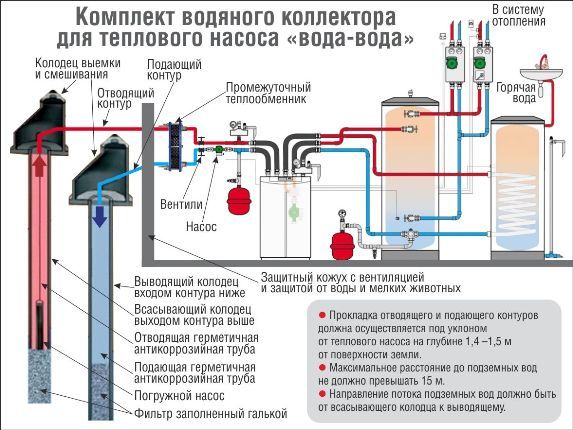

- Ground water pumps involve the circulation of water through a ground source heat pump system, which acts as a working heat exchange fluid. After it passes along the entire contour, the final stage is its safe return to the ground.

- Water source heat pumps are the most attractive option in terms of cost. They can be located in any body of water, the freezing depth of which is higher than the depth of equipment laying. Also, during the installation process, it is necessary to comply with the existing requirements for the volume of water in the reservoir and its size.

To date, all four types of collectors are used quite actively, they are selected based on operating conditions and user capabilities - building characteristics, budget, etc.

Recommended Equipment

Selecting the type of heat pump

The main indicator of this heating system is power. First of all, the financial costs for the purchase of equipment and the choice of one or another source of low-temperature heat will depend on the power. The higher the power of the heat pump system, the greater the cost of components.

First of all, this refers to the compressor power, the depth of wells for geothermal probes, or the area to accommodate a horizontal collector.Correct thermodynamic calculations are a kind of guarantee that the system will work efficiently.

If there is a reservoir near the personal area, the most cost-effective and productive choice will be a water-to-water heat pump

The use of the heat of the earth, on the contrary, involves a large number of works associated with excavation. Systems that use water as low-grade heat are considered the most efficient.

The device of a heat pump that extracts thermal energy from the ground involves an impressive amount of earthworks. The collector is laid below the level of seasonal freezing

There are two ways to use the thermal energy of the soil. The first involves drilling wells with a diameter of 100-168 mm. The depth of such wells, depending on the parameters of the system, can reach 100 m or more.

Special probes are placed in these wells. The second method uses a collector of pipes. Such a collector is placed underground in a horizontal plane. This option requires a fairly large area.

The construction for the intake of thermal energy by one deep well may turn out to be a little cheaper than digging a pit

But a significant plus lies in the significant savings in space, which is important for owners of small plots. In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other. In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other

In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other.

The extraction of thermal energy in such systems by pumping groundwater in a closed circuit, parts of which are located in wells. Such a system requires the installation of a filter and periodic cleaning of the heat exchanger.

The simplest and cheapest heat pump scheme is based on extracting thermal energy from the air. Once it became the basis for the construction of refrigerators, later air conditioners were developed according to its principles.

The simplest heat pump system obtains energy from the air mass. In summer it is involved in heating, in winter in air conditioning. The disadvantage of the system is that, in an independent version, a unit with insufficient power

The effectiveness of different types of this equipment is not the same. Pumps that use air have the lowest performance. In addition, these indicators are directly dependent on weather conditions.

Ground varieties of heat pumps have stable performance. The efficiency coefficient of these systems varies within 2.8 -3.3. Water-to-water systems are the most efficient. This is primarily due to the stability of the source temperature.

The main parameter characterizing the efficiency of a heat pump is its conversion factor. The higher the conversion factor, the more efficient the heat pump is considered.

The conversion factor of a heat pump is expressed through the ratio of the heat flow and the electrical power spent on the operation of the compressor

Selecting the type of heat pump

The main indicator of this heating system is power. First of all, the financial costs for the purchase of equipment and the choice of one or another source of low-temperature heat will depend on the power. The higher the power of the heat pump system, the greater the cost of components.

First of all, this refers to the compressor power, the depth of wells for geothermal probes, or the area to accommodate a horizontal collector. Correct thermodynamic calculations are a kind of guarantee that the system will work efficiently.

If there is a reservoir near the personal area, the most cost-effective and productive choice will be a water-to-water heat pump

First you need to study the area that is planned for the installation of the pump. The ideal condition would be the presence of a reservoir in this area. Using the water-to-water option will significantly reduce the amount of excavation.

The use of the heat of the earth, on the contrary, involves a large number of works associated with excavation. Systems that use water as low-grade heat are considered the most efficient.

The device of a heat pump that extracts thermal energy from the ground involves an impressive amount of earthworks. The collector is laid below the level of seasonal freezing

There are two ways to use the thermal energy of the soil. The first involves drilling wells with a diameter of 100-168 mm.The depth of such wells, depending on the parameters of the system, can reach 100 m or more.

Special probes are placed in these wells. The second method uses a collector of pipes. Such a collector is placed underground in a horizontal plane. This option requires a fairly large area.

For laying the collector, areas with wet soil are considered ideal. Naturally, drilling wells will cost more than a horizontal reservoir. However, not every site has free space. For one kW of heat pump power, you need from 30 to 50 m² of area.

The construction for the intake of thermal energy by one deep well may turn out to be a little cheaper than digging a pit

But a significant plus lies in the significant savings in space, which is important for owners of small plots. In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other

In the case of the presence of a high-lying groundwater horizon on the site, heat exchangers can be arranged in two wells located at a distance of about 15 m from each other.

The extraction of thermal energy in such systems by pumping groundwater in a closed circuit, parts of which are located in wells. Such a system requires the installation of a filter and periodic cleaning of the heat exchanger.

The simplest and cheapest heat pump scheme is based on extracting thermal energy from the air. Once it became the basis for the construction of refrigerators, later air conditioners were developed according to its principles.

The simplest heat pump system obtains energy from the air mass.In summer it is involved in heating, in winter in air conditioning. The disadvantage of the system is that, in an independent version, a unit with insufficient power

The effectiveness of different types of this equipment is not the same. Pumps that use air have the lowest performance. In addition, these indicators are directly dependent on weather conditions.

Ground varieties of heat pumps have stable performance. The efficiency coefficient of these systems varies within 2.8 -3.3. Water-to-water systems are the most efficient. This is primarily due to the stability of the source temperature.

It should be noted that the deeper the pump collector is located in the reservoir, the more stable the temperature will be. To obtain a system power of 10 kW, about 300 meters of pipeline are needed.

The main parameter characterizing the efficiency of a heat pump is its conversion factor. The higher the conversion factor, the more efficient the heat pump is considered.

The conversion factor of a heat pump is expressed through the ratio of the heat flow and the electrical power spent on the operation of the compressor

The use of heat pumps in the Russian climate

Having become acquainted with the above descriptions of various types of heat pumps, you can easily answer the question of which pump is most suitable for operation in the Russian climate.

Air heat pumps are suitable for use only in a limited number of regions of our country - where the air temperature in winter almost never drops below zero.Of course, the inhabitants of Siberia, the Far East, the north of the European part of Russia should not even think about air heat pumps.

There are many limitations to the application of water source heat pumps. We have already talked about some of them, it remains to mention one more. More than half of the territory of our country is located in the permafrost zone. Even if some resident of Eastern Siberia or the north of the Far East is “lucky” and there is groundwater in his area that is not too deep, then all the same, this groundwater is in the form of ice, which means it is not suitable for use in the heating system .

Thus, most of our compatriots have to rely on the only win-win option - a ground source heat pump. At the same time, in the conditions of the Russian climate, a pump is more suitable not with a horizontal collector, but with a geothermal probe, which allows reaching a depth where the soil temperature is more stable.