- The principle and scheme of operation of a heat pump, types

- Principle

- Scheme of work

- Types of heat pumps

- Ground or earth ("ground-air", "ground-water")

- Water pump ("water-air", "water-water")

- Air (air-to-water, air-to-air)

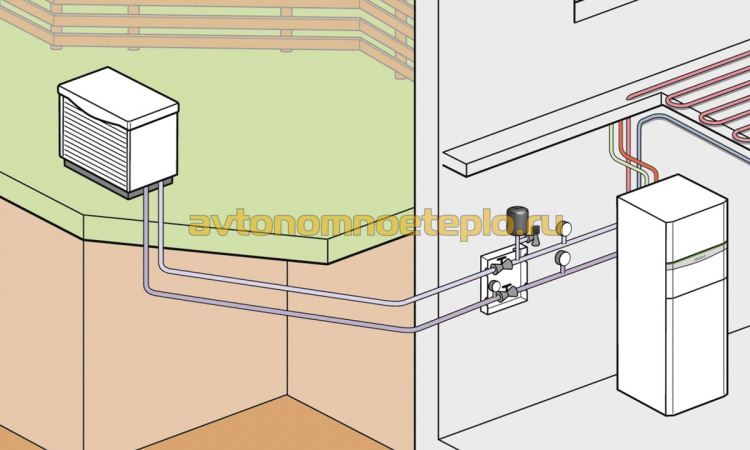

- Monoblock heat pump indoor installation

- Advantages

- Flaws

- Features of mounting the device

- Recommendations and rules for the installation of air-to-water heat pumps

- How profitable is an air-to-water heat pump

- Types of heat pumps

- Prospects for the use of heat pumps in the world

- Editor's Choice

- Air-to-air heat pump for home

- Work principles

- Advantages and disadvantages

- Installation capacity calculation

- How to make a heat pump yourself? ↑

- The main varieties, their principles of work

- ground water

- water-water

- Air to water

- Air

- conclusions

The principle and scheme of operation of a heat pump, types

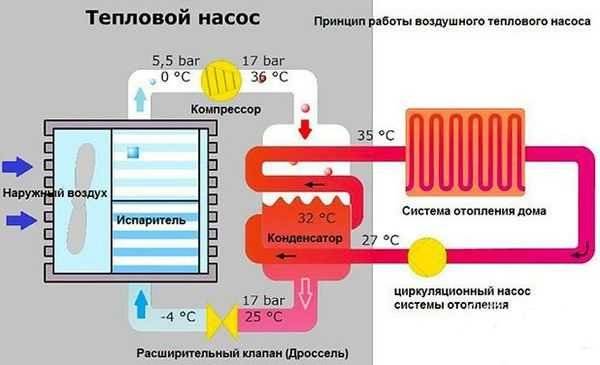

Principle

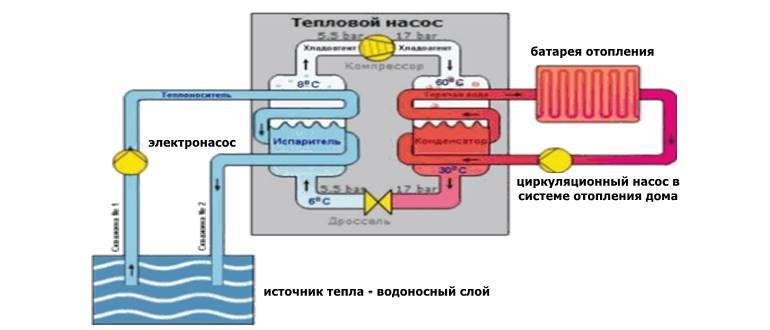

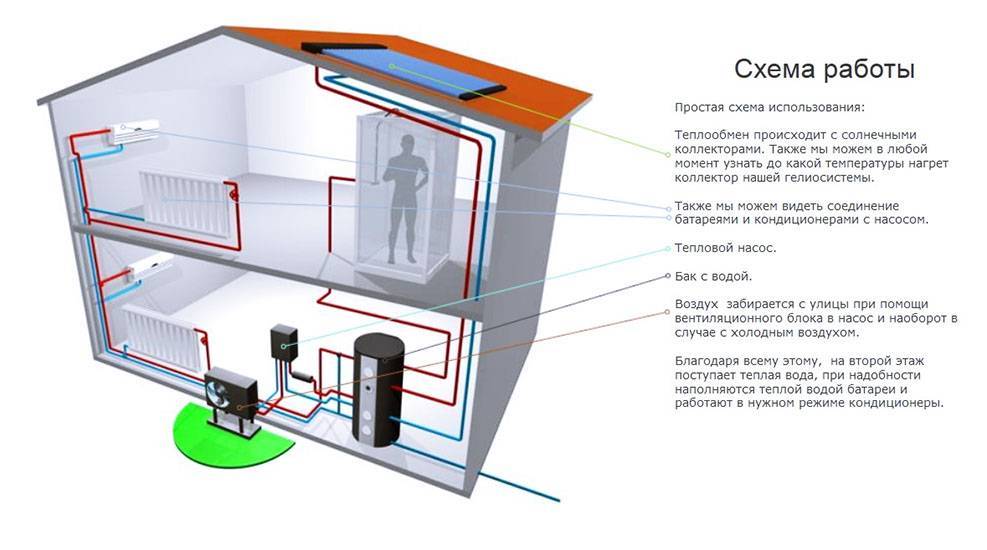

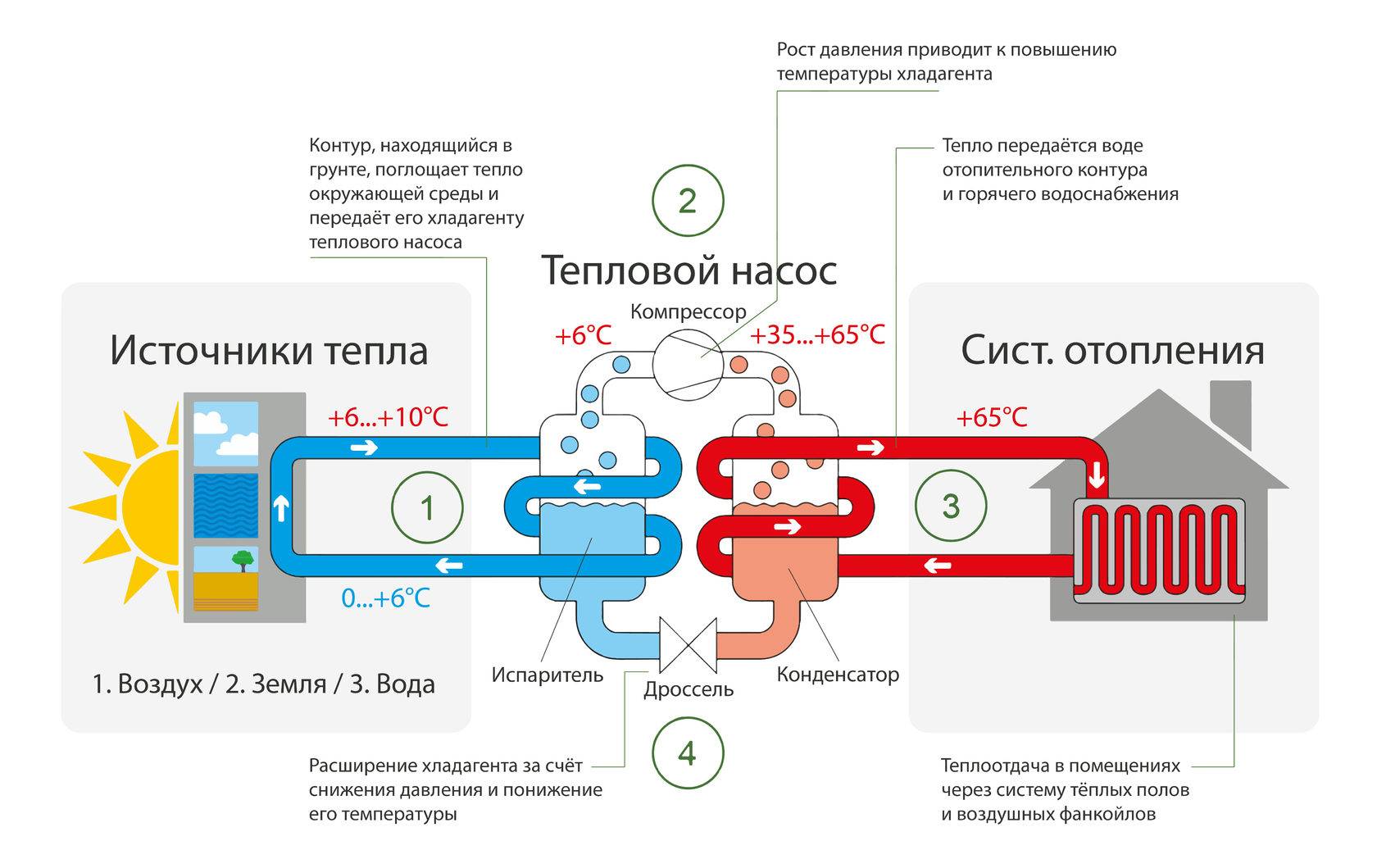

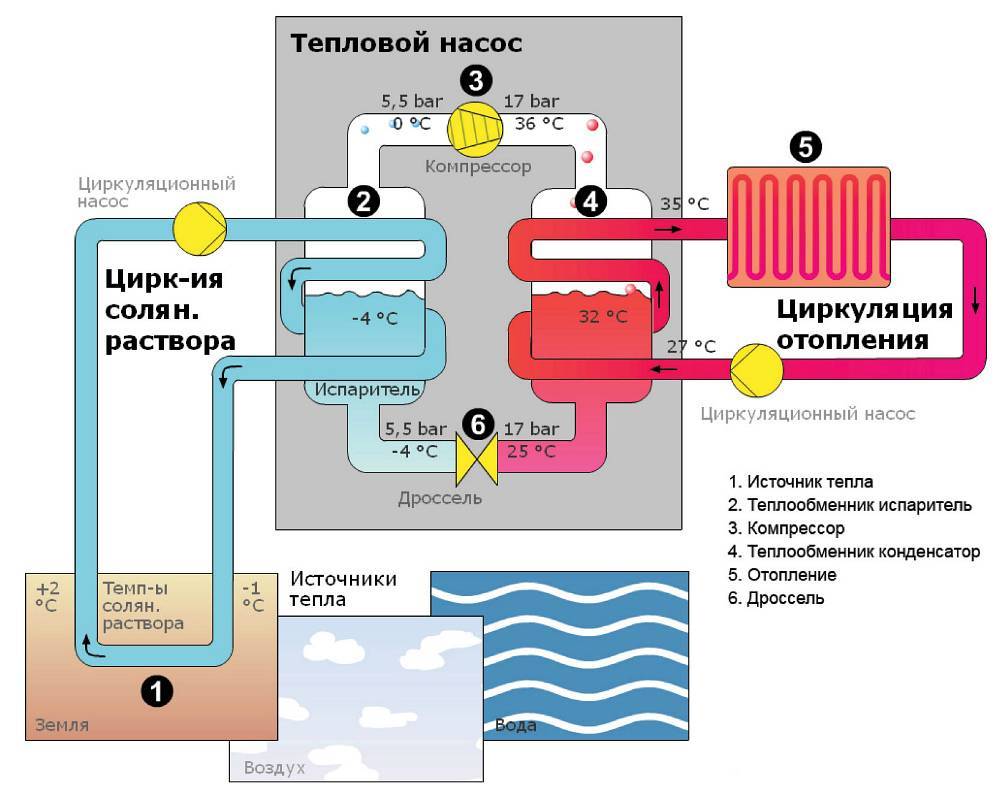

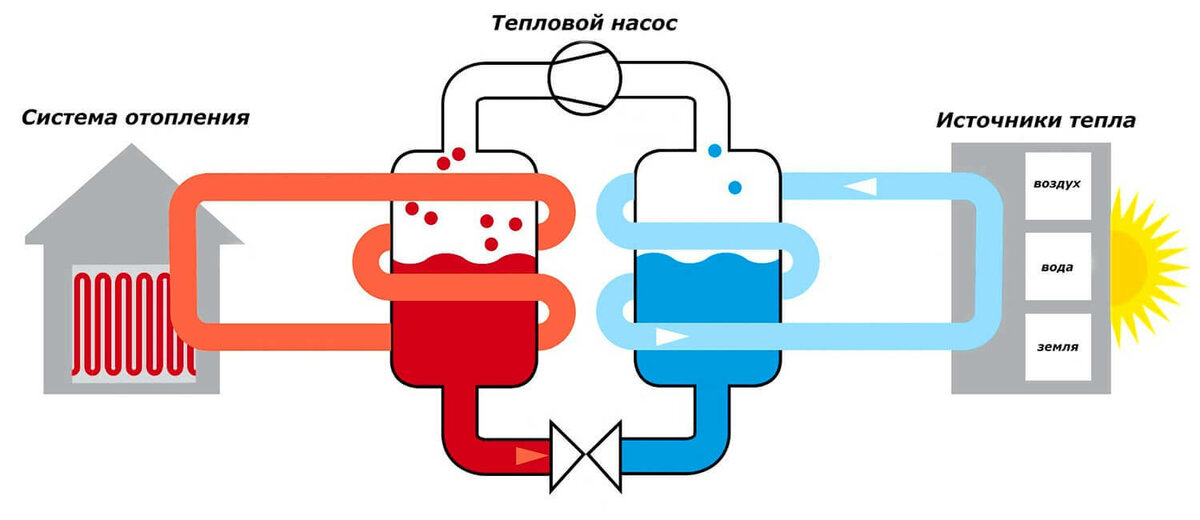

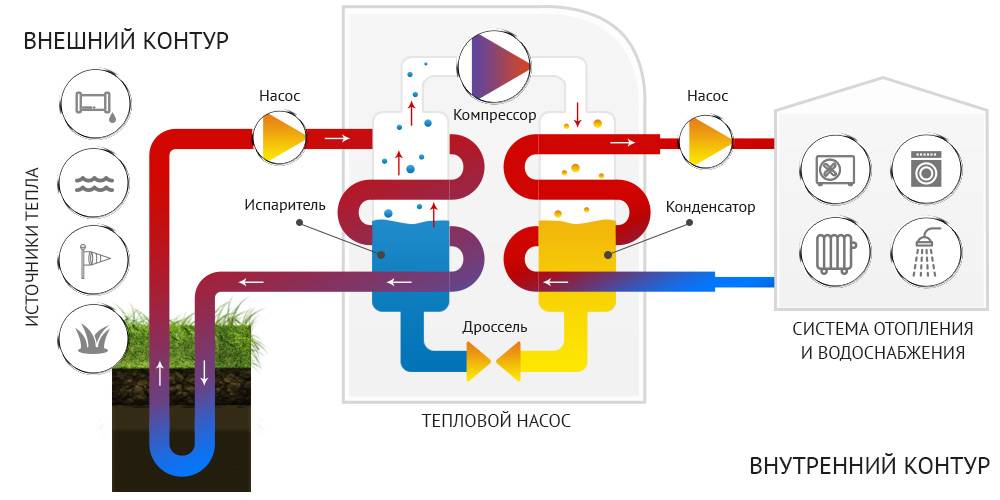

The design of any heat pump provides for 2 parts: external (absorbs heat from external sources) and internal (transfers the withdrawn heat directly to the heating system of the room). External renewable sources of thermal energy are, for example, the heat of the earth, air or groundwater.This design allows you to significantly reduce the cost of heating or cooling for a private house, because approximately 75% of the energy is generated thanks to free sources.

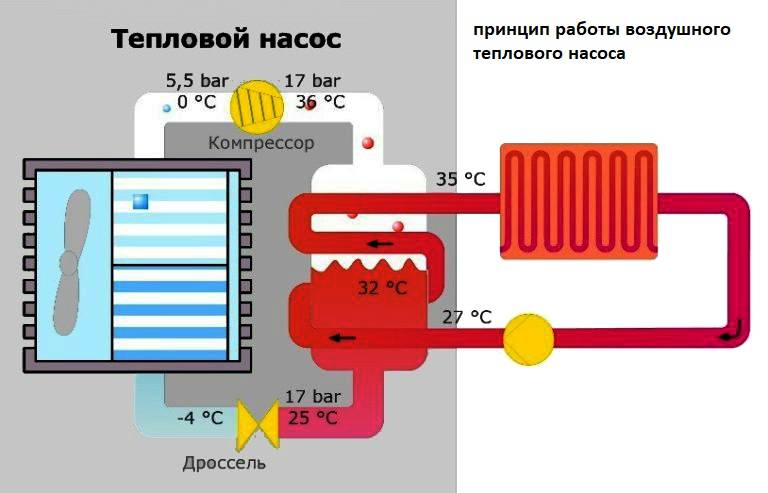

Scheme of work

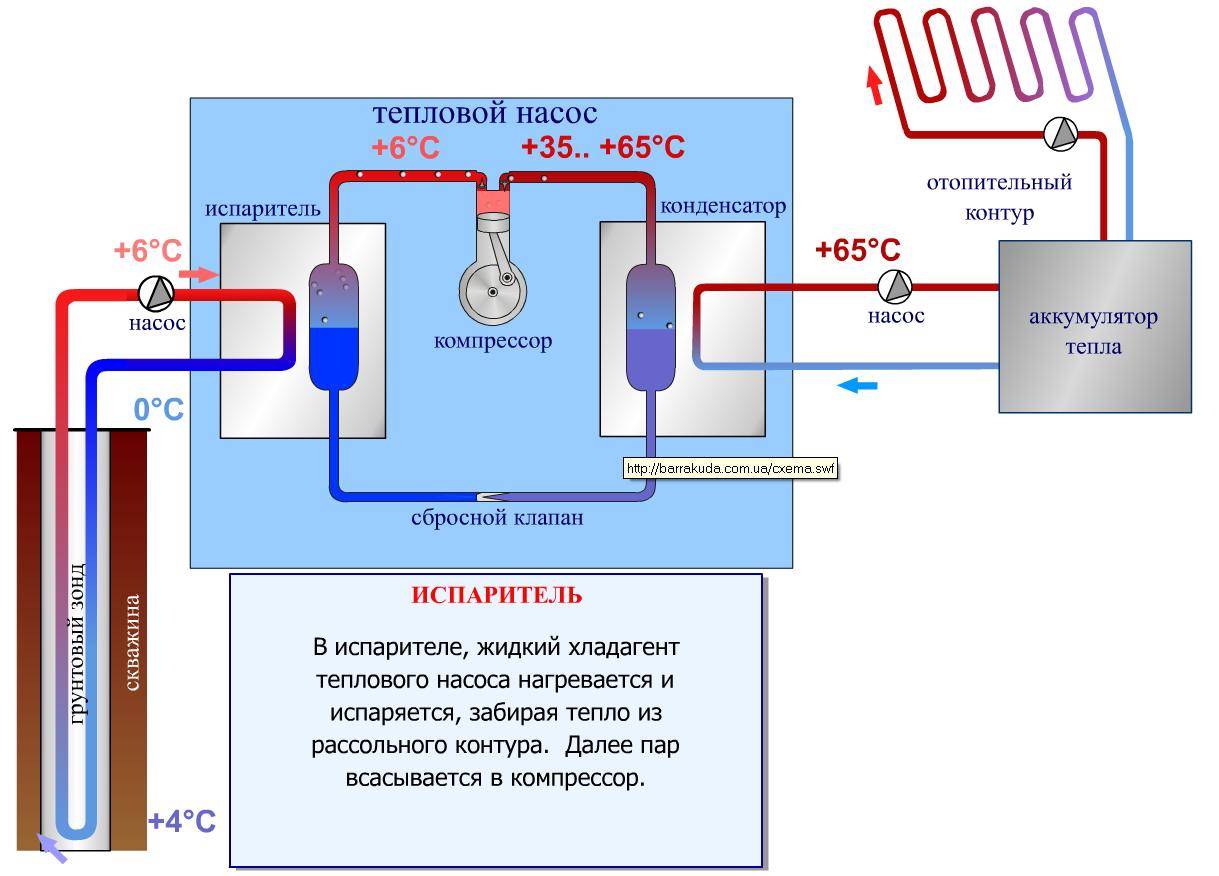

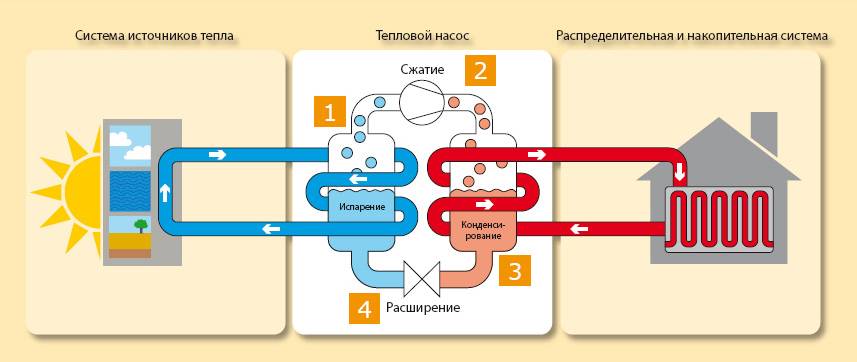

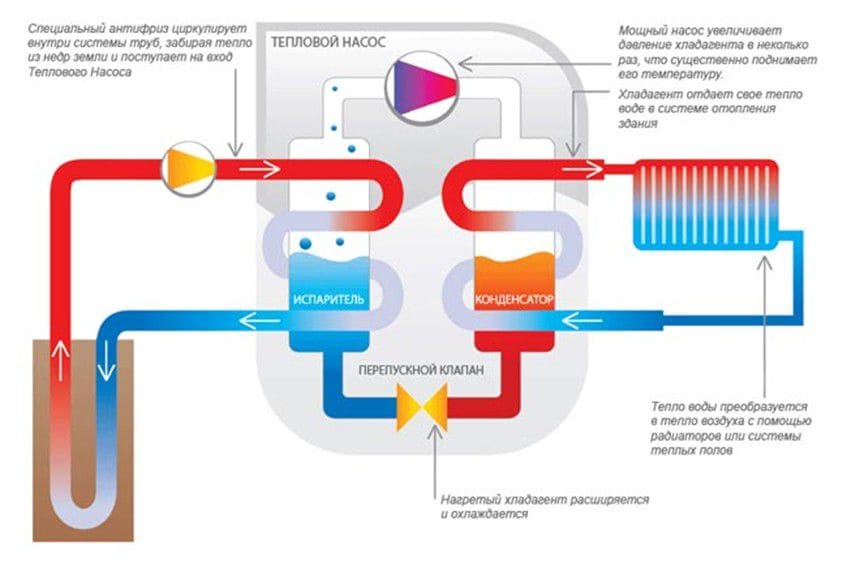

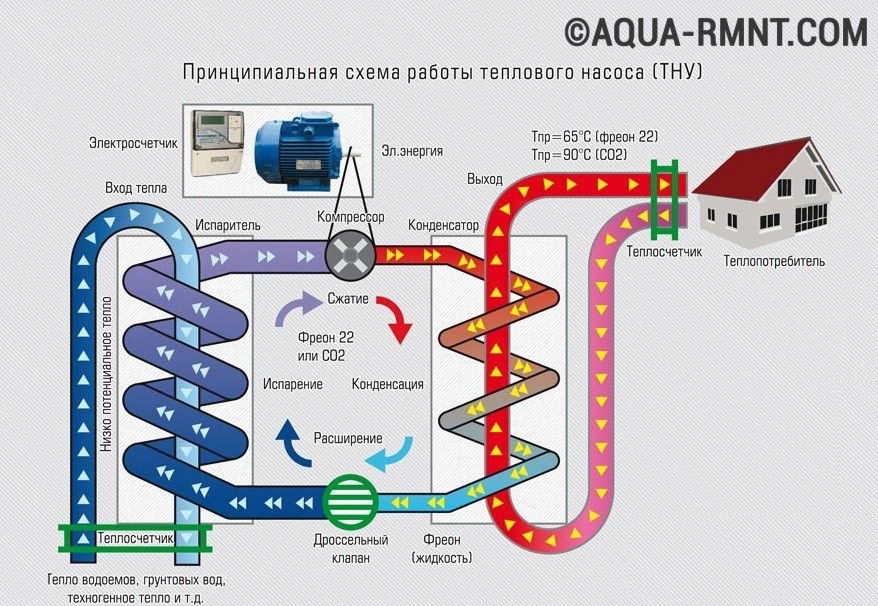

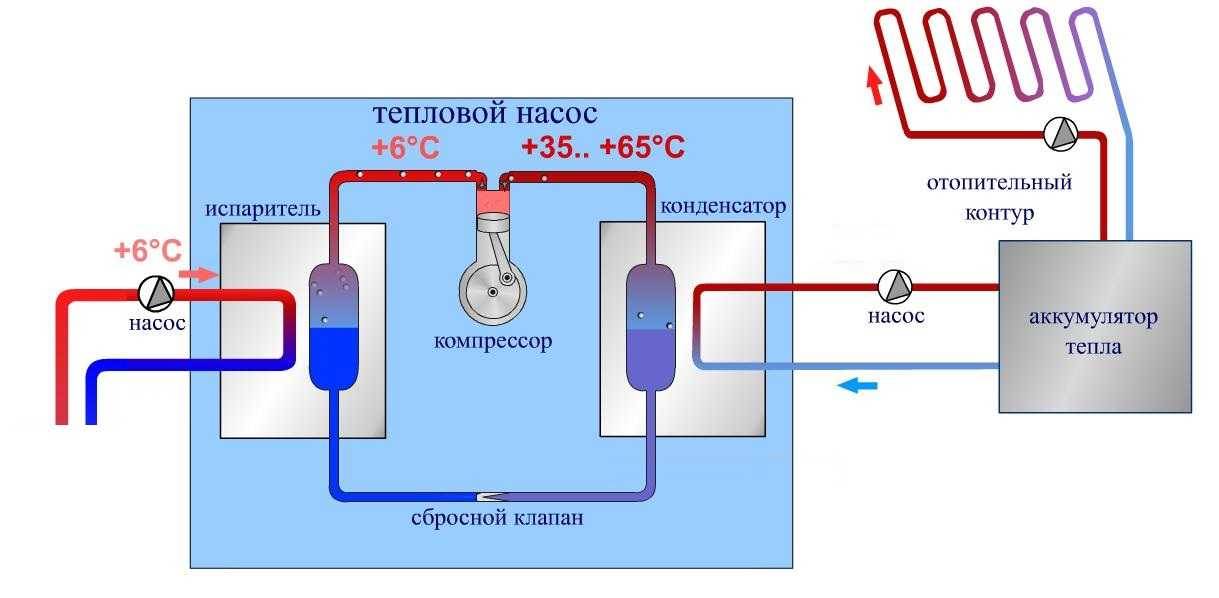

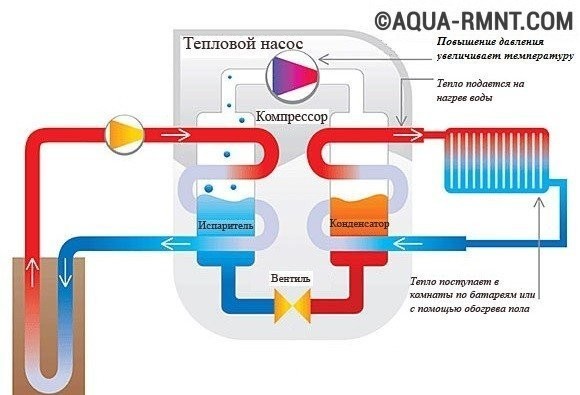

The composition of the heating installation includes: evaporator; capacitor; a discharge valve that lowers the pressure in the system; pressure booster compressor. Each of these nodes is connected to each other by a closed circuit of the pipeline, inside which the refrigerant is located. The refrigerant in the first cycles is in a liquid state, in the next - in a gaseous state. This substance has a low boiling point, therefore, with the option of earth-type equipment, it is able to transform into gas, reaching the level of soil temperature. Next, the gas enters the compressor, where there is a strong compression, which leads to rapid heating. After the hot steam enters the inside of the heat pump, and is already used directly here for space heating or to heat water. The refrigerant then cools down, condenses and re-liquids. Through the expansion valve, the liquid substance flows into the underground part to repeat the heating cycle.

The principle of cooling of such an installation is similar to the principle of heating, but not radiators, but fan coil units are used. The compressor does not work in this case. Cold air from the well directly enters the air conditioning system.

Types of heat pumps

What are the types of heat pumps? Equipment is distinguished by an external source of heat energy that is used in the system. Among household options, there are 3 types.

Ground or earth ("ground-air", "ground-water")

The use of an earthen heat pump as a source of heat energy will ensure eco-cleanliness and safety. The cost of such equipment is high, but its functionality is huge. No frequent service is required, and a long service life is ensured.

Ground source heat pumps can be of two types: with vertical or horizontal installation of pipelines. The vertical laying method is more costly as deep well drilling is required in the range of 50-200 meters. With a horizontal arrangement, the pipes are laid to a depth of about a meter. In order to ensure the collection of the required amount of heat energy, the total area of pipelines should exceed the area of heated premises by 1.5-2 times.

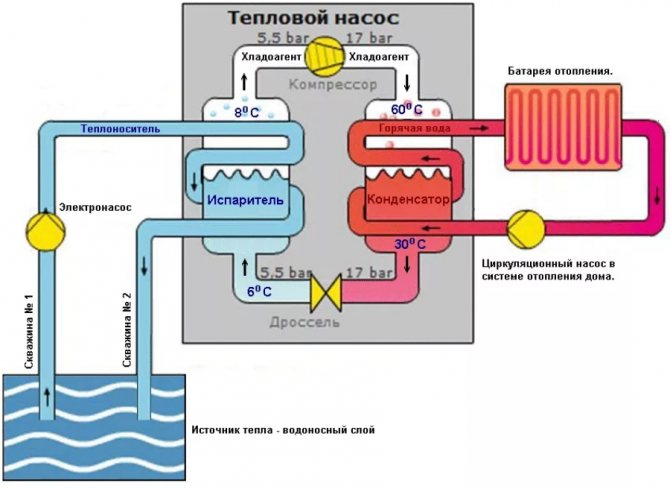

Water pump ("water-air", "water-water")

For southern regions with a warm climate, water installations are suitable. In warm in the sun water temperature on water bodies a certain depth is relatively stable. It is preferable to lay the hoses in the bottom soil itself, where the temperature is higher. A weight is used to fix underwater pipelines.

Air (air-to-water, air-to-air)

In an air-type unit, the source of energy is air from the external environment, which enters the evaporator heat exchanger, where the liquid refrigerant is located. The temperature of the refrigerant is always lower than the temperature of the air entering the system, so the substance instantly boils and becomes a hot vapor.

In addition to classic models, combined installation options are in demand. Such heat pumps are supplemented with a gas or electric heater.In case of bad climatic conditions, the performance of the heating device decreases and the device switches to an alternative heating option. Such an addition is especially relevant for air-to-water or air-to-air equipment, since it is these types that tend to reduce efficiency.

For regions with long cold winters, it is most reliable to use geothermal (ground) heat pumps. Air heat pumps are suitable for areas with a mild southern climate. Also, when installing equipment that uses earth energy, the characteristics of the soil should be taken into account. The productivity of the heat pump will be much higher in clay soil than in sandy soil. In addition, the depth of the pipelines is important, the pipes must be laid deeper than the ground freezing level during cold periods.

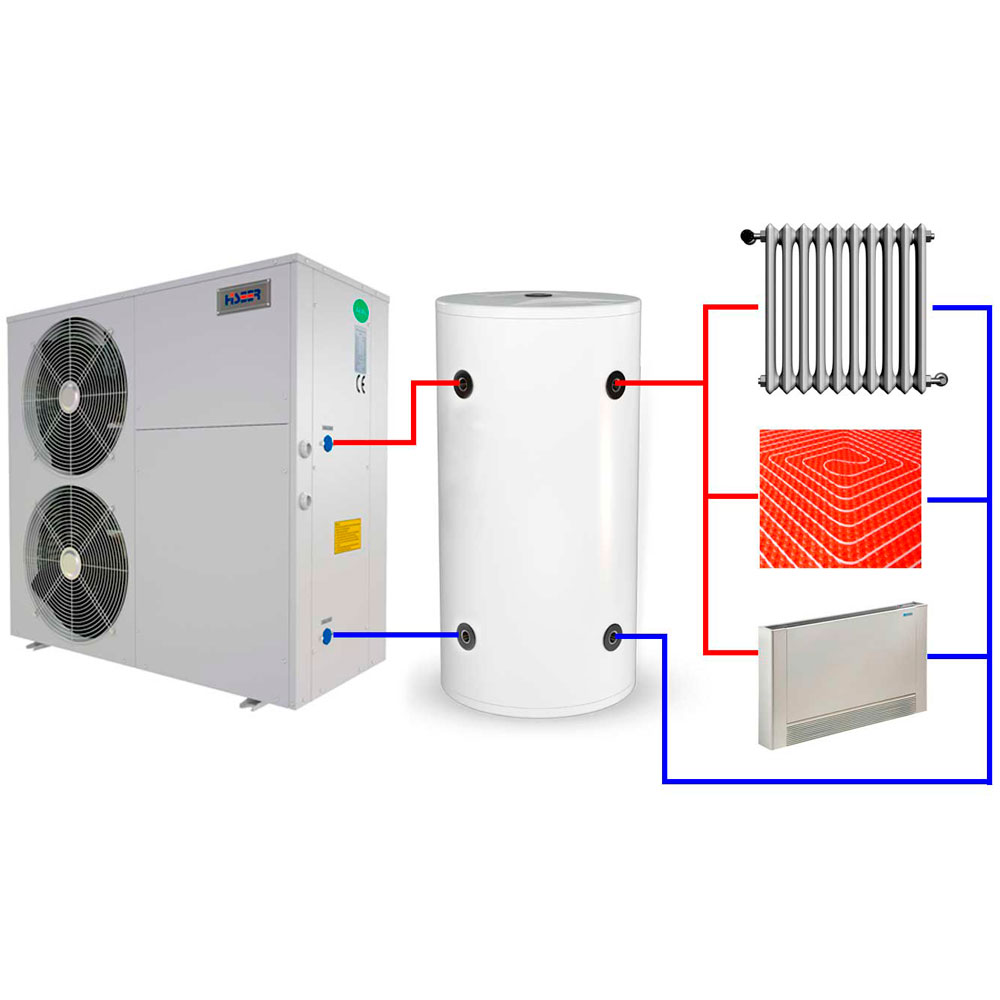

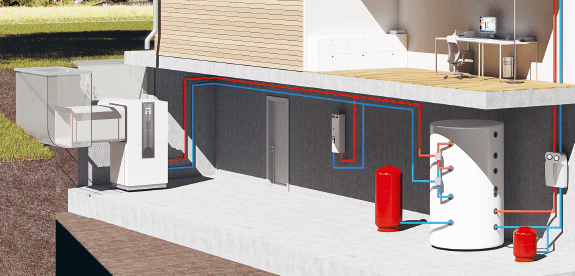

Monoblock heat pump indoor installation

This air-to-water heat pump is a monoblock with an indoor option. For the operation of such a system, it is necessary to provide air ducts for pumping the required amount of air.

Variant of installation of a monobloc air-to-water heat pump indoors

Advantages

- All components of the heat pump are located indoors and are therefore protected from adverse weather conditions.

- The absence of visible components does not affect the exterior of the building.

- No risk of freezing the system.

- During installation, there is no need to intervene in the refrigerant (freon) circuit.

Flaws

- The need to organize large holes in the walls of the boiler room, which may not always be suitable for the reconstruction of the system.

- All noise emitting elements are located in the room.

Features of mounting the device

The procedure for connecting the thermal pool pump depends on the particular model. Therefore, before starting work, you should carefully study the manufacturer's instructions and strictly follow the requirements and recommendations set out in it. Typically, industrial models are supplied already assembled and with a set of components necessary for installation.

Diagram of the operation of a heat pump connected to a pool: 1 - Pool heat pump 2 - Remote control device 3 - Clean water for the pool 4 - Circulation pump 5 - Bypass (bypass) and control valves 6 - Pool water supply pipe 7 - Filter

During the connection, you will need to install a pair of pipes, as well as provide power. In the pool maintenance system, the heater is installed in such a way that it is located after the filtration system and before the chlorinator.

As shown in this diagram, the heat pump should be connected after the water filter but before the water chlorinator

It is very important to choose the right place to install the equipment. Typically, an air-to-water heat pump is an impressively sized unit, reminiscent of the outdoor unit of a split air conditioner.

To install an air source heat pump, it is necessary to choose a place that is large enough and protected from external influences, for example, with a canopy.

The location for the installation of such equipment must meet the following requirements:

- good ventilation;

- lack of obstacles for the movement of air masses;

- distance from open fire and other heat sources;

- protection from external environmental factors: precipitation, debris falling from above, etc.;

- availability for maintenance and necessary repairs.

Most often, a heat pump is installed under a canopy. For added protection, you can install a couple of side walls, but they should not interfere with the airflow that is pumped by the fans.

The pump is mounted on a metal frame, the base must be strictly horizontal. This will minimize problems such as vibration and noise during operation of the device, and also protect the device from damage.

The air source heat pump must be installed on a solid and strictly horizontal base. This will reduce vibration during its operation and reduce the amount of noise.

When installing the heat pump and connecting it to the system, it is important to make sure that all its parts are clean. It does not hurt to check the inner surface of the pipes with which the connection is made.

All junctions of pipes through which water circulates must be carefully sealed and checked for leaks. To prevent the vibration from the heat pump from being transmitted to the rest of the system during its operation, it makes sense to consider the connection option using flexible hoses.

The power supply of the heat pump will require special attention. It must fully comply with the rules for the installation of electrical equipment, taking into account all fire safety requirements.

There is usually a high level of humidity around the pool, and the likelihood of electrical equipment coming into contact with water increases significantly.Therefore, it is necessary to carefully insulate all places of electrical contacts, additionally protecting them from possible contact with moisture.

It is mandatory to include circuit breakers in the circuit for connecting the heat pump to the power supply, which are equipped with sensors that respond to temperature increases. You will also need protection devices that will prevent current leakage.

All conductive nodes must be grounded without fail. To connect cables, both power and control, you will need special terminal blocks. The manufacturer's instructions usually indicate the required cross-section of electrical cables through which equipment can be connected to the power supply.

These data must be adhered to. The cross section of the cable may be more than recommended, but not less.

The installation of a heat pump for heating water in the pool is carried out in accordance with the manufacturer's recommendations. It is usually installed after the water treatment system, but before the chlorination device, if any.

Recommendations and rules for the installation of air-to-water heat pumps

Air-to-water heat pumps are installed anywhere in the local area. There are general rules regarding installation:

- The distance to the residential building is from 2 to 20 m.

The minimum distance to the boiler room, with which the unit is connected by several pipes and electrical cables.

A storage tank is located in the boiler room, circulation equipment is installed.

There is a slight noise level during operation. However, if you plan to install a monoblock for indoor installation, it is worth allocating a separate soundproof room for it.

The outdoor unit looks like an air conditioner case.At the bottom are legs for installation, as well as wall mounts.

Most models have a freeze prevention function. Therefore, the outdoor unit does not need insulation.

One of the most common decisions regarding the operation of a heat pump is the use of a pool heating system. With the help of equipment, water is heated in the summer, as well as space heating in the winter.

How profitable is an air-to-water heat pump

The benefits of using air-to-water heat pumps have become particularly evident since the advent of COP. Under this term is hidden a coefficient that compares the required energy costs when heating with an air-to-water heat pump. In practice, this means the following:

- VT requires electricity to operate. Voltage is needed by the compressor, which pressurizes the system. COP indicates how much heat was received due to the consumption of electricity per day.

If the COP is 3, then the pump generates 3 kW of thermal energy for every kW of electricity consumed.

Everything, it would seem, is simple, if not for one thing, but! There is a temperature dependence of the air-to-water pump. As the temperature drops, heat transfer drops significantly. Work efficiency is reduced in winter. It is for this reason that the reviews of real owners about air-to-water heat pumps from central Russia are contrary to the same comments from residents of northern latitudes.

All the shortcomings of the operation of air-to-water heat pumps mainly come down to dependence on external temperature factors

But this can be taken into account when choosing a model, paying attention to the parameter indicating the lower temperature limit to maintain the HP performance

Before making a purchase decision, it is worth reading a few reviews showing the advantages and disadvantages of heat pumps, as well as the possibilities and scope of equipment.

Types of heat pumps

- air-to-air;

- air-water;

- earth-water;

- water-water.

The first word in these combinations means the external environment from which energy is taken. The second word is the type of coolant, which provides space heating.

The use of geothermal and hydrothermal installations is less profitable. The fact is that obtaining thermal energy from soil or water in reservoirs requires an increase in costs for drilling a well, ensuring protection of the lowered part of the system from the effects of corrosion and siltation. The extraction of heat from the surrounding air makes operation of heat pumps more profitable and economically justified, due to the rapid payback of capital costs. At the same time, the service life of the equipment is several times longer.

Prospects for the use of heat pumps in the world

The decline in oil prices affected other heat transfer media, so the demand for heat pumps decreased. However, it is growing, which stimulates production. This largely depends on the fact that such installations can be installed without connecting the infrastructure, with the exception of the mains.

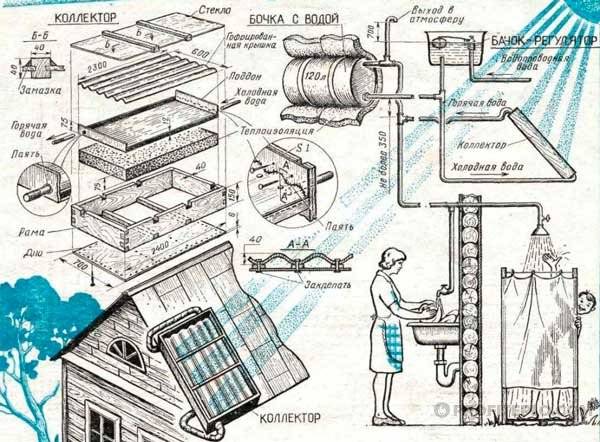

The use of alternative energy sources in combination with a heat pump allows you to increase its efficiency.For example, for its operation, you can receive electricity from solar panels and wind turbines, and use solar vacuum or flat collectors.

According to experts, the market for heat pumps will grow in the coming years, despite the active development of new fossil fuel deposits. As a result, competition will increase, which will lead to a decrease in the cost of equipment.

In many countries of the second and third world, government programs are being implemented that stimulate the use of alternative energy. As a result, this will lead to a wide distribution and increase in sales of heat pump installations.

Don't forget to share the post on social media!

Editor's Choice

Many years of experience in the production and operation of heat pumps in Northern Europe has allowed our compatriots to reduce the search for the most profitable way to heat their home. Real options exist for any request.

It is necessary to provide heat circuit DHW or heating system residential building up to 80 - 100 m²? Consider the potential of NIBE F1155 – its “intelligent” filling saves without sacrificing heat supply.

stable temperature in the underfloor heating circuits, CO, hot water supply of a cottage of 130 m² will be provided by Daikin EGSQH - a hot water heat exchanger (180 liters) is involved here.

DANFOSS DHP-R ECO produces a constant heat flow simultaneously for all consumers. The possibility of creating a cascade of 8 HP allows you to provide heat to the object area not less than 3,000 m².

Each of these models is not an unconditional, but a basic option. If you have found a suitable VT - view the entire line, study optional offers.The range of equipment is large, there is a risk of missing your ideal option.

Air-to-air heat pump for home

Air-to-air systems are best known to the general public as air conditioners (more precisely, split systems). Despite the abundance of names, we are talking about the same device, the design of which is based on the use of the Carnot cycle. It describes the processes that take place during the successive evaporation of a liquid, strong compression of the resulting gas, condensation and re-formation of a liquid. During compression, the temperature of the gas rises greatly, and when the liquid evaporates, it decreases. These two phenomena are used in refrigerators, air conditioners and heat pumps, only in the first two cases cold is a useful product, and in the last case heat.

Work principles

The air-to-air HP design is based on a closed circuit filled with refrigerant (freon). This circuit consists of two parts, an evaporator and a condenser. In the evaporator, liquid freon passes into a gaseous state, actively taking away thermal energy from the environment. The resulting gas is fed into the compressor, where it is highly compressed, causing its temperature to rise. From the compressor, hot gas passes into the condenser, where it passes into the liquid phase. After that, freon is passed through the step-down valve and enters the evaporator, and the whole cycle repeats again.

Thus, for the operation of an air-to-air heat pump, only a closed circuit with freon and two fans is required, which greatly simplifies and reduces the cost of the design in comparison with other types of heat pumps. If it is necessary to cool the room, then air from the evaporator is supplied inside, and the flow from the condenser is discharged outside.

Advantages and disadvantages

The advantages of air source heat pumps include:

- versatility. The system can cool or heat the room without any modifications or complex reconfiguration

- ecological purity. The system does not require hydrocarbon fuel, does not use environmentally hazardous substances

- simplicity of design. Installing your purchased heat pump is easy

- the possibility of self-production

- efficiency. Air heating quickly heats the room and has a low inertia, which allows you to quickly cool it if necessary.

- economy. Compressor and fan power costs pay off many times over

- low prices. Compared to other types of heat pumps, this option is the cheapest.

- Fire safety

There are also disadvantages:

- the need to use electricity, and the system does not tolerate power outages

- the result of work is directly related to the external air temperature, which reduces stability and forces you to constantly adjust the operating mode

- the constant presence of fine dust and suspension due to active air convection

- small but noticeable background sound during system operation

Installation capacity calculation

It is not recommended to calculate the heat pump on your own. It is necessary to use a lot of special data, coefficients and other values, which only specialists are able to use. If you need to calculate the system, you need to contact professionals. They have the experience and knowledge that is needed in this business.

How to make a heat pump yourself? ↑

The cost of a heat pump, even without calling specialists to install it, is quite high.Unfortunately, not everyone has the opportunity to spend such a significant amount of money at a time, even in the hope of saving in the near future. Is it possible to make a heat pump with your own hands? Yes, it is quite. In addition, you can build it from existing parts or buy used spare parts on occasion.

So let's get started. If you are going to install a similar heating system in an old house, be sure to check the condition of the wiring and the electricity meter. Make sure that the measuring device is at least 40 amps.

First of all, you need to take care of buying a compressor. In specialized firms or in a regular refrigeration repair shop, you can buy a compressor from an air conditioner. It is quite suitable for our purposes. It needs to be attached to the wall. with bracket L-300. Now we turn to the manufacture of the capacitor. To do this, we need a stainless steel tank with a volume of 100-120 liters. It must be cut in half and installed inside a coil, which is quite easy to make from a copper tube from a refrigerator or an ordinary plumbing copper pipe of small diameter

Important! Do not use a very thin-walled tube - its fragility can cause a lot of inconvenience during operation. The wall thickness of the copper tube should be at least 1 mm

- To obtain a coil, we take a gas or oxygen cylinder and wind a copper tube around it, observing the distance between the turns.In order to fix the tube in this position, the easiest way is to take a perforated aluminum corner, which is used to protect corners under putty, and attach it to the coil so that each turn is opposite the hole in the corner. This will ensure the same pitch of the turns and the strength of the entire structure.

- After installing the coil, we weld the halves of the tank, not forgetting to weld the threaded connections.

Homemade heat pump evaporator

The evaporator can be a plastic container with a volume of 60-80 liters, in which a coil is mounted from a pipe with a diameter of ¾ inches. For delivering and draining water normal water pipes can be used. The evaporator must also be mounted on the wall using an L-bracket of the desired size. When everything is ready, it's time to invite a refrigeration specialist. It is needed in order to assemble the system, weld copper pipes and pump freon

Important! If you do not have special education or skills in working with refrigeration equipment, do not attempt the last step of the work yourself. This can lead not only to the failure of your structure, but also to injury.

The main varieties, their principles of work

All heat pumps differ from each other in terms of energy source. The main classes of devices are ground-to-water, water-to-water, air-to-water, and air-to-air.

The first word indicates the source of heat, and the second - what it turns into in the device.

For example, in the case of a ground-water device, heat is extracted from the ground, and then it is converted into hot water, which is used as a heater in the heating system.Below we will consider the types of heat pumps for heating in more detail.

ground water

Ground-water installations extract heat directly from the ground using special turbines or collectors. In this case, the earth is used as a source, which heats the freon. It heats the water in the condenser tank. In this case, the freon is cooled and fed back to the pump inlet, and the heated water is used as a heat carrier in the main heating system.

The liquid heating cycle continues as long as the pump receives electricity from the network. The most costly, from an economic point of view, is the ground-water method, since for the installation of turbines and collectors, it will be necessary to drill deep wells or change the location of the soil on a large plot of land.

water-water

By their own specifications pumps type water-water are very similar to devices of the ground-water class, with the only difference being that in this case, water is not used as the primary heat source. As a source, both groundwater and various reservoirs can be used.

Photo 2. Installation of a structure for a water-to-water heat pump: special pipes are immersed in a reservoir.

Water-to-water devices are much cheaper than ground-to-water pumps, since they do not require deep wells to be installed.

Reference. For water pump operation it is enough to immerse several pipes into the nearest body of water, so it does not need to drill wells for its operation.

Air to water

Air-to-water units receive heat directly from the environment. Such devices do not need a large external collector for collecting heat, and ordinary street air is used to heat freon. After heating, freon gives off heat to water, after which hot water enters the heating system through pipes. Devices of this type are quite cheap, since an expensive collector is not needed to operate the pump.

Air

An air-to-air unit also receives heat directly from the environment, and it also does not require an external collector for its operation. After the contact of warm air, the freon is heated, then the freon heats the air in the pump. Then this air is thrown into the room, which leads to a local increase in temperature. Devices of this type are also quite cheap, since they do not require the installation of an expensive collector.

Photo 3. The principle of operation of an air-to-air heat pump. A coolant with a temperature of 35 degrees enters the heating radiators.

conclusions

By their example, users broke the stereotypes about the inefficiency of the operation of air-to-water heat pumps at low temperatures

Important. The air-to-water heat pump works optimally in conjunction with water heated floor - system, for which it is not required to heat the coolant to high temperatures

If you connect heating radiators to the HP, you will have to increase their area by 3-4 times in order to switch to low-temperature mode, without reducing the efficiency of work. In severe frosts, the air-to-water heat pumps are backed up by electric heating elements.

Heat pumps - an output in case of a lack of allocated electrical power.

In case of an accident or a power outage, in order not to be left without heat in winter, provide a backup independent heat generator, for example, a gas convector or a fireplace stove.Calculate the payback of HP in the long term, taking into account the steady increase in prices for energy carriers, electricity and the high cost of connecting main gas. Do not forget about the ease of use of heat pumps and the entire system.

Read articles:

- Is it profitable to build an energy efficient house? We study the problem of energy-efficient construction in Russia on the basis of real experience, with the calculations of specialists and the advice of portal users.

- Cheap heating of a country house with electricity. The material contains the real experience of a portal user who spent 1,500 rubles on heating a cottage in winter. per month, heating water in a heat accumulator for underfloor heating at a nightly rate with electric heating elements.

- How to calculate and install a water heated floor. Portal participants share their experience of operation, self-calculation and the nuances of installing a low-temperature heating system.

- Backup heating of a country house with gas cylinders. Pros, cons and features of heating a private cottage with a convector that runs on liquefied gas from cylinders.

- Homemade heat accumulator: advantages, design, tie-in scheme in the heating system. The portal user shares his experience in the manufacture and operation of a heat accumulator from a metal tank for a heating system based on a solid fuel boiler.

In the video - technologies of passive housing construction. Engineering communications: heat pump, heat recovery ventilation, solar collectors.

Source