- Recommendations for using the device

- Top 5 Benefits for Plant Owners

- The principle of operation of the device

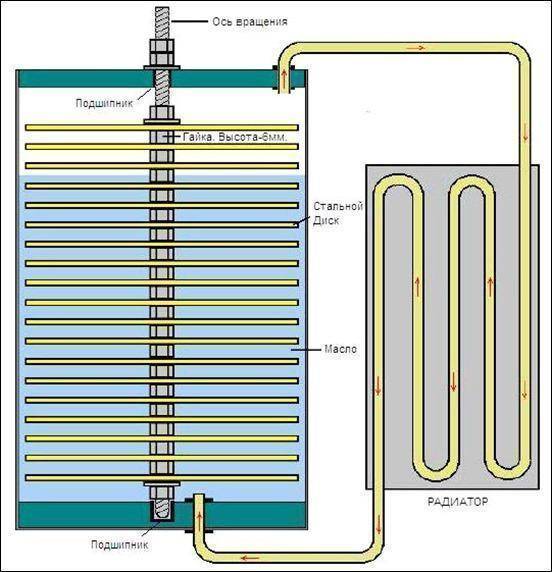

- Heat pump interior

- Advantages of the installation

- Heat pump for home heating, principle of operation

- Do-it-yourself Frenetta heat pump assembly process: drawings

- Frenette Pump Design Options

- How a heat pump works

- The principle of operation of the device

- Production of a geothermal installation

- Calculation of the circuit and pump heat exchangers

- Necessary equipment and materials

- How to assemble the heat exchanger

- Arrangement of the soil contour

- Refueling and first start

- How to make such a device yourself?

- Conclusion

Recommendations for using the device

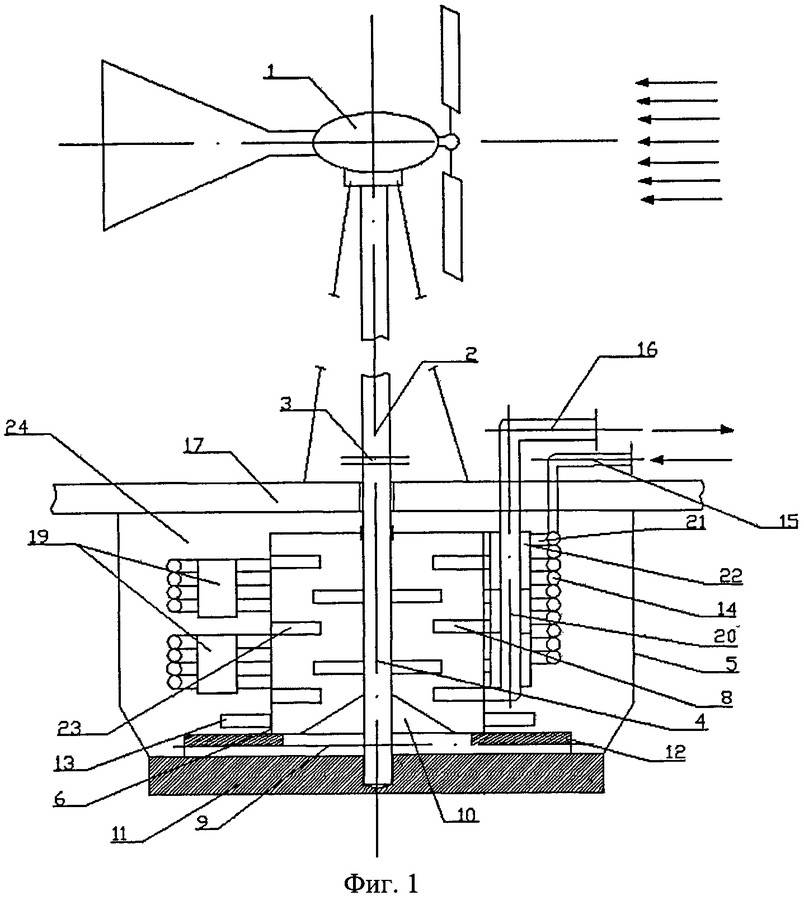

It is worth noting that variations of the Eugene Frenette pump using water as a coolant still exist. But usually these are large industrial models that are used in specialized enterprises. The operation of such devices is strictly controlled with the help of special devices. To provide such a level of security at home is almost impossible.

The most popular version of the Frenett pump, which uses water rather than oil as a coolant, is a device developed by scientists from Khabarovsk: Nazyrova Natalya Ivanovna, Leonov Mikhail Pavlovich and Syarg Alexander Vasilyevich. In this mushroom-shaped structure, water is deliberately brought to a boil and converted into steam.

Then, the reactive power of the steam is used to increase the speed of movement of the heat transfer fluid through the pump channels up to 135 meters per minute. As a result, the energy costs for moving the coolant are minimal, and the return in the form of thermal energy is very high. But such a unit must be extremely durable, and its operation must be constantly monitored in order to avoid an accident.

What to do if with the help of the Frenette pump it is supposed to organize the heating of a large room or the whole house? Water is a traditional coolant, most heating systems are designed specifically for it. Yes, and filling the entire heating system with the right liquid oil can be a costly business.

This issue is resolved very simply. It is necessary to additionally build a conventional heat exchanger in which the heated oil will heat the water circulating through the heating system. Some heat will be lost in this case, but the overall effect will remain quite noticeable.

An interesting idea would be to use a Frenett pump in combination with a floor heating system. At the same time, the coolant is allowed through narrow plastic pipes laid in a concrete screed. Such a heating system functions in the same way as a conventional water heated floor.Of course, a project of this type can only be implemented in a private house, since only electric underfloor heating is allowed for high-rise apartment buildings.

A practical and convenient way to use such a device is to heat a small room: a garage, a barn, a workshop, etc. The Frenett pump allows you to effectively and quickly solve the problem of autonomous heating in such places. The cost of electricity for its operation is small compared to the resulting thermal effect, and it is not difficult to build such a unit from the simplest materials.

Top 5 Benefits for Plant Owners

The advantages of heating systems with heat pumps include the following:

- Economic efficiency. With the cost of 1 kW of electrical energy, you can get 3-4 kW of heat. These are average indicators, because. the heat conversion coefficient depends on the type of equipment and design features.

- Environmental Safety. During the operation of the thermal installation, combustion products or other potentially hazardous substances do not enter the environment. The equipment is ozone safe. Its use allows you to get heat without the slightest harm to the environment.

- Versatility of application. When installing heating systems powered by traditional energy sources, the owner of the house becomes dependent on monopolists. Solar panels and wind turbines are not always cost-effective. But heat pumps can be installed anywhere. The main thing is to choose the right type of system.

- Multifunctionality. In the cold season, the installations heat the house, and in the summer heat they are able to work in air conditioning mode. The equipment is used in hot water systems, connected to the contours of underfloor heating.

- Operational safety.Heat pumps do not require fuel, they do not emit toxic substances during their operation, and the maximum temperature of equipment units does not exceed 90 degrees. These heating systems are no more dangerous than refrigerators.

There are no ideal devices. Heat pumps are reliable, durable and safe, but their cost directly depends on the power.

High-quality equipment for full-fledged heating and hot water supply of a house of 80 sq.m. will cost about 8000-10000 euros. Homemade products are low-power, they can be used to heat individual rooms or utility rooms.

The efficiency of the installation depends on the heat loss of the house. It makes sense to install the equipment only in those buildings where a high level of insulation is provided, and heat loss rates are not higher than 100 W / m2.

The efficiency of the installation depends on the heat loss of the house. It makes sense to install the equipment only in those buildings where a high level of insulation is provided, and heat loss rates are not higher than 100 W / m2.

Heat pumps can last 30 years or more. Their use is especially profitable for hot water supply, as well as in combined heating systems, including underfloor heating.

Equipment is reliable and rarely breaks down

If it is homemade, then it is important to choose a high-quality compressor, best of all - from a refrigerator or air conditioner of a proven brand

The principle of operation of the device

Those who come into contact with the issues of cost-effective heating, the name "heat pump" is well known. Especially in combination with terms like “land-water”, “water-water”, or “air-water”, etc.

Such a heat pump has practically nothing in common with the Frenette device. In addition to the name and the end result in the form of thermal energy, which is ultimately used for heating.

Heat pumps operating on the Carnot principle are very popular both as a cost-effective way to organize heating and as an environmentally friendly system.

The operation of such a complex of devices is associated with the accumulation of low-potential energy contained in natural resources (earth, water, air) and its conversion into thermal energy with a high potential.

The invention of Eugene Frenette is arranged and works in a completely different way.

The principle of operation of this device is based on the use of thermal energy, which is released during friction. The design is based on metal surfaces located not close to each other, but at some distance. The space between them is filled with liquid.

Parts of the device rotate relative to each other with the help of an electric motor, the liquid inside the case and in contact with the rotating elements is heated.

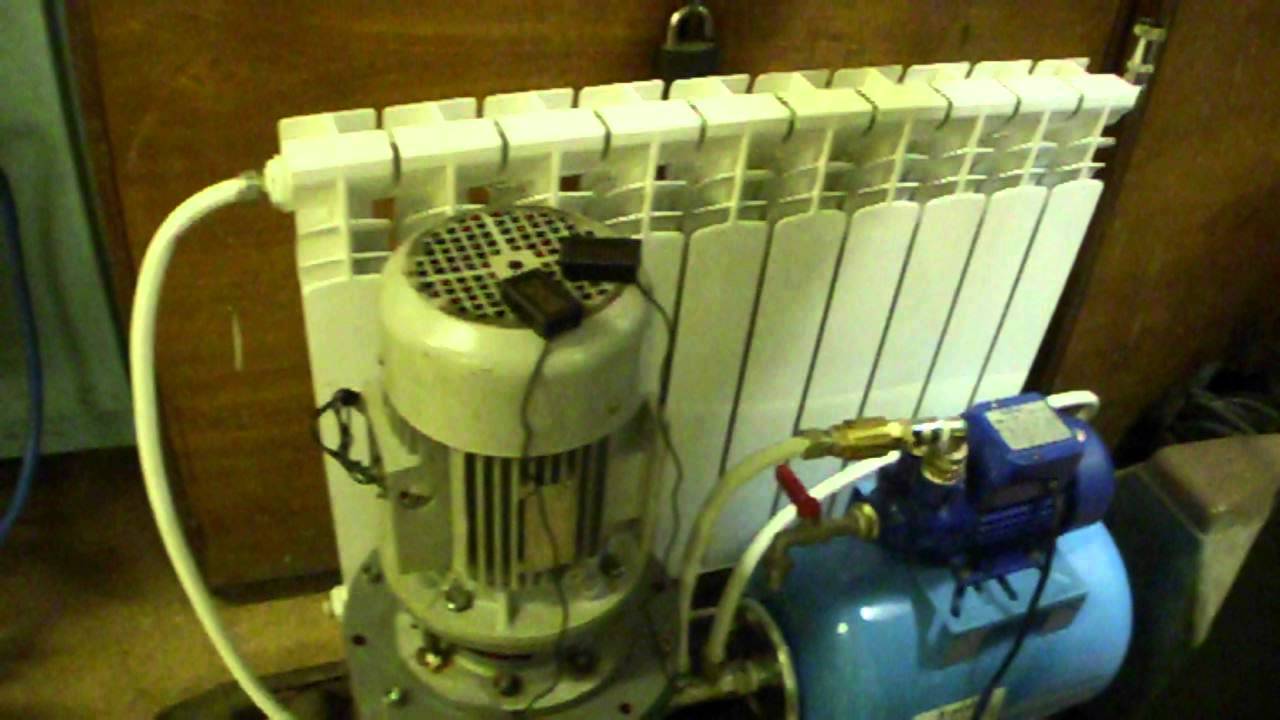

The resulting heat can be used to heat the coolant. Some sources recommend using this fluid directly for the heating system. Most often, a regular radiator is attached to a homemade Frenett pump.

Experts strongly recommend using oil rather than water as the coolant of the heating system.

During the operation of the pump, this liquid tends to heat up very strongly. Water in such conditions can simply boil. Hot steam in a confined space creates excess pressure, and this usually leads to rupture of pipes or a casing. It is much safer to use oil in such a situation, since its boiling point is much higher.

To make a Frenette heat pump, you will need an engine, a radiator, several pipes, a steel butterfly valve, steel discs, metal or plastic rod, metal cylinder and nut set (+)

To make a Frenette heat pump, you will need an engine, a radiator, several pipes, a steel butterfly valve, steel discs, metal or plastic rod, metal cylinder and nut set (+)

There is an opinion that the efficiency of such a heat generator exceeds 100% and can even be 1000%. From the point of view of physics and mathematics, this is not a completely correct statement.

Efficiency reflects the energy losses spent not on heating, but on the actual operation of the device. Rather, the phenomenal claims about the incredibly high efficiency of the Frenette pump reflect its efficiency, which is truly impressive. The cost of electricity for the operation of the device is negligible, but the amount of heat received as a result is very noticeable.

Heating the coolant to the same temperatures using a heating element for heating, for example, would require a much larger amount of electricity, perhaps ten times more. A household heater with such a consumption of electricity would not even heat up.

Why are not all residential and industrial premises equipped with such devices? The reasons may be different.

Firstly, water is a simpler and more convenient coolant than oil. It does not heat up to such high temperatures, and it is easier to clean up the consequences of water leaks than to clean up spilled oil.

Secondly, by the time the Frenette pump was invented, a centralized heating system already existed and functioned successfully. Its dismantling for replacement with heat generators would be too expensive and would bring a lot of inconvenience, so no one even seriously considered this option. As they say, the best is the enemy of the good.

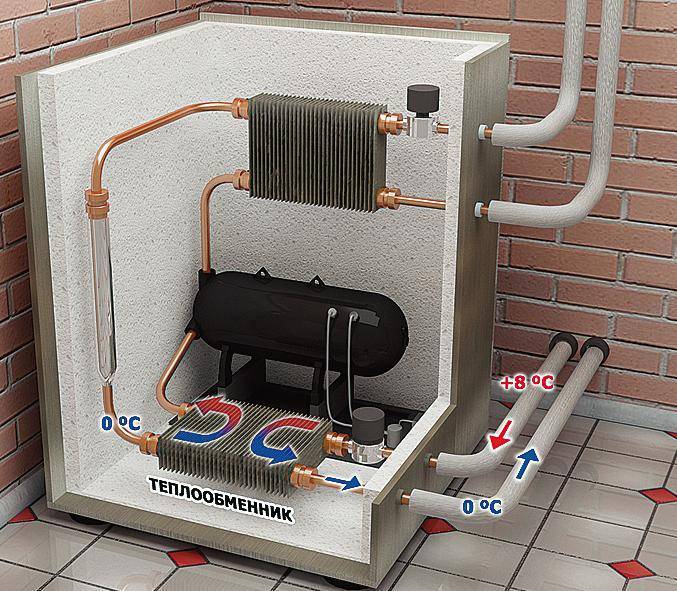

Heat pump interior

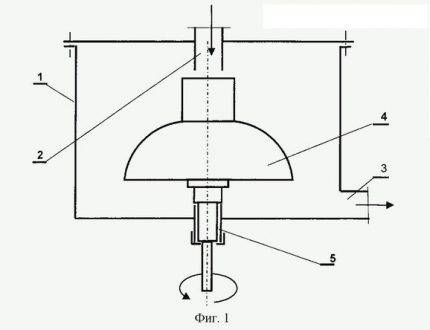

Classical the heat pump consists of several components:

- rotor;

- shaft;

- blade fan;

- stator.

A pair of cylinders - a rotor and a stator - determine the operation of the TNF.The stator is a large and empty cylinder from the inside, and the rotor is a less voluminous cylinder installed in the stator. Oil (coolant) is poured into the stator, where it is heated under the action of the rotor. The rotor itself is powered by a shaft on which a bladed fan is installed. The latter blows hot air into the room, due to which the heating function is carried out.

Heat pump interior

This is how the first heat pump worked. In the future, his work was improved. In more modern models, the rotor was no longer needed - it was replaced by steel discs. In addition, there is no need for a bladed fan.

Factors that ensure high efficiency for a heat pump:

- the coolant is in a closed system;

- no need for a heat exchanger;

- high heating power;

- the main part of the TNF has a conical shape, which favors the appearance of vacuum zones and an increase in temperature.

Advantages of the installation

Frenetta heat pump can be connected to the underfloor heating system

Frenetta heat pumps, in comparison with other units of this type, are especially popular. The installation is widely used in heating systems.

Also, the pump can be connected to modern floor heating systems.

Such widespread use of the heat pump is explained by the fact that it has many advantages compared to other units.

These include:

- high productivity;

- profitability;

- the ability to operate in automatic mode;

- versatility of the pump;

- easy customization for certain needs;

- compact dimensions;

- silent operation and much more.

The introduction of new modifications to the design of the pump leads to an improvement in its technical characteristics.

Frenett heat pumps are widely used in various fields. Most often they are installed in country houses. An important advantage of the unit is that it can be assembled by hand.

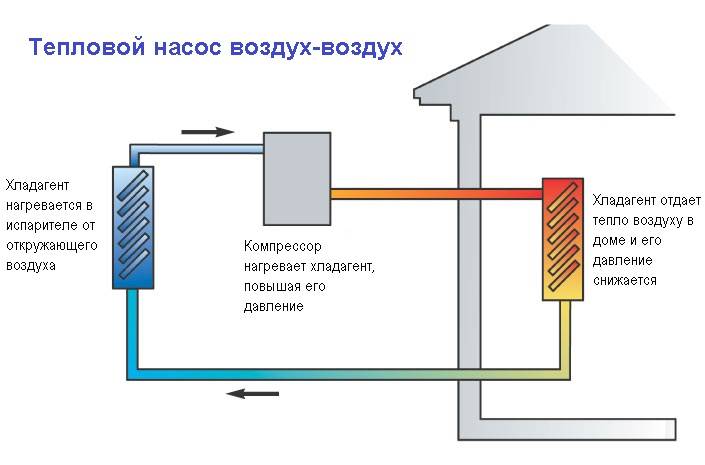

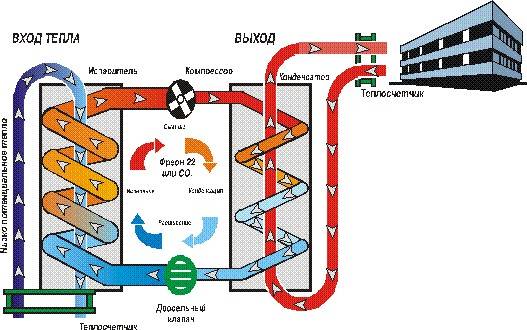

Heat pump for home heating, principle of operation

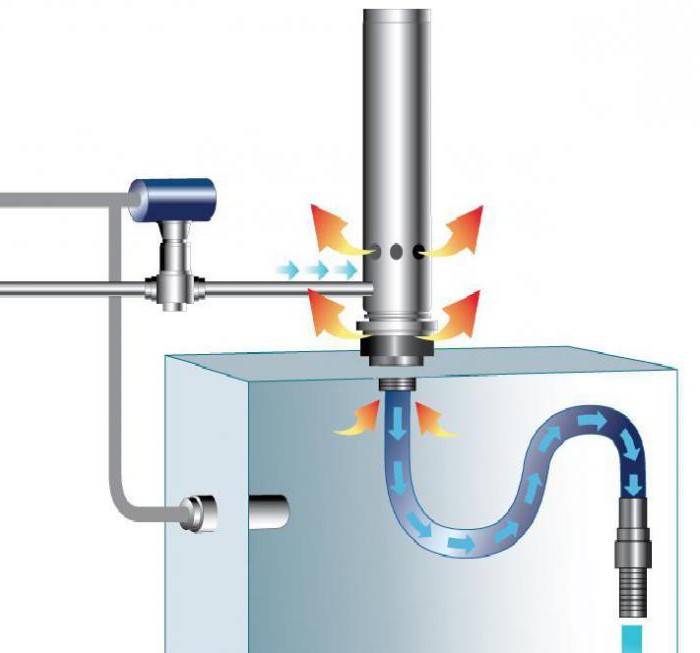

The operation of the heat pump, refrigerator and air conditioner is based on the Carnot cycle. A heat pump for heating transfers heat from a zone with a lower temperature to a consumer, where the value of this parameter should be higher. In this case, it is taken from outside, where it is accumulated, and after some transformations it goes into the house. It is natural heat, and not the energy released during the combustion of traditional fuel, that increases the temperature of the coolant passing through the pipes of the heating system.

In fact, the principle of operation of the pump is much more complicated. Therefore, devices of this class are often compared with refrigeration units, only working in reverse. But the general order of operation is identical, despite the fact that there is a big difference both in the engineering solution and in the purpose of the main parts of the devices. From traditional heating system the circuit assembled on a heat pump differs in the number of circuits and the specifics of their operation.

The external circuit is mounted outside a private house. It is laid where heat accumulates when surfaces are heated by sunlight or for another reason. Energy can be taken, for example, from the air, soil, water. Even from a well, if the house is on rocky soil or there are restrictions on pipe installation.Therefore, there are several modifications of heat pumps, despite the fact that heating is organized according to the same type of scheme.

The principle of operation of the pump

The internal circuit (not to be confused with the heating in the house) is geographically located in the unit itself. The cooled coolant circulating in the external one partially raises its temperature due to the environment. Passing through the evaporator, it transfers the extracted energy to the refrigerant with which the internal circuit is filled. The latter, due to its specific property, boils and passes into a gaseous state. Low pressure and temperatures above -5°C are sufficient for this. That is, the liquid medium turns into a gas.

Further - to the compressor, where the pressure is artificially increased, due to which the refrigerant is heated. It is in this structural element, which is the second heat exchanger, that thermal energy is transferred to the liquid (water or antifreeze), passing through the return line of the heating system of the house. A rather original, efficient and rational heating scheme.

The heat pump needs electricity to operate. But it is still much more profitable than using only an electric heater. Since an electric boiler or electric heater spends exactly the same amount of electricity as it produces heat. For example, if a heater has a power of 2 kW, then it spends 2 kW per hour and produces 2 kW heat. A heat pump produces heat 3-7 times more than it consumes electricity. For example, 5.5 kWh is used to operate the compressor and pump, and 17 kWh of heat is obtained. It is this high efficiency that is the main advantage of a heat pump.

It remains to be added that a saline solution or ethylene glycol circulates in the external circuit, and Freon, as a rule, circulates in the internal circuit. The composition of such a heating scheme includes a number of additional devices. The main ones are a valve-reducer and a subcooler.

Do-it-yourself Frenetta heat pump assembly process: drawings

First, two holes are made in the housing for heating pipes specifically for heating pipes. The threaded rod is installed in the center of the body. Screw the nut onto this thread, put the disk, then screw the next nut, etc. And so the installation of the disks continues until the body is completely filled.

Then oil is poured into the system, for example, cottonseed. The case is closed and fixed on the rod. Bring the radiator pipes to the holes made. The electric motor is attached to the central rod, it guarantees rotation. The device can be connected to the network and its operation can be checked.

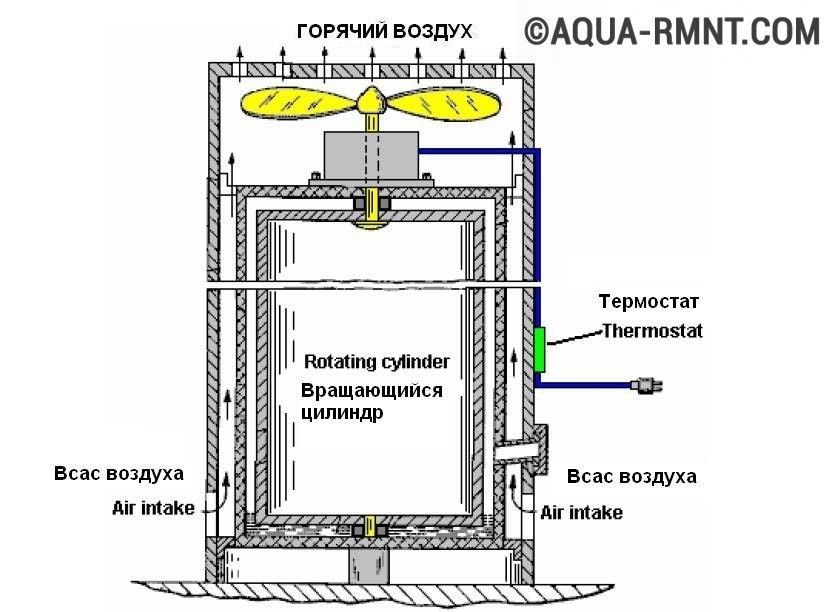

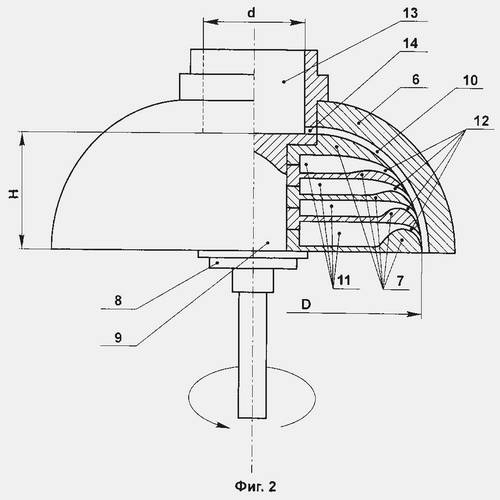

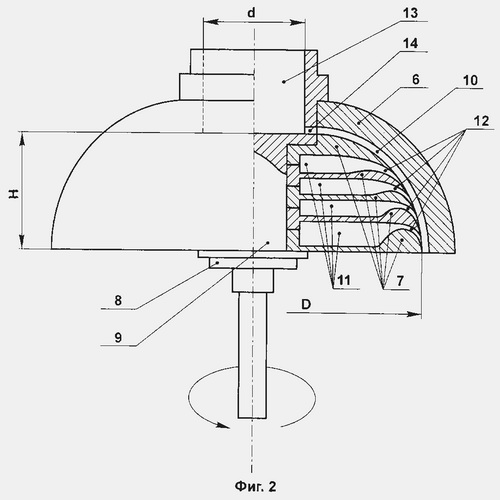

Frenette Pump Design Options

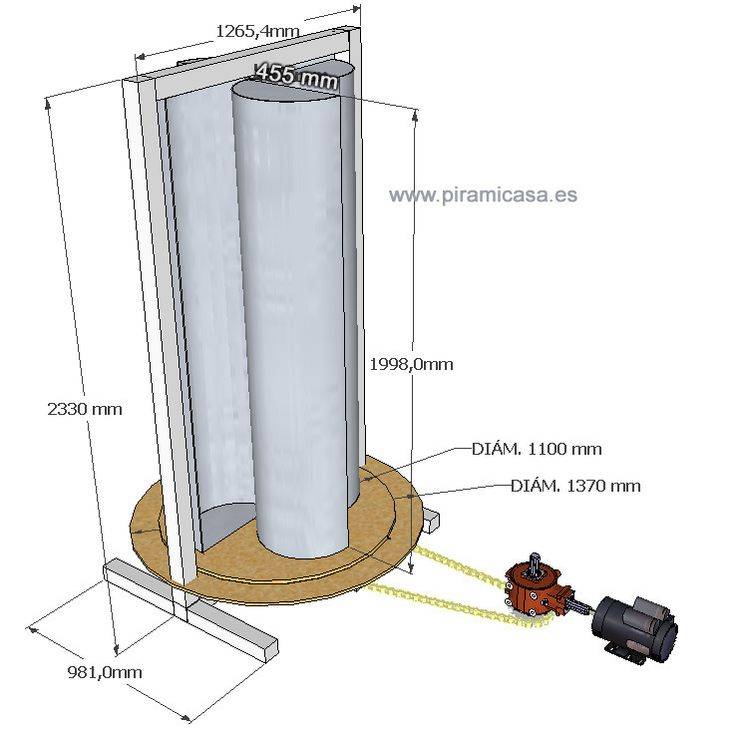

Eugene Frenette not only invented the device named after him, but also repeatedly improved it, inventing new, more efficient versions of the device. In the very first pump, which the inventor patented in 1977, only two cylinders were used: an external one and an internal one. The hollow outer cylinder was larger in diameter and was in a static state. In this case, the diameter of the inner cylinder was slightly smaller than the dimensions of the cavity of the outer cylinder.

This is a diagram of the very first version of the Frenette heat pump. The rotating shaft is located horizontally, the coolant is placed in a narrow space between two working cylinders

The inventor poured liquid oil into the resulting narrow space between the walls of the two cylinders.Of course, the part of the structure that contained this heat transfer fluid was carefully sealed to prevent oil leaks.

The inner cylinder is connected to the motor shaft in such a way as to ensure its rapid rotation relative to the stationary large cylinder. A fan with an impeller was placed at the opposite end of the structure. During operation, the oil heated up and transferred heat to the air surrounding the device. The fan made it possible to quickly distribute warm air throughout the entire volume of the room.

Since this design heated up quite a lot, for the sake of convenient and safe use, the design was hidden in a protective case. Of course, holes were made in the case for air circulation. A useful addition to the design was a thermostat, with which the operation of the Frenett pump could be automated to some extent.

The central axis in such a heat pump model is located vertically. The engine is at the bottom, then nested cylinders are installed, and the fan is at the top. Later, a model with a horizontal central axis appeared.

A Frenette heat pump model with a horizontally oriented rotating shaft was used in conjunction with a heating radiator with heated oil circulating inside.

It was such a device that was first used in combination not with a fan, but with a heating radiator. The motor is placed on the side, and the rotor shaft passes through the rotating drum and out. In device this type of fan missing.The coolant from the pump moves through the pipes to the radiator. In the same way, the heated oil can be transferred to another heat exchanger or directly into the heating pipes.

Later, the design of the frenet heat pump was significantly changed. The rotor shaft still remained in a horizontal position, but the inner part was made of two rotating drums and an impeller placed between them. Here again liquid oil is used as a heat carrier.

In this version of the Frenette heat pump, two cylinders rotate side by side, they are separated by a specially designed impeller made of very durable metal.

When this design rotates, the oil heats up additionally, as it passes through special holes made in the impeller, and then penetrates into a narrow cavity. between the walls of the pump casing and its rotor. Thus, the efficiency of the Frenett pump has been significantly improved.

Small holes are made along the edges of the impeller for the Frenett heat pump. The coolant quickly and efficiently heats up, passing through them

However, it is worth noting that this type of pump is not very suitable for home manufacturing. First you need to find reliable drawings or calculate the design yourself, and only an experienced engineer can do this. Then you need to find a special impeller with holes of a suitable size. This element of the heat pump operates under increased loads, so it must be made of very durable materials.

How a heat pump works

At its core, the technology of operation of TNF is similar to the principle of operation of a refrigerator.Refrigeration equipment, to lower the temperature, takes heat from the chambers and releases it outside with the help of radiators. HNF works in exactly the same way: in order to produce heat, it takes it from the soil or liquid, processes it and transfers it to the heating system of a private house, workshop, greenhouse or any other room.

How a heat pump works

The refrigerant, which can be ammonia or freon, moves inside the external and internal circuits. In this case, the external circuit is responsible for receiving heat from the atmosphere, earth or water.

Every natural environment has in its composition a certain amount of disparate thermal energy. The refrigerant is able to collect it and send it for recycling. To initiate this process, it is necessary that the temperature of the heat carrier rise by 4-5 degrees.

Then, from the outer circuit, the refrigerant is directed to the inner one. Here the evaporator converts the heat carrier from liquid to gas. The process occurs due to the fact that freon at low ambient pressure has a low boiling point.

After the evaporator, freon in the form of a gas rushes into the compressor, where compression occurs and, as a result, an increase in temperature. Next, the gas is in the condenser. There, the gas shares its temperature with the liquid (heat carrier). As a result of cooling, the gas returns to a liquid state, and a new cycle of circulation begins in the system.

The main parameter that determines the productivity of the TNF is the conversion factor. This indicator is the result of a certain ratio of thermal power produced by TNF to the volume of thermal energy consumption.

The principle of operation of the device

Those who come into contact with the issues of cost-effective heating, the name "heat pump" is well known. Especially in combination with terms like “land-water”, “water-water”, “water-air”, etc. Such a heat pump has practically nothing in common with the Frenette device, except perhaps for the name and the end result in the form of thermal energy, which is ultimately used for heating.

Heat pumps operating on the Carnot principle are very popular both as a cost-effective way to organize heating and as an environmentally friendly system. The operation of such a complex of devices is associated with the accumulation of low-potential energy contained in natural resources (earth, water, air) and its conversion into thermal energy with a high potential. The invention of Eugene Frenette is arranged and works in a completely different way.

Image gallery

Photo from

The heat generating system developed by E. Frenett cannot be unconditionally attributed to the class of heat pumps. According to the design and technological features, this is a heater

The unit does not use geo- or solar energy sources in its work. The oil coolant inside it is heated by the friction force created by rotating metal disks.

The working body of the pump is an oil-filled cylinder, inside of which the axis of rotation is located. This is a steel rod equipped with parallel discs set approximately 6 cm apart.

Centrifugal force pushes the heated coolant into the coil connected to the device. The heated oil exits the instrument at the top connection point. The cooled coolant is returned back from below

Appearance of the Frenette heat pump

Warming up the device during operation

Main structural components

The actual dimensions of one of the models

The principle of operation of this device is based on the use of thermal energy, which is released during friction. The design is based on metal surfaces located not close to each other, but at some distance. The space between them is filled with liquid. Parts of the device rotate relative to each other with the help of an electric motor, the liquid inside the case and in contact with the rotating elements is heated.

The resulting heat can be used to heat the coolant. Some sources recommend using this fluid directly for the heating system. Most often, a regular radiator is attached to a homemade Frenett pump. As a heating fluid, experts strongly recommend using oil, not water.

During the operation of the pump, this coolant tends to heat up very strongly. Water in such conditions can simply boil. Hot steam in a confined space creates excess pressure, and this usually leads to rupture of pipes or a casing. It is much safer to use oil in such a situation, since its boiling point is much higher.

To make a Frenette heat pump, you will need an engine, a radiator, several pipes, a steel butterfly valve, steel discs, a metal or plastic rod, a metal cylinder and a nut kit (+)

There is an opinion that the efficiency of such a heat generator exceeds 100% and can even be 1000%. From the point of view of physics and mathematics, this is not a completely correct statement. Efficiency reflects the energy losses spent not on heating, but on the actual operation of the device.Rather, the phenomenal claims about the incredibly high efficiency of the Frenette pump reflect its efficiency, which is really impressive.

The cost of electricity for the operation of the device is negligible, but the amount of heat received as a result is very noticeable. Heating the coolant to the same temperatures with the help of a heating element, for example, would require a much larger amount of electricity, perhaps ten times more. A household heater with such a consumption of electricity would not even heat up.

Why are not all residential and industrial premises equipped with such devices? The reasons may be different. Still, water is a simpler and more convenient coolant than oil. It does not heat up to such high temperatures, and it is easier to clean up the consequences of water leaks than to clean up spilled oil.

Another reason may be that by the time the Frenette pump was invented, a centralized heating system already existed and functioned successfully. Its dismantling for replacement with heat generators would be too expensive and would bring a lot of inconvenience, so no one even seriously considered this option. As they say, the best is the enemy of the good.

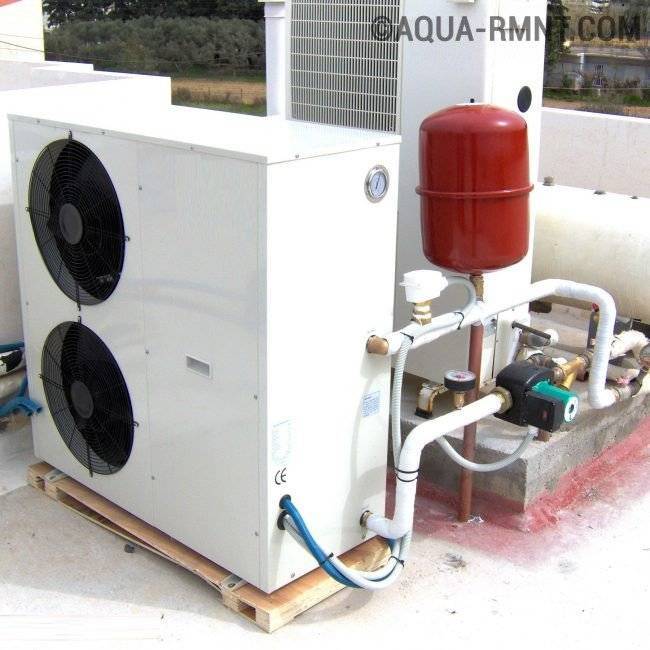

Production of a geothermal installation

It is quite possible to make a geothermal installation with your own hands. At the same time, the thermal energy of the earth is used to heat the dwelling. Of course, this is a laborious process, but the benefits are significant.

Calculation of the circuit and pump heat exchangers

The circuit area for HP is calculated at the rate of 30 m² per kilowatt. For a living space of 100 m², about 8 kilowatts / hour of energy is needed. So the area of the circuit will be 240 m².

The heat exchanger can be made from a copper tube. The temperature at the inlet is 60 degrees, at the outlet 30 degrees, the thermal power is 8 kilowatts / hour. The heat exchange area should be 1.1 m². Copper tube with a diameter of 10 millimeters, a safety factor of 1.2.

Circumference in meters: l \u003d 10 × 3.14 / 1000 \u003d 0.0314 m.

Number of copper tube in meters: L = 1.1 × 1.2 / 0.0314 = 42 m.

Necessary equipment and materials

In many ways, success in the manufacture of heat pumps depends on the degree of preparedness and knowledge of the contractor himself, as well as on the availability and quality of everything necessary for the installation of a heat pump.

Before starting work, you need to purchase equipment and materials:

- compressor;

- capacitor;

- controller;

- polyethylene fittings intended for assembly of collectors;

- pipe to the earth circuit;

- circulation pumps;

- water hose or HDPE pipe;

- manometers, thermometers;

- copper tube with a diameter of 10 millimeters;

- insulation for pipelines;

- sealing kit.

How to assemble the heat exchanger

The heat exchange block consists of two components. The evaporator must be assembled according to the "pipe in pipe" principle. The inner copper tube is filled with freon or other rapidly boiling liquid. On the outside circulates water from the well.

Before assembling the condenser, it is necessary to wind the copper tube in the form of a spiral and place it in a metal barrel with a capacity of at least 0.2 m³. The copper tube is filled with freon, and the barrel of water is connected to the house heating system.

Arrangement of the soil contour

In order to prepare the necessary area for the soil contour, it is necessary to perform a large amount of earthwork, which is desirable to be carried out mechanically.

You can use 2 methods:

one.In the first method, it is necessary to remove the top layer of soil to a depth below its freezing. At the bottom of the resulting pit lay a free snake part of the outer pipe evaporator and recultivate the soil.

2. In the second method, you must first dig a trench over the entire planned area. A pipe is placed in it.

Then you need to check the tightness of all connections and fill the pipe with water. If there are no leaks, you can fill the structure with earth.

Refueling and first start

After installation is complete, the system must be filled with refrigerant. This work is best entrusted to a specialist, because special devices are used to fill the internal circuit with freon. When filling, the pressure and temperature must be measured at compressor inlet and outlet.

How to make such a device yourself?

The most practical for heating homes is the Frenette heat pump model, which lacks a fan and an inner cylinder. Instead, many metal discs are used that rotate inside the instrument. The role of the coolant is performed by the oil that enters the radiator, cools and then returns to the system. The operation of such a device is convincingly demonstrated in the video:

For those who know English, this video may be useful:

It is not difficult to make a heat pump according to the principle of Eugene Frenette at home. For this you will need:

- metal cylinder;

- steel discs;

- nuts;

- steel rod;

- a small electric motor;

- pipes;

- radiator.

The diameter of the steel discs should be slightly smaller than the diameter of the cylinder so that there is a small gap between the walls of the housing and the rotating part. The number of discs and nuts depends on the dimensions of the structure.The discs are successively strung on a steel rod, separating them with nuts. Usually nuts are used, the height of which is 6 mm. The cylinder should be filled with discs to the top. An external thread is applied to the steel rod along its entire length. Two holes are made in the body for the coolant. Through the upper hole, the heated oil will flow into the radiator, and from the bottom it will return to the system for further heating.

As a coolant, the developers of the device recommend using liquid oil, not water, since the boiling point of such an oil is several times higher. If the water heats up quickly, it can turn into steam and overpressure the system, which can lead to structural damage.

This is an approximate diagram of the design of a Frenett heat pump, which is not difficult to implement using improvised means and available materials.

To mount a threaded rod, you will also need a bearing. As for the electric motor, any model that provides a sufficient number of revolutions will do, for example, a working motor from an old fan.

The assembly process of the device is as follows:

- Two holes are made in the body for heating pipes.

- A threaded rod is installed in the center of the body.

- A nut is screwed onto the thread, a disk is placed, the next nut is screwed on, etc.

- Mounting of disks is continued until the case is filled.

- Liquid oil is poured into the system, for example, cottonseed.

- The case is closed and the rod is fixed.

- The pipes of the heating radiator are brought to the holes.

- An electric motor is attached to the central rod, which provides rotation.

- Connect the device to the network and check its operation.

In order to improve the performance of this type of heat pump and make its use more convenient and economical, it is recommended to use an automatic on-off system for the engine. Such a system is controlled using a temperature sensor, which is mounted directly on the device body.

Conclusion

Of course, heating your home with a heat pump is the dream of many homeowners. Unfortunately, the cost of installations is too high, and only a few can cope with their own production. And then often there is enough power only for hot water supply, we are not talking about heating. If everything were so simple, then we would have a home-made heat pump in every house, but for now it remains inaccessible to a wide range of users.

Number of blocks: 15 | Total number of characters: 28073

Number of donors used: 6

Information for each donor: