- Heat pump "Frenetta": exposure or tips regarding use

- Selection Tips

- How to assemble?

- How to make a heat pump with your own hands from an old refrigerator

- Assembling the units and installing the heat pump

- The principle of operation of the device

- Design features

- Frenette Pump Design Options

- Benefits of a homemade air conditioner

Heat pump "Frenetta": exposure or tips regarding use

There are some recommendations regarding the use of pumps. Not everyone follows them, and there are complaints that an industrial or home-made pump does not work well, and in general, this device is over-praised. The following tips will be helpful.

Pump Operation Tips:

- Use oil as a heat transfer medium - it can be rapeseed oil, cottonseed oil or mineral oil;

- Do not use water to construct the pump, because then there will be excess pressure in the heating system due to the release of steam from heating the water;

- If you make the pump yourself, then the engine from some old electrical appliances, the same fan is used as an electric motor;

- It is desirable to install a temperature sensor on the body of such a heat pump, it is responsible for regulating the automatic switching on and off of the device;

- When installing the discs on the axle inside the pump, make sure that the entire space is filled with the discs.

The version of the Frenetta pump deserves special mention, created by Alexander Vasilievich Syarg, Natalya Ivanovna Nazyrova and Mikhail Pavlovich Leonov. These Khabarovsk scientists have created such a heat generator that can be called universal. The working part of the device is similar to a mushroom, as the working fluid is water, which reaches a boil and turns into steam. But do not try to make such a generator at home, it is used only in industry.

Selection Tips

Buying a Frenette heat pump is advised more often for large industrial organizations - as they need more power. It is provided by high temperatures, which means that you need to work with the installation carefully.

Such an installation for a private house is a rather rare solution - it is not easy to find an installation for sale, due to its structural complexity.

Unfortunately, despite such an impressive efficiency, this installation did not take root as a household heater - so you can’t just go to any climate equipment store and buy such a heater.

And yet, for the home, some manage to make Frenette heat pumps with their own hands.

It is easy and profitable to do this - the cost of fuel and elements will be much lower than the estimated cost of the energy generated by such a device.

Some craftsmen make a Frenette heat pump, reviews of which are then often posted, sharing their own opinions:

Eugene, 43 years old, Moscow:

Sergey, 39 years old, Yekaterinburg:

Although, it would seem, everything was done correctly and according to the drawing, and our people are literate - it’s even strange that it didn’t work.

A colleague somehow showed a diagram and a description of the Frenette pump, well, I caught fire - there is enough free time, there is a small cottage - there, in fact, I experimented.

What can I say - I was looking for sensible information for an unexpectedly long time - despite the fact that there are plenty of drawings and videos on the Internet on the topic, some subtleties are still missed, attention is paid only to the main essence. As a result, I managed to assemble the installation with grief in half, and it works very efficiently. But I doubt that an ordinary person who does not have specific knowledge will cope with such a task.

But I doubt that an ordinary person who does not have specific knowledge will cope with such a task.

As a result, I managed to assemble the installation with grief in half, and it works very efficiently. Only now I doubt that an ordinary person who does not have specific knowledge will cope with such a task.

How to assemble?

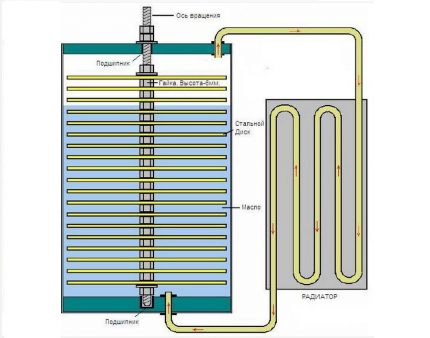

In practice, the easiest way is to make a Frenette heat pump with your own hands without a fan and a small cylinder. The oil remains as a coolant.

A dozen metal discs are placed inside a large cylinder. It is they who will rotate, replacing the small cylinder.

A radiator is attached to the device - it is into it that the oil will flow, cool, give off heat, and return to the pump. Thus, we will need:

- Cylinder;

- Metal discs;

- Fixing elements (nuts);

- Kernel;

- Pipes and radiator;

- Oil - can be any technical (rapeseed, cottonseed) or mineral;

- Motor (electric), the shaft of which must be extended.

Just like in the original model, it is necessary to provide a gap between the large cylinder and the disks - for this, their diameter is calculated in advance.

A hole is made at the top and bottom for a pipe that goes to the radiator.

The oil heated in the case will exit through the upper hole, give off heat through the radiator and return through the lower one for subsequent heating.

When mounting the rod, you need to install the bearing in the base - for easy rotation of the discs and reduce friction. Otherwise, the device will work worse, and in addition, it will become unusable many times faster.

The engine will suit any required power for a particular installation. If we make the Frenett pump ourselves, then the motor from the old fan may be at hand, for example - it will fit well into the design.

For convenience, thermal sensors can be added to the system, which will turn on / off the engine. This will make the pump even more economical and rational in use, thereby automating the control of the installation.

After completing the assembly of the structure itself, you should fill the installation with oil, then connect the working rod to the drive, and the input and output lines in oil with the lines leading to the heating radiator.

After completing the final check of the correctness of the assembly, you can try to include the installation in the work.

An installation of this type can be equally effectively used both for heating a building and for a separate room. In practice, it has been found that it is most expedient to use it, combining it with underfloor heating systems.

Such a solution will allow you to get a fairly efficient heating circuit that allows you to cope with low indoor temperatures.

How to make a heat pump with your own hands from an old refrigerator

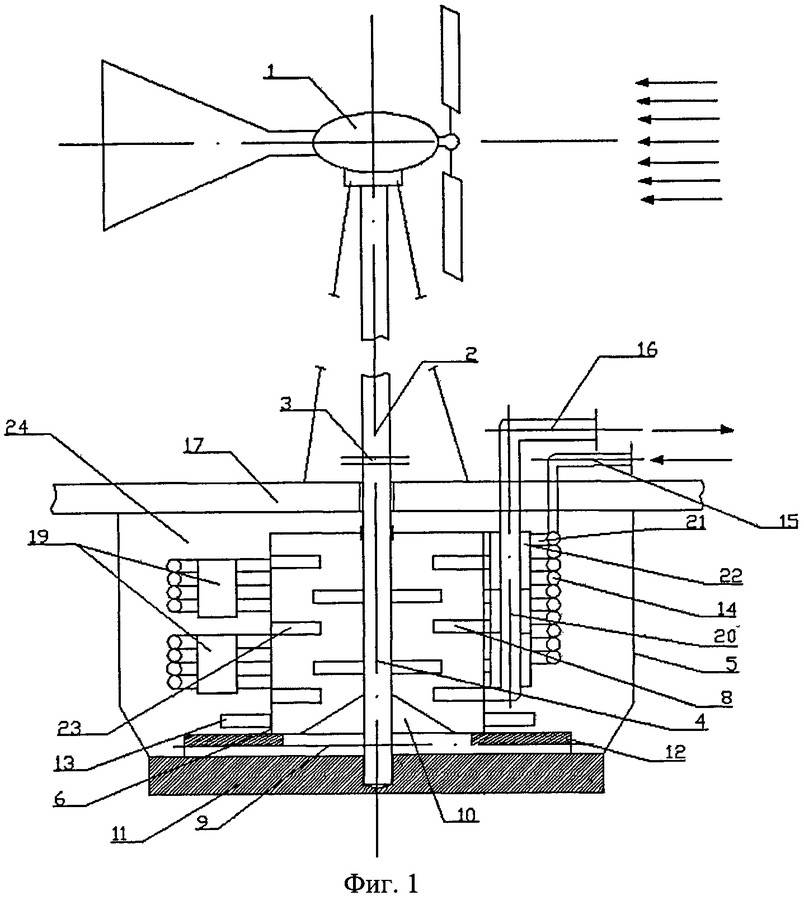

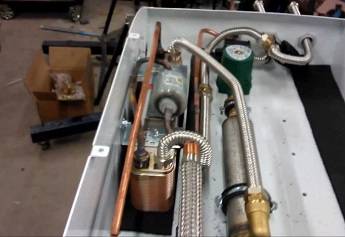

Before proceeding with the manufacture of a heat pump, it is necessary to select a heat source and resolve the issue with the scheme of operation of the installation. In addition to the compressor, you will need other equipment, as well as tools.

Implementation of diagrams and drawings. To install a heat pump, you need to make a well, because the energy source must be underground. The depth of the well should be such that the temperature of the earth is at least 5 degrees. For this purpose, any reservoirs are also suitable.

The designs of heat pumps are similar, so no matter what the heat source will be, you can use almost any scheme found on the net. When the scheme is selected, it is necessary to complete the drawings and indicate in them the dimensions and junctions of the nodes.

Since it is rather difficult to calculate the power of the installation, you can use the average values. For example, a dwelling with low heat loss will require a heating system with a power of 25 watts per square meter. meter. For a building that is well insulated, this value will be 45 watts per square meter. meter. If the house has sufficiently high heat losses, the installation power should be at least 70 W per sq. meter.

Selecting the required details. If the compressor removed from the refrigerator is broken, then it is preferable to purchase a new one. It is not recommended to repair the old compressor, because in the future this may adversely affect the operation of the heat pump.

Additionally, you will need to purchase the following parts:

- sealed stainless steel container with a volume of 120 liters;

- plastic container with a volume of 90 liters;

- three copper pipes of different diameters;

- plastic pipes.

To work with metal parts, you will need a welding machine and a grinder.

Assembling the units and installing the heat pump

First of all, you should install the compressor on the wall using brackets. The next step is to work with the capacitor. The stainless steel tank must be divided into two parts using a grinder. A copper coil is mounted in one of the halves, then the container must be welded and threaded holes made in it.

To make a heat exchanger, you need to wind a copper pipe around a stainless steel container and fix the ends of the turns with slats. Attach plumbing transitions to the conclusions.

As soon as work with the nodes is completed, you need to select a thermostatic valve. The design should be assembled and filled with freon system (R-22 or R-422 brand is suitable for this purpose).

Connection to the intake device. The type of device and the nuances of connecting to it will depend on the scheme:

- "Water-Earth". The collector should be installed below the frost line of the ground. It is necessary that the pipes are at the same level.

- "Water-air". Such a system is easier to install, since there is no need for drilling wells. The collector is mounted anywhere near the house.

- "Water-water". The collector is made of metal-plastic pipes, and then placed in a reservoir.

You can also install a combined heating system to heat your home. In such a system, the heat pump works simultaneously with the electric boiler and is used as an additional source of heating.

It is quite possible to assemble a heat pump for heating a house yourself.Unlike buying a ready-made installation, this will not require large financial costs, and the result will certainly please.

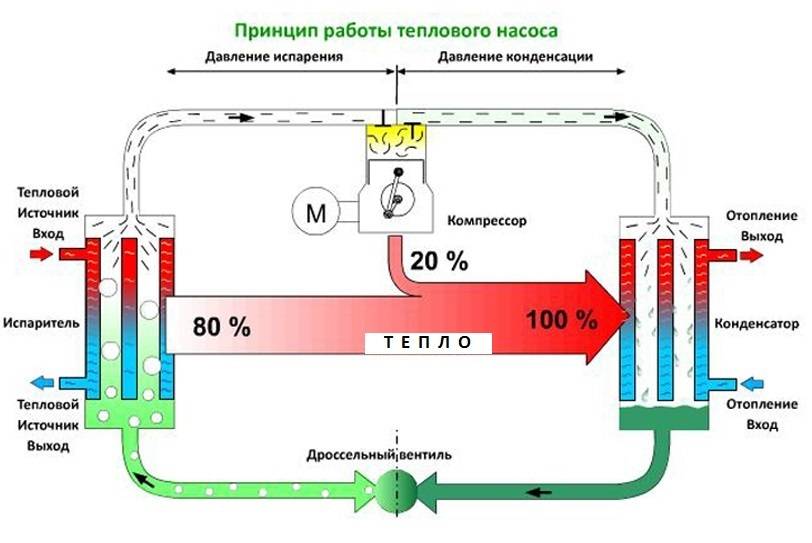

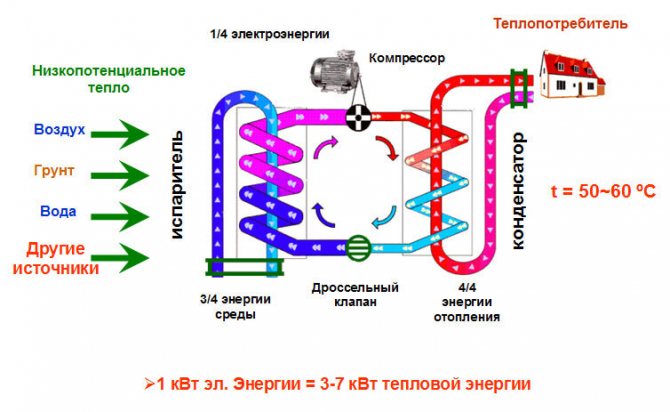

The principle of operation of the device

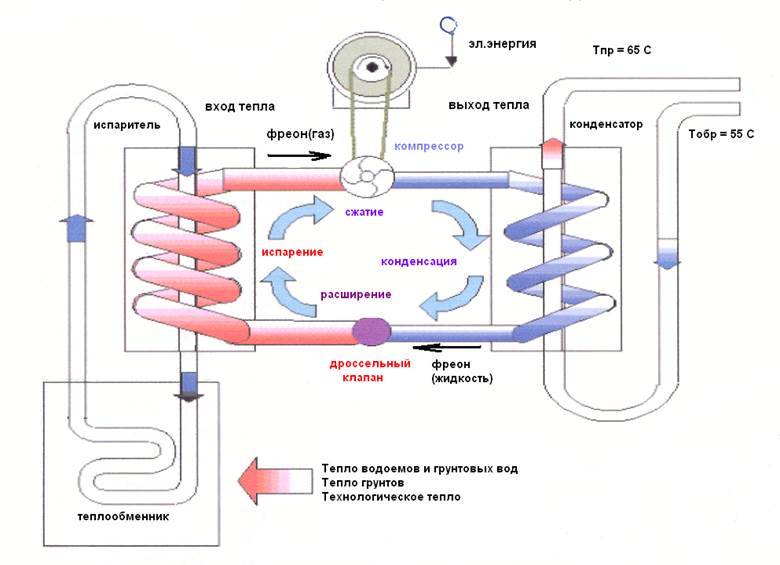

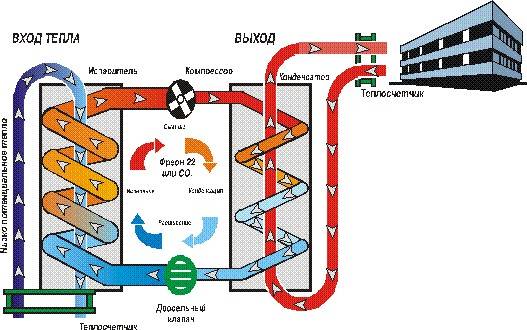

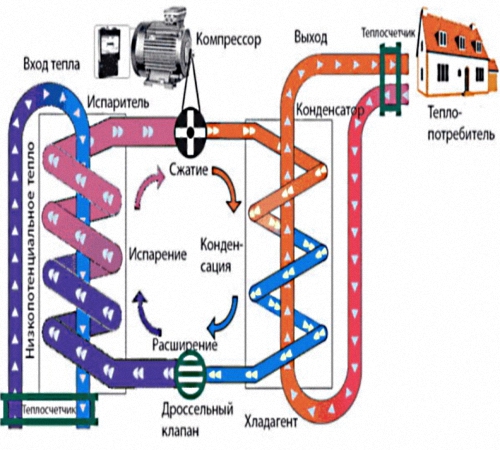

Those who come into contact with the issues of cost-effective heating, the name "heat pump" is well known. Especially in combination with terms like “land-water”, “water-water”, “water-air”, etc. Such a heat pump has practically nothing in common with the Frenette device, except perhaps for the name and the end result in the form of thermal energy, which is ultimately used for heating.

Heat pumps operating on the Carnot principle are very popular both as a cost-effective way to organize heating and as an environmentally friendly system. The operation of such a complex of devices is associated with the accumulation of low-potential energy contained in natural resources (earth, water, air) and its conversion into thermal energy with a high potential. The invention of Eugene Frenette is arranged and works in a completely different way.

Image gallery

Photo from

The heat generating system developed by E. Frenett cannot be unconditionally attributed to the class of heat pumps. According to the design and technological features, this is a heater

The unit does not use geo- or solar energy sources in its work. The oil coolant inside it is heated by the friction force created by rotating metal disks.

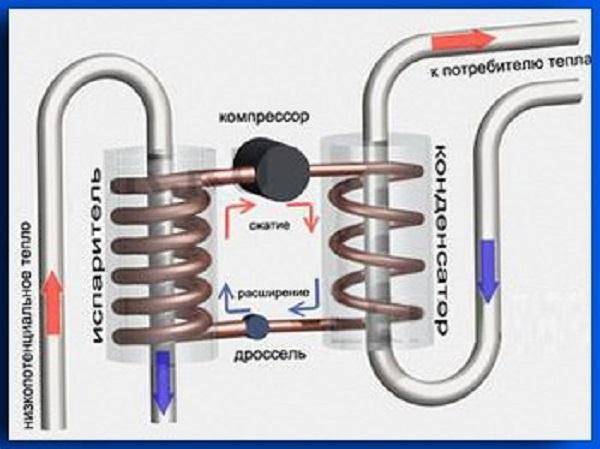

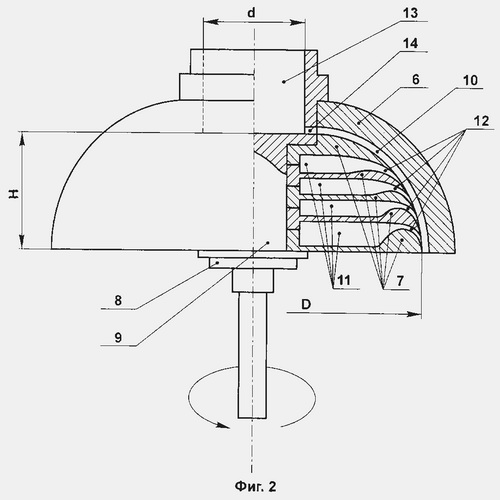

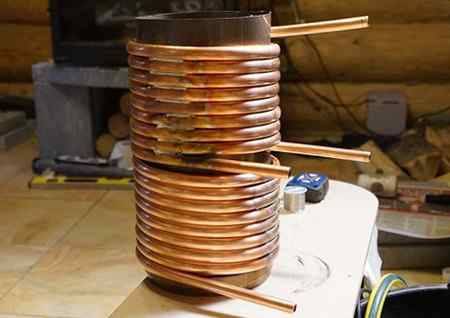

The working body of the pump is an oil-filled cylinder, inside of which the axis of rotation is located. This is a steel rod equipped with parallel discs set approximately 6 cm apart.

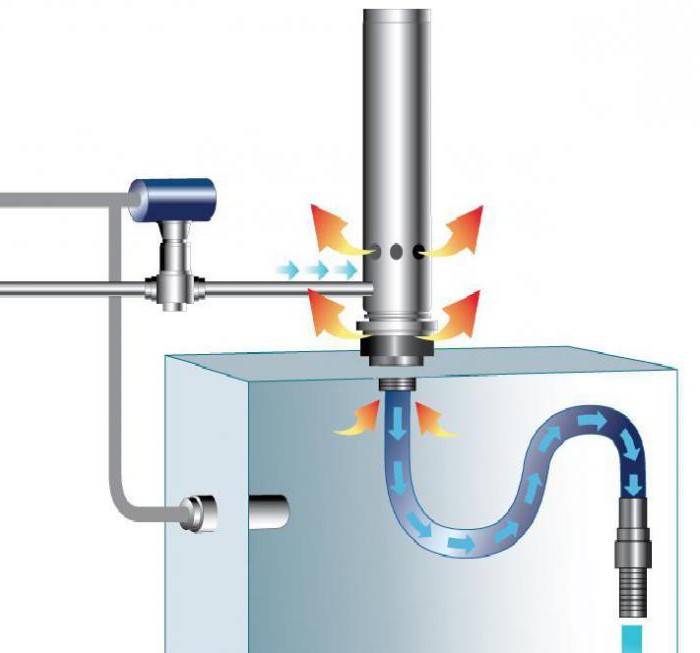

Centrifugal force pushes the heated coolant into the coil connected to the device. The heated oil exits the instrument at the top connection point. The cooled coolant is returned back from below

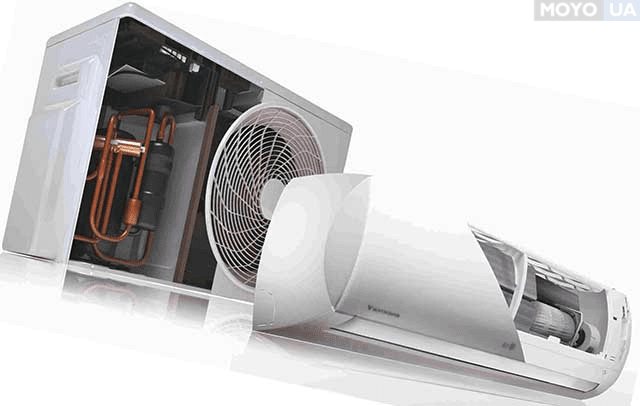

Appearance of the Frenette heat pump

Warming up the device during operation

Main structural components

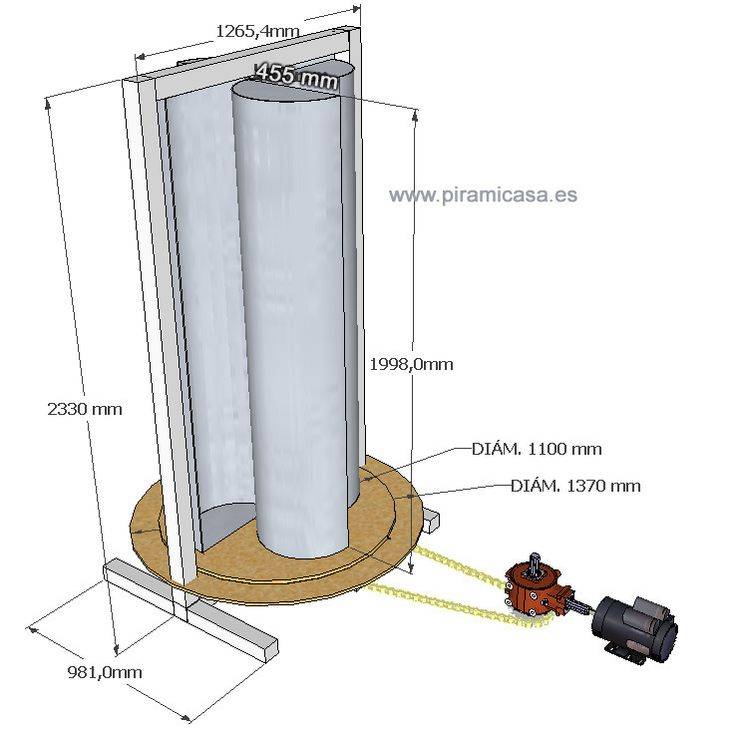

The actual dimensions of one of the models

The principle of operation of this device is based on the use of thermal energy, which is released during friction. The design is based on metal surfaces located not close to each other, but at some distance. The space between them is filled with liquid. Parts of the device rotate relative to each other with the help of an electric motor, the liquid inside the case and in contact with the rotating elements is heated.

The resulting heat can be used to heat the coolant. Some sources recommend using this fluid directly for the heating system. Most often, a regular radiator is attached to a homemade Frenett pump. As a heating fluid, experts strongly recommend using oil, not water.

During the operation of the pump, this coolant tends to heat up very strongly. Water in such conditions can simply boil. Hot steam in a confined space creates excess pressure, and this usually leads to rupture of pipes or a casing. It is much safer to use oil in such a situation, since its boiling point is much higher.

To make a Frenette heat pump, you will need an engine, a radiator, several pipes, a steel butterfly valve, steel discs, a metal or plastic rod, a metal cylinder and a nut kit (+)

There is an opinion that the efficiency of such a heat generator exceeds 100% and can even be 1000%. From the point of view of physics and mathematics, this is not a completely correct statement. Efficiency reflects the energy losses spent not on heating, but on the actual operation of the device. Rather, the phenomenal claims about the incredibly high efficiency of the Frenette pump reflect its efficiency, which is really impressive.

The cost of electricity for the operation of the device is negligible, but the amount of heat received as a result is very noticeable. Heating the coolant to the same temperatures with the help of a heating element, for example, would require a much larger amount of electricity, perhaps ten times more. A household heater with such a consumption of electricity would not even heat up.

Why are not all residential and industrial premises equipped with such devices? The reasons may be different. Still, water is a simpler and more convenient coolant than oil. It does not heat up to such high temperatures, and it is easier to clean up the consequences of water leaks than to clean up spilled oil.

Another reason may be that by the time the Frenette pump was invented, a centralized heating system already existed and functioned successfully. Its dismantling for replacement with heat generators would be too expensive and would bring a lot of inconvenience, so no one even seriously considered this option. As they say, the best is the enemy of the good.

Design features

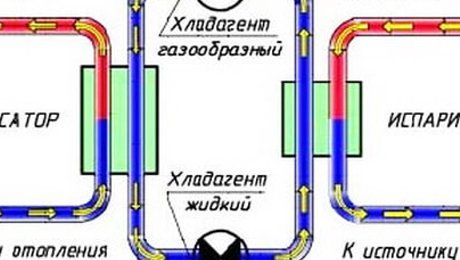

The classical design of devices consists of a pair of circuits.

The most important role in it is played by a heat exchanger, which acts as a provoking factor.

The outer circuit is pipes with high thermal conductivity, the refrigerant circulates through them.

This circuit has a variety of locations and implements the action of the device in different ways, but it has one function:

due to the circulation of freon (ammonia), heat from the environment moves to the compressor.

The second circuit consists of:

- compressor (read about high-pressure plastic hoses here);

- evaporator;

- condenser;

- reducing valve.

A hydrodynamic heat pump differs from others in its design - the device consists of a connecting coupling that transfers the generated energy to the generator, where the liquid is heated, the engine and the heat generator.

Frenette Pump Design Options

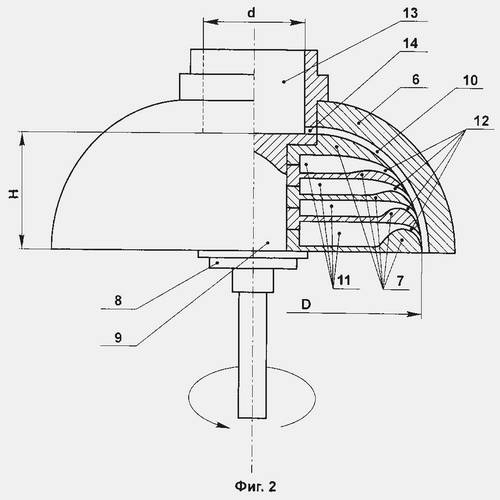

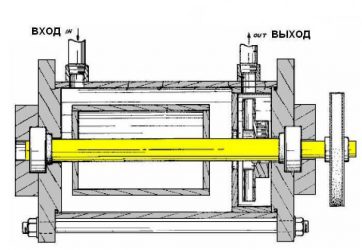

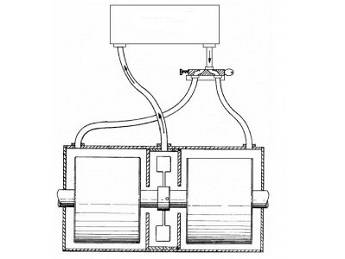

Eugene Frenette not only invented the device named after him, but also repeatedly improved it, inventing new, more efficient versions of the device. In the very first pump, which the inventor patented in 1977, only two cylinders were used: an external one and an internal one. The hollow outer cylinder was larger in diameter and was in a static state. In this case, the diameter of the inner cylinder was slightly smaller than the dimensions of the cavity of the outer cylinder.

This is a diagram of the very first version of the Frenette heat pump. The rotating shaft is located horizontally, the coolant is placed in a narrow space between two working cylinders

The inventor poured liquid oil into the resulting narrow space between the walls of the two cylinders. Of course, the part of the structure that contained this heat transfer fluid was carefully sealed to prevent oil leaks.

The inner cylinder is connected to the motor shaft in such a way as to ensure its rapid rotation relative to the stationary large cylinder. A fan with an impeller was placed at the opposite end of the structure. During operation, the oil heated up and transferred heat to the air surrounding the device. The fan made it possible to quickly distribute warm air throughout the entire volume of the room.

Since this design heated up quite a lot, for the sake of convenient and safe use, the design was hidden in a protective case. Of course, holes were made in the case for air circulation. A useful addition to the design was a thermostat, with which the operation of the Frenett pump could be automated to some extent.

The central axis in such a heat pump model is located vertically. The engine is at the bottom, then nested cylinders are installed, and the fan is at the top. Later, a model with a horizontal central axis appeared.

A Frenette heat pump model with a horizontally oriented rotating shaft was used in conjunction with a heating radiator with heated oil circulating inside.

It was such a device that was first used in combination not with a fan, but with a heating radiator. The motor is placed on the side, and the rotor shaft passes through the rotating drum and out. This type of device does not have a fan. The coolant from the pump moves through the pipes to the radiator. In the same way, the heated oil can be transferred to another heat exchanger or directly into the heating pipes.

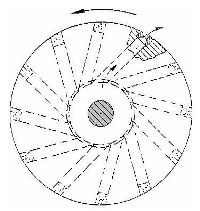

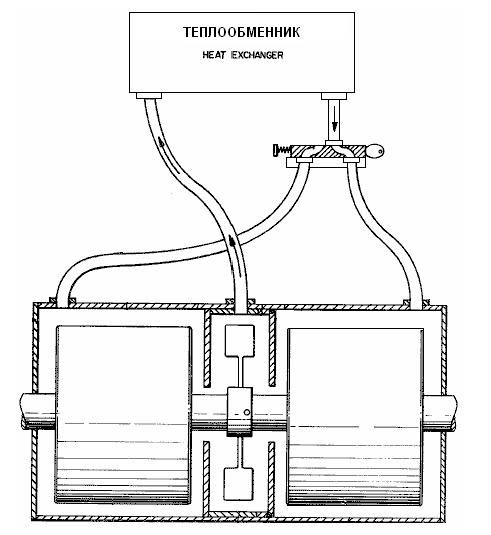

Later, the design of the frenet heat pump was significantly changed.The rotor shaft still remained in a horizontal position, but the inner part was made of two rotating drums and an impeller placed between them. Here again liquid oil is used as a heat carrier.

In this version of the Frenette heat pump, two cylinders rotate side by side, they are separated by a specially designed impeller made of very durable metal.

During the rotation of this design, the oil is additionally heated, as it passes through special holes made in the impeller, and then penetrates into a narrow cavity between the walls of the pump housing and its rotor. Thus, the efficiency of the Frenett pump has been significantly improved.

Small holes are made along the edges of the impeller for the Frenett heat pump. The coolant quickly and efficiently heats up, passing through them

However, it is worth noting that this type of pump is not very suitable for home manufacturing. First you need to find reliable drawings or calculate the design yourself, and only an experienced engineer can do this. Then you need to find a special impeller with holes of a suitable size. This element of the heat pump operates under increased loads, so it must be made of very durable materials.

Benefits of a homemade air conditioner

1. Refrigerator air conditioner saves a lot of money

This is especially important when neither the dollar exchange rate nor the salary of a Ukrainian contributes to a comfortable summer microclimate.

2. Allows you to create comfortable and cool conditions in rooms where you do not visit very often and where it would be too expensive or impractical to install an expensive independent air conditioner, for example, in a country house, and possibly in an office.

3. By making the air conditioner from the refrigerator yourself, you save yourself from the need to decide on the model, resort to the help of professionals to install the unit, and you also a priori cease to need specialized maintenance and possible repair of equipment.

4. There is no need to buy and replace special filters that are usually used in air conditioners and need to be replaced from time to time. (And this, by the way, translates into a round penny). Just in the refrigerator, such a detail as filters is simply not provided.

5. It is pleasant to use cool air on a hot summer day, and getting cold from a device designed by oneself is doubly pleasant. In addition, you will always know the design of your air conditioner and, in the event of a breakdown, you can quickly fix it yourself.