- Devices for countercurrent

- Production of a geothermal installation

- Calculation of the circuit and pump heat exchangers

- Necessary equipment and materials

- How to assemble the heat exchanger

- Arrangement of the soil contour

- Refueling and first start

- Overview of heat pump models

- Thermal Unit #1 - Zodiak

- Thermal Unit #2 - Azuro

- Heat Unit #3 - Fairland

- Laying piping and fittings in the pool system

- Step-by-step instruction

- How to install correctly?

- How to serve?

- Maintenance

- Types of pool pumps

- filter pump

- Submersible pump

- Calculation and selection

- Types of heat pumps

- View overview

- By volume and size

- By power

- According to body material

- By type of work

- Type of internal heating element

- Features of mounting the device

- Selection of the pump depending on the type of pool

- Pump selection

- A few words about calculations

- Pros and cons of homemade equipment

Devices for countercurrent

With the help of such products you can swim in a small home pool. Such pumps are divided into two types:

- Mounted. They are suitable for small seasonal pools. There is a pump, nozzles, lighting, handrails, automation and a control system. The design is fairly easy to install. This does not require serious effort.

- Embedded models.They are equipped with a suction element that extracts water when it is below or above the required level. This is a more expensive and complex design, unlike the previous version. Such designs are suitable for stationary pools.

The counterflow platform should be about 12-14 cm above the water level. If this fact is not taken into account, then its work will be extremely inefficient.

Basically, choosing a pump for your pool shouldn't be a difficult task. You can not bother and buy an option in which all the charms of this mechanic are concentrated. If you show imagination, then you can create an excellent system of circulation, heating and the like in your reservoir.

Production of a geothermal installation

It is quite possible to make a geothermal installation with your own hands. At the same time, the thermal energy of the earth is used to heat the dwelling. Of course, this is a laborious process, but the benefits are significant.

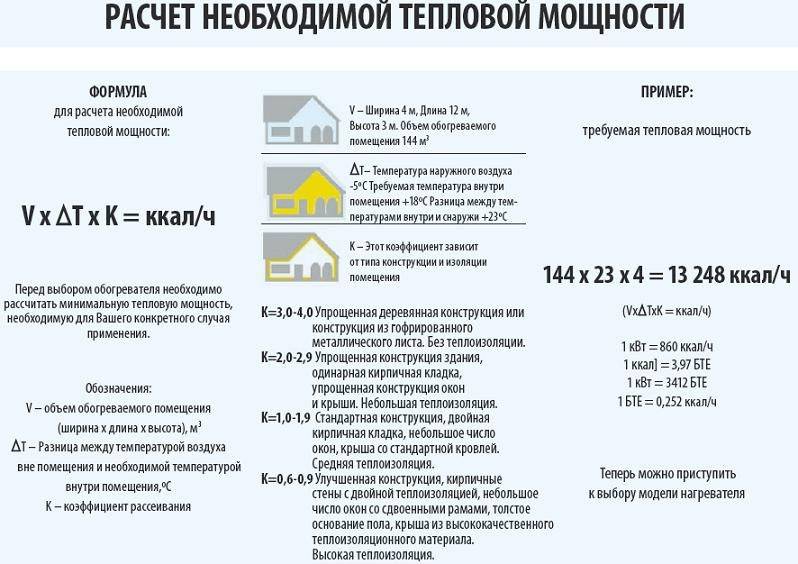

Calculation of the circuit and pump heat exchangers

The circuit area for HP is calculated at the rate of 30 m² per kilowatt. For a living space of 100 m², about 8 kilowatts / hour of energy is needed. So the area of the circuit will be 240 m².

The heat exchanger can be made from a copper tube. The temperature at the inlet is 60 degrees, at the outlet 30 degrees, the thermal power is 8 kilowatts / hour. The heat exchange area should be 1.1 m². Copper tube with a diameter of 10 millimeters, a safety factor of 1.2.

Circumference in meters: l \u003d 10 × 3.14 / 1000 \u003d 0.0314 m.

Number of copper tube in meters: L = 1.1 × 1.2 / 0.0314 = 42 m.

Necessary equipment and materials

In many ways, success in the manufacture of heat pumps depends on the degree of preparedness and knowledge of the contractor himself, as well as on the availability and quality of everything necessary for the installation of a heat pump.

Before starting work, you need to purchase equipment and materials:

- compressor;

- capacitor;

- controller;

- polyethylene fittings intended for assembly of collectors;

- pipe to the earth circuit;

- circulation pumps;

- water hose or HDPE pipe;

- manometers, thermometers;

- copper tube with a diameter of 10 millimeters;

- insulation for pipelines;

- sealing kit.

How to assemble the heat exchanger

The heat exchange block consists of two components. The evaporator must be assembled according to the "pipe in pipe" principle. The inner copper tube is filled with freon or other rapidly boiling liquid. On the outside circulates water from the well.

Arrangement of the soil contour

In order to prepare the necessary area for the soil contour, it is necessary to perform a large amount of earthwork, which is desirable to be carried out mechanically.

You can use 2 methods:

- In the first method, it is necessary to remove the top layer of soil to a depth below its freezing. At the bottom of the resulting pit, lay the free part of the outer pipe of the evaporator with a snake and recultivate the soil.

- In the second method, you must first dig a trench over the entire planned area. A pipe is placed in it.

Then you need to check the tightness of all connections and fill the pipe with water. If there are no leaks, you can fill the structure with earth.

Refueling and first start

After installation is complete, the system must be filled with refrigerant.This work is best entrusted to a specialist, because special devices are used to fill the internal circuit with freon. When filling, it is necessary to measure the pressure and temperature at the compressor inlet and outlet.

After refueling, you need to turn on both circulation pumps at the lowest speed, then start the compressor and monitor the operation of the entire system using thermometers. When the line is warmed up, frosting is possible, but after the system is completely warmed up, the frosting should melt.

Overview of heat pump models

The review includes thermal air-to-water pumps, as the most simple to use and do not require special and complex calculations. There is no fundamental difference between heat pumps for home heating and swimming pool heating.

Thermal Unit #1 - Zodiak

Zodiak is a representative of the French company for the maintenance and care of swimming pools.

Ranked at the forefront with continuous innovation, such as the water robot vacuum cleaner.

The pump is installed after the filter and before the disinfection systems. It is necessary to mount the pump closer to the pool to reduce heat loss.

The pump is installed after the filter and before the disinfection systems. It is necessary to mount the pump closer to the pool to reduce heat loss.

Main characteristics:

- power consumption - 1.6 kW;

- thermal power - 9 kW;

- water flow - 4000 l / h.

The heat exchanger of the pump is made of titanium. Special electrical and water connectors make installation easy. The device is equipped with a digital display.

Thermal Unit #2 - Azuro

Azuro is a trademark of a Czech manufacturer. Specializes in the production of frame pools, equipment and accessories. Particularly popular are models made specifically for summer cottages.

At air temperatures below +8 °C it has a very low efficiency, and at +35 °C there is a danger of overheating

In order not to carry the heat pump every time, it is installed under a canopy.

Main characteristics:

- power consumption - 1.7 kW;

- thermal power - 8.5 kW;

- pool volume - 20-30 m3.

The material of the heat exchanger is titanium. Digital display and built-in thermostat. There is an automatic defrosting function for the evaporator. Easy installation.

Heat Unit #3 - Fairland

Fairland is a Chinese manufacturer founded in 1999. The company specializes in the design and production of thermal equipment. Successfully sells products in more than fifty countries.

Inverter technology allows you to adjust the power of the turbine and compressor in an extended range

Such a pump can be connected to the heating system of the cottage.

Main characteristics:

- power consumption - 1.7 kW;

- thermal power - 7.5 kW;

- water flow - 4000-6000 l / h.

As with previous models, the heat exchanger is made of titanium. Due to the use of inverter technology, it has extended operating conditions: from -7 degrees to +43 °C.

The device is equipped with a soft start to avoid power surges. All control is done from the digital panel.

The development of technology every year makes the use of heat pumps more efficient. The average payback period for a heat pump is 4-5 years.

Laying piping and fittings in the pool system

To fill the pool bowl, it is important to choose high quality cement, marked M-400. Since pipes, wires, all elements are mounted in concrete from which the bowl is poured.

Be sure to qualitatively connect the embedded elements of the pool and equipment with the pipeline

Put in an electrician.

Remember that if you make a mistake, it will be extremely difficult to correct it, and in some cases impossible. Violation of the integrity of the concrete base will lead to its destruction in the future.

The final step is to install the equipment by hand:

- metal railings,

- stairs,

- slides,

- holders.

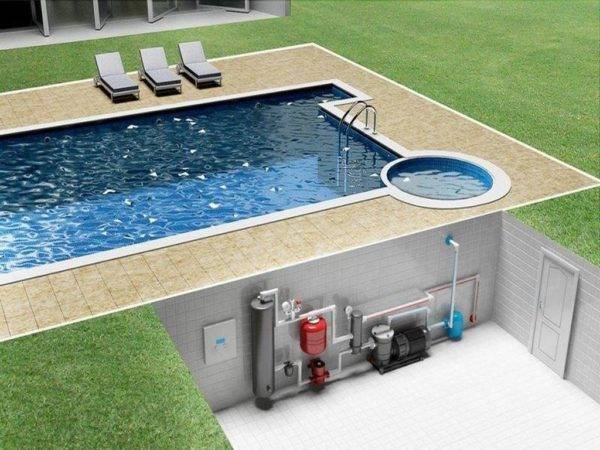

Installation pool equipment complex painstaking process. The pool is a cardiovascular system of pipes, electricity and equipment. From the correct installation depends on the integral work of the body. If the pool is collapsible, then it will not be difficult to install it. But if this is a large stationary reservoir, then the slightest oversight should be excluded.

Step-by-step instruction

In order to avoid installation errors and breakdowns during operation, it is important to study the instructions for pumping equipment for the pool

How to install correctly?

The pump is installed below the water level in the bowl, since even a powerful self-priming device, when installed above the line, will work with an increased load. This threatens to shorten the life of the engine.

The system is mounted on a flat, solid base with a low level of vibration. The optimal distance from pool bowls - 3 m.

It is important to ensure that the equipment is protected from precipitation, moisture, frost, flooding, as well as access to the installation for regular maintenance. How to connect the pump unit:

How to connect the pump unit:

- Connect the filter housing to the motor water inlet, align the coupling.

- Install the suction pipe with a slope to prevent air pockets.

- Connect the motor pre-filter unit to the filter.

- Install a valve with pipes for connecting pipes.

- Make sure the outlet on the valve points towards the pool and the inlet is connected to the outlet on the motor.

- Check the correct connection of all components, the tightness of the pipes and the tightness of the fasteners.

- Connect to the electrical network.

- Fill the system with water, start up.

The power source for the pump must be located at a distance of 3.5 m from the pool bowl. Connection is only allowed to a grounded socket.

How to serve?

Regular maintenance extends the life of your appliances and prevents breakdowns. For this you need:

- check and clean the pre-filter;

- clean the filter by backwashing;

- inspect equipment for sealing hoses and connections;

- wipe dust on the engine and other components.

All maintenance work should only be carried out when the pump is disconnected from the power supply.

For outdoor pools, another maintenance action is pump assembly and storage during the cold season. Dismantling, water draining, drying of parts and assemblies, sending to a warm room are being carried out. If the pump is stored at sub-zero temperatures, it will shorten its service life.

Maintenance

Replacing parts and repairing a pumping station requires experience and skills

It is important to note that independent intervention in the work can cause breakdowns and complete failure of the device.

Damage is caused by the following factors:

Damage is caused by the following factors:

- Incorrect operating mode.

- Mechanical damage.

- Power failures.

A typical malfunction is water leakage from the system. The reasons:

- defects in seals and gaskets;

- impeller damage;

- exhaust hose leakage.

The problem is solved by finding the cause of the malfunction and replacing spare parts. Any accessories and parts for the device are recommended to be purchased from the same manufacturer that produces the pump.

If the device is under warranty, you should contact the service center for repair.

Types of pool pumps

For the normal operation of the pool, there are several types of devices:

- Water drain device. This unit is used to pump out water at the end of the season, for maintenance or repair work.

- Circulation unit. It is used to set the water in motion and supply it to filtration or heating devices.

- Thermal pump. A unit used to generate heat energy instead of a classic heating element.

- Effect pump. It is used for hydromassages, waterfalls, rides and other pool add-ons.

Each of these types has its own characteristics and nuances in the work. But in addition to the classic variety, there are also options depending on the principle of operation.

The first ones have an impeller, which is represented by blades with curved ends. They bend in the opposite direction of movement. Its body is shaped like a snail.

The impeller rotates very quickly, which helps the water to move to the walls. In this case, rarefaction occurs in the center, due to which the water gets a greater speed and comes out with force.

The vortex pump has a slightly different impeller configuration, which is called an impeller. The body fully corresponds to the impeller in diameter, but there are gaps on the sides, due to which the water is twisted like a whirlwind.

It is very convenient that such devices do not require long-term filling with water and can work if the liquid is interspersed with air.

Vortex devices are completely opposite in characteristics: they have high outlet water pressure, strong noise during operation and small volumes of treated water.

Such electric pumps are more popular, since they can be installed not directly into the water, which is very valuable for frame or inflatable pool models, because in this case it is not possible to place the equipment directly under the tank.

The self-priming device can take in water even if it is located above its surface at a height of 3 meters. However, it is worth considering the fact that the capture of water takes a lot of energy, therefore, if possible, it is better to install the pump as low as possible.

When choosing a self-priming pumping mechanism, the following factors must be considered:

- Filter water flow rate. It must necessarily correspond to the performance of the pump.

- Pipe diameters.

- The volume of water for pumping, which must comply with sanitary standards.

- Possibility of long working time.

- The material of the case and internal components. Usually it is reinforced plastic for the body and stainless steel for the shaft and fasteners.

- Noise level.

filter pump

These units are used for frame or inflatable pools and are completed immediately with a filter element. Thanks to this solution, one pump can be dispensed with.

Filter elements can be sand or cartridge. The first option is designed for a large volume of water and is more efficient. Water in them is passed through quartz sand, so that all polluting particles remain inside. The filter is cleaned in reverse.

Intex pool pumps with cartridge-type filters are installed only in small pools. They also purify water with high quality, but get dirty faster and need to be replaced.

The main disadvantage of a device with a filter element is that they are in the same housing. That is why, if one of the units becomes unusable, you will have to buy both.

An ordinary pool can only do with this type of pump. It is designed to provide a constant passage of water through the filters.

The circulation pump differs from others in the following characteristics:

- The presence of a filter and a certain body material. This indicator eliminates such a problem as jamming of the pump impeller.

- The resistance of manufacturing materials to chemicals that are often used to clean the pool, and corrosion.

Submersible pump

Such specialized devices are used to pump water from the tank. Many people use self-priming and circulating models for this purpose, but they are completely not designed for this and can fail.

Submersible pumps are distinguished by wide intake windows and are able to take water from the pool, leaving only 1 cm at the bottom.

Calculation and selection

It should be noted that choosing the right heat exchanger for the pool is not as easy as it might seem at first glance. To do this, you need to calculate a number of parameters.

- The volume of the pool bowl.

- The amount of time it takes to heat water. The fact that the longer the water is heated, the lower the power of the device and its cost can help in this moment. The normal indicator will be a time of 3 to 4 hours for complete heating. True, for an outdoor pool it is better to choose a model with a higher power. The same applies when the heat exchanger is to be used for salt water.

- Water temperature coefficient, which is set directly in the network and at the outlet of the circuit of the device used.

- The volume of water in the pool that passes through the device in a certain time period. In this case, an important aspect will be that if there is a circulation pump in the system that purifies water and then circulates it, then the flow rate of the working medium can be taken as a coefficient that is indicated in the pump data sheet.

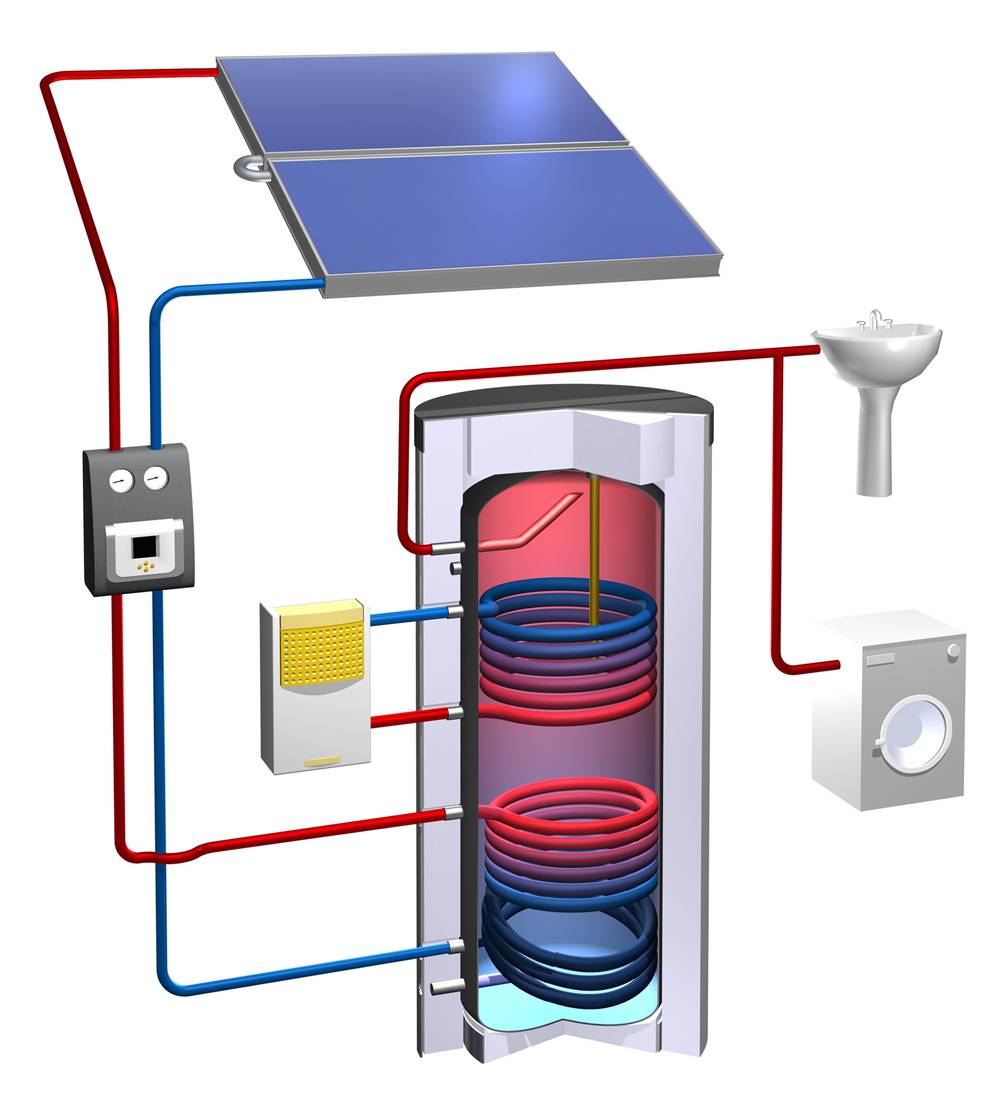

Types of heat pumps

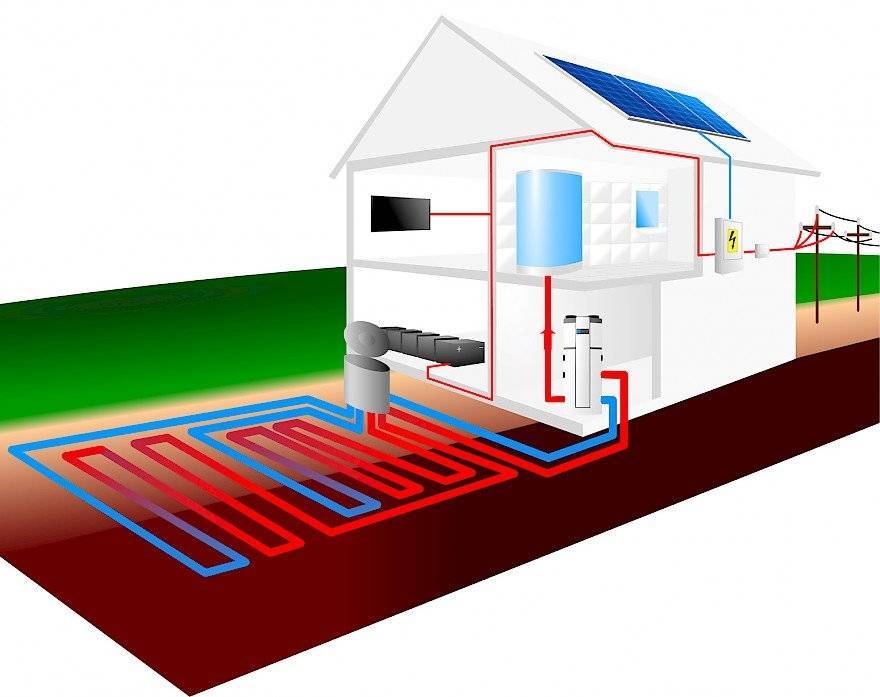

Heat pumps are divided into three main types according to the source of low-grade energy:

- Air.

- Priming.

- Water - The source can be groundwater and water bodies on the surface.

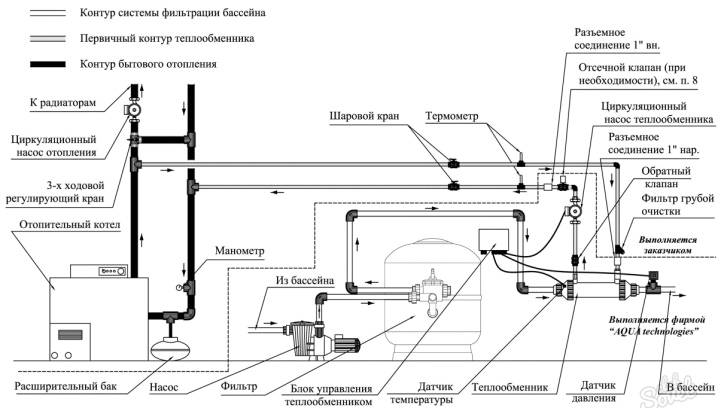

For water heating systems, which are more common, the following types of heat pumps are used:

- air-water;

- ground-water;

- water-water.

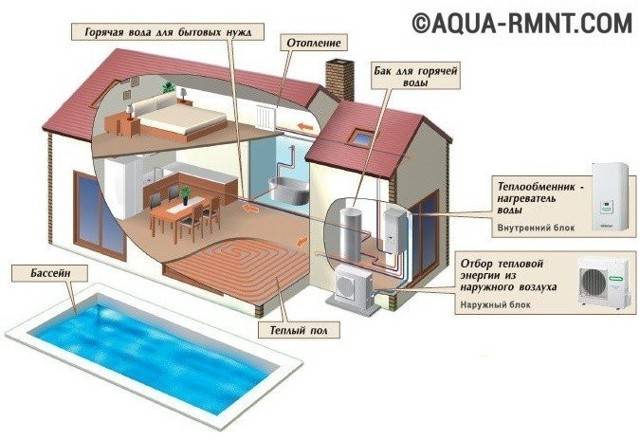

"Air-to-water" - an air type heat pump that heats the building by drawing air from outside through an external unit.It works on the principle of an air conditioner, only in reverse, converting the energy of the air into heat. Such a heat pump does not require large installation costs, it does not need to allocate a piece of land for it and, moreover, drill a well. However, the efficiency of operation at low temperatures (-25ºС) decreases and an additional source of thermal energy is required.

"Air-to-water" - an air type heat pump that heats the building by drawing air from outside through an external unit.It works on the principle of an air conditioner, only in reverse, converting the energy of the air into heat. Such a heat pump does not require large installation costs, it does not need to allocate a piece of land for it and, moreover, drill a well. However, the efficiency of operation at low temperatures (-25ºС) decreases and an additional source of thermal energy is required.

The “ground-water” device refers to geothermal and produces heat from the ground using a collector laid to a depth below the freezing of the soil. There is also a dependence on the area of the site and the landscape, if the collector is located horizontally. For a vertical arrangement, a well will need to be drilled.

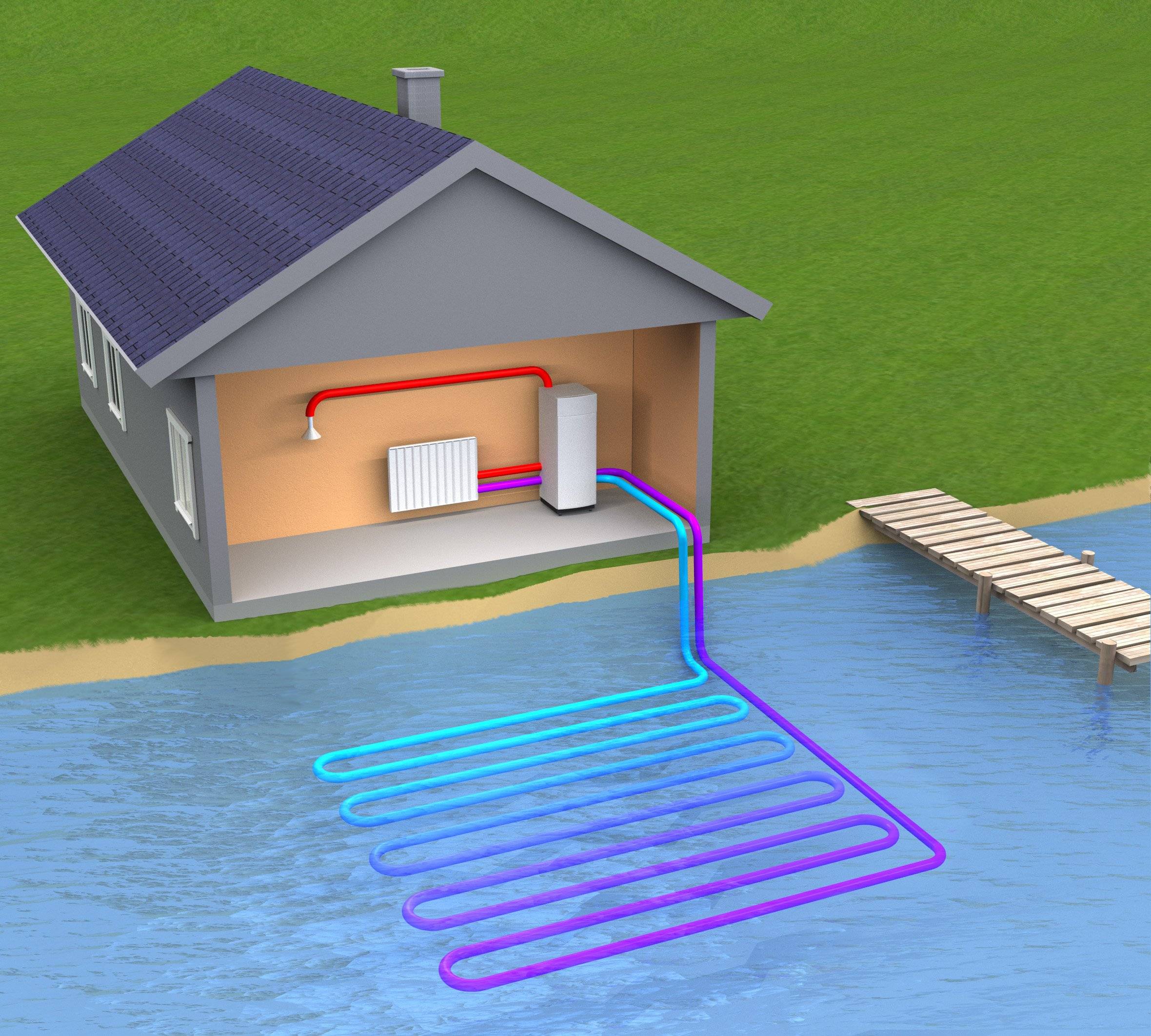

"Water-water" is installed where there is a reservoir or groundwater nearby. In the first case, the collector is laid on the bottom of the reservoir, in the second, a well is drilled or several, if the area of the site allows. Sometimes the depth of groundwater is too great, so the cost of installing such a heat pump can be very high.

"Water-water" is installed where there is a reservoir or groundwater nearby. In the first case, the collector is laid on the bottom of the reservoir, in the second, a well is drilled or several, if the area of the site allows. Sometimes the depth of groundwater is too great, so the cost of installing such a heat pump can be very high.

Each type of heat pump has its advantages and disadvantages, if the building is far from a body of water or the groundwater is too deep, then water-to-water will not work. "Air-water" will be relevant only in relatively warm regions, where the air temperature during the cold season does not fall below -25º C.

View overview

It should be said that there are different types of heat exchangers. As a rule, they differ according to the following criteria:

- by physical dimensions and volume;

- by power;

- according to the material from which the body is made;

- by type of work;

- according to the type of internal heating element.

Now let's talk a little more about each type.

By volume and size

It must be said that pools differ in design and volume of water placed. Depending on this, there are various types of heat exchangers. Small models simply will not cope with a large volume of water, and the effect of their use will be minimal.

By power

Models differ in power. Here you need to understand that on the market you can find samples with a power of 2 kW, and 40 kW, and so on. The average value is somewhere around 15–20 kW. But, as a rule, the required power is also calculated depending on the volume and dimensions of the pool where it will be installed. Here you need to understand that models with a power of 2 kW will not be able to effectively cope with a huge pool.

According to body material

According to the material of the body, heat exchangers for the pool are also different. For example, their body can be made of various metals. The most common are titanium, steel, iron. Many neglect this factor, which should not be done for 2 reasons. First, each of the metals reacts differently to contact with water, and using one may be better than the other in terms of durability.

By type of work

According to the type of work, heat exchangers for the pool are electric and gas. As a rule, automation is used in both cases. A more efficient solution in terms of heating rate and energy consumption would be a gas appliance. But it is not always possible to bring gas to it, which is why the popularity of electric models is higher. But the electrical analogue has a high energy consumption, and it heats the water a little longer.

Type of internal heating element

According to this criterion, the heat exchanger can be tubular or plate.Plate models are more popular due to the fact that here the area of \u200b\u200bcontact of cold water with the exchange chamber will be larger. Another reason is that there will be a lower resistance to fluid flow. And the pipes are not so sensitive to possible contamination, unlike the plates, which eliminates the need for preliminary water purification.

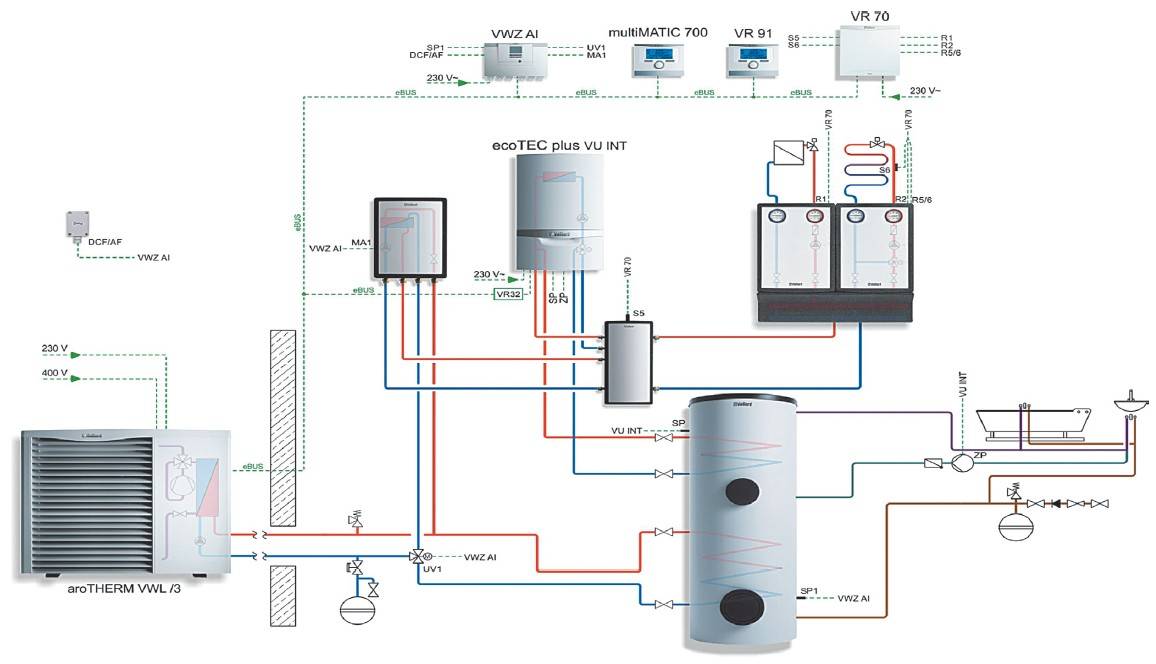

Features of mounting the device

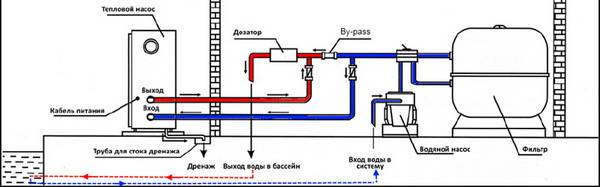

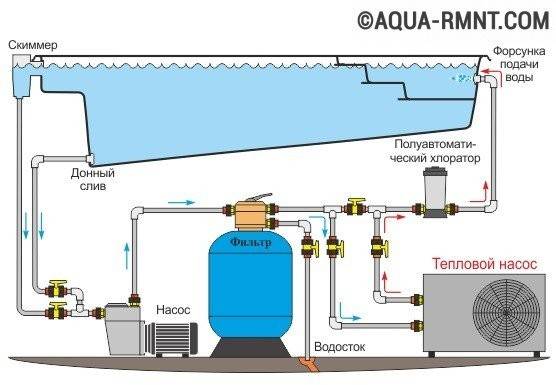

The procedure for connecting a pool heat pump depends on the features of a particular model. Therefore, before starting work, you should carefully study the manufacturer's instructions and strictly follow the requirements and recommendations set out in it. Typically, industrial models are supplied already assembled and with a set of components necessary for installation.

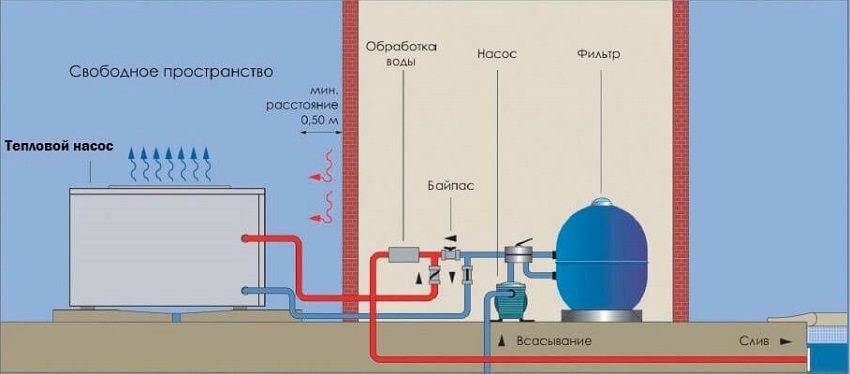

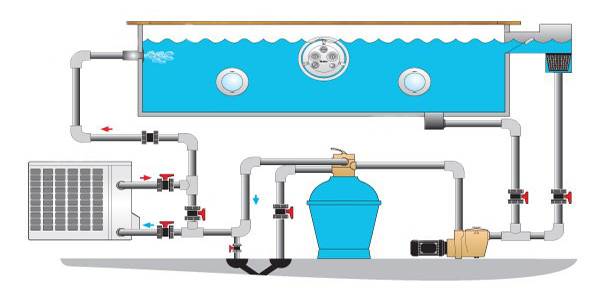

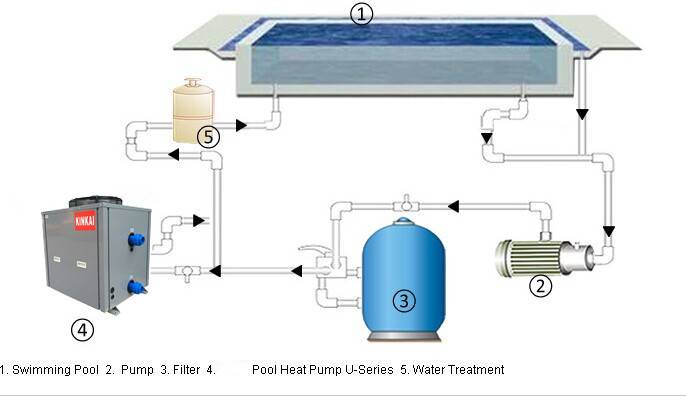

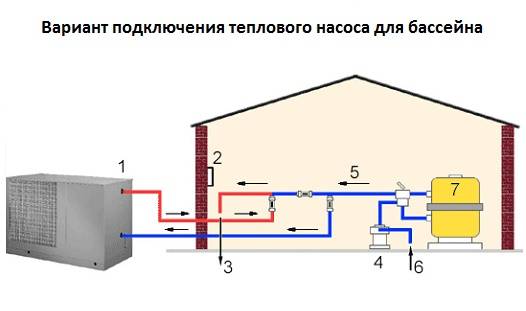

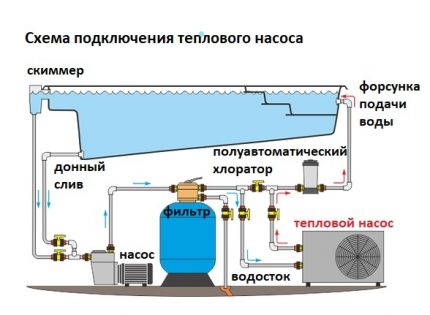

Diagram of the operation of a heat pump connected to a pool: 1 - Pool heat pump 2 - Remote control device 3 - Clean water for the pool 4 - Circulation pump 5 - Bypass (bypass) and control valves 6 - Pool water supply pipe 7 - Filter

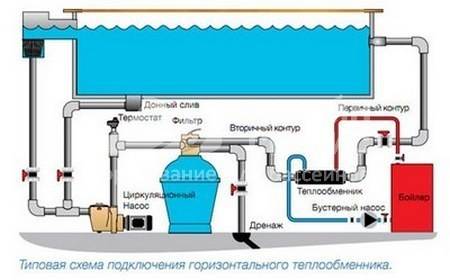

During the connection, you will need to install a pair of pipes, as well as provide power. In the pool maintenance system, the heater is installed in such a way that it is located after the filtration system and before the chlorinator.

As shown in this diagram, the heat pump should be connected after the water filter but before the water chlorinator

It is very important to choose the right place to install the equipment. Typically, an air-to-water heat pump is an impressively sized unit, reminiscent of the outdoor unit of a split air conditioner.

To install an air source heat pump, it is necessary to choose a place that is large enough and protected from external influences, for example, with a canopy.

The location for the installation of such equipment must meet the following requirements:

- good ventilation;

- lack of obstacles for the movement of air masses;

- distance from open fire and other heat sources;

- protection from external environmental factors: precipitation, debris falling from above, etc.;

- availability for maintenance and necessary repairs.

Most often, a heat pump is installed under a canopy. For added protection, you can install a couple of side walls, but they should not interfere with the airflow that is pumped by the fans.

The pump is mounted on a metal frame, the base must be strictly horizontal. This will minimize problems such as vibration and noise during operation of the device, and also protect the device from damage.

The air source heat pump must be installed on a solid and strictly horizontal base. This will reduce vibration during its operation and reduce the amount of noise.

When installing the heat pump and connecting it to the system, it is important to make sure that all its parts are clean. It does not hurt to check the inner surface of the pipes with which the connection is made.

All junctions of pipes through which water circulates must be carefully sealed and checked for leaks. To prevent the vibration from the heat pump from being transmitted to the rest of the system during its operation, it makes sense to consider the connection option using flexible hoses.

The power supply of the heat pump will require special attention. It must fully comply with the rules for the installation of electrical equipment, taking into account all fire safety requirements.

There is usually a high level of humidity around the pool, and the likelihood of electrical equipment coming into contact with water increases significantly. Therefore, it is necessary to carefully insulate all places of electrical contacts, additionally protecting them from possible contact with moisture.

It is mandatory to include circuit breakers in the circuit for connecting the heat pump to the power supply, which are equipped with sensors that respond to temperature increases. You will also need protection devices that will prevent current leakage.

All conductive nodes must be grounded without fail. To connect cables, both power and control, you will need special terminal blocks. The manufacturer's instructions usually indicate the required cross-section of electrical cables through which equipment can be connected to the power supply.

These data must be adhered to. The cross section of the cable may be more than recommended, but not less.

The installation of a heat pump for heating water in the pool is carried out in accordance with the manufacturer's recommendations. It is usually installed after the water treatment system, but before the chlorination device, if any.

Selection of the pump depending on the type of pool

The pump is selected based on the parameters of the pool and the conditions of use. The most important value is the volume of pumped water.

The pool type outdoor/indoor is a critical condition for heaters, including heat pumps. Outdoor water bodies have a higher heat loss coefficient and depend on external climatic factors.

If sea water is used in the pool, it is recommended to use pumps with hydraulic parts made of bronze or a special salt-resistant polymer. Ordinary plastic or stainless steel is more likely to wear out in salt water.

As a rule, pumps for transfer and filtration are located below the water level. To implement the connection, when the pump is placed above the water level, it is strongly recommended to choose self-priming models of the centrifugal type.

Pump selection

The filtering system is necessarily equipped with a pump that provides forced supply of contaminated water to the filter and reverse flow of purified water to the pool. The device is purchased depending on the operating mode of the artificial reservoir and the nature of possible pollution. With intensive use of the pool, it is recommended to purchase a powerful filter pump capable of separating large particles. In the future, with its help, water is supplied to the purification system, where smaller inclusions are neutralized.

It is possible to ensure economical operation of a high-performance pump by applying different modes. During the absence of bathers, the system is transferred to a passive state, operating at low power. During intensive use of the pool, the cleaning pump turns on at maximum values.

The range offered by manufacturers of pumping equipment includes heating or heat pumps.

It is important to know that they are not intended to be used during a hot period of time.But for the cool season, such equipment can be a real gift. Each pump model has its own service life

So that it does not turn out to be shorter than the period indicated by the manufacturer, the installation must be hidden for the winter. But at the same time, one should not forget that the unit must first be washed and freed from water. Pump parts are lubricated if this stage is prescribed in the operating instructions. It is recommended that you familiarize yourself with all the requirements and nuances even before buying a pump.

Each pump model has its own service life. So that it does not turn out to be shorter than the period indicated by the manufacturer, the installation must be hidden for the winter. But at the same time, one should not forget that the unit must first be washed and freed from water. Pump parts are lubricated if this stage is prescribed in the operating instructions. It is recommended that you familiarize yourself with all the requirements and nuances even before buying a pump.

A few words about calculations

One of the basic indicators that you need to be guided by when choosing a heat pump for your pool is the power of the heat exchanger responsible for the process of heating water to the optimum temperature. To calculate this indicator, it is necessary to determine the level of energy that will be spent on increasing the water temperature to a given level per unit of time:

P = 1.16 X ΔT/t X V (kW), where

- 1.16 - coefficient that corrects for heat loss in contact with the pool structures;

- ΔT is the difference between the initial water temperature and the temperature to which the water in the pool must be heated, ºС;

- t is the time during which the heat pump allows the water to be heated to the set temperature, hour;

- V is the volume of the pool, cub. m.

This calculation allows you to determine the type of equipment at the initial stage, but it should be noted that factors such as pool room ventilation, air conditioning, air humidity control, etc. are not taken into account. To make such detailed calculations, more complex methods should be used, about which it is better to consult with specialists.

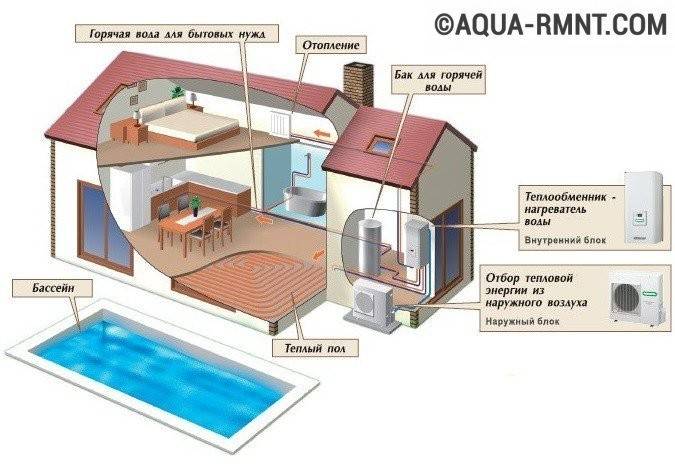

The energy received with the help of a heat pump can be effectively used not only for the pool, but also for other purposes: heating rooms, heating hot water in the plumbing, for underfloor heating, etc.

This is how the classic scheme for connecting a heat pump to an equipment circuit looks like. It connects almost at the very end of the circuit, in front of the water chlorinator

The maximum effect from the operation of a heat pump depends not only on the correct choice of equipment, but also on other factors. For example, experts recommend using vibration-resistant pipelines that are covered with a protective sheath when installing internal heat exchangers. An important point is the diagnostics of the state of the equipment at each stage of installation.

Particular attention should be paid to the additional protection of all electrical connections, as well as the use of auxiliary materials, components and installation equipment recommended by the manufacturer of the selected heat pump.

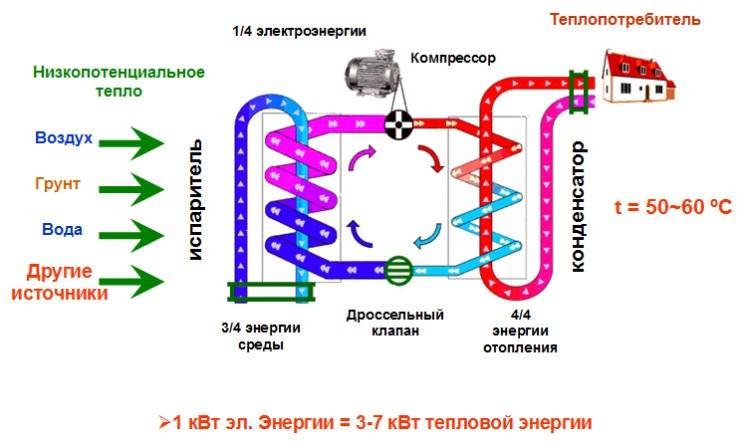

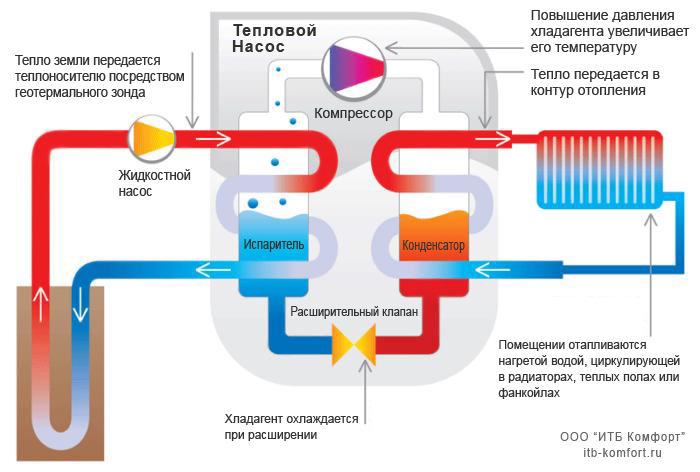

Pros and cons of homemade equipment

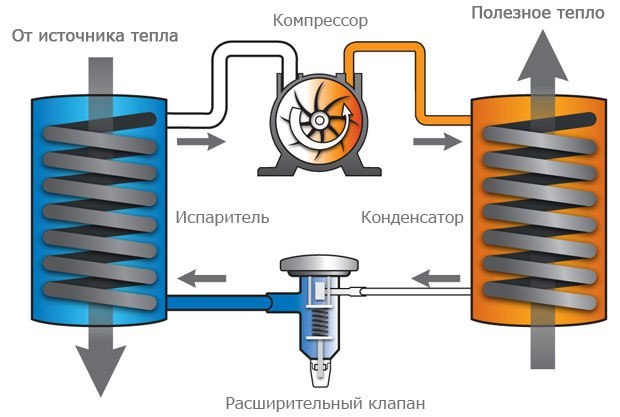

A heat pump is a device that does not produce heat, but moves it from one place to another, while raising the temperature through compression. This process proceeds according to the principle of the Carnot cycle, which consists in the movement of the working fluid (refrigerant) through a closed system.When its state changes from liquid to gaseous and vice versa, a large amount of energy is released or absorbed. This principle is used in the design of refrigerators, but the mechanism of action of a heat pump is to absorb heat from the outside and transfer it to the room.

Stages of the Carnot cycle:

- liquid freon enters the evaporator through the tube;

- interacting with the coolant, which is water, air or soil, the refrigerant evaporates, taking on a gaseous state;

- the working fluid passes through the compressor, is compressed under pressure, which contributes to an increase in its temperature

- then it enters the condenser, which acts as a heat exchanger;

- gives the received heat to the coolant and again takes the form of a liquid;

- in this form, freon enters the expansion valve, where, at low pressure, it again moves to the evaporator.

The device of industrial production is expensive, the payback period is an average of 5-7 years. The popularity of a heat pump from an old refrigerator is due to the minimum material investment in the manufacture of the unit and the possibility of saving energy costs during its operation.

Additionally, the following advantages of using home-made equipment are distinguished:

- no noise, no odors;

- installation of auxiliary structures, a chimney is not required;

- the operation of the equipment does not harm the environment, as it does not involve the emission of combustion products into the atmosphere;

- the ability to install the system in a convenient place;

- multifunctionality. In winter, the device is used as a heater, and in summer as an air conditioner;

- safety. Operation does not involve the use of fuel, and the maximum temperature of the units of the unit does not exceed 90 0C;

- durability, reliability. The service life of the unit when using high-quality components is 30 years or more.

The main disadvantage of home-made devices is their low productivity, so they are often used as an additional option for heating individual rooms in the house. It is recommended to assemble such a system in rooms with good thermal insulation and a heat loss level of not more than 100 W / m2.