- Submersible systems

- Heat pumps for swimming pools

- How a heat pump works

- Heat pump selection criteria

- Benefits of geothermal pumps

- What do we consider when choosing

- Circulation pumps

- Design features of a pump for heating a private house

- wet rotor

- Dry Rotor

- Heat pumps

- Principle of operation

- Types of pool pumps

- filter pump

- Submersible pump

- Budget

- Boilers

- snails

- Bedspreads

- Firewood

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Why do you need a pump in the heating system

- The principle of operation of the circulation pump

- Principle of operation

- Classification

- Thermal collector "ground-water"

- "Water-water"

- "Air-water"

- Manufacturer Market Overview

Submersible systems

Submersible pumps are lowered into the pool and pump water out of it. Household installations can remove water up to 5-10 cm from the bottom of the reservoir, pumping is carried out in a few hours. And more professional ones leave only 1 cm, but such installations are needed mainly by public pools.

Such devices are used once a season to clean swimming pool for the winter or during maintenance work for cleaning. If you need to change all the water, completely clean the bottom or walls, resort to the help of submersible systems.The previously used filter is removed: when pumping out water, dirt should not be sifted out, on the contrary, the design is designed to receive particles even as small as 5 cm, and allows various debris to pass through.

Heat pumps for swimming pools

In most of our country, summer is coming to an end very quickly. During the night or in cloudy weather, the water in the pool cools down. It is expensive to heat a pool with traditional heaters.

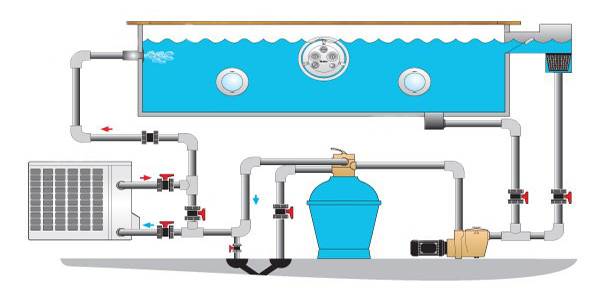

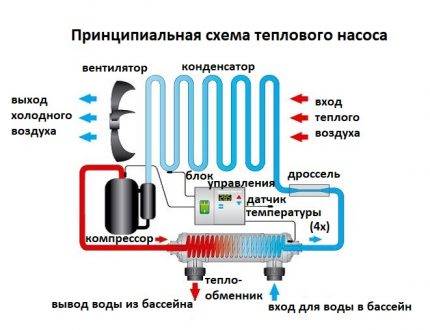

How a heat pump works

The principle of operation of a heat pump can be clearly seen on the example of a domestic refrigerator. The composition of the heat pump includes: heat exchanger, compressor, evaporator.

Freon circulates in the heat pump system - a gas that can turn into a liquid state at room temperature. During the transition of the phase state of freon, heat is taken from the environment and then the circulating water is heated in the heat exchanger.

In short, the refrigerator is the opposite: the environment is cooled, the water is heated.

According to the interaction with the environment, there are three types of heat pumps: ground-water, water-water, air-water.

Pool heat pumps not only heat the water, but also maintain its stable temperature.

Pool heat pumps not only heat the water, but also maintain its stable temperature.

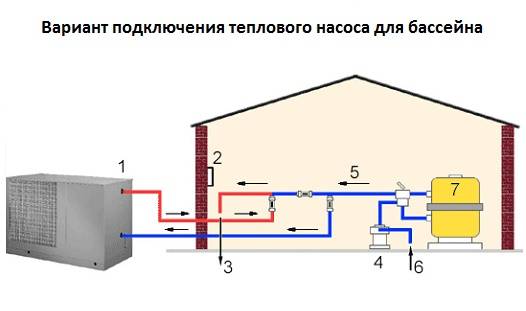

Heat pump selection criteria

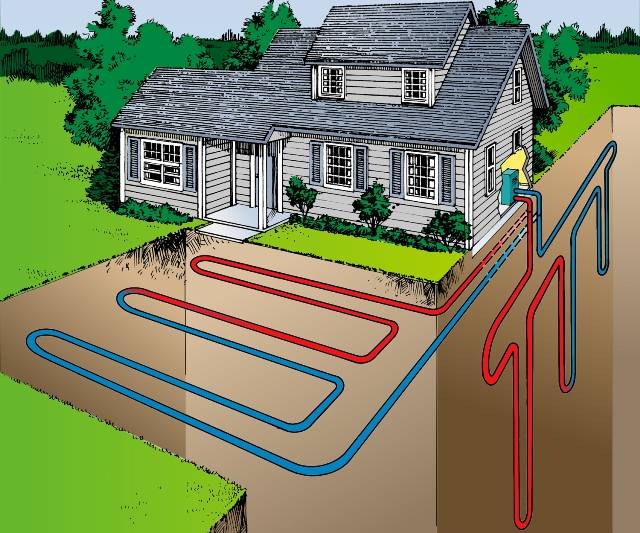

Each type of pump has its own circuit installation rules. For ground-water pumps, horizontal or vertical pipes are required.

In any case, pipe laying must be carried out at a depth of at least 2-3 meters - to the freezing depth. From above it is impossible to plant trees with a powerful root system.

Water-to-water pumps use the energy of reservoirs. Such pumps are an advantageous option, since they do not require excavation of the previous type of pumps.

In these systems, laying to a freezing depth of 2-3 meters is also required. The distance from the reservoir to the pool should not be more than 100 meters.

Air-to-water systems do not require complex piping and are easy to install. However, air-to-water pumps are less efficient, as they extract the thermal energy of the air and depend on its temperature at a particular time period.

When choosing heat pump air- water must be taken into account:

- pump installation location (sun or shade);

- average air temperature;

- pool volume;

- pool type (outdoor or indoor).

Regardless of the chosen heat pump system, on average, approximately 5-8 kW of thermal energy is generated per 1 kW of electricity consumed. Modern heat pump systems are able to heat even an outdoor pool all year round.

Benefits of geothermal pumps

Ordinary circulation pool pump is gradually being forced out of the market by new thermal models.

The advantages of using geothermal units are obvious:

- Significant cost savings on water heating.

- Possibility of heating the swimming pool itself in winter.

- Can be used in ventilation and air conditioning systems.

- Safe operation in high humidity conditions.

- Ease of installation: the installation of a heat pump does not require complex project documentation and approvals.

- Explosion and fire safety.

- Environmental friendliness: the absence of exhaust gases and combustion products allows you to install the pump indoors without special modifications to the ventilation system.

Geothermal pumps for pools are successfully used in everyday life.The unit is mounted in a heating circuit for heating the coolant, used in a hot water supply or air conditioning system at home.

What do we consider when choosing

How to choose a circulation pump for heating system private house, and what parameters you need to know for this. Since the pump is a power unit, the first selection criterion will be its power. Next, we determine the type of rotor, and lastly, the type of control.

To determine the power, you need to know the parameters of the heating system. For large objects: industrial, multi-storey - measurements are taken. In private homes, such accuracy is not needed, so it is enough to know:

Boiler performance. The calculation is made theoretically according to the formula: W thermal boiler * K throughput (1l / min = 60l / hour). For 25 kW 25*60= 1500 l/h; for 40 kW 40*60= 2400 l/h.

Boiler characteristics that can be used for preliminary calculations are indicated in the instructions

- Head. Indicated in meters of water column. For this calculation, you need to measure the total length of the contour and multiply by a factor of 0.6 (10 running meters correspond to 0.6 m of w.st.). For the contours of a one-story house, standard equipment of 6 m w.st. is sufficient, while 2;- or more floors require the installation of a station or several pumps.

- Rotor type. Affects the cost and subsequent maintenance. Increased efficiency allows it to be used in complex systems. But given the possibility of remote installation and regular maintenance.

- Control. It also affects the cost of the unit itself, but the convenience and efficiency more than cover this drawback. In complex systems, it is recommended to use only this type of control.

- Pressure and air relief valve. It is not installed in all models, but you can overpay for this function, as it prevents the pump from turning on “dry” and provides a trouble-free stop when the power is turned off (the water heats up to a critical temperature, the pressure increases and opens the outlet valve).

Pressure relief valve can be installed separately

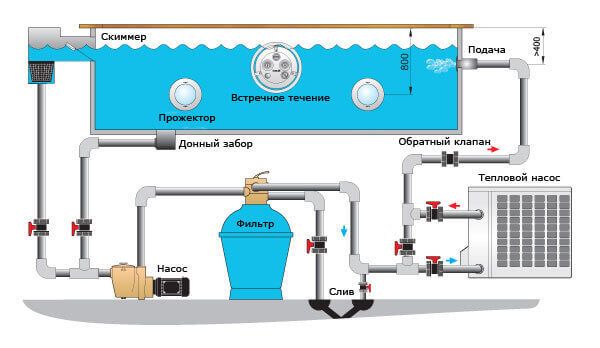

Circulation pumps

These installations provide a constant renewal of water flows. Thanks to them, large particles are removed from the water, and the risk of algae formation is reduced. At the same time, the water looks clean and warms up evenly, and pumping is almost silent.

Device types:

- vortex;

- centrifugal.

Centrifugal ones are faster and cost less, but can only take water in one direction and should be used in smaller water bodies. Vortex ones are distinguished by a more complex device, an increased price. They can take water in several directions at once, but they are noisier. If you need an inexpensive device with quiet operation, it is better to take a centrifugal type.

Design features of a pump for heating a private house

In principle, a circulation pump for heating is no different from other types of water pumps.

It has two main elements: an impeller on a shaft and an electric motor that rotates this shaft. Everything is enclosed in a sealed case.

But there are two varieties of this equipment, which differ from each other in the location of the rotor. More precisely, whether the rotating part is in contact with the coolant or not. Hence the names of the models: with a wet rotor and dry. In this case, we mean the rotor of the electric motor.

wet rotor

Structurally, this type of water pump has an electric motor in which the rotor and stator (with windings) are separated by a sealed glass. The stator is located in a dry compartment, where water never penetrates, the rotor is located in the coolant. The latter cools the rotating parts of the device: the rotor, impeller and bearings. Water in this case acts for bearings, and as a lubricant.

This design makes the pumps quiet, because the coolant absorbs the vibration of the rotating parts. A serious drawback: low efficiency, not exceeding 50% of the nominal value. Therefore, pumping equipment with a wet rotor is installed on heating networks of small length. For a small private house, even 2-3 floors, this would be a good choice.

The advantages of wet rotor pumps, in addition to silent operation, include:

- small overall dimensions and weight;

- economical consumption of electric current;

- long and uninterrupted work;

- Easy to adjust rotation speed.

Photo 1. Scheme of the device of a circulation pump with a dry rotor. Arrows indicate parts of the structure.

The disadvantage is the impossibility of repair. If any part is out of order, then the old pump is dismantled, installing a new one. There is no model range in terms of design possibilities for pumps with a wet rotor. All of them are produced of the same type: vertical execution, when the electric motor is located with the shaft down. The outlet and inlet pipes are on the same horizontal axis, so the device is installed only on a horizontal section of the pipeline.

Important! When filling the heating system, the air pushed out by water penetrates into all voids, including the rotor compartment. To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover. To bleed the air plug, you must use a special bleed hole located in the upper part of the electric motor and closed with a sealed rotating cover

To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover.

Preventive measures for "wet" circulation pumps are not required. There are no rubbing parts in the design, cuffs and gaskets are installed only on fixed joints. They fail due to the fact that the material has simply grown old. The main requirement for their operation is not to leave the structure dry.

Dry Rotor

Pumps of this type do not have a separation of the rotor and stator. This is a normal standard electric motor. In the design of the pump itself, sealing rings are installed that block the access of the coolant to the compartment where the elements of the engine are located. It turns out that the impeller is mounted on the rotor shaft, but is in the compartment with water. And the entire electric motor is located in another part, separated from the first by seals.

Photo 2. A circulation pump with a dry rotor. There is a fan at the back to cool the device.

These design features have made dry rotor pumps powerful.The efficiency reaches 80%, which is quite a serious indicator for equipment of this type. Disadvantage: the noise emitted by the rotating parts of the device.

Circulation pumps are represented by two models:

- Vertical design, as in the case of a wet rotor device.

- Cantilever - this is a horizontal version of the structure, where the device rests on the paws. That is, the pump itself does not press on the pipeline with its weight, and the latter is not a support for it. Therefore, a strong and even slab (metal, concrete) must be laid under this type.

Attention! O-rings often fail, becoming thin, which creates conditions for the penetration of the coolant into the compartment where the electrical part of the electric motor is located. Therefore, once every two or three years, they carry out preventive maintenance of the device, inspecting, first of all, the seals

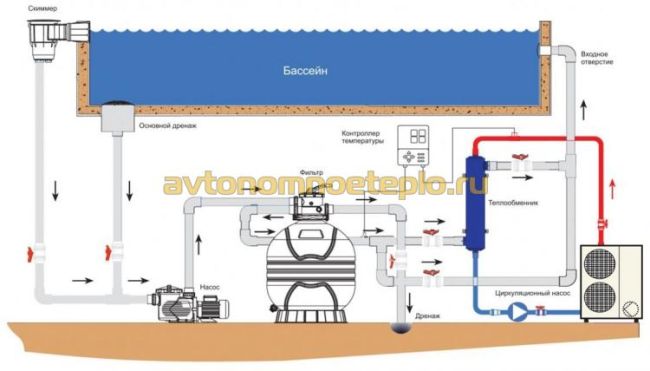

Heat pumps

As you know, in the summer there are quite cool nights, during which the water in the pool has time to cool down. Thus, by the morning it will be already quite cold. Therefore, it is customary to use special heat pumps that allow you to maintain the required water temperature in the pools.

Principle of operation

The structure of the device, as a rule, includes: an evaporator, a compressor and a heat exchanger. Freon gas circulates in the system itself, capable of turning into a liquid state at room temperature.

The structure of the device, as a rule, includes: an evaporator, a compressor and a heat exchanger. Freon gas circulates in the system itself, capable of turning into a liquid state at room temperature.

When the transition of the phase state of freon occurs, the selection of heat from the environment is organized. This allows you to heat the water that circulates in the heat exchanger. The system is similar to the operation of a refrigerator, only in reverse.

Types of pool pumps

For the normal operation of the pool, there are several types of devices:

- Water drain device.This unit is used to pump out water at the end of the season, for maintenance or repair work.

- Circulation unit. It is used to set the water in motion and supply it to filtration or heating devices.

- Thermal pump. A unit used to generate heat energy instead of a classic heating element.

- Effect pump. It is used for hydromassages, waterfalls, rides and other pool add-ons.

Each of these types has its own characteristics and nuances in the work. But in addition to the classic variety, there are also options depending on the principle of operation.

The first ones have an impeller, which is represented by blades with curved ends. They bend in the opposite direction of movement. Its body is shaped like a snail.

The impeller rotates very quickly, which helps the water to move to the walls. In this case, rarefaction occurs in the center, due to which the water gets a greater speed and comes out with force.

The vortex pump has a slightly different impeller configuration, which is called an impeller. The body fully corresponds to the impeller in diameter, but there are gaps on the sides, due to which the water is twisted like a whirlwind.

It is very convenient that such devices do not require long-term filling with water and can work if the liquid is interspersed with air.

Vortex devices are completely opposite in characteristics: they have high outlet water pressure, strong noise during operation and small volumes of treated water.

Such electric pumps are more popular, since they can be installed not directly into the water, which is very valuable for frame or inflatable pool models, because in this case it is not possible to place the equipment directly under the tank.

The self-priming device can take in water even if it is located above its surface at a height of 3 meters. However, it is worth considering the fact that the capture of water takes a lot of energy, therefore, if possible, it is better to install the pump as low as possible.

When choosing a self-priming pumping mechanism, the following factors must be considered:

- Filter water flow rate. It must necessarily correspond to the performance of the pump.

- Pipe diameters.

- The volume of water for pumping, which must comply with sanitary standards.

- Possibility of long working time.

- The material of the case and internal components. Usually it is reinforced plastic for the body and stainless steel for the shaft and fasteners.

- Noise level.

filter pump

These units are used for frame or inflatable pools and are completed immediately with a filter element. Thanks to this solution, one pump can be dispensed with.

Filter elements can be sand or cartridge. The first option is designed for a large volume of water and is more efficient. Water in them is passed through quartz sand, so that all polluting particles remain inside. The filter is cleaned in reverse.

Intex pool pumps with cartridge-type filters are installed only in small pools. They also purify water with high quality, but get dirty faster and need to be replaced.

The main disadvantage of a device with a filter element is that they are in the same housing. That is why, if one of the units becomes unusable, you will have to buy both.

An ordinary pool can only do with this type of pump. It is designed to provide a constant passage of water through the filters.

The circulation pump differs from others in the following characteristics:

- The presence of a filter and a certain body material. This indicator eliminates such a problem as jamming of the pump impeller.

- The resistance of manufacturing materials to chemicals that are often used to clean the pool, and corrosion.

Submersible pump

Such specialized devices are used to pump water from the tank. Many people use self-priming and circulating models for this purpose, but they are completely not designed for this and can fail.

Submersible pumps are distinguished by wide intake windows and are able to take water from the pool, leaving only 1 cm at the bottom.

Budget

Budget categories of devices are:

- boilers;

- snails;

- bedspreads;

- firewood.

Boilers

The boiler can be easily heat water in a small pool for kids. However, when using this method, you must follow the safety rules: do not touch the water while the boiler is in operation and do not lean it against the walls of the pool. As an example, to obtain the desired temperature, you can simply add a little hot water.

snails

A homemade solar battery is called a snail. Such devices are often sold in the markets at a fairly reasonable price.The snail will quite cope with heating, but only in sunny weather.

Photos of pools of our contractors:

-

4 months ago

#pools

-

4 months ago

#pools

-

4 months ago

#pools

-

4 months ago

#pools

-

4 months ago

#pools

Bedspreads

The bedspread is considered, probably, the most economic way of heating. This simple device provides a temperature increase of 3-4 degrees within a few hours.

Firewood

Another budget option for heating in small pools is heating with wood.This will require a special oven, which is not difficult to find on sale. And the process itself is very simple! A circular pump is installed in the pipeline, firewood is laid in the oven. While the pump is turning on, a fire is ignited by the circulation of water under the furnace serpentine. In this way, it is possible to provide constant heat of 27 degrees in a ten-cube pool for 24 hours.

There are many ways to make a pond warm. And depending on preferences and financial capabilities, everyone can choose the best option for themselves.

- Enter the parameters of your pool or just leave a request

- We will receive an estimate for your project from each of our contractors

- We will select the best offer and contact you

- You will get the pool at the best price

Your promo code: "Pool for you"! Tell it to our employee and the departure of the measurer will be free for you.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow.So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. It's necessary take into account when choosing models.

Why do you need a pump in the heating system

Circulation pumps for heating private houses are designed to create a forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will operate continuously. For this reason, high demands are placed on circulation equipment regarding:

- performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings it is used for hot water systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency and uniform heating along the entire length of the water circuit increase.

The only disadvantage of such a solution is the dependence of the operation of pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new one and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps may differ slightly, depending on the type of construction, but the principle of operation remains the same. Manufacturers offer more than a hundred models of equipment, with various performance and control options. According to the characteristics of pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used. The designs differ in the location of the impeller and moving mechanisms in the housing. So, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. "Dry" models have high performance, but have several drawbacks: a high level of noise is generated from the operation of the pump, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely encased in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of the "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in domestic premises of a small area, has a mechanical regulator with three fixed speeds. It is quite inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode.At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose a suitable model, it will be enough to know about the above nuances.

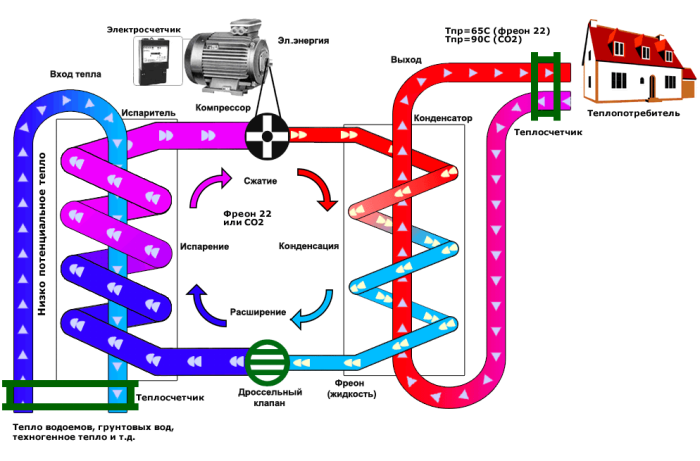

Principle of operation

All the space around us is energy - you just need to know how to use it. For a heat pump, the ambient temperature must be greater than 1C°. Here it should be said that even the earth in winter under snow or at some depth retains heat. The work of a geothermal or any other heat pump is based on the transportation of heat from its source using a heat carrier to the heating circuit of the house.

Scheme of operation of the device by points:

- the heat carrier (water, soil, air) fills the pipeline under the soil and heats it;

- then the coolant is transported to the heat exchanger (evaporator) with subsequent heat transfer to the internal circuit;

- the external circuit contains the refrigerant, a liquid with a low boiling point under low pressure. For example, freon, water with alcohol, glycol mixture. Inside the evaporator, this substance is heated and becomes a gas;

- the gaseous refrigerant is sent to the compressor, compressed under high pressure and heated;

- hot gas enters the condenser and there its thermal energy is transferred to the heat carrier of the house heating system;

- the cycle ends with the conversion of the refrigerant into a liquid, and it, due to heat loss, returns back to the system.

The same principle is used for refrigerators, so home heat pumps can be used as air conditioners to cool a room. Simply put, a heat pump is a kind of refrigerator with the opposite effect: instead of cold, heat is generated.

Do-it-yourself heat pumps can be designed based on three principles - according to the energy source, the coolant, and their combination. The source of energy can be water (reservoir, river), soil, air. All types of pumps are based on the same operating principle.

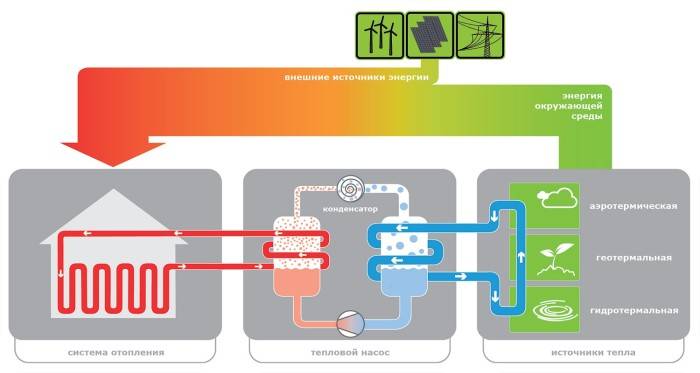

Classification

There are three groups of devices:

- water-water;

- groundwater (geothermal heat pumps);

- use water and air.

Thermal collector "ground-water"

A do-it-yourself heat pump is the most common and efficient way to generate energy. At a depth of several meters, the soil has one constant temperature and is little affected by weather conditions. On the external contour of such a geothermal pump, a special environmentally friendly liquid is used, popularly called "brine".

The outer contour of the geothermal pump is made of plastic pipes. They are dug into the ground vertically or horizontally. In the first case, one kilowatt may require a fairly large area of work - 25–50 m2. The area cannot be used for planting - only planting annual flowering plants is allowed here.

Vertical energy collector requires several wells in 50–150 m. Such a device is more efficient; special deep probes transfer heat.

"Water-water"

At great depths, the water temperature is constant and stable. The source of low-potential energy can be an open reservoir, groundwater (well, borehole), wastewater. There are no fundamental differences in the design for heating of this type with different heat carriers.

The “water-water” device is the least labor-intensive: it is enough to equip pipes with a heat carrier with a load and place them in water if it is a reservoir.For ground water, a more complex design will be required and it may be necessary to build a well for the discharge of water passing through the heat exchanger.

"Air-water"

Such a pump is slightly inferior to the first two and in cold weather its power decreases. But it is more versatile: it does not need to dig the ground, create wells. It is only necessary to install the necessary equipment, for example, on the roof of the house. This does not require complex installation work.

The main advantage is the ability to reuse the heat leaving the room. In winter, it is recommended to have another source of heat, since the power of such a heater can be significantly reduced.

Manufacturer Market Overview

Today's market offers a variety of different models: a large number of manufacturers make it difficult for a simple user to choose. But, despite this, reliable equipment from well-known manufacturers such as Grundfos, Wilo, Speroni, Wester and others took the leading position.

With all this, it does not require any maintenance. The disadvantage of this equipment is its very high cost. Usually it is 2-3 times higher than the cost of other well-known brands. Although, rationally speaking, the price-quality ratio will play in favor of the purchase of electrical equipment from these companies. The cheapest, of course, is Chinese-made equipment.

But, the problem is that cheap models break down very quickly, are very noisy and need constant maintenance. If, first of all, it is necessary that the heating system is reliable and efficient, then it is better not to buy cheap equipment and give preference to more expensive models.