- Types of thermal imaging devices

- Device and principle of operation

- Ways to display information from a thermal imager

- Where is thermal imaging used?

- What are thermal imaging cameras used for in construction?

- Checking procedure

- Rules for using the thermal imager

- How to use the thermal imager correctly

- What is thermal imaging and where is it used?

- Regulations

- in plain language

- Rules for using the thermal imager

- Mobile thermal imager for a smartphone - how real are the readings

- Thermal imager for Android smartphone

- Thermal imager for iOS smartphone

- Classification

Types of thermal imaging devices

Checking a private house for heat loss with an IR camera makes it possible to carry out the most accurate measurements and qualitative analysis of all temperature indicators. And after that, on the basis of promptly received data, competently carry out repair work and / or modernization of a residential facility.

For thermal imaging diagnostics, two types of devices are used:

- stationary thermal imagers;

- portable infrared cameras.

Stationary devices are used mainly in manufacturing plants. They are designed for regular checks of the state of electrical networks and continuous monitoring of complex technical equipment. Stationary thermal imaging systems are made on semiconductor matrices of photodetectors.

With the help of portable thermal imagers, an energy audit of residential multi-apartment buildings and private buildings is carried out. These devices are used both for a one-time local check and for complex diagnostics of houses.

Portable thermal imagers are based on uncooled silicon microbolometers and are excellent for use in hard-to-reach places.

Thermal imaging is an effective non-contact survey method, which is advisable to combine with the use of an air door to measure and control the air permeability of buildings.

Depending on the functionality, there are three types of thermal imagers:

- Observation devices - provide only visualization of various heat-contrasting objects, often in monochrome.

- Measuring devices - create a graphic image within the limits of infrared radiation and assign a certain temperature value to each point of the light signal.

- Visual pyrometers are designed for non-contact temperature measurements and visualization of the thermal field of specific objects in order to detect zones with deviations from normal values.

The price of good functional thermal radiation receivers starts at $ 3,000. Their purchase for a one-time examination at home is simply unprofitable. Many companies today offer building thermal imagers for rent for a day. This is a very convenient service.

You can also order a complete professional thermal imaging inspection of the cottage / house. The average cost of shooting with a thermal imager is $ 5 per 1 square meter of a private residential facility.

As a rule, the cost of thermal imagers is an indicator of their functionality.But even budget models effectively perform infrared diagnostics. Therefore, when choosing, it is worth focusing on the basic technical characteristics and the ability to solve specific problems.

The functionality of thermal imaging cameras depends on the resolution of the infrared sensor, its sensitivity and operating temperature range.

Various accessories will greatly simplify thermal imaging diagnostics at home - removable optical wide-angle lenses for viewing the general plan and telephoto lenses for detailing critical areas, folding tripods, containers for storing batteries.

Device and principle of operation

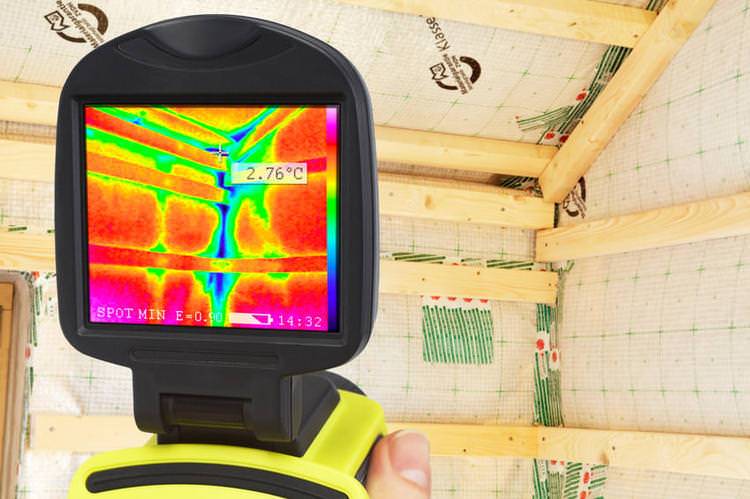

The sensitive element of any thermal imager is a sensor that transforms the infrared radiation of various objects of inanimate and living nature, as well as the background into electrical signals. The received information is converted by the device and reproduced on the display in the form of thermograms.

In all living organisms, as a result of metabolic processes, thermal energy is released, which is perfectly visible to the equipment.

In mechanical devices, the heating of individual components occurs due to constant friction at the junction points of the moving elements. Electrical-type equipment and systems heat up conductive parts.

After aiming and capturing an object, the IR camera instantly generates a two-dimensional image containing complete information about temperature indicators. The data can be stored in the memory of the device itself or on external media, or can be transferred using a USB cable to a PC for detailed analysis.

Some models of thermal imagers have built-in interfaces for instant wireless transmission of digital information.Registered thermal contrast in the field of view of the thermal imager makes it possible to visualize signals on the screen of the device in halftones of a black and white palette or in color.

The thermograms display the intensity of infrared radiation of the structures and surfaces under study. Each individual pixel corresponds to a specific temperature value.

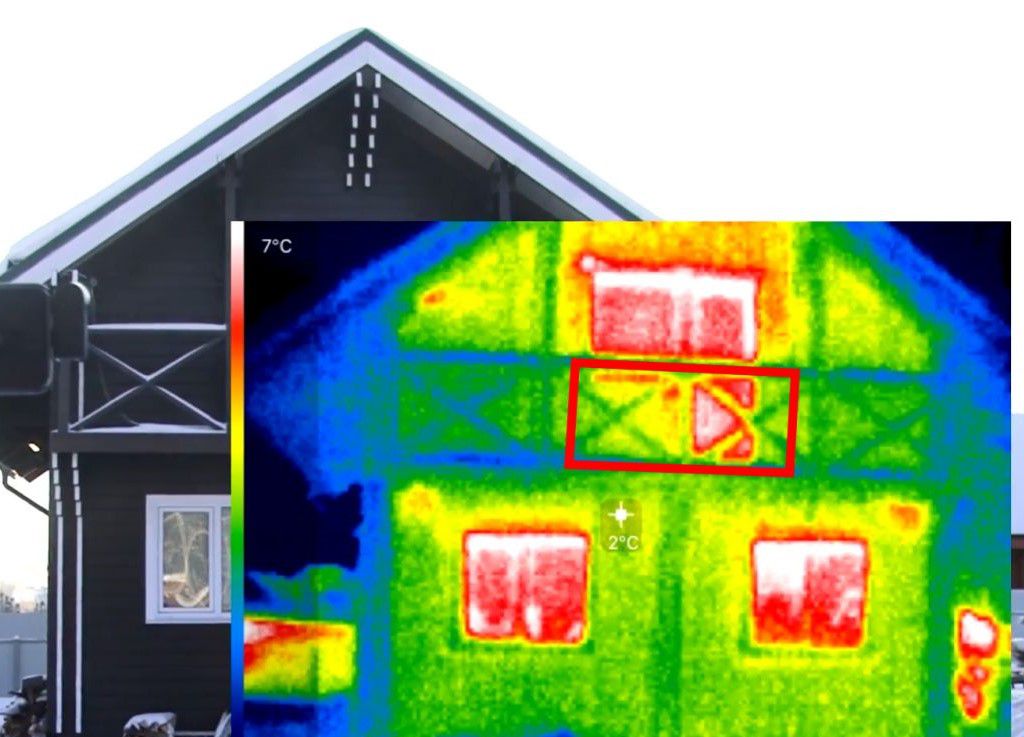

According to the heterogeneity of the thermal field, errors in the engineering structures of the house and defects in building materials, shortcomings in thermal insulation and poor-quality repairs are revealed.

On the black-and-white screen of the thermal imager, warm areas will be displayed as the brightest. All cold objects will be practically indistinguishable.

On the color digital display, areas that radiate heat the most will glow red. As the intensity of the radiation decreases, the spectrum will shift towards violet. The coldest zones will be marked in black on the thermogram.

To process the results obtained by the thermal imager, it is enough to connect the device to a personal computer. This will allow you to reconfigure the color palette on the thermogram so that the required temperature range is best seen.

Modern multifunctional devices are equipped with a special detector matrix, which consists of a huge number of very tiny sensitive elements.

The infrared radiation recorded by the lens of the thermal imager will be projected on this matrix. Such IR cameras are able to detect a temperature contrast equal to 0.05-0.1 ºC.

Most models of thermal imagers are equipped with a liquid crystal control display for displaying information. However, the quality of the screen does not always indicate the high level of infrared equipment in general.

The main parameter is the power of the microprocessor used to encode the received data. The speed of information processing plays a major role, since pictures taken without a tripod can be blurry.

The functioning of thermal imaging devices is based on fixing the temperature difference between the general background and the object, and converting the received data into a graphic image visible to the human eye.

Another important parameter is the resolution of the matrix. Devices with a large number of sensing elements provide better two-dimensional images than thermal imaging devices with a lower resolution of the detector array.

This difference is explained by the fact that one sensitive cell has a smaller surface area of the object under study. In high-resolution graphic images, optical noise is almost imperceptible.

Ways to display information from a thermal imager

The price of a telescopic examination also depends on the method of transmitting the information received after the examination. There are several options. The first method is called Full IP, which is a full-screen infrared image.

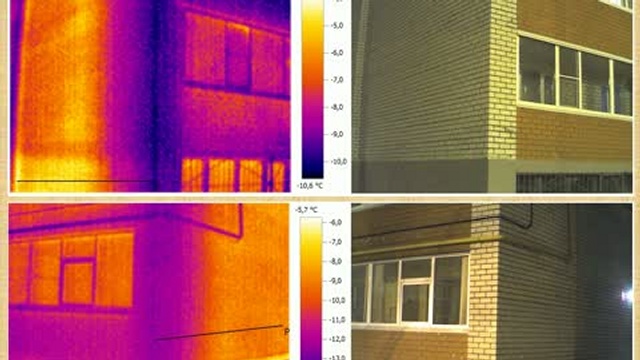

Picture-in-Picture mode creates a picture in a picture. The thermal image is displayed as a normal photograph, making it easier to find an area with low heat levels. The Alpha Blending mode promotes superimposition of normal and thermal photos on top of each other. This feature contributes to a more visual, understandable and informative image.

When using the IR/Visible Alarm mode, you can get an infrared image of those places that are characterized by a temperature that is within the specified range.The remaining areas are displayed as ordinary digital photographs.

An infrared camera can help diagnose a range of problems

To create such pictures as with a digital camera, the Full Visible Light mode will allow. The temperature of the building is not taken into account here. This mode is useful in certain cases. Even some models of budget thermal imagers equipped with a built-in digital camera designed for 3-5 megapixels have this function.

Where is thermal imaging used?

Due to the efficiency and reliability of this method, the scope of its application is quite wide. Now checking with a thermal imager is used not only in private homes. Even various large commercial establishments, factories and enterprises carry out this type of diagnostics of the energy efficiency of buildings. The most important reason, of course, is the quality of the heating system. The audit identifies defects that affect the operation of the system and that need to be corrected. It also helps for the subsequent more economical and efficient organization of the heating system.

At the same time, there are a number of recommendations and features for examining an apartment with a thermal imager.

- The most important recommendation is that the room should be checked immediately before the installation of the heating system. So it is possible to identify and eliminate all errors made during construction in time. Thus, it is possible to save money and identify problems in time, before they make themselves felt.

- During the construction process, such a survey will help to immediately identify possible problems. At this stage, they are easy to eliminate.

- Checking the leak with a thermal imager will help with the repair work. The reports, graphs and scale of indications provided can be used to file a complaint against the developer.

- The installation of the power supply line will be much more efficient and of high quality. After all, the use of an accurate instrument can say much more than a specialist.

This examination of the apartment with a thermal imager solves a number of problems associated with the operation of heating, ventilation systems, as well as the power supply system. It is recommended not only for heat leakage, but also for high humidity. The thermal imager detects problem areas that lead to mold due to condensation or moisture.

What are thermal imaging cameras used for in construction?

An inspection of a cottage, dacha or residential building with a building thermal imager makes it possible to see on the thermogram what is happening inside various objects and structures of the building, without touching them at all. This is called non-destructive testing.

This kind of inspection will show the condition of the heating pipelines in the walls and underfloor heating without opening the plaster or tiles.

Thermal diagnostics is based on the principle of fixing the inhomogeneities of the thermal field, which makes it possible to judge the state of the objects under study.

The unique advantage of modern thermal imagers over other means of control is precisely the ability to look inside objects without violating their integrity. Even a minimal deviation of temperature indicators from the norm will indicate the presence of problems, for example, in the power grid.

Checking a private house with a thermal imager will help solve a variety of problems:

- localize the places of heat leaks and determine the degree of their intensity;

- control the effectiveness of the vapor barrier and detect the formation of condensate on various surfaces;

- choose the right type of insulation and calculate the required amount of heat-insulating material;

- detect leakage of the roof, pipelines and heating mains, leakage of coolant from the heating system;

- check the airtightness of window panes and the quality of installation of door blocks;

- diagnose ventilation and air conditioning systems;

- determine the presence of cracks in the walls of the structure and their dimensions;

- find places of blockages in the heating system;

- diagnose the condition of the electrical wiring and identify weak contacts;

- find the habitats of rodents in the house;

- find sources of dryness / high humidity inside a private building.

A construction thermal imager makes it possible to quickly check the compliance of the parameters of the erected building with technical requirements, evaluate the quality of a real estate object before purchasing it, and diagnose the operation of internal communications.

A survey of the house with a thermographic scanner before the start of laying thermal insulation materials will help to correctly calculate the cost of insulation

And after the completion of the work, thermal imaging will allow you to control the final result and detect installation flaws that create heat loss. The check will also show cold bridges, which can be quickly eliminated in preparation for the winter season.

7 models of thermal imagers for construction Budget options for surveying private houses, cottages and small public buildingsStandard options for surveying apartment buildings, office, retail and small industrial buildings

| 1. RGK TL-80 |

Ideal for: inspections of building envelopes in operation or continuous monitoring of a building under construction. The resolution of the detector of the device is not enough for a full-fledged examination with a report. | 59 920 rubles |

| 2. Testo 865 |

Ideal for: Routine monitoring of HVAC systems. The image enhancement function will help to identify imperceptible defects in communications. | 69 000 rubles |

| 3. FLIR E8 |

Ideal for: Professionals with little experience. The intuitive and minimalistic interface is easy to understand. | 388 800 rubles |

| 4 Fluke Ti32 |

Ideal for: Shooting from any distance and in bad weather. | 391,000 rubles |

| 5 Fluke Tis75 |

Ideal for: shooting from a safe distance and quick reporting without a PC. | 490 000 rubles |

| 6. Testo 890-2 |

Ideal for: Shooting large objects.High-tech filling will help you perform complex examinations. | 890 000 rubles |

| 7 Fluke TiX580 |

Ideal for: filming large industrial sites from various distances. | 1,400,000 rubles |

Checking procedure

The process of conducting research performed with a thermal imager is called an energy audit. It is performed using special equipment. Versions with purely temperature sensors without visualization on the screen are called pyrometers. Thermal imagers have a screen that allows you to visually demonstrate the temperature difference.

When conducting inspections using such equipment, it is very important to follow certain regulations - it is determined by the requirements of GOST R 54852-2011. If the data is subsequently used as an official basis for contacting the technical supervision authorities or the Ministry of Emergency Situations, the management company, the inspection report must fully comply with all established standards

In his work, the specialist not only relies on the measurements obtained, but also compares them with the established standards. Quite strict requirements are also imposed on the energy audit performers themselves. Only highly qualified specialists with a specialized engineering education and a certificate of the necessary admission are allowed to work.

The procedure for conducting thermal imaging studies should be as follows.

- Primary inspection. It is necessary for assessing the object, presumably identifying areas where temperature indicators are the most stable.

- Definition of control points.In the future, they become the basis for mathematical calculations on which the operation of the device is based.

- Measurement of temperature inside and outside the object. Determination of air humidity. When checking outside, the wind speed is also indicated and recorded.

- Immediate shooting with the use of a thermal imager. If a panorama is to be built, all shots capture 10% of the previous frame.

The sequence of actions is applied to all parts and details of the object. The study is carried out by zones, with mandatory frame-by-frame registration of all stages of the survey. Processing of the results of the performed measurements is carried out with the help of computer programs, the correction factors that are relevant for a particular object are necessarily taken into account. Based on the results, the necessary reporting documentation is drawn up with the signature of an expert.

Checking with a thermal imager is not a quick procedure. On average, it takes from 1 to 5 hours. But there are mobile thermal imagers that allow you to quickly identify problem areas.

Rules for using the thermal imager

The main task of a thermal imaging survey is to accurately identify heat losses and defects in the operation of engineering systems, as well as to detect possible weaknesses in a residential facility during the construction phase.

Thermal imaging diagnostics of buildings includes:

- examination in the long-wave infrared region of the spectrum in the range of 8-15 microns;

- building a temperature map of the objects and surfaces under study;

- monitoring of the dynamics of thermal processes;

- accurate calculation of heat flows.

The inspection of a residential facility is carried out both outside and inside the building.In the first case, infrared photography makes it possible to detect gross defects in the infiltration of air flows through the building envelope and defects in thermal insulation. In the second - to identify errors in the functioning of the heating system and the power supply network.

It is better to carry out thermal imaging diagnostics in the cold season, when the temperature difference between the street and the house is more than 10 degrees Celsius

The higher the temperature difference, the more accurate the test results. In addition, in order to obtain correct data, the surveyed residential object must be uninterruptedly heated for at least 2 days. In the summer, it is practically useless to inspect the building with a thermal imager due to the minimal temperature difference.

Checking buildings with thermal radiation receivers shows the distribution of temperature fields over the surfaces of objects or structures at a particular point in time. Therefore, holding shooting with an infrared camera strongly depends on a number of conditions, the observance of which is critical for obtaining correct results.

The operation of the device is affected by strong wind, sun and rain. Under their influence, the house will cool or heat up, which means that the check can be considered ineffective. The examined structures and surfaces should not be in the area of bright direct rays of the sun or reflected radiation for 10-12 hours before the start of thermal imaging diagnostics.

It is recommended to keep door and window blocks in a fixed position for 12 hours before shooting with an infrared camera and during the building inspection process.

Before starting a survey at home, it is necessary to set the basic settings on the device, namely:

- set the lower and upper temperature limits;

- adjust the range of thermal imaging;

- select the intensity level.

Other indicators are regulated depending on the type of thermal insulation, materials of walls and ceilings. The energy audit of a private house begins with checking the foundation, facade and roof of the building.

At this stage, it is very important to conduct a thorough diagnosis, since the areas on the same plane differ significantly and thermal radiation receivers will definitely show this. After checking the external part, they proceed to diagnostic measures inside the residential building

About 85% of all construction defects and malfunctions of engineering systems are detected here.

After checking the external part, they begin diagnostic measures inside the residential building. About 85% of all construction defects and malfunctions of engineering systems are detected here.

Shooting is carried out in the direction from the window blocks to the doors, slowly exploring all the technological openings and walls. At the same time, the doors between the rooms are left open to stabilize the flow of heated air and minimize the likelihood of measurement errors.

Thermal imaging control implies a step-by-step check of different zones of building envelopes, which must be open for shooting with an infrared camera. To do this, you need to free up window sill space, organize unhindered access to skirting boards and corners.

The walls during the internal thermography of the building must be freed from carpets and paintings, peeling off old wallpaper and other objects that prevent direct visibility of the object under study.

It is customary to rent houses equipped with heating radiators only from the outside.Diagnostics of facades is carried out under favorable weather conditions - the absence of wet fog, smoke, precipitation.

How to use the thermal imager correctly

Not every builder can afford to become the owner of such a device as a thermal imager. Such devices are bought by organizations involved in assessing the quality of work performed on the construction of buildings or structures. Checking heat losses with a thermal imager can be performed both independently and with the help of relevant organizations.

If you contact the relevant organization, the cost of research activities will depend on the amount of work and the time spent. Determination of heat loss is carried out outside the buildings and inside. The determination is carried out by an experienced specialist, using an apparatus for determining heat loss. The results of the study are recorded in the form of photographs, which is capable of doing most modern devices. Based on the research, a conclusion is made with the subsequent provision of a report.

It's important to know! Not every day is suitable for determining the heat loss of buildings, which is indicated in the manual for the device. To perform a correct study, work must be carried out in spring or winter.

Moreover, there should be no sun on the day of the study, since sunlight significantly distorts the readings. Differences in temperature values inside and outside buildings should differ by at least 15-20 degrees. If the procedure is carried out indoors, then excess items are removed

To perform a correct study, work must be carried out in spring or winter. Moreover, there should be no sun on the day of the study, since sunlight significantly distorts the readings.Differences in temperature values inside and outside buildings should differ by at least 15-20 degrees. If the procedure is carried out indoors, then extra items are removed.

The use of a thermal imager: what is seen on the screen of the device

What is thermal imaging and where is it used?

The surface of all materials and structures has a certain temperature. Temperature uniformity depends on the integrity of the surfaces, the type of base material. When assessing the surface temperature, it is possible to determine the presence of cracks and defects, the location of hidden networks and pipes inside the walls, damage to electrical wiring and heating systems. And this is not a complete list of areas where thermal imaging inspection can be used.

Regulations

Thermal imaging inspection is a non-destructive method for monitoring the condition of surfaces, materials, networks and structures. This means that there is no need to disassemble or open structures to obtain heat maps.

This is especially important when a current inspection of the object is carried out for possible defects and shortcomings. Receiving information about the state of networks and structures without their analysis, the customer saves money

To conduct thermal imaging surveys and process their results, the following regulations are applied:

- Urban Planning Code of the Russian Federation (download);

- GOST 26629-85 Methods of thermal imaging control (download);

- GOST 23483-79 Non-destructive testing. Thermal View Methods (download);

- PB 03-372-00 Certification rules and requirements for non-destructive testing laboratories (download);

- GOST R 54852-2011 Method for thermal imaging quality control of thermal insulation of enclosing structures (download);

- a number of other standards, regulations.

To conduct a thermal imaging survey and issue official documents, it is not enough to purchase equipment. The reliability and accuracy of checks will be guaranteed if the specialist has passed the appropriate training, received a qualification certificate, a certificate. If these requirements are met, the documents resulting from the surveys can be used for the design and examination of HIFs, as evidence in courts, and for other purposes. The fact that the organization has its own certified laboratory and membership in the SRO will allow the use of documents after a thermal imaging survey in an energy audit. The results of the surveys are used in the design, are indicated in the relevant sections of the project according to Decree No. 87.

in plain language

A thermal imager is a scanner that uses infrared radiation. By scanning surfaces with such devices, specialists obtain a heat map. It can be almost homogeneous (for example, if a one-piece metal structure has no defects and cracks), or heterogeneous (if the surface consists of different materials, is damaged). Obtaining results during a thermal imaging survey is as follows:

- the design, surface or engineering communications that need to be examined are determined;

- equipment is selected, mandatory settings are made (for example, the setting always takes into account the composition and type of materials being examined, the temperature regime in the premises and weather conditions);

- the entire surface or individual sections are scanned;

- specialists receive thermograms of the examined surfaces;

- survey results are processed in the software, reflected in reports and conclusions.

The accuracy of surveys depends on the surrounding temperature and weather conditions.

This is especially important when scanning enclosing structures (for example, the walls of a building). For example, GOST R 54852-2011 states that during surveys and 12 hours before, the object should not be exposed to sunlight.

The difference in temperatures inside the building and premises and outside is also evaluated. Only qualified specialists can ensure proper conditions for thermal imaging inspection.

Professional equipment allows you to see the result of the shooting immediately on the screen, however, to decrypt the data, they need to be processed in software

Rules for using the thermal imager

The main task of a thermal imaging survey is to accurately identify heat losses and defects in the operation of engineering systems, as well as to detect possible weaknesses in a residential facility during the construction phase.

Thermal imaging diagnostics of buildings includes:

- examination in the long-wave infrared region of the spectrum in the range of 8-15 microns;

- building a temperature map of the objects and surfaces under study;

- monitoring of the dynamics of thermal processes;

- accurate calculation of heat flows.

The inspection of a residential facility is carried out both outside and inside the building. In the first case, infrared photography makes it possible to detect gross defects in the infiltration of air flows through the building envelope and defects in thermal insulation. In the second - to identify errors in the functioning of the heating system and the power supply network.

It is better to carry out thermal imaging diagnostics in the cold season, when the temperature difference between the street and the house is more than 10 degrees Celsius

The higher the temperature difference, the more accurate the test results. In addition, in order to obtain correct data, the surveyed residential object must be uninterruptedly heated for at least 2 days. In the summer, it is practically useless to inspect the building with a thermal imager due to the minimal temperature difference.

Checking buildings with thermal radiation receivers shows the distribution of temperature fields over the surfaces of objects or structures at a particular point in time. Therefore, shooting with an infrared camera is highly dependent on a number of conditions, the observance of which is critical for obtaining correct results.

The operation of the device is affected by strong wind, sun and rain. Under their influence, the house will cool or heat up, which means that the check can be considered ineffective. The examined structures and surfaces should not be in the area of bright direct rays of the sun or reflected radiation for 10-12 hours before the start of thermal imaging diagnostics.

It is recommended to keep door and window blocks in a fixed position for 12 hours before shooting with an infrared camera and during the building inspection process.

Before starting a survey at home, it is necessary to set the basic settings on the device, namely:

- set the lower and upper temperature limits;

- adjust the range of thermal imaging;

- select the intensity level.

Other indicators are regulated depending on the type of thermal insulation, materials of walls and ceilings. The energy audit of a private house begins with checking the foundation, facade and roof of the building.

At this stage, it is very important to conduct a thorough diagnosis, since the areas on the same plane differ significantly and thermal radiation receivers will definitely show this.After checking the external part, they proceed to diagnostic measures inside the residential building

About 85% of all construction defects and malfunctions of engineering systems are detected here.

After checking the external part, they begin diagnostic measures inside the residential building. About 85% of all construction defects and malfunctions of engineering systems are detected here.

Shooting is carried out in the direction from the window blocks to the doors, slowly exploring all the technological openings and walls. At the same time, the doors between the rooms are left open to stabilize the flow of heated air and minimize the likelihood of measurement errors.

The walls during the internal thermography of the building must be freed from carpets and paintings, peeling off old wallpaper and other objects that prevent direct visibility of the object under study.

It is customary to rent houses equipped with heating radiators only from the outside. Diagnostics of facades is carried out under favorable weather conditions - the absence of wet fog, smoke, precipitation.

Mobile thermal imager for a smartphone - how real are the readings

Using a special thermal imager module for smartphones is simply an ingenious solution. This is a small device that is inserted into the connector and with the help of special software allows you to turn an ordinary smartphone into a full-fledged thermal imager. In fact, the module itself contains only a detector and hardware that captures a thermal image. And special software already shows this picture to the user.

Thermal imager for Android smartphone

Small compact module has good performance

Small compact module has good performance

The thermal imager module for an Android smartphone looks like a compact webcam. It has a micro-USB plug with which it connects to a phone or tablet. The most popular brand in this industry is Seek Thermal. The range of prices for modules is quite large. In different regions and stores you can find prices from 18,000 to 22,000 rubles. At the same time, the module has very attractive characteristics comparable to full-fledged thermal imagers. The temperature range is from -40ºС to 330ºС. The resolution of the detector is 320 by 240 points. The gadget allows you to use different color schemes, from grayscale to full color images.

Thermal imager for Android smartphone

Thermal imager for iOS smartphone

This is how the module from Flir for iPhone looks like

This is how the module from Flir for iPhone looks like

The company Seek Thermal, already mentioned by us, also produces thermal imagers for Apple products. But for a change, we will look at another brand - Flir and their product - Flir One Gen 3. The cost of the device is approximately 20,000 rubles. Externally, the device is much larger in size than products from Seek Thermal. Inside it has both a temperature detector and a separate simple chamber.

The thermal imager can measure temperature in the range of -20ºС to 120ºС. The measurement accuracy is quite high - 0.1ºС. The resolution of the thermal detector is 80 by 60 points, which is incomparably small. But the resolution that can be displayed on the screen is already 1440 by 1080 pixels. According to the developers, on a single battery charge, the device can last up to 1 hour.

Thermal imager for iOS smartphone

Classification

There are many criteria for classifying thermal imaging equipment. According to the type of execution, they are stationary and portable.A stationary thermal imager is designed to monitor one area, therefore it is installed fixedly in a certain place. For example, in a factory, such a model can be installed to monitor the temperature of objects on a conveyor.

Portable thermal imagers are used in construction, energy, and some industries. They are designed in such a way that they can be moved to various objects of observation. Their weight ranges from 300 g to 2 kg. Different models are equipped with the necessary systems: a screen, optics, built-in cameras, lighting and other headsets. Portable devices have an autonomous battery that provides power to equipment for up to 8 hours.

One of the important features is that all recorded data is stored in the instrument and can then be transferred to a computer for further processing. The files are saved as photos and videos.

You can always find more information in the Study Guide.