- Varieties of diesel heat guns

- Advantages of indirect heat guns

- Unit #3 - gas heat gun

- What is better to choose?

- How to choose a gas gun in the store and what to focus on

- Basic provisions for designing a heat gun

- The main malfunctions of gas heat guns

- Calculation of the power of the device

- Table: dependence of the required power of the gun on the area of \u200b\u200bthe room

- Do-it-yourself gun

- Homemade heater device

- Necessary parts and materials

- Installation of the device for testing

- Tips for Using Heat Guns

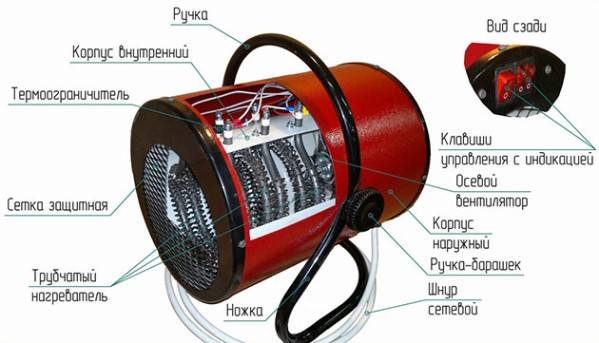

- Electric heat guns

- Diesel fuel design

- Principle of operation

- Assembly Features

- Step-by-step instruction

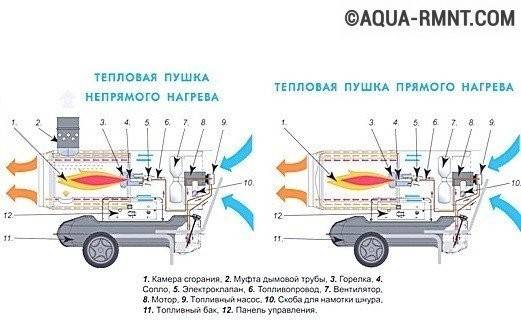

Varieties of diesel heat guns

Guns of this type are also called liquid fuel: they can be used as fuel for both diesel and kerosene or diesel fuel. It is strictly forbidden to use gasoline, alcohol and other flammable liquids to refuel such devices.

Diesel heat guns can be not only mobile, but also stationary. Similar designs have an outlet pipe connected to a chimney through which combustion waste is removed.

The choice of fuel must be approached very carefully, since the use of poor quality or contaminated fuel can clog the nozzle and / or filter, which will require the intervention of repairmen. Diesel guns are characterized by high power, high efficiency, as well as compact size, so that such units are quite mobile.

All units operating on economical diesel fuel can be divided into two types: with direct and indirect heating.

The basis of devices with direct heating is an elementary principle of operation: a burner is arranged inside the body, through the flame of which air blown by a fan passes. As a result, it heats up, and then breaks out, giving off heat to the environment.

Diesel heat gun with open heating cannot be used for residential heating, since its design does not provide for exhaust pipes. As a result, waste substances, including carbon monoxide, enter the room, which can lead to poisoning of people in it.

Such devices are distinguished by high power of 200-250 kW and almost 100 percent efficiency. They are inexpensive, easy to install, but they have an important drawback: not only warmed air flows into the outer space, but also combustion products: soot, smoke, fumes.

Even good ventilation will not be able to completely rid the air of unpleasant odors and the smallest particles, and if it is completely absent, living beings in the room can get severe poisoning.

A device with indirect heating is much more complicated.In such models, the air is heated indirectly, through a special chamber - a heat exchanger, where heat is transferred to the air flow.

Diesel heat guns with indirect heating have a higher cost and lower efficiency compared to similar products with a direct heat source. However, they are widely used due to the best indicators of environmental friendliness and safety.

In such units, the heated exhaust gases, together with the heat, enter the heat exchanger, from where they are discharged into the smoke channel, to which a special pipe is connected. With its help, the products of combustion are removed from the closed space to the outside, providing fresh air in the heated room.

Advantages of indirect heat guns

Particular attention of consumers, primarily owners of garages, is used by heat guns with indirect heating. Models of diesel heat guns with high power may have large dimensions

They are used for heating large premises: warehouses, factory floors

Models of diesel heat guns with high power may have large dimensions. They are used for heating large premises: warehouses, factory floors

The advantages of such models include:

- Mobility. Although the dimensions and weight of such devices are somewhat larger than those with open heating, they are still quite compact in size, which allows them to be transported around the room within the length of the connecting element and the chimney.

- Great power. Although this figure is higher for devices with direct heating, the power of indirect diesel guns is enough to heat a large area in a short time.

- Reliability.Such devices have a well-thought-out design, which minimizes the risk of fire, and also increases the durability of the guns.

- Many factory models have a special protection system that automatically turns off the gun immediately after the room temperature reaches the set point.

- Factory-made products are equipped with thermal insulation pads to prevent heat build-up in the case, reducing the risk of burns to the user.

- On some models, tanks of large volumes are provided, which allows them to be used for a long time without thinking about fuel.

The disadvantage of such structures can be considered a high noise level, especially for high-power units.

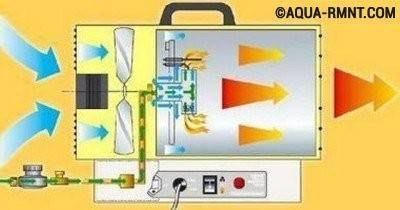

Unit #3 - gas heat gun

The design of a gas heat gun is in many ways similar to the design of a diesel unit. It also has a combustion chamber built into the body. Instead of a tank with liquid fuel, a liquefied gas cylinder is used.

As with diesel fuel, the removal of combustion products is of great importance, since it is impossible to ensure complete combustion of gas in home-made devices. The air that enters the room is heated by contact with the combustion chamber. Exhaust gases leave the device through a branch led to the street. This indirect heating system is safer than open flame heating.

Indirect heat guns are equipped with a closed combustion chamber that prevents contact between open fire and air - this design is more complicated, but safer than direct models

To increase heat transfer, longitudinal plates can be welded to the combustion chamber body, usually 4-8 of them are made.At the same time, the dimensions of the combustion chamber with additional plates must be smaller than the diameter of the body so that the chamber does not touch its walls and does not overheat the body of the heat gun.

The body of a gas heat gun gets very hot during operation, so it must be covered with a layer of thermal insulation to avoid possible burns or fire.

To create a gas heat gun, you will need the following elements:

- liquefied gas cylinder;

- burner;

- reducer;

- metal case;

- fan;

- device for remote ignition;

- frame for mounting the body.

The gas cylinder is connected to the reducer, which ensures a uniform supply of fuel to the burner. The air around the combustion chamber is heated, the fan blows it into the room. The procedure is almost the same as in the manufacture of a diesel heat gun. The device of a gas heater is clearly shown in the diagram:

This diagram clearly demonstrates the device of a heat gun operating on liquefied household gas. The fan must be powered

With a gas heat gun, only cylinders that are filled with gas on professional equipment should be used. Do-it-yourself cylinders may leak

In the time of manufacture and operation of the gas heat gun is recommended to adhere to the following rules:

- The gas supply pipes at the joints must be carefully sealed.

- It is mandatory to install a remote ignition device, since manual ignition can lead to an explosion.

- Make sure that the gas ball is always at a sufficient distance from the heater, otherwise the bottle will overheat and the gas will explode.

- Never use hand-made cylinders with a gas gun.

- Do not leave a working device unattended for a long time.

Another important point is the ratio of the power of the gas gun and the size of the heated room. Do not use a device that is too powerful in a small room, as this can easily lead to a fire.

What is better to choose?

An electric convector, a fan heater, an oil heater look like much more familiar solutions for heating a house than a heat gun. That's just to use them as the main heating device will not work.

The choice of a heat gun is usually due to the need for rapid heating of large rooms that are not heated on a permanent basis. To dry the basement, to ensure the correct temperature for drying the concrete screed, to maintain a comfortable atmosphere in a greenhouse or country house - such heat engineering will cope with these tasks 100%. In winter, electric heat guns are used by repairmen, and in the garage they can quickly warm up the air if you need to “defrost” the car.

Heat guns, when used on an ongoing basis, are much more expensive to operate. Compared to oil heaters, they consume energy 3-5 or more times more intensively. Such a purchase will be profitable only if there are no other heating alternatives.

How to choose a gas gun in the store and what to focus on

When choosing a gas gun for domestic use, you should first of all pay attention to the following parameters:

- Power.It is measured in kW, sometimes manufacturers additionally indicate the volume of heated air for 1 hour of operation. In the first case, the formula is followed: 1 kW per 10 m2 is a minimum. Secondly, it is necessary to calculate the total volume of the room planned for heating with a gun and divide the resulting figure by 2. This will give the minimum power of the gun, with which the room can be heated in 30 minutes of continuous operation of the heater. For example, the heated volume of air with a gun is 300 m3. Accordingly, it is optimally suited for a room with a volume of 150 m3 (volume and area should not be confused - these are completely different indicators).

- Connection type. Meaning, with a closed or open burner. The first ones are more expensive and they are used for "emergency" heating of residential premises. For other purposes, you should not buy them. Open - the best option for garages, sheds, warehouses and other non-residential premises.

- The presence of auto arson. Basically, the function is optional. Moreover, piezo elements quickly fail, but at the same time their presence increases the cost of the gun by almost 10 - 20%.

- Availability of additional features. This means adjusting the fan speed, a system of sensors, temperature controllers, and so on. All of them help to automate the operation of the gun, but at the same time, manufacturers do not recommend leaving heaters of this type operating without supervision. And the presence of those same sensors also increases the cost of the final cost of the device. If you need to save money, you can buy a gun without all these sensors.

- Fan power. It is found either from 220V or from 12V DC.The latter option is convenient in that the gun can be used as a mobile one by launching it even in the absence of a household power supply. If such functionality is not needed, then it is better to take it with the simplest 220V engine. Even better - without brushes (such motors are very reliable and durable, but they are quite expensive).

The principle of operation of a gas gun

Table 1. Key parameters of gas guns to consider when buying.

| Power | Not less than 1 kW per 10 m 2 of heated space |

| The type of gas that the gun runs on | Methane - for connecting to a household gas network, propane - for cylinders. There are also “universal” guns, but they are expensive, and often break down due to a complex technical design (2 separate valves work there simultaneously) |

| Auto arson | It is recommended to take without auto-ignition - such models are cheaper, their launch is not dangerous |

| Availability of additional sensors | Not necessary. Most of them will not be used by anyone - proven in practice |

| Fan motor power supply | With support for connecting to 12V, buy if the heater will be used as a mobile one. In other cases - only 220V |

| Closed or open burner | Closed - for heating residential premises, open - for all others |

The option of using gas guns is for mounting stretch ceilings. Under the influence of high temperature, the PVC fabric is easily stretched, it does not leave wrinkles and dents.

Basic provisions for designing a heat gun

To design a heat gun yourself, you need to find a large-diameter pipe. Then, a little at the two ends on opposite sides, make two holes: one large caliber, the second small.The final products of combustion will exit through the large one, and fuel will flow through the small one. Then it is necessary to install a combustion chamber with an automatic catalyst, which will bring the gas mixture to a burning state.

It is very important to observe a high degree of tightness throughout the structure in order to avoid leakage. Then you need to attach the fan to the end of the pipe, where the small-caliber hole is located, and the design is ready.

How to do electric heat gun - this question is not difficult, the main thing is to properly observe the safety rules when using it

This position is especially important for a tank with a gas mixture, it must be at least a meter away from other items in the room. If possible, it is advisable to temporarily remove very flammable materials while using a homemade heating device.

Because warm air can catalyze many chemical reactions.

A do-it-yourself electric heat gun does not require specialized skills or professional knowledge, and what is even more important is the absence of any material costs for design. However, when building, it is very important to observe the points that are indicated in the drawing.

(See also: Heating do-it-yourself greenhouses)

A home-made heat gun of the electric type allows you to properly provide heat to a large area.

Since from a practical point of view there is a double heating. The first source of heat is simple warm air, while the second source is a gas mixture, after the combustion of which a sufficiently significant amount of heat is released.

This design is mainly used for heating rooms in which, due to circumstances, it is impossible to ensure proper tightness, for example, repairs in the winter season. An electric-gas gun is mainly used for heating rooms that have a large footage or for quickly heating small residential areas.

For the manufacture of a diesel heat gun, you will need a number of components, namely:

- the combustion chamber;

- diesel fuel tank;

- large-caliber metal pipe;

- catalyst;

- fan.

First you need to make a hole at the two ends of the metal pipe: one large and one small. Then it will be necessary to mount the catalyst in the combustion chamber in the metal pipe itself. In no case should you start designing without having a plan for the future design, since in this case it will either not be possible to assemble the unit, or its final work will simply be energy inefficient. (See also: DIY gas-fired oven)

The smallest diesel heat gun is mainly used for heating a small room and its main advantage is efficiency. The main feature of its design is the use of a small metal pipe and the absence of a fuel tank. That is, such a unit functions solely by converting cold air into warm air. The main thing to remember is that the fan must always have a separate power source in order to avoid a short circuit in the mains.

To build a diesel heat gun, it is necessary to determine the footage of the future room, as well as take into account the degree of air insulation of the room where it is planned to use the future thermal unit. From a practical point of view, it is possible to determine the degree of air insulation by only one parameter: air ventilation is noticeable or not. Depending on this, you need to plan the future design. If the room is sufficiently insulated, then the gas mixture can be dispensed with and, consequently, the energy costs will be much lower.

Often many people ask the question, how to make a diesel heat gun on your own? The answer is very simple, it is paramount to draw up your own plan, and then carefully implement it point by point. The most common practical mistake of many people is just the same non-compliance with all points of the plan or lack of due attention. If you started designing, then take your time, otherwise you will have to redo it many times. The pipe must be wrapped with copper wire to ensure the proper functioning of the self-made heating device.

The main malfunctions of gas heat guns

Most gas gun malfunctions can be completely eliminated on your own, without contacting a workshop. Most often they fail:

- fan;

- piezoelectric element;

- burner;

- protection elements.

Typically, owners of these devices are faced with the following problems:

- Unable to ignite gas. This is how the piezo element malfunctions. It should be cleaned, and if this procedure did not help, then replace the part with a new one.

- The gas does not enter the combustion chamber. The cause of this malfunction is a clogged burner.The problem is solved by blowing the burner with a powerful air jet.

- There was a smell of gas. This problem is usually related to gas leaking from the hoses. Either tightening the fasteners or replacing the hoses is required. The easiest way to detect gas leaks is to use a soapy solution.

- Gas consumption has increased - the gearbox needs to be replaced.

- When the burner burns, warm air does not enter the room - the fan should be checked for proper operation. If there is a power supply and the contact group is in good condition, it must be replaced.

The purchase of a gas heat gun equipped with all the necessary safety features will cost the buyer a substantial amount. Such an acquisition justifies itself with the constant need to heat large areas.

Therefore, many people make heat guns that run on gas fuel on their own. In this case, it should be remembered that such devices should not be left to work unattended under any circumstances.

How to make an indirect gas heat gun do-it-yourself heating find out from the video below:

Calculation of the power of the device

In order for the gun to be as efficient as possible in your room, you first need to calculate the minimum power of the device using the formula.

Qt=V×∆T×K/860, where

- Qt - the minimum power of the heater in kW / h;

- V is the volume of the heated room in m3;

- ∆T is the difference between the minimum outdoor temperature and the required indoor temperature in °C;

- K - heat loss coefficient:

- 3.0 - 4.0 if the building is not thermally insulated;

- 2.0–2.9 if there is ineffective thermal insulation;

- 1.0–1.9 with medium-level thermal insulation (walls 2 bricks thick, few windows, simple roof without openings);

- 0.6–0.9 if the thermal insulation is good (the walls are insulated, there is a contour seal of doors and windows, double-glazed windows).

If your premises are not industrial (the ceiling height is not higher than 3 m), you can use the data from the table.

Table: dependence of the required power of the gun on the area of \u200b\u200bthe room

| Heat gun power, kW | The volume of premises in the new house, m3 | Room volume in the old building, m3 | Area of a modern greenhouse with heat-insulated glass, m2 | Area of a glass greenhouse without thermal insulation, m2 |

|---|---|---|---|---|

| 5 | 70–150 | 60–110 | 35 | 18 |

| 10 | 150–300 | 130–220 | 70 | 37 |

| 20 | 320–600 | 240–440 | 140 | 74 |

| 30 | 650–1000 | 460–650 | 210 | 110 |

| 40 | 1050–1300 | 650–890 | 300 | 150 |

| 50 | 1350–1600 | 900–1100 | 370 | 180 |

| 60 | 1650–2000 | 1150–1350 | 440 | 220 |

| 75 | 2100–2500 | 1400–1650 | 550 | 280 |

| 100 | 2600–3300 | 1700–2200 | 740 | 370 |

| 125 | 3400–4100 | 2300–2700 | 920 | 460 |

Do-it-yourself gun

The design of the heat gun is quite simple, therefore, having certain work skills, you can try to assemble such a unit yourself.

Homemade heater device

To perform the device yourself, you can use a simplified scheme of the heat gun. At the bottom of the structure is a fuel tank, above which there is a fan and a working chamber. Fuel is supplied to the latter, while the fan blows hot air into the room.

A self-made thermal device for testing will cost much less than purchased in a store, but its technical characteristics are slightly lower

In addition, the device provides for a pump, a filter and a connecting tube through which fuel passes, a nozzle for the exit of combustion products, a pipe for heated air and a number of other elements.

Necessary parts and materials

Before starting work, stock up on materials or finished components of the device.

In the manufacture of a waste oil thermal heater, a sawn off part of an old gas cylinder can be used as a body

The body of the heat gun, for which it is necessary to use thick-walled metal. As this part, for example, a pipe section of a suitable size or another suitable product is suitable. You can also make a case from a sheet of thick stainless steel (3-4 mm) by welding a seam.

The combustion chamber. A metal cylinder is suitable for this part, the diameter of which is half that of the same indicator of the body.

Fuel tank. This element is a bowl made of a material with low thermal conductivity. An ordinary metal tank, carefully closed with a heat insulator, is also suitable.

The fan, which is necessary for the device of a thermal device for working out, can be purchased at a store or use an existing device, provided that it is in good condition

Fan. To ensure simplicity and reliability of the design, it is preferable to use a reliable and economical 220 volt vane fan, which is easy to use and durable.

There are several articles on our website in which we examined in detail how to build a heat gun with our own hands. We recommend reading them:

- Heat gun on different types of fuel.

- Heat gun on waste oil.

- Diesel heat gun.

- Thermal gas gun.

Installation of the device for testing

First of all, you should take a pipe, cylinder or other outer shell of the device.

Below is a heater and a fuel tank, which must be separated from the top of the device at a distance of 15 cm. To make this part of the device look neater, it can be hidden in a metal box.

A combustion chamber is installed in the center of the free space, for which a galvanized pipe can be used. On both sides, the compartment is sealed, after which holes are made in it for the nozzle and chimney. The combustion chamber is firmly fixed to the walls of the housing. It is desirable to equip the working compartment with a piezo ignition, and also connect a fan to it.

Next, you need to install a fuel pump with a nozzle, adding a filter between these parts

It is also important to organize an outlet pipe from the tank through which the waste will enter the fuel filter and nozzle.

It is also necessary to resolve the issue of the fan power supply. If there is an electrical outlet within reach, this item can be plugged into an outlet

In its absence, you will have to use the battery.

At the end, it is necessary to cover the holes located at the top with nets.

Tips for Using Heat Guns

Experts recommend paying attention to the following points in the production of heating devices:

- When operating the device, you should follow the safety rules: remember that at a distance of 1 meter from the device, the temperature of the heated air jet can reach 300 °C.

- To warm up a room of 600 square meters, only 10 liters of fuel are enough.

- It is necessary to clean the evaporation bowl, removing slag from mining, once after 20-50 hours of operation of the device.

- Water must not be allowed to enter the fuel cell along with used oil or other fuel. If a large amount of this liquid enters the tank, the burner may go out.

You should also not forget about fire safety rules: it is better not to leave home-made thermal devices unattended, and also to have a fire extinguisher or other fire extinguishing device within reach.

Electric heat guns

These heating units are the simplest and most inexpensive, besides, they do not emit any harmful substances. AT as a heating element they use an air heater of a special shape, repeating the roundness of the body.

In fact, the “barrel” of such a gun is empty from the inside, at one end there is an axial fan, and on the other side, where the air comes out, there is an electric heating element. In more powerful models, several heaters are installed. The device can be used in any enclosed space, the main thing is that they have a source of electricity.

Electrical appliances are much easier to operate than gas appliances. Therefore, the electric heat gun is equipped with a step-by-step power regulator and overheating protection, and can also be powered by 220 and 380 V networks. Due to this simple design, an electric fan heater is most suitable for both self-production and for use in the household.

If you carefully study the device of diesel and gas fan heaters, it will become clear that it is not easy to make them at home. And even then, it will be possible to collect direct heating gun, but it will be difficult to make an efficient heat exchanger for separating flows. True, some home craftsmen solve this issue with the help of 2 pipes placed one inside the other, but such a design is ineffective and will throw a lot of heat into the chimney.

But almost anyone can make a heat gun with their own hands if it runs on electricity. For this you will need:

- thin sheet metal for the manufacture of the case;

- nichrome heating coil;

- a small electric motor or a ready-made axial fan of a suitable size;

- insulating pads for fastening the spiral. Can be independently cut from asbestos;

- terminals, wires, switches.

The power of the unit will depend on the spiral, so it should be selected according to the resistance. For example, if we need 3 kW of heat, then the current flowing through the coil will be 3000 W / 220 V = 13.6 A. Then, according to Ohm's law, the resistance of the coil should be 220 V / 13.6 A = 16.2 Ohm. After selection, it is attached inside the case using insulating blocks. The metal case can be made from two pre-bent halves, fastening them together with self-tapping screws. An axial fan is placed at the end of the resulting pipe.

The heating element and the fan are connected to the network through switches, after which the heater is ready for operation. But such a home-made heat gun is too primitive and cannot be adjusted, in addition, the spiral actively burns oxygen. Advanced users with knowledge in electrical engineering can use air heating elements of the required power with thermostats instead of nichrome. You can also add step control to the unit if you turn on the heating elements in turn.

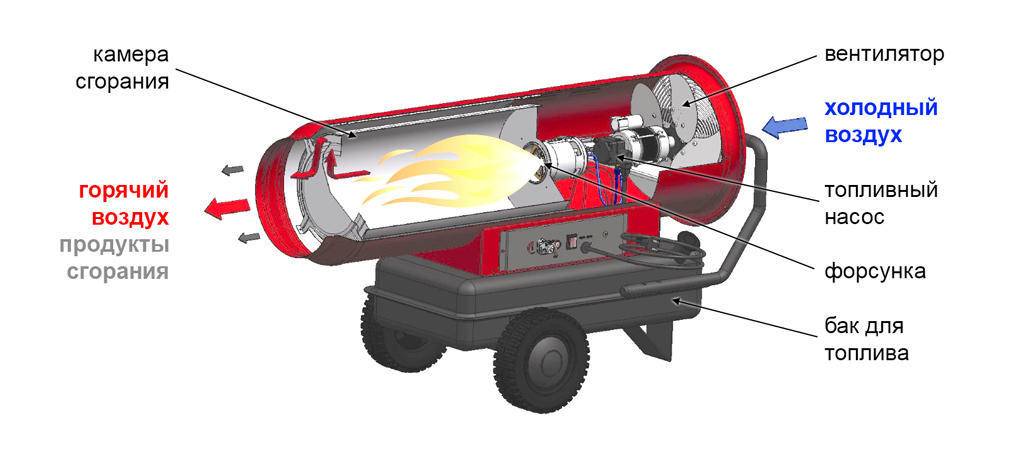

Diesel fuel design

In areas where access to power is impossible or limited, it is optimal to make a diesel heat gun with your own hands.This equipment is a little more difficult to make on your own, unlike the electrical counterpart, since you will need to make two cases and use welding. It takes about 15 liters of fuel to heat a room of approximately 700 m².

Principle of operation

The bottom element in this design is the diesel fuel tank. A gun is directly installed on top, in which there is a fan and a combustion chamber. Fuel enters the chamber, and the fan transmits heated air. To ignite and transfer fuel, a fuel pump, connecting hose, nozzle and filter will be needed. An electric motor is connected to the fan.

Read more: diesel heat guns for heating.

The combustion chamber is installed in the center at the top of the body. This is an iron cylinder with a diameter approximately 2 times smaller than the diameter of the body. The products of fuel combustion are removed from the chamber using a vertically installed pipe.

Assembly Features

The lower part must be located at a distance of at least 20 cm from top corps. So that the fuel container does not heat up excessively, it must be made of a material with low thermal conductivity. You can also choose a conventional metal tank, which must be covered with a heat-insulating layer.

The upper part must be made of thick metal. A piece of metal pipe will do. In the case you need to place:

- fan with electric motor;

- nozzle with fuel pump;

- combustion chamber with a pipe for the output of combustion products.

After that, a fuel pump is attached, and a metal pipe is brought to the tank, with the help of which fuel is supplied first to the fuel filter, and then to the nozzle.Protective nets are installed along the edges of the upper body. You need to think about the power supply for the fan to work first. If access to the mains is limited, a rechargeable battery can be used.

During the operation of a diesel heater, safety precautions must be observed. Even at a distance of one meter, the hot airflow can reach 450 degrees. It is not advised to use this device in enclosed spaces, as the combustion products of diesel fuel are dangerous to humans.

In addition to heaters that run on diesel fuel, other combustible materials are also used for guns, for example, engine oil.

Step-by-step instruction

The first step is to make the body. You can use sheet steel with a thickness of 3-4 mm or a regular pipe. The sheet must be given the required parameters, and then it must be rolled into a pipe. The edges are fixed with bolts or a special connecting lock.

After that, the pipe is sawn, which is used for gas supply. This is necessary so that later it will be possible to weld the next element to it.

Homemade gas gun:

Now you need to increase the diameter of the hole, which is intended for the flow of gas into the system. You need to bring it up to 5 mm.

Then the heat exchanger is made. A metal pipe with a diameter of 80 mm is taken. The end must be welded to the wall of the burner and a hole drilled. The torch extension passes through this element.

To exit the heated air in the heat exchanger housing, you need to make a hole. Then, in that place, weld a tube with a diameter of 8 cm.

Then a fan is installed that will distill the hot air. You also need to provide for the supply of electricity.You can connect it to the mains or battery.

Finally, you need to drill holes for igniting the gas. It is also necessary to provide for the structure on which the heat gun will be located. You can use a ready-made stand or weld from reinforcement.

Heat gun. do it yourself: