- Description and use of units

- Do-it-yourself gun

- Homemade heater device

- Necessary parts and materials

- Installation of the device for testing

- Tips for Using Heat Guns

- Electric heat guns

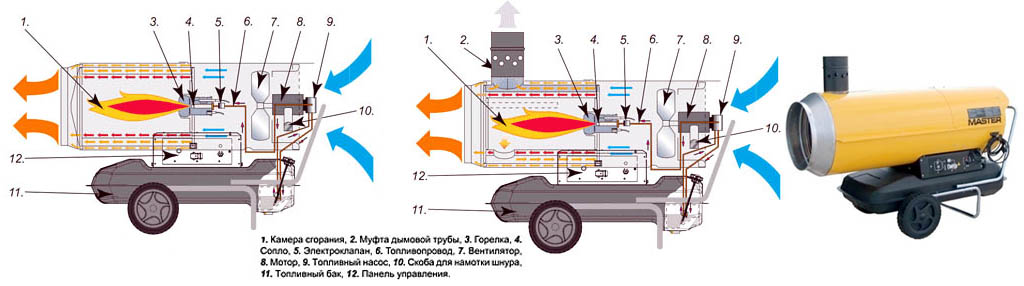

- Device and principle of operation

- Heating level adjustment

- Safety

- Comments 79

- Calculation example

- Step-by-step instruction

- Important details, safety rules

- Varieties of gas heat guns

- Manufacturers of heat guns in development

- Kroll - truly German quality

- Master is a company with half a century of experience

- EnergyLogic - waste oil heaters

- Hiton - budget devices

- How to make your own heat gun

Description and use of units

Heat guns create a stream of hot air, dispersed throughout the room with a fan built into its body. This method of heating compares favorably with others. Here are some of the advantages of heat guns:

- Environmentally friendly - the electric motor does not produce hazardous waste that occurs when combustible substances are burned. The oxygen content in the heated air practically does not decrease. Since there is no open flame, the device is considered fireproof.

- Ease of use - the heat gun does not need to install complex electrical equipment and other conditions, for example, hoods.You just need to plug it into the electrical network using a regular outlet with the required voltage.

- Small size - despite the shape of the body, the gun is quite compact when compared with other heating devices that run on gas or diesel fuel. It easily fits in the trunk of a car, and it can be freely transported, for example, to the country.

- Lack of noise - during operation, the heat gun does not make loud sharp sounds. Their level, as a rule, does not exceed 35055 dB. The upper figure of this range is considered the normal noise level for office work.

Heat guns are very practical due to their size and weight.

Do-it-yourself gun

The design of the heat gun is quite simple, therefore, having certain work skills, you can try to assemble such a unit yourself.

Homemade heater device

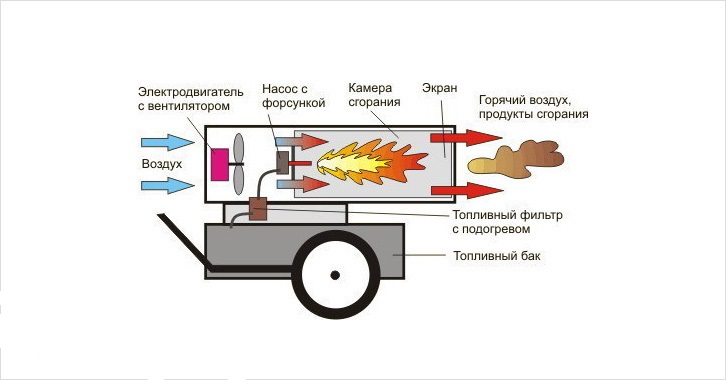

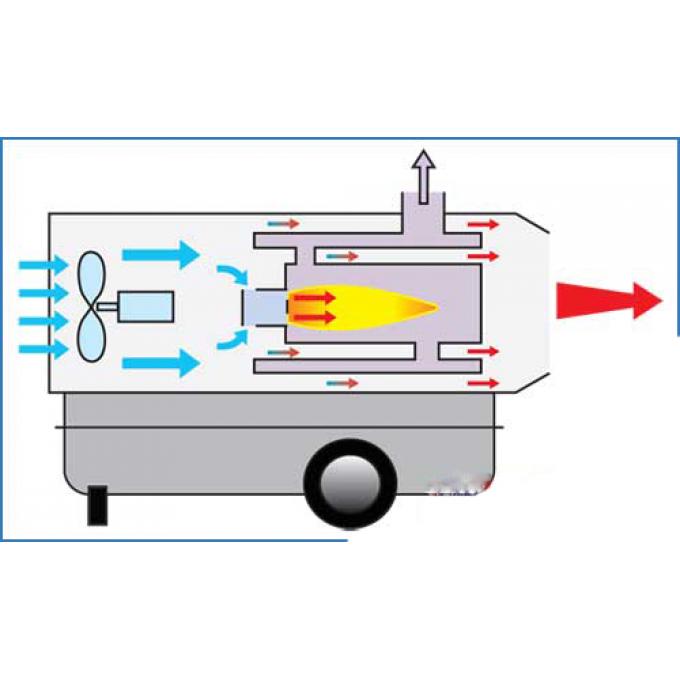

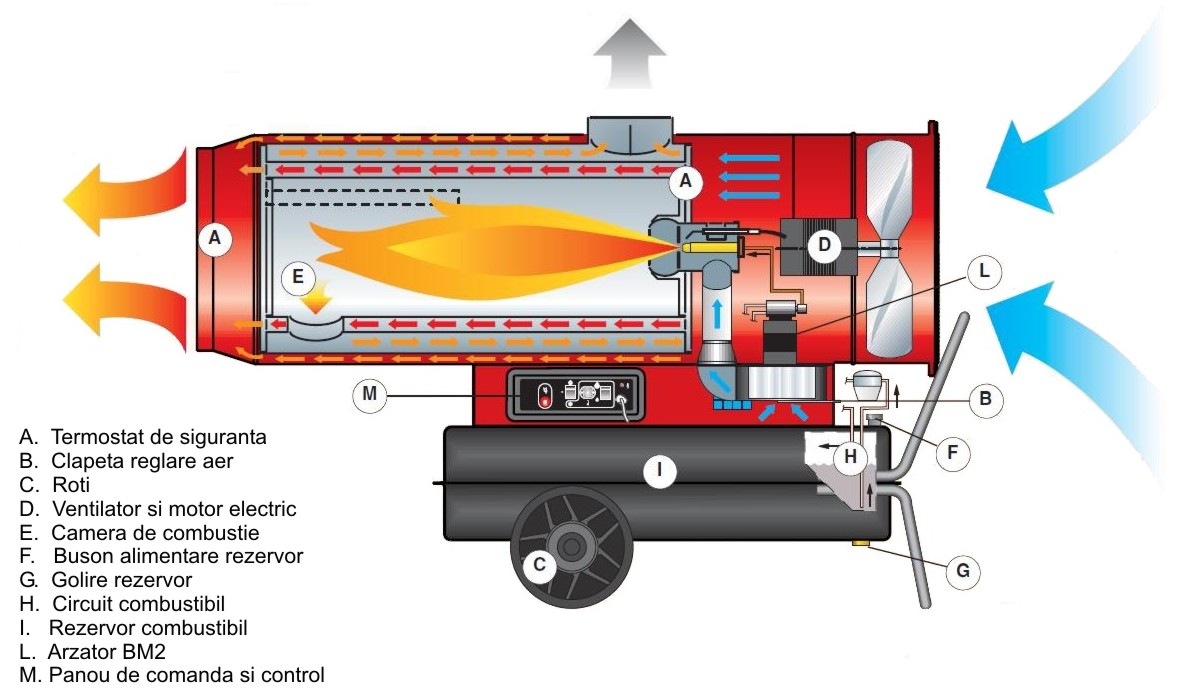

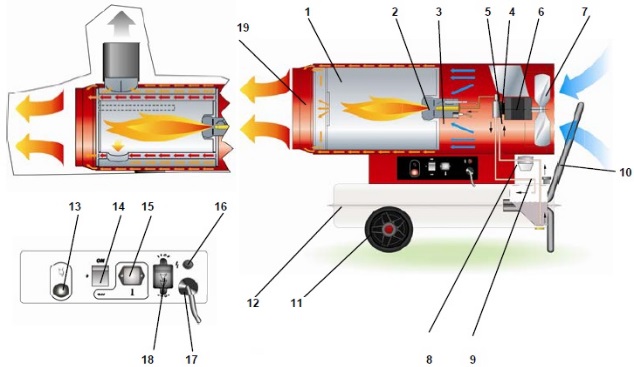

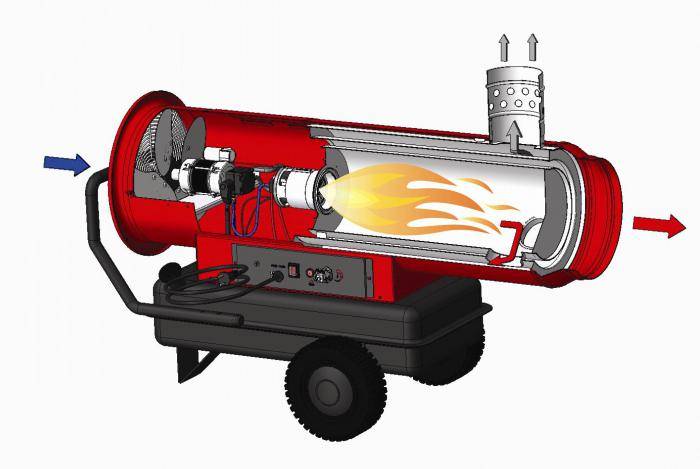

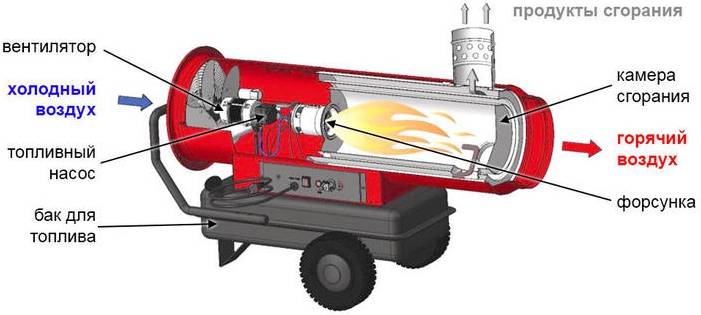

To perform the device yourself, you can use a simplified scheme of the heat gun. At the bottom of the structure is a fuel tank, above which there is a fan and a working chamber. Fuel is supplied to the latter, while the fan blows hot air into the room.

A self-made thermal device for testing will cost much less than purchased in a store, but its technical characteristics are slightly lower

In addition, the device provides for a pump, a filter and a connecting tube through which fuel passes, a nozzle for the exit of combustion products, a pipe for heated air and a number of other elements.

Necessary parts and materials

Before starting work, stock up on materials or finished components of the device.

In the manufacture of a waste oil thermal heater, a sawn off part of an old gas cylinder can be used as a body

Heat gun body, for which it is necessary to use thick-walled metal. As this part, for example, a pipe section of a suitable size or another suitable product is suitable. You can also make a case from a sheet of thick stainless steel (3-4 mm) by welding a seam.

The combustion chamber. A metal cylinder is suitable for this part, the diameter of which is half that of the same indicator of the body.

Fuel tank. This element is a bowl made of a material with low thermal conductivity. An ordinary metal tank, carefully closed with a heat insulator, is also suitable.

The fan, which is necessary for the device of a thermal device for working out, can be purchased at a store or use an existing device, provided that it is in good condition

Fan. To ensure simplicity and reliability of the design, it is preferable to use a reliable and economical 220 volt vane fan, which is easy to use and durable.

There are several articles on our website in which we examined in detail how to build a heat gun with our own hands. We recommend reading them:

- Heat gun on different types of fuel.

- Heat gun on waste oil.

- Diesel heat gun.

- Thermal gas gun.

Installation of the device for testing

First of all, you should take a pipe, cylinder or other outer shell of the device.

Below is a heater and a fuel tank, which must be separated from the top of the device at a distance of 15 cm.To make this part of the device look neater, it can be hidden in a metal box.

A combustion chamber is installed in the center of the free space, for which a galvanized pipe can be used. On both sides, the compartment is sealed, after which holes are made in it for the nozzle and chimney. The combustion chamber is firmly fixed to the walls of the housing. It is desirable to equip the working compartment with a piezo ignition, and also connect a fan to it.

Next, you need to install a fuel pump with a nozzle, adding a filter between these parts

It is also important to organize an outlet pipe from the tank through which the waste will enter the fuel filter and nozzle.

It is also necessary to resolve the issue of the fan power supply. If there is an electrical outlet within reach, this item can be plugged into an outlet

In its absence, you will have to use the battery.

At the end, it is necessary to cover the holes located at the top with nets.

Tips for Using Heat Guns

Experts recommend paying attention to the following points in the production of heating devices:

- When operating the device, you should follow the safety rules: remember that at a distance of 1 meter from the device, the temperature of the heated air jet can reach 300 °C.

- To warm up a room of 600 square meters, only 10 liters of fuel are enough.

- It is necessary to clean the evaporation bowl, removing slag from mining, once after 20-50 hours of operation of the device.

- Water must not be allowed to enter the fuel cell along with used oil or other fuel. If a large amount of this liquid enters the tank, the burner may go out.

You should also not forget about fire safety rules: it is better not to leave home-made thermal devices unattended, and also to have a fire extinguisher or other fire extinguishing device within reach.

Electric heat guns

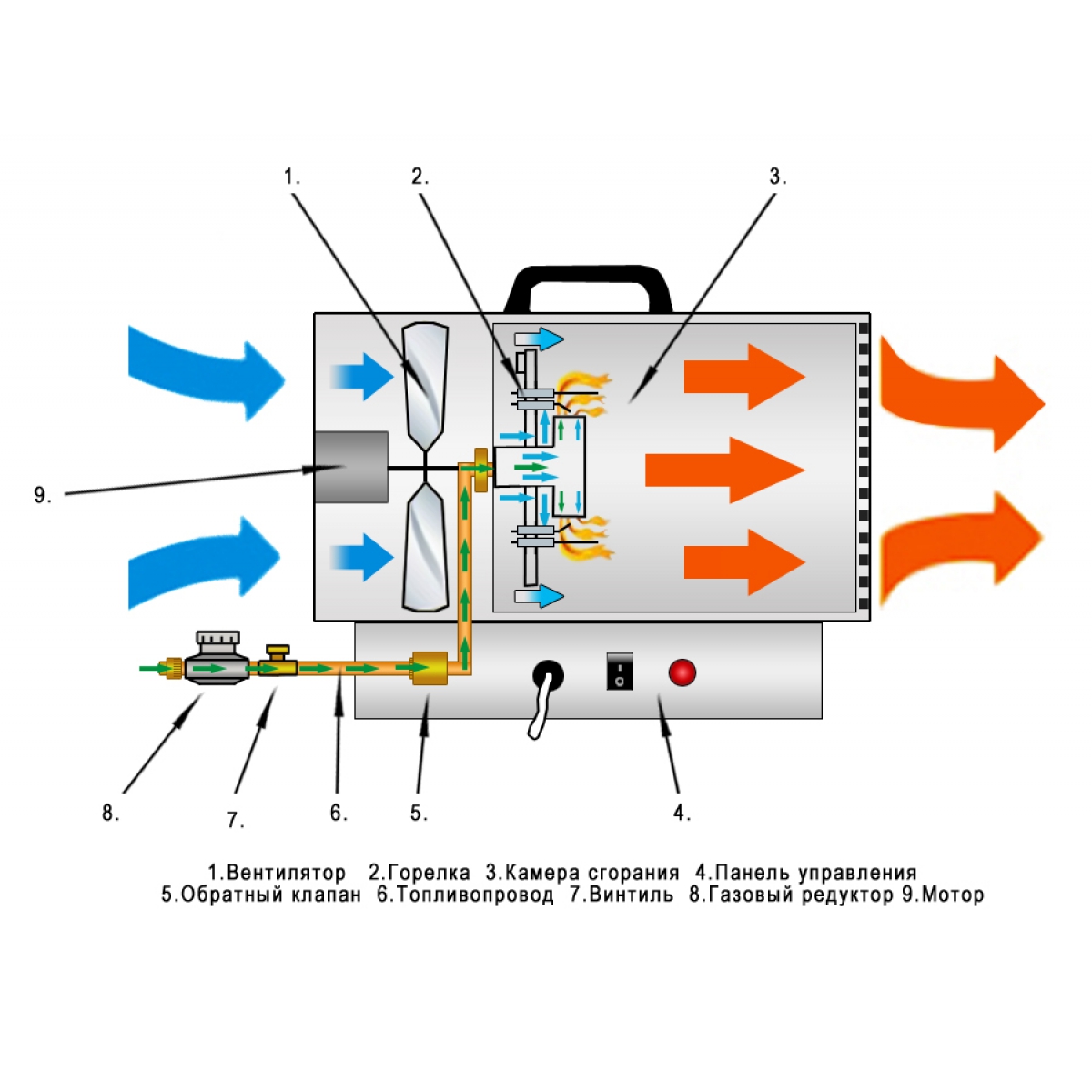

These heating units are the simplest and most inexpensive, besides, they do not emit any harmful substances. As a heating element, they use an air heater of a special shape, repeating the roundness of the body.

In fact, the “barrel” of such a gun is empty from the inside, at one end there is an axial fan, and on the other side, where the air comes out, there is an electric heating element. In more powerful models, several heaters are installed. The device can be used in any enclosed space, the main thing is that they have a source of electricity.

Electrical appliances are much easier to operate than gas appliances. Therefore, the electric heat gun is equipped with a step-by-step power regulator and overheating protection, and can also be powered by 220 and 380 V networks. Due to this simple design, an electric fan heater is most suitable for both self-production and for use in the household.

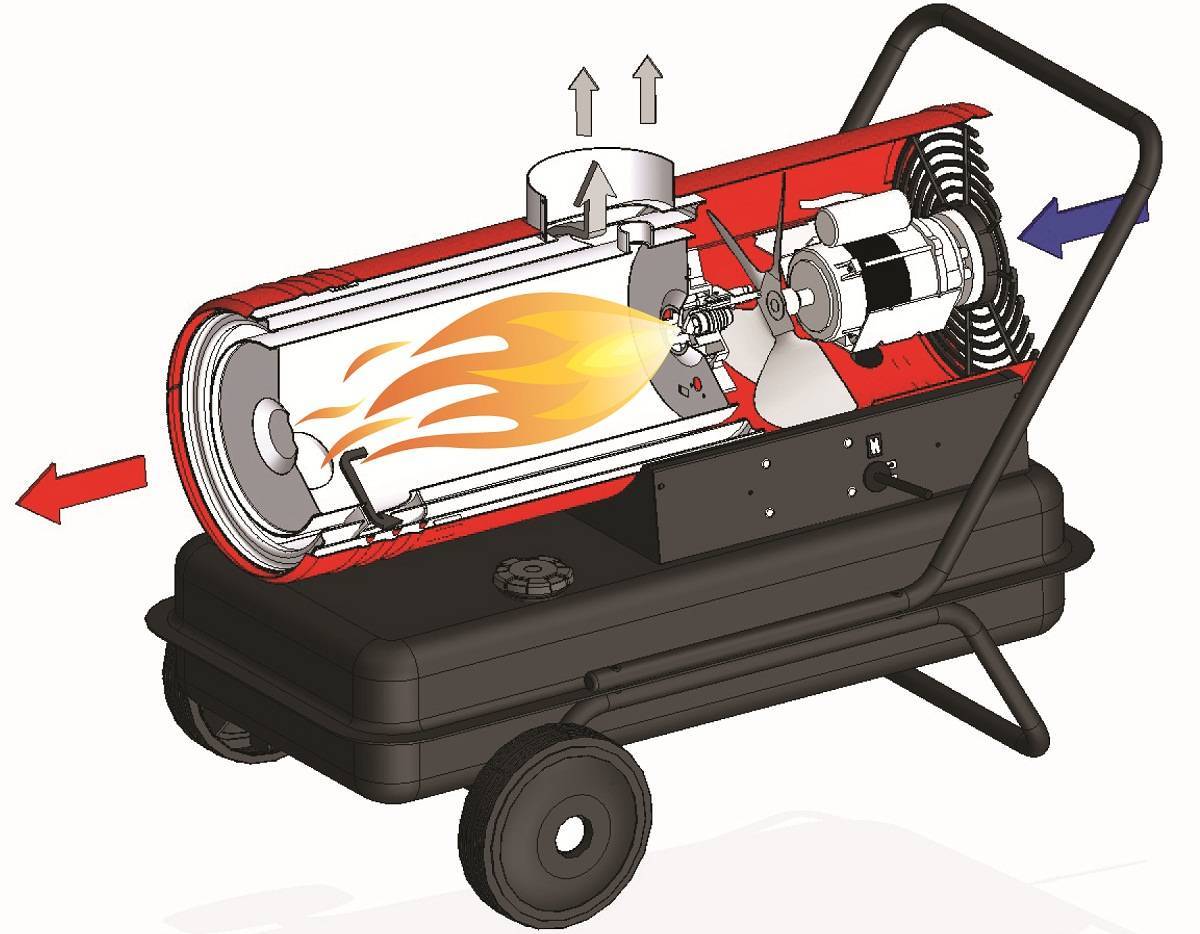

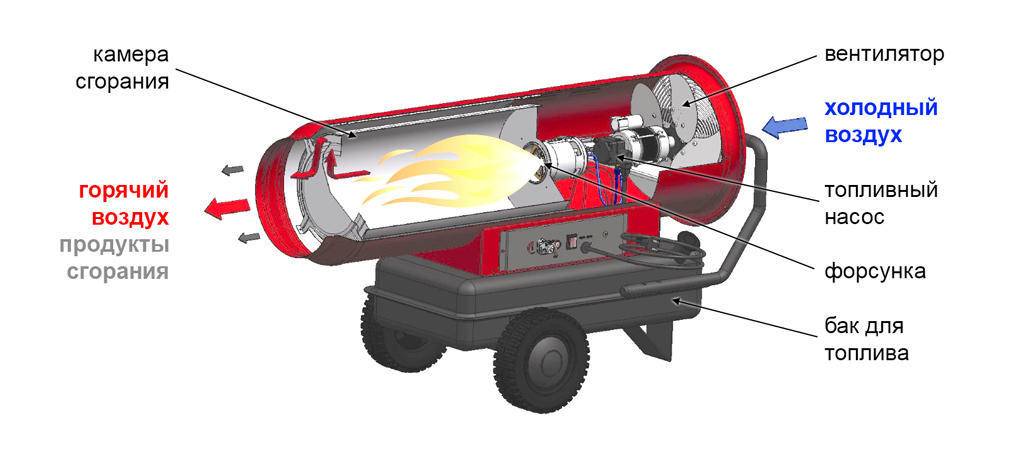

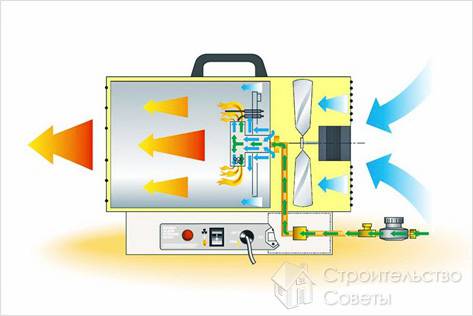

Device and principle of operation

In the most general case, a heat gun is a small-sized mobile heat generator that works by using energy of one kind or another.

According to the type of energy carrier used, all mobile units of this type are usually divided into the following groups:

- electric heat guns;

- units operating on liquid fuel (kerosene, diesel fuel, gasoline or "working off");

- devices that use gas or hot water for heating.

Immediately make a reservation that for work performed at home (in a personal garage or in a subsidiary plot, for example), a heating device with a working power of 2 to 10 kW is quite suitable.

The simplest models of electric heat guns have such power, while units operating on petroleum products are usually intended for heating large production areas. At the same time, their operating power can reach values of 200-300 kW.

That is why, when choosing the option of making a heat gun with your own hands, preference should be given to devices with an electric heating method.

The principle of operation of such devices is quite simple and is as follows.

Through the heating element installed in the heat gun (which can be used as a conventional heating element), air is passed at a given speed, accelerated by a built-in fan.

Due to the inertia of the movement, the heated air mass flies out with force, forming a powerful heated jet. The thermal power of the heated jet can be regulated in this case both by increasing the heating intensity and by changing the speed of the air flow.

The thermal energy of the jet is usually enough to heat any medium-sized utility room in a matter of minutes.

Heating level adjustment

In addition to the heating power, many models provide power control. The step switch can turn on full power to warm up the room quickly, or partial power for constant heat support, and also be used as a secondary source of heating. Some models are equipped with a fan that works without heating, only for air circulation.

For an electric heat gun, insurance against overheating is important. Reaching a critical temperature threshold during operation, the gun turns off. This can happen if the body of the device is accidentally covered with something - the protective system is triggered, and the heating stops.

Safety

Such a device is a fire hazardous technique, so all safety rules must be observed. Requirements for the operation of the device:

- A homemade gas gun must not be left unattended. Factory ones often have an automatic security system that shuts off the gas supply in case of emergency.

- Do not use devices in places where there are flammable objects and substances.

- The room must be well ventilated.

- The open air heater must only be placed on level surfaces so that the position is stable.

- Cannot be used outdoors during rainfall.

Before using the device, make sure that the socket is grounded. The ends of the gun can be covered with a metal mesh to disperse the air flow.

With the onset of cold weather, it becomes necessary to heat the garage. Previously, I used a potbelly stove for heating, but with firewood there is a lot of fuss, garbage, they take up a lot of space, and it’s problematic to buy dry ones (in season). Two weeks ago I came across a video on youtube

Comments 79

In the video, the apparatus that he builds is interesting, and the stove is fire, I like the idea, but I don’t like that it’s not on the water, but the air

It can also be converted to liquid heating. I need a mobile gun so that at any time I can roll to another garage.

Fuck the collider! Why such difficulties?

On the contrary, everything is extremely simple.

I understand that solarium, gasoline, kerosene, etc. should not have direct combustion, carbon monoxide. Why propane?

There is also carbon monoxide, but it has almost no smell, which is why it is dangerous. My friend was buried last week, fell asleep in a running car in the garage (the car ran on natural gas)

And what about the kitchen? The dead don't lie there. A friend died from incomplete combustion of gas in the engine.

In the kitchen, there is an extractor hood in the wall above the stove and a small amount of gas burned.

In the kitchen, there is an extractor hood in the wall above the stove and a small amount of gas burned.

In the 90s apartments were heated with gas stoves and ovens and all alive.

There is also carbon monoxide, but it has almost no smell, which is why it is dangerous. My friend was buried last week, fell asleep in a running car in the garage (the car ran on natural gas)

And yet, so for development. Carbon monoxide does not smell when burning any product!

And yet, so for development. Carbon monoxide does not smell when burning any product!

That’s the joke, that the boilers in the huts that were standing were with an exhaust gas, at least where I lived, and the stove was turned on when they couldn’t get warm

Phew! God forbid you fly into the air with your invention.

I understand that solarium, gasoline, kerosene, etc. should not have direct combustion, carbon monoxide. Why propane?

A lot of moisture is generated.

good idea, I'll make one myself. and skeptics in .opu

I myself deal with stretch ceilings, so for me personally, when it is necessary to heat the garage, I heat it with an ordinary gas gun, and I don’t feel any fumes in the garage, maybe because I have to heat for a maximum of half an hour and + 20-25 degrees in the garage. It cools down to zero for about a couple of hours.Garage frame shield (beam 10x15, chipboard sewn from the inside, 10mm isover and sewn from the outside with an ordinary encrusted board), garage 4.2x7.6 meters.

I have to work in the garage all day. At the moment I am preparing my car for painting and the materials need to be dried.

I myself deal with stretch ceilings, so for me personally, when it is necessary to heat the garage, I heat it with an ordinary gas gun, and I don’t feel any fumes in the garage, maybe because I have to heat for a maximum of half an hour and + 20-25 degrees in the garage. It cools down to zero for about a couple of hours. Garage frame shield (beam 10x15, chipboard sewn from the inside, 10mm isover and sewn from the outside with an ordinary encrusted board), garage 4.2x7.6 meters.

We also heat gas, BUT in order to be comfortable in the room for more than one hour, we made an air intake for the gun from the street. 3 minutes, then we turn it down and it slowly burns) ... but it happened when they fumbled for 5-7 hours, she eats a little, and it is always warm and comfortable in the garage.

Often, heat guns sold in stores are either too weak, or consume a lot of energy, or are simply expensive. If you have a small set of spare parts, tools and ingenuity, you can assemble the heater yourself.

Calculation example

The dimensions of the heated object are 10 square meters. m, and the level of its upper boundary is 3 m. Therefore, the volume of the object will be 30 cubic meters. m. Suppose that the device must heat the air in the room to at least + 15 ° C, while outside - frost -20 ° C.Therefore, the difference between these values reaches 35°C. Let's say that the walls of the building are excellent at retaining heat, and the thermal conductivity multiplier will be 1 unit.

In this video you will learn the pros and cons of a heat gun:

The required power is calculated as follows: multiply 30 by 35 and multiply by 1, then divide the resulting number by 860. The sum is 1.22 kW. This means that for a room with an area of 10 square meters. m, a heat gun with a power of 1.22 kW will be optimal for the best heating in the winter. But at the same time, it is better to purchase a model with some reserve, for example, with a power of 1.5 kW.

If you systematize the heating equipment by power, then products up to 5 kW are considered as household ones. Such heat guns operate from an electrical network with a voltage of 220 V. They are very easy to use in summer cottages, car garages, offices, private cottages. Sometimes such units are called fan heaters.

Read also: how to make a heat gun with your own hands.

Step-by-step instruction

The first step is to make the body. You can use sheet steel with a thickness of 3-4 mm or a regular pipe. The sheet must be given the required parameters, and then it must be rolled into a pipe. The edges are fixed with bolts or a special connecting lock.

After that, a pipe is sawn, which is used to supply gas. This is necessary so that later it will be possible to weld the next element to it.

Homemade gas gun:

Now you need to increase the diameter of the hole, which is intended for the flow of gas into the system. You need to bring it up to 5 mm.

Then the heat exchanger is made. A metal pipe with a diameter of 80 mm is taken.The end must be welded to the wall of the burner and a hole drilled. The torch extension passes through this element.

To exit the heated air in the heat exchanger housing, you need to make a hole. Then, in that place, weld a tube with a diameter of 8 cm.

Finally, you need to drill holes for igniting the gas. It is also necessary to provide for the structure on which the heat gun will be located. You can use a ready-made stand or weld from reinforcement.

Heat gun. do it yourself:

Important details, safety rules

Homemade electric guns are much more dangerous than factory ones, because in the process of assembling them it is not always possible to take into account all the nuances. The main safety rules for heating such devices are:

Homemade electric guns are much more dangerous than factory ones, because in the process of assembling them it is not always possible to take into account all the nuances. The main safety rules for heating such devices are:

- Never leave a working appliance unattended, even if it is equipped with residual current circuit breakers and seems perfectly safe.

- Do not leave diesel or gas heat guns switched on at night in a residential building, do not risk the lives of people and the safety of property.

- For heat guns on wood, diesel fuel or gas, be sure to equip a good hood and carefully monitor its serviceability, clean it from soot and combustion products in a timely manner.

- Tanks with fuel and gas cylinders should not be in the vicinity of a working gun, in order to avoid a fire.

- An open flame must be covered with a protective screen so that the coals or splashes of burning diesel fuel do not enter the room.

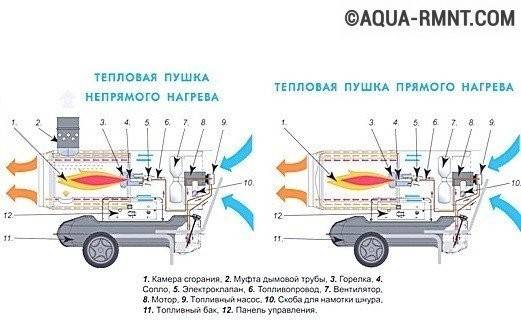

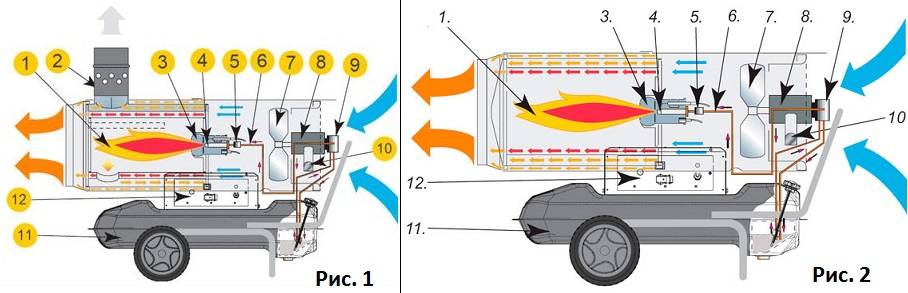

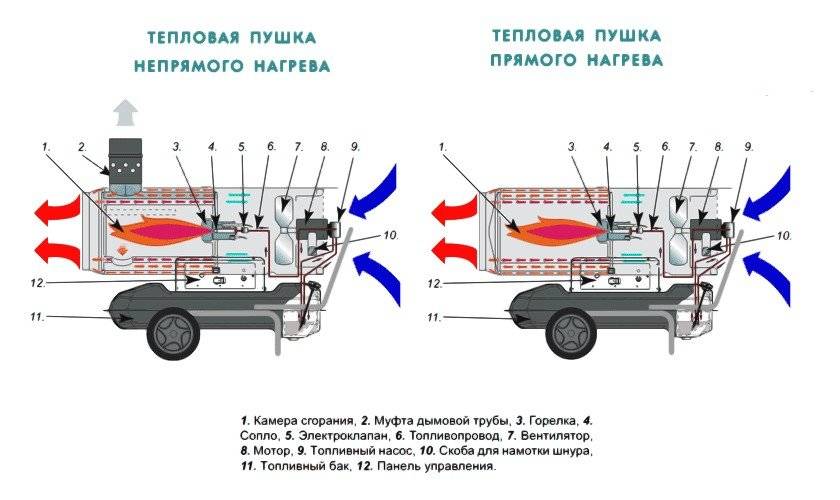

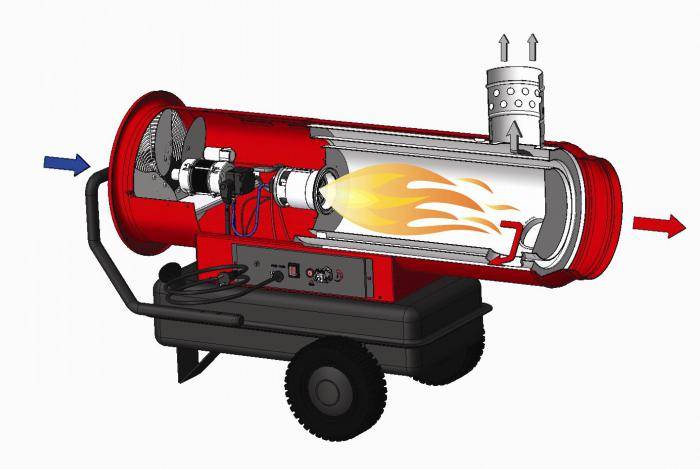

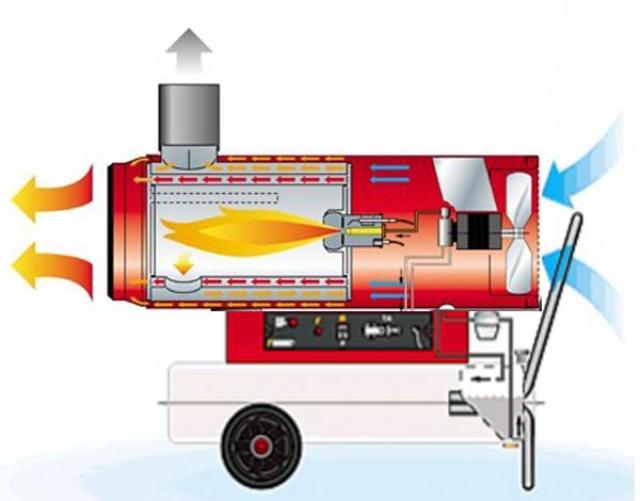

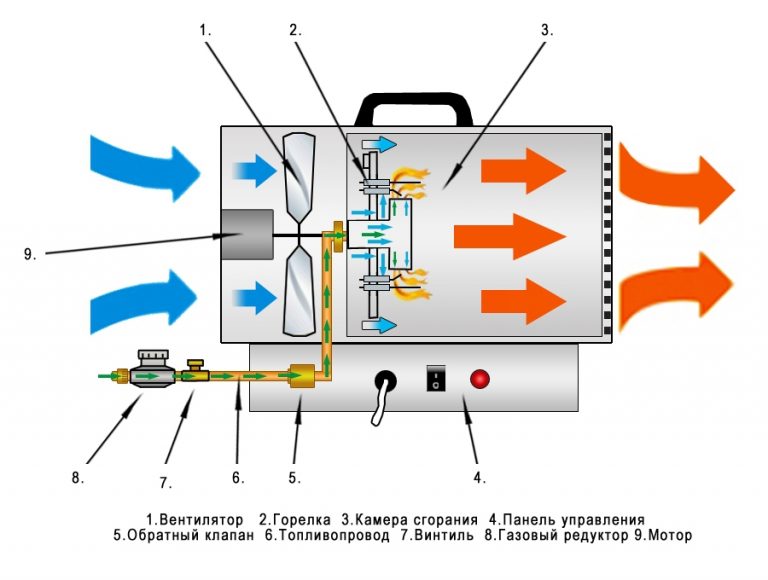

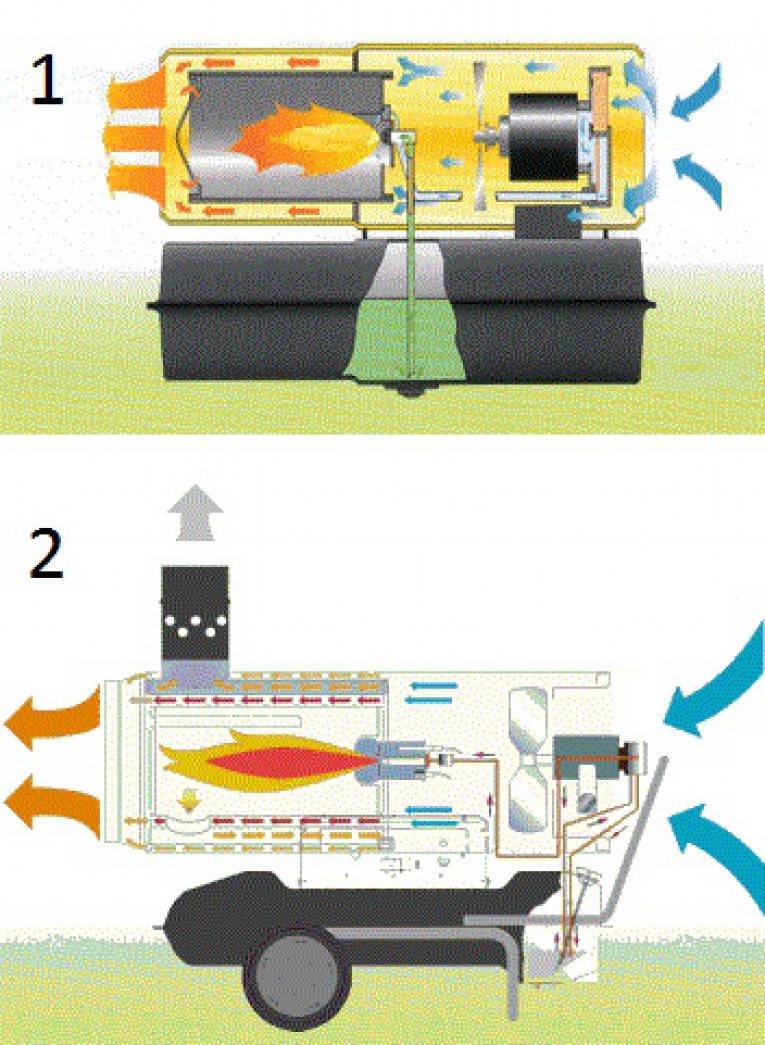

Varieties of gas heat guns

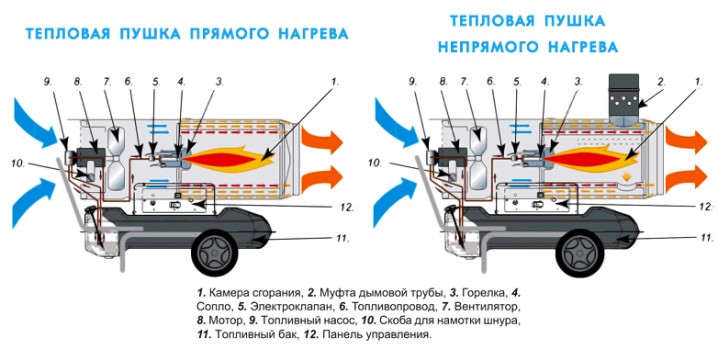

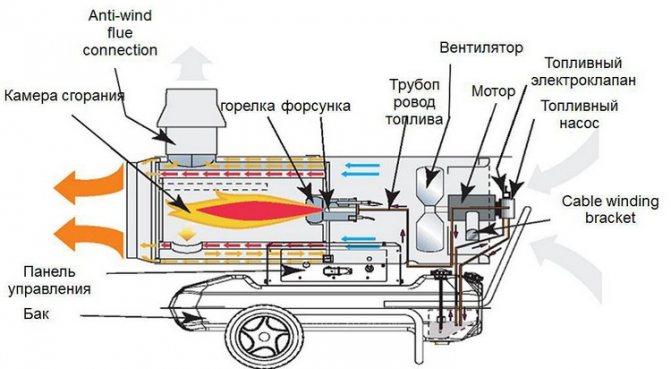

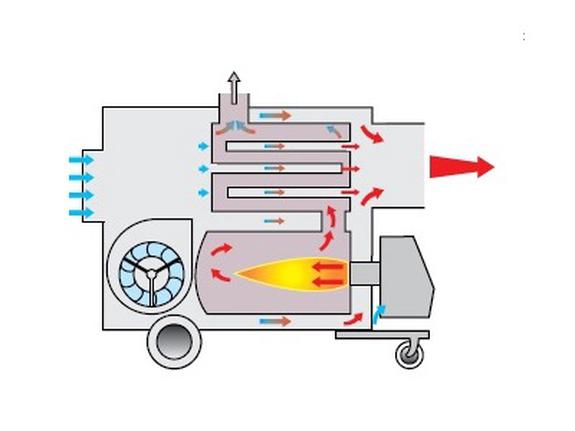

However, the method of heating the air flow for each of the two available types of heating devices has fundamental differences. For this reason, their requirements for operating conditions also differ.

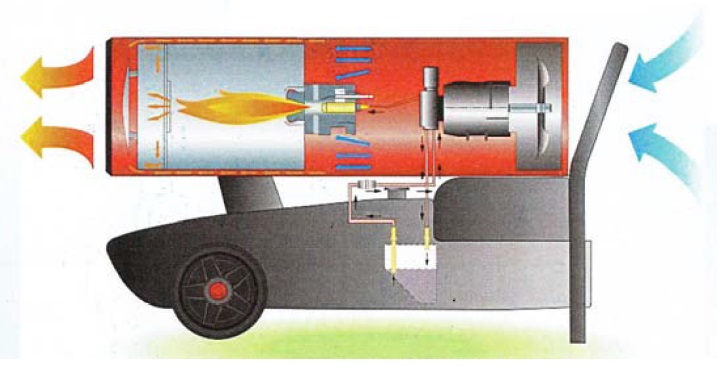

In a heat gun made with direct heating, fuel combustion products are present in the heated air. Purification of the air flow from impurities in the design is not provided. In fact, the polluted air obtained after forcing it directly onto the flame by the fan is distributed throughout the room.

Such a design feature of a direct heating gas gun requires good ventilation in the room. However, this does not prevent them from being popular. The reasons for the high demand for this design are obvious - rapid heating of the room with minimal fuel consumption allows you to get almost 100% efficiency of the heat gun.

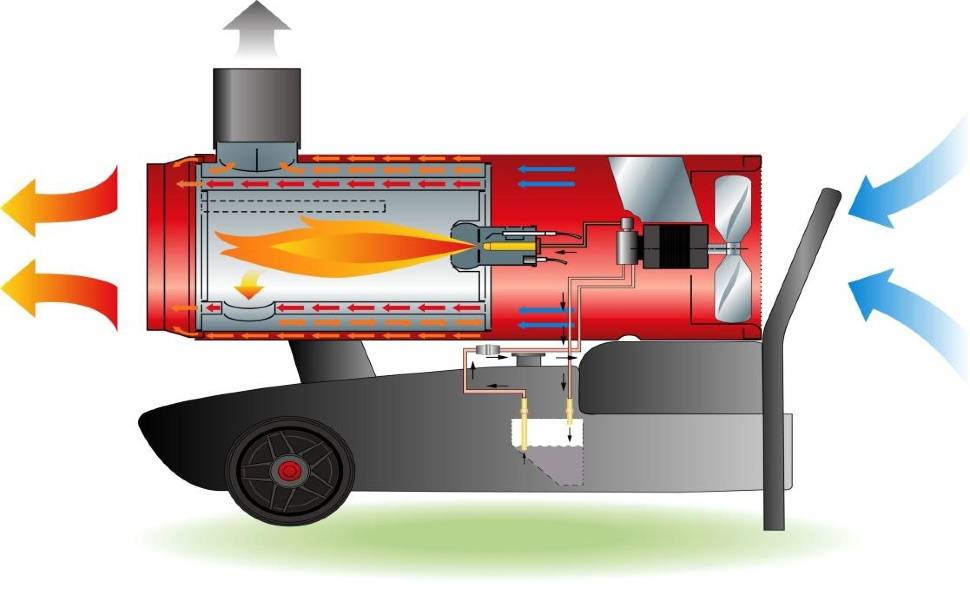

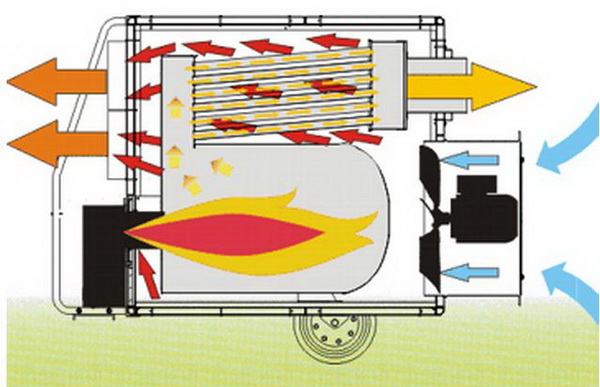

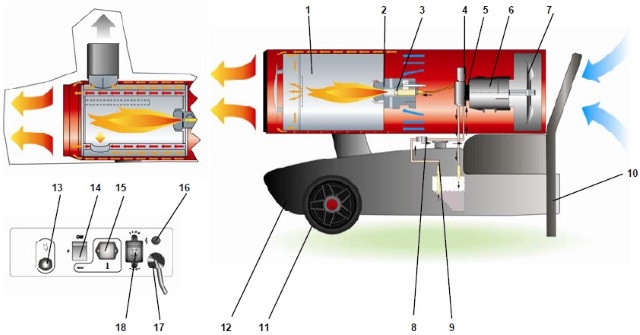

In gas guns of indirect heating, the heating element is an annular heat exchanger. All combustion products remain in the heat exchanger and are then removed through the chimney. At the same time, the heat exchanger heats up, air flows with the help of a fan flow around its outer walls and also heat up. Air enters the room, devoid of harmful impurities.

The design of such heat guns necessarily has a chimney through which combustion products are removed from the room. This feature makes it difficult to move the heating device, so these models of heat guns are usually used as stationary heaters.

Important: To ensure safe operation gas heat guns manufacturers supply them with protective devices that control the presence of a flame and the temperature of the case.

Manufacturers of heat guns in development

On sale you can find ready-made models of devices that work on used oil.They differ from home-made devices in their aesthetic appearance, high efficiency, energy intensity, and high technical characteristics.

Modern models are equipped with electric ignition and automation, thanks to which you can adjust the fuel supply, urgently turn off the device in emergency situations, set various thermal modes, and adapt the unit to work on different types of fuel.

The devices operating on used oils are produced by companies that are deployed in Europe, the USA, and Asia. We will name only a few reputable manufacturers and their top models.

Kroll - truly German quality

A well-known company, founded more than 30 years ago, is considered one of the world leaders in the field of heating technology (burners, dryers, heat guns, generators).

Kroll models are affordable and small in size. Due to the minimum amount of automation, their maintenance does not require complex equipment and the help of specialists.

The products of this brand, which have all the necessary Russian and European quality certificates, are safe, economical, reliable in operation, and also have an attractive design.

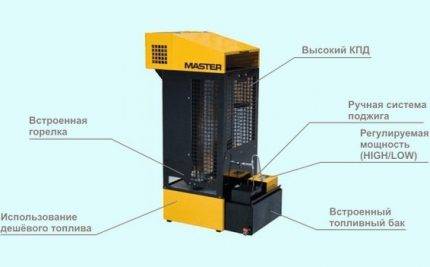

Master is a company with half a century of experience

A well-known American manufacturer, one of the leaders in sales of thermal equipment, especially heat generators. The technical parameters of the proposed devices demonstrate record performance in the industry, at the same time, almost all options are compact and mobile.

Stationary heater MASTER WA 33B, producing up to 30 kilowatts of heat, can work on any type of mining. The design of the device provides for manual ignition, wear-resistant and completely safe housing

The MASTER WA range includes a series of economical devices that can operate on almost any type of spent fuel: motor and biological oils, hydraulic fluid. The power of the models included in the series varies from 19 to 59 kW, so you can easily choose a device for heating a space of a certain area.

EnergyLogic - waste oil heaters

The American company, which has 30 years of experience and dozens of patented innovations, pays special attention to the production of boilers, burners, heaters and other equipment that runs on waste oil. The EnergyLogic EL-200H model has a fuel pump, which makes it possible to accurately dose various types of fuel

It also has louvers for the outlet of hot air, which can have a different arrangement.

The EnergyLogic EL-200H model has a fuel pump, which makes it possible to accurately dose various types of fuel. It also has louvers for the outlet of hot air, which can have a different arrangement.

The EnergyLogic EL-200H model has a fuel pump, which makes it possible to accurately dose various types of fuel. It also has louvers for the outlet of hot air, which can have a different arrangement.

The products are mainly made of stainless steel, which has excellent corrosion resistance and high temperature resistance. It uses standard parts that are widely available on the market, which facilitates operation, simplifies installation and maintenance.

Hiton - budget devices

Polish company founded in 2002.

The company specializes in the production of eco-fuel heaters, including heat generators and heat guns that run on used engine oil.

Hiton heaters, whose efficiency can reach 91%, equipped with a fuel tank and a burner, are simple in structure, do not require complicated installation, and function reliably for a long time.

Hiton heaters, whose efficiency can reach 91%, equipped with a fuel tank and a burner, are simple in structure, do not require complicated installation, and function reliably for a long time.

Heaters of this brand of drip type HP-115, HP-125, HP-145, HP-145R can operate on used mineral oils, on diesel fuel or on a mixture of these two types of combustibles, as well as on vegetable oils.

How to make your own heat gun

A heating gun is a compact device for home heating, which anyone can design. The most important point in the design is the observance of safety precautions and the principle of assembly. In order to make a thermal pillow, it is necessary to determine its future components. To make a thermal pillow, you will need the following components:

metal spiral;

copper wire;

small fan;

cable for connecting to the mains.

A metal spiral can be taken from an old kitchen electric oven, then the length of the spiral will need to be shortened with pliers or pliers. This procedure is needed to reduce the current resistance. Thus, the efficiency of the future heating structure will increase significantly. Next, the question of how to make a heat gun yourself - you will not cause difficulties. We wind the copper wire around the spiral, after which we attach the fan to one of the ends of the spiral.An important nuance is that the spiral at one end, where the fan will be placed, should not be completely wound. (See also: Diesel, crucible, rotary, camping and rotary kilns)

There must be two separate power supplies for the spiral and the fan, otherwise a banal short circuit will occur. The final stage of design is the connection of the wire from the spiral to the mains, and now the design is ready for successful operation.

The thermal pillow is an economical and affordable means of heating. Of course, this method of heating is far from ideal, but it is quite acceptable for everyday use. Depending on the room temperature, the duration of the use of the thermal cushion depends. Considering the modern cost of a fireplace, an independent means of heating, which can be constructed with one's own hands, is a completely acceptable solution of our time.

Since the heating season in most cases is quite short, therefore, buying a fireplace that will then just stand after a short use is not a very cost-effective solution. A homemade heat gun is easy, simple and affordable, and most importantly, effective. It practically does not require material costs, and the use of electricity is easily comparable to a fireplace of medium thermal power

It is very important that the heating device is located in a sufficiently isolated place and that there should not be any flammable materials near it. Observing the elementary safety rules that everyone knows, you can provide yourself with safe and quite comfortable heating. (Cm

See also: How to choose a heater for your home)

(Cm.See also: How to choose a heater for your home)

The heat gun has many variations, including when using a gas mixture. This option is used mainly to increase the efficiency of thermal heating of a room, when the square area is significant and in this case a powerful power unit is simply needed.

A home-made gas heat gun is exactly the solution that will ensure that the room is heated properly, while not requiring practically material costs for design. To construct a gas gun, it will be necessary to find a metal pipe of large diameter and make a large hole at the top of the pipe at the top. Through it, the gas will actually come out. Then it will be necessary to mount a combustion chamber in the pipe, the general design plan is freely available on the Internet. Therefore, there will be no difficulties to understand.

There is one very important nuance that is of paramount importance, and in most cases little attention is paid to it - this is the tightness of the fuel chamber. From a practical point of view, an incompletely sealed or poorly sealed fuel chamber does not pose an ultra-high source of danger, since the fan still sets the desired direction for the gas. The main disadvantage is a significant decrease in the efficiency of the unit, that is, partly lost material efficiency

(See also: Heating batteries)

The main disadvantage is a significant decrease in the efficiency of the unit, that is, partly lost material efficiency. (See also: Heating batteries)