Features of operation and care

If you want the device to serve as long as possible, you must:

- use only high-quality fuel (gas, diesel, gasoline);

- avoid strong voltage drops in the mains (if they happen often in your region, you should connect the gun through an RCD - a residual current device);

- do not allow water to get on the electric heat gun, and do not use it in rooms with high humidity (over 93%);

- protect the device from shocks, falls and mechanical loads;

- place the device further than 0.5 m from flammable things, including fabrics and furniture;

- withstand a period of addiction (from 2 hours) after transporting the device in the cold (below 0°C);

- Regularly clean the protective grilles and housing.

Clear indications for repair:

- visually noticeable damage to the body, tubes, wires;

- sparking at the points of connection of wires;

- repeated operation of the protective relay.

Please note: causes and remedies are valid for electric heat guns

If you purchased a heat gun, you can get more detailed information about its operation from the warranty card or the booklet attached by the manufacturer. Those who assembled the device on their own can familiarize themselves with the rules by searching the net for instructions for a similar model.

As you can see, with due attention and diligence, you can build a heat gun that will provide you with comfort in any unheated room.

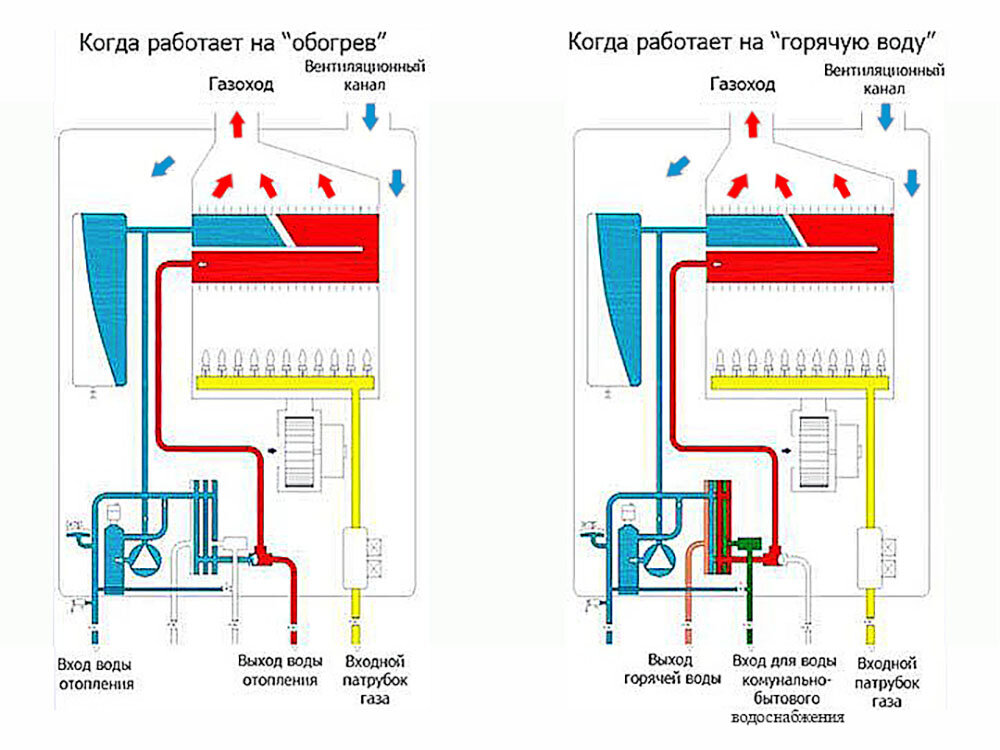

Features of gas heat guns

Gas guns are often used not only in industry, but also in everyday life, for example, for heating of country houses or garages. Such devices are inferior to electric in mobility, but are more economical. In addition, such devices have a fairly high power, the figure of which can reach 140 kW.

Heaters can run on natural gas or liquefied gas, but they also need access to electricity, since the operation of the fan, thermostat and other components is impossible without electricity.

For the operation of gas heat guns, various modifications of natural gas can be used:

- blue fuel passing through highways;

- butane or propane in specialized cylinders.

High power models can be connected to the gas pipeline with a special hose, which ensures their continuous operation. It should be noted that such units are usually stationary, since their movement is somewhat difficult.

Compact mobile devices operate on bottled fuel. In some cases, the gun is connected by a hose to a large cylinder, which is stationary.In others, a small gas tank is a structural element of the unit.

For the operation of portable gas devices (made independently or in the factory), gas is used in cylinders of various types

In many modern models of gas heat guns, additional functions are provided, for example, protection of the case from overheating, automatic shutdown of the device, and flame control.

Additional information about the device and various modifications of gas guns is given in this article.

Safety rules during operation

Thermal devices, including gas ones, are fire-hazardous equipment that requires strict adherence to safety regulations.

First of all, you should familiarize yourself with the regulatory documents relating to the regulations for working with gas equipment, namely GOST R ISO 11439-2010 for working with gas cylinders and GOST 17356-89 (gaseous fuel burners).

Requirements for the use of devices:

- Do not leave gas heat guns unattended, especially for do-it-yourself appliances. Factory models often have an emergency shutdown function, for example, when the outer shell is heated.

- In a room heated with such devices, it is undesirable to keep flammable substances. In extreme cases, they should be stored as far away from the device as possible.

- During the operation of devices with open heating, it is necessary to ensure proper ventilation of the room. When working with a device with indirect heating, be sure to check the chimney for proper operation and make sure that harmful exhausts come out.

- Do not use aerosol cans when operating the gas heat gun.

- It is not recommended to use such devices if the air contains the finest sawdust or other flammable fibers. Such a device is also not suitable for heating a room in which vapors of gasoline, acetone or other combustible substances are sprayed.

- The functioning device must be placed on a flat surface, which ensures its stable position.

- Do not connect any hoses to the inlet or outlet as this may impair airflow resulting in concentrations of carbon monoxide and/or other harmful substances.

- The gas gun cannot be used in rooms with a high content of vapors, for example, in a swimming pool, bathhouse, sauna. It is also not recommended to use it outdoors, especially in rain and snow conditions.

- Do not cover the switched on gas device with anything, as well as close the opening of the device.

Before connecting to the mains, make sure that the socket is grounded; also, during operation, do not close the opening of the gun and cover the device itself.

It is advisable to cover the ends of the gas gun with a metal mesh. This will dissipate a powerful stream of hot air, the temperature of which can exceed +250 ° C.

The main elements of the gun

To begin with, let's turn to engineering, which suggests that a heat gun should consist of several basic elements.

- Housing made of durable and heat-resistant material. Therefore, metal is chosen.

- Burner. A simplified design can be used here, for example, a burner from any gas heating boiler.Although you can use the option made by yourself.

- Fan. To supply oxygen and squeeze out heat from the body of the device, you will need some kind of unit. You won't find anything better than a fan. So you can use an old household appliance of low power.

- Gas supply source. It can be a gas pipeline or a gas cylinder.

An obligatory element that you have to do with your own hands is a combustion chamber. There is nothing complicated about this, so you can start manufacturing. But for assembly work, you will need a welding machine powered by an electric current.

So, we will make a heat gun from a large diameter pipe - at least 150 mm. Of course, the size of the unit will affect its performance, but for a small space like a garage, the unit may not be very large. Practice shows that a power of 2 kW is more than enough.

What parts will be assembled

Before starting the assembly, you need to clearly understand the principle of operation of the device.

- There is a heating element.

- The fan circulates air around the room.

- The thermostat helps you set the heating temperature.

- The temperature sensor protects the device from overheating.

Therefore, for the manufacture of any heat gun, we need:

- Flame retardant material, preferably metal,

- electric fan,

- Heater (heater, gas burner or divider),

- electrical cable,

- For gas heat guns, you need a cylinder and a hose with a valve,

- Stand or support for the case,

- Controllers and temperature sensors.

Tools

For work we need:

For work we need:

- screwdrivers;

- Riveter or welding;

- soldering iron;

- Tester;

- Hands growing from the right place.

If the latter is not about you, then it is better to buy a ready-made heat gun in the store.

Calculations

Before proceeding with the assembly of the heat gun, you need to decide on several important aspects.

The first thing you need to calculate is the power of the heat gun, which will be required for heating. On average, 1 kilowatt is enough for 10 square meters. But in different regions and in different conditions it varies. Here are a few values that can serve as a basis:

- In the south of Russia, for a room of 10 meters, where the ceilings are not too high, 0.5-0.8 kilowatts is enough.

- In the northern regions, the same area needs 1.2-1.5 kilowatts.

- Depending on the material of the walls, cracks and other heat losses, the power of the heat gun has to be doubled or more.

The second important factor is the condition of the wiring. This is especially true for electric heat guns. It is possible that weak wiring will not withstand a powerful heating element, knock out plugs or a short circuit will occur. In such cases, you need to run a separate high-power cable from the meter to the outlet where the device will be turned on.

The principle of operation of the device

Household fan heaters are compact devices that can be easily installed in almost any suitable place. To operate the device, electricity is needed: both for the fan and for the heating element.

Such devices are often used in apartments and garages, and even for heating workshops, greenhouses and other premises. It all depends on the power of the device.

In any model of a fan heater there are three components:

- fan;

- heating element;

- frame.

The fan drives a stream of air through the case, the spiral heats this air, streams of warm air spread around the room.

If the device is supplemented with automatic controls, it will be possible to set an acceptable air temperature. The device will turn on and off without human intervention, which will save energy.

For the manufacture of a homemade fan heater, an ordinary household fan is suitable, the dimensions of which correspond to the body of the device. Sometimes the case is made, focusing on the size of the fan

When operating the fan heater, it is necessary to follow the safety rules. Do not place any objects or materials directly on the fan heater housing or too close to the protective grid.

If the device is equipped with an overheating protection system, it will simply turn off. But if this module was not installed at the time of assembly, overheating of the device, its breakdown and even fire may occur.

A homemade fan heater can be of almost any suitable size and power. As a case, you can use a piece of asbestos-cement pipe, a metal pipe, a rolled sheet of metal, and even a case from an old system unit.

Usually, a fan is first selected and a heating coil is made, and then they are determined with the type of device case, depending on its filling.

The most important point in the creation of this heating device is safety: fire and electrical.

The heating coil in home-made devices is most often of an open type, it is simply twisted from a suitable wire. Direct contact with a heated coil may cause fire, burns, etc.

To make a fan heater with your own hands, you will need the most common tools, as well as basic knowledge of installing household electrical equipment.

Therefore, the spiral must be properly fixed inside the case, and the device must be closed from the outside with a reliable grill. Attention also requires the installation of the power supply of the device.

All contacts must be insulated, at the bottom they usually make a base from materials that do not conduct current: rubber, plywood, etc.

Self-assembly of a gas heat generator

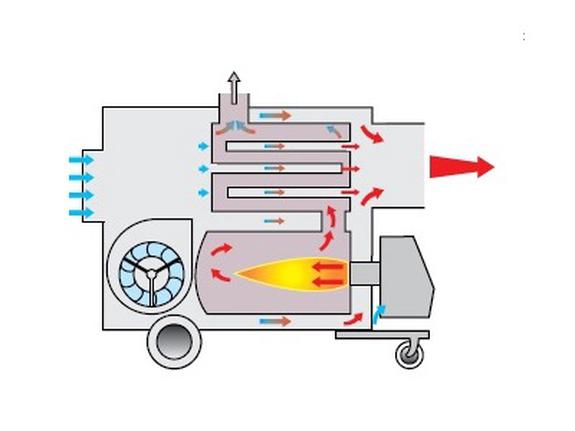

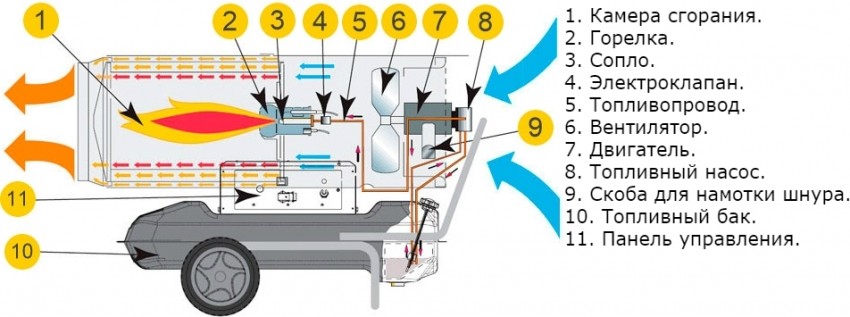

Many "Kulibins" ask: how to do it yourself, to quickly heat up a garage or country house. There is nothing complicated in this, it takes a little diligence, accuracy, the availability of source materials and knowledge of the principle of its operation. The principle of operation is as follows: gas flows from a cylinder into a combustion chamber equipped with a burner. When burned, the gas heats up the combustion chamber. The air supplied by the fan goes around the combustion chamber, thereby heating up and, going outside, raises the temperature in the room.

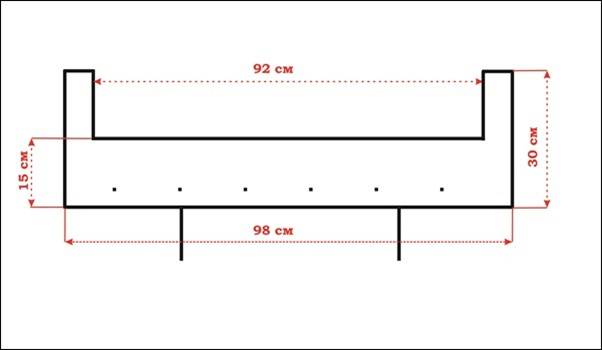

For the manufacture of a thermal carcass on liquefied gas, you will need:

- Pipe for the body with a diameter of 180 mm and a length of 1 m.

- Pipe for the combustion chamber, 80 mm in diameter and 1 m long.

- Gas-burner. As it, you can use any burner from a gas boiler or independently modify various burners for collet cylinders, which are sold in abundance in our stores by manufacturers from the Middle Kingdom. The main thing is that the burner is equipped with a piezo ignition.

- Fan. For such work, any axial fan with a round flange for mounting in the gun body is suitable.

A homemade gas heat gun is assembled like this:

- Two holes are made on the sides of a thicker pipe (body) on its opposite sides.One, with a diameter of 80 mm, for welding the warm air outlet pipe. The second hole, 10 mm in diameter, is for the burner to which the gas hose will be connected.

- The combustion chamber is made from a smaller diameter pipe. For its rigid fastening inside the body, it is necessary to weld several plates that will center the combustion chamber.

- A plug should be cut out of a metal sheet, according to the diameter of the body and with a hole for the combustion chamber. In fact, the plug will close the resulting gap between the housing and the combustion chamber. Next, everything should be assembled together, weld the fins of the combustion chamber to the inner surface of the housing, weld a pipe for the outlet of warm air and a plug on the housing from the side of the air flow outlet.

- The next step will be the installation of the burner in the combustion chamber and its hard fasteners.

- Installing a fan should not cause any difficulties. Usually they are sold already with a standard mount or holes in the flange.

Now it remains to connect the fan to the mains and apply power to the piezoelectric element. You also need to connect the gas hose to the burner, carefully fixing it with a clamp. After all the preparations and checks, the do-it-yourself gas heat gun is ready for use.

Gas gun

Heating small utility rooms is an urgent and very necessary thing today. The unheated garage is a thing of the past. But not every owner can provide this small room with the necessary and sufficient heat.

Therefore, skilled car owners turn their attention to the experience of builders who heat objects in winter by covering them with plastic wrap and using heat guns. By the way, making a small heat gas gun with your own hands is not a problem.

It does not require any instructions and drawings. Everything is tritely simple and very effective.

Unit #3 - gas heat gun

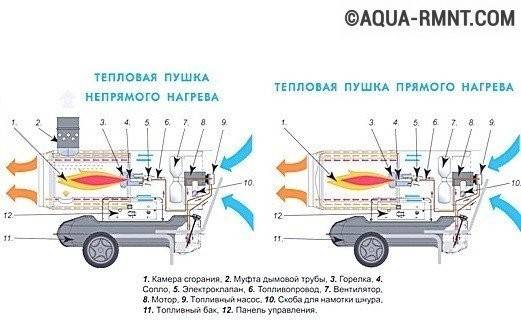

The design of a gas heat gun is in many ways similar to the design of a diesel unit. It also has a combustion chamber built into the body. Instead of a tank with liquid fuel, a liquefied gas cylinder is used.

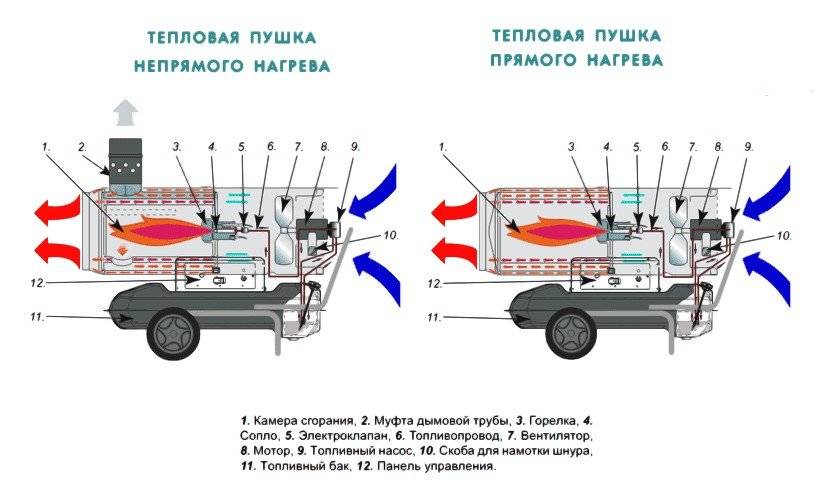

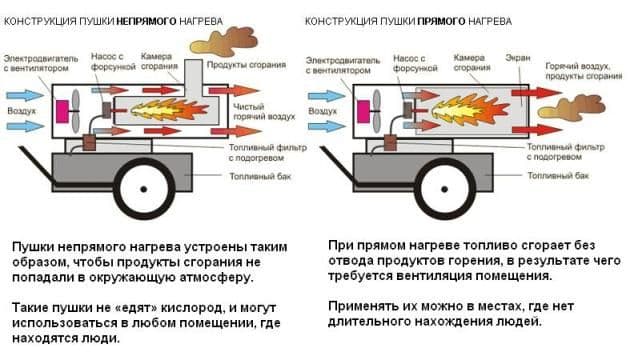

As with diesel fuel, the removal of combustion products is of great importance, since it is impossible to ensure complete combustion of gas in home-made devices. The air that enters the room is heated by contact with the combustion chamber. Exhaust gases leave the device through a branch led to the street. This indirect heating system is safer than open flame heating.

Indirect heat guns are equipped with a closed combustion chamber that prevents contact between open fire and air - this design is more complicated, but safer than direct models

To increase heat transfer, longitudinal plates can be welded to the combustion chamber body, usually 4-8 of them are made. At the same time, the dimensions of the combustion chamber with additional plates must be smaller than the diameter of the body so that the chamber does not touch its walls and does not overheat the body of the heat gun.

The body of a gas heat gun gets very hot during operation, so it must be covered with a layer of thermal insulation to avoid possible burns or fire.

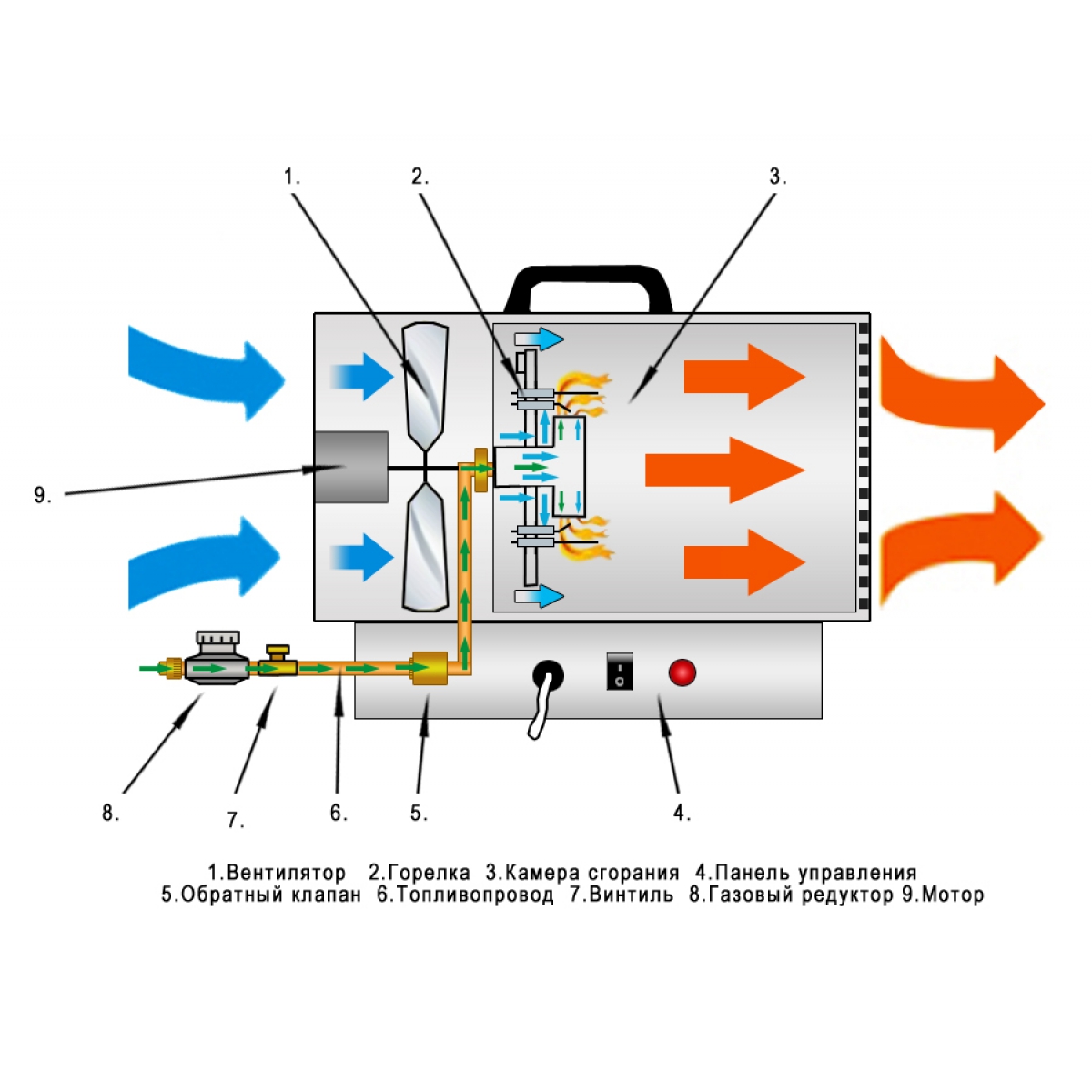

To create a gas heat gun, you will need the following elements:

- liquefied gas cylinder;

- burner;

- reducer;

- metal case;

- fan;

- device for remote ignition;

- frame for mounting the body.

The gas cylinder is connected to a reducer, which ensures a uniform supply of fuel to the burner. The air around the combustion chamber is heated, the fan blows it into the room. The procedure is almost the same as in the manufacture diesel heat gun. The device of a gas heater is clearly shown in the diagram:

This diagram clearly demonstrates the device of a heat gun operating on liquefied household gas. The fan must be powered

With a gas heat gun, only cylinders that are filled with gas on professional equipment should be used. Do-it-yourself cylinders may leak

During the manufacture and operation of a gas heat gun, it is recommended to adhere to the following rules:

- The gas supply pipes at the joints must be carefully sealed.

- It is mandatory to install a remote ignition device, since manual ignition can lead to an explosion.

- Make sure that the gas ball is always at a sufficient distance from the heater, otherwise the bottle will overheat and the gas will explode.

- Never use hand-made cylinders with a gas gun.

- Do not leave a working device unattended for a long time.

Another important point is the ratio of the power of the gas gun and the size of the heated room. Do not use a device that is too powerful in a small room, as this can easily lead to a fire.