- Pros and cons of Penoplex thermal insulation

- Insulation of a house made of aerated concrete with Penoplex

- Rough nuance

- Penoplex: foundation insulation

- Video - Insulation of a pitched roof

- Advantages and disadvantages

- Application and types of foam

- Facade insulation: stages of mounting plates on glue

- Video description

- How not to lose money

- Conclusion

- Insulation characteristics

Pros and cons of Penoplex thermal insulation

For more than 20 years, the company, whose branches are located in various cities of Russia, has been manufacturing and selling insulating material with high thermal protection parameters. Due to the wide range and high quality of its products, Penoplex has occupied a convenient niche in the Russian market and successfully exports goods abroad.

Penoplex plates are made of synthetic material - polystyrene by extrusion, that is, by mixing granular polystyrene with a blowing agent under conditions of high pressure and temperature. Additives are needed to give the boards a uniform “airy” structure of hermetic cells.

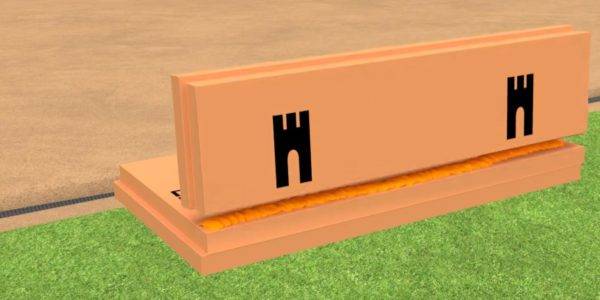

The design of Penoplex thermal insulation products is recognizable - these are bright orange plates and blocks with the brand name placed over the entire surface. Lettering printed in black

The design of Penoplex thermal insulation products is recognizable - these are bright orange plates and blocks with the brand name placed over the entire surface. Lettering printed in black

Thermal insulation benefits:

- minimum thermal conductivity;

- almost zero water absorption;

- resistance to biological environment;

- flexural and compressive strength;

- wear resistance and durability:

- environmental friendliness - does not emit harmful substances.

Like all heaters, Penoplex allows you to minimize the cost of air conditioning and heating, and due to the low weight, the installation of plates is easy and fast. The material itself can withstand temperatures from -70 ° C to +70 ° C, and it can be laid at any time of the year.

Another plus is the variety of types - there are options for finishing the roof, facade, walls, differing in thickness and degree of thermal conductivity.

Also, the company's engineers thought out complexes for thermal insulation of brick, frame, concrete, aerated concrete, wooden houses, and the manufacturer gives recommendations on the use of plates or a sprayed composition from the outside or from the inside.

It is preferable to install outdoor plates on the walls of houses - in order to save internal space, however, for brick buildings with well masonry, it is recommended to use intra-wall thermal insulation

It is preferable to install outdoor plates on the walls of houses - in order to save internal space, however, for brick buildings with well masonry, it is recommended to use intra-wall thermal insulation

The main disadvantage of the material is the flammability class - G4 or G3. Expanded polystyrene in this indicator is inferior to heaters with a natural base. For comparison: mineral wool has NG (non-combustible) or G1 (low-combustible). More characteristics of extruded polystyrene foam we have given here.

Another disadvantage is the high cost of plates and spray products. For example, a package of 10 mm Comfort plates (4 pcs.) of the 585 * 1185 standard costs an average of 1650 rubles.

Insulation of a house made of aerated concrete with Penoplex

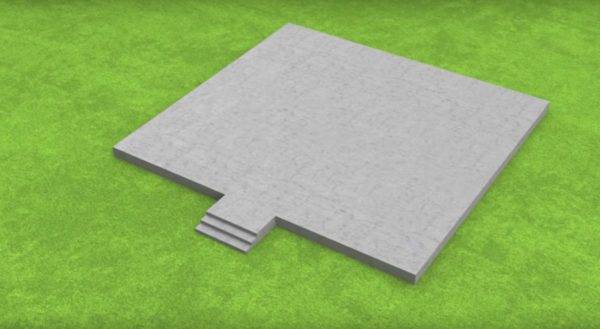

Step 1. Consider how the house is insulated from aerated concrete using Penoplex.So, the first step is to build the foundation of the structure.

The foundation is built first

The foundation is built first

Step 2. Next, along the perimeter of the foundation and along the perimeter of all load-bearing walls, it is required to lay cut-off waterproofing.

Laying cut-off waterproofing

Laying cut-off waterproofing

Step 3. After that, according to the standard technology, it is necessary to build walls from aerated concrete blocks to the level of the upper border of window and door openings.

Building walls at home

Building walls at home

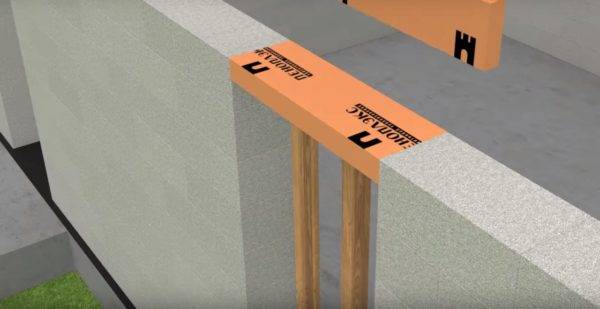

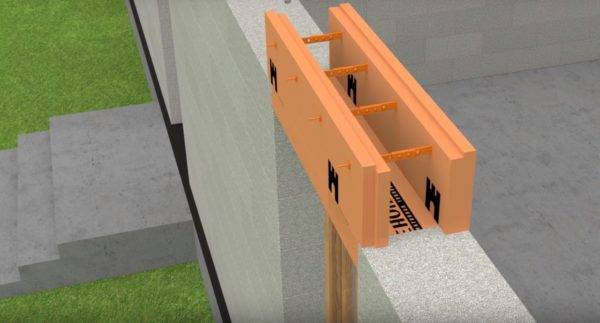

Step 4. The next stage is the installation of window and door openings, and here the use of Penoplex begins. The material is laid on top of the window opening, and then above it, perpendicular to it, two pieces of Penoplex need to be installed, pulled together with ties.

The material is laid over the window opening

The material is laid over the window opening

Above set two segments

Above set two segments

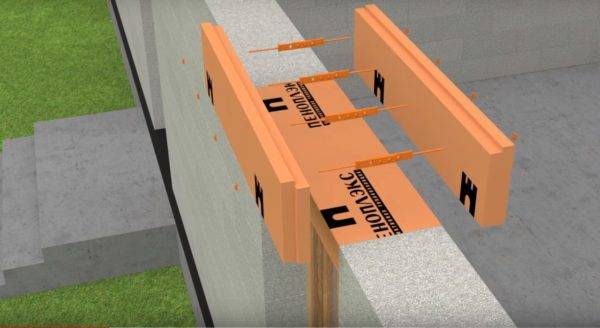

Segments shrink

Segments shrink

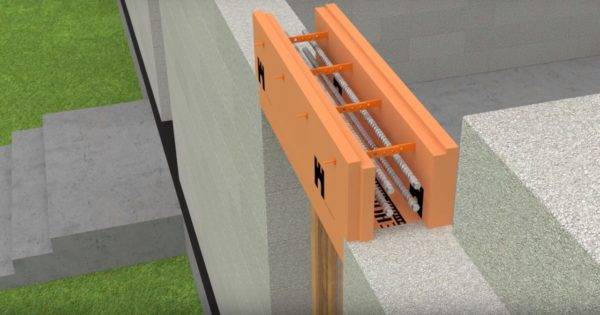

Step 5 Between two segments of Penoplex, it is required to lay reinforcing bars and continue to build walls further. The rods will connect two gas blocks, lying along the edges of the window opening.

Laying reinforcing bars

Laying reinforcing bars

Rods will connect two gas blocks

Rods will connect two gas blocks

Step 6. The cavity between the two segments of Penoplex needs to be filled with concrete.

The cavity is filled with concrete

The cavity is filled with concrete

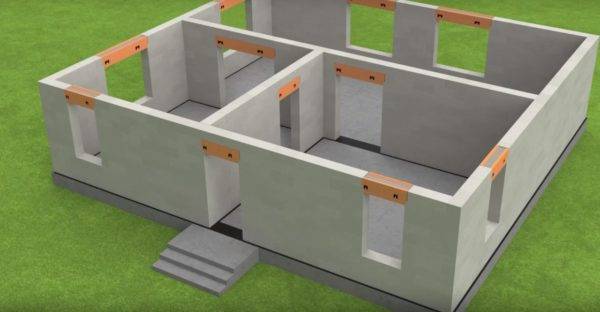

Step 7. Thus, you need to equip all door and window openings.

All door and window openings are equipped

All door and window openings are equipped

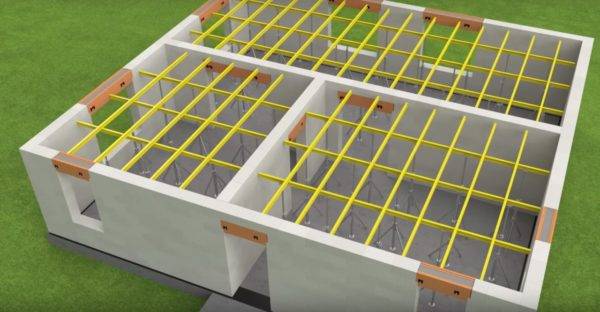

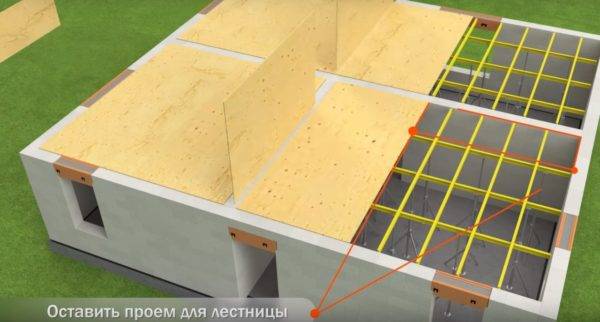

Step 8. After that, formwork is created for arranging the floor of the second floor

If there is a staircase in the house, then it is important to leave an opening for it according to the project.

Formwork is being created

Formwork is being created

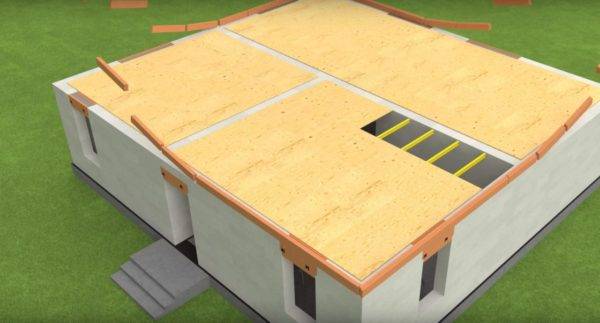

Step 9. Now you should close the formwork with sheet material, creating a full overlap.

Don't forget to leave a hole for the stairs

Don't forget to leave a hole for the stairs

Step 10. Next, Penoplex should be laid around the perimeter of the building at the level of the floor. Slabs, if necessary, are sawn according to the design of the building.

Laying material around the perimeter of the building

Laying material around the perimeter of the building

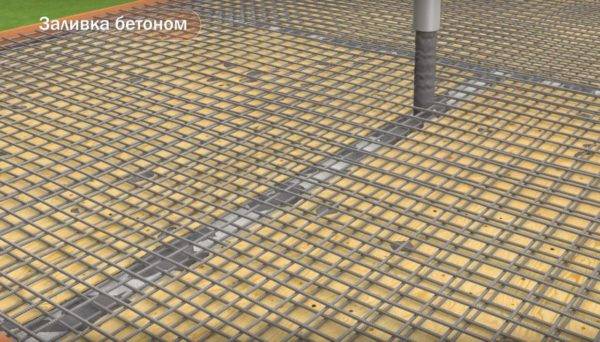

Step 11. After that, the reinforcing mesh is laid and the floor surface is poured with concrete. That is, you need to make a concrete screed. Work can be continued after 7 days.

pouring concrete

pouring concrete

Step 12. The next step is the same as step 2 in this guide - you need to lay the waterproofing.

Reinstalling the waterproofing

Reinstalling the waterproofing

Step 13. Next, you need to build the second floor of the house, not forgetting to finish the window and door openings with Penoplex as in the previous steps.

Second floor erected

Second floor erected

Step 14. After installing the roof, you can use heat guns to dry the inside of the house from the inside.

Drying the house from the inside

Drying the house from the inside

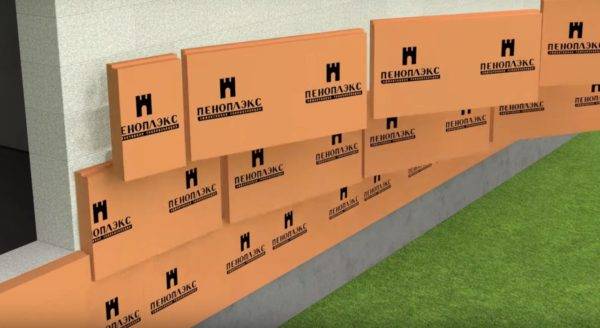

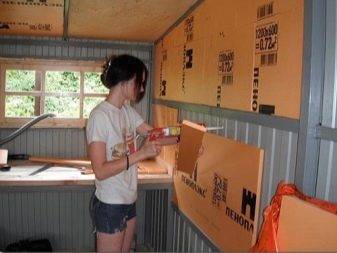

Step 15. Now that the building has been erected, you can begin to insulate the facade of the house with the help of insulation boards.

You can begin to insulate the facade

You can begin to insulate the facade

Step 16. First, the Penoplex plates must be put on glue. It must be applied to each slab along the perimeter, retreating 1-3 cm from the edge, as well as to the middle of the slab from one edge to the other along the length.

Applying adhesive to the board

Applying adhesive to the board

Step 17. Plates need to be glued along the entire facade.

Bonding boards to the façade

Bonding boards to the façade

The result of the work

The result of the work

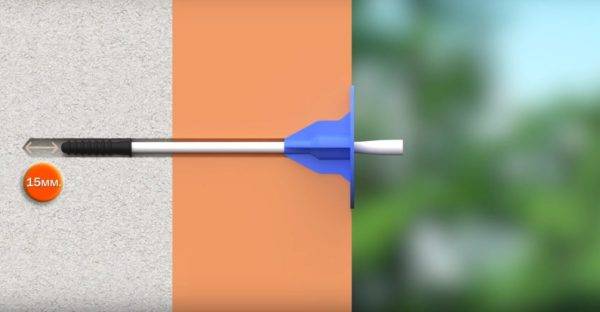

Step 18. Now you need to prepare holes for the dowels by drilling both Penoplex and the concrete under it to the desired depth, focusing on the length of the dowel.

Hole drilling

Hole drilling

Depth depends on the length of the dowel

Depth depends on the length of the dowel

Step 19. Using an anchor for aerated concrete, Penoplex is additionally fixed. You can knock out the dowel with a hammer.

Anchor for aerated concrete

Anchor for aerated concrete

There should be a small gap

There should be a small gap

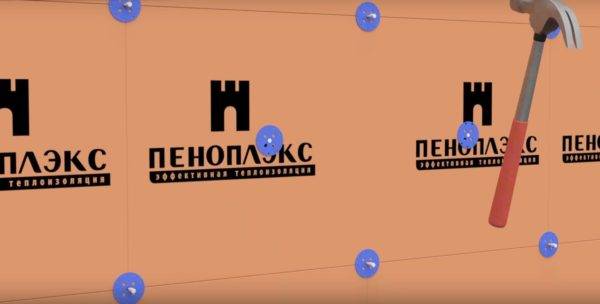

Step 20Fixation of one Penoplex plate with dowels is carried out in two places in the middle and along the perimeter of the plate (corners, middle of the long side).

Additional fixation Penoplex

Additional fixation Penoplex

Step 21. Now Penoplex can be mechanically processed, making it rough, and covered with reinforcing plaster-adhesive material. It remains only to complete the finishing, and the insulation of the house is completed.

Material machining

Material machining

Application of the base reinforcing plaster-adhesive layer

Application of the base reinforcing plaster-adhesive layer

Rough nuance

This is useful where a rough surface is indispensable. PENOPLEXSTENA boards are used for thermal insulation of walls with finishing without mechanical fastening. In other words, where the finishing material cannot be attached with nails or dowels with self-tapping screws, but one has to rely only on adhesion forces (adhesion). We are talking about finishing with plaster and tiles.

Recall that the plaster system is built as follows. A layer of basic plaster-adhesive composition is applied to the heat-insulating layer of PENOPLEX boards with a rough surface, a reinforcing mesh is embedded into it, then, after drying, a facade primer is applied and, finally, a finishing layer of decorative and protective plaster. Therefore, for the reliability of such a plaster system, high adhesion (adhesion strength) of the insulation surface with basic plaster and adhesive compositions is required. For the rough side of the PENOPLEXSTEN board, this indicator is, of course, significantly higher than for the smooth surface of the PENOPLEXSTEN board and the surfaces of other heat-insulating materials. In particular, it exceeds the adhesion of foam plastic by more than 1.5 times, mineral wool - by more than 2.5 times.

It is important to note that the adhesion strength of the rough surface of PENOPLEXSTEN is 3 times higher than the standard value specified in the technical specifications for the use of adhesives.

Thus, PENOPLEXSTENA boards are designed for wall insulation with subsequent finishing with various types of plaster: cement, lime, lime-gypsum, cement-lime, polymer-cement, acrylic, etc. At the same time, PENOPLEXSTENA can be used both for external insulation with a plastered wall, as well as and internal with wall decoration with interior decorative plaster.

An example of a wall construction with PENOPLEXSTEN thermal insulation and external finishing with plaster on a polymer mesh.

PENOPLEXSTEN is a highly specialized insulation, in contrast to PENOPLEX COMFORT, which can be called a wide profile insulation.

Finishing the story about the differences between the brands PENOPLEX COMFORT and PENOPLEXSTEN, we note one more important possibility of using thermal insulation. PENOPLEXSTEN boards go on sale with a rough surface of factory quality. However, you can prepare a plate for applying the plaster composition with your own hands. To do this, immediately before installation, notches are applied to the PENOPLEX COMFORT boards to improve adhesion. But it is more expedient to purchase specialized PENOPLEXSTEN boards, which are prepared for plastering work in the factory.

Penoplex: foundation insulation

Step 1 Consider how the foundation slab will be insulated. The figure shows a diagram of what should happen.

Foundation insulation scheme

Step 2First, it is required to mark the territory according to the design of the building, as well as to remove the top layer of soil to a depth of 40 cm.

Territory marked

Territory marked

Step 3. The finished recess must be filled with sand by making a sand cushion

It is important to compact and compact it without fail

The sand needs to be compacted well.

The sand needs to be compacted well.

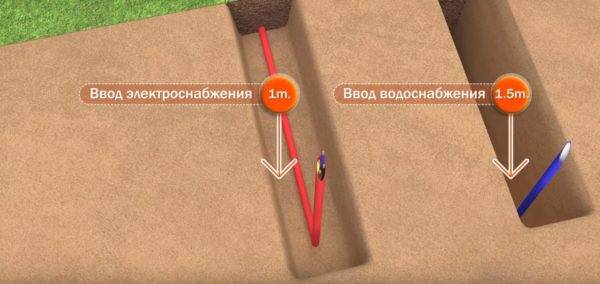

Step 4

Further, if necessary, it is important to immediately lay communications by laying them in trenches in a sand cushion. Entering electricity and water supply is also better done immediately

Laying communications

Laying communications

Commissioning of electricity and water supply

Commissioning of electricity and water supply

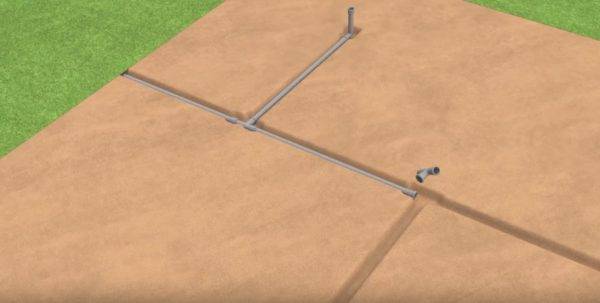

Step 5. Immediately along the perimeter of the house, you need to lay rain pipes with storm water inlets.

Rain pipes with rain inlets are laid

Rain pipes with rain inlets are laid

Step 6. Now it's time to lay Penoplex. For part of the slabs that will be laid at the edge of the territory, you need to cut off the edge on one side. Also, part of the plates must be cut in half along the length.

Edge cut off

Edge cut off

Step 7. Now on the first plate without an edge, you need to apply glue just on the side where the edge was cut off. And on top of it, you need to glue half of the other plate on top of it.

Half of the plate is glued on the end

Half of the plate is glued on the end

Step 8 Stepping back from the side edges of the resulting structure, you need to additionally fasten the glued plates with special fasteners. Quite a lot of such side structures need to be made.

Additional fastening of plates

Additional fastening of plates

Step 9. From the side structures, you need to form a kind of side along the perimeter of the building.

Formation of the edge around the perimeter

Formation of the edge around the perimeter

Step 10. Install stakes along the outer perimeter of the boards to strengthen them and fix them in place. The distance between the stakes is 30 cm.

Reinforcement of slabs

Reinforcement of slabs

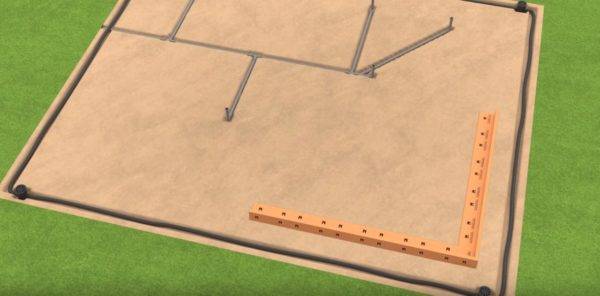

Step 11. Now you can close the rest of the sand cushion with Penoplex plates.Plates do not need to be fixed.

The entire sand cushion is covered with slabs

The entire sand cushion is covered with slabs

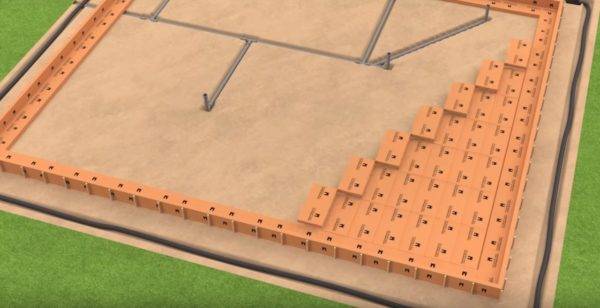

Step 12. It is better to lay the plates in two layers. Moreover, when laying the second layer, it is necessary to leave gaps for arranging the walls. Inside, a reinforcing cage for them will be mounted.

Laying the second layer of slabs

Laying the second layer of slabs

Reinforcing cage inside the gap

Reinforcing cage inside the gap

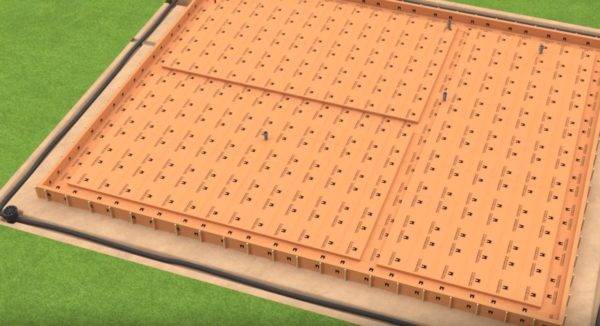

Step 13. Now the Penoplex slabs need to be poured with a concrete screed and that's it, the foundation is insulated. You can continue to build a house after the screed has dried.

The process of creating a concrete screed

The process of creating a concrete screed

Video - Insulation of a pitched roof

Penoplex Comfort is not in vain so popular with experienced and novice builders. This material has all the necessary advantages to take a leading position in the market of heaters. Its main disadvantage is the cost. But perhaps it is better to pay more once and live for many decades in a warm house than to change a cheaper insulation after a while?

Advantages and disadvantages

Penoplex is a popular material that is in great demand. Its popularity is due to many positive qualities:

- Penoplex is a hydrophobic material.

- It is light in weight, so it is quite easy to work with it. Moreover, you will not spend a lot of money on transporting this material.

- Penoplex is distinguished by excellent strength characteristics. It is not so easy to damage this material - it is not subject to the appearance of mechanical defects.

- The composition of this heat-insulating coating is anti-corrosion, so it can be safely laid on bases consisting of a variety of materials.

- Penoplex installation can be started in almost any conditions.You do not have to wait for the right moment to proceed with the installation of plates.

This insulation does not attract the attention of insects and rodents, which, as a rule, are quite difficult to get rid of.

Penoplex is an environmentally friendly and safe material - it does not adversely affect human health.

Penoplex is easy to install. With a minimum set of knowledge, you can install this heater yourself.

Many buyers prefer this heater, as it has a reasonable price.

Penoplex is characterized by minimal water absorption.

Penoplex does not cause allergic reactions.

- This material is quite strong in compression.

- Such insulation is universal - modern manufacturers produce high-quality coatings designed not only for walls, but also for floors and roofing "pie".

- Penoplex is not subject to decay, which once again confirms its durability and resistance to wear.

- This material has a long service life.

- Such extruded polystyrene can be used both in the construction of new buildings and in the restoration of old buildings.

Penoplex is not an ideal heat-insulating material. It has its own weaknesses, which you should also be aware of if you decide to purchase such products for your home. Among them:

- This material is combustible. It burns and actively supports combustion.

- Penoplex does not withstand contact with solvents. Under their influence, polystyrene is destroyed and deformed.

- Not all manufacturers offer penoplex at affordable prices.In many stores there are expensive products.

- Another disadvantage of penoplex is its low vapor permeability (in certain situations). For example, if this material is installed incorrectly or exposed to adverse conditions, condensation may accumulate in it (from the outside). That is why this material becomes susceptible to the formation of fungus and mold. To avoid such problems, the room must be provided with good ventilation, otherwise normal air exchange will be hopelessly disrupted.

- This material for high-quality thermal insulation cannot boast of good adhesion. It has an absolutely smooth surface, so gluing it to walls and ceilings is often not very convenient.

- This thermal insulation material is recommended to be protected from direct sunlight. Under their influence, the penoplex may undergo deformation or damage to the upper layer.

- To make extruded polystyrene more resistant to fire, special substances are added to it during the production process - fire retardants. Materials with such additives become self-extinguishing, but when burning or smoldering, this insulation will emit black clouds of smoke with toxic compounds.

Of course, penoplex has much more positive qualities than negative ones.

Application and types of foam

Considering that penoplex has a number of advantages, then its scope quite extensive. XPS serves as an excellent insulation both indoors and outdoors. It is perfect for apartments, houses, cottages and other structures. Penoplex can be used to insulate roofs, attics, balconies, and in any climatic region without the use of an additional moisture-proof layer. Since the material practically does not absorb water, it is quite possible to use it in an environment with high humidity. At the same time, its thermal conductivity remains almost unchanged. XPS sheets are commercially available in various thicknesses, and depending on specific requirements, you can always choose the best option.

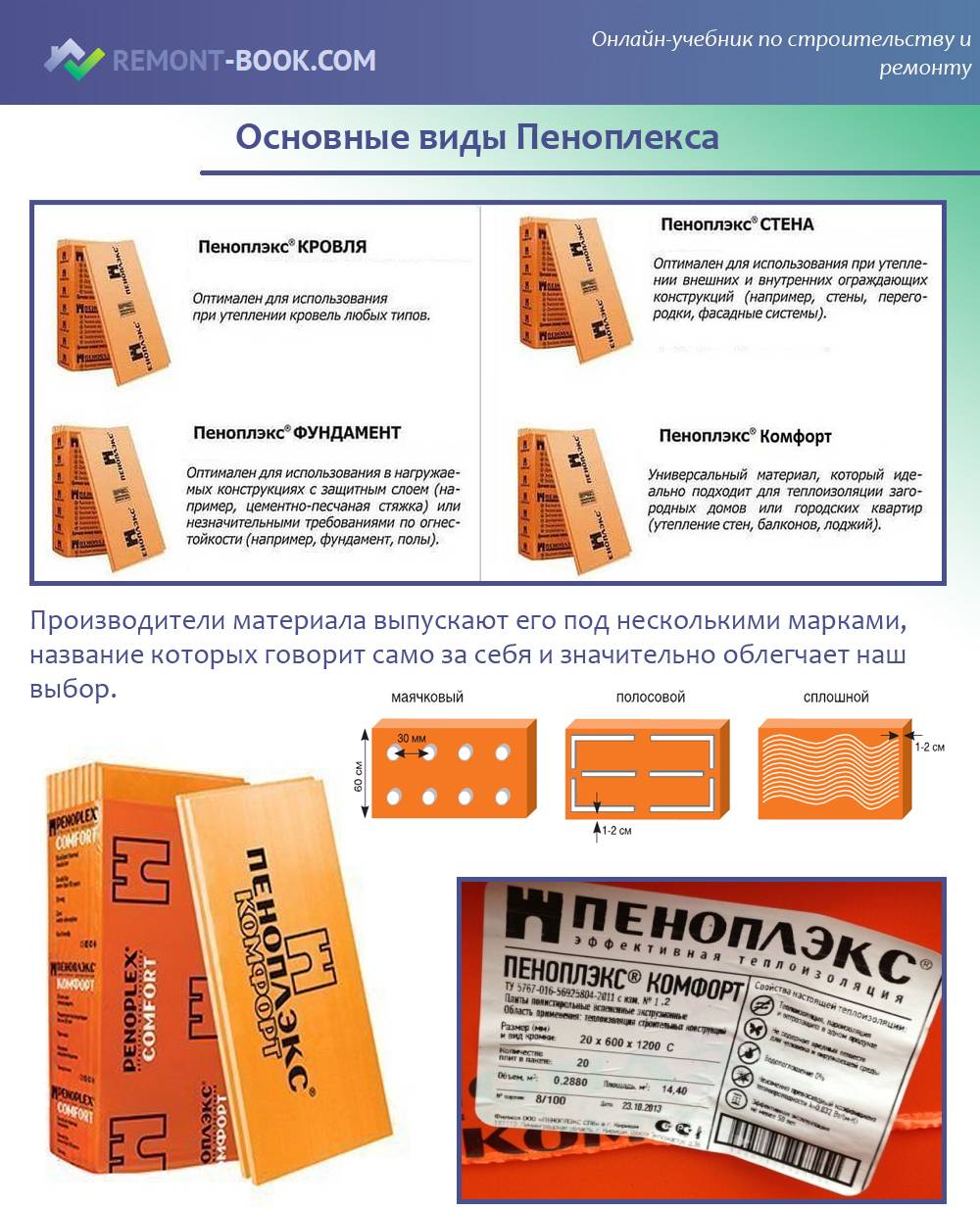

In addition to a variety of sizes, extruded polystyrene foam is available in several types depending on the density and application. Let's look at each type:

Penoplex Wall. The old name is Penoplex 31 with flame retardants. This material has a density of 25-32 kg / m³ and is designed for effective insulation of external and internal walls, partitions, plinths. These plates are also used in the construction of buildings during the construction of walls with “well masonry”. Compared to traditional brick walls, such walls are much thinner, but they are not inferior to them either in reliability or in the ability to retain heat. In the case of insulation of external walls with foam plastic, a plaster system can be made over the insulation on a grid, or lined with any facing facade material (siding, tile, lining).

Penoplex Foundation. The old name is Penoplex 35 without flame retardant. This material has a density of 29-33 kg / m³ and has high thermal insulation characteristics, a minimum water absorption coefficient and resistance to chemical and biological destructive factors. Its water repellency allows it to be used as a waterproofing coating.Penoplex Foundation is a rigid slab with a stepped edge, used in the construction of basements, the construction of foundations, and the insulation of septic tanks. The plates are very durable and able to withstand significant loads. Therefore, they can also be used as a basis for garden paths, plinths, floors.

Penoplex Roof. The old name is Penoplex 35. This material has a density of 28-33 kg / m³ and well insulates the building from cold air, has minimal water absorption, the ability to isolate noise well, and has a long service life. The plates have a standard size of 600x1200 mm, but if necessary, they can be easily cut with any tool at hand. And the small weight of plates allows to use them without strengthening of roofing designs. The stepped edge located along the perimeter acts as an additional guarantee that “cold bridges” will not form at the joints of the plates. Penoplex of this type can isolate the roof of any type. However, more often this insulation is used for warming flat roofs, as well as for warming the attic of a ventilated roof.

Penoplex Comfort. The old name is Penoplex 31C. This material has a density of 25-35 kg/m³ and has an extremely low thermal conductivity, high hydrophobicity, and excellent noise isolation. It does not rot and is not a favorable environment for the settlement of insects, mold and fungi. Penoplex Comfort is produced in the form of plates measuring 600x1200 mm, which have an edge in the form of a step around the perimeter. It serves as an additional guarantee of accurate installation. Being a kind of universal, this insulation for thermal insulation of a private house is just perfect.They can insulate the floor, foundation, basement, roof and walls.

Penoplex 45. This material has a density of 35-47 kg / m³ and is used as a heater for road surfaces, in particular runways, to prevent them from frost heaving of the soil and destruction of the upper layer of the canvas. It is also widely used for insulation of operated roofs, on which pedestrian zones and various sites are located, including parking lots.

Facade insulation: stages of mounting plates on glue

The process of facade insulation with foam boards is as follows:

- Surface preparation. Dirt and the old lining layer are removed from the working base. If there are mold spots, then they are treated separately (disinfected with copper sulphate). If necessary, the surface is leveled and primed.

- Mounting. Sheets are glued in rows, from bottom to top, with dressing (with displacement) of the seams. The adhesive composition is applied to the foam sheet in two lines across. In an alternative method, if the adhesive is applied to the work surface, then this is done in a continuous layer. Each plate is pressed against the wall, its position is checked by level.

Video description

About thermal insulation with penoplex pitched roof in the following video:

Making a window box with foam

Finishing work. After the glue on the reinforcing mesh dries, they proceed to the finishing cladding with plaster.

How not to lose money

If designers and builders do not take into account the physical and chemical characteristics of the foam, its strength and thermal characteristics deteriorate long before the end of its service life, which leads to a decrease in the thermal efficiency of the house. The most common mistakes include the following solutions:

The use of material with a density lower than technologically justified. Penoplex, like any polymer, is oxidized by atmospheric oxygen. The rate of oxidation (change in chemical structure and deterioration in performance) depends on the density of the material. The use of plates with a lower density (quite an understandable desire to save money) worsens the thermal protection of the structure 2-3 times faster, and this is noticeable already in the first 7-10 years of operation.

Internal insulation

- Use of incompatible materials. Extruded polystyrene foam boards will break down at an accelerated rate if substances hazardous to the foam structure are used during construction (for example, oil-based paints containing volatile hydrocarbons).

- Ignorance of marking features. An inexperienced person, seeing the words “Mark 25” on the package, makes a logical, in his opinion, conclusion that there are plates with a density of 25 kg / m3 inside. But in technical conditions, a material with a density of 15.1 to 25.0 kg / m3 is designated this way. Some manufacturers, taking care of maximum profits, supply penoplex of the lowest density under this brand (15.1 kg / m3, the density of packaging plastic). The result of the replacement rather soon appears on the "insulated" facade - wet spots and mold.

- Incorrect insulation. Incorrect insulation leaves an air gap between the wall and the slab material.The design becomes inhomogeneous, the dew point shifts into the gap. The condensate is inevitably absorbed into the denser material (wall), the thermal efficiency drops, sometimes significantly.

Insulation completed, ahead - finishing cladding

Conclusion

Each owner, investing significant amounts in the construction of a country house, expects that housing will serve faithfully for many years, decades. The reliability of the walls and internal comfort to a large extent depend on the correct insulation. The competent use of penoplex will make significant savings in thermal energy (the main goal of any insulation), and, therefore, the family budget.

Insulation characteristics

Appearance of the heater

Appearance of the heater

The material is made on the basis of finely crushed polystyrene. It is mixed with special additives and heated. Due to the release of gas under the influence of high temperatures, the molten mass of polystyrene foams. At the final stage of manufacturing, foam plastic is squeezed out of the extruder, after which it cools evenly on the conveyor belt, taking the form of a plate.

The result is extruded polystyrene foam, called penoplex or penoflex - a heater with a uniform structure and a pore size of less than 0.3 mm. The bulk of the building material falls on the gas filler, which gives a high degree of thermal protection, as well as low weight with significant dimensions. Insulation sheets are orange in color and usually have typical dimensions: length - 120 or 240 cm, width 60 cm and thickness from 20 to 100 mm.

Table of characteristics of thermal insulation Penoplex

Technical indicators of building materials:

- Thermal protection. Plates have good thermal insulation characteristics.Penoplex has a low coefficient of thermal conductivity due to the cellular structure, which is 0.03 W / m ºK.

- Moisture resistance. Due to the fact that expanded polystyrene does not absorb moisture, it can be successfully used for thermal insulation of the roof, basement and foundation. The water absorption rate is 0.5 percent by volume per month.

- Chemical resistance. Does not react with most building materials, excluding solvents.

- Resistance to mechanical damage. Tolerates high loads. For example, at 10% linear deformation, the strength of the material is not less than 0.2 MPa.

- High compressive and fracture strength - 0.27 MPa. This quality makes it possible to use the panels not only as a heater, but also as a building material that is not subject to the formation of structural cracks.

- Wide temperature range. The average value of operating temperatures at which foam plastic does not lose its mechanical qualities and physical properties is from minus 50 to plus 75 degrees. If during operation the material heats up more, it can melt, and in frosts below 50 degrees, the insulation will become brittle and brittle.