- Top 5 best heat accumulators

- How to improve boiler performance

- Various types and schemes for piping a solid fuel boiler

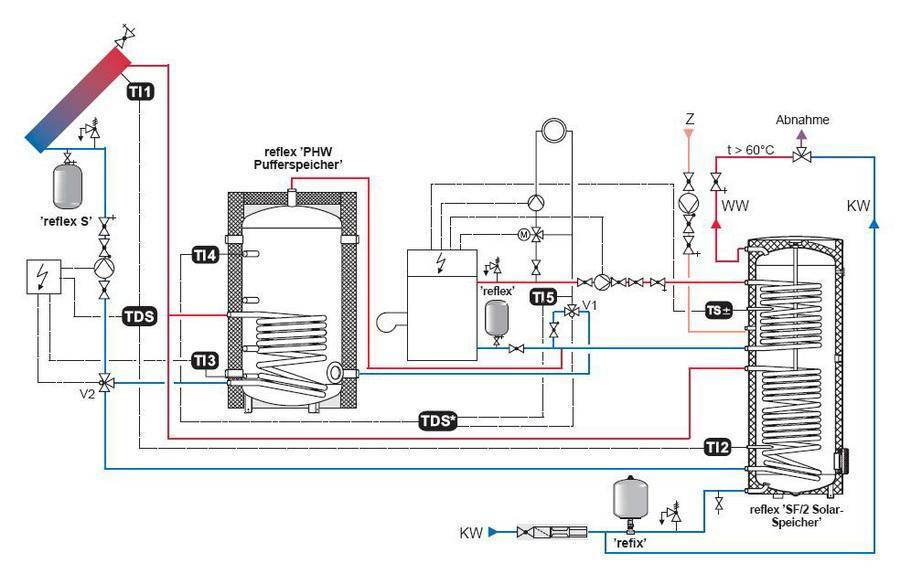

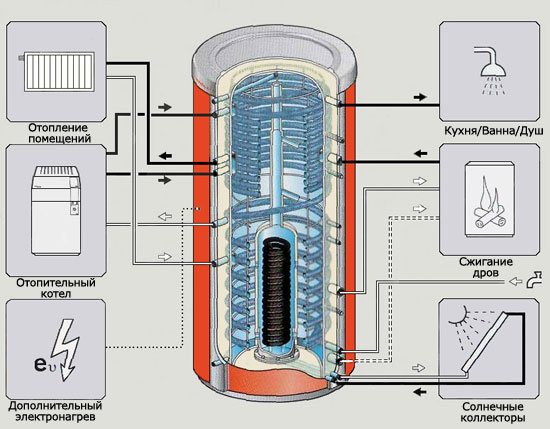

- The storage tank acts as a DHW boiler

- Connecting a heat storage tank and a separate DHW tank

- Parallel connection of two heating boilers

- Selection of a heat accumulator

- The device and features of the heat accumulator

- The principle of operation of pyrolysis boilers and their features

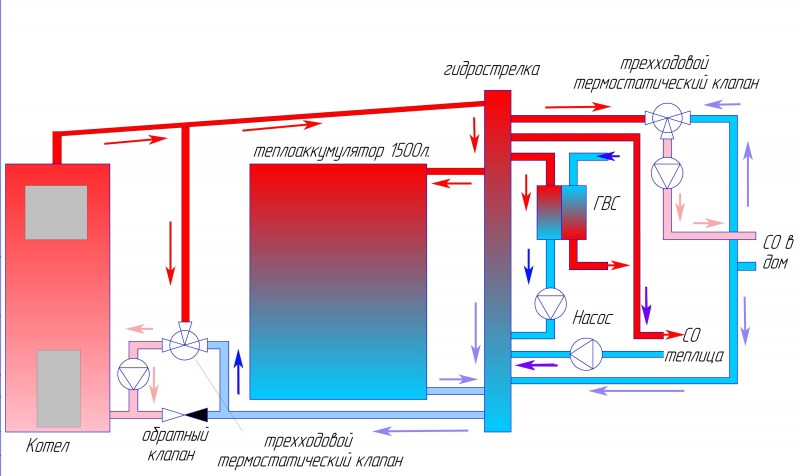

- Diagrams for connecting a heat accumulator to a solid fuel boiler and a heating system

- Some Features

- Design calculation

- Thermal accumulator: what is it

- The principle of operation of the heating system with a heat accumulator

- The main functions of heat accumulators

- The use of a heat accumulator: when equipment is needed

- Hot water mixing and valve addition

- The principle of operation of solid fuel boilers and their device

Top 5 best heat accumulators

______________________________________________________________________________________

| Model | Characteristic | Advantages |

| S-TANK AT PRESTIGE - 500 (Belarus) | Weight - 105 kg. Diameter - 78 cm. Height - 157 cm. Tank volume - 500 l. | ease of maintenance and easy installation; Water heats up quickly Protected from overheating multifunctionality; Compatible with various heat sources. |

| HAJDU PT 300 (Hungary) | Height - 1595 mm. Weight - 87 kg. Tank volume - 300 l. | Works in a closed system, with pumps, heat and solar batteries; · can install heating elements; simple installation, construction and maintenance; good thermal insulation. |

| HAJDU AQ PT 1000 (Hungary) | Tank volume - 750 l. Weight - 93 kg. Diameter - 79 cm. Height - 191 cm. | ergonomics; The presence of thermal insulation; Removable insulation and casing; compatibility with various boilers; long-term operation. |

| S-TANK AT AT-1000 (Belarus) | Weight - 131 kg. Height - 2035 mm. Diameter - 92 cm. Tank volume - 1000 l. | · from above the device is heat-insulated (70 mm); · for convenient connection, the branch pipes are turned at an angle of 90° and located at different heights; · There are 4 holes of 0.5 inches for thermostatic pressure gauges and sensors. |

| S-Tank AT 300 (Belarus) | Weight - 65 kg. Height - 1545 mm. Diameter - 500 mm. Tank volume - 300 l. | · it is well combined with any types of coppers; · isolation has high fire resistance; The tank is protected from the outside by a sheathing (plastic or cloth, The top of the tank is painted with heat-resistant paint. |

______________________________________________________________________________________ Heat accumulators for heating boilers Russian-made products have proven themselves in the market. They do not lose to foreign analogues, they also have high quality and a long service life, and the price is much lower. Well-known models of protective devices are produced by brands: Prometey, Vodosistema, BTS, Gorynya, RVS-engineering LLC, Teplodar.

How to improve boiler performance

A self-assembled solid fuel boiler, as a rule, is characterized by significant heat losses associated with the escape of heat into the chimney. Moreover, the straighter and higher the chimney, the more heat is lost.The way out in this case will be the creation of a so-called heating shield, that is, a curved chimney, which allows you to transfer more thermal energy to the brickwork. The brick, in turn, will give off heat to the air in the room, heating it. Often such moves are arranged in the walls between rooms. However, such an approach is feasible only if the boiler is located in the basement or on the basement floor, or if a bulky multi-stage chimney is built.

Alternatively, the efficiency of the boiler can be increased by installing a water heater around the chimney. In this case, the heat of the flue gases will heat the walls of the chimney and be transferred to the water. For these purposes, the chimney can be made from a thinner pipe, which is built into a larger pipe.

The most effective way to increase the efficiency of a solid fuel boiler is to install a circulation pump that forcibly pumps water. This will increase the productivity of the plant by about 20-30%.

Of course, it is necessary to design the boiler so that the coolant can circulate on its own if the electricity is turned off in the house. And if it is available, the pump will speed up the heating of the house to comfortable temperatures.

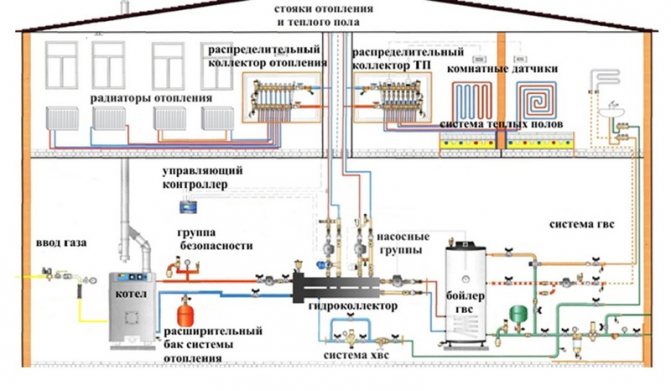

Various types and schemes for piping a solid fuel boiler

There are many ways to connect the boiler and related equipment to the general heating system of the house. Let's consider the most common of them.

The storage tank acts as a DHW boiler

The design of the storage tank is a spiral located inside the heat accumulator. The hot coolant that is inside heats the running water of the hot water circuit.In the event of a burnout and shutdown of the boiler, the heat accumulator allows you to maintain an acceptable temperature in the room, up to 2 days. Provided that the DHW function is not used.

To control the flow and temperature of the coolant, an automatic thermo-mixing device is used:

- ball valve;

- Thermometer;

- Pump.

Also, the device is equipped with a check valve, an emergency automatic valve of natural circulation (in case of a power outage), a built-in thermal valve and a fitting.

The principle of operation of the device is as follows. When the coolant reaches a certain temperature (780C), the thermal valve opens the water supply from the accumulator. The temperature is kept at a given level by regulating the cross section of the return passage from the central heating system to the bypass channel.

Scheme for connecting a solid fuel boiler to a dual-use heat accumulator:

1. Security group; 2. Thermal storage tank; 3. Thermal mixer;

4. Expansion tank of membrane type; 5. System make-up valve; 6. Circulation pump of the heating system;

7. Radiators; 8. Mixing three-way valve; 9. Check valve; 10. DHW circulation pump.

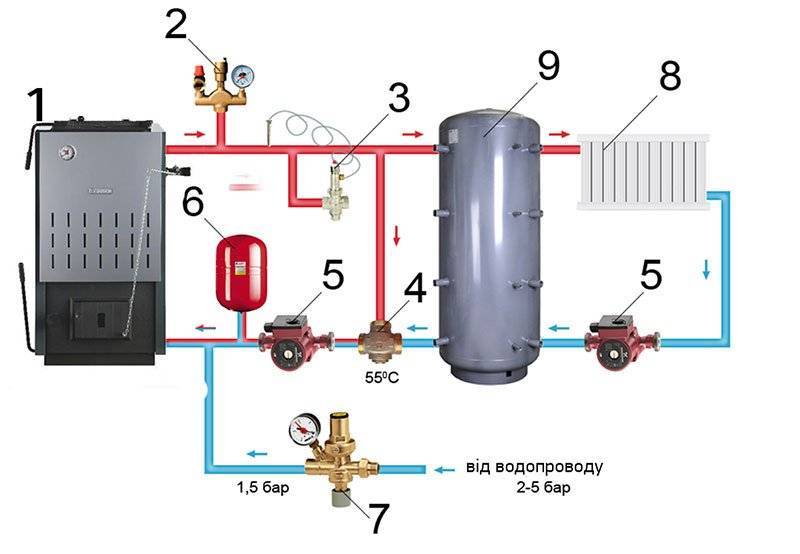

Connecting a heat storage tank and a separate DHW tank

The volume of the boiler for passive heating of the DHW system depends on the number of consumers and the power of the equipment used. At binding of pellet boilers It is not recommended to use polypropylene materials and structures. The temperature of the heat exchanger at the outlet at peak loads often exceeds the performance of pipes made of polymer materials.

Piping a solid fuel boiler with a separate hot water boiler:

1. Boiler.2. Security group.3.Expansion membrane tank.

4. Circulation pump. 5. Manual three-way mixing valve.6. System make-up valve.

7. Heating radiator.8. DHW boiler indirect heating.9. Thermal storage tank.

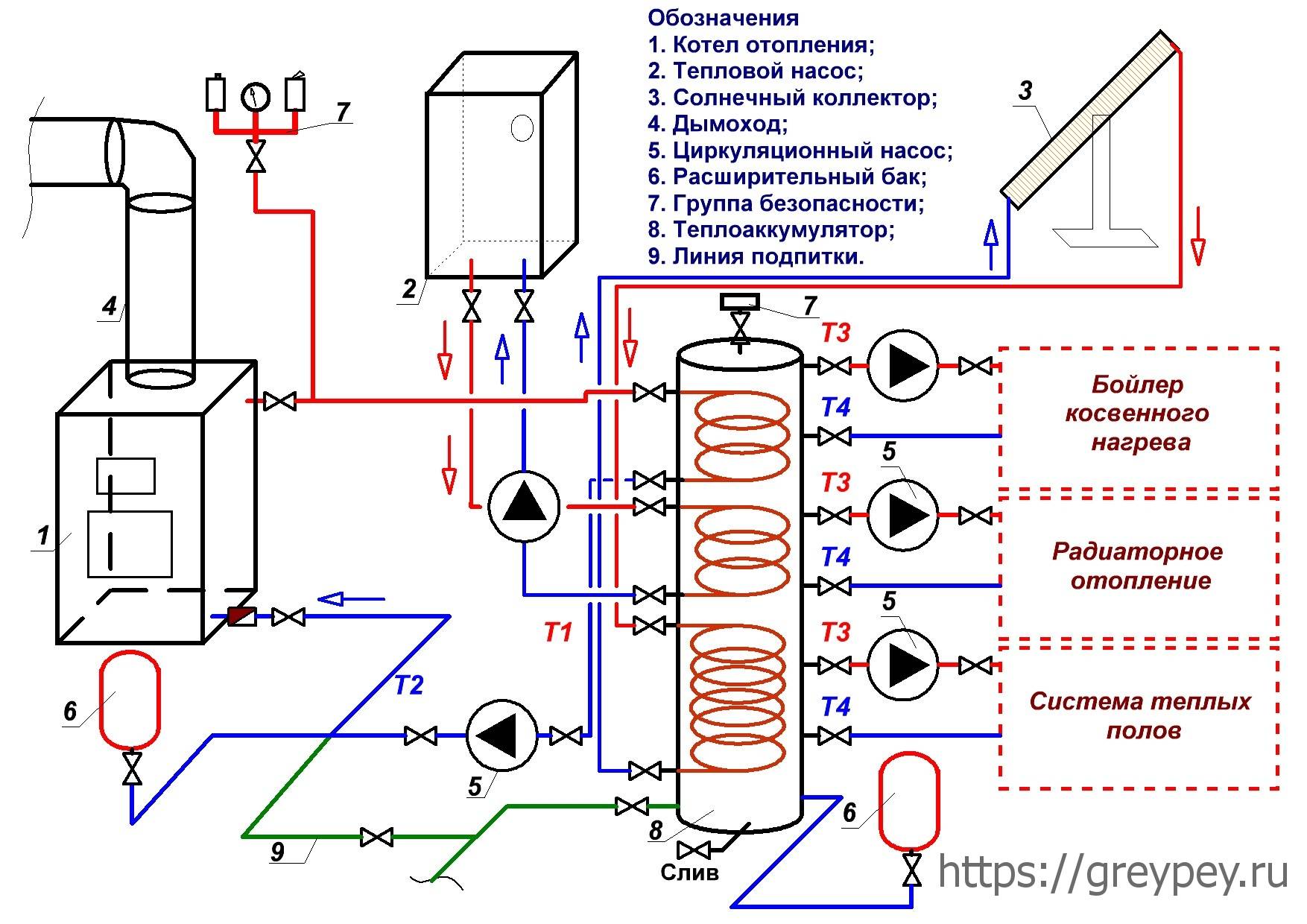

Parallel connection of two heating boilers

In order to extend the service life and evenly distribute the resources used, users often combine two different types of heating sources into a single heat supply scheme. In this case, the main source of heat in winter is a solid fuel boiler. The electric boiler is switched on in emergency mode and during the summer months when it is used to heat water.

Strapping scheme solid fuel heating boiler with parallel electrical connection:

1. Pellet boiler.2. Group of safety of system of heating.3. Alternative boiler (electric or gas).4. Separator for removing air from the system.

5. Circulation pump.6. Manual three-way mixing valve.7. Dry running protection valve.8. Expansion tank.

9. Valve for feeding the system with water.10. Thermal storage tank.11. Heating radiator.12. Washbasin.13. DHW circulation pump.

A heating system based on a pellet boiler is quite complex and requires careful tuning. Before performing installation work, carefully read the instructional material provided by the manufacturing companies.

Selection of a heat accumulator

The remaining criteria for choosing a capacity are not so important and mainly relate to different options. One of them is a built-in coil that heats water for household needs. It can be useful if there are no other means of heating, but for high costs in the DHW network, this method is definitely not suitable.In addition, the heat exchanger will take away part of the “charge” of the heat accumulator, reducing the heating battery life.

A useful option is a heating element built into the upper part of the tank, capable of maintaining the temperature of the coolant at a certain level. Thanks to electric heating, the system will not defrost in the event of an accident and will even be able to heat the house for some time after the battery has “discharged” and the boiler has not yet been started.

The second coil for connecting the solar system is useful only in the southern regions, where solar activity will allow loading the heat accumulator

But what you should pay attention to when choosing is the working pressure of the tank. It should be borne in mind that most solid fuel boilers are designed for jacket pressures up to 3 bar, which means that the buffer tank should easily withstand the same amount.

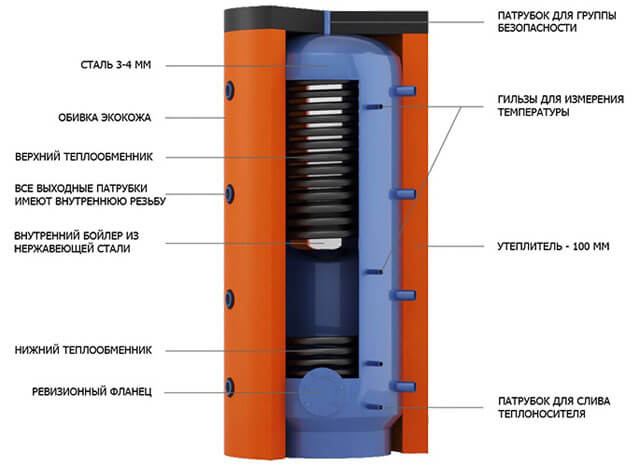

The device and features of the heat accumulator

By design, a typical heat accumulator is a steel tank with nozzles at the top and bottom, which are at the same time the ends of a coil made of copper tube. The lower branch pipes are connected to the heat source, the upper ones - to the heating system. Inside the installation is a liquid that the consumer can use to solve the problems he needs.

Wiring diagram

The principle of operation of the unit is based on the high heat capacity of water. In general, the mechanism of action of a heat accumulator can be described as follows:

- two pipes are cut into the side walls of the container. Through one, cold water enters the tank from the water supply system or from tanks, through the second, the heated coolant is discharged to the heating radiators;

- the upper end of the coil installed in the tank is connected to the cold water pipe of the boiler, the lower end to the hot water pipe;

- circulating through the coil, hot water heats the liquid in the tank. After turning off the boiler, the water in the heating pipes begins to cool down, but continues to circulate. When it enters the heat accumulator, the cool liquid pushes the hot coolant accumulated there into the heating system, due to which the heating of the premises continues for some time (depending on the storage capacity) even when the boiler is turned off.

Important! To ensure the movement of the coolant, the system is equipped with a circulation pump

The principle of operation of pyrolysis boilers and their features

By creating pyrolysis boilers hands, people tend to save money in their wallet. If gas equipment is quite cheap, then solid fuel units are simply amazing at their price. A more or less decent model with a capacity of 10 kW will cost 50-60 thousand rubles - it is cheaper to conduct gas if a gas pipeline passes nearby. But if it is not there, then there are two ways out - to purchase factory equipment or make it yourself.

Make a pyrolysis long burning boiler You can do it yourself, but it's difficult. Let's first understand why pyrolysis is needed at all. In conventional boilers and stoves, wood is burned in the traditional way - at high temperature, with the release of combustion products into the atmosphere. The temperature in the combustion chamber is about + 800-1100 degrees, and in the chimney - up to + 150-200 degrees. Thus, a substantial part of the heat simply flies out.

Direct combustion of wood is used in many heating units:

Solid fuel pyrolysis boilers can use several types of fuel, including waste from woodworking and agricultural processing.

- solid fuel boilers;

- Fireplace stoves;

- Fireplaces with water circuits.

The main advantage of this technique is that it is simple - it is enough to create a combustion chamber and organize the removal of combustion products outside the equipment. The only regulator here is the blower door - by adjusting the clearance, we can adjust the intensity of combustion, thereby affecting the temperature.

In a pyrolysis boiler, assembled with your own hands or bought in a store, the process of fuel combustion is somewhat different. Firewood is burned here at a low temperature. We can say that this is not even burning, but a slow smoldering. Wood at the same time turns into a kind of coke, while releasing combustible pyrolysis gases. These gases are sent to the afterburner, where they burn with the release of a large amount of heat.

If it seems to you that this reaction will not give a special effect, then you are deeply mistaken - if you look into the afterburner, you will see a roaring flame of bright yellow, almost white color. The combustion temperature is slightly above +1000 degrees, and more heat is released in this process than with standard wood combustion.

In order for a self-assembled pyrolysis boiler to be able to show maximum efficiency, firewood with a low moisture content is needed. Wet wood will not allow the equipment to reach its full capacity.

The pyrolysis reaction is familiar to us from the school physics course.In a textbook (and maybe in a laboratory room), many of us saw an interesting reaction - the wood was placed in a sealed glass flask with a tube, after which the flask was heated over a burner. After a few minutes, the wood began to darken, and pyrolysis products began to come out of the tube - these are combustible gases that could be set on fire and watch the yellow-orange flame.

Do-it-yourself pyrolysis boiler works in a similar way:

On one load of fuel, pyrolysis boilers operate for about 4-6 hours. So a large and steadily replenished supply of firewood should be taken care of in advance.

- Firewood is kindled in the firebox until a steady flame appears;

- After that, the access of oxygen is blocked, the flame goes out almost completely;

- The blower fan starts - a high-temperature flame appears in the afterburner.

The device of the pyrolysis boiler is quite simple. The main elements here are: a combustion chamber in which firewood is stored, and an afterburner chamber in which pyrolysis products are burned. Heat is transferred to the heating system through a heat exchanger

In the scheme of the pyrolysis boiler, special attention is paid to it

The thing is that heat exchangers in do-it-yourself pyrolysis boilers are arranged differently than in gas equipment. Combustion products with air pass here through many metal pipes washed by water. To increase efficiency, boiler water washes not only the heat exchanger itself, but also all other nodes - a kind of water jacket is created here, which takes away excess heat from the hot elements of the boiler unit.

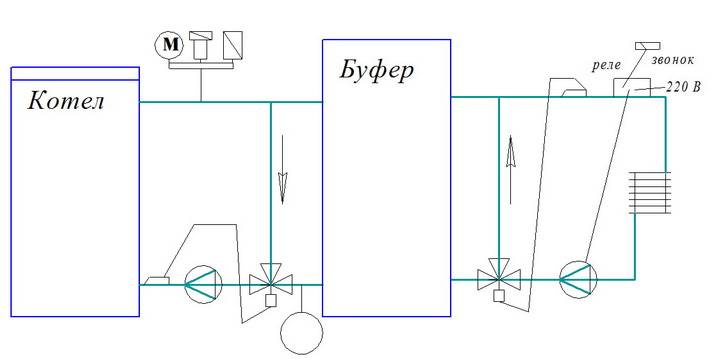

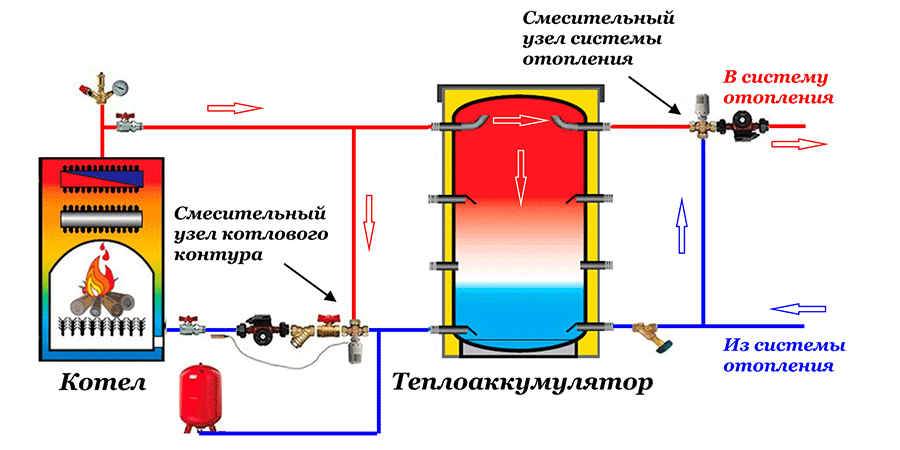

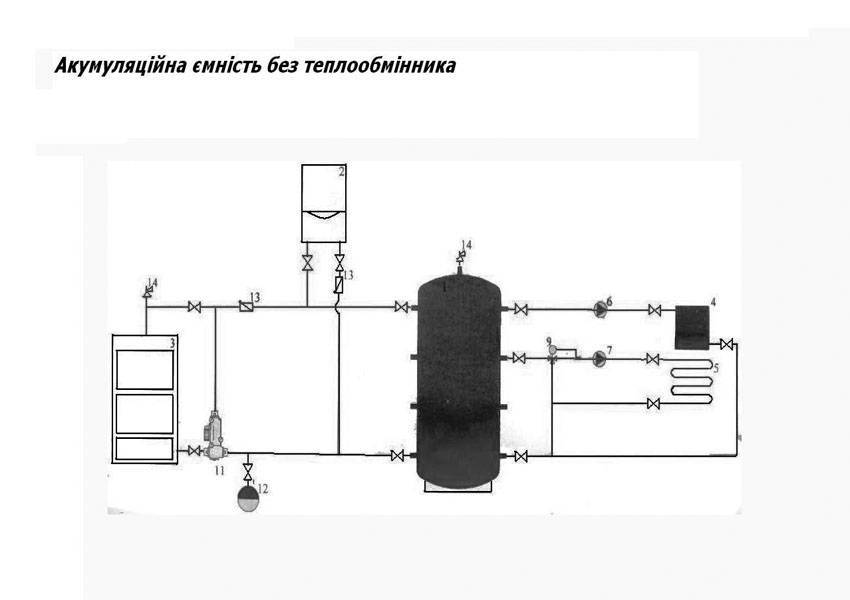

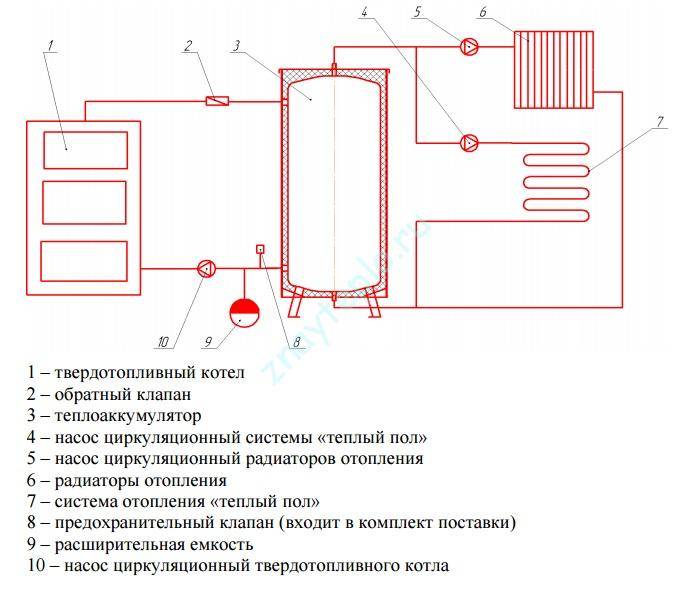

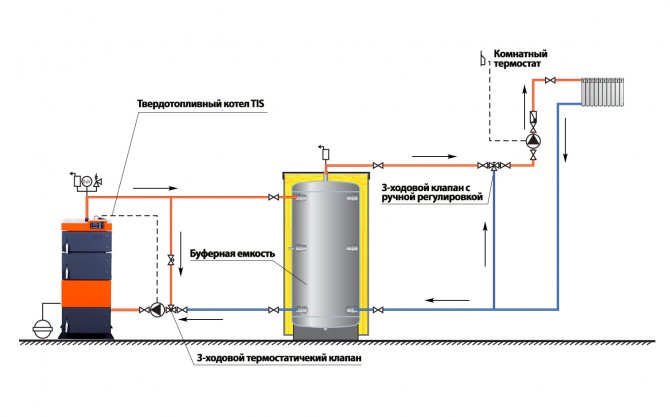

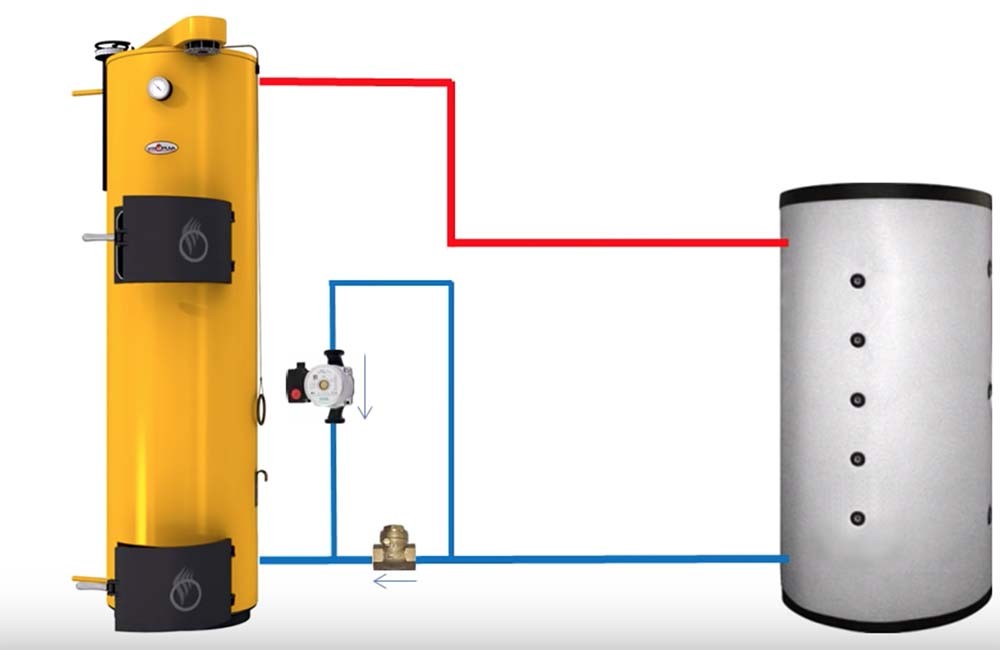

Diagrams for connecting a heat accumulator to a solid fuel boiler and a heating system

The simplest connection scheme is a drive connection scheme with a direct circuit.

The tank has four branch pipes - the upper ones for the hot coolant supply and the lower ones for the return connection. Circulation pumps are installed on the return pipes. Cold coolant from the radiator circuit enters the tank. Further, through the circulation pump, water enters the casing of the solid fuel boiler, heating up, it enters the accumulator back, only through the upper pipe. Then again through the upper pipe, only heating circuit coolant enters the radiators, where it is cooled. In the storage tank, during the period when the main volume is filled with the cooled coolant, active mixing of hot and cooled water does not occur, but hot water flows into the batteries. But as the fuel begins to burn more intensely, more hot water enters the tank and, thus, it is filled with a heated coolant. Given that the tank itself has a large layer of thermal insulation, the heated water cools down slowly, which makes it possible to maintain a stable temperature in the circuit for a long time.

For private houses, depending on the equipment of the system with heating and hot water supply devices, 7 main connection schemes are used:

- Direct connection scheme for solid fuel units;

- Scheme with a diagonal arrangement of pumps and a three-way valve;

- Boiler closed loop circuit;

- Scheme with external heat exchanger;

- Scheme with a heat exchanger of a hot water supply system;

- Device with a hot water storage tank;

- Scheme with additional connection of the solar collector;

Some Features

The configuration of the boiler, its characteristics, drawings will depend on many factors:

- material. Ordinary steel (sheet) is suitable, but heat-resistant stainless steel or cast iron is best.

- Possibilities of good steel processing, reliable connection of structural parts. Usually for this they use mainly a grinder, a gas cutter and electric welding.

- Type, characteristics of fuel (liquid or solid). Steel must withstand high temperatures, not deform, not melt under their influence. Withstand the internal pressure of vapors and gases without breaks and cracks.

- Correct calculation of the method of circulation of the coolant. Will it be natural (due to the correct manipulation of pipe diameters, their slope, tank height, etc.) or forced (using a pump in the circuit).

- Accounting for vapor pressure, the use of valves to discharge excess gases, condensate (return installation).

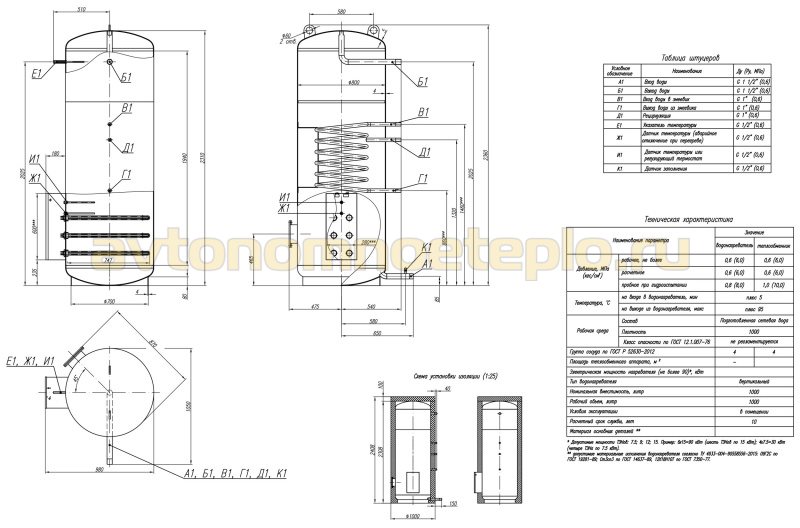

Design calculation

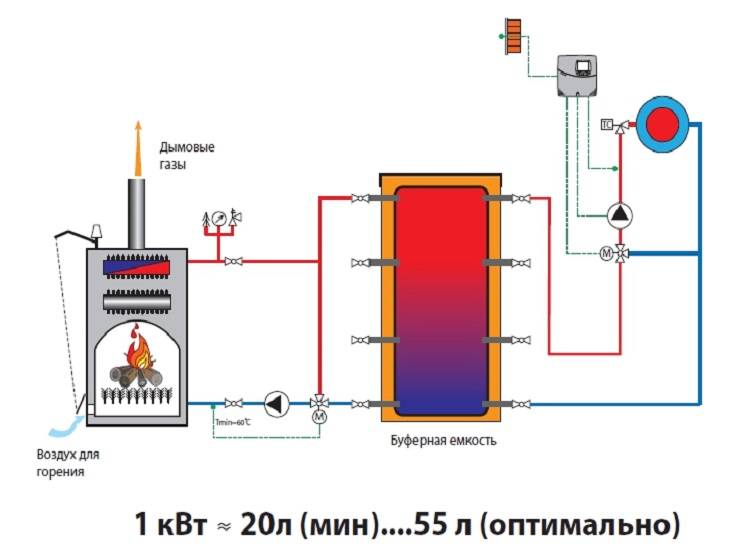

Before preparing drawings and developing schemes for connecting a heat accumulator to a boiler and pipelines, a number of calculations are required.

First of all, it is necessary to calculate the thermal performance of the heating system. But the indicator should be average, and not with a margin for frosty days, otherwise the volume of the tank will be excessively large and a high-power boiler will be required to heat it.

A rational solution is to fully calculate the heat loss of the house, but here it is more convenient to use the simplified principle, according to which 1 kW of heat is required per 10 m2 of the house area to warm it up in severe frosts. The average value will be less than half.Thus, to heat your house of 100 m2, you need a maximum of 10 kW, and an average of 5 kW.

It follows from the fact that the period of time during which the system must function when the boiler is not working is 8 hours. That is, if 5 kW is required per hour, then the required supply of thermal energy for 8 hours will be 8 × 5 = 40 kW.

The maximum water temperature in the tank will be 90 degrees, and the optimum temperature of the coolant in the local radiator system is approximately 60 degrees, so we find the temperature difference, it will be 30 degrees.

To calculate the volume of a heat accumulator (TA) for a heating boiler, we use the formula, and we need to find the value of m, that is, the formula will look like this:

- Q is the consumption of thermal energy (we have 40 kW);

- Δt is the temperature difference (we have 30°С);

- c is the value of the specific heat capacity of water, equal to 0.0012 kW / kg ºС (4.187 kJ / kg ºС);

We carry out calculations: m \u003d 40 / 0.0012 x 30 \u003d 1111 kg, that is, if rounded up, the volume of the tank should be about 1.2 m3. Knowing the required volume and using simple geometric formulas, it is possible to calculate the dimensions of a cylindrical or rectangular tank.

Such a device is able to maintain the temperature of the coolant in the radiators at 60 degrees for 8 hours, then the temperature will gradually decrease, but it will take about 3-4 more hours until the rooms cool completely.

Thermal accumulator: what is it

Structurally, a solid fuel heat accumulator is a special container with a heat carrier, which quickly heats up during the combustion of fuel in the boiler furnace.After the heating unit stops working, the battery gives off its heat, thereby maintaining the optimum temperature in the building.

In combination with a modern solid fuel boiler, the heat accumulator allows to achieve almost 30% fuel savings and increase the efficiency of the system. In addition, the number of loads of the thermal unit can be reduced up to 1 time, and the equipment itself works at full capacity, burning all the loaded fuel as much as possible.

Learn also about the advantages of plastic pipes for heating.

Design and purpose of capacitive tanks

All thermal accumulators are made (and this can be seen in many photos or videos on our website) in the form of some buffer tanks - tanks that are insulated with special materials. At the same time, the volume of such tanks can reach 350-3500 liters. The devices can be used both in open and closed heating systems.

The principle of operation of the heating system with a heat accumulator

As a rule, the main difference between a system with a solid fuel boiler and a heat accumulator from a conventional one is cyclic operation.

In particular, there are two cycles:

- The product of two bookmarks of fuel, burning it in the maximum power mode. At the same time, all excess heat does not fly out “into the pipe”, as with the traditional heating scheme, but accumulates in the battery;

- The boiler does not heat up, and the optimal temperature regime of the coolant is maintained due to heat transfer from the tank. It should be noted that when using modern heat accumulators, it is possible to achieve downtime of the heat generator for up to 2 days (it all depends on the heat loss of the building and the outside air temperature).

Learn also about the features of the process of installing heating boilers.

The main functions of heat accumulators

A solid fuel boiler with a heat accumulator is a very profitable and productive tandem, due to which you can make the heating system more practical, economical and productive.

Heat accumulators perform several functions at once, among which are:

- Accumulation of heat from the boiler with its subsequent consumption at the request of the heating system. Often, this factor is provided by the use of a three-way valve or special automation;

- Protection of the heating system from dangerous overheating;

- Possibility of simple linking in one scheme of several different heat sources;

- Ensuring the operation of boilers with maximum efficiency. Actually, this function appears due to the operation of equipment at elevated temperatures and a decrease in fuel consumption;

Heat accumulators as per selection

- Stabilization of temperature conditions in the building, reducing the number of fuel loadings into the boiler. At the same time, these indicators are quite significant, which makes the installation of such equipment a more efficient and financially profitable solution;

- Providing the building with hot water. Mandatory installation of a special thermostatic safety valve at the outlet of the heat accumulator tank is required, since the water temperature can reach more than 85C.

Calculation heat accumulator for solid fuel boilers can be produced in various ways. But, if you need to quickly perform all the calculations, then it is better to use the option proven in practice - at least 25 liters of volume should fall on 1 kW of solid fuel boiler power.The higher the power of heat engineering, the larger the volume required to install the battery.

Design features of tanks

The use of a heat accumulator: when equipment is needed

The instructions for heat accumulators of solid fuel boilers indicate that such units should be used in several main cases:

- The need for efficient hot water supply in large volumes. For example, if the house has two or more bathrooms, a large number of taps, then you can’t do without heat accumulators, because the technique significantly increases water production without extra financial costs;

- When using solid fuels with different heat release coefficients. Due to this technique, it is possible to smooth out the combustion peaks and reduce the number of bookmarks;

- If there is a need in the house to charge the batteries with heat at the “night rate”;

- When using heat pumps. In the event that, in addition to a solid fuel boiler, there is also an alternative heating system in the building, the battery will help optimize the operating time of the compressor of the installation.

Hot water mixing and valve addition

In order for the system to work, it is necessary to provide automatic mixing of hot water into the return line. Thus, we increase the temperature of the water entering the boiler. If too cold coolant gets into it, the boiler can quickly fail. There are several common strapping schemes with the addition of a return line. We use a three-way mixing thermostatic valve.Installing this valve allows you to form a small circle of circulation of the coolant, as a result of which the heating of the boiler will accelerate. This approach prevents the formation of condensate, thereby protecting the heat exchanger from damage due to a significant temperature difference.

Let's imagine a simulated situation. We set the built-in petal valve to operate when the temperature reaches 55 degrees. When the boiler is started, the water in the system is not heated and while it is cold, the valve closes and starts the carrier in a small circle. After the supply water heated up to the threshold value of 55 degrees, the valve opened slightly and began to mix in chilled water from the return. At the next stage, the entire barrel is heated, while the return temperature will also rise above 55 degrees. At this point, the valve will fully switch and let water flow through the large ring.

After connecting the return flow, we add a pressure relief valve to the solid fuel boiler piping circuit. It is necessary in case of exceeding performance. The solid fuel boiler has a special hole for mounting the valve. In other models, the valve can be installed through a tee. We include an expansion tank in the system. After it, to complete the piping on the side of the heat generator, it is necessary to connect an electric boiler. It is included in the circuit in parallel with the already installed solid fuel boiler.

We have formed two feeds, on each of them it is necessary to install check valves. This is done so that the pump of one of the boilers did not pump water along the working contour in opposition to another. Recall that on a solid fuel boiler we use not an ordinary, but a petal valve.

The principle of operation of solid fuel boilers and their device

Solid organic fuel is the most ancient source of energy for mankind. To refuse it completely, even in the modern world, is impossible. Moreover, in addition to firewood and coal, many other types of combustible solids have appeared today:

- peat briquettes - dried and pressed peat releases a lot of heat during combustion;

- briquettes from woodworking waste - compressed sawdust, shavings and tree bark;

- birch charcoal - the same as for the barbecue;

- recycled garbage from landfills;

- fuel heating pellets - fine fuel obtained by pressing sawdust. Can be fed automatically

- ordinary dry sawdust.

Various raw materials for use in solid fuel boilers

It is clear that all this fuel is obtained by processing various wastes, which solves the problem of recycling at enterprises and goes in line with the "green" economy.

Useful advice! The most affordable fuel listed above is sawdust. If you intend to use them for heating, make sure they have less than 20% humidity. Large values of this parameter will not allow pyrolysis gas to be produced, since most of the heating energy will go to dry the fuel.

As a result of human activity, a huge amount of waste is generated that can be converted into high-energy fuel, which led to the appearance on the market of heating boilers for long-burning solid fuels. Unlike conventional furnaces, these units do not work on the combustion of the fuel itself, but on its splitting as a result of heating. In the working chamber of such boilers, gaseous decomposition products of solid fuels are burned.This scheme of work is several times more efficient than the conventional combustion of fossil fuels. Pyrolysis gas gives off a large amount of energy.

The principle of operation of a solid fuel boiler for long burning

The device of such a gas generator installation is not very complicated. You can even build a long-burning solid fuel boiler with your own hands. The drawing of the simplest version looks like this:

- a closed cylindrical tank, which has a hatch for laying fuel, a blower and a hole for installing a chimney;

- an air distributor is located inside the tank, which creates a swirl of the pyrolysis gas. It is attached to a movable telescopic tube. This whole structure, similar to a piston, presses on the fuel from above. The combustion of gas occurs above the piston, and the fuel smolders below it;

- the heat exchanger is built into the upper chamber where the maximum temperature is reached.

Slow smoldering of solid fuel occurs in the lower chamber. It is achieved by adjusting the air supply to the blower. The released gas burns intensively in the upper chamber and heats the coolant.

Scheme of the heating system of a private house using a solid fuel boiler

Useful advice! Do not use the simplest design for the manufacture of a boiler that will heat a residential building on an ongoing basis. To do this, you need to either purchase a finished product, or make a more complex and reliable version.

Long-burning solid fuel boilers can be indispensable in private homes, outbuildings, garages and greenhouses. They will be especially beneficial where there is a large wood processing industry, since waste at such enterprises is given away almost free of charge.These units are also needed in areas where there are regular interruptions in gas supply. Such installations have many advantages, but there is also one important drawback - a very high cost. That is why today it is important to make do-it-yourself solid fuel boilers for long burning. Drawings for this can be used with varying degrees of complexity. It depends on the skill level.

Do-it-yourself water heating of a private house, design schemes. Pros and cons. The difference between natural and forced water circulation.