- How does a solid fuel system with a storage tank work?

- The nuances of using heat accumulators and operating tips

- Heat accumulator piping schemes

- Schemes for connecting a buffer tank to a solid fuel boiler and a heating system

- Rules for safe operation

- Calculation of the volume of the storage tank

- Making a solid fuel boiler with your own hands

- What is a heat accumulator for, and how is it calculated

- Calculation Explanations

- Thermal accumulator: what is it

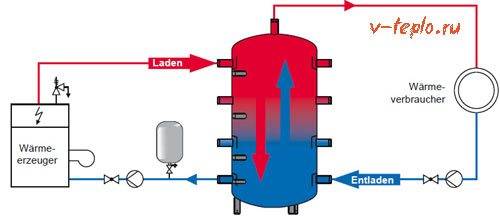

- The principle of operation of the heating system with a heat accumulator

- The main functions of heat accumulators

- The use of a heat accumulator: when equipment is needed

- The use of heat accumulators in TT heating systems

- Modernization of the heat accumulator

- Simple heat accumulator

- Buffer capacity calculation

How does a solid fuel system with a storage tank work?

The greatest savings in resources will be achieved when a heat accumulator is connected for solid fuel heating boilers.

The principle of the device of such a system can be divided into two stages:

- heat from fuel combustion enters through a heat exchanger to heating radiators, which, in turn, give off heat to the environment;

- after cooling, the water from the radiators rushes down and re-enters the boiler heat exchanger for subsequent heating.

And then everything repeats in a circle. Such a scheme has two significant negative points that affect heat loss:

- water as a heat carrier is directed from the boiler to the radiators directly and cools down quickly;

- insufficient volume of water-coolant in the heating system does not allow to maintain a constant temperature, so it has to be regularly heated in the boiler circuit.

This is extremely wasteful. Especially when it comes to solid fuels. Essentially, the following is happening. Fuel is put into the boiler, which at first burns quite intensively. Therefore, the room warms up very quickly. However, when the fuel stops burning, the temperature of the water in the radiators immediately drops, and the house immediately becomes cold. In order to constantly maintain a comfortable temperature in the room, it is necessary to put more and more batches of fuel into the boiler.

The nuances of using heat accumulators and operating tips

- If you plan to leave home for a long time, then you need to set the thermostat of the three-way valve to the minimum temperature. With this "economical" mode of operation, the heating circuit can operate for several days;

- The weather-dependent automation unit, built into the system with TA, will regulate the temperature of the coolant in the radiators as the weather conditions change;

- If you make a relay thermostat with an immersion sleeve in the upper part of the buffer tank and set it to, for example, 35 °C, and 60 °C on the valve thermostat, then when the thermostat shows 25 °C (60-35 \u003d 25 °C), the pump circulation will automatically turn off;

- If the calculation showed a large volume of TA that does not fit into the dimensions of the room, then it can be replaced with two smaller containers, connecting them with pipes in the upper and lower parts;

- To prevent electrochemical corrosion of the TA, it is necessary to connect grounding to it;

- If the circuit includes an electric boiler, then it is better to use the night-time tariff to heat the water volume of the storage tank, if such is provided for in the service conditions.

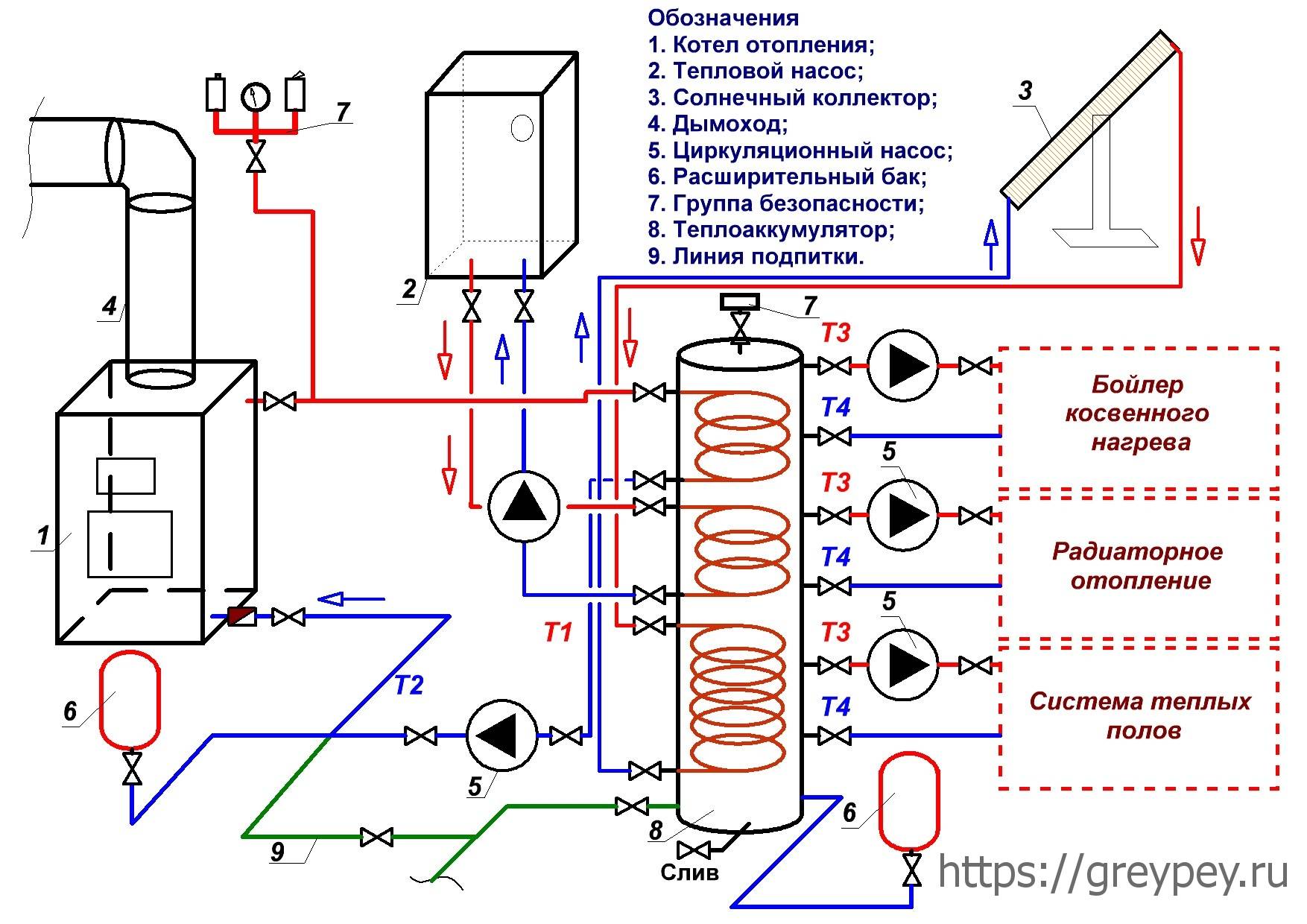

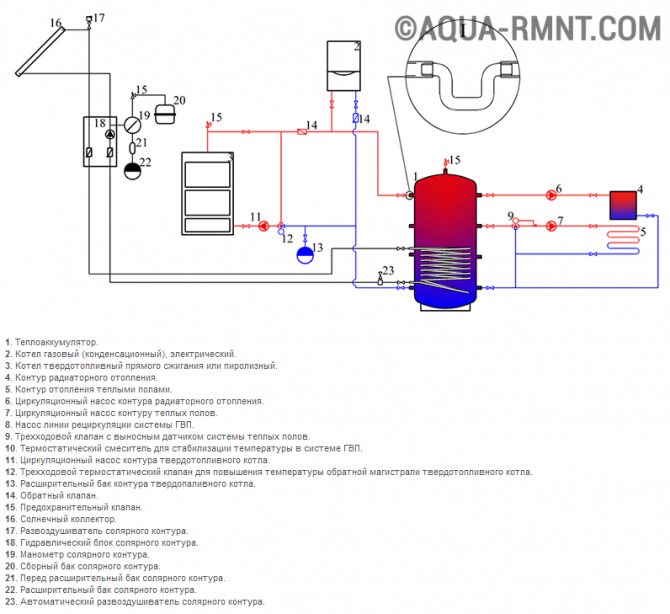

Heat accumulator piping schemes

We dare to assume that if you are interested in this article, then most likely you decided to make a heat accumulator for heating and tie it yourself. You can come up with a lot of connection schemes, the main thing is that everything works. If you correctly understand the processes taking place in the circuit, then you can quite experiment. How you connect the HA to the boiler will affect the operation of the entire system. Let's first analyze the simplest heating scheme with a heat accumulator.

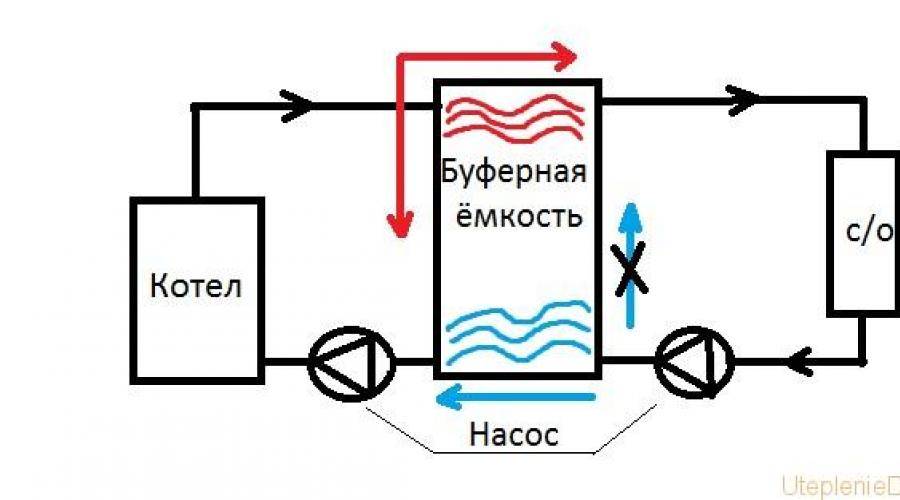

A simple TA strapping scheme

In the figure you see the direction of movement of the coolant

Please note that upward movement is prohibited. To prevent this from happening, the pump between the TA and the boiler must pump a larger amount of coolant than the one that stands up to the tank. Only in this case will a sufficient retracting force be formed, which will take part of the heat from the supply

The disadvantage of such a connection scheme is the long heating time of the circuit. To reduce it, you need to create a boiler heating ring. You can see it in the following diagram.

Only in this case will a sufficient retracting force be formed, which will take part of the heat from the supply.The disadvantage of such a connection scheme is the long heating time of the circuit. To reduce it, you need to create a boiler heating ring. You can see it in the following diagram.

TA piping scheme with a boiler heating circuit

The essence of the heating circuit is that the thermostat does not mix water from the TA until the boiler warms it up to the set level. When the boiler is warmed up, part of the supply goes to the TA, and the part is mixed with the coolant from the reservoir and enters the boiler. Thus, the heater always works with an already heated liquid, which increases its efficiency and the heating time of the circuit. That is, the batteries will get warm faster.

This method of installing a heat accumulator in the heating system allows you to use the circuit in offline mode when the pump will not work.

Please note that the diagram shows only the nodes for connecting the TA to the boiler. The circulation of the coolant to the radiators occurs in a different way, which also passes through the TA. The presence of two bypasses allows you to play it safe twice:

The presence of two bypasses allows you to play it safe twice:

- the check valve is activated if the pump is stopped and the ball valve on the lower bypass is closed;

- in the event of a pump stop and a failure of the check valve, circulation is carried out through the lower bypass.

In principle, some simplifications can be made in such a construction. Given the fact that the check valve has a high flow resistance, it can be excluded from the circuit.

TA piping scheme without check valve for gravity system

In this case, when the light disappears, you will need to manually open the ball valve. It should be said that with such a wiring, the TA should be above the level of the radiators.If you do not plan that the system will work by gravity, then the piping of the heating system with a heat accumulator can be performed according to the scheme shown below.

Scheme of piping TA for a circuit with forced circulation

In TA, the correct movement of water is created, which allows ball after ball, starting from the top, to warm it up. Perhaps the question arises, what to do if there is no light? We talked about this in an article about alternative power sources for a heating system. It will be more economical and more convenient. After all, gravity circuits are made of large-section pipes, and besides, not always convenient slopes must be observed. If you calculate the price of pipes and fittings, weigh all the inconveniences of installation and compare it all with the price of a UPS, then the idea of installing an alternative power source becomes very attractive.

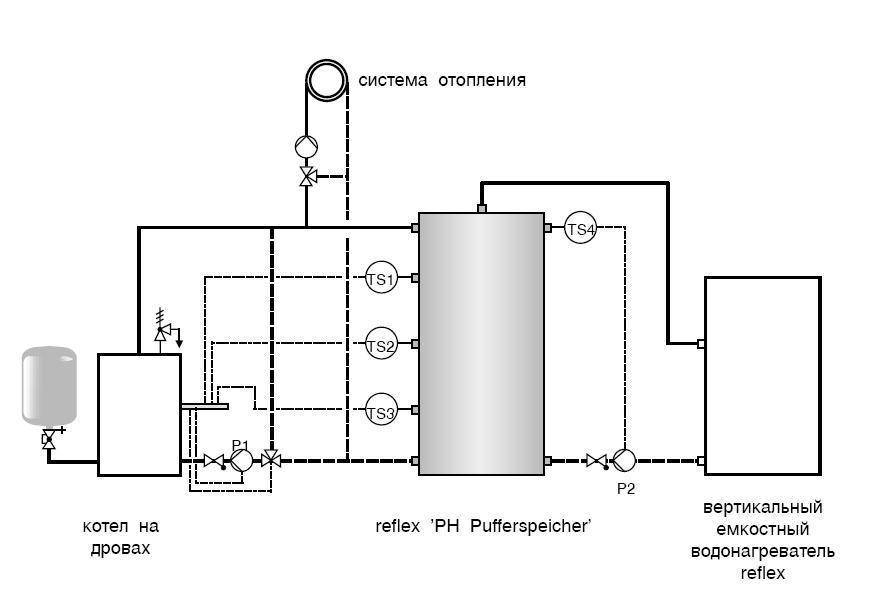

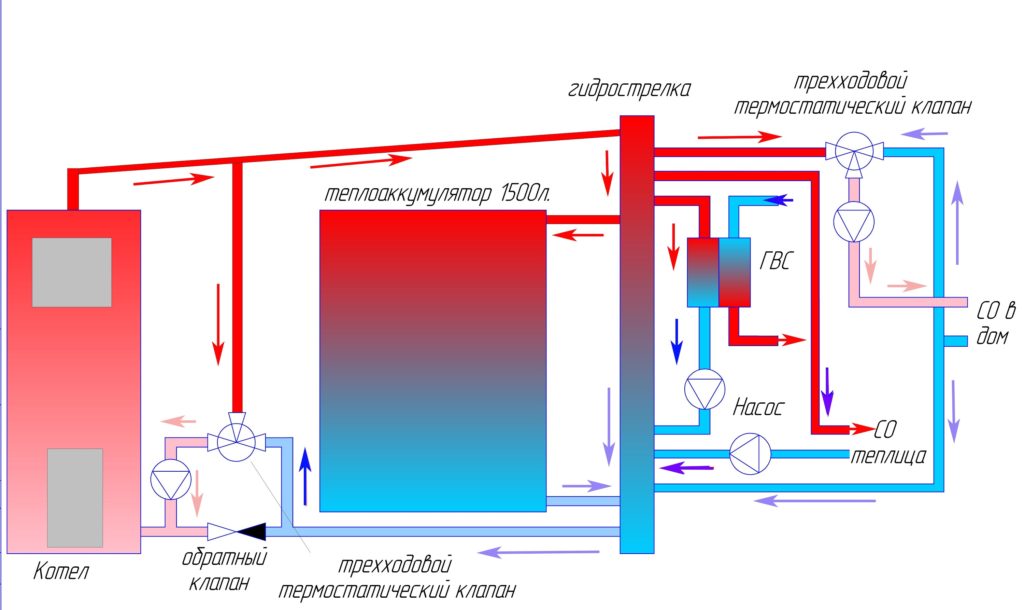

Schemes for connecting a buffer tank to a solid fuel boiler and a heating system

The Sjawa topic aroused great interest on the portal. Users began to discuss the scheme for connecting the TA to the boiler.

ZelGenUser

Looked at the scheme of the heating system. The question arose, why is the entrance to the TA located just above the middle of the tank? If the inlet is made from the top of the buffer tank, then the hot carrier from the TT boiler is immediately fed to the outlet, without mixing with the colder carrier in the TA. The container is gradually filled with hot coolant from top to bottom. And so, until the upper half of the TA warms up, which is approximately 500 liters, the hot carrier in the TA is mixed and cooled.

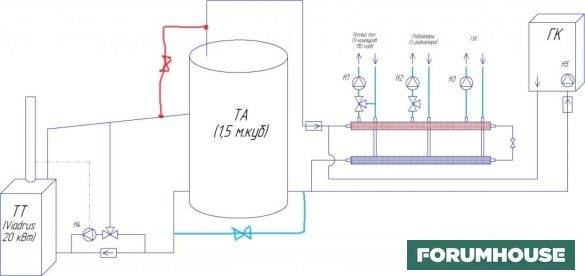

According to Sjawa, the input to the heat accumulator is designed for better EC (natural circulation in case of a power outage) and to reduce unnecessary mixing of the coolant at a time when CO does not remove heat or takes little of it. Becausethe scheme of the heating system with TA laid out at the beginning is general, then the user sketched out more detailed options for the operation of the tank.

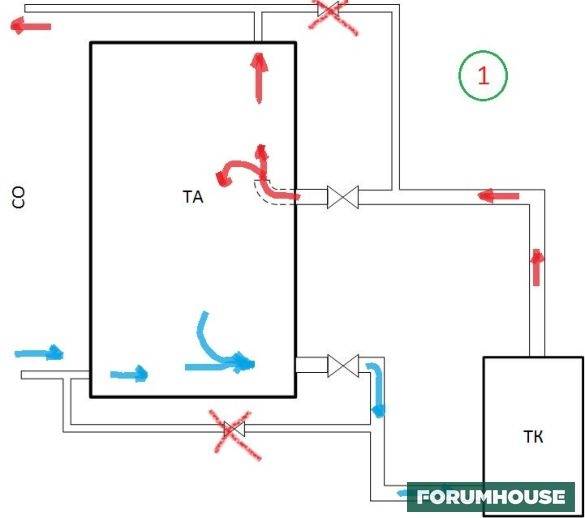

Scheme 1.

Advantages - if the light is turned off, then natural circulation works. The disadvantage is the inertia of the system.

Advantages - if the light is turned off, then natural circulation works. The disadvantage is the inertia of the system.

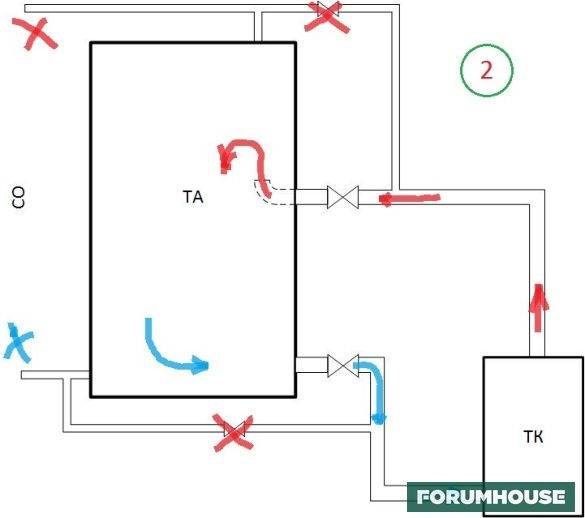

Scheme 2.

An analogue of the first scheme, but if all thermal heads are closed in the heating system, then the upper part of the heat accumulator is the warmest and there is no intensive mixing. When the thermal heads are opened, the coolant is immediately supplied to the CO. This reduces inertia. There is also an EC.

An analogue of the first scheme, but if all thermal heads are closed in the heating system, then the upper part of the heat accumulator is the warmest and there is no intensive mixing. When the thermal heads are opened, the coolant is immediately supplied to the CO. This reduces inertia. There is also an EC.

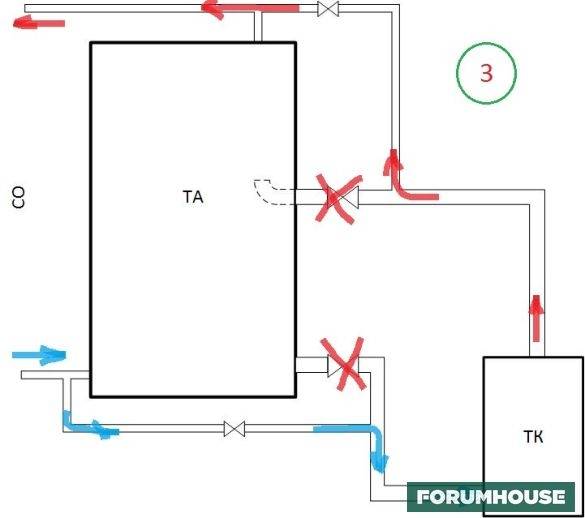

Scheme 3.

The heat accumulator is placed parallel to the system. Advantages - fast supply of coolant, but natural circulation in the system is in doubt. Possible boiling of the coolant.

The heat accumulator is placed parallel to the system. Advantages - fast supply of coolant, but natural circulation in the system is in doubt. Possible boiling of the coolant.

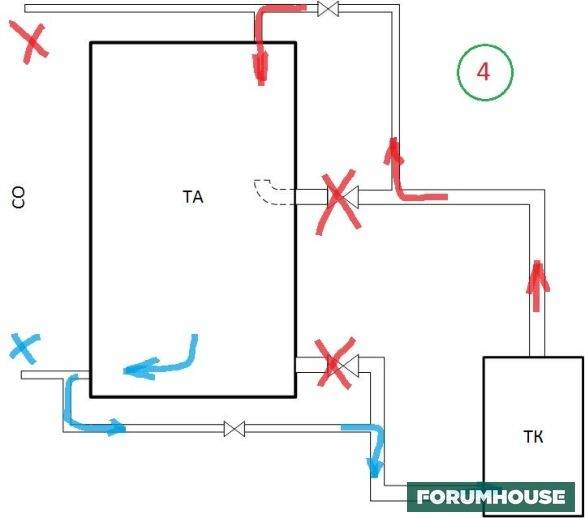

Scheme 4.

Development of the third scheme with closed thermal heads. The disadvantage is that there is a complete mixing of all layers of water in the heat accumulator, which is bad with natural circulation if there is no electricity.

Development of the third scheme with closed thermal heads. The disadvantage is that there is a complete mixing of all layers of water in the heat accumulator, which is bad with natural circulation if there is no electricity.

SjavaUser

As you can see, when opening and closing the taps, you can implement different switching options, but I'm set to option 1 and 2. The bottom of the heat accumulator is 700 mm higher than the bottom of the boiler. Branch pipes included in TA 1 1/2 ', and outgoing in CO 1 '. The variant with the top placement of the branch pipe is suitable for HE with coils inside, for indirect heating of the coolant.

As a result, the user slightly modified the circuit by putting bypasses between the input to the heat accumulator from the solid fuel boiler and the supply to the heating system and to the return.

This made it possible to change the connection scheme of the heat accumulator from parallel to serial.For example, the heating season has ended and the heat accumulator has cooled down, but it has become colder, then, without heating the heat accumulator, you can quickly heat the house with a boiler.

Rules for safe operation

Do-it-yourself heat accumulators are subject to special safety requirements:

- The hot parts of the tank must not come into contact with or otherwise come into contact with flammable and explosive materials and substances. Ignoring this item can provoke the ignition of individual objects and a fire in the boiler room.

- A closed heating system assumes a constant high pressure of the coolant circulating inside. To ensure this point, the design of the tank must be completely tight. In addition, it is possible to strengthen its body with stiffeners, and equip the lid on the tank with durable rubber gaskets that are resistant to intense operating loads and elevated temperatures.

- If an additional heating element is present in the design, it is necessary to insulate its contacts very carefully, and the tank must be grounded. In this way, it will be possible to avoid electric shock and short circuit, which can disable the system.

Subject to these rules, the operation of a self-made heat accumulator will be completely safe and will not cause any problems or troubles to the owners.

Calculation of the volume of the storage tank

This solution lies in the fact that a do-it-yourself heat accumulator is a conventional insulated container with two nozzles for connecting to the heating system.The bottom line is that the boiler, during operation, partially directs the coolant into the storage tank when the radiators do not need it. After turning off the heat source, the reverse process occurs: the operation of the heating system is supported by water coming from the accumulator. To do this, it will be necessary to correctly tie the storage tank with the heat generator.

The first step is to determine the volume of the tank for the accumulation of thermal energy and assess the possibility of placing it in the boiler room. In addition, it is not necessary to start the manufacture of heat accumulators for solid fuel boilers from scratch; there are various options for selecting ready-made vessels of suitable capacity.

We propose to roughly determine the volume of the tank in the simplest way, based on the laws of physics. To do this, you need to have the following initial data:

- thermal power required for heating the house;

- the time during which the heat source will be turned off and a storage tank for heating will take its place.

We will show the calculation method with an example. There is a building with an area of 100 m2, where the heat generator is idle for 5 hours a day. On a larger scale, we accept the required thermal power in the amount of 10 kW. This means that every hour the battery must supply 10 kW of energy to the system, and for the entire period of time it must be accumulated 50 kW. At the same time, the water in the tank is heated to at least 90 ºС, and the temperature at the supply in the heating systems of private houses in the standard mode is assumed to be 60 ºС. That is, the temperature difference is 30 ºС, we substitute all these data into the formula well known from the physics course:

Since we want to know the amount of water that the heat accumulator should contain, the formula takes the following form:

- Q is the total consumption of thermal energy, in the example it is 50 kW;

- c - specific heat capacity of water, is 4.187 kJ / kg ºС or 0.0012 kW / kg ºС;

- Δt is the temperature difference between the water in the tank and the supply pipe, for our example it is 30 ºС.

m \u003d 50 / 0.0012 x 30 \u003d 1388 kg, which occupies an approximate volume of 1.4 m3. So, a thermal battery for a solid fuel boiler with a capacity of 1.4 m3, filled with water heated to 90 ºС, will provide a house with an area of 100 m2 with a heat carrier with a temperature of 60 ºС for 5 hours. Then the water temperature will drop below 60 ºС, but it will take some more time (3-5 hours) to completely “discharge” the battery and cool the rooms.

Important! In order for a do-it-yourself heat accumulator to be fully “charged” during the operation of the boiler, the latter must have at least one and a half power reserves. After all, the heater must simultaneously heat the house and load the storage tank with hot water

Making a solid fuel boiler with your own hands

A solid fuel boiler for a private house can theoretically be made independently. To do this, you need to take a large 300 mm pipe, from which a meter piece is cut off. From the steel sheet, you need to cut the bottom according to the diameter of the pipe and weld the elements. The legs of the boiler can be 10 cm channels.

When making a solid fuel boiler for a private house, you will need to make an air distributor in the form of a circle from a sheet of steel. Its diameter should be less than the pipe by 20 mm. In the lower part of the circle, it is necessary to weld the impeller from the corner.The size of its shelf should be 50 mm. For this, a channel with the same dimensions is also suitable. A 60 mm pipe should be welded into the central upper part of the distributor, which should be located above the boiler. A hole is made through the pipe in the middle of the distributor disk to form a through tunnel. It is necessary for air supply.

A damper is attached to the top of the pipe, which will provide adjustment of the air supply. If you are faced with the question of how to make a solid fuel boiler, then you should familiarize yourself with the technology. The next step indicates the need to complete the lower part of the equipment, where the door to the ash pan will be located. Holes are cut at the top. At this point, a 100 mm pipe is welded. At first, it will go at a certain angle to the side. Then up 40 cm, and then strictly vertically. Through the overlap, the passage of the chimney must be protected according to fire safety rules.

The completion of the manufacture of the boiler is accompanied by work on the top cover. In its central part there should be a hole for the distributor pipe. The attachment to the wall of the equipment must be tight. Air ingress is excluded.

Having made a solid fuel boiler for long burning on wood, you will need to kindle it for the first time. To do this, remove the lid, lift the regulator, and fill the equipment to the top. Fuel is doused with a flammable liquid. A burning torch is thrown inside through the regulator tube. As soon as the fuel flares up, the air flow will need to be reduced to a minimum in order for the firewood to begin to smolder. As soon as the gas ignites, the boiler will start.

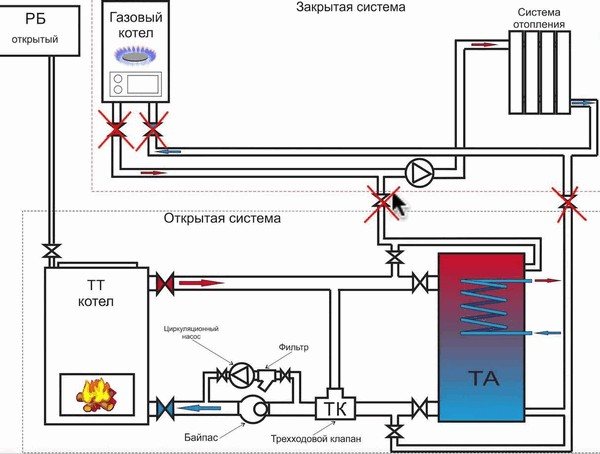

What is a heat accumulator for, and how is it calculated

Not all heating systems require a heat accumulator. But here is the owner of houses with electric or wood-burning boilers - there is something to think about.

Let's first look at the operation of a wood-fired boiler. Immediately striking is the pronounced cyclicity of heat generation with alternation of various stages. From the complete absence of heat input with regular mandatory cleaning of the chambers and loading the firebox with firewood, to maximum heat transfer when reaching full power. And so on - according to the established mode of operation of the system.

It turns out that with the active burning of firewood, heat is most likely generated in excess, and when the bookmark burns out, it is clearly not enough. The heat accumulator in such a situation helps to “smooth out these sinusoids” - excess heat accumulates during the period of activity, and, if necessary, is dosed into the heating circuit.

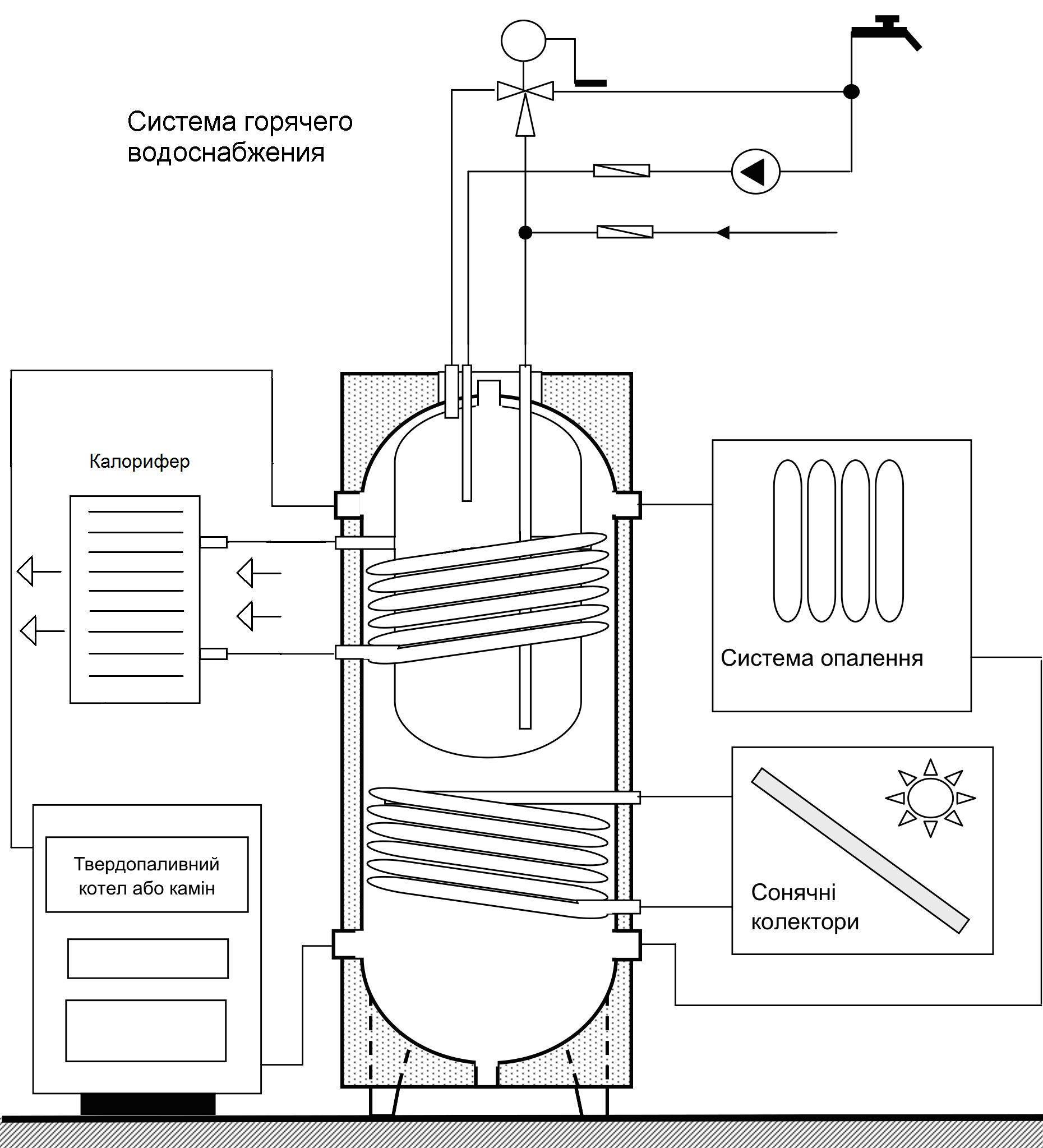

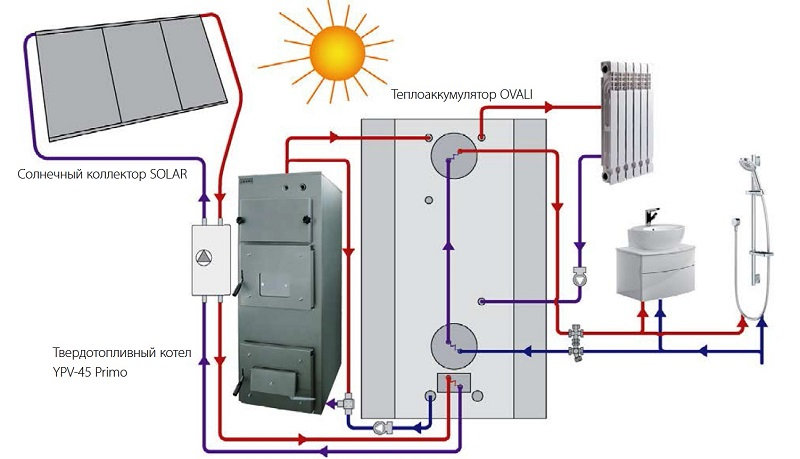

One of the simplest options for tying a solid fuel boiler with a heat accumulator

Electric boilers are among the most convenient and safe to use, extremely simple and obedient to operate. But the high cost of electrical energy "spoils the whole picture." In order to somehow reduce costs, it probably makes sense to postpone the operation of electric boiler equipment for the duration of preferential tariffs - for the night. That is, during this period of time, “pump up” the heat accumulator with heat, and then gradually spend the created reserve during the day.

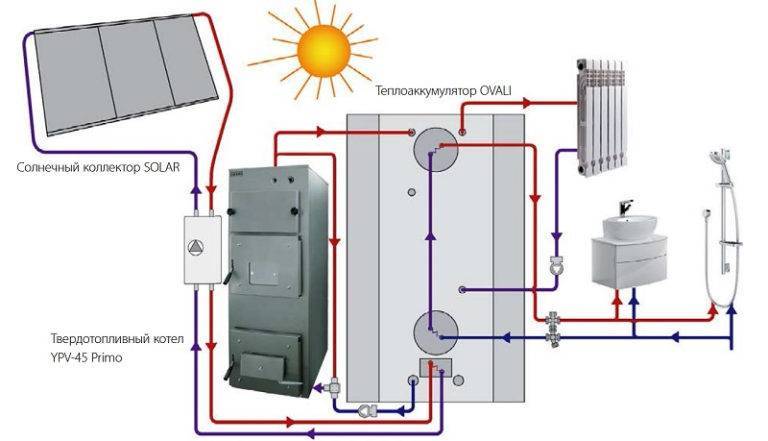

By the way, the presence of a heat accumulator is a big plus for those who intend to use alternative sources. For example, if desired, connects to it and rooftop solar collector, which on a fine day can give out a very significant influx of heat.

The principle of this battery is not so complicated - in fact, it is a capacious tank filled with water. Due to the high heat capacity of water, it gets the opportunity to accumulate heat, which is then rationally used by a well-tuned heating system.

But how much buffer capacity is needed? This must be known at least for those reasons in order to provide free space in the boiler room for the installation of such large-sized equipment.

For the calculation, there is a special formula, on the basis of which an online calculator was compiled, which is offered to the attention of readers.

Calculation Explanations

To calculate, the user must specify several initial values in the fields of the calculator.

The estimated amount of heat required to fully heat the house. In theory, the owners should have such information if they have been living in the house for more than a year. If not, then you will have to calculate, and we will help with this too.

- The next parameter is the nameplate power of the existing boiler. You should feel the difference between this and the previous values, as they are often confused.

- Boiler activity period.

- For solid fuel, this is the burn-out time of a wood-burning bookmark, which is known to the owners from the experience of maintenance, that is, the period when the boiler actually supplies heat to the common “piggy bank”.

- For electric - the period of time for which the operation of the boiler is programmed during the period of the preferential night tariff.

- The efficiency of the boiler - you have to look in the technical description of the model.Sometimes it is abbreviated as efficiency, sometimes it is denoted by the Greek letter η.

- Finally, the last two fields of the calculator are the temperature regime of the heating system. That is - the temperature in the supply pipe at the outlet of the boiler, and in the "return" pipe at the inlet to it.

Now it remains only to press the "CALCULATE ..." button - and the result will be displayed in liters and cubic meters. From this minimum value, they “dance” already when choosing a suitable model of a heat accumulator. Such a device is guaranteed to provide the most economical operation of the heating system.

Thermal accumulator: what is it

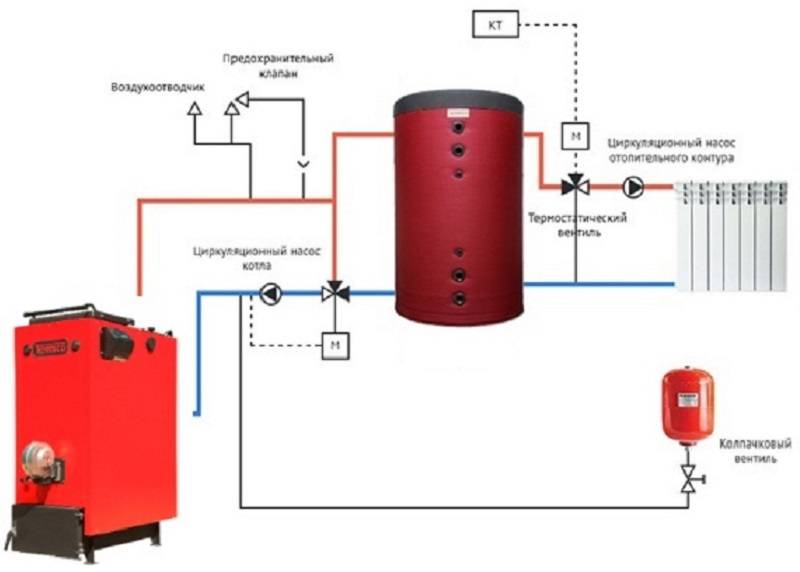

Structurally, a solid fuel heat accumulator is a special container with a heat carrier, which quickly heats up during the combustion of fuel in the boiler furnace. After the heating unit stops working, the battery gives off its heat, thereby maintaining the optimum temperature in the building.

In combination with a modern solid fuel boiler, the heat accumulator allows to achieve almost 30% fuel savings and increase the efficiency of the system. In addition, the number of loads of the thermal unit can be reduced up to 1 time, and the equipment itself works at full capacity, burning all the loaded fuel as much as possible.

Learn also about the advantages of plastic pipes for heating.

Design and purpose of capacitive tanks

All thermal accumulators are made (and this can be seen in many photos or videos on our website) in the form of some buffer tanks - tanks that are insulated with special materials. At the same time, the volume of such tanks can reach 350-3500 liters. The devices can be used both in open and closed heating systems.

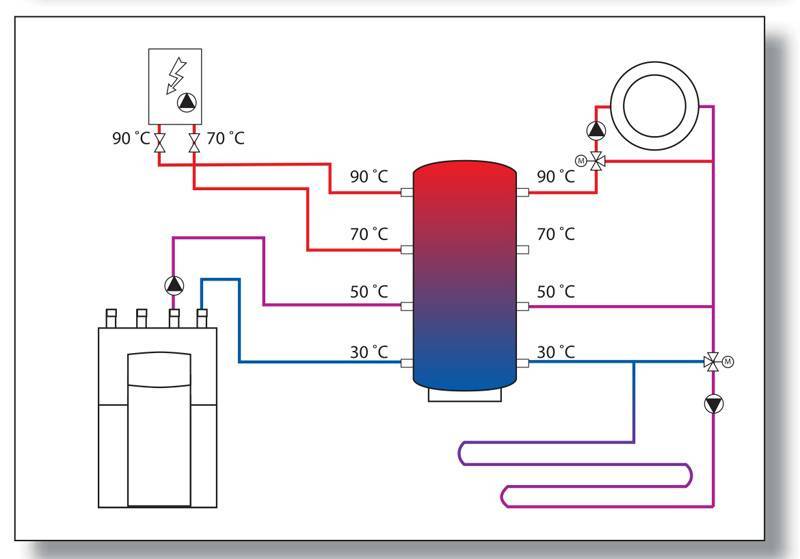

The principle of operation of the heating system with a heat accumulator

As a rule, the main difference between a system with a solid fuel boiler and a heat accumulator from a conventional one is cyclic operation.

In particular, there are two cycles:

- The product of two bookmarks of fuel, burning it in the maximum power mode. At the same time, all excess heat does not fly out “into the pipe”, as with the traditional heating scheme, but accumulates in the battery;

- The boiler does not heat up, and the optimal temperature regime of the coolant is maintained due to heat transfer from the tank. It should be noted that when using modern heat accumulators, it is possible to achieve downtime of the heat generator for up to 2 days (it all depends on the heat loss of the building and the outside air temperature).

Learn also about the features of the process of installing heating boilers.

The main functions of heat accumulators

A solid fuel boiler with a heat accumulator is a very profitable and productive tandem, due to which you can make the heating system more practical, economical and productive.

Heat accumulators perform several functions at once, among which are:

- Accumulation of heat from the boiler with its subsequent consumption at the request of the heating system. Often, this factor is provided by the use of a three-way valve or special automation;

- Protection of the heating system from dangerous overheating;

- Possibility of simple linking in one scheme of several different heat sources;

- Ensuring the operation of boilers with maximum efficiency. Actually, this function appears due to the operation of equipment at elevated temperatures and a decrease in fuel consumption;

Heat accumulators as per selection

- Stabilization of temperature conditions in the building, reducing the number of fuel loadings into the boiler. At the same time, these indicators are quite significant, which makes the installation of such equipment a more efficient and financially profitable solution;

- Providing the building with hot water. Mandatory installation of a special thermostatic safety valve at the outlet of the heat accumulator tank is required, since the water temperature can reach more than 85C.

The calculation of the heat accumulator for a solid fuel boiler can be done in various ways. But, if you need to quickly perform all the calculations, then it is better to use the option proven in practice - at least 25 liters of volume should fall on 1 kW of solid fuel boiler power. The higher the power of heat engineering, the larger the volume required to install the battery.

Design features of tanks

The use of a heat accumulator: when equipment is needed

The instructions for heat accumulators of solid fuel boilers indicate that such units should be used in several main cases:

- The need for efficient hot water supply in large volumes. For example, if the house has two or more bathrooms, a large number of taps, then you can’t do without heat accumulators, because the technique significantly increases water production without extra financial costs;

- When using solid fuels with different heat release coefficients. Due to this technique, it is possible to smooth out the combustion peaks and reduce the number of bookmarks;

- If there is a need in the house to charge the batteries with heat at the “night rate”;

- When using heat pumps.In the event that, in addition to a solid fuel boiler, there is also an alternative heating system in the building, the battery will help optimize the operating time of the compressor of the installation.

The use of heat accumulators in TT heating systems

A standard heat accumulator (or, as it is also called, a buffer tank) is an insulated tank (barrel) filled with a coolant, used to accumulate excess heat that occurs during the operation of TT boilers. Its design is such that without much difficulty you can make a heat accumulator yourself from improvised means. The main thing is an accurate calculation and a competent switching scheme.

The main advantages of this element:

- Tying a solid fuel boiler with a heat accumulator allows you to save fuel. During operation, the boiler heats the coolant not only in the heating circuit, but also directly in the tank. When the fuel burns out in the combustion chamber, the temperature of the coolant in CO is maintained by the accumulated heat of the heat accumulator. Proper insulation and properly selected capacity of the device allows you to save heat in CO throughout the day, which significantly reduces fuel consumption.

- The storage tank can significantly increase the service life of the TT boiler equipment. Thanks to the buffer tank, the TT boiler runs much less, as a result of which its service life is more than doubled.

The third, but no less important advantage can be considered the safety of the TT boiler, which is provided by the heat accumulator. This design is the most effective mechanism for absorbing excess thermal energy, which often leads to emergency situations due to boiler overheating.

Modernization of the heat accumulator

The classical design of a heat accumulator was previously described, however, there are several elementary tricks with which you can make the operation of this device more efficient and economical:

- Below you can place another heat exchanger, the operation of which will be based on the use of solar collectors. This option is suitable for users who prefer green energy;

- If the heating system has several circuits of work, then it is best to divide the barrel inside into several sections. This will allow in the future to maintain the temperature at a very acceptable level for the longest possible time;

- If financial resources allow, then polyurethane foam can be taken as a heater. This material is much more expensive, but it retains heat much better. The water will keep the temperature for a very long time;

- You can install several pipes at once, which will make the heating system more complex, equip it with several circuits at once;

- It is allowed to install an additional heat exchanger together with the main one. The water heated in it will be used for various household needs - this is quite convenient.

Simple heat accumulator

The simplest heat accumulator with your own hands can be made based on the principle of operation of a thermos - due to its non-conductive heat walls, it does not allow the liquid to cool down over a long period of time.

For work it is necessary to prepare:

- Tank of the desired capacity (from 150 l)

- Thermal insulation material

- Scotch

- Heating elements or copper pipes

- concrete slab

First of all, you should think about what the tank itself will be. As a rule, use any metal barrel at hand. Everyone determines its volume individually, but taking a capacity of less than 150 liters does not make practical sense.

The selected barrel must be put in order. It should be cleaned, dust and other debris removed from the inside, and areas where corrosion has begun to form should be treated.

Then a heater is prepared, which will wrap the barrel. He will be responsible for keeping the heat inside as long as possible. Mineral wool is perfect for a home-made design. Having wrapped the container on the outside, it is necessary to wrap it well with tape. Additionally, the surface is covered with sheet metal or wrapped in foil.

In order for the water to be heated inside, you must select one of the options:

- Installation of electric heaters

- Installation of a coil through which the coolant will be launched

The first option is quite complicated and not safe, so it is abandoned. The coil can be built independently from a copper tube with a diameter of 2-3 cm and a length of about 8-15 m. A spiral is bent from it and placed inside.

In the manufactured model, the upper part of the barrel is the heat accumulator - it is necessary to let the outlet pipe out of it. Another pipe is installed from below - an inlet through which cold water will flow. They should be equipped with cranes.

A simple device is ready for use, but before that, a fire safety issue has to be resolved. It is recommended to place such an installation exclusively on a concrete slab, if possible fenced off with walls.

Buffer capacity calculation

The main criterion by which a buffer tank for a solid fuel boiler is selected is its volume, determined by calculation. Its value depends on such factors:

- heat load on the heating system of a private house;

- heating boiler power;

- expected duration of operation without the aid of a heat source.

Before calculating the capacity of the heat accumulator, it is necessary to clarify all of the above points, starting with the average heat output that the system consumes during the winter period. The maximum power should not be taken for calculation, this will lead to an increase in the size of the tank, and hence to an increase in the cost of the product. It is better to endure inconvenience for several days a year and load the firebox more often than to pay a crazy price for a large heat accumulator that will be used irrationally. And yes, it will take up too much space.

The normal operation of the heating system with a heat accumulator is impossible when the heat source has a small power reserve. In this case, it will never be possible to fully “charge” the battery, since the heat generator must simultaneously heat the house and load the container. Remember that selection solid fuel boiler for piping with a heat accumulator assumes a double margin for thermal power.

The calculation algorithm is proposed to be studied using the example of a house with an area of 200 m² with a boiler downtime of 8 hours. It is assumed that the water in the tank will heat up to 90 °C, and during the heating operation it will cool down to 40 °C. To heat such an area in the coldest time, 20 kW of heat will be needed, and its average consumption will be about 10 kW / h. This means that the battery must store 10 kWh x 8 h = 80 kW of energy.Further, the calculation of the volume of the heat accumulator for a solid fuel boiler is carried out through the formula for the heat capacity of water:

m = Q / 1.163 x Δt, where:

- Q is the estimated amount of thermal energy to be accumulated, W;

- m is the mass of water in the tank, kg;

- Δt is the difference between the initial and final temperatures of the coolant in the tank, equal to 90 - 40 = 50 °С;

- 163 W/kg °С or 4.187 kJ/kg °С is the specific heat capacity of water.

For the example under consideration, the mass of water in the heat accumulator will be:

m = 80000 / 1.163 x 50 = 1375 kg or 1.4 m³.

As you can see, as a result of calculations, the size of the buffer capacity is larger than the expert recommends. The reason is simple: inaccurate initial data were taken for the calculation. In practice, especially when the house is well insulated, the average heat consumption per 200 m² area will be less than 10 kWh. Hence the conclusion: in order to correctly calculate the dimensions of the heat accumulator for a solid fuel boiler, it is necessary to use more accurate initial data on heat consumption.