- A little about the heating device itself

- In what cases are used

- Positive aspects of heating elements

- How to make a purchase of a heating element

- Operating tips

- Heating elements for heating radiators: comfortable heating

- What is a heater for heating

- Scope of application of heating elements

- Advantages of heating elements

- The right choice of heating element model

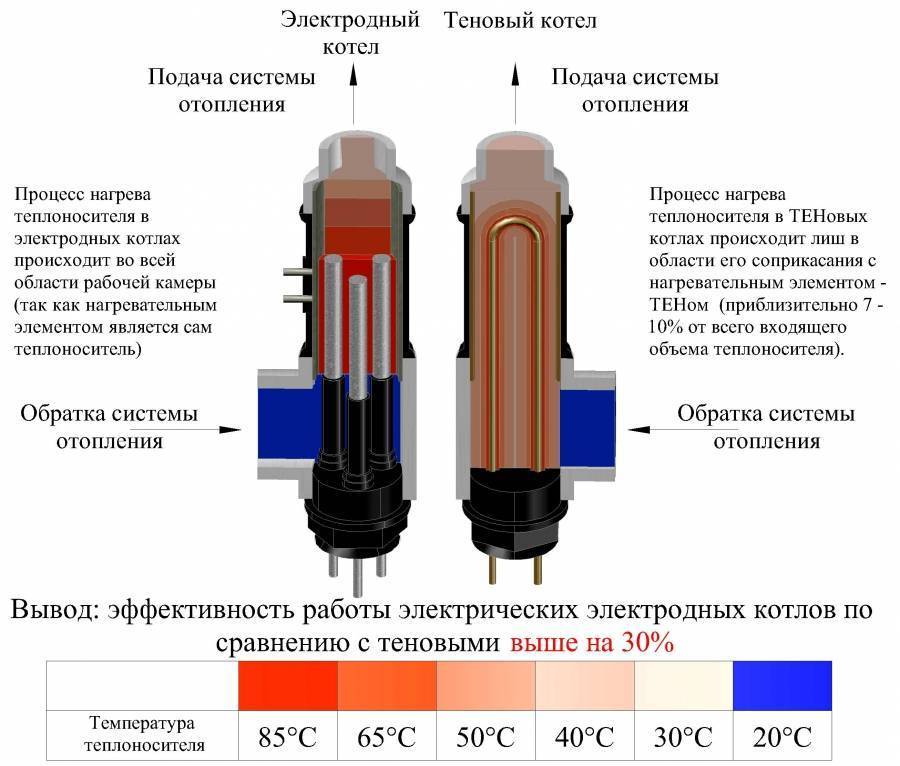

- Solid fuel heating boilers with heating element

- How to choose heating elements

- Types of heating elements with thermostat

- Tubular Electric Heater

- Peculiarities

- Advantages and disadvantages

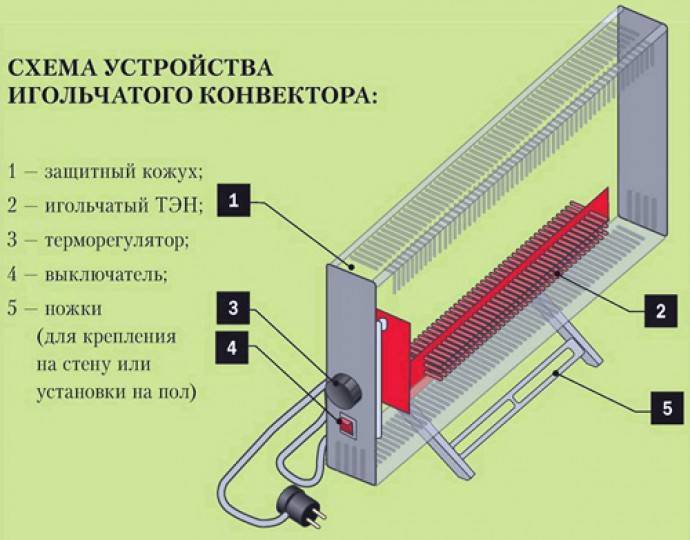

- Tenovye electric heaters finned

- Peculiarities

- Advantages and disadvantages

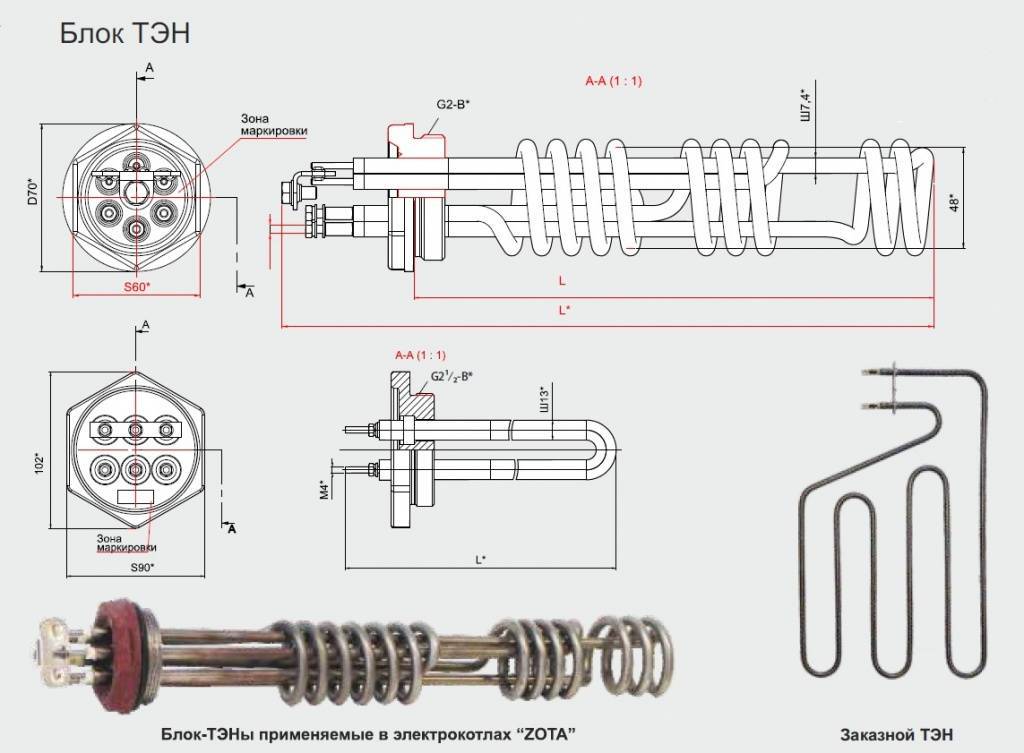

- Block of heating elements

- Advantages and disadvantages

- Heating element installation

- Making calculations

- Installation

- Device and types of thermostat

- Varieties and methods of manufacturing heating elements

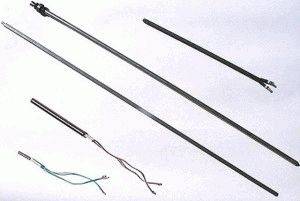

- Tubular electric heaters

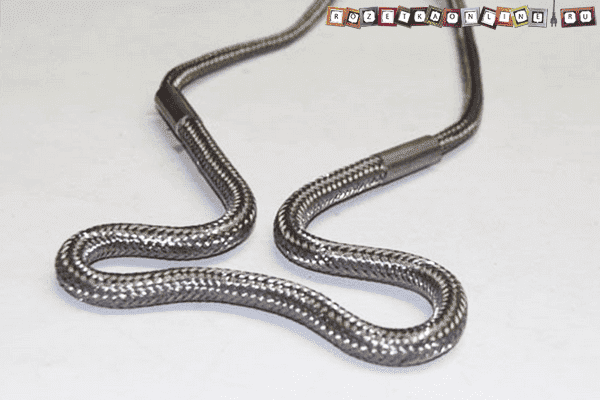

- Tubular finned electric heaters

- Block of electric heaters

- Cartridge type electric heaters

- Ring electric heaters

- Electric heaters with thermostat

- Installation steps

- The main types of heating elements and their purpose

- 1. TEN for air heating

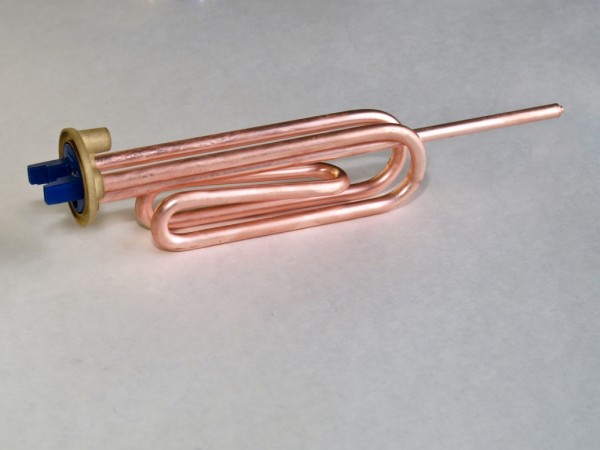

- 2. TEN for water

- 3. Flexible heating elements

- 4. Cartridge heating elements

A little about the heating device itself

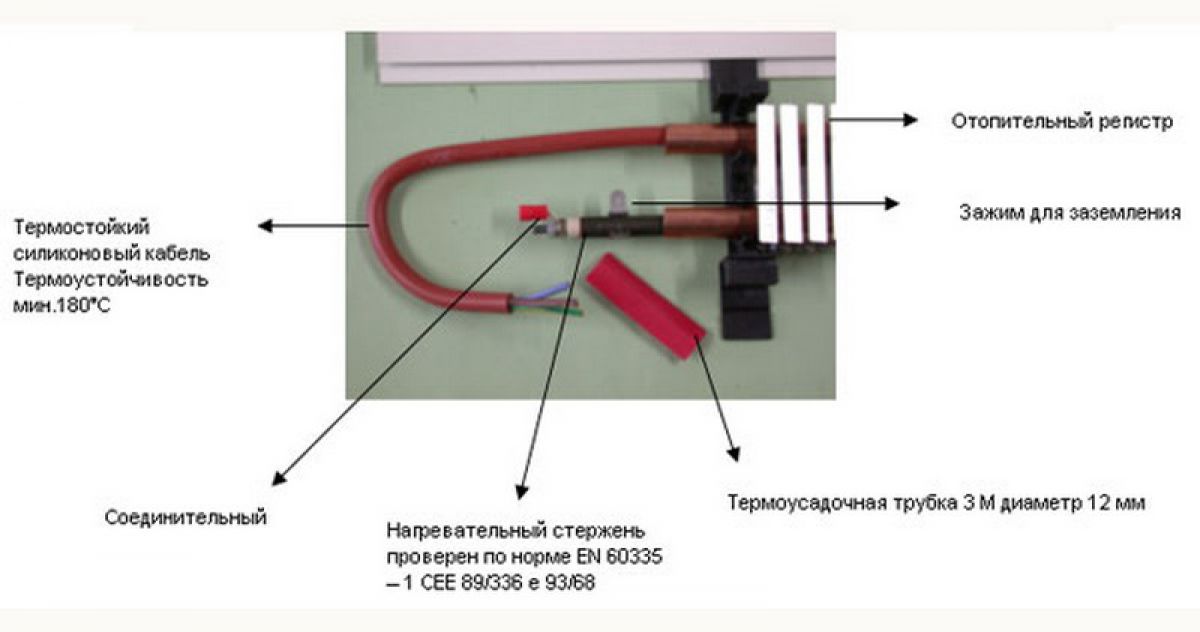

Tubular heating elements

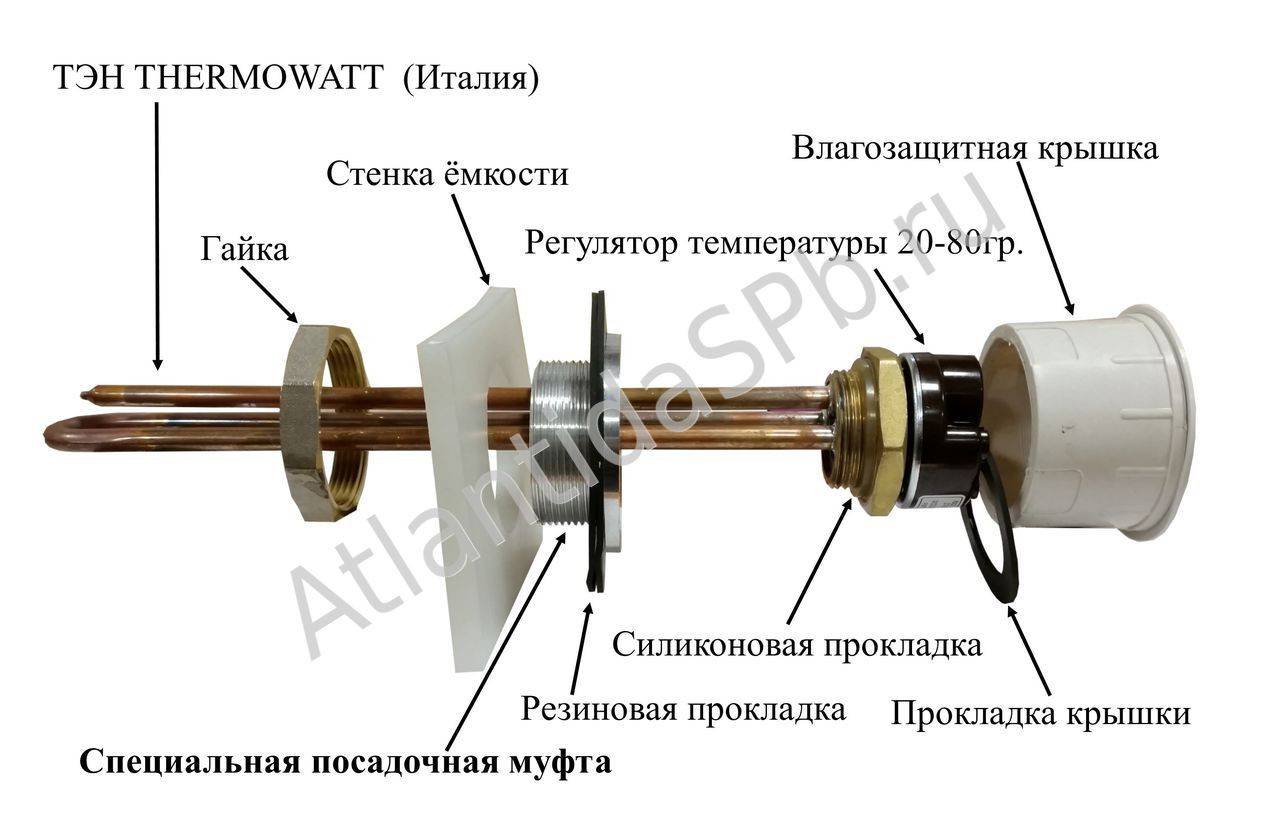

TEN for heating - electric heaters of the coolant circulating inside the radiator (water or non-freezing liquid).They are installed on heating radiators of various designs: cast iron, metal, aluminum.

Heating elements for heating radiators are easy to operate - the unit is simply screwed into a special socket of the battery filled with coolant and connected to the power supply. It should be noted that the set of any such device should include a thermostat and a protective casing that protects the heating element from liquid getting into it, and people from contact with electric current.

In addition, during the manufacturing process, these heating elements undergo a galvanization stage (chromium and nickel plating), which gives them durability and reliability.

Electric heater

In addition to the main characteristics, electric heating elements can come with additional functions.

For example:

- The "Turbo" function - when it is turned on, the heating element operates at maximum power for some time, which makes it possible to quickly and efficiently heat the room to the desired temperature.

- Anti-freeze function - designed to maintain a minimum temperature (usually 10 ° C), which in turn does not allow the coolant to freeze in the radiator.

Advanced unit with additional features

In what cases are used

TENA for heating radiators can be used to create local, autonomous heaters, together with a central heating system or for additional heating of the coolant.

Such a solution is especially popular as an “emergency” heating of an apartment or house. Unfortunately, in our country, central heating is unstable, and sometimes it becomes completely unavailable.In this case, the heating element will be an ideal alternative - it will help protect your house from freezing, and the batteries from defrosting.

TEN - an ideal "emergency" device for a radiator

Positive aspects of heating elements

As heating elements, heating elements have a lot of positive properties:

-

Profitability - almost all electricity is converted into heat, without noticeable losses.

- Simple installation - the heating element is easily installed in the radiators with your own hands and does not require coordination with any authorities.

In addition, each electric heater comes with detailed instructions for its installation and operation. - Durability achieved, as mentioned above, by double processing of heating elements (chromium and nickel plating).

- Compact dimensions.

- Absolute security.

- High accuracy of temperature control due to the use of a capillary thermostat.

- The electric heater works in pulses, which saves energy.

- Useful additional features.

- Affordable prices for products available to everyone.

Among the disadvantages of this method of heating, one can note the very high cost of heat and the fact that not all corners of our country can get the required electrical power from a local substation.

How to make a purchase of a heating element

Tubular electric heater

To do this, you need to inform the seller of the following specifications:

- The shape, diameter and length of the tube;

- The total length and length of the insulator cap;

- Power;

- fastening type;

- Connection type.

How to calculate the power of a heating element for heating water?

Here is a formula that will help you easily select an electric heater for the amount of water you need:

P=0.0011×m×(tK-tH)/T

where

P is the power of the heating element, measured in kW;

m is the mass of the circulating (heated) liquid, measured in kilograms;

tK is the final temperature of the liquid, measured in °C;

tH is the initial temperature of the liquid;

T is the liquid heating time.

Operating tips

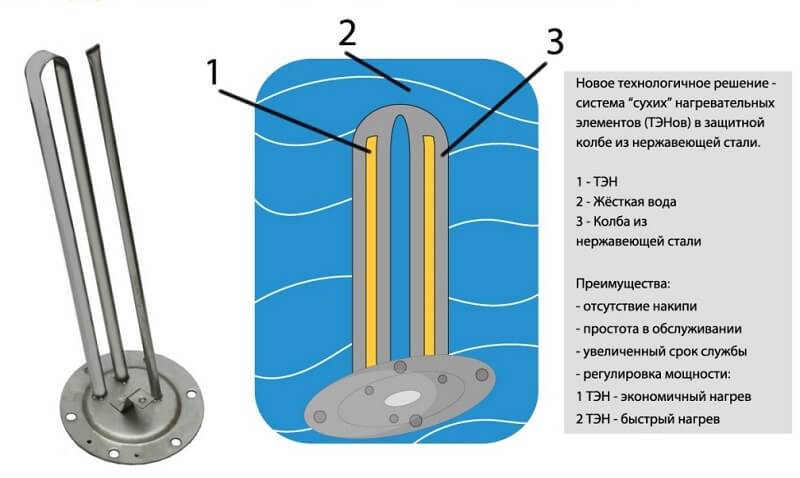

When installing an electric boiler, it is important to pay attention to the nature of the water that is used as the working fluid. In the presence of too hard water, the heating elements quickly become covered with scale. The result is insufficiently efficient operation of the heating system, as well as an increase in the amount of energy consumed by electrical equipment.

The result is insufficiently efficient operation of the heating system, as well as an increase in the amount of energy consumed by electrical equipment.

To extend the life of the heating unit, it is necessary to carry out regular maintenance of the boilers, in particular, cleaning the heating elements from scale. However, you can prevent the problem by pouring distilled or soft water into the heating system. A less effective option is to install devices for filtering the working fluid.

Heating elements for heating radiators: comfortable heating

What is a heater for heating

Electrical Heating elements for heating - These are heating elements that heat the liquid coolant circulating inside the radiator. They are installed on electric radiators made of different materials and alloys - cast iron, aluminum, etc.

Scope of application of heating elements

It is possible to use a heating element for a heating radiator (shown in the photo) when arranging autonomous heaters simultaneously with a centralized heating system in order to provide additional heating of the coolant.

Most often, the decision to install a heating element in a battery is made by property owners if the heating in an apartment or house is unstable or is often turned off. This heater is a good alternative to keep the building from getting cold and the batteries from defrosting.

Advantages of heating elements

Heating elements (heating elements) have many positive characteristics:

- economy and efficiency - when converting electricity into heat, there is practically no energy loss;

- simple installation - you can even install a heating element for a heating battery yourself and for this you do not need to issue a special permit in various instances. Each device is accompanied by detailed manufacturer's instructions explaining the connection procedure and operating rules;

- durability - it is achieved through chrome and nickel plating;

- compactness;

- safety;

- electric heater with a thermostat for capillary heating allows you to control the temperature with a high degree of accuracy;

- save electricity consumption allow the device to work with impulses;

- affordable cost;

- availability of additional functions.

In addition to the positive qualities, such a device as a heating element for heating batteries has several disadvantages:

- high cost of electric heating of residential premises due to electricity prices;

- not in all settlements on the territory of the country, the electric power from the substation allows the use of these devices.

The right choice of heating element model

Going to buy a heating element, the buyer needs to know a number of technical characteristics:

- the required power of the device;

- length, diameter and shape of the tube;

- length of the insulator cap;

- overall length;

- connection type;

- fastening method.

To calculate the power of a heating element designed to heat water of a certain volume, use the formula:

Solid fuel heating boilers with heating element

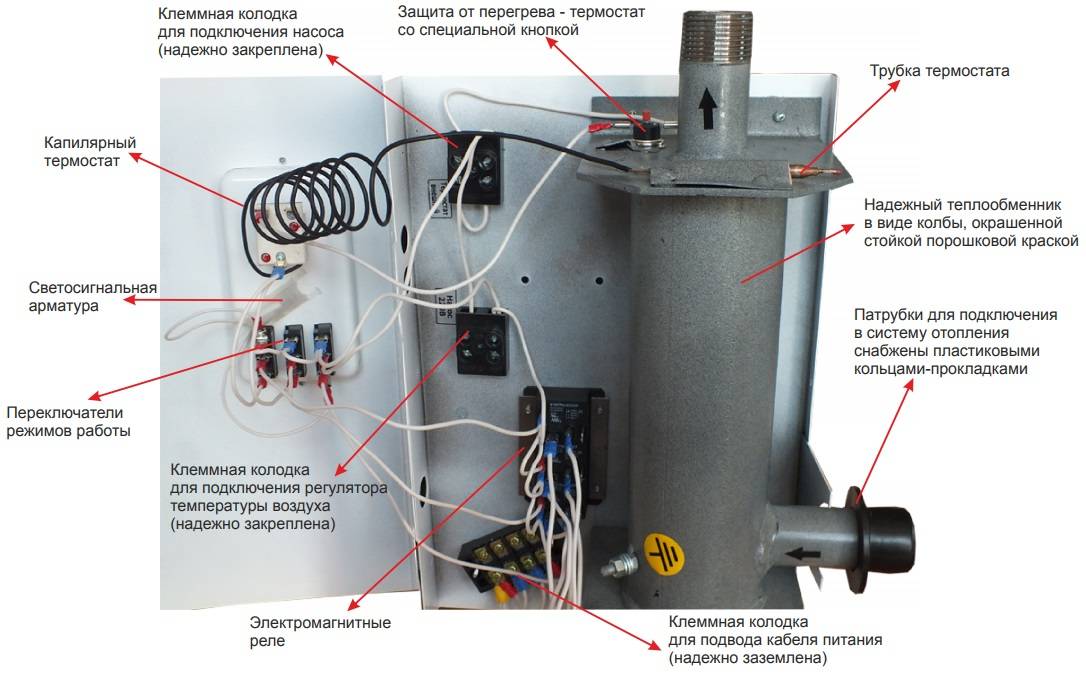

Currently, solid fuel boilers are rarely used. Instead, the domestic market offers a wide range of combined and universal heat units that operate not only on solid fuels, but additionally on other types of energy carriers. In a large assortment, consumers are offered electric solid fuel heating boilers for heating.

The solid fuel boiler has the following advantages:

Some models have additional elements:

- TEN for a heating boiler with a power of 2 kW, equipped with a thermostat and a temperature limiter;

- draft regulator, which allows you to automatically regulate the flow of air into the combustion chamber of the device.

In the event of a breakdown, heating elements for heating boilers can be replaced with new products.

How to choose heating elements

Heating element for heating with plates

How to choose the right heater for the heating system? Currently, there are many manufacturers that offer similar products. However, both the quality and the technical parameters do not always correspond to the required

Therefore, before purchasing, you need to pay attention to the following performance characteristics of the heater:

- Rated and maximum power. If a heating element is needed in the heating boiler, its power should be enough to operate the system. The simplest calculation method is for 10 sq.m. houses need 1 kW of thermal energy;

- Mains type. For models with a power of up to 3 kW, you can use a 220 V home network. If it is planned to install a heater for a heating system of greater power, a three-phase 380 V network should be installed. This may be due to difficulties in paperwork;

- The presence of a thermostat. For an electric radiator heating system, this is the main selection factor. If you purchase a ten without the ability to adjust the power, it will constantly work at maximum mode. Thus, electricity costs will rise sharply;

- Price. The average price of a 2 kW model starts at 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. Often they are made to order.

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a finned heating element in a heating boiler. It differs from the usual ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heaters in radiators larger diameter heating Reviews about them speak of increased heat transfer even with a minimum operating mode. But not always their overall dimensions make it possible to install them in a battery. Therefore, most often they purchase simple tubular-type heaters. To increase the efficiency, you can buy a block of heating elements with a thermostat.It differs from traditional ones by the presence of several heating elements on the same basis.

Types of heating elements with thermostat

It must be understood that when current is applied to the spiral inside the tube, it immediately begins to heat up and cannot turn off on its own. The thermostat monitors the parameters of the media, turning off the power when the required temperature is reached.

This saves electricity costs and prolongs the life of the heating element. At the same time, there is no connection between the type of heating element and the manufacturer of the thermostat, these two components are completed together based on economic feasibility.

Three types of heaters are used for heating.

Tubular Electric Heater

The most common type, which is found almost everywhere where you need to heat a liquid or the surrounding space.

Peculiarities

The outer tube can be coated with a special composition to resist corrosion, have a bizarre shape. It is possible to choose a heating element for any request.

Specifications:

- tube diameter from 6 to 20 millimeters;

- length is from 0.2 meters to 6;

- fabrication metal:

- steel;

- stainless steel;

- titanium;

- almost any configuration, power and performance is selected by the buyer individually.

Advantages and disadvantages

The advantages include:

- high efficiency (about 98%);

- use without additional projects and permits;

- affordable price.

There were also some negatives:

- high cost of heating when using a heating element as the main heater;

- relatively short lifespan

- the formation of an electromagnetic field that adversely affects human health.

Tenovye electric heaters finned

Another type that is used to heat air or gas.

Peculiarities

Metal ribs are attached to a smooth tube, which are located perpendicular to the surface of the heating element. The easiest way to make such a design feature is from a metal tape, which is attached to the base with special nuts.

A heating tube of this shape allows more heat to be removed from the surface, often used with a fan that blows air through the heaters.

Advantages and disadvantages

The pros and cons of the device are the same as in the previous version, except that the price is slightly higher. But the efficiency of the fins in heating the air pays for the costs.

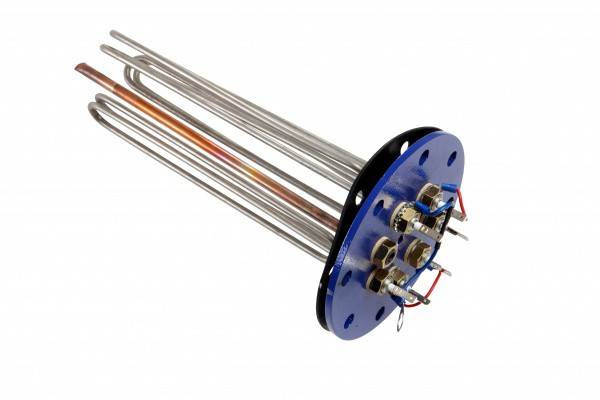

Block of heating elements

It is considered an industrial option, but is often used at home. Such a solution will be especially effective when using several heating elements of low power.

Advantages and disadvantages

Pros:

The main positive quality of the design is that when one of the elements burns out, the heating of the coolant continues with a slightly lower efficiency.

Therefore, emergency replacement is not required, which is especially important at the height of the heating season with frost outside the window;

The second feature is an increase in power without increasing the length, which is vital for some configurations of radiators .. Problems with heating elements are standard for this type

To them is added weak efficiency when heating air, it is designed for liquids and bulk solids.

The problems with the heaters are standard for this type.To them is added weak efficiency when heating air, it is designed for liquids and bulk solids.

Heating element installation

Before installing the device, it is necessary to make power calculations, taking into account the type of battery and the average thermal characteristics, which are the norm in the area.

Making calculations

When determining the power indicator, you can use the average value of thermal data in the Russian Federation. Thus, when installing a tubular electric heater as the main heating device for 10 square meters, a power of 1 kilowatt is sufficient.

For radiator heating elements that are supposed to be installed as an addition to the main heating system, it is recommended to use a power indicator three times lower.

The rated power of an electric heater can be calculated according to the formula:

Q=0.0011*M(T1-T2)/t

In this case, M is the mass of the energy carrier, T1 is the temperature after heating, T2 is the temperature before heating, and t is the time required to maximize the temperature rise.

An important factor is the technical characteristics of the electric heater itself, as well as the heat transfer of the battery. All the necessary data about the device can be read in the passport attached to it. The heat output of one section of a cast iron radiator averages 1.40 watts, and aluminum - 180 watts. Therefore, the power of the heating element for the same volume of batteries from different materials will be slightly different.

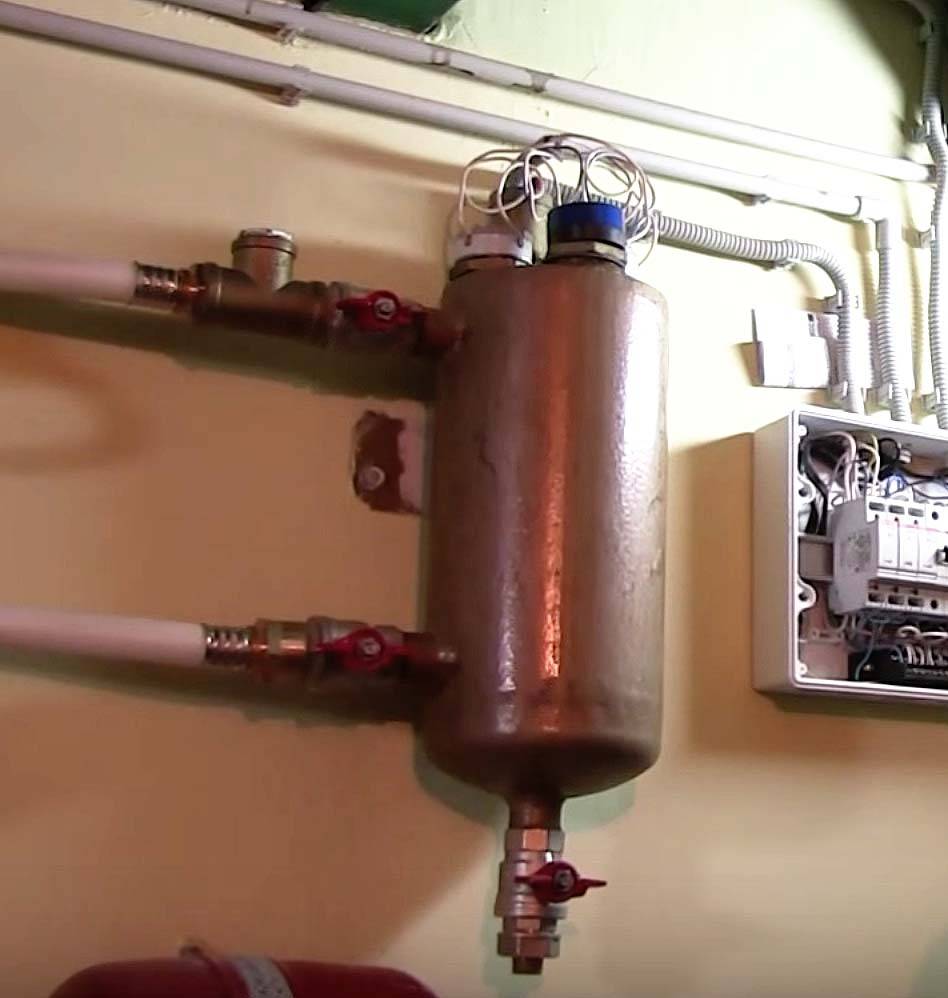

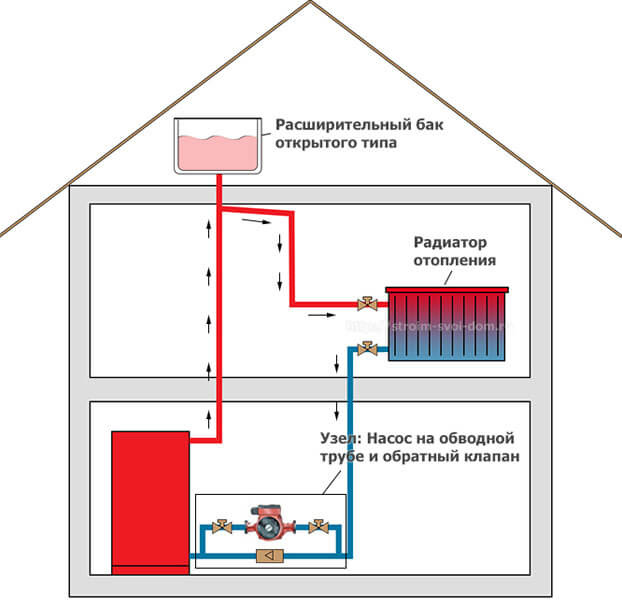

Installation

Installation of a tubular electric heater is not difficult. For this you need:

- unscrew the cap on the battery on one side;

- install due to threaded fastening and gasket made of rubber heater.

The process of connecting a tubular electric heater has some features:

- When the coolant heats up, it increases the pressure in the battery. In this regard, it is required to install a small expansion vessel. It is also possible to equip the radiator with a pressure regulating valve in a closed system.

- The fasteners of the heating element are quite fragile. Therefore, when installing the device, it should be carried out carefully, without additional effort.

To ensure maximum efficiency of the electric heater, it is best to connect it to the bottom of the battery. This is due to the fact that the coolant, cooling down, falls, and when heated, it rises to the top.

Device and types of thermostat

The thermostat is a device for automating the heating process. It serves to regulate the temperature of the liquid. According to the set parameters, it turns off the power to the heating element when the water has reached the desired temperature, and, accordingly, turns on the heater again when the “degree has dropped”. According to their design, there are 3 types of such regulators:

Strezhnevoy - the first and cheapest option. The principle of operation is based on the action of thermal expansion. The key part is a metal rod placed in the liquid along with a tubular heater. As the water heats up, the rod expands and at the moment of the desired temperature and, accordingly, the expansion activates the thermostat, which turns off the power. At the same time, cooling down, the rod decreases in volume and, at a low degree, turns on the control device again, which supplies electricity to the heating element.

More recently, such a thermostat device was the most common, until it turned out that its operation was not so perfect. The paradox is that when cold water is added to the heating tank, the rod, which was previously in the hot liquid, begins to narrow sharply, thereby turning on the heating element for heating in an already heated system.

The imperfect type of thermostat was replaced by another - capillary. The operation is based on the same thermal expansion, only now, instead of a rod, the key part is a capillary tube with a liquid inside, which, when expanded, exerts pressure on the regulator. Structurally, the problem of a false signal is solved when adding cold water. Most modern models of heating elements are equipped with such regulators, while the rod thermostat remains on the market only as a spare part for older models.

The third type is, of course, a modern solution - an electronic protective thermostat. Its design includes two sensors: thermal and protective. The first controls the temperature of the water - performs the main function. The second monitors the possibility of overheating of the tubular heater. The principle of operation of sensors is based on a change in active resistance with a change in temperature. With the help of the dielectric abilities of the conductor, such heating elements for heating with a thermostat are able to provide water temperature with high accuracy. The electronic device belongs to the class of advanced models and is far from cheap. When choosing this thermostat as a means of controlling the heating system, it is recommended to rely primarily on long-term use.Equipment costs are justified if long-term operation of the heater is implied. Accuracy and functionality allow you to conveniently manage the system and significantly save on electricity consumption.

Varieties and methods of manufacturing heating elements

Modern electric heating elements have high strength and the ability to change shape and size under the influence of high temperatures without compromising their technical characteristics. They are used not only in household heating appliances, but also in industrial ones. True, in the latter, more powerful analogues with large sizes are installed. All modern heating elements have a high rate of long-term operation.

Manufacturers produce two types of heating elements, which differ in the way they are made. There are products that are mass-produced, and there are those that are produced in small batches. They usually correspond to specific customer requests. They are used in special heating installations with specific requirements. By the way, the price of the second is much higher than the first.

Tubular electric heaters

This is the most common type of heating elements, which is used in almost all electrically powered heating appliances. With the help of tubular analogues, the heat carrier is heated according to the principle of convection, radiation and thermal conductivity as a result of the conversion of electrical energy into thermal energy.

Such a heating element has the following characteristics:

- The tube diameter is 6.0-18.5 millimeters.

- The length of the heating element is 20-600 centimeters.

- The tube can be made of steel, stainless steel or titanium (a very expensive device).

- Device configuration - unlimited.

- Parameters (power, performance, etc.) - as agreed with the customer.

Tubular finned electric heaters

Used to heat air or gas that heats a room

TENRs are the same tubular electric heater only with fins that are located in planes perpendicular to the axis of the heating tube. Typically, the fins are made of metal tape and attached to the tube with special clamping nuts and washers. The heater itself is made either of stainless steel or structural steel.

This type of electric heater is used to heat the air or gas that heats the room. They are often used in heating devices such as thermal curtains and convectors - where heating is required using heated air.

Block of electric heaters

TENB is used only if it is necessary to increase the power of the electric heater. Usually they are installed in devices in which the coolant is a liquid or any bulk material.

A distinctive design feature of the heating element is its fastening to the heating device. It can be threaded or flanged. Especially popular today is a block-type heating element with collapsible flanges. Such a heating element can be used for different devices repeatedly. The burned-out heating element can be removed, and a new one can be put in its place.

Cartridge type electric heaters

For heating systems, this type is not used.

For heating systems, this type is not used.It is used as a part of a mold to create any products, since it is part of industrial equipment. They are not found in everyday life, but it is necessary to mention them, because this type of heating elements is included in the category of “tubular electric heaters”.

A distinctive feature of this analogue is a shell made of stainless steel, which is polished to the maximum. This is necessary so that the heating element can enter the mold with a minimum gap between the tube and the walls of the mold. The standard gap should not exceed 0.02 mm. That's how tight it should be.

Ring electric heaters

This type of heating element is also used only in industrial installations. Their purpose is to heat injectors, injection nozzles and injection molding equipment.

Electric heaters with thermostat

Heating element with thermostat TECHNO 2 kW

This is the most common heating element today, which is used to heat liquids. It is it that is installed in all household electrical appliances that are associated with water heating. The maximum temperature of the released heat is +80C.

It is made from nickel-chromium wire, which is filled inside the tube with a special compressed powder. The powder is magnesium oxide, which is a good insulator electric current, but at the same time it has a high thermal conductivity.

Installation steps

Regardless of the manufacturer, a heating element is installed in heating radiators according to a single principle. To install the heating element yourself, just follow the instructions:

- The device where the installation will be made must be de-energized.

- The supply of working fluid to the batteries is suspended, after which it is drained.

- Instead of the bottom plug, a heating element is installed, which must enter the water supply pipe.

- The fluid supply is restored, and then the radiator is checked for leaks.

- The heating element is connected to the mains.

Precautionary measures

When using a heating element for radiators of a heating system, certain safety requirements must be observed.

When installing heating, it is important to check the reliability of the ventilation. Also, when performing work, it is necessary to move flammable and explosive substances to a protected, hard-to-reach place at a safe distance from the heater.

Before connecting a heating device with a heating element and a thermostat, it is worth once again checking how the electrical wiring copes with the load placed on it

Exceeding the permissible power is fraught with overheating of the wires, the occurrence of short circuits and fires.

- When connecting heaters with heating elements, the use of ordinary household carriers should be avoided. The best option is the operation of network filters. This solution allows you to automatically de-energize the device during power surges in the system.

- It is absolutely unacceptable to use batteries with an electric heating element to dry things.

- During the operation of the heating element, the working fluid is intensively heated. Its operation for a long time leads to the burning of oxygen. Therefore, a long stay in such a room hides a health hazard.

The main types of heating elements and their purpose

Tens are most often classified by type and main application, they distinguish:

1. TEN for air heating

The temperature of such heating elements reaches 450 degrees Celsius. Such tubular electric heaters are used for air heating in industrial and domestic premises.

They are the basis of convectors, air curtains, various drying chambers. Similar electric heaters are made with smooth tubes and with tubes that have fins.

The fins of such heat electric heaters are made from a steel tape attached to the tube in a spiral. The use of ribs increases the surface area of the heating element and therefore the load on the heating filament of the heating element is reduced by almost three times, which in turn increases the service life.

2. TEN for water

Such heat electric heaters are used in boilers, washing machines. In such units, water can be heated up to one hundred degrees Celsius.

For large volumes of water, where a large heating power is required, block heating elements are used.

By the way, we have already described in some detail how to connect the heating elements of an electric boiler.

Often in electric heaters use a thermostat. It disconnects the electric heater from the power supply when the water is heated to the desired temperature. When the water cools down, the temperature controller reconnects the power supply to the heater for heating.

3. Flexible heating elements

They find application in molds and hot runner systems. They are very handy when it comes to shaping the contour of hot runner systems. Such electric heaters of any sizes are made.

A kind of flexible electric heater, familiar to us in everyday life, is a self-regulating cable for the "warm floor" system. This cable is used for space heating.

4. Cartridge heating elements

Cartridge heaters can be attributed to a separate type, the conclusions for connecting the power supply are located, most often, on one side. The size of such heaters can reach 350 centimeters. Their main difference from other types is a compact body, most often they are a stainless steel sleeve with electrical leads.

This type stands out for its high power density. Heat from the heater is transferred both by contact method and by convection.

These heat electric heaters are widely used in industry for heating oils, for heating various metal forms, mounting them in a drilled hole. They are equipped with units in the shoe industry, foundry, and the automotive industry.