- Important Features

- Dependence of temperature and heating power on the connection scheme option

- Features of choice

- Radiator type

- Heating element length

- Automation

- Manufacturer

- Cons and pros of a radiator heater

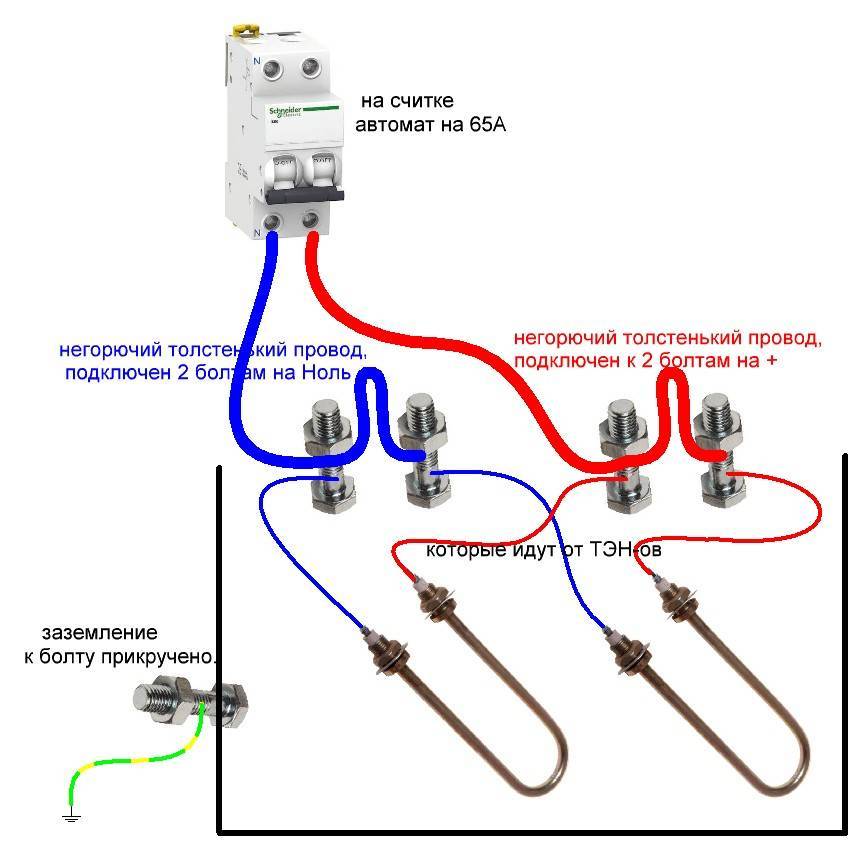

- Electrical connection diagram

- How to connect a thermostat to an infrared heater

- Necessary materials

- Wiring diagram

- Standard

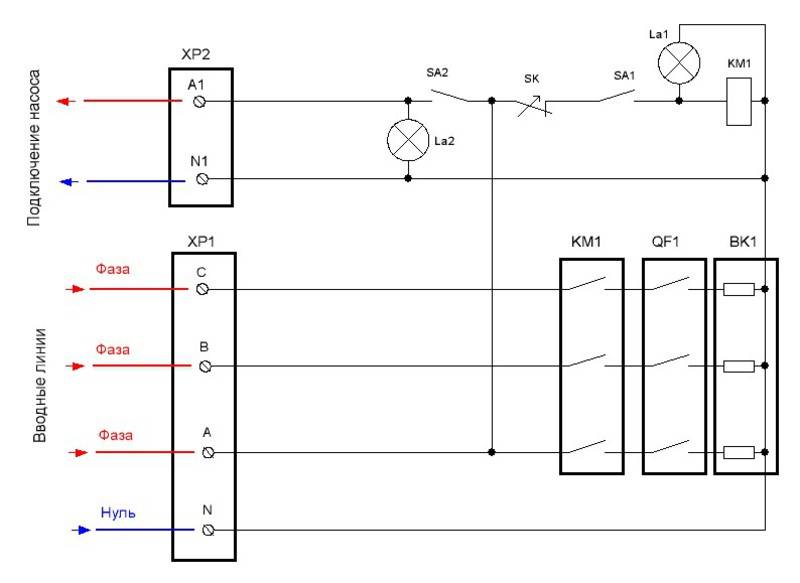

- With a magnetic starter

- Connection methods

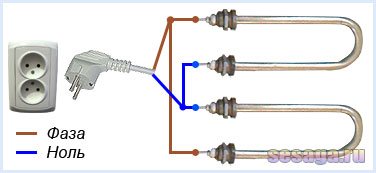

- Parallel connection

- Series connection

- Combined method

- Features of choice

- Radiator type

- Heating element length

- Automation

- Manufacturer

- Option for connecting to a three-phase power supply network of the TRIANGLE type

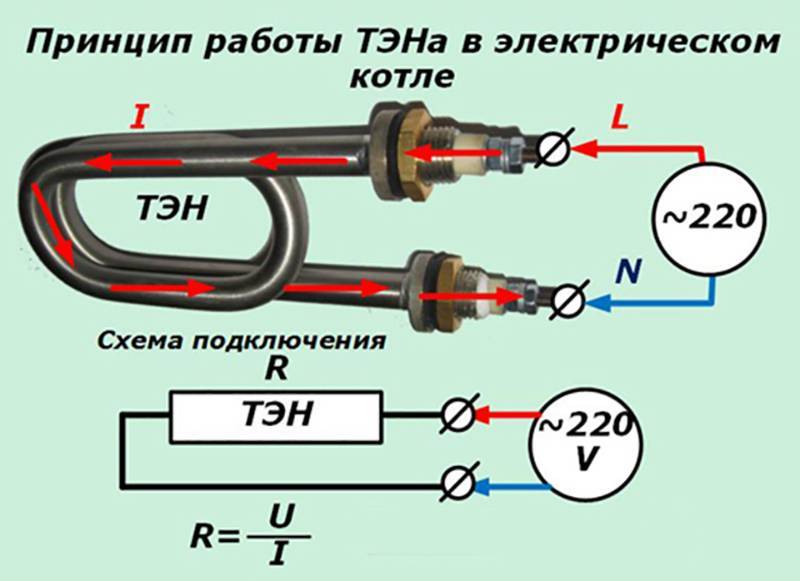

- General characteristics and principle of operation

- Varieties and methods of manufacturing heating elements

- Tubular electric heaters

- Tubular finned electric heaters

- Block of electric heaters

- Cartridge type electric heaters

- Ring electric heaters

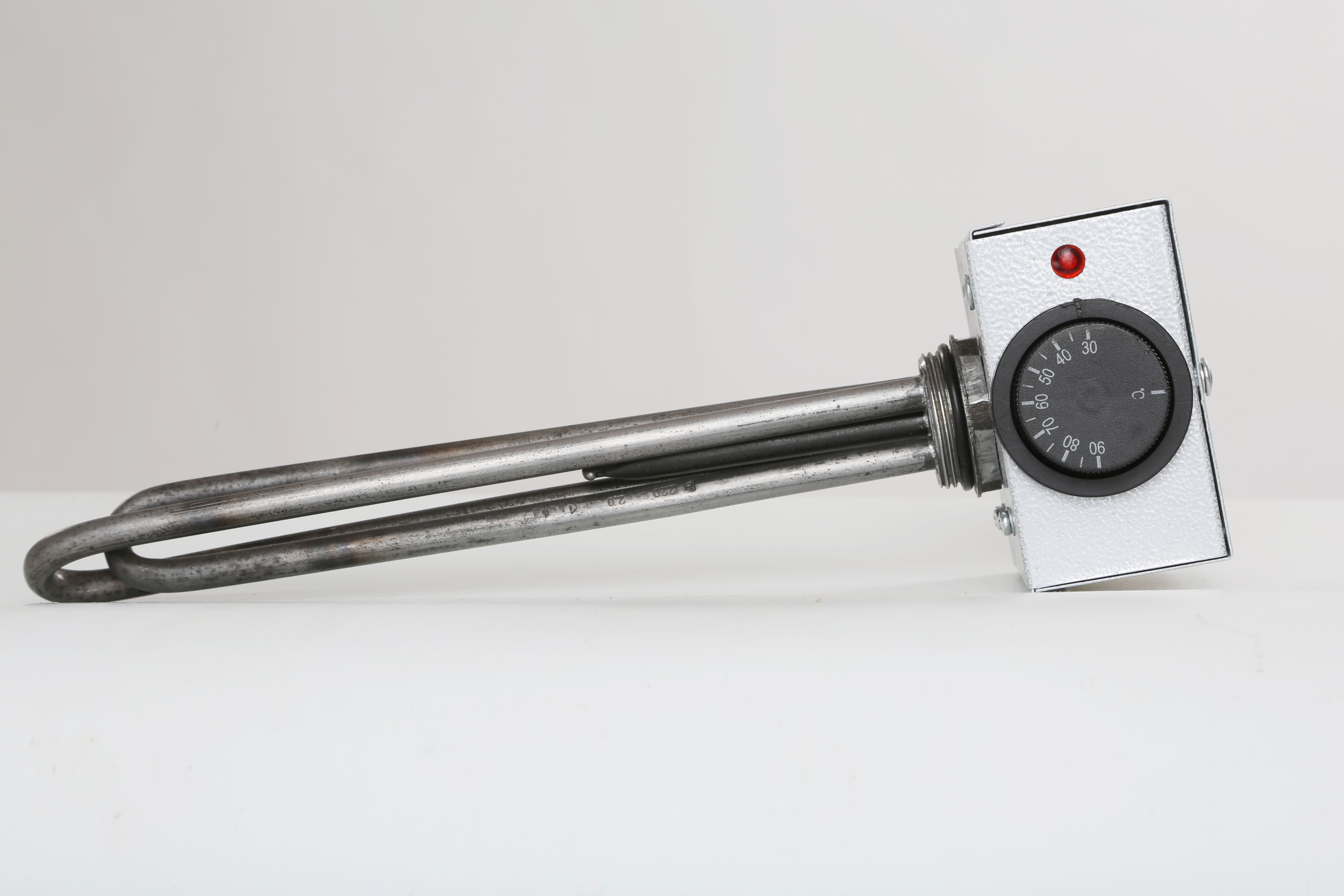

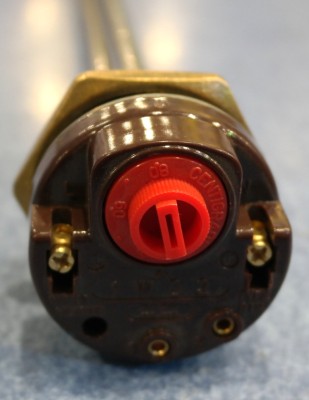

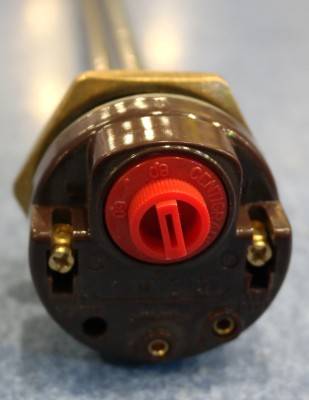

- Electric heaters with thermostat

- Heating elements with thermostat

- Criterias of choice

- Scope of application

- Advantages of heating elements

Important Features

- Ten is relevant to use in cases where you need to quickly heat the room, you need an additional heating system, or you want to reduce your costs.

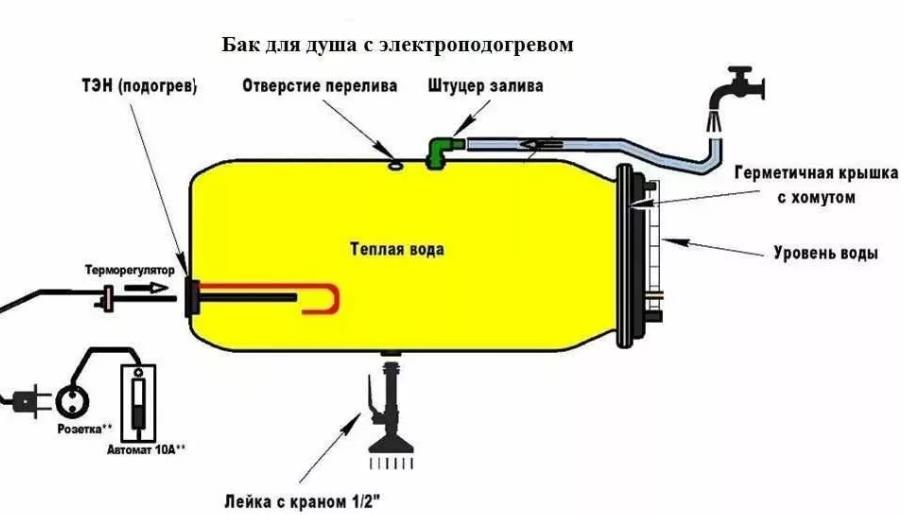

- You can turn on the heating element in the network only when it is in the water. When lowering a heated coil into water, an explosion may occur.

- The main danger for heating elements and thermostats are salts dissolved in water. This occurs due to electricity in the process of heating water and hydrolysis of salts, which leads to the formation of deposits on the surfaces of the tubes, and often salts interact with the materials of the apparatus. Therefore, the device contains a magnesium anode, which, gradually dissolving, protects the heating element.

- On the market you can also buy dry heating elements with a thermostat. They are placed in a protective flask, they do not interact with water, and therefore they serve much longer than conventional heating devices.

- If there are problems with the quality of the power supply or with the supply of energy, then it is better to connect a stabilizer or uninterruptible power supply.

- Installing a heater requires studying the electrical wiring in the house and setting its power limit. Regardless of the type of electric water heater, their maximum power reaches 3 kW, but the electric cable must be designed for a large load. Therefore, it is recommended to install a separate power line. In this case, it is necessary to ground the boiler with a separate wire.

- The ideal option for connecting a heating element together with a thermostat is to power it through an RCD circuit breaker. If the heating element breaks down, it will disconnect the device from the network.

By following the instructions for use and safety precautions, of course, you can extend the service life, but there are still factors that disrupt the operation of the device: corrosion processes of the shell, its rupture as a result of severe overheating, frequent voltage drops, general depressurization of the tube.

Dependence of temperature and heating power on the connection scheme option

Heater power is a very important parameter that many buyers are guided by when buying a heating element. In fact, the power of the heating element depends only on the resistance index of the heating coil. Of course, if you do not use transformers and the power from a certain network will be constant. This dependence property can be easily calculated using a simple formula from a school physics course:

Power (P) = Voltage (U) * Current (I)

In this case, we take the potential difference between the terminals of the electric heating element as the voltage value, and the current strength must be measured that which will flow through the heating coil.

The current strength can be calculated by the formula I \u003d U / R, where R is the electrical resistance of the heating coil. Now we substitute this value into the power formula, and it turns out that the power of the heating element depends only on voltage and resistance.

Thus, we conclude that at a constant voltage of the power supply, the power of the electric heater will change only when the resistance changes.

The resistance value of the resistive element in the bulk of the heaters is directly dependent on the value of temperature release. But in heaters with a nichrome or fechral spiral, for example, within a hundred or two degrees, the resistance practically does not change.

In the situation with high-temperature silicon carbide heaters or molybdenum disilicide, the picture will be quite different. In high-temperature heaters, as the temperature increases, the resistance drops very significantly in the range from 5 to 0.5 ohms, which makes them very advantageous in terms of electricity consumption in furnaces.

But because of this quality of high-temperature CENs, they cannot be connected directly even to a 220V power supply, not to mention 380V. Technically, it is possible to connect to 220v CENs if they are connected in series. However, with this method, it will be impossible to control the power and temperature output of the heaters in the furnace. To connect high-temperature non-metallic type heaters, special adjustable transformers or standard static EM devices should be used.

At Polimernagrev, you can buy electric heaters that are manufactured specifically for connection to a three-phase power supply. These are dry ceramic heating elements, block heating elements for water and three-rod heating elements. The type of connection of these heaters depends on the voltage indicator according to the star or delta scheme.

When connecting electric heating elements in accordance with the TRIANGLE scheme, three heating coils are connected, which have equal resistance values and 380V will be supplied to the power supply. Connection of STAR heating elements implies the presence of a zero output, and 220V will be supplied to each heating element. The neutral wire allows you to connect consumers with different resistance values.

If you still have questions about the types of connecting heaters to a three-phase network, you can contact our specialists by phone in Moscow or ask your question in the form below, we will try to answer you in detail as soon as possible.

Features of choice

Electric heaters designed for heating batteries can differ in several parameters. Therefore, the choice should be approached wisely

Below we will consider what you should pay attention to when choosing a heating element.

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m 2. For a more accurate calculation, it is necessary to take into account the region and the heat loss of the room. True, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used.

Bimetal radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries do not structurally differ from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Stub material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The plug diameter for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions that are included in the kit.

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniformity of heating of the battery and the circulation of the liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery.In this case, the heating of the liquid will be carried out as evenly as possible.

Automation

Automation can be built-in and outdoor. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

Inexpensive heating element with a thermostat for a cast-iron radiator

Manufacturer

As for the manufacturer, in this case the choice is not so important. The fact is that well-known European companies are not engaged in the production of this equipment. Therefore, on the market, as a rule, you can find products of Polish, Ukrainian and Turkish production.

All these heating elements are quite similar in quality, so more attention should be paid to their characteristics. The only thing is that it is better to refrain from purchasing Chinese products, since suppliers often import the cheapest, low-quality models. However, even among them worthy heaters sometimes come across.

Here, perhaps, are all the main points that are important when choosing heating elements for batteries.

The use of heating elements for radiators does not provide any benefit compared to other types of electric heating. However, these heaters are an excellent option for heating all kinds of utility rooms.In addition, they can be used as an additional or emergency source of heat.

You can get additional and useful information on the designated topic from the video in this article.

Cons and pros of a radiator heater

Tubular-type electric heaters make it possible to assemble a practical and fairly efficient heating system for the main or additional heating.

The advantages of the devices include:

- Extreme ease of installation. Every novice master will cope with this work.

- The low cost of the device, however, refers to the price of one heating element, without additional equipment.

- Greater reliability compared to oil coolers. In addition, batteries with heating elements are maintainable. If the equipment fails, it will be enough to replace the heater.

- Availability of additional options and functionality.

- The possibility of automatic control of the heating system, but this will require additional equipment.

We have listed the main advantages of radiator heating elements, consider their significant disadvantages. There are quite a few of them. First of all, these are impressive operating costs, which is explained by the high cost of electricity. They can be reduced if the control of the heating system is fully automated.

In this case, the heating elements will be switched on only after the temperature in the room drops to a certain minimum value. And turn off when the temperature is determined as comfortable. Working in this mode is the most economical.

The simplest in design radiator heating elements are not equipped with automatic control. To automate such a system, you will need to purchase additional equipment.

However, automation equipment will require financial investments. If we consider the purchase of a heating element complete with a radiator and with automation, the cost of such a kit will be much higher than the price of an electric convector or an oil cooler.

But at the same time, the latter are in no way inferior in terms of the level of comfort provided, and in some ways even surpass radiators with heating elements. For example, the latter require a fixed installation, while electric convectors and oil coolers are more mobile and compact.

In addition, like any other electrical device, heating elements generate a magnetic field during operation. Its danger to the body has not been proven, as well as safety. Therefore, the presence of such a field should be attributed to the negative qualities of devices, because they are mounted in radiators, that is, they are in close proximity to people.

In other heating systems powered by electricity, this disadvantage is to some extent leveled. For example, electric boilers are located in non-residential premises where the presence of a person is short-term.

One of the most significant drawbacks of radiator heating elements is their relatively low efficiency. When compared with the efficiency of traditional systems operating with a liquid heat carrier, it will be significantly lower.

This is due to the fact that in the first case the coolant moves at a fairly high speed. Thanks to this, the radiator warms up quite quickly and completely.

To increase the heat transfer of radiators equipped with heating elements, you can cover the wall on which the device is fixed with a reflective foil screen. Thermal radiation will only move into the room

The functioning of the heater is not able to provide such a high speed. As a result, the heating of the battery case will be uneven. At the bottom, the temperature will be much higher than at the top.

Given that for safety reasons, the battery should not be allowed to warm up above + 70ºС, such a temperature will be present only in the lower part of the radiator, where the heating element is located. Therefore, in order to prevent overheating of the equipment, it will be necessary to reduce its power by about a third.

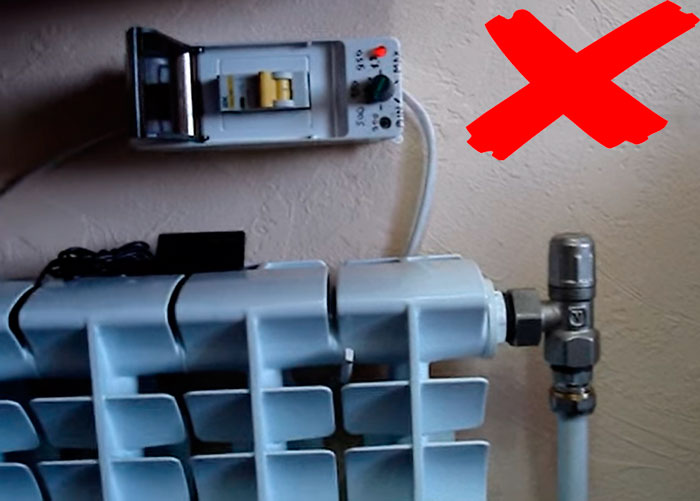

Electrical connection diagram

As for ensuring safety when connecting voltage, here the entire circuit must be powered only through an RCD or a differential machine with a leakage current of 30mA.

Mistake #14

A simple modular automaton is not suitable for this.

Otherwise, you will have to move near this miracle only in rubber boots and gloves. Water shadows are destroyed over time and the heating coil, originally protected by the shell, is exposed.

When in contact with water, current flows to the metal case of the heater. As soon as you touch any of the sections, you will be energized.

Something similar happens in electric titans or boilers, when the water from the tap begins to “pinch” and “shock”.

UZO saves from all this. True, it will work on its own only when the battery is grounded.

Otherwise, the RCD will wait until you touch the battery with your hand. Starting to knock out the RCD - immediately change the heating element.

The thermostat itself is connected with a flexible wire PVA 3 * 2.5mm2.

On one side of the wire, a euro plug is mounted, which is stuck into the nearest outlet.

Do not clamp a stranded wire without lugs under the thermostat screws.

This is especially true for powerful heating elements of 1.5-2.0 kW. For the reliability of contact, the ends of the cores must be crimped with NShVI sleeves.

Mistake #15

Another problem is the exposed contacts on the thermal relay.

If there are small children and pets in the house, it is very dangerous.

Some masters advise to close the thermostat from above with a plastic case from the socket. It just fits the diameter.

How to connect a thermostat to an infrared heater

Using the thermostat is very convenient, you just need to determine how to properly connect the thermostat to the infrared heater in order to get the maximum effect from using this device.

Necessary materials

Preparation for the installation of the thermostat will not take much time, as well as the installation itself. Even in the absence of experience in connecting thermostats, all work can be easily done independently.

But if you do not have experience with electrical equipment and even installing an outlet is difficult, and you are not familiar with the principle of operation of an indicator screwdriver, you should not try to figure out how to connect a mechanical or electronic thermostat. In such cases, it is safer to entrust this work to a professional.

For those who are well versed in electricity and know for sure that appliances and equipment should be de-energized before work, it is necessary to prepare such a set of tools:

- Drill or screwdriver. They are only needed to drill a hole in the wall for mounting the thermostat.

- Pliers for working with electrical cables.

- Indicator screwdriver or tester.

- Pencil, tape measure. They will help determine and designate the place where the temperature controller will be located.

Also, for work, you will need an electric cable that will connect the thermostat and the infrared heating device, a collapsible socket and hardware for attaching the regulator and fixing the cable. When the materials and tools are prepared, you can begin marking and installation.

Electronic thermostat that controls the operation of the IR heater

Wiring diagram

The scheme for connecting the thermostat to an infrared domestic heater is selected depending on the device used, the experience and knowledge of the electrical installation specialist.

Standard

In the standard scheme, the thermostat is installed in a ready-made network between the heater itself and the circuit breaker on the shield. The starting point of the network will be the automaton. Two wires depart from it - phase and zero, which are connected to the corresponding contacts of the thermostat. Two wires also come from the thermostat, which are already connected to the heater.

This scheme is also convenient if two or three heaters must be connected to one thermostat. Located in different rooms, they provide the same temperature throughout the apartment. For their effective operation, the connection is made in this way:

- Two wires lead from the machine to the thermostat: phase and zero.

- Two wires for each heater depart from the machine.

- Infrared heaters are not connected to each other.

Parallel connection allows you to safely control several devices at once, without buying additional controllers for each of them.

Options for connecting infrared heaters through a thermostatImportant: For several heaters, serial connection is allowed. But it is considered less convenient, therefore it is used extremely rarely.

With a magnetic starter

This circuit is a little more complicated and will take a little longer. But thanks to the use of additional equipment in the form of a magnetic starter, it is possible to connect several heaters to one thermostat at once, including equipment with higher power, industrial systems.

Devices are connected in the following sequence:

- Using a cable (phase and zero), a thermostat is connected to the machine.

- Through the output terminals, the thermostat is connected to the magnetic starter.

- The magnetic starter is connected to heating devices.

In this case, the circuit for connecting the magnetic starter is calculated individually. This will ensure the safe and efficient operation of the devices.

With a magnetic starter

Connection methods

It should be noted that heating elements for boilers can be mounted in the device either one at a time or several at once.

Parallel connection

This connection option must meet certain requirements.

- The voltage both in the electrical network and in each individual element must be the same.

- To determine the total power of the boiler, you need to sum up the power of all installed elements.

- If for some reason one of the heating elements breaks, the circuit will continue to work. In this case, the only thing that needs to be done is to change the broken element.

Series connection

The second option is to connect in series. In this case, it is necessary to observe the principles of work:

- If one of the heating elements breaks down, the operation of the entire network will be interrupted.

- To find out the total resistance, it is necessary to sum all the resistances in the network.

- The total voltage cannot be greater than the total voltage of all heating elements.

Combined method

Given this scheme, different connection options must be used in several sections of the electrical circuit. Quite often, the combined method is advisable if it is impossible to purchase heating elements of the required power. In this case, available heating elements are installed, and the required value is achieved using various connection methods.

Features of choice

Electric heaters designed for heating batteries can differ in several parameters. Therefore, the choice should be approached wisely

Below we will consider what you should pay attention to when choosing a heating element.

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m 2. For a more accurate calculation, it is necessary to take into account the region and the heat loss of the room. True, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used.

Bimetal radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries do not structurally differ from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Stub material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The plug diameter for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions that are included in the kit.

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniformity of heating of the battery and the circulation of the liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery. In this case, the heating of the liquid will be carried out as evenly as possible.

Automation

Automation can be built-in and outdoor. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

Inexpensive heating element with a thermostat for a cast-iron radiator

Manufacturer

As for the manufacturer, in this case the choice is not so important.The fact is that well-known European companies are not engaged in the production of this equipment. Therefore, on the market, as a rule, you can find products of Polish, Ukrainian and Turkish production.

All these heating elements are quite similar in quality, so more attention should be paid to their characteristics. The only thing is that it is better to refrain from purchasing Chinese products, since suppliers often import the cheapest, low-quality models. However, even among them worthy heaters sometimes come across.

Here, perhaps, are all the main points that are important when choosing heating elements for batteries.

The use of heating elements for radiators does not provide any benefit compared to other types of electric heating. However, these heaters are an excellent option for heating all kinds of utility rooms. In addition, they can be used as an additional or emergency source of heat.

You can get additional and useful information on the designated topic from the video in this article.

Option for connecting to a three-phase power supply network of the TRIANGLE type

Consider in the diagram the second option for connecting heating elements to a three-phase network called TRIANGLE.

With this option, the heaters are connected to each other in series. As a result, we should have three shoulders for phases A, B and C. For example:

-

For phase A - we connect the first output of the heating element No. 1 and the first output of the heating element No. 2

-

For the B phase - we connect the second output of the heating element No. 2 and the second output of the heating element No. 3

-

For the C phase - we connect the second output of the heating element No. 1 and the first output of the heating element No. 3

Now that we have become acquainted with two types of heating element connection, we can consider the dependence of the power and temperature of the heaters on the type of connection scheme.

General characteristics and principle of operation

A radiator heater is a device that can be used as an additional or main heating device. The device consists of a cylindrical metal body. A copper spiral or steel wire is mounted in the middle of it. Internal parts are insulated.

The heater, designed for radiators, is equipped with a thermostat. Due to this, the device can be used both for heating and for temperature control.

The principle of operation of such electrical appliances is quite simple:

- tubular electric heater is installed in the battery;

- the heating element is connected to the electrical network;

- the coils are heated, due to which heat is supplied to the coolant.

What does the heating element for the radiator look like Setting the required temperature is allowed if there is a regulator in the device. When the level of the specified mode is reached, the electrical circuit is opened and the heating element is turned off. When the temperature falls below the set upper limit, automatic heating takes place. You can connect the heating element to almost any battery.

Varieties and methods of manufacturing heating elements

Modern electric heating elements have high strength and the ability to change shape and size under the influence of high temperatures without compromising their technical characteristics. They are used not only in household heating appliances, but also in industrial ones.True, in the latter, more powerful analogues with large sizes are installed. All modern heating elements have a high rate of long-term operation.

Manufacturers produce two types of heating elements, which differ in the way they are made. There are products that are mass-produced, and there are those that are produced in small batches. They usually correspond to specific customer requests. They are used in special heating installations with specific requirements. By the way, the price of the second is much higher than the first.

Tubular electric heaters

This is the most common type of heating elements, which is used in almost all electrically powered heating appliances. With the help of tubular analogues, the heat carrier is heated according to the principle of convection, radiation and thermal conductivity as a result of the conversion of electrical energy into thermal energy.

Such a heating element has the following characteristics:

- The tube diameter is 6.0-18.5 millimeters.

- The length of the heating element is 20-600 centimeters.

- The tube can be made of steel, stainless steel or titanium (a very expensive device).

- Device configuration - unlimited.

- Parameters (power, performance, etc.) - as agreed with the customer.

Tubular finned electric heaters

Used to heat air or gas that heats a room

TENRs are the same tubular electric heater only with fins that are located in planes perpendicular to the axis of the heating tube. Typically, the fins are made of metal tape and attached to the tube with special clamping nuts and washers. The heater itself is made either of stainless steel or structural steel.

This type of electric heater is used to heat the air or gas that heats the room. They are often used in heating devices such as thermal curtains and convectors - where heating is required using heated air.

Block of electric heaters

TENB is used only if it is necessary to increase the power of the electric heater. Usually they are installed in devices in which the coolant is a liquid or any bulk material.

A distinctive design feature of the heating element is its fastening to the heating device. It can be threaded or flanged. Especially popular today is a block-type heating element with collapsible flanges. Such a heating element can be used for different devices repeatedly. The burned-out heating element can be removed, and a new one can be put in its place.

Cartridge type electric heaters

For heating systems, this type is not used.

For heating systems, this type is not used. It is used as a part of a mold to create any products, since it is part of industrial equipment. They are not found in everyday life, but it is necessary to mention them, because this type of heating elements is included in the category of “tubular electric heaters”.

A distinctive feature of this analogue is a shell made of stainless steel, which is polished to the maximum. This is necessary so that the heating element can enter the mold with a minimum gap between the tube and the walls of the mold. The standard gap should not exceed 0.02 mm. That's how tight it should be.

Ring electric heaters

This type of heating element is also used only in industrial installations.Their purpose is to heat injectors, injection nozzles and injection molding equipment.

Electric heaters with thermostat

Heating element with thermostat TECHNO 2 kW

This is the most common heating element today, which is used to heat liquids. It is it that is installed in all household electrical appliances that are associated with water heating. The maximum temperature of the released heat is +80C.

It is made from nickel-chromium wire, which is filled inside the tube with a special compressed powder. The powder is magnesium oxide, which is a good insulator of electric current, but at the same time has a high thermal conductivity.

Heating elements with thermostat

A heating element for heating with thermostats is installed on all household heating appliances, without exception, where liquid is used as a heat carrier. The maximum heating temperature of the coolant is 80°C.

A heating element with a built-in temperature controller consists of a heating element and a temperature sensor with a temperature controller.

Criterias of choice

When choosing a tubular electric heater with a thermostat, you need to pay attention to several important points:

- Tube material. The body of the heating element can be made of acid-resistant stainless steel or more durable copper. Typically, the outer tube has a diameter of 13 mm, but there are also less powerful budget options with diameters of 10 or 8 mm;

- Work in water and weak alkaline solutions. In the marking of the device, this is indicated by the letter P before the designation of the operating voltage;

- Power.In order not to overload household wiring, it is better to purchase a heating element with a power of no more than 2.5 kW, otherwise it will have to be laid from the shield a separate cable of a larger cross section;

- Thermal sensor device. So that the failed temperature sensor can be easily separated and replaced with a new one, it must be located together with the thermostat in a separate tube and can be easily removed from it. A failed thermal sensor causes the heating element to turn off at low temperatures.

Scope of application

- in radiators for organizing temporary heating;

- in a shower tank where temporary water heating is needed.

That is, for temporary use, a heating element with a thermostat is the cheapest device before the start of operation. A budget model with accessories is unlikely to cost more than $ 5-6, and mounting it yourself will not be a problem, because any device comes with installation instructions.

Tubular electric heaters are included in any electrical equipment associated with heating. With the development of science and technology, they are being improved, becoming more economical, safer and acquiring additional useful functions. And less and less home-made devices are used, which are cheap to install, but in terms of performance and, most importantly, safety, are far from factory-assembled devices.

Advantages of heating elements

Heating elements (heating elements) have many positive characteristics:

- economy and efficiency - when converting electricity into heat, there is practically no energy loss;

- simple installation - a heating element for a heating battery can even be installed independently and for this it is not required to issue a special permit in various instances.Each device is accompanied by detailed manufacturer's instructions explaining the connection procedure and operating rules;

- durability - it is achieved through chrome and nickel plating;

- compactness;

- safety;

- electric heater with a thermostat for capillary heating allows you to control the temperature with a high degree of accuracy;

- save electricity consumption allow the device to work with impulses;

- affordable cost;

- availability of additional functions.

In addition to the positive qualities, such a device as a heating element for heating batteries has several disadvantages:

- high cost of electric heating of residential premises due to electricity prices;

- not in all settlements on the territory of the country, the electric power from the substation allows the use of these devices.