- Legislative decision on the issue of property

- How to stop a leak with your own hands

- Repair of coolant leaks in a warm floor

- How to drain water from the heating system

- The essence of the

- Causes of leakage

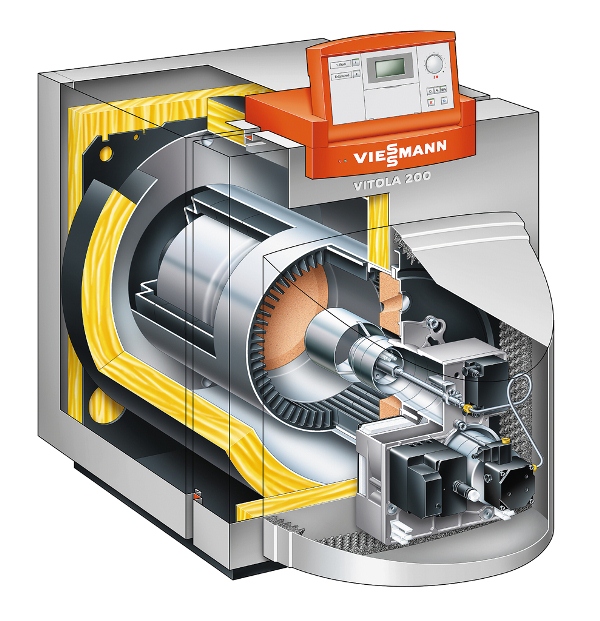

- We use the boiler correctly. How to extend the service life?

- What to do to prevent boiler leaks

- Prerequisites for draining water

- The management company refuses to change radiators - what should residents do?

- Devices for detecting leaks in walls and floors

- Leak elimination methods

- Elimination of leaks by mechanical means

- Workmanship

- Downpipe pipes leaking

- How to drain water from the water supply system

- Replacing a faucet without blocking the riser

- Steps to fix leaks with liquid sealant

- Preparing the heating system

- Sealant preparation

- Pouring sealant

- How does the sealing effect work?

- Conclusions and useful video on the topic

Legislative decision on the issue of property

Are the batteries common property or is it private property for which the owner is responsible?

The Government approved Decree No. 491 dated 13.08.06, which provides a list of property common to residents of an apartment building. In this list:

- risers;

- shut-off and control valves;

- collective metering devices, heating elements.

According to this decree, the design of radiators can officially be considered the property of common use, common house property.

But management companies and housing office enterprises serving the house prefer to hide this information. And as a result, the tenants, the owners of the apartment, when the battery is leaking, they try to repair it themselves.

Replace with a similar or better, improved design. Management companies save on repair work by shifting their responsibilities to consumers.

How to stop a leak with your own hands

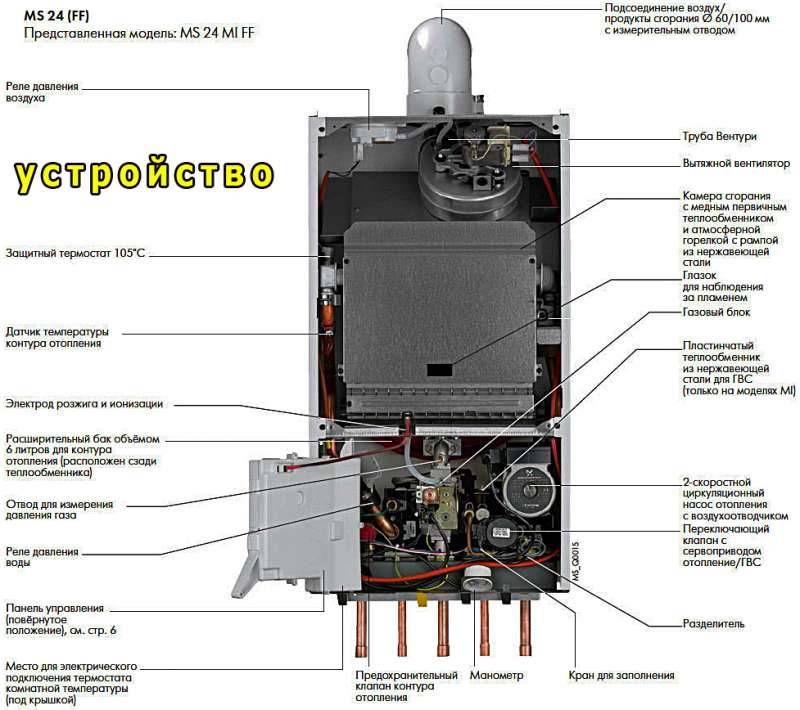

How to fix a leak - the leak elimination algorithm is the same for both solid fuel boilers, such as Don, KChM, and gas ones, for example, AOGV, Alixia 24, Ariston (Ariston), Deu, Arderia, Electrolux.

- Turn off the device.

- Drain the water.

- Wait for the boiler to cool completely.

- Remove the heat exchanger, as described below.

- Solder, eliminate the fistula.

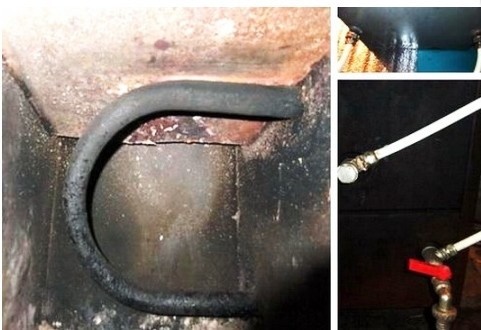

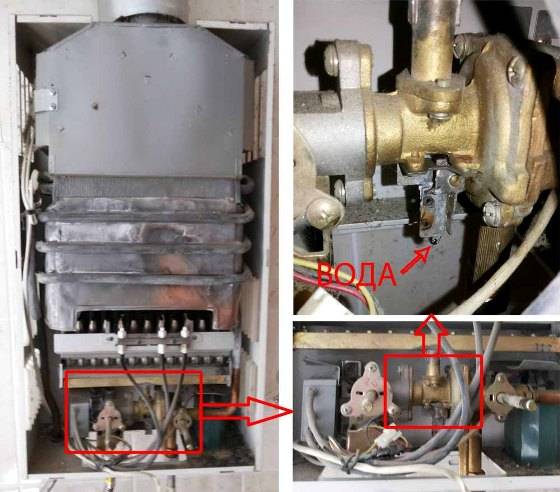

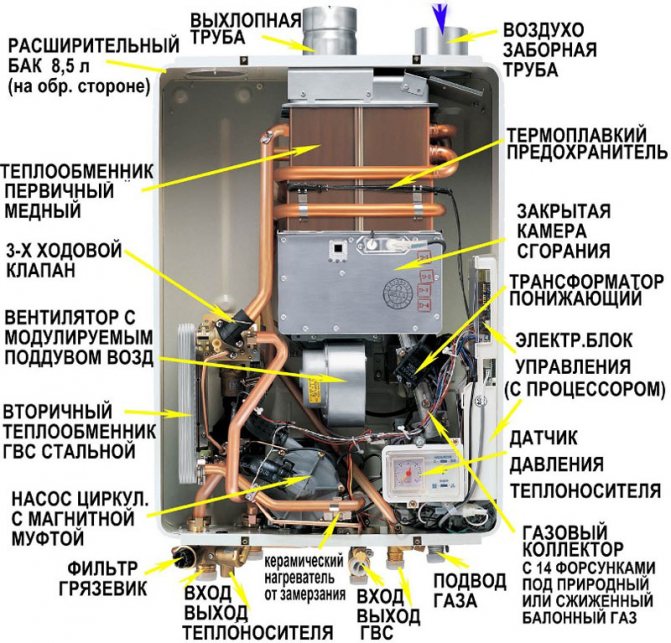

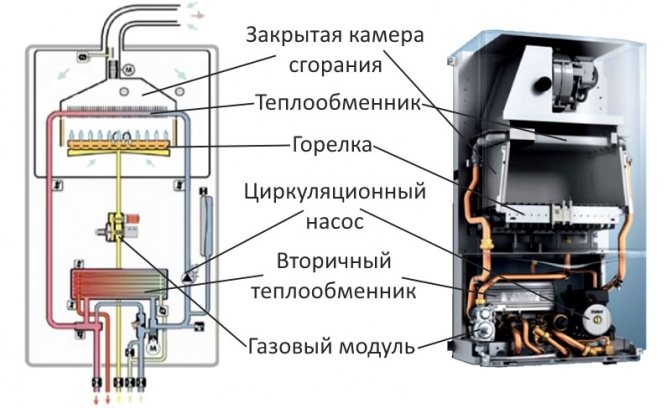

What does a heat exchanger look like - it is a metal or cast iron housing heated by a burner flame and transferring the thermal energy of the liquid that is inside it.

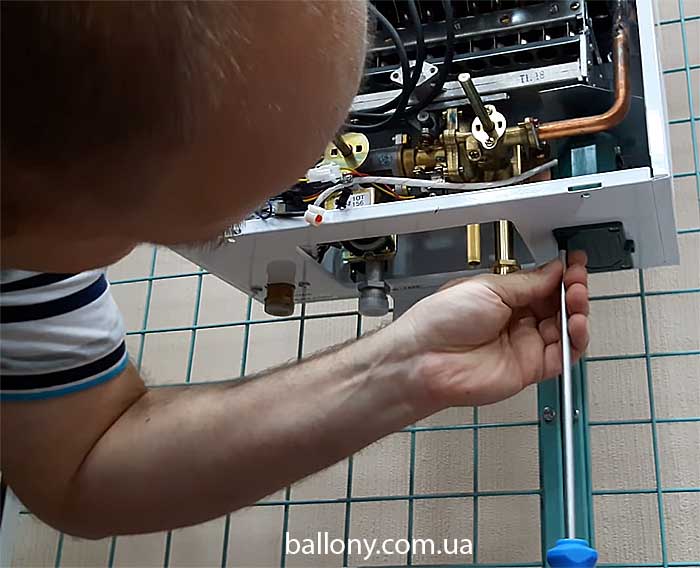

To disassemble it and solder it yourself, you need to remove the front panel, protective cover and combustion chamber protection with a long screwdriver. Then disconnect the sensor wires and pipelines suitable for the heat exchanger, try not to damage the pipes and tubes, hold them with a wrench.

In order to connect everything correctly later, you must first photograph the insides of the heat generator. Then disconnect the fan and smoke sensor

When removing the heat exchanger, do not use force or make sudden movements, do everything very carefully

If you find a gap between the circuits in the tube - it is impossible to close such a hole, you will have to change the heat exchanger. It is impossible to weld the heat exchanger; soldering with a gas burner should be used.

Heat exchanger soldering

In order to do soldering with your own hands, you must first clean the place where the fistula formed. This can be done with fine sandpaper. Soldering is carried out with a gas-oxygen mixture with a solder containing the same chemical elements from which the heat exchanger is made.

It is impossible to use tin in this case, since such repairs will again lead to the formation of a fistula after a while. After soldering, a protective coating should be applied to the problem area, for example, a layer of aluminum.

Repair of coolant leaks in a warm floor

Here is a selection of materials for you:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, radiators, pipes, floor heating, circulation pumps. Chimney cleaning. Conditioning

After six years of operation, collets on a metal-plastic pipe began to leak. Looks like the rubber seals have dried out and worn out. And this pipe laid a warm floor throughout my house. Moreover, some connections are made so that they are available for inspection and repair, and some are inside the walls. If open ones began to leak, then surely leaks arose in hidden ones. The pressure in the heating system began to gradually decrease. I had to add water to the circuit every two days, although no water leaks were observed. At this intensity of the leak, the water apparently had time to evaporate.But I'm afraid the leak could gradually increase.

I used a liquid to fix leaks in the car radiator (radiator sealant). I took a bottle, designed for 15 liters. I have 80 liters of coolant in my system. With the next addition of water to the system, the sealant was also pumped. The leak didn't stop right away. As water was added, another bottle of sealant was added. Filled 4 bottles in total. As a result, the leak completely stopped.

Of course, there is no guarantee that such a method will help. If the leak occurs due to a large hole, then the sealant will not help. But if the leak is not very intense, 5-7 liters per day flows out, then you can try.

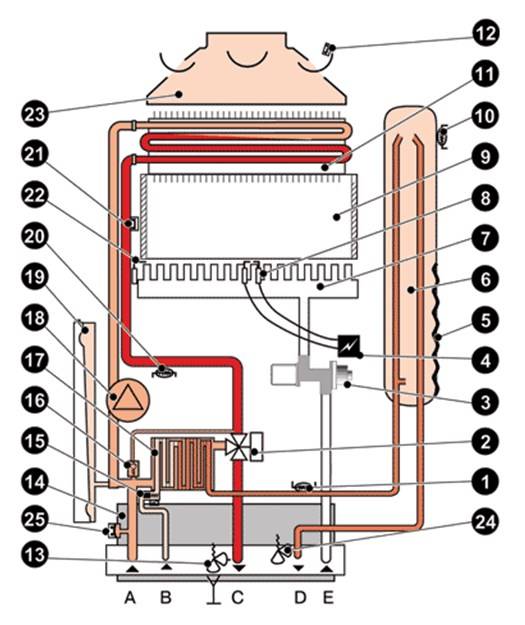

How to drain water from the heating system

When is it necessary to drain the water from the heating system? Most often, the need for it arises when it is necessary to clean or replace the heating radiator, for example. If we are talking about a city apartment that is connected to a central heating system, then such an operation can be carried out independently on the internal segment of the network. In the case when it is necessary to drain the heating system of a private house equipped with a boiler, it will have to be temporarily emptied.

The essence of the

The first step is to block the branch of the heating riser, which goes to the apartment. It is enough just to close the distribution valve located here. For a private house with an autonomous heating system, this process is somewhat different:

- first, you need to stop the supply of fuel or electrical energy;

- secondly, you should carefully read the user manual for this case.

Only then can the boiler be turned off. Then you should close the valve, through which water is drawn into the system.

Only then can the boiler be turned off. Then you should close the valve, through which water is drawn into the system.

To speed up the process a little, you will need to know the places in the system where taps with air-type valves can be located. All of them must be opened. In this case, nothing will interfere with the process of draining water to the hose.

During this operation, small water leaks from the system to the floor are possible. Therefore, at the very beginning, it is better to place a large bowl or basin under the place where the hose is connected to the tap (drain). As soon as all the water leaves the system, it is necessary to disconnect the hose and drain the remaining water from it into a substituted container.

Only after completing all the described procedures, you can proceed to the main thing - to the work for which the water was drained from the heating system of a residential apartment or private housing construction.

If the owner of an apartment or house is not entirely clear how to drain the water from the heating without detrimental consequences, then it is better to contact a qualified contractor. For example, to the plumber of a company that services a particular house.

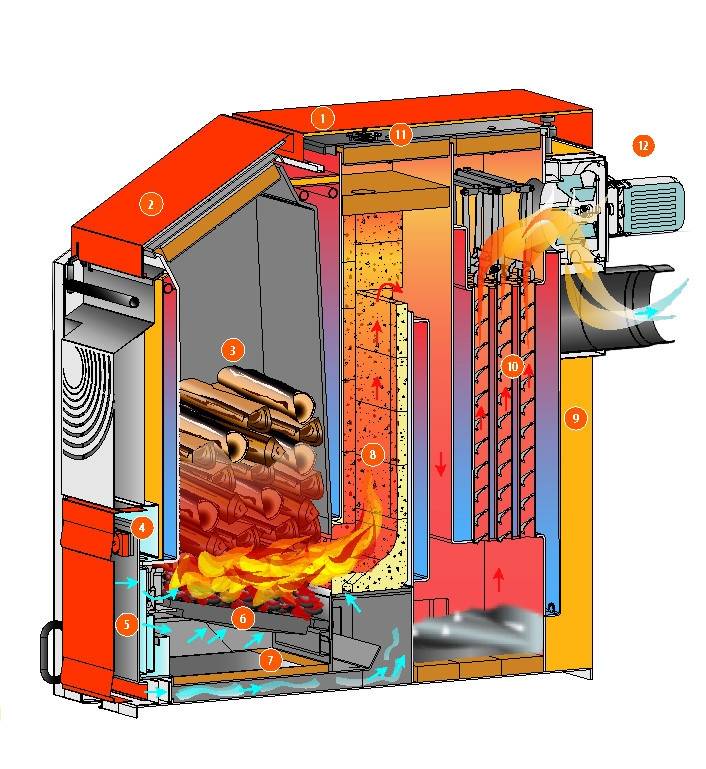

Causes of leakage

The accident is caused by a number of factors. Based on our experience, we argue that the most common causes are:

- Excessive pressure created by expanding water under the influence of heating.

- Boiler pipe heating under the influence of the burner flame.

- Corrosion due to contact with water in the system.

- Salts and other impurities found in unfiltered water.

- Poor quality welds that allow water to pass through.

It should be remembered that leakage is possible not only when the pipe is destroyed, but also through the sealing gasket.The heat exchanger may also be leaking. Regardless of the cause of the leak, the owner's actions are approximately the same.

We use the boiler correctly. How to extend the service life?

The first thing we must do is check the pressure in the system. If this indicator exceeds 3 atmospheres, then you will have to additionally install a gearbox that can reduce it. As you know, the reason for the increase in pressure can be an increase in temperature, and this is also very dangerous for the boiler.

The reducer itself must be installed in front of the device, it is important that the system pressure is no more than 2 atmospheres.

It is also undesirable to set the water heater too high a temperature. Ideally, it should not exceed 50 degrees.

The boiler needs periodic cleaning, moreover, we need to constantly monitor the condition of the rod (at least every two to three years)

If this rod becomes unusable, we immediately install a new one, otherwise it will adversely affect the functionality of the heating element.

Finally, experts advise installing a special filter in front of the water heater, also made of magnesium. Thanks to this filter, the hardness of the incoming liquid will noticeably decrease.

Note! It is recommended to set the water heater so that you can take a shower without diluting the water. This will not only save time, but also extend the life of the equipment.

What to do to prevent boiler leaks

Leakage can be avoided by taking preventive maintenance of your equipment in a timely manner.

To protect the boiler from corrosion, it should be periodically treated with anti-corrosion agents, which can be found in abundance in any specialized store.

To avoid repairs due to burnout, you should purchase the device only from a trusted manufacturer. Additionally, you should regularly monitor the operation of the boiler, make sure that it works without overloads and does not heat up to the maximum possible temperatures.

To prevent leaks due to high pressure in the equipment, the condition of the valve and pressure gauge should be constantly monitored. When detecting even small faults. They should be removed as soon as possible. Additionally, at least once every six months, it is necessary to check the diaphragm valve.

Failure to comply with these recommendations threatens equipment failure and costly repairs, and in the worst case, the purchase of a new boiler.

Climate technology Boiler

Prerequisites for draining water

This procedure is carried out in the following cases:

- Replacement of heating equipment.

- Correction of malfunctions of the boiler and repair of individual mechanisms.

- Elimination of leaks on the contacts of valves, fittings and other branch pipes.

- Turning off the heating in winter for a long time.

- Coolant replacement.

It is also important to know when such emptying should not be performed. There are three situations here:

- The boiler is not threatened by cold. You need to leave some water in it to protect the interior from rust.

- Water has stagnated in the machine, as it has been turned off for some time. Stale water is renewed. To do this, a full tank is collected several times.

- The boiler is still under warranty.

The management company refuses to change radiators - what should residents do?

The repair of the municipal heating system, the replacement of its elements within the house is handled by the management company serving the apartment building.

She must monitor the condition of the risers of an apartment building, heating pipes, and carry out repairs if necessary.

Batteries are being replaced. If there are shut-off valves in front of the apartment, the owner of the home usually pays for the replacement of radiators.

If the risers of the management company repair unconditionally, then the management company often refuses to change the equipment in the apartment for free.

If the management company ignores consumers and does not deal with its direct business, a written appeal will become the basis for going to court.

Devices for detecting leaks in walls and floors

There are few such devices:

- Thermal imager. It detects temperature rises of several degrees. But:

- the water may be slightly warm;

- the leak may be hidden by a thick layer of concrete;

- location may be inaccessible to the instrument.

- Surface moisture meter - allows you to measure the high humidity of the wall surface.

The method gives low accuracy, it takes a lot of time. It is better to duplicate it with a thermal imager showing a large problem area, and then look for it with a moisture meter.

- Acoustic device, analogue of a hospital phonendoscope. Allows you to hear the sounds of a "trickle" flowing in the wall and find a leak.

Our company can eliminate almost all problems associated with leaks in heating systems, both in a private house and in Moscow enterprises.

We provide the following types of services:

search for leaks and localize these places;

we find the location of hidden plumbing and heating pipelines;

we carry out diagnostics of the state of pipelines;

we examine the premises and find the places of heat loss with the help of a thermal imager;

we localize and completely eliminate leaks in pipes with hot and cold water;

we can find places of violation of thermal insulation, and much more.

In case of problems, call our specialists at any time of the day. Departure of specialists within Moscow is free of charge and promptly on the day of treatment.

Water leakage is a phenomenon that, sooner or later, any homeowner who has a steam heating system in his home faces. Finding it is quite simple if the pipes are not laid in the thickness of the walls or floor. But fixing a leak in the heating system is a more difficult and even critically dangerous task if boiling water is gushing out of a torn pipe. It is better not to bring such a situation and take measures to eliminate coolant leaks at the first sign.

Leak elimination methods

How to fix leaking heating pipes? First of all, it is required to prevent flooding of the apartment and lower neighbors. For this:

- a container is installed under the leak to collect the coolant. If the leak is small, then you can hang a plastic bottle or jar. If the system is severely damaged, a basin or bucket will be required;

Bank for collecting coolant

If the coolant is sprayed in different directions, then it is recommended to throw any fabric or blanket over the damage site, which will allow the liquid to be absorbed and gradually fall into the collection container.

- the heating system is turned off:

- If an individual heating system with separate shut-off fittings is installed in the room, then it is enough to turn off the corresponding valve installed in front of the meters.

- If the room has a common system, then the taps are installed in the basement.In this situation, employees of the management company or emergency service can shut off the coolant supply. The emergency phone numbers of the house and the management company can be found on utility bills.

After localizing the consequences, you can begin to choose a way to fix the problem. Fistula on the pipe heating can be closed:

- mechanical methods;

- chemical compounds.

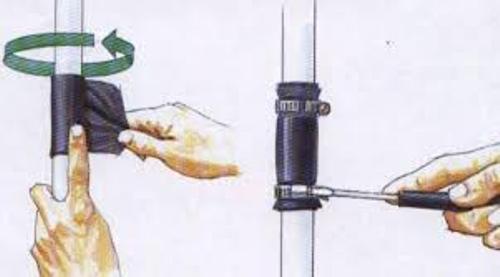

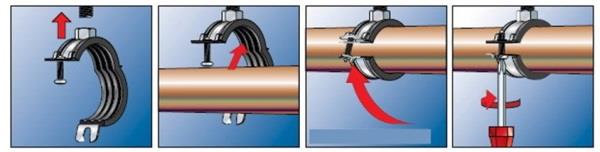

Elimination of leaks by mechanical means

How to fix the current heating pipe? The simplest and most popular way is to install a crimping device. The main advantages of this method are:

- ease of manufacture of the bandage;

- low repair cost;

- the ability to eliminate leakage without turning off the heat supply to the room.

For a bandage you can use:

- special clamps, which are fastened with a coupler or bolts. The devices are easy to install and low cost. Application is possible only on flat sections of the highway. The main thing is to choose the right equipment according to the size of the fistula;

- automotive clamps with rubber seals;

Clamps for fixing leaks on pipes

For a strong fixation, the diameter of the clamp must correspond to the diameter of the pipes of the heating system.

a special sealant (ready-made bandage for pipes), which is fixed with clamps or on an adhesive composition. The product allows you to get a stronger and more durable connection. In most cases, the application requires turning off the heat supply and removing the coolant from the system;

Leak bandage

reusable plastic collar. The device is reliable, easy to install and high cost.In most cases, it is used by professionals to fix a leak before a major overhaul;

Professional plastic pipe clamp

self-vulcanizing tape. It can be used to seal leaks both on a flat surface of the pipeline, and at the joints. The tape can only be applied to a dry surface, i.e. after the coolant has been removed.

Self-adhesive tape for pipes

To use a ready-made bandage or self-adhesive tape, it is enough to wind the selected sealant around the place where the leak occurs. Clamps are installed according to the following scheme:

- the leak site is cleaned of dirt and rust and cleaned. With a significant leak, this step can be neglected;

- the clamp, equipped with bolts for fastening, is disassembled and put on the pipe with a rubber seal to the fistula;

- the device is fixed with a bolt using a conventional screwdriver.

Scheme of installing a clamp on a pipe

How to fix a leak in a heating pipe with a clamp, see the video.

Workmanship

The stability of the boiler depends on the quality of the welded joints made. If there are cavities, irregularities on the weld, someday this seam may leak. A void is considered very dangerous, which is located in the middle of the seam. Perfectly, the seams should be translucent with an X-ray machine, but not all manufacturers do this.

Although heating boilers are pressure vessels and must be subjected to high requirements during the manufacturing process, defects often occur. And, basically, dripping from the heating boiler after the end of the warranty. brew boiler

in the middle andstop flow does not always work.

It depends on how the heat exchanger is arranged. In models where a bithermal heat exchanger is installed (secondary and primary are in the same housing, heat exchange occurs due to the 2 in one design), it is problematic to do this. However, even if you have done this, as practice says, it will not help you for a long time.

Downpipe pipes leaking

For hidden laying pipes, reliable ones are used. But even in this case, leaks can occur. Breaking walls or floors is an option, to put it mildly, “not very”. There are two ways to eliminate this heating leak:

- Old-fashioned method, but working. By the way, it will also help in cases of open wiring - if there is a caplet somewhere, but it is difficult to get there. Eliminating a leak in the heating system in this case is simple: a couple of packs of mustard powder are poured into the expansion tank and the system is started with such a coolant. After a couple of hours, the leaks are tightened: they are clogged with suspension. So it is possible to “clog” small leaks in the boiler. Then the mustard coolant is drained, the system is washed and it is started up with clean water. The method is working, but risky: something else can clog at the same time, and the filters and mud collectors will have to be cleaned for sure.

- On the same principle, but only with the use of polymers, the work of factory sealants for heating systems is based. They are poured into the system for a certain period of time. Circulating through the system, the polymers settle on the walls; in those places where there are leaks, they are not carried away by the coolant flow. Gradually, a blockage forms. When the leaks are blocked, the composition is drained, clean water is poured into the system and the heating continues to work.

Sealants of heating systems close up all leaks

Of course, it is cheaper to use mustard, and much cheaper: a canister of such a sealant with a volume of 1 liter (added at the rate of 1 * 100) costs from 6 thousand rubles. But the result may be different: mustard is organic, and the sealant contains a suspension of polymers. Moreover, there are ready-made sealants for antifreezes, for water, for leaks of different intensity.

And by the way, this is almost the only way to eliminate antifreeze leaks: it is very fluid, and often also poisonous (ethylene glycol) and you need to work with it extremely carefully. It is impossible to live in a room where ethylene glycol flows: its vapors are also toxic.

There are enough ways to eliminate a leak in the heating system. But everything, except for the replacement of a damaged part, only gives only some respite - to survive until the end of the heating season. Then you need to change pipes or radiators, redo the connections. Read about how to change radiators here.

How to drain water from the water supply system

From time to time, it may be necessary to completely turn off all taps, fittings, plumbing fixtures, or even drain water from the entire plumbing network (for example, if the house is left unheated all winter).

In this case, it is necessary to perform the following operations, which we present in the technological sequence.

Draining. We turn off the water supply to the house. We turn off gas and electricity from water heating systems. In the presence of central heating, it is necessary to open the outlet cock located on the boiler or on the pipes, for which they usually resort to using a hose. Then you need to open all the valves on the radiators. Starting from the top floor of the house or mansion, open all the hot water taps in the shower, bath, etc. Do not forget to drain the toilet bowl as well.

We remind you once again: all water outlet taps on the heater and other equipment must be open. And the last thing: it is necessary to open the outlet taps of the main water supply line so that all the remaining water leaves. If you leave your house or cottage for the winter for a long time, then do not be too lazy to make sure that all the water has left the system. As an additional protection against frost, add salt or a tablet of glycerin to the water remaining in the siphons. This will protect the siphons from possible rupture and exclude the possibility of odors from the pipelines entering the room.

Rice. one.

1 - compression plug; 2 - pin; 3 - threaded plug; 4 - nozzle

In the process of draining water from the system, it often becomes necessary to disconnect some of its sections. In this case, you need to use plugs. The most common plugs are shown in Figure 26.

Filling the system with water. First of all, you need to close the drain valves on the main pipes. Then you need to close all the taps in the house, including the taps of the boiler and water heater. If there is a cold water heater, open the tap on the radiator and let air in. After all these manipulations, slowly open the main valve of the system and gradually fill the system with water.

Even before turning on the boiler, the batteries must be purged with air. At the final stage, turn on the gas and electricity to turn on the heater and boiler.

Measures to prevent freezing of water. There is a possibility of cold penetration from the street due to malfunctions in the heating system

In this case, it is very important to immediately take the necessary measures against the freezing of pipes, since the water frozen in them will immediately break the pipeline.In very cold weather, even those pipelines that were laid without violating the requirements can freeze, which often happens with pipes for supplying heat to a garage or basement. What measures can be taken to prevent this? If the country house is electrified, in a cold area where the pipe runs, turn on the electric heater or simply place a 100-watt lamp near the pipe

For these purposes, you can even use a hair dryer. It is very good if you insulate the pipe before the onset of winter by wrapping it with newspapers and tying it with a rope

What measures can be taken to prevent this? If the country house is electrified, in a cold area where the pipe runs, turn on the electric heater or simply place a 100-watt lamp near the pipe. For these purposes, you can even use a hair dryer. It is very good if you insulate the pipe before the onset of winter by wrapping it with newspapers and tying it with a rope.

If the pipe is already frozen, wrap it with rags of any material and pour a thin stream of hot water over it so that the fabric around the pipe remains constantly hot.

A properly functioning heating system is an essential component of comfortable living in a house or apartment. Occasionally, there is a need to replace radiators, eliminate leaks in the network, move or move the riser closer to the wall.

Any work in the system requires draining the coolant. And this is understandable. After all, it is impossible to open pipes when the network is full. Therefore, before starting repair and maintenance work, it is necessary to drain the heating riser.

Replacing a faucet without blocking the riser

Is it possible to replace the stopcock without shutting off the water.

Do not practice on the upper floors! Do not do this with hot water and heating!

One of the readers of the site under the nickname, stefano asked a similar question:

Tell me how to proceed. The house has a riser and water outlets from polypropylene pipes. The crane flew on one of the outlets. Can I somehow replace it without shutting off the water in the whole house? And what is better to put? We turn off the water every day before leaving for work.

The first thing to do is to fix the pipes on which the meters hang. Meters should not hang on pipes. To replace the faucets, you will have to turn off the riser. Of course, you can install a duplicate if this one also overlaps, but this is only in a very extreme case.

In your case, it is better to disable the riser. If this is possible, then after disconnecting, you will have to solder something here, namely: if you look at the photo, then after the meters you have two 90-degree bends that lead the pipe closer to the wall. With the same two taps, take the faucet and meters to the wall immediately after the riser. Next, the meters must be put on clamps so that they do not hang on the pipes.

For example, use the following clamps:

They fit very well into the girth of the counters. After installation, they are almost invisible.

As for the valves, install reinforced faucets Valtek, or for example Bugatti.

There is a material about shutoff valves here and here.

Steps to fix leaks with liquid sealant

Before you start sealing possible leaks in the heating system, you need to make sure that the expansion tank is working.

The procedure for using liquid sealants to repair a home heating system can seem quite complicated.In some cases, clots of sealing fluid cause partial blockage and prevent the movement of the coolant. Therefore, in order not to harm the heating equipment due to your inexperience, it is better to invite a specialist. In any case, you need to study the instructions for using a particular type of sealant for radiators and strictly follow it.

Having decided to use a liquid sealant to fix a problem in the heating system, you need to make sure that:

- the cause of the pressure drop is precisely the leakage of the coolant, and is not associated with a malfunction of the expansion tank;

- the selected type of sealant for heating systems corresponds to the type of coolant in this system;

- the sealant is suitable for this heating boiler.

German sealant liquid type BCG-24 is used to eliminate leaks in heating systems

When using liquid sealant for pipes and radiators, it is important to maintain the correct concentration. On average, its values range from 1:50 to 1:100, but it is desirable to determine the concentration more accurately, since factors such as:

- coolant leakage rate (up to 30 liters per day or more);

- the total volume of water in the heating system.

If the volume does not exceed 80 liters, 1 liter of sealant will be enough to fill the heating system. But how to more accurately calculate the volume of water in the system? You need to calculate how many meters of pipes and what diameter were laid in the house, and then enter this data into one of the online calculators. To the resulting volume of pipelines, you must also add the passport characteristics of the volumes of all radiators and the boiler.

Preparing the heating system

- Dismantle or cut off all filters with taps so that they are not clogged with a viscous solution of sealant for heating systems;

- Unscrew the Mayevsky tap from one radiator (the first in the direction of the coolant) and connect a pump to it (such as "Kid");

- Start the heating system and let it warm up for an hour to a temperature of 50–60 ° C at a pressure of at least 1 bar;

- Open all valves on pipelines and radiators for free passage of sealant through them;

- Remove air from the entire system, including radiators and circulation pump.

Sealant preparation

- It is possible to pour liquid sealant into the heating system, including using a manual pressure pump. Drain about 10 liters of hot water from the system into a large bucket, most of which should be used to prepare the sealant solution, and leave a few liters for subsequent flushing of the pump;

- Shake the canister (bottle) with sealant for radiators and heating pipes, then pour its contents into a bucket;

- Rinse the canister thoroughly with hot water so that all the sediment remaining in it gets into the prepared solution.

Sealant solutions for heating systems must be prepared immediately before use so that the liquid does not come into contact with atmospheric air for too long.

Pouring sealant

Liquid sealant for heating systems must have time to mix with the coolant before it reaches the boiler, so it is more expedient to fill it into the supply:

- Introduce a solution of liquid sealant into the system using a pump;

- Pump the remaining hot water through the pump so that absolutely all of the sealant residue enters the system;

- Release the air from the system again;

- Raise the pressure to 1.2–1.5 bar and maintain the system operating cycle for 7–8 hours at a temperature of 45–60°C. This period is needed for the complete dissolution of the sealant in the coolant.

How does the sealing effect work?

The liquidation of the leak should not be expected immediately, but only on the 3rd or 4th day. During this time, the sealant for heating pipes will condense and close the cracks in problem areas from the inside. Eliminating the problem of coolant leakage will manifest itself in the fact that the sound of falling drops of liquid will no longer be heard in the house, the moist places on the floor will dry out, and the pressure in the system will no longer decrease.

At the same time, one of the negative effects may be a slight blockage of passages in devices for distributing the flow of coolant, as well as in thermostats. But this problem can be easily solved by periodically opening and then bringing into position such regulators in order to prevent them from sticking further.

The video lesson will help you understand how to fix a leak in the heating system yourself using a liquid sealant.

Based on the foregoing, you can be sure that the liquid sealant is undoubtedly worth it to use it to eliminate leaks in the heating system. Even though its price "bites". However, it should be understood that the hidden installation of heating pipes is not only a convenience, but also a certain risk, for which you sometimes have to pay.

What to do with a small leak in the heating system? (10+)

Repair of leaks in the heating system, heating boiler, underfloor heating

Sometimes coolant leaks can occur in the autonomous heating system. There may be several reasons. Firstly, antifreeze was poured into the system after it worked on water.In this case, the rubber gaskets and the sealing winding were first swollen with water, and then slightly dried out. Secondly, heating boilers usually consist of cast iron or steel structures connected by threaded connections sealed with sealant. During operation, the tightness may be broken. Thirdly, overheating, freezing or overpressure (too small expansion tank) in the heating system can lead to cracks in pipes, radiators and the boiler.

In the latter case, nothing can be done. Damaged equipment and piping must be replaced. In other cases, you can try to restore tightness without costly repairs.

Conclusions and useful video on the topic

Methods for sealing threaded connections in individual heating systems using various materials:

Elimination of leakage from the overpressure valve in a double-circuit gas boiler:

In heating boilers, coolant leakage can occur in different parts of the heating and hot water circuits. Replacing the seal on threaded connections is not difficult to do on your own. To eliminate leakage through the fistula of the heat exchanger, you will need the skills of a plumber and a welder, considerable experience, and tools.

Repair of damaged elements is not always possible, sometimes it is more expedient to replace them. With the prompt elimination of leaks, there are no negative consequences and the boiler is operated in the same mode.