- MEGEON 00100

- The best polypropylene pipes for plumbing

- Berke SDR7.4 PN-20

- Pro Aqua Rubis SDR6 20

- Valfex Aluminium, SDR 6 PN25

- Banninger G8200FW032

- The design of the welding machine for PPR

- Typical soldering iron design

- PACE PS90 with stand

- Functionality

- How to choose a welding machine for polypropylene pipes

- Piping material and types of connections

- How to use the machine for welding polypropylene pipes

- Training

- Marking and cutting pipes

- Connecting elements and heating

- The best manual machines for welding polypropylene pipes

- Dytron SP-4a 850W TraceWeld Mini

- Voll V-Weld R110

- Fora Pro 1600W

- TOPEX 200 W 44E031

- The best machines for butt welding of polypropylene pipes

- Rothenberger Roweld HE 200

- Brexit B-Weld G 315

- Rijing Makina HDT 160

MEGEON 00100

A portable soldering iron is a miniature device with a USB interface. A flexible system of settings allows you to conveniently use the model. The OLED display makes it possible to control working moments visually. Main characteristics:

- voltage - 19 V;

- power - 50 W;

- heating temperature - 100-400 degrees.

The copper tip has a protective coating.

Thanks to the USB interface, it is possible to connect to a computer and make settings. MEGEON has good functionality with small size and weight.The device is equipped with a sleep mode and heats up quickly.

The device is fast in discharging. Sometimes there is a subsidence of power (after all, work is not from the network). The price is too big for him, despite his features.

The best polypropylene pipes for plumbing

Manufacturers producing polypropylene pipes for plumbing use polymers with a minimum emission of organic substances. This ensures that drinking water does not have an unpleasant odor. Products with a small weight are distinguished by the presence of thick walls. This guarantees acoustic comfort during the operation of the water supply.

Berke SDR7.4 PN-20

The Turkish brand Berke manufactures products at Kaldi's production facilities located in Russia. In production, copolymers of the third type and PP-R 100 are used. This allows the use of SDR7.4 when laying water pipes with drinking and industrial water.

Reinforcement with fiberglass provides a minimum linear expansion, which is 4 times less than that of analogues of competing companies. Recommended for installation of systems with pressure up to 20 PN.

It is supplied with 4 m rods, which makes it convenient to transport by cars and light trucks.

Advantages:

- Service life exceeds 50 years;

- High strength characteristics;

- The possibility of reducing the number of supports during installation;

- Low price.

Flaws:

Simplified design.

With a small wall thickness, the products have high strength characteristics, which increases the throughput of the water supply.

Pro Aqua Rubis SDR6 20

Produced by a Russian company from domestic raw materials. Reinforced with fiberglass composite material.To a lesser extent subjected to thermal deformation, which simplifies the operation of water pipes and increases the service life.

The technology of multilayer extrusion is used, which allows to stabilize the linear dimensions. Indicators of linear thermal expansion are 75% less than those of analogues without a reinforcement system. It is applied at installation of pipelines with cold and hot water. Permitted coolant temperature - up to 95ºС.

Advantages:

- High strength;

- Easy installation;

- Working pressure up to 20PN;

- A smooth surface has a positive effect on throughput;

- Low price.

Flaws:

The lack of longitudinal lines on the surface makes centering difficult.

Valfex Aluminium, SDR 6 PN25

Products of a Russian company designed for domestic and drinking water supply. It has been on the market since 2005. The outer and inner layers of the Aluminum line are made of PPR copolymer. Reinforcement - aluminum foil, developed by Valfex specialists. In the manufacture, the screw extrusion method is used, which ensures a stable polymer structure.

Installation is carried out using socket polyfusion welding technology. Working pressure can reach 25PN. The recommended temperature is 80 ºС, peak values of 90 ºС are allowed. The polymer thickness of 4.2 mm provides a high degree of acoustic comfort.

Advantages:

- Low linear expansion;

- The manufacturer gives a guarantee of 10 years;

- Convenient form of delivery - rods 2 and 4 meters long;

- Wide range of fittings.

Flaws:

Smell during installation.

Banninger G8200FW032

German water pipes made of PP-R copolymer with high thermal stability.They have increased rigidity when transporting a coolant heated to high temperatures, and can be used for hot water supply.

Reinforced with fiberglass for low thermal expansion. Recommended working pressure 20PN. The polymer thickness of 3.6 mm ensures a low noise level during the operation of the water supply. The manufacturer's catalog contains a full range of fittings for laying hot and cold water supply in private homes, at retail and commercial real estate.

Advantages:

- Good chemical resistance;

- Durability;

- Fire resistance.

Flaws:

- Overcharge;

- Green color.

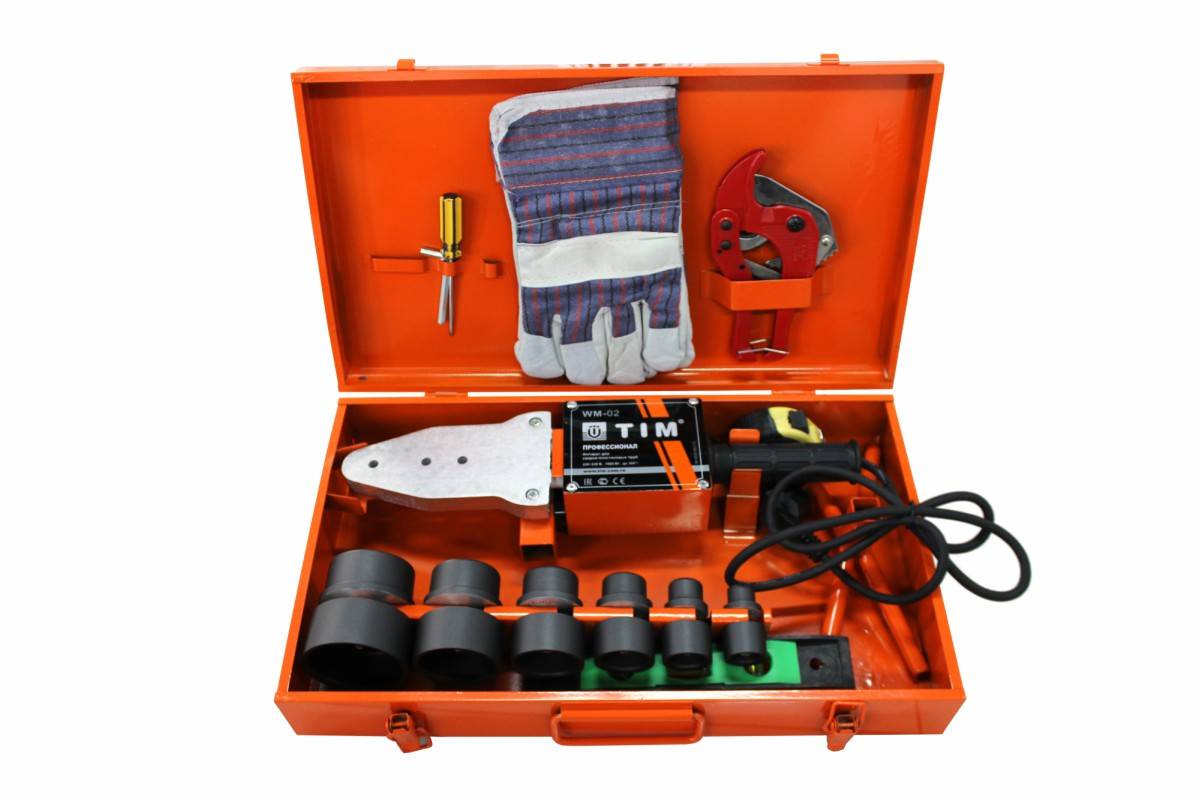

The design of the welding machine for PPR

A manual electric soldering iron (masters call it an “iron”), designed for soldering plastic pipes and fittings, consists of the following parts:

- housing with a transformer unit, thermostat and controls, equipped with a handle;

- a heating element with a power of 500 to 2 kW is installed in front of the case, depending on the model;

- stand and power cable connected to a conventional 220 volt outlet.

Using the regulator, you can set the heating temperature of the mandrel in the range of 0 ... 300 degrees

Heating of polypropylene parts is carried out using nozzles with a diameter of 16 ... 63 mm (household series), coated with a Teflon non-stick layer. The appearance and principle of operation of the device has a certain similarity with a conventional iron:

- The user turns on the heating and sets the required temperature with the regulator, for polypropylene - 260 ° C.

- When the platform with nozzles reaches a predetermined temperature threshold, the thermostat turns off the heating element.

- In the process of soldering pipes, the surface of the “iron” begins to cool, so the automation again activates the heating.

Teflon-coated nozzles consist of 2 parts - a pipe is inserted into one, a fitting into the second

For welding parts from PP-R, a deviation from the established limit of no more than 5 degrees is allowed, polypropylene is heated to the melting threshold. Exceeding the temperature leads to a change in the structure of the material - the plastic "flows" and fills the flow area of the pipe.

Insufficient heating gives a poor-quality connection, which loses its tightness after 3-12 months. How to properly weld a polypropylene joint, read in a separate material.

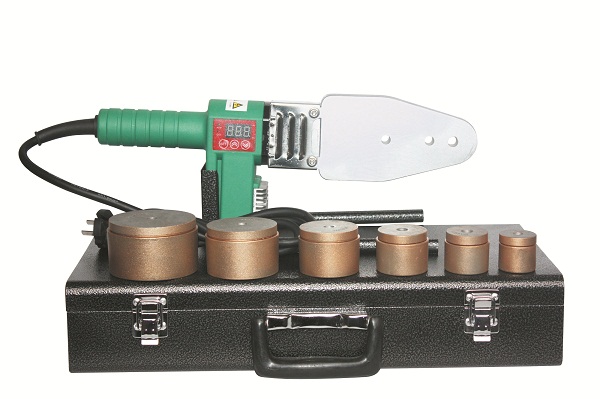

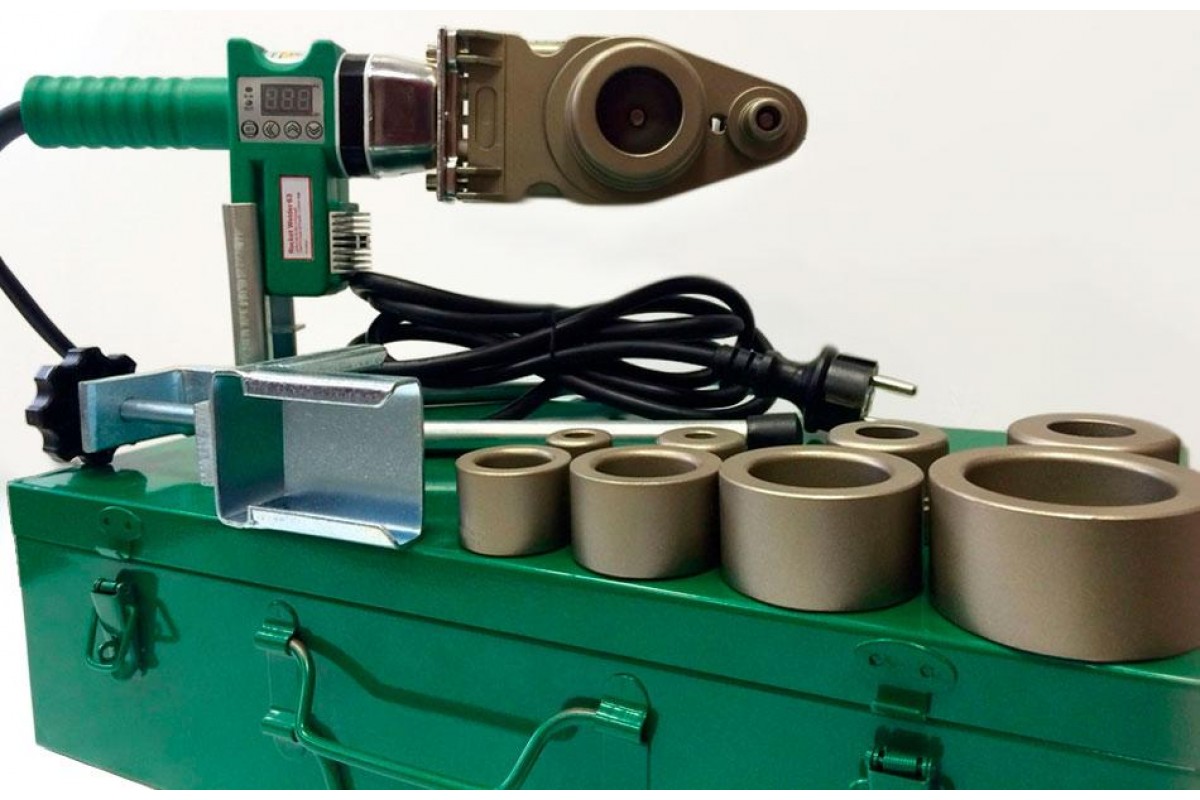

Typical soldering iron design

The design features of welding machines are similar to each other. The heating elements responsible for melting are located inside the case. There is also a holder, it is thermally insulated for safety, this allows you not to change the position of the tool during operation.

The design features of welding machines are similar to each other. The heating elements responsible for melting are located inside the case. There is also a holder, it is thermally insulated for safety, this allows you not to change the position of the tool during operation.

When welding large diameter propylene pipes, a complex device is used to control the process. The heating temperature is of great importance, because if it is violated, it is possible to melt the tube or coupling more than is required for soldering.

This is what a good soldering iron differs in, it does not allow such situations. The design is often equipped with a block responsible for the operating temperature of the heating device, as well as for the heating time of the elements.

When choosing a device, you should pay attention to the binding of the heating temperature not only to time, but also the wall thickness and diameter of the product should be taken into account.

PACE PS90 with stand

American universal soldering iron with stand that works with ST and MBT stations. Its power is 51 watts. It has a high heat dissipation, and the limited power eliminates the possibility of overheating of the tool after soldering. As a result, it is used when working with the most sensitive elements. This effect is available due to the special heat-conducting insulating materials of the winding structure. There is no barrier between heater and handpiece.

American universal soldering iron with stand that works with ST and MBT stations. Its power is 51 watts. It has a high heat dissipation, and the limited power eliminates the possibility of overheating of the tool after soldering. As a result, it is used when working with the most sensitive elements. This effect is available due to the special heat-conducting insulating materials of the winding structure. There is no barrier between heater and handpiece.

The advantages of the device are excellent thermal stability (with a strong heat sink, the set temperature is maintained). It is compatible with most PACE stations and requires no calibration. Convenient design of connection of the handle with the heater. Pleased with the anti-static coating of the handle.

Given the shape of the handle, it is not very comfortable in the hand (individually). After several uses, the device may work poorly (possibly a single defect). Other than that, it does its job perfectly.

Functionality

To solder polypropylene pipes, it is necessary to heat the ends of the pipes to the required temperature using a welding machine and connect them. The device comes with several nozzles of different diameters, which allows you to work with different sizes of pipes. To carry out high-quality soldering, it is necessary to know the exact temperature range.

The minimum set of welding equipment for the installation of propylene pipes consists of:

- heating elements;

- soles;

- nozzles.

The principle of operation resembles a home iron, only there are at least two heating elements in the soldering iron, and one in the iron. The thermostat is also different. The welding machine is equipped with a precise regulator.

Before proceeding directly to work, it is recommended to worry in advance and purchase the necessary additional tool:

- roulette;

- level;

- alcohol marker;

- cutter for cutting a propylene pipe.

How to choose a welding machine for polypropylene pipes

It is required to understand that there are certain requirements for choosing a particular model. Everyone should know exactly how they will use the device. Only then can you understand which soldering iron for plastic pipes is better to buy.

There are certain parameters that you need to pay attention to:

- Temperature Range. It is optimal if the device supports from 50 to 300 degrees. If the temperature is lower, then this may not be enough. And if the lower threshold is higher, then there will be difficulties in working with pipes of small diameter.

- Power. The minimum figure is 600 watts. Less powerful priors are not worth buying. But most professional devices have a power of up to 5 kW. Starting from 2 kW, there are semi-professional devices that are used quite often.

- Additional security options available. They make the job easier and more convenient. And they allow you to be safe to a large extent. It is necessary that a stable and reliable support and a clear temperature regulator be included in the package.

- Equipment. We are talking about the presence of matrices for working with pipes of various diameters. The more nozzles, the better.

Soldering iron for polypropylene pipes

At the same time, there is also a gradation by manufacturers. There are some of the most well-known companies that have proven themselves in this area.

Table. The best manufacturers of soldering irons for polypropylene pipes

| Manufacturer | Short description |

|---|---|

| Union | A Russian organization that supplies good household-class devices. They work stably. There are many service centers. The extended warranty is another reason to choose units from this company. |

| Resanta | This is a Latvian brand that offers a wide range of products from this category: from appliances for beginners to professional gadgets. |

| Elitech | This manufacturer offers devices for beginners and experienced professionals. The quality is high, some of the best components are used in the assembly. |

| Candan | This is a Turkish company that has been operating on the market for a long time. She offers a choice of soldering iron for polypropylene pipes, the diameter of which does not exceed 75 mm. |

| Wester | A great company that provides devices with a high level of security. There is protection against overvoltage, overheating and so on, which reduces the level of risk during operation. |

| Rothenberger | European manufacturer whose products comply with the requirements of the EU and the Russian Federation. Products can be purchased at many specialized stores. The price range is quite wide. |

| Gerat | Well-known brand of professional equipment. However, this company specializes in devices of the middle price segment. |

When deciding which plastic pipe welding machine to choose, all the above factors must be taken into account. It is strongly recommended to buy a reliable unit from a well-known global manufacturer. This will allow you to work for a long time without the need to perform maintenance on the tool.Those devices that are listed in the rating of machines for welding polypropylene pipes are definitely distinguished by high reliability. They can be found in many specialized stores.

Piping material and types of connections

There are two ways to connect engineering networks: detachable and one-piece. Detachable include threaded flange and socket connections. One-piece - electrowelded and brazed. When installing copper internal systems for cold and hot water, soldering was indeed used. In some special-purpose buildings, this installation method is still used today.

Until recently, all this applied to metal water pipes: steel, non-ferrous, cast iron. Steel is subject to corrosion. This is a serious disadvantage for water networks. Stainless steel is expensive and is used only in industry. It is no coincidence that polypropylene and polyethylene water pipes have recently gained well-deserved popularity. Their use significantly reduces the cost of installation work, increases the service life of water supply systems. Refusal of electric welding improves the environmental component of installation and the quality of drinking water. The installation of light, cheap, durable, durable and harmless plumbing systems is carried out by joining into a socket, using special welding machines, popularly nicknamed "soldering iron".

How to use the machine for welding polypropylene pipes

The pipe connection process is fast. For example, soldering pipes with a diameter of 20 mm will take 5-7 seconds to warm up, 4 seconds to join, and 3 minutes to cool. In total it turns out 3 minutes 9 seconds. The main requirement that must be observed is to perform actions without delay, without creating a hitch.

Training

Before you start soldering pipes, you should prepare the connecting elements, consumables and tools. The list of required funds includes:

- polypropylene pipes;

- couplings, plugs, angles, tees;

- clips for attaching pipes to the wall;

- pipe cutter;

- shaver (facer) for stripping edges from reinforcement;

- measuring devices (tape measure, marker, level, etc.);

- gloves.

The main tool used for soldering can be rented if one-time work is performed. It is advisable to purchase a bell-shaped apparatus in cases of assembling the system from scratch and subsequent maintenance.

Marking and cutting pipes

Even before soldering, you need to cut the pipes into fragments corresponding to the drawn up scheme. It is easier to assemble the system when small sections of pipes are connected by fittings, forming separate nodes.

Pipe cutting is done with a pipe cutter. Fittings are selected according to their diameter. These include: tees, couplings, corners. When using reinforced products, it is necessary to first remove the aluminum layer with a trimmer.

It is easier to fix the connecting elements if the pipe sections are even. Therefore, cutting is performed strictly perpendicular to the axis of the pipeline. After cutting, the edges are cleaned and degreased with a special tool.

Connecting elements and heating

The soldering process begins with the preparation of assemblies and fittings, as well as the connection of the apparatus. The device should warm up to +260 degrees. This value is indicated in the device manual.

Further execution in the following order:

- make marks along the edges of the pipes that determine the depth of surface heating;

- check the condition of pipes and fittings, they must be dry and free of grease;

- insert the end of the pipe into the coupling to the basting, install the connecting element on the mandrel to the stop;

- warm up the parts in compliance with the time, quickly insert the pipe into the fitting (immediately you need to make a high-quality connection, amendments are not allowed);

- after joining the parts, you need to wait until the heated surface cools down (this takes an average of 3-4 minutes, depending on the diameter of the pipe);

- repeat the process with the rest of the nodes.

If the soldering technology is followed, a strong hermetic connection is formed. The system is an integral line, ready for operation.

The best manual machines for welding polypropylene pipes

Similar models are used to connect pipes of small diameter. Their advantages include low cost, small size and long service life.

The use of a hand tool does not require special knowledge from the operator, so it is often chosen for small household work.

Dytron SP-4a 850W TraceWeld Mini

5.0

★★★★★

editorial score

100%

buyers recommend this product

The main advantages of the model include protection against overheating and high-precision temperature control thanks to a microprocessor controller.

The device is equipped with a system to prevent uncontrolled temperature rise above 300 °C and audible alarm modes.

The total power of the device is 850 watts. The soldering iron is able to fasten pipes with a diameter of 16 to 75 mm at negative temperatures and strong winds in the work area.

The special shape of the heating element allows you to simultaneously install two pairs of nozzles of different diameters.

Advantages:

- temperature setting accuracy;

- overheating protection;

- high performance;

- insensitivity to weather conditions;

- warranty period - 2 years.

Flaws:

high price.

The Dytron TraceWeld Mini is safe and comfortable to use. An almost indispensable solution for high-quality welding of small diameter pipes.

Voll V-Weld R110

4.9

★★★★★

editorial score

94%

buyers recommend this product

This device combines a powerful engine and compact dimensions. Thermostatic adjustment allows you to maintain the set temperature throughout the entire time of use. For convenience, it is possible to connect with a support or a clamp.

The device is used for welding pipes with a diameter of 75-110 mm. The package includes interchangeable nozzles, auxiliary installation tools and a metal stand. With their help, you can start installing the pipeline immediately after purchasing the device.

Advantages:

- motor power 1200 W;

- the presence of nozzles with a diameter of 75, 90 and 110 mm;

- indication of operating modes;

- overheat protection;

- compactness.

Flaws:

short power cable.

Voll V-Weld is small and weighs only 1.2 kg. The device will be an excellent acquisition for welding polypropylene pipes in hard-to-reach places.

Fora Pro 1600W

4.8

★★★★★

editorial score

91%

buyers recommend this product

See review

The model is distinguished by a rich equipment and an engine of increased power. The device maintains the set temperature throughout the welding process.

The soldering iron has a two-stage heating mechanism and three paired holes for the simultaneous processing of six parts.

Heat-resistant silicone insulated cable ensures operator safety and stable operation of the device in various environments.

The package includes: a clamp for fixing, a set of five nozzles 20-63 mm, pipe cutters, a screwdriver, a hex key and a tape measure.

Advantages:

- engine power 1600 W;

- extended equipment;

- high performance;

- long service life.

Flaws:

long cooling.

Fora Pro 1600W is used for fast and efficient welding of small diameter pipes. It is worth buying for both professional and home use.

TOPEX 200 W 44E031

The tool is electric and has a working temperature of 410 degrees. Used to join metal parts with low temperature solder. Manufactured in China, so the price is very affordable. It is operated during roofing and mechanical works. Cuts vinyl materials, useful as a marking tool and for soldering sheet metal. He is one of the first in the ranking of sales of inexpensive soldering irons.

The quality of the unit is excellent for the price. Heating up to the maximum temperature occurs very quickly. The handle is well made, comfortable to hold, does not slip. She is protected. Suitable for soft soldering only.

The cord could be longer. When you first turn it on, there is a terrible smell of burning.

The best machines for butt welding of polypropylene pipes

This type of welding does not require special couplings. The process of connecting tubular elements is based on heating their end parts and bonding under pressure.

Butt welding machines are characterized by a large range of machined diameters and high productivity.

Rothenberger Roweld HE 200

4.9

★★★★★

editorial score

96%

buyers recommend this product

The distinctive characteristics of the model include PTFE-coated heating elements and easy replacement of nozzles.

Thanks to this, melted areas do not stick to the device, and switching between pipes of different diameters takes place in a matter of minutes. The power of the device is 800 watts. A long service life is ensured by a mechanism that protects against overheating.

The temperature is electronically controlled and distributed evenly over the entire surface of the soldering iron.

Advantages:

- durability;

- status indication;

- ease of setup;

- quick nozzle change.

Flaws:

high price.

Rothenberger Roweld is used when connecting pipes made of synthetic materials with a diameter of not more than 20 mm. It can be bought for fast and efficient butt welding.

Brexit B-Weld G 315

4.9

★★★★★

editorial score

94%

buyers recommend this product

The heating element of the model is coated with Teflon and has a removable design, which makes it easy to replace.

The device is equipped with a high-precision temperature control system and a two-channel timer that allows you to keep statistics of the time spent on heating and cooling.

The motor power of the device is 3800 W, which guarantees efficient processing of pipes with a diameter of up to 315 mm. Low starting pressure and hydraulic drive ensure high welding quality.

Advantages:

- precise temperature control;

- powerful engine;

- welding of large diameter pipes;

- built-in pressure gauge and timer.

Flaws:

great weight.

Brexit B-Weld G 315 is used in the construction and manufacturing sectors. This is a professional tool for welding polypropylene pipes of various diameters.An excellent choice for quality and productive work.

Rijing Makina HDT 160

4.8

★★★★★

editorial score

88%

buyers recommend this product

The main features of the model are small dimensions, stability and reliability of the design. Clamping inserts of the device are equipped with force and fixation regulators.

The temperature of the heating element can be precisely adjusted, evenly distributed over the entire surface and maintained throughout the entire operation time.

The motor power is 1000W. The package includes reducing inserts for fixing pipes with a diameter of 40, 50, 63, 75, 90, 110, 125 and 160 mm. The high speed of processing is reached by means of the electric facer installed on the case.

Advantages:

- rich equipment;

- stability;

- compactness;

- the presence of a trimmer.

Flaws:

short cable.

Rijing Makina HDT 160 is worth buying for welding in hard-to-reach places, such as basements or wells.

Ease of use and ease of setup make it possible to successfully use it both in the professional field and in domestic work.