- So which machine is suitable for pipe welding?

- HAMER MULTIARC-250 Evolution

- Necessary equipment and tools

- 4 Regulatory framework for butt welding

- Manufacturers of manual electrofusion welding machines

- What equipment exists?

- Mechanical welding unit

- Manual welding machine (iron)

- Peculiarities

- Kinds

- Criteria for selecting a welding tool

- 5 ELITECH SPT 800

- Manufacturers of welding machines for polypropylene pipes, a brief overview of models.

- Butt welding method

- Apparatus types

- Manual

- Mechanical

- hydraulic

- Electrofusion equipment

- How to choose the right device?

- Manual apparatus

- Mechanical

- Conclusions and useful video on the topic

So which machine is suitable for pipe welding?

Summing up, here is a list of requirements for pipe welding equipment:

- Welding modes: MIG/MAG; MMA TIG

- Welding current: in the range from 20 to 250 A (MMA); 20 to 250 A (MIG); 20 to 200 (TIG);

- Wire diameter: 0.6 to 1.2 mm;

- Electrode diameter: up to 1.5 to 5 mm;

- Voltage: 220V/380V;

- Efficiency: 70-90%;

- Weight: 15-20 kg.

These requirements are fully met by the welding machine HAMER MULTIARC-250 Evolution

HAMER MULTIARC-250 Evolution

-

- Welding current 20-250 A (MMA); 15-60 A (CUT); 20-200 A (TIG);

- Type of welding MMA/CUT/TIG;

- Voltage 220 V/ 50 Hz;

- Load duration for MMA mode 250 A / 35%; 118.5 A/100%;

- Load duration for CUT mode 60 A/35%; 29.6A/100%;

- Load duration for TIG mode 200 A/35%; 118.5 A/100%;

- Efficiency 85%;

- Weight 15 kg;

- Suitable for operation with unstable mains voltage (garages, farms, countryside, etc.)

HAMER MULTIARC-250 Evolution is a multifunctional welding machine operating in MMA, TIG, CUT modes. The combination of several modes significantly expands the list of welding processes, allowing you to work with different types of metals. This makes HAMER MULTIARC-250 Evolution an indispensable assistant in production, in particular for welding repairs, preparation for installation and installation of pipes.

Get 90 rubles as a gift!

Necessary equipment and tools

For welding plastic pipes, it is convenient to use sword-shaped soldering irons with removable nozzles. The heating element for pipe welding is a flat platform called an iron, it has holes for attaching heating nozzles.

The welding machine for welding plastic pipes must have a temperature controller, a heating indicator light. In addition to welding equipment, tools are needed for cutting blanks and removing the foil layer. Cut plastic rolled products in any convenient way:

- pipe cutter, similar to wire cutters;

- scissors for metal;

- hacksaw with a narrow blade.

Fine-cut files or sandpaper are used to clean cuts, remove sagging. To cut pipeline elements before welding, you need to prepare a ruler, square, felt-tip pen or marker.

4 Regulatory framework for butt welding

As can be seen from, until recently in Russia there was considerable confusion with butt welding technology, since several current regulatory documents gave their own interpretation of it, and therefore most welders preferred to trust the slender German DVS technology. And the requirements for butt welding equipment in Russia were not defined by any standard at all.

Since the beginning of 2013, two regulatory documents have come into force in the Russian Federation at once:

- GOST R 55276 - for the technology of butt welding of PE pipes during the installation of water and gas pipelines, based on the translation of the international standard ISO 21307;

- GOST R ISO 12176-1 - for butt welding equipment, based on the translation of the international standard ISO 12176-1.

The adoption of GOST for equipment was certainly useful. Unfortunately, this does not mean that the most low-grade imported equipment was immediately weeded out. But, in any case, a few Russian equipment manufacturers are now forced to work on quality, and the consumer has received a hint on assessing the quality of the purchased equipment.

GOST on the technology of butt welding brought relative order. In any case, it led to the uniformity of the technology of butt welding of PE pipes on the territory of the Russian Federation. But the problems remained.

IMPORTANT! GOST R 55276, along with the traditional low pressure welding mode (similar to DVS 2207-1 and old Russian standards), legalized the high pressure welding mode for polyethylene pipes, which was previously used only in the USA. This mode imposes increased requirements on the equipment, but it can significantly reduce the welding cycle time.

IMPORTANT! GOST R 55276 is hardly suitable for direct use on a construction site, since it is focused not on a welder, but on a developer of a technological chart for welding polyethylene pipes. IMPORTANT! GOST R 55276 did not solve the problem of limitations that the old Russian standards suffered from and to this day all foreign standards suffer

Firstly, the allowable air temperature range is from +5 to +45°C, while a huge part of the territory of the Russian Federation is forced to start welding when the swamps freeze. Secondly, the maximum wall thickness of the pipes is 70 mm, while the wall thickness of actually produced pipes has long ago exceeded 90 mm. And thirdly, the pipe material is only traditional low-pressure polyethylene (HDPE) with a melt flow rate of at least 0.2 g / 10 min (at 190/5), while non-flowing grades of polyethylene have long been used for the production of large diameter pipes medium pressure with MFI below 0.1 g/10 min (at 190/5). For conditions outside the proven limits of air temperature and wall thicknesses, some manufacturers have calculated the technology for welding polyethylene pipes by extrapolating current regulations, but this theoretical technology has not yet been verified by long-term tests. For non-flowing grades of polyethylene, there is no technology for pipe welding, even in theory. As a result, about 80% of all welding is performed in Russia under conditions that go beyond the limitations of proven technology!

IMPORTANT! GOST R 55276 did not solve the problem of limitations that the old Russian standards suffered from and to this day all foreign standards suffer. Firstly, the allowable air temperature range is from +5 to +45 ° С, while a huge part of the territory of the Russian Federation is forced to start welding when the swamps freeze

Secondly, the maximum wall thickness of the pipes is 70 mm, while the wall thickness of actually produced pipes has long ago exceeded 90 mm. And thirdly, the pipe material is only traditional low-pressure polyethylene (HDPE) with a melt flow rate of at least 0.2 g / 10 min (at 190/5), while non-flowing grades of polyethylene have long been used for the production of large diameter pipes medium pressure with MFI below 0.1 g/10 min (at 190/5). For conditions outside the proven limits of air temperature and wall thicknesses, some manufacturers have calculated the technology for welding polyethylene pipes by extrapolating current regulations, but this theoretical technology has not yet been verified by long-term tests. For non-flowing grades of polyethylene, there is no technology for pipe welding, even in theory. As a result, about 80% of all welding is performed in Russia under conditions that go beyond the limitations of proven technology!

Previous

2

Track.

Manufacturers of manual electrofusion welding machines

in the welding market soldering machines HDPE pipes are most in demand products of the following manufacturers:

- Rothenberger. This company was founded in Germany in 1949. Over the past years, the company has been able to achieve very great success, becoming one of the leading manufacturers of welding machines. Products manufactured under the Rothenberger brand are distinguished by the highest possible quality and the highest degree of reliability.

- Ritmo. The Italian company Ritmo was founded in 1979. Today it belongs to the category of leading companies engaged in the processing of polymers and polymer products. In its activities, Ritmo constantly follows the most modern and strict standards.The company's business is at a very high level, and the same can be said about the products - Ritmo products are distinguished by variety, versatility and the highest quality.

- DYTRON. Against the background of older analogues, the products of the Czech company DYTRON, founded in 1992, do not seem to be of insufficient quality - everything is in order with that. The product range is unusually wide - the company produces both manual and automatic equipment that allows you to connect HDPE pipes. In addition, the model ranges are constantly expanding and supplemented, so finding good equipment at the stands of this brand will not be a problem. It is also worth noting the compliance of the released devices with the most modern requirements.

Conclusion

When choosing a device for soldering HDPE pipes, it is necessary to build on the requirements due to a particular situation. Proper selection of equipment will allow you to create a reliable and tight connection that can last as long as solid pipes.

What equipment exists?

According to its design, the welding machine is a device in which pipe sections are heated, thereby making it possible to obtain a permanent connection. There is no need to explain that the equipment used for welding plastic pipes will have a different design than the machine for welding metal pipes.

To date, on There are two types of devices available on the market used for welding polypropylene pipes:

- mechanical apparatus for welding;

- manual welding machine.

It is worth thinking about using the first one in cases where it is necessary to combine the joints, making a lot of effort for this, or the task of installing pipes that have a rather large diameter has arisen.

A manual plastic pipe welding machine will be the best choice when it is planned to assemble the pipeline on its own and it is planned to use pipes that differ in their diameter for work.

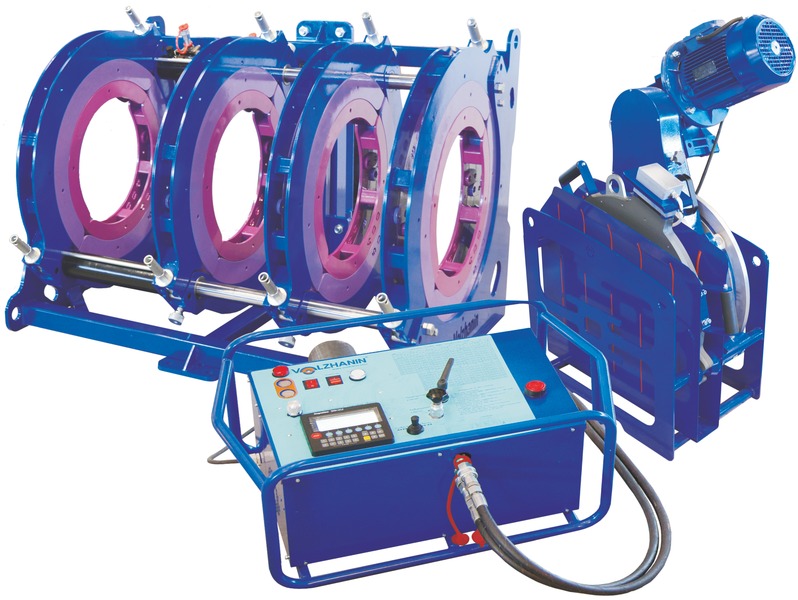

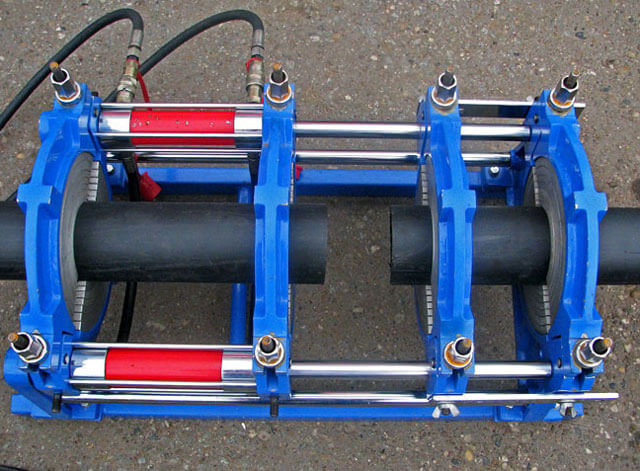

Mechanical welding unit

In terms of design, a mechanical apparatus for welding pipes made of polypropylene is made in the form of a support frame, on which there is an instrument unit and a hydraulic unit. On the left and right sides there are grips, each of which has a pair of half rings. The grips are separated by inserts to help balance pressure and center. In terms of their inner diameter, they do not differ from the pipes with which to work.

In terms of design, a mechanical apparatus for welding pipes made of polypropylene is made in the form of a support frame, on which there is an instrument unit and a hydraulic unit. On the left and right sides there are grips, each of which has a pair of half rings. The grips are separated by inserts to help balance pressure and center. In terms of their inner diameter, they do not differ from the pipes with which to work.

In the design of the device there is an electric trimmer, the main purpose of which is to align the ends of the pipes. This device is a rotating disk equipped with double-sided knives, which also has a locking mechanism that ensures safe operation. The main working heating element is a steel disc with a non-stick coating containing heating elements inside. The design of many models of such devices often contains temperature controllers and temperature control sensors.

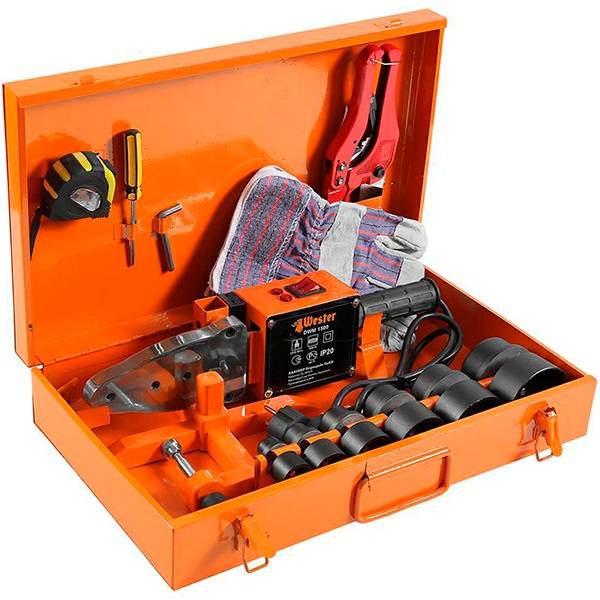

Manual welding machine (iron)

Considering that the ordinary consumer is unlikely to have the task of installing long networks, he should not buy a bulky welding device.

Most consumers usually use a device such as a welding iron to assemble pipes.If we evaluate it by its design and features in operation, then in this respect it differs little from a traditional household appliance. Of its features, only a different design can be distinguished.

The main elements of its design are a heating plate, a thermostat and an ergonomic handle. If you look closely, you can find two holes in the heating plate, which are necessary for attaching paired welding elements that differ in their diameter. They are distinguished, first of all, by the presence of a Teflon coating, thanks to which the plastic does not stick to a hot surface.

Peculiarities

When choosing a machine for welding pipes from PE, you need to clearly understand what kind of work will be done with it. The features of the desired equipment will largely depend on the welding method that you plan to use most often.

There are four main methods for soldering polyethylene products.

- Butt welding - this method is the most common, and it is based on the connection of heated pipe ends to each other or to fittings using a special welding mirror. Butt jointing allows you to get a fairly high-quality joint at an affordable price of equipment, but the method is not suitable for joining products with a wall thickness of less than 4.5 mm. The use of butt welding requires thorough cleaning of the surfaces to be joined, maximum precision in trimming products and applying the correct pressure to the pipes during their connection.

- Docking pipes into a socket (or coupling method) is a reliable, but less common and more expensive method based on connecting products through a special coupling.There are also options for connecting two pipes of different diameters directly to each other. This method is not used for laying pipelines located outdoors.

- Electrofusion (or thermistor) welding of pipes - this method is similar to joining into a socket, but the coupling used in it contains a metal heating element, which contributes to more uniform heating of the connected products and the electric coupling. Each electric clutch has a special barcode that encodes the electric current parameters necessary for this clutch, so devices of this type are often equipped with a barcode scanner. The thermistor method is even more reliable (and more expensive) than the coupling method, therefore it is mainly used in cases where it is necessary to provide a very stable connection (for example, when laying pipelines in areas of frequent earthquakes). This method is used to connect pipes with a diameter of 20 mm or more with any wall thickness, and the requirements for the accuracy of holding technological parameters in it are much lower than with butt soldering.

- Extrusion welding is a method similar to electric welding, in which heated polyethylene is fed through a special extruder into the welding area, forming a connection between the pipes. The strength of the resulting connection usually does not exceed 80% of the strength of polyethylene, so the extrusion method is usually used mainly for connecting pipes with other plastic products and installing pipes with a diameter of 630 mm or more in places that are not likely to be subjected to high loads.

Kinds

All polyethylene welding devices consist of four main modules - a generator (usually operating on the principle of an inverter with a transformer or a switching power supply), a power control module, a temperature control module and a technological unit in which the connection process itself takes place. Each of the four welding methods discussed above is performed using the appropriate tool.

The existing machines for each of the 4 methods can be further divided into 3 categories according to the degree of automation.

Semi-automatic devices are divided according to the type of drive used into mechanical and hydraulic. In devices with a mechanical drive, the force necessary to center and hold the pipes during the welding process is created with the help of the operator, therefore they are used only when working with pipes with a diameter of less than 160 mm. The hydraulic drive does not require the application of force from the operator and is used for welding products of any diameter, including those larger than 160 mm.

Another important characteristic of the welding machine is the diameter of the pipes that it can connect, because the standard sizes of PE pipes are in the range from 16 to 1600 mm. For example, for plumbing in apartments, pipes with a diameter of 20 to 32 mm are usually used, but for the installation of main pipelines, a device capable of soldering pipes with a diameter of 90/315 mm or more may already be needed.

Currently, the most popular devices are Georg Fischer (Switzerland), Rothenberger (Germany), Advance Welding (Great Britain), Eurostandard, Technodue and Ritmo (Italy), Dytron (Czech Republic), KamiTech and Nowatech (Poland).There are also Russian manufacturers of polyethylene welding devices, for example, the Volzhanin plant, which produces equipment for butt-soldering products with a diameter of 40 to 1600 mm and electrofusion devices capable of connecting pipes with a diameter of up to 1200 mm.

Criteria for selecting a welding tool

When deciding the issue with the preferred class of welding equipment, it is necessary first of all to pay attention to the scope of the planned work. Here the following parameters are of great relevance:

- The range of pipe diameters to work with.

- Power consumption.

- Device price.

It is noteworthy that there is a clear relationship between these parameters. So, with an increase in the outer diameter of the pipe, it is necessary to consider models with higher power. It is generally accepted that the power indicator, the unit of which is watts, should be 10 times the diameter, calculated in millimeters. In other words, if it is supposed to weld pipes with an outer diameter of 30 mm, then you can limit yourself to a model whose power rating is 300 watts. It is worth noting that the figures given are not final and accurate, and therefore errors within 30% are allowed here.

Therefore, if the model of welding equipment has a large power consumption, then this allows the owner to weld pipes of a larger diameter. However, the acquisition of such equipment will require large expenditures.

5 ELITECH SPT 800

Rich equipment Country: Russia (produced in China) Average price: 1 638 rubles. Rating (2019): 4.5

This budget soldering iron for polypropylene pipes can be seen not only in the hands of novice installers, but also professionals.The model can work with 6 pipe sizes, from 20 to 63 mm. Experts note high-quality nozzles coated with Teflon. With a heater power of 800 W, the device can quickly heat up to 300°C. The heater also cools down fairly quickly. The manufacturer has completed its product with 6 nozzles, a stand, a reliable metal case, and a set of tools (screwdriver, hex key).

Analyzing consumer reviews, there are several advantages and disadvantages of the device. On the one hand, the model deserves praise for its power, fast heating and cooling, smooth seams, affordable price. Complaints come to the uncomfortable stand, flimsy case, poor-quality Teflon coating.

Manufacturers of welding machines for polypropylene pipes, a brief overview of models.

When choosing any equipment, one of the determining criteria is the reputation of the manufacturer. And although machines for manual welding of polypropylene pipes cannot be called too complex and high-tech devices, there are also certain authorities in this area.

So, "trendsetters" in the production of such equipment are considered "Rothenberger", "Valfex", "Dytron", "BRIMA", "Gerat", "KERN". Elitech, Sturm, Caliber, Enkor, PATRIOT, Energomash, DeFort devices are no less reliable and in demand. The main thing is that the purchased equipment is really original, not a fake, and is accompanied by a manufacturer's factory warranty.

In conclusion, traditionally, a small review of popular models and the average price level for them.

| Model name, illustration | Brief description of the model | Average price level, rub. (April 2016) |

|---|---|---|

"BRIMA TG-171", Germany - China  | Power 750 W, welding diameter - up to 63 mm, electromechanical thermostat, heating temperature - up to 300 °C. Warm-up time - no more than 15 minutes. The set includes six pairs of nozzles from 20 to 63 mm. | 3900 |

"ENCOR ASP-800", Russia - China  | Power 800 W, welding diameter - up to 63 mm, electromechanical thermostat, heating temperature - up to 300 °C. Stable platform stand. The kit includes six pairs of nozzles from 20 to 63 mm with a Teflon coating. | 2200 |

Elitech SPT 1000, Russia - China  | Apparatus with a cylindrical heating element. Power - 1000 watts. Welding diameter - from 16 to 32 mm. A set of nozzles (4 diameters) with a Teflon coating is included in the delivery. Ergonomic shape of the body and handle, allowing you to work in hard-to-reach places. Electromechanical thermostat. | 2700 |

"Sturm TW7219", Germany - China  | High power model - 1900 W, with the possibility of turning on full and half power (one or two heating elements). Six pairs of Teflon-coated tips. The maximum welding diameter is 62 mm. Heating time - about 12 minutes. Extended delivery package that does not require the purchase of additional accessories. | 3300 |

Dytron Polys P-1a, Czech Republic  | High quality professional equipment. Power - 650 watts. Cylindrical heater with high precision capillary thermostat. Welding diameter - up to 32 mm. Patented 3 diameter shoe type tips, coated with high quality blue Teflon. Six temperature settings. Automatic overheating protection. Weight - only 1.3 kg, which facilitates work in hard-to-reach places. | 11200 in the minimum configuration - a device, a stand and three nozzles. |

Rothenberger ROWELD P 40T, Germany  | Power - 650 watts.The maximum welding diameter is 40 mm. Sword-shaped heater with the possibility of installing two pairs of sleeve-mandrel. The kit includes 4 pairs of nozzles from 20 to 40 mm, high-quality Teflon coating. Features of this device - the built-in thermostat is designed specifically for polypropylene pipes and is programmed for high-precision maintenance of a stable temperature of 260 ° C. The mass of the device is 2.8 kg. | 14500 |

KERN Welder R63E, Germany  | Professional grade model. Relatively low power, 800 W, and at the same time - the possibility of welding pipes with a diameter of up to 63 mm. Six pairs of Teflon coated tips included. High-precision electronic installation of the set temperature with the microprocessor controller, digital display. | 13500 |

In conclusion - a video about another welding machine for polypropylene pipes

Butt welding method

This method allows you to connect polyethylene pipes with a weld using special equipment for butt welding. The weld (or "joint") is equal in tensile strength to the polyethylene pipe itself. By welding with a heated tool, PE pipes with diameters from 50 mm to 1600 mm inclusive are connected. Standard technological welding modes are designed for operation at air temperature from -10°C to +30°C. If the air temperature in the street goes beyond the standard temperature intervals, then welding of polyethylene pipes must be carried out in a shelter in order to comply with technological parameters. Butt welding of pressure HDPE pipes is divided into two main stages: preparatory work and welding itself. The preparatory stage includes:

- checking the performance and preparation for operation of welding equipment,

- preparation of a place for placement of welding equipment,

- selection of the necessary parameters for welding,

- fixing PE pipes and centering in the clamps of the welding machine,

- mechanical processing of the ends of the welded surfaces of pipes or parts.

When preparing the equipment, inserts and clamps are selected that correspond to the diameter of the pipe to be welded. The working surfaces of the heater and the tool for processing PE pipes must be cleaned of dirt and dust. The operability of the equipment is checked during a visual inspection of the units and components of the welding machine, as well as during the control inclusion. At the welding machine, the smooth running of the movable clamp of the centralizer and the operation of the facer are checked. Placement of welding equipment is carried out on a pre-prepared and cleared site or pipeline route after PE pipes are stored on it. If necessary, the welding site is protected with awnings to protect it from precipitation, sand and dust. In wet weather, it is recommended to install welding equipment on wooden shields. And it is recommended to close the free end of the polyethylene pipe with inventory plugs to prevent drafts inside the pipe during welding.

The assembly of welded pressure HDPE pipes and parts, including the installation, centering and fixing of the ends to be welded, is carried out in the clamps of the centralizer of the welding machine. The clamps of the welding machine for PE pipes are tightened so as to prevent slipping of the pipes and eliminate, to the extent possible, ovality at the ends.When butt welding large-diameter PE pipes, since they have a sufficiently large dead weight, supports are placed under the free ends to align the pipe and prevent the welded end of the pipe from moving. The sequence of the welding process:

- first measure the force required to move the movable clamp with a fixed pipe,

- a heater is installed between the ends of the pipes, heated to the required temperature,

- carry out the reflow process by pressing the ends of the PE pipes to the heater, creating the necessary pressure,

- the ends are squeezed for some time (according to the welding technology for this polyethylene pipe) until the appearance of a primary burr with a height of 0.5 to 2.0 mm,

- after the appearance of the primary burr, the pressure is reduced and maintained for the time necessary to warm up the ends of the pipes,

- after the end of the warm-up process, the movable clamp of the centralizer is retracted 5-6 cm back and the heater is removed from the welding zone,

- after removing the heater, bring the ends of the polyethylene pipes to contact, creating the pressure necessary for precipitation,

- the precipitation pressure is maintained for the time necessary for the joint to cool, and then a visual inspection of the resulting weld is carried out in terms of the size and configuration of the outer burr,

- then mark the resulting weld.

Apparatus types

According to the principle of connecting parts, welding units are divided into 2 types:

- for electrofusion connection;

- for socket and butt.

According to the principle of operation, all types of equipment are divided into manual and mechanical. Any welding equipment, regardless of type, has 4 main units: a generator, a temperature controller, a power module and a technological unit where parts are connected.The latter has a different structure (depending on the type of welding).

Manual

Manual small-sized welding machines have the form of a plate with tips for fixing the ends of HDPE parts. To connect the prepared surfaces, human effort is required, so the pipe diameter should not exceed 125 mm. A hand-held device is chosen for home use, it is the easiest to master, it has a low price.

Mechanical

These devices are designed for professionals. They include the following:

- centralizer with tips for clamping parts;

- end cutter with sharpened knives for pipe processing;

- heating element (welding mirror);

- compression device.

The compression of the connected pipes is provided by the mechanic, so their diameter is unlimited. Welding with a mechanically driven device is a more advanced method: it facilitates the work of the operator and makes the joint more reliable.

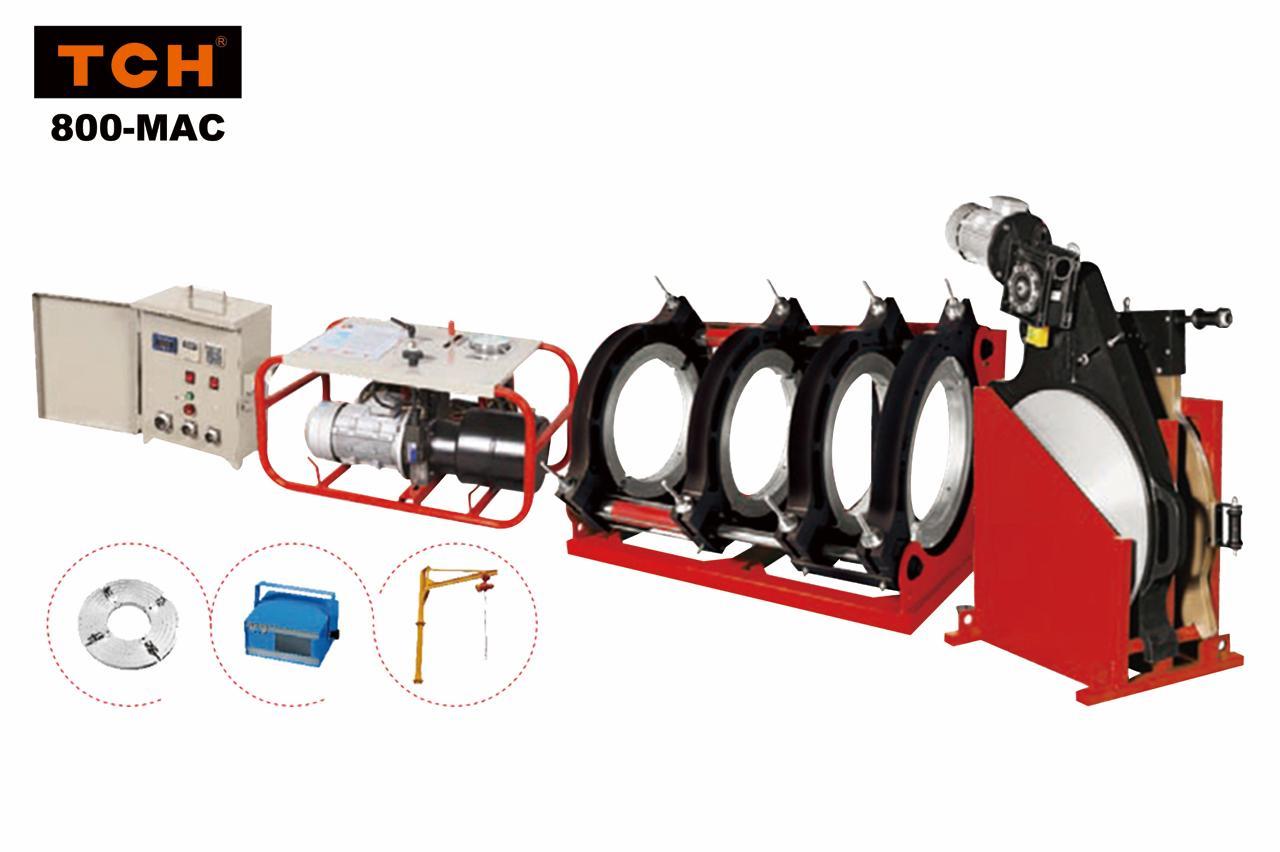

hydraulic

In hydraulic equipment, the compression of products is carried out by a hydraulic drive. Such devices are designed for butt welding and there are 3 types:

- Manual. All operations are carried out manually. Are applied to welding of pipelines with an average and low pressure.

- Semi-automatic. Manual work involves only laying pipes. The connection takes place automatically.

- Automatic. The movements of all units of the unit from the beginning to the end of the process are controlled by a computer, the operator only enters the necessary parameters.

Modern machines work with high accuracy. They can read the necessary information from the bar code printed on the HDPE or on the electric couplings, at the end of the process they issue a reporting protocol, indicate errors.

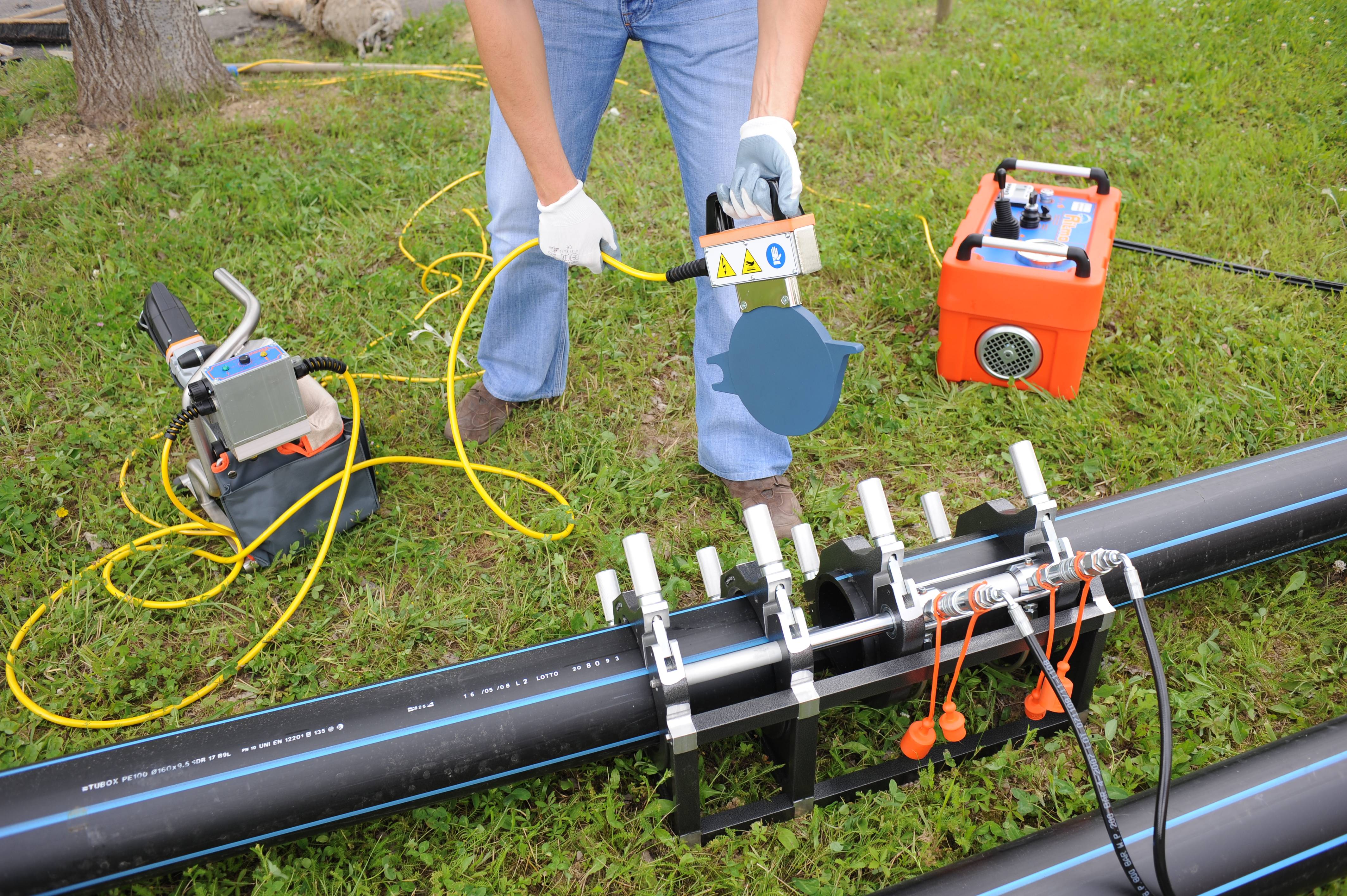

Electrofusion equipment

The technology of electrofusion welding is as follows.At the production stage, a heating element is laid into each coupling from the inner surface with two leads to its outer surface.

The technology of electrofusion welding is as follows.At the production stage, a heating element is laid into each coupling from the inner surface with two leads to its outer surface.

The pipes to be connected are inserted into the coupling. With a special cable, the outputs of the coupling and the welding machine are connected. After that, the element inside the coupling is heated.

Due to this, the section of the polypropylene pipe and the coupling melts in the area of the heating element. When the device is turned off, the reverse polymerization of the connected parts of the product occurs. The result is a monolithic connection.

can work with products of almost any diameter. They can weld polypropylene pipes, as well as low-pressure polyethylene (HDPE) products.

The main element is a microprocessor unit with regulated power supply. It saves the welding protocol for monitoring operation and generates the necessary current to obtain the required heating temperature.

At a given time, depending on the diameter of the product and other conditions, it turns off the device. The device can operate outdoors in the temperature range -20…+60 °C.

For example, the Rothenberger ROWELD ROFUSE PRINT apparatus, with its low weight and dimensions (a small box weighing about 20 kg), allows you to connect HDPE and polypropylene pipes with a diameter of up to 1200 mm.

Data on them can be entered manually or read from a barcode installed on the pipe by the manufacturer. The device is easy to use and comes with detailed instructions.

How to choose the right device?

Apparatus for welding plastic work like a soldering iron and are conventionally divided into 2 types - manual and mechanical.

Manual apparatus

Represents a heating plate with tips for the ends of pipes and the handle.According to the principle of operation, it is similar to an iron and an electric soldering iron.

Requires human effort to compress the products to be joined. Suitable for PE pipes with a diameter of no more than 12.5cm. Accordingly, it is not suitable for large volumes of work, and it is worth choosing it for home use.

Mechanical

The mechanical soldering apparatus is a support frame with disks for fixing pipes and an instrument block. The heating element with heating elements inside heats the ends of the connected pipes, and the mechanics provides a strong compression of these places.

It is applied to welding of the products which are exposed to high operational loading. The diameter of the products is unlimited.

Professionals should choose this option.

Helpful tips for making the right choice:

Pay attention to the package

The device with a key for nozzles is suitable for working with one, maximum two diameters. If the scope of work is larger, choose equipment with nozzles of various diameters;

Unit power

The professionals have one secret. The minimum power of the equipment is calculated by a simple formula - the largest pipe diameter that you have to work with is multiplied by 10.

For example, if you are going to cook pipes with a diameter of 50 mm at home, then the minimum power of the unit = 50 × 10 = 500W;

Which manufacturer to choose?

The highest rating is for the products of Czech companies (for example, TM "Daitron"). But the price of products - bites. Therefore - as an alternative - Turkish manufacturers. There are good models of domestic production.

Conclusions and useful video on the topic

Comparison and useful tips for choosing welding machines:

This video demonstrates the step-by-step process of assembling a welder for pp pipes with your own hands:

Choosing a suitable welding machine for polyethylene pipes is not so difficult. It is better to give preference to products of well-known manufacturers in an acceptable price category. With strict adherence to welding technology, a reliable connection can be obtained.

Tell us about how you chose a welding machine for assembling a polymer pipeline at home or in the country. Share the reasons behind your choice. Please leave in the block below, post a photo on the topic of the article, ask questions.