- Welding machines: types and characteristics

- Among the advantages that welding rectifiers have, we can distinguish:

- Inverter Selection Criteria

- Conclusion

- The principle of operation and the device of the welding inverter

- welding transformer

- Popular Models

- Principle of operation and distinctive features

- We choose a welding machine for home and garden - which one is better

- Related publications

- The best inverters for TIG welding

- AuroraPRO Inter TIG 202 - works in any weather

- Svarog Real TIG 200 – an inexpensive TIG/MMA inverter

- Resanta SAI-250AD AC/DC - double inverter model

- Wert MMA 200 - the lightest inverter

- And other "small" groups

- Spot welding devices

- Apparatus for gas cutting and welding

- Plasma welding devices

- Kinds

- Transformer

- Welding rectifiers

- inverters

- Choice

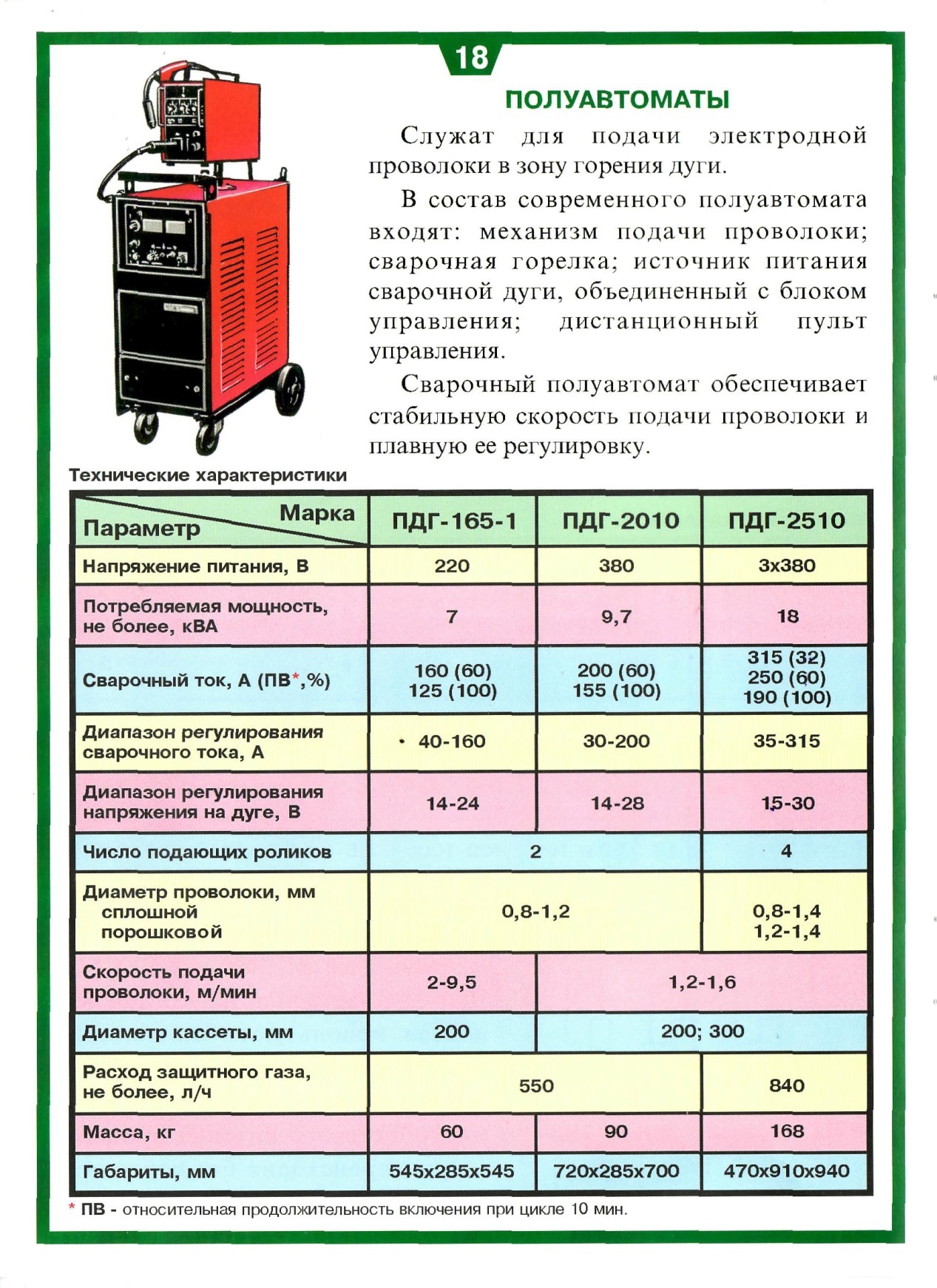

- Automatic and semi-automatic

- Generators

- TIG

- MIG/MAG

- For aluminum

- Argon arc welding machine - for whom the equipment is intended and the principle of its operation

- Welding inverters

Welding machines: types and characteristics

To date, the industry produces three main types of equipment designed for joining metals - transformers, inverters and rectifiers.Among them, the most widespread are welding transformers, which have such advantages as an affordable price, simple design and high reliability in operation. They do not have electronic components, so any owner can repair them on their own.

But for all their advantages, transformers also have a number of disadvantages, which, unfortunately, outweigh their advantages. They show themselves most clearly when using transformers at the cottage or in a private house.

- They are large and heavy.

- The demonstrated efficiency is not high enough and most often does not exceed 80%.

- A serious problem for owners when using such units is the impossibility of connecting them to the household electrical network, since they require a lot of energy to work.

Experts identify another important drawback of welding transformers. If a master who does not have sufficient experience works with such a device, he will not be able to use it effectively. It is unlikely that a novice welder will be able to make a high-quality seam, since it will be quite difficult to hold the welding arc without having the necessary skills.

This is mainly due to the fact that this unit operates on alternating current. To change the current strength in such units, the secondary winding on the core is intended, which is moved mechanically. But an amateur is unlikely to be able to set the required value of the operating current if he has not previously had to work with such devices.

Much easier to operate are welding rectifiers, which during operation provide a more stable arc that works without interruptions and jumps.In general, they function on the same principle as welding transformers. True, unlike the latter, they allow you to supply direct current to the welding rod. They got this opportunity by adding selenium or silicon blocks to the design of rectifiers.

Among the advantages that welding rectifiers have, we can distinguish:

- Ability to work with welding equipment even without special skills.

- The ability to perform a high-quality weld when working with products made of non-ferrous metals, as well as those with increased heat resistance of metal alloys and cast iron.

- Ensuring a reliable welded connection.

- The formation of a small amount of metal spatter that occurs when using an additive.

In addition to the above, welding rectifiers differ from transformers in weight. In general, it is rectifiers that are more preferable for use in the country than welding transformers. However, they also have a number of shortcomings that do not allow them to be used effectively for the home. The main ones among them are:

- Low efficiency (about 80%).

- Problems with connecting to the household electrical network. High-quality and stable operation of the unit is possible only when connected to a network that supports a voltage of 380 V.

- High price.

There is another issue that needs to be mentioned. Welding rectifiers have a rather complex design. In addition to standard operating units, they also contain additional elements in the form of measuring and protecting units, thermostats, various chokes, ballasts, which greatly complicates the repair of these devices at home.

This is interesting: Sewer cleaning cable - types, device + instructions for use

Inverter Selection Criteria

To know how to choose an inverter welding machine, you need to understand its main characteristics:

- Operating current;

- Voltage on the electrodes;

- type of welding;

- Duration of inclusion;

- Mains voltage;

- temperature regime;

- Additional features.

The thickness of the welded metal directly depends on what current the welding inverter produces. The open circuit voltage on the electrodes is different from the welding voltage. In the first case, the voltage can be equal to 60-80 V, and the welding arc is stable at a voltage of 25-35 V. In domestic conditions, only manual arc welding (RDS) or MMA.

On-duty (TO) is sometimes referred to as useful time or load duration (LO). This parameter is indicated together with the current, for example, (150A - 80%). This means that at the specified current, 20% of the time the welding machine must cool down.

The household network is not suitable for connecting professional welding machines with high current, therefore, to power powerful welding inverters, an additional tap must be installed on the power input.

Electronic welding machines are quite critical to the temperature values of the environment. Most of them are not designed to operate at temperatures below -10°C, so when choosing a device, you need to carefully read its technical characteristics.

Which welding inverter is better can be determined by the presence of additional useful options:

- Active start;

- Afterburner of the welding arc;

- Anti-stick.

It often happens that during welding, the electrode firmly sticks to the metal, and a short circuit occurs.The "anti-stick" function at the moment of a short circuit turns off the electronic circuit that supplies voltage to the electrode. This avoids the failure of the semiconductor devices of the welding inverter.

Conclusion

To determine which inverter welding machine is best for home or summer cottage, you should know in advance what it will be used for. Usually, in the conditions of a country house or a personal plot, there is a need for welding in the manufacture of small metal structures.

It can be a frame for a greenhouse, a fence made of metal structures or a garage box. For these purposes, a corner, pipes or sheet metal with a thickness of not more than 5 mm is used. The diameter of the electrode used depends on the current strength.

With a metal thickness of up to 2 mm, electrodes with a diameter of 2.0-2.5 mm can be used. In this case, a welding current of 60-80 amperes is sufficient. For metal 2-5 mm, electrodes with a diameter of 3-4 mm will be required at a current strength of 80-120 amperes. For welding metal 5-10 mm, electrodes 4-6 mm are used, and the value of the welding current can be in the range of 130-230 amperes.

From the above data, we can conclude that for individual use in a summer cottage, an inverter-type welding machine is suitable, powered by a single-phase 220 volt network, taking into account mains voltage fluctuations of 10-15%. The device must provide welding current up to 160 amperes and have additional options.

In addition, the question of which inverter welding machine is better can be answered unambiguously - of course, domestic production.European models are expensive, buying Chinese goods you can get completely different parameters than those written in the passport, but there will be no problems with Russian inverters, since they are perfectly adapted to our electrical networks.

The principle of operation and the device of the welding inverter

The inverter differs significantly from a conventional welding machine by the difference in current frequency. Both devices receive alternating voltage, but at the transformer it remains the same as in the network (50 Hz), while at the inverter it rises to 50000-80000 Hz and is converted to DC. This has a great effect on the penetration of the filler metal deep into the base metal and forms a smooth fine-flake seam.

Such a scheme minimizes the formation of pores during the release of carbon and increases the resistance of the created connection to fracture and rupture.

The use of inverters is quite wide, because with its help you can make:

- gate or gate in a private house;

- tank for water supply and tank for fuel of a truck;

- entrance metal doors;

- fence or fence;

- a large greenhouse and a small greenhouse;

- plumbing and heating;

- heated towel rail;

- patch the bottom of the car;

- weld a crack in the engine block.

Welding inverters are used in private workshops, large enterprises and just in the country for various small jobs. It is indispensable at a construction site, especially in modern technology of monolithic-frame houses, where welding of reinforcement is required inside the filler columns. Such a unit can weld cast iron, low alloy steel, stainless steel, aluminum and copper. You can't do this with a transformer.

The inverter device includes the following elements:

- frame;

- diode bridge;

- transistors with heatsinks;

- transformer;

- rectifier;

- interference filters;

- current sensors;

- integral stabilizer;

- cooler;

- relay;

- contactors and control board.

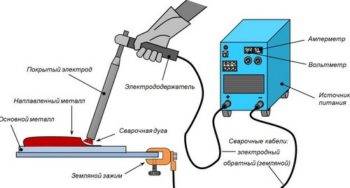

For operation, the device is connected to a voltage network corresponding to its characteristics. The mass cable (-) is attached to the product or the metal table on which it is located. The holder (+) is taken in hand by the welder. An electrode is inserted into it, which is both a filler material and protects the molten metal from exposure to ambient air.

Touching the electrode to the product produces a short circuit of the poles of the welding machine and an electric arc occurs. To perform manipulations to create a seam, it is necessary to hold the end of the electrode at a distance of 3-5 mm from the surface. This will allow the arc to burn freely, melt the base and filler metal and not stick to the product.

To obtain a constant voltage, the current in the device passes through several nodes. From the network, it enters a rectifier, consisting of diodes and a bridge. After that, a constant voltage is applied to the switches containing transistors and radiators, where its frequency is significantly increased. The step-down transformer then reduces the voltage to safe values while simultaneously increasing the current to a value capable of melting steel.

welding transformer

Its task is to lower the voltage from the electrical network to the required level (below 141 V) and adjust the welding current to the desired values.

The design of any transformer must comply with GOST 95-77, it includes a steel magnetic circuit (core) and two insulated windings - primary (connected to the network) and secondary (connected to the electrode holder and the welding object). In transformers of the popular TDM series, the primary winding is rigidly connected to the core, the secondary winding coils are removed from the primary coils (there are two of them for each winding) at a certain distance. Starting the arc requires a voltage on the secondary winding in the range of 55-60 V, for most electrodes used in manual welding, 50 V is sufficient.

By turning the screw with the handle, the coils of the secondary winding connected to the core move vertically - the welding current is adjusted to the required parameters. When the windings approach each other (the handle is rotated clockwise), the inductive resistance and the magnetic leakage flux decrease, the welding current increases, and its decrease is achieved by reverse rotation. Welding current adjustment range: with parallel connection of coils in both windings - 65-460 A, with series connection - 40-180 A. The handle on the transformer cover is designed to switch current ranges.

What happens in a welding transformer when it is connected to an AC mains? The flow of alternating current into the primary winding causes the core to be magnetized. Having passed through the secondary winding, the magnetic flux of the core induces in it an alternating current of a lower voltage than the incoming to the primary winding. With more number of turns per secondary winding, the voltage will be higher, with a smaller one, the voltage will be lower.

The value of the welding current is controlled by means of a controlled inductive resistance that changes the flux of magnetic leakage. There are two ways to change the welding current: movable coils (as in TDM transformers), magnetic shunts or turn (step) regulation; supplementing the design of transformers with a reactive coil. The choice of regulation method depends on the magnetic dissipation in a given transformer: with increased dissipation, the first regulation method is used; under normal - the second.

The efficiency of welding transformers is low - rarely exceeds the 80% barrier, their weight is impressive. When carrying out welding work with this equipment, it is difficult to achieve a high quality of the seam, except to use special stabilizing electrodes that can improve the weld. However, the disadvantages of welding transformers are offset by a low price (from 6,000 rubles) and their unpretentiousness.

Popular Models

The model ranges of welding machines are constantly replenished with new units - the developers come up with new tricks that make the design a little more convenient and practical. A responsible consumer in the case of welding machines cannot be guided by public opinion - you choose what is useful to you, and not at all what everyone likes.

Already from its lineup, you should choose a specific model, focusing on the parameters you need.

Most of the well-known brands of welding units today are foreign. These include Dytron, CAC, EWM, Jasic, FoxWeld, Kruger, P.I.T., Eurolux, Telwin, BlueWeld, Tesla, Sturm, Patriot.

Principle of operation and distinctive features

First, a few words about modes of operation. Semiautomatic devices confidently support the following modes:

- MIG - welding in carbon dioxide;

- MAG - an argon cloud is created above the weld pool;

- some have MMA (manual covered electrode arc welding) mode.

Semi-automatic welders are purchased for TIG - argon arc welding using a non-consumable electrode. Leading manufacturers produce combined professional devices that support all modes. But now we are talking about household appliances.

The main difference between welding inverters and semiautomatic devices is the type of additive used. The latter feed the welding wire into the working area at a certain speed. When working with an inverter, electrodes with various types of coating are more often used, which create a protective layer of slag on the melt bath. It is more difficult to make an even seam bead with an electrode. Semi-automatic welding is beyond the power of beginners, experience is required.

An ordinary welding inverter is a universal power source with a compact transformer, semiconductor converters. Equipped with additional features:

- by limiting the open circuit voltage, maintains a stable arc in conditions of high humidity;

- hot start (Hotstart), providing easy ignition of the arc;

- protection against sticking of the electrode (Antistick), in case of a short circuit drop by drop, the electrode is re-ignited;

- arc force (ArcForce), stable welding is ensured.

It is convenient for beginners to work with the inverter, the equipment has simple settings, convenient knobs for adjusting the welding current.

A semiautomatic device is a complex device consisting of three main parts:

- current converter;

- the mechanism that feeds the filler wire, a special cassette with guide rollers is mounted;

- systems for supplying gas to the working area to protect the melt from oxidation.

A holder with a non-fusible electrode creates an arc that melts the workpiece and wire. If the powder welding consumable contains a flux, shielding gas can be omitted. The equipment works like a conventional electric arc manual welding, only you do not need to change the electrodes as they burn out, the wire makes the welding process continuous.

We choose a welding machine for home and garden - which one is better

From the above analysis, each master can draw the appropriate conclusions about the need to purchase certain types of welding equipment. I want the welding equipment to meet the following needs:

- Has a compact size and light weight

- Was easy to use

- Contributed to the welding of various types of materials

- It had a low cost, and was maintainable

One of the most suitable devices for the above criteria are inverter models. However, before purchasing them, it is recommended to take into account some technical parameters when choosing

How to choose a welding machine for home and garden, consider against the background of important technical parameters that you should pay attention to

The value of the operating input voltage. Devices, depending on their type and power, are available for connection to single- or three-phase networks. Household voltage is 220V, and industrial voltage is 380V. If there is no 380V voltage in the house, then feel free to choose among 220V models. Although they are inferior in power, they provide quite high performance.

Power - there are no difficulties with the choice of power equipment operating from a three-phase network

If you buy a device for a household network, then it is important to take into account the maximum power value. If you choose a model with a maximum permissible power value, then strong voltage drops and tripping of circuit breakers will occur in the home network

However, there are no such problems with inverter models.

The magnitude of the current and the welding mode - according to these criteria, it is important to choose equipment depending on how thick the metal is planned to be welded. For home use, there are quite enough devices that are designed for a maximum current of 160A. Smooth adjustment of the current value improves the quality of the weld

Duration of work or load - this value is also indicated in the technical specifications of the equipment, and it plays an important role. This value indicates the maximum operating time of the machine under maximum load. This maximum load is important to take into account, since the smaller its value, the more often you will have to take breaks in work.

The supply voltage range is the variation in the input voltage. The optimal value is a deviation of 20-30%. If the device is not designed to work with a decrease or increase in voltage, then it will not be able to provide a high quality weld, and will also lead to its rapid failure.

The presence of additional useful options, which is especially important for beginner welders. These are such different options as hot start, anti-stick electrode, arc force, etc.

It is important to pay attention to the equipment manufacturer, since the purchase of devices from unknown companies is not justified in most cases. It is recommended to choose models from well-known manufacturers (Fubag, Resanta, Wester, Svarog and others), which have mostly positive reviews and recommendations from experts

Related publications

Tape screwdriver bit for quick installation of drywall

Electric hacksaw purpose and use of the tool

How to choose a good wall chaser

Learning how to use a glue gun with rods

The best inverters for TIG welding

Inverter devices for argon welding are used for welding thin, alloyed, stainless and non-ferrous metals in an inert argon environment.

AuroraPRO Inter TIG 202 - works in any weather

4.9

★★★★★

editorial score

89%

buyers recommend this product

This low cost inverter features high reliability and stable performance due to the use of MOSFET technology. And he also received a non-contact arc ignition system and is able to work in difficult conditions at a temperature of -20 .. +50 ° С.

The characteristics of the device do not stand out from the general range: the welding current is regulated within 10-200 A, the PV coefficient shows quite decent 60%.

Additional functionality also allows the inverter to be used in MMA mode, providing easy ignition and a stable arc.

Advantages:

- Dual mode TIG/MMA operation;

- Inexpensive MOSFET transistors;

- Contactless ignition;

- Dust-waterproof case;

- Good basic equipment.

Flaws:

Lack of additional features.

Inter TIG is an entry level model for beginners in TIG welding.Simple to disgrace, but reliable and convenient in operation.

Svarog Real TIG 200 – an inexpensive TIG/MMA inverter

4.8

★★★★★

editorial score

88%

buyers recommend this product

See review

The Svarog device, similar in its functionality, also supports two welding technologies: manual and TIG.

In the first case, the current strength can be changed within 10-200 A, in the second case, the “ceiling” is already lower and is only 160 A.

But the model works stably at an input voltage of 160 V, and does not require long breaks even at maximum currents, if the ambient temperature is +18..+25°С.

Advantages:

- Ease of use;

- The purge time is adjustable within 1-10 seconds;

- High-frequency arc ignition;

- Efficiency index at the level of 85%;

- Relatively light weight.

Flaws:

Few settings, and almost no additional functions.

Svarog Real is the best model for those who are looking for a budget inverter for argon arc welding without unnecessary bells and whistles.

Resanta SAI-250AD AC/DC - double inverter model

4.7

★★★★★

editorial score

87%

buyers recommend this product

Indestructible TIG installation with dual inverter allows you to work on direct and alternating current, which greatly expands the possibilities of welding various metals and their alloys. The device provides a stable arc in the range currents from 15 to 250 A.

The welder can work in MMA mode, and also has many useful functions: Hot Start, Pre Flow and Post Gas purge. There is also a Down Slope option with a smooth arc decay for welding the final crater.

Advantages:

- Two- and four-stroke modes;

- Ability to work with direct and alternating current;

- Automatic lowering of amperes;

- Rich equipment;

- Good set of features.

Flaws:

- Short cables;

- There is no carrying handle.

Resanta 250AD is worthy of the attention of professional welders who understand all the intricacies of setting. This inverter will help you get a flawless seam on any metal.

Wert MMA 200 - the lightest inverter

4.6

★★★★★

editorial score

86%

buyers recommend this product

A professional welder in both manual and TIG mode can work with maximum current up to 200 A.

It does not differ in particular voracity, consuming no more than 4.2 kW. Drawdowns and power surges are not terrible for him either: the device does not respond to drops in the range of 136-264 V.

The case of the inverter is compact, and the device itself is very light - a little more than 2.5 kg. It is comfortable to wear on the shoulder or even put on around the neck thanks to the long woven belt.

Advantages:

- Indication and protection against overheating;

- Protection against dust and splashes (ip 21);

- Hot start function;

- Minimum weight;

- The price is within 4-5 thousand rubles.

Flaws:

- Complete cables are short;

- Possible sticking at low currents.

Wert is a lightweight and convenient "home" inverter, which is convenient to work with at a height where the device has to be hung around the neck.

And other "small" groups

Spot welding devices

Spot welding

What is the point? In an instant, we will answer. Heating occurs with an instantaneous current pulse, which heats the metal to the melting point. Thus, a liquid zone of the metal is formed - common for both blanks. The current supply is stopped, and this zone begins to cool and solidify with continued pressure. This pressure lasts until the complete crystallization of the metal blanks.

Electrode welding.

The advantages of spot welding are the strength of the seam, economy and ease of execution.There is only one distinguishing property of a spot seam: it does not have tightness in any way. Therefore, the use of point technology is limited.

Apparatus for gas cutting and welding

Acetylene, hydrogen, natural gas are the main combustible heroes of this method. They burn great in the air. With their help, metal blanks are heated to the melting point. If you smell carbide near the welder, then this is a method for working with acetylene: it is obtained from calcium carbide and water. This gas is the most popular in use.

This method

Plasma welding devices

It's more cutting

The temperature eventually reaches crazy values - these are tens of thousands of degrees. Metal cutting occurs both due to metal melting and due to metal washing out of the working area by an ionized stream of the highest speed.

Kinds

Transformer

An electric welding transformer is a power equipment operating at a frequency of 50 Hz. Mains current is supplied to the primary winding, and already removed from the secondary suitable for welding. The current is regulated by the movement of the secondary winding in relation to the statically fixed primary.

An electric welding transformer is a power equipment operating at a frequency of 50 Hz. Mains current is supplied to the primary winding, and already removed from the secondary suitable for welding. The current is regulated by the movement of the secondary winding in relation to the statically fixed primary.

The transformer is used only for manual welding with meltable electrodes, since at the output it is capable of delivering only alternating current. Its arc is unstable, the quality of the seam depends on the experience and skill of the welder.

Welding rectifiers

In devices of this type, in addition to the transformer, there is also a rectifier that generates direct current with stable characteristics.

Rectifier welding machines for the home are used to connect elements made of ferrous and most non-ferrous metals. The quality of the resulting seam is better than that of transformers.

inverters

In modern models of welders, an inverter current source is installed in combination with a rectifier and a high-frequency transformer. The electronic unit simplifies tuning and ensures that the output current is obtained with optimal parameters.

A welding inverter for home and summer cottages allows you to weld ferrous and non-ferrous metals and alloys with alternating current, even those that are difficult to weld. Most household models are used for argon arc welding, provided that additional accessories are connected.

Choice

Experienced welders have no doubts about which of the devices is better. Of course, it is better to choose an inverter than a transformer. The advantages of such home appliances are as follows:

- seam quality;

- many times smaller weight and dimensions;

- fine tuning and adjustment;

- economy.

The only disadvantage of inverters is the high cost. In the rating of models, you can choose a device that is not suitable for professional use, but quite suitable for home or country work.

Automatic and semi-automatic

Sophisticated devices, the performance of which is an order of magnitude higher. In addition to the standard equipment, the machines have a wire feeder, a torch and a control unit.

The welding process takes place in a shielding gas environment, the connection is carried out using a filler wire, which makes it possible to weld thin-walled products and parts made of non-ferrous metals.

Important! Due to insufficient performance, such devices are not suitable for welding elements of considerable thickness. In this case, it is better to choose devices for electric arc manual welding.

Generators

Complex devices that combine a current source and a liquid-fuel generator. Welding is performed both from alternating and direct current.

Generators can be called the optimal solution for non-electrified construction sites or with frequent power outages.

TIG

When working with stick electrodes, scale is formed on the surface of the seam

Their design is similar to inverter units, but the functionality is higher. A burner is connected to some models.

MIG/MAG

Semi-automatic devices of this type are equipped with a wire insertion mechanism that acts simultaneously as an electrode and filler material. The burner is moved by the operator along the line of the formed seam.

Devices can operate in two modes:

- MIG. Welding is carried out in a gas environment, while alloying additives are retained in stainless steels.

- MAG. Active gases are added to the melting area, protecting the metal from contact with oxygen contained in the air.

For aluminum

Aluminum has a low melting point, and products made from it have a small thickness. Therefore, for the connection of aluminum parts, manual welding is in most cases unacceptable - a lot of experience is required to form a high-quality seam.

For such work, welding in a protective gaseous environment (MIG semiautomatic devices) or an argon-arc apparatus (TIG welding) is used.

Argon arc welding machine - for whom the equipment is intended and the principle of its operation

A specialized type of welding equipment that is designed exclusively for working with non-ferrous metals is argon arc welding. Tungsten tips are used as electrodes, and an inert gas (argon or helium) is used to protect the weld during operation.

Initially, consider the constituent elements of argon arc welding, as well as the principle of its operation. The equipment consists of a welding machine with an open circuit voltage of 60-70V, a contactor for transferring voltage to the burner, an oscillator for converting the input voltage to 2000-6000V and increasing the current frequency to 150-500Hz, a cooling device, non-consumable electrodes, cylinder with argon, as well as a ceramic burner.

Now about how such equipment works, and how it differs from other devices. It is necessary to take a burner with a non-consumable electrode in one hand, and a wire is taken in the second. There is a special button on the burner, when pressed, gas is supplied to the welding area. Moreover, the gas supply must be carried out 10-20 seconds before the arc appears. A tungsten electrode is installed in the burner, which should not protrude more than 5 mm. Lean the electrode against the surface to be welded by 2 mm, and turn on the machine. As a result, the arc will ignite. To get a weld, the welder needs to feed a wire into the arcing zone.

It is interesting! The ignition of the arc is carried out by placing the electrode from the surface to be welded at a distance of 2 mm, but not less. Contact of the electrode with the surface is contraindicated. During welding, gas will come out of the burner.

The advantages of the considered devices include:

- Low heating temperature, which does not contribute to the deformation of the shapes of non-ferrous metal parts to be welded

- Protection of the welding zone by means of an inert gas, which has a positive effect on the absence of the development of oxidative processes

- High speed of metal welding

- Ease of use of devices

- The possibility of connecting not only two homogeneous types of non-ferrous metals, but also dissimilar

Among the shortcomings of the devices under consideration, experts distinguish:

- Decrease in the quality of the weld, if the work is carried out in a draft or in the wind

- The complex design of welding equipment, which complicates the features of setting modes

- The need to use additional devices for cooling the arc when operating with a large current

Argon arc welding can take place in four modes. The most common is manual mode, when the welder holds the torch in one hand and the wire in the other. There is also a mechanized type, which differs from the manual one in that the wire is fed into the welding zone automatically, similar to semi-automatic devices. More advanced types of argon-arc devices are automatic and robotic.

It is interesting! Argon-arc welding is used when it is necessary to work with non-ferrous metals, and especially when it is necessary to join two dissimilar materials. In this case, the use of only argon-arc devices will be effective.

Welding inverters

Inverter-type units are a relatively recent invention. The welding inverter (SI) is today the leader in the field of amateur use.

It contributes to:

- ease of use - many settings are provided, including current strength;

- high functionality - the unit allows you to weld ferrous and non-ferrous metals and alloys with different characteristics, work with parts regardless of their spatial position;

- increased efficiency, reaching 95%, combined with efficiency due to low energy losses;

- increased degree of electrical safety;

- long continuous operating time;

- splashing of liquid metal is minimal;

- the unit is protected from power surges;

- it is possible to work with different electrodes;

- high quality of welded seams is provided;

- The device has a compact body and low weight.

Due to the fact that the arc is ignited easily and automatically stabilizes, any home master without welding experience can use the inverter.

The disadvantages include:

- cooling coolers draw dust into the case, and the unit should be periodically cleaned with a vacuum cleaner or a soft brush to avoid contact closure;

- the equipment is not designed for operation and storage at low temperatures and high humidity;

- due to the complexity of the design, the unit is noticeably more expensive than other types of welders;

- high repair cost.

Conclusion

So, we have analyzed the main types of welding machines and from the foregoing we can conclude that if you do not have experience with a welder, then it is best for you to pay attention to inverter units

Video on the topic "how to choose a welding machine for domestic use":