- Advantages and disadvantages

- Welding technology

- Horizontal hardfacing

- Welding technology

- Mistakes in pipe welding

- Technology of work with fixed joints

- Vertical pipe arrangement

- Welding horizontal pipes

- Pipes at an angle of 45 degrees

- Preparation for work

- Types of pipelines and welding

- Method of working with a horizontal joint

- Safety

- Various arc welding techniques

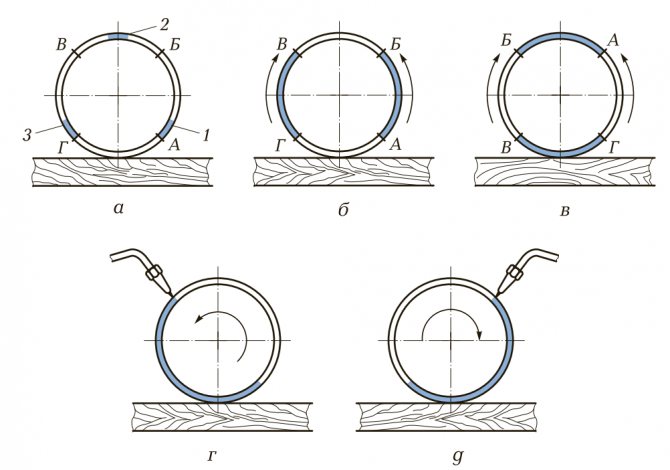

- Welding with a turn of the joint

- Welding without joint rotation

- Pipe welding in winter conditions

- Vertical welding of fixed joints

- Types of pipelines and welding

- Horizontal arrangement

Advantages and disadvantages

The tee joint is the most common, one of the strongest. This connection makes it possible to obtain products and structures of complex shape. The arrangement of parts with the letter "T" provides additional rigidity of the structure. Qualitatively performed work guarantees practicality and reliability.

The disadvantage of such a connection may be defects:

-

craters are a recess in the weld that occurs when the arc breaks;

- pores are a consequence of the accumulation of gases in the seam, the reason for such a defect lies in poor-quality metal preparation;

- lack of penetration is a local non-fusion of the base metal with the electrode, the reason: high welding speed, as well as burns, cracks, and so on.

Such defects depend on the quality of work performed.

The low qualification of the worker will directly cause defects, but the equipment and consumables (welding machines, wire, electrodes, shielding gas) are also important. The process itself is dangerous, you must follow all safety rules without exception

Welding technology

After ignition of the arc, the process of melting metals immediately begins - electrode and main

Depending on the length of the arc, the productivity and quality of the seam is determined, so it is very important to choose the correct length of the arc. It is necessary to feed the electrodes into the arc at the rate of melting of the electrode

The more experience a specialist has, the better he copes with holding the length of the arc.

An arc between 0.5 and 1.1 electrode diameters is normal. In order to more accurately calculate the exact length of the arc, you need to find out what brand and type of electrodes are used. Also of considerable importance is the position and importance of the place of welding. If the arc is longer than the normal size, then the combustion stability decreases, the losses due to waste increase, the penetration depth becomes uneven, and the seam is uneven.

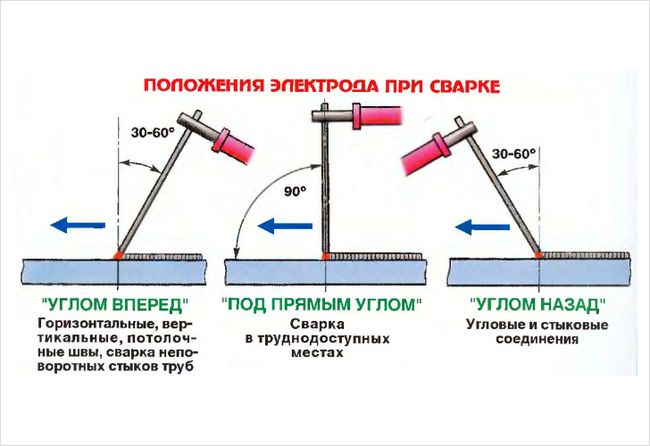

In order to make a high-quality seam, you should pay attention to the angle of inclination of the electrode. For bottom position, the electrode angle is typically 10 to 30 degrees back

Often the arc is directed in the direction where the electrodes are directed. The correct slope, in addition to a reliable seam, also gives a lower cooling rate of the substance.

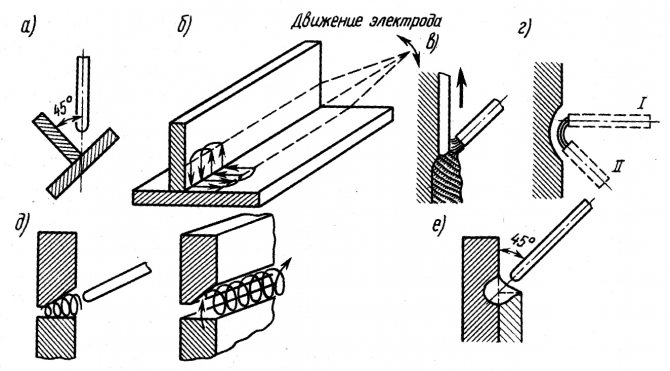

To obtain a metal roller of the required size, it is necessary to perform oscillatory actions of the electrode in a perpendicular direction. Using oscillatory movements, the seams with a bead size from 1.5 to 4 electrode diameters.These stitches are the most commonly used.

Obtaining a reliably boiled root is achieved by moving triangles. This movement is performed with fillet welds with weld legs over 6 millimeters and butt edges with a bevel.

Seams can be divided according to the way they are filled into multi-layer, single-layer, multi-pass, single-pass.

A multi-layered seam is such if the number of layers corresponds to the number of arc passes. Such seams are often used in problem areas and joints.

Multi-run welds are used in tee joints and in corners.

To increase the strength index, the seam is used in sections, cascades or blocks. All these seams are made using the reverse step welding technology.

Horizontal hardfacing

Welding of fixed horizontal butt pipes is considered a rather complex technology. Only a professional welder with certain skills and experience can perform such work. The most difficult is the constant adjustment of the electrode to change the angle of inclination.

Welding is performed in three consecutive positions:

- Ceiling.

- Vertical.

- Lower.

Each seam is made with an individual current value. Ceiling position provides for welding on high power level. All stages involve continuous welding, at the beginning it is best to use the “backward angle” method, and to complete the work - “forward angle”.

Welding technology

Welding of rotary joints of pipes can be carried out in the left or right way.

Pipe welding in a fixed position has a more complex technology. This largely depends on how the welded pipes are located in space and their diameter.

Existing joint locations:

- in the vertical plane. The axis of the pipe is horizontal.

- in the horizontal plane. The axis of the pipe is vertical.

- Located at an angle.

If the pipes have a wall size of more than three millimeters, then they are welded by applying layers. The height of each of them should not be more than four millimeters. If fixed pipes are welded by arc welding, then the width of the bead is made equal to the sum of 2-3 diameters of the electrode used.

The most rational is the use of welding by the reverse-step method. In this case, the length of the section should be in the range of 150-300 millimeters. Welding is carried out using a short arc, the value of which is equal to half the diameter of the electrode used.

The overlap of the seams, called the lock, depends on the size of the cross-section of the pipes, and is usually 20-40 millimeters. The position of the electrode plays a role in pipe welding. The “back angle” method is used at the beginning of welding, and the “forward angle” method ends it.

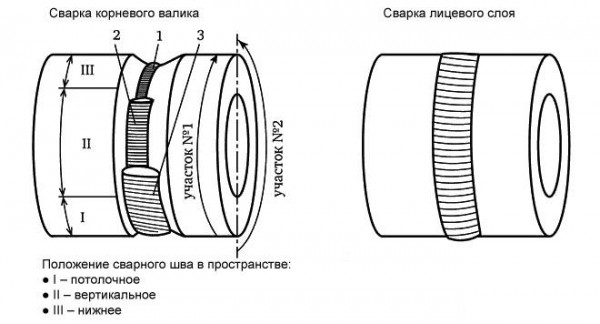

The most commonly used welding in three layers. First, the radical seam is made, then the edges are filled, and then the front seam is performed.

Welding starts from the ceiling position, located at the bottom of the pipes, and then moves to the vertical and lower.

The first layer is performed by making reciprocating movements with the electrode, while holding the arc over the bath, where the molten metal will flow. The current strength is chosen on the order of 140-170 amperes. It is necessary to ensure that large splashes do not fall on the metal to be welded.

In order to avoid burns in the metal, welding must be carried out with a short arc, without removing it from the bath by more than a couple of millimeters.The next layer should be applied in such a way that it overlaps the previous one. The electrode must move from one edge to the other, making transverse oscillations according to the “crescent” principle.

Mistakes in pipe welding

Since in practice, through-hole welding of pipes is a difficult job, novice welders often reject parts. It is impossible to get rid of it without practice and personal experience.

Analysis of the theory of welding business and standards for welding through clearance can speed up learning.

The following will be presented errors in the translucent processing of pipes and ways to prevent them.

And it is the accumulation of experience that will prevent the occurrence of lack of penetration in the future.

Experience and intuition are important in translucent welding, however, studying the technical documentation for the task will greatly facilitate the work.

A couple more tips to avoid common mistakes:

- Despite the complexity, welding is carried out with a short length of the welded arc. Even if you want to make the task easier, you can not change the length of the arc. Welding already at an average value will degrade the quality of the connection.

- During the welding process, the bar does not come off. The separation of the filler rod is carried out only if it is necessary to renew it.

- From part to part, you need to follow the current settings.

- Do not ignore the preparatory stage. Proper trimming and bevelling makes the job easier.

- Work is carried out only with dry filler rods.

- It is not necessary to carry out the welding process in the light during bad weather.

- The quality of equipment and additional elements also has a weight in the reliability of the result.

Technology of work with fixed joints

Most often, a three-layer suture technology is used (radical, edge filling and front suture). In this case, all adjacent welds must overlap by at least 15-20 mm. For pipes with a diameter of 9 mm, the establishment of 3 layers (each 3 mm) is used, while it is necessary to select the operating mode with an arc of minimum length (up to 25 mm).

Welding of fixed joints of pipes can be performed using several technologies, the spatial position of the workpieces plays an important role.

Vertical pipe arrangement

Technological process:

- The root weld is welded in two passes, and when setting up the second bead, it is necessary to melt the first layer, this will guarantee the quality of the root weld. The mode of operation (the value of the welding current and the speed of work) is determined based on the thickness of the pipe wall and the size of the gap between the connected elements.

- Edge filling can be carried out at a sufficiently high speed, using the position of the electrode at an angled back or at right angles.

- Locks of adjacent layers should be carried out with a minimum offset of 5-10 mm.

- The front layer is welded with narrow beads; the plane of the resulting surface will largely depend on the welding speed.

Welding horizontal pipes

Such joints should be welded on their own only if there is already significant experience in performing other types of welding work, for example, welding of rotary pipe joints has already been carried out.

As already mentioned, the main difficulty lies in the need to perform welding in three positions - lower, vertical, ceiling.

This requires constant adjustment of the strength of the welding current, the angle of inclination of the electrode, and changes in the speed of work:

- At each stage, the process must be performed continuously.

- For each of them, it is necessary to choose a certain strength of the welding current. When performing a ceiling seam, it should be increased (by 10-20%).

Pipes at an angle of 45 degrees

In this case, the weld is located at a certain angle to the horizon. In this regard, the performer must have universal skills that allow welding in a horizontal and vertical position. The welding seam can only be formed by performing many manipulations with the electrode (changing the direction of welding, changing the angle of inclination).

It is worth dwelling on this technology in a few words, because welding of pipe joints must be mastered to perfection before performing work with fixed joints.

The choice of technology in this case depends only on the diameter of the pipes to be welded:

- When connecting gas pipes (up to 200 mm in diameter), welding is performed in several layers without stopping. To do this, the pipe is gradually rotated as the weld is filled. Welding of rotary joints of metal gas pipes has its own characteristics. So the 2nd and 3rd layers of the seam should be applied in the direction opposite to the first layer, the lock (overlapping of the previous layer) should not be less than 10-15 mm.

- When welding other pipes of small and medium diameter, their circumference is divided into four sectors and their phased welding is performed. After the metal is deposited on the first two sectors, the pipe is rotated half a turn, after which the work continues.

- When welding pipes of significant diameter (more than 50 cm), the circumference of the pipe is divided into a larger number of sectors (150-300 mm each).The filling of the seam is also carried out segment by segment, only the front (3rd layer) is welded solid.

Especially when it comes to pipelines with increased requirements for the tightness of welded joints.

Preparation for work

The technology of preparation for the start of welding work includes the following steps: initially it is necessary to prepare the metal, that is, to mark, assemble and cut pipes on it. To do this, it is necessary to install the parts of the pipes in their original position and clean each joint from rust, putty, dirt, a layer of paint and other layers. Then you need to markup using a square, tape measure and scriber to transfer the dimensions of the structure to the metal from the drawing. For this purpose, you can use a metal template. It is worth remembering that parts of the pipes are slightly shortened during welding, therefore, during work, you need to leave an allowance, based on an error of 1 millimeter per transverse joint, and 0.1-0.2 per 1 millimeter of the longitudinal seam.

Due to the fact that most pipes have a round cross section, thermal cutting is most often used in the preparation of pipe parts.

Approximately 30% of the total process time is the assembly of parts for welding. During assembly, it is necessary to take into account the product manufacturer, pipe diameter, product series and other factors. For assembly, welding tacks are used. They are light seams with a cross section of up to 1/3 of a full seam. The size of the tack depends on the pipe diameter and wall thickness and ranges from 20 to 120 millimeters. Welding tacks are used to reduce the likelihood of displacement of sections of the structure, which can cause cracks during cooling.When welding with electricity or gas pipes with a large diameter and thickness, or welding at an inconvenient location during assembly, mechanical equipment is used.

If you need to ignite the arc, then you need to make a short circuit of the pipe with the end of the electrode and tear off the electrode from the surface of the structure. The distance is approximately equal to the diameter of the coated electrode. This is necessary to heat the metal to a certain temperature in the cathode spot. When heated, primary electrons are released.

For ignition of the arc, sliding or back-to-back technology is used.

During back-to-back ignition, the metal heats up at the short circuit. When the arc is ignited using the sliding technology, the metal is heated in several places at once on the welding surface of the product. The first method is more often used, the second, as a rule, is used when welding small pipes with a difficult location.

Types of pipelines and welding

Welding of pipelines is carried out taking into account their type:

- trunk;

- water;

- technological and industrial;

- sewer;

- gas supply structures.

The following types of welding are distinguished:

- mechanical (due to friction);

- thermal (melting using plasma, gas or electro-beam method);

- thermomechanical (magnetically controlled arc obtained with the butt contact method).

The use of a certain type of connection also depends on the material of the pipes:

| Material | Weld type |

| Copper | Electric arc, gas or contact. More effective is the first connection method using a tungsten non-consumable electrode and filler wire.Argon or nitrogen recommended as shielding gas |

| Steel | Semiautomatic devices are used, as well as electric and gas welding |

| Galvanized pipes | You can use any type of connection, but a flux that protects the product from fading of the coating is considered an obligatory component. |

| Profile structures | Welding is performed by gas or arc method. The experience of the welder is important here |

How to solder a copper pipe yourself In a modern apartment there are many copper pipelines. They can be found in heating radiators, some parts of the plumbing, air conditioners, refrigeration units. With full or...

Method of working with a horizontal joint

The method of action with fixed joints of the pipeline in a horizontal position is different in that it is not necessary to cut the edges completely. These actions must be carried out by medium arc welding. Only a minor cut of 10 degrees can be saved. Such actions provide an improvement in the process of joining metal parts and maintaining their quality at the same level. It is better to cook horizontal joints of the pipeline in separate, narrow layers. The root of the seam is boiled with the first roller, using electrodes 4 mm in diameter. The force limit according to Ohm's law must be set in the range from 160 to 190 A. The electrode receives a movement characteristic of reciprocating, while a thread-like roller 1-1.5 mm high should appear inside the joint. The coating of layer No. 1 is subject to thorough cleaning.Interlayer No. 2 is made in such a way that it closes the previous layer when the electrode moves in a reciprocating manner and when it sways almost imperceptibly between the edges of the upper and lower edges.

Table of the ratio of welding currents depending on various indicators

The direction of the second layer does not differ from the first. Before performing the third layer, the current must be increased to 250-300 A. To make the process of connecting metal elements more productive, you need to use electrodes with a diameter of 5 millimeters. The direction of cooking of the third layer is opposite to the directions of the previous two layers. The third roller is recommended to be performed at higher modes. The speed must be chosen so that the roller is convex. It is necessary to cook at an "angle back" or at a right angle. The third roll should fill two-thirds of the width of roll #2. The execution of the fourth roller should be carried out in the modes used when performing the third. The angle of inclination of the electrode is 80-90 degrees from the surface of the pipe, which is located vertically. The direction of the fourth roller remains the same.

The technology for performing electric welding with horizontal joints in the presence of more than 3 layers has its own peculiarity: the third layer with all subsequent ones is performed in directions, each of which is opposite to the previous one. Pipes reaching a diameter of 200 mm are usually subject to continuous seam welding. The reverse stepwise method is typical for the welding process of pipeline joints with a diameter of more than 200 mm. Each section is recommended to be approximately 150-300 mm long.

Safety

Various types of welding (electricity, gas, etc.) must be carried out on prepared sites with specialized equipment installed. It includes shields for protection against the influence of an electric arc and special screens. Such protection devices must be in such a position that people present at work, but not participating in the process, are also protected from the effects of welding.

If a pipe with a large cross section and a mass of more than 20 kilograms is being welded, then transport and lifting machines must be available. The width of the approach to the site must be at least one meter. The temperature in the building where pipes are welded must be at least +16 degrees Celsius. In addition, the room needs ventilation and a sufficient level of lighting on site for welding work.

Workers must be equipped with a special protective uniform. The welding process requires the metal parts of the device to be grounded, the case and work table must also be grounded. On all wires and cables, the insulating material must be protected from thermal and mechanical damage, and must not have defects.

All elements of the equipment must be made of material resistant to high temperatures. In the event of a malfunction in the electrical circuit, repair work can only be carried out by a professional electrician with the breaker disconnected.

Now we give data on how to calculate the mass and volume of deposited metal.

If we take into account the total length of the electrode of 47 centimeters and the cross-sectional area of \u200b\u200bthe weld equal to half a centimeter, as well as the specific volume of the deposited material for 7.8 grams per centimeter, then the volume of the substance is equal to the product of the specific volume by the section and by the length.

If the section is denoted by the letter S, the length by the letter L, and the specific volume Vsp, then the total volume of the deposited substance is equal to the product of S, L and Vsp and is equal to 1880 grams.

The mass of the welded substance is equal to the product of the coefficient of the deposited metal by the volume and is equal to 1.88 kg/m3, if electrodes of the VSP-1 type with a coefficient of 10 are used during operation.

Various arc welding techniques

Welding of pipelines can be performed in several technological ways:

Welding with a turn of the joint

First, three tacks are made at 4, 8 and 12 hours. Then two main seams are performed from about 1 to 5 o'clock and from 11 to 7 o'clock. After that, the pipe is rotated 90 degrees and the final seams are applied, which completely seal the connection of the two seams.

To prevent burns, it is recommended to use a 4-mm electrode of the SM-11, VCC-1 or UONI-11 / 45 (55) brands for the first layer, and set the current to 130 A (± 10 A) to create an electric arc. To perform the second and third layers, it is necessary to take 5-6 mm electrodes, and the current strength should be increased to 200-250 A.

Welding without joint rotation

This technology is used when working with stationary pipelines that cannot be moved. The first layer is performed from the bottom up, and the second and third can be performed both from the top down and from the bottom up.

Welding of hard-to-reach places, for example, a part of a pipeline pressed against a concrete pad or a brick wall, must be done through a tie-in - a technological hole on top of the pipe. When the welding work is completed, the technological hole is also welded.

Pipe welding in winter conditions

At negative temperatures, the welding zone is rapidly cooled, and the removal of hot gases from the molten metal, on the contrary, is difficult. Because of this, pipe steel becomes brittle, which sharply increases the risk of thermal destruction of steel, the appearance of hot cracks extending from the weld, as well as hardening structures.

To avoid these defects, it is necessary, firstly, to connect the elements of the pipeline with each other as tightly as possible, secondly, it is necessary to heat the metal surface to a light red hue, and finally, thirdly, the current strength must be increased by 10-20%. This will make it possible to achieve a viscous and ductile weld, which reliably seals the gap between the pipes even in severe frost.

Vertical welding of fixed joints

Vertical welding on non-rotating pipe ends is performed similarly to horizontal welding with one difference: a constant change in the electrode inclination with respect to the weld perimeter.

The welding process involves the following steps:

- A joint is created, obtained during the welding of the pipe, which refers to the root bead.

- Three rollers are formed, which must fill the cut.

- A lock is created connecting the beginning and end of the roller.

- A decorative seam is in progress.

The first step is considered the most important, as it is at this time that the joint is created that forms the basis of the seam.The range of welding current is determined by the thickness of the metal and the gap between the mating parts. At the first stage, two main rollers are created.

To create a joint on the pipe, the base of each joined edge is captured, at the same time the second root layer is formed and the first layer is corrected.

The formation of a reverse bead using electrodes with a diameter of 3 mm is performed only in cases where the welded joint must be of high quality.

To perform work, select the average or minimum current range, taking into account the following:

- The thickness of the metal workpiece.

- The distance between the edges of the products.

- Blunt thickness.

The slope of the electrode is determined by the direction of the weld and depends on the penetration of the first layer of the weld.

The length of the arc also depends on the degree of penetration:

- A short arc is used when the root bead is not sufficiently penetrated.

- Medium arc - with good penetration.

Speed indicators of welding largely depend on the volume of the weld pool. A roller of great height at the joints of metal parts leads to the fact that it does not freeze for a long time. This can lead to the formation of various defects. When choosing the welding speed, it must be remembered that only a high-quality edge alloy ensures the normal state of the bead.

Processing of metal of a certain thickness, as well as sampling and welding, is recommended to be performed with electrodes with a diameter of 4 mm. In this case, the slope of the electrode must be different from the angle of inclination when working with the root roller. Here you should apply a method called "back angle". The speed in this case should be such that the roller remains normal.

It is interesting: How to work with electric welding - understand in detail

Types of pipelines and welding

There are a huge number of pipelines that are used to move various materials and working fluids. Based on their purpose, there is the following classification:

- technological;

- trunk;

- industrial;

- gas supply pipelines;

- water;

- sewer.

See also: Machine for coupler of springs of car struts

In the manufacture of the pipeline, various materials are used - ceramics, plastic, concrete and various types of metals.

Modern welders for joining pipes use three main methods:

- Mechanical is carried out due to explosions as a result of friction.

- Thermal, which is carried out by melting, for example, gas welding, plasma or electric beam.

- Thermomechanical is produced by a magnetically controlled arc by means of a butt contact method.

There are many types of welding, which are divided into many classifications. Before you weld pipes, you need to figure out which way is best to do it. Theoretically, each type is suitable for welding small and large diameter pipes. It can be carried out by melting and pressure. Melting methods include electric arc and gas welding, and pressure methods include gas pressure, cold, ultrasonic and contact. The most common ways to connect communications are manual arc and mechanized.

Horizontal arrangement

Welding horizontal pipe joints is not an easy operation, so it is recommended that it be performed by experienced craftsmen. Of particular difficulty is the need for constant adjustment of the angle of inclination of the electrode.

Pipe welding in a horizontal position is carried out in the following sequence:

- Ceiling. Located below.

- Vertical. Positioned vertically.

- Lower. Located at the top.

Each of the stages is performed continuously. You should start from the ceiling part, moving away from the vertical axis to the right for a short distance, and then move clockwise up.

When performing a ceiling seam, the current strength is increased.

Electrodes for horizontal welding use a diameter of four millimeters. The electrodes are moved in a reciprocating way, which allows you to create a thread roller with a height of not more than one and a half millimeters. After creating the first roller, it is necessary to clean its surface.

The second roller closes the bottom. When welding the last roller, the current strength is increased from 160 to 300 amperes, and the electrodes are selected with a diameter of five millimeters.