- Expert advice

- 3 Purpose of butt welding technology

- Connection with an electrical coupling

- Reasons for the uniqueness of PE

- What are the advantages of HDPE pipe?

- Advantages and disadvantages

- 2 General idea

- Thermistor welding and its features

- Electrofusion welding

- How to perform butt welding?

- Flash welding

- resistance welding

- What to choose for polyethylene pipes?

- Nuances of preliminary preparation for welding work

- Extruder welding

- HDPE pipes

- Butt welding method

Expert advice

After installation, the system must be carefully checked by filling it with water. If a leak has been detected, the fittings must be tightened. However, the press fitting in such a situation must be completely replaced. It is necessary to check underfloor heating systems before installing the screed. In such a situation, it is forbidden to use compression assembly technology. Secondary compression of press fittings must not be allowed, therefore, during installation, maximum physical effort must be applied.

HDPE pipes of small diameter can be bent without the use of tools. When laying the pipeline under the ground, where the aesthetic component does not matter, it is recommended to warm up the required area with a hair dryer, and then gently bend the pipe.If you need to create neat bends of small diameter, after heating the product, put it in a mandrel made from improvised materials. After heating, the pipes should cool down for 10-15 minutes. If possible, it is advisable to use a special pipe bender.

3 Purpose of butt welding technology

Butt welding is one of three methods for welding polyethylene pipes, which ensure the strength of the welded joint is not lower than the strength of the pipe itself. Two other methods are welding with embedded heaters and welding with a heated tool into a socket.

Butt welding technology allows you to connect pipes from any thermoplastics of groups I and II - PE, PP, PVDF, PVC, etc. In other words, from polymers that, when heated, are able to go into a viscous-fluid state, and after cooling, harden again without a significant change physical and chemical properties.

The main advantage of butt welding technology over other types of welding of plastic pipes is that for laying straight sections of pipelines, no expenses are required for connecting parts; pipe sections are welded directly.

The disadvantage is that, regardless of the diameter of the pipes to be welded, strict compliance with the numerous requirements of butt welding technology is required, and welding of one butt seam takes a relatively long time.

The higher the diameter of the welded pipes, the more tangible is the superiority of the advantages of butt welding technology over its shortcomings. Therefore, for diameters below 63 mm, butt welding with a heated tool is very rarely used. As for plastic pipes with a diameter above 110 mm, these are, as a rule, pipes made of polyethylene.Therefore, in the vast majority of cases, butt welding technology is used to connect polyethylene pipes.

Conversely, polyethylene pipes are in most cases connected using butt welding technology. It can be said that “polyethylene pipe welding” and “pipe butt welding” are almost synonymous.

The only limitation is that butt welding is not recommended on free-flow sewerage pipelines. from polymer pipes, because on the inner surface of the pipeline, as a result of welding of the butt joint, a bead of fused material (so-called flash) is formed, which can become a place for the accumulation of solid particles and cause clogging of a non-pressure pipeline. If the internal flash is cut off, then butt welds can even be used for sewerage. The problem is that on a finished pipeline, the fact of removing the internal flash is almost impossible to verify. This is probably why the main “legalized” application of butt welding technology is the installation of pressure pipelines:

External water pipes from polyethylene pipes

Regulatory document - SNiP 3.05.04-85*. Pipe material:

- Polyethylene (HDPE), welding methods - butt or socket (clause 3.58. SNiP);

- PVC, connection by gluing into a socket (clause 3.62. SNiP).

Regarding the technology of butt welding of polyethylene pipes, SNiP 3.05.04-85 * refers to one of the first Russian regulatory documents in which this technology is described - OST 6-19-505-79.

External gas pipelines made of polyethylene pipes

The regulatory document is SP 62.13330.2011, which is an updated version of SNiP 42-01-2002. We are talking only about underground gas pipelines (clause 4.11 of the joint venture).The material of the pipes is only PE, the methods of welding polyethylene pipes are “... end-to-end with a heated tool or using parts with embedded electric heaters” (clause 4.13 of the joint venture).

There is neither its own description of the butt welding technology, nor a reference to another regulatory document. But its own technology for butt welding of polyethylene pipes is described in the Gazprom STO 2-2.1-411-2010.

Oil pipelines from polyethylene and polypropylene pipes

The installation of oil pipelines from plastic pipes is subject to VSN 003-88 of the Ministry of Oil and Gas Construction. Pipe material - PE or PP, welding methods - with a heated tool butt or socket (clause 7.5.3.1. VSN).

VSN 003-88 contains a description of the technology for butt welding of polyethylene (HDPE) and polypropylene pipes, similar to the most common technologies in Russia DVS 2207-1 and DVS 2207-11, respectively.

Process pipelines

Installation of technological pipelines from plastic pipes is subject to SNiP 3.05.05-84. Pipes made of polymeric materials are collectively referred to here as "plastic". Welding methods are not defined. However, the quality control methods for welding plastic pipes are defined here, including for butt joints (clause 4.23. SNiP).

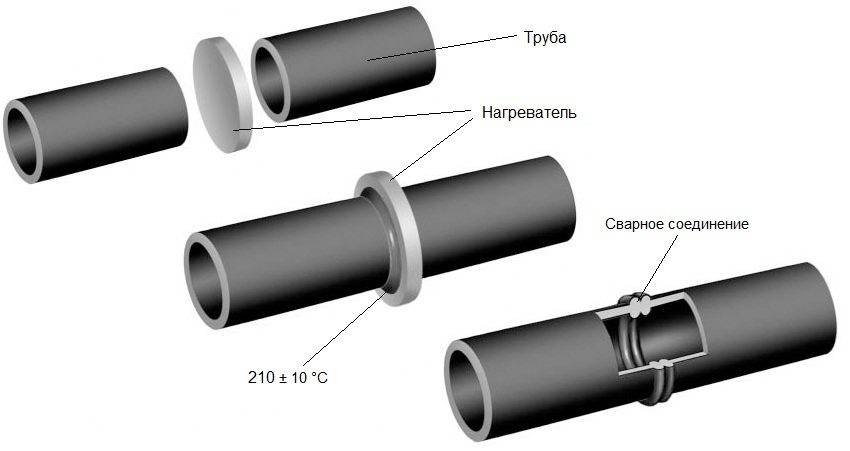

Connection with an electrical coupling

When comparing 2 technologies, it turns out that welding with an electrofusion is not very profitable, but it is a very convenient process if it is required to be carried out in cases where there is very little free space.

In most cases, such welding is used in the repair of polyethylene pipes of small diameter (as a rule, it is used on diameters up to 160 mm). The seams resulting from such work are able to withstand up to 16 atmospheres of pressure.

The electrocoupling is a shaped polyethylene element, in the body of which there are electric spirals. Each diameter has its own coupling, they have a designation of the maximum temperature regime, the duration of continuous operation, and so on.

If it is necessary to weld ordinary pipelines, the shape of the coupling will be simple, and when welding tees and other elements, special devices must be used.

The principle of operation with an electric clutch is as follows:

- Immediately after the supply of electricity to the coupling spirals, the temperature of the nearby polyethylene begins to increase and, accordingly, its melting.

- Next, the end elements of the polyethylene pipe, which are located under the coupling itself, are heated.

- The pipe itself expands somewhat from heating, due to which the pressure that is necessary to obtain a high quality seam is obtained.

- When the coupling is disconnected from the network, the pipe begins to cool.

- The joint, after hardening, forms a rigid and highly hermetic joint.

Reasons for the uniqueness of PE

We can talk about the noticeable rigidity of high-density polyethylene pipes. This is due to the strong bond of this product at the molecular level. For this reason, the production is considered extremely durable.

The main advantage of low pressure PE is that it is made from petroleum. Such material is resistant to low temperatures, does not emit harmful substances into the environment and is not considered dangerous to humans.

According to the purpose, the following types of pipeline from high-density PE are distinguished:

- Technical (used in sewerage, gas supply and cable manufacturing);

- Food (applicable in the design of drinking elements).

Depending on the connection method, there are detachable (easily disassembled after soldering) and one-piece (they cannot be detached, they are applicable at high pressure).

What are the advantages of HDPE pipe?

HDPE pipes are made of high quality (light and durable) low pressure polyethylene. He began to conquer the market of pipeline fittings in the early 80s and today about 75% of all products on this market are made of polyethylene.

The material has excellent technical characteristics, which are often considered its own advantages:

- is not afraid of exposure to almost any aggressive chemicals;

- is not an electrical conductor;

- incredibly high degree of wear resistance - retains its appearance for about 50 years;

- absolute environmental safety of the material;

- the material is completely not subject to corrosive destruction;

- resistance to low temperatures;

- the material is not damaged by fungus and mold;

- acceptable cost.

HDPE pipes

HDPE pipes

Due to such a large number of advantages, HDPE is widely used in various fields (both in industry and in everyday life). For example, it is used to protect electrical cables (power and communication cables). The material is often used in the installation of water / sewer pipelines and the construction of artesian wells.

It is worth noting that despite such a variety of applications of the material, it is quite simple to mount it - even a person without relevant experience is quite capable of coping with this task.

But pipes created on the basis of HDPE should in no case be used in heating systems and hot water supply, since the maximum temperature that the material can withstand while maintaining its properties and aesthetic appearance is about 60 degrees. Say, at a temperature of about +75, it will already begin to soften little by little.

Advantages and disadvantages

HDPE is low pressure polyethylene, which is a polymer of ethylene. It has a PE or PE marking and is white (thin designs are completely transparent). Sometimes HDPE products are painted in black, blue, gray and other colors. A blue stripe on the pipe means that it can be used for water supply systems.

Most often, the installation of polyethylene pipes is carried out for the installation of cold water pipes, sewers and a number of aggressive environments. The diameter of such products reaches 1600 mm. In addition, they are used for internet wiring, telephone, electricity.

The main advantages of low pressure polyethylene:

- long service life - some manufacturers give a 50-year warranty on their products;

- affordable cost;

- frost resistance - HDPE pipes can withstand repeated thawing / freezing cycles;

- inertness to chemicals - HDPE is highly resistant even to acids and alkalis;

- resistance to corrosion;

- environmental friendliness;

- safety for the human body;

- smooth inner surfaces prevent salts from settling on the walls;

- excellent plasticity;

- high level of strength;

- small mass;

- easy maintenance;

- simple and fast installation.

Despite the wide range of advantages of polyethylene, it also has a number of disadvantages. The main ones are:

- Low resistance to UV radiation. The material is gradually destroyed in the sun, so it cannot be laid on the street without the use of special boxes and covers.

- Low temperature resistance. HDPE products can only be used to transport water with a temperature of not more than +60 degrees. For the device of heating systems it is necessary to use products from cross-linked polyethylene.

- Unaesthetic. Some designs may not fit black or striped HDPE pipes.

- The operational characteristics of these structures do not allow their use in the industrial sector.

- Reinforced products have minimal flexibility.

2 General idea

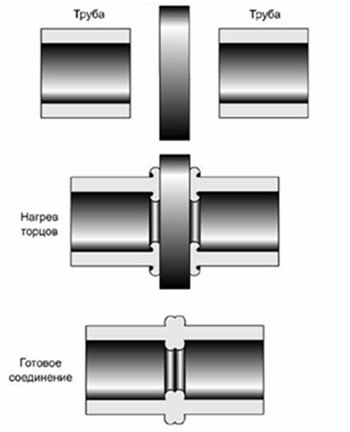

Butt welding of plastic pipes with a heated tool consists, in principle, in heating the ends until the material melts and in subsequent compression of the ends to form a butt joint and cool the seam (Fig. 1).

Heating of the surfaces to be welded is carried out with a flat metal heated tool with a Teflon coating, which, after heating, is removed from the welding zone.

| Rice. 1 Pipe butt welding |

However, welding a quality butt joint requires the operator to carefully fulfill a number of conditions. As a result, the process of butt welding with a heated tool consists of 5 main phases with precisely normalized modes.

Thermistor welding and its features

This technology is also called electrofusion. Contact is made by couplings that have a special heating element.

PND welding is done in the usual way in such cases:

- Butt joint cannot be made;

- It is necessary to carry out welding in the old pipeline;

- Branches to working pipes are required.

- Elements of thermistor welding are not cheap, but sometimes you can’t do without it.

- The stages of this type of connection look like this:

- First you need to cut off the elements, clean them from debris and dirt;

- Using a marker, we mark on the details those places to which the finished pipeline will enter the fitting;

- We protect with the help of nozzles those elements that cannot be welded. This is necessary so that dirt does not get on them;

- The final stage is the connection of the electric coupling with the welding machine. You need to connect the wires and turn on the device. The equipment will turn itself off as soon as it reaches the desired temperature.

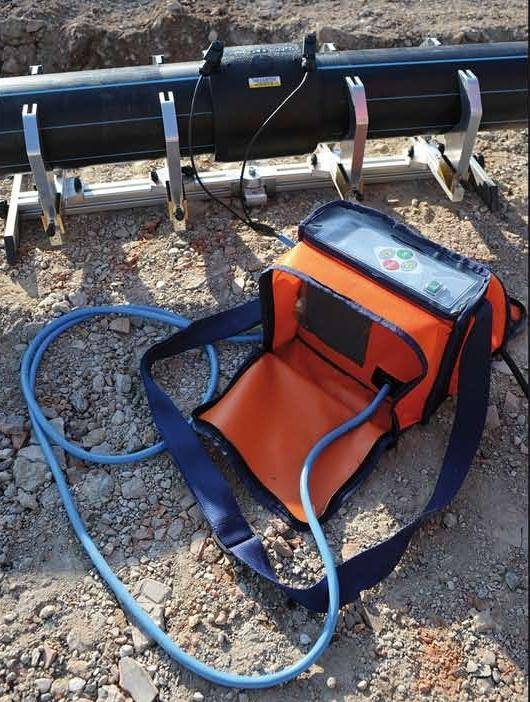

Electrofusion welding

For this type of connection, a shaped element is used, inside which electric spirals work, which heat and firmly fix the pipeline parts. This method allows you to weld pipes of different diameters, but the difference in size should be no more than 10%. The maximum allowable external diameter of the HDPE pipe is 160 mm.

The mechanism of action is as follows:

1. Cut and prepare the surface to be welded as in resistance welding.

2. Using the positioner, temporarily fix the parts in the correct position.

3. Insert the parts into the coupling, turn on the device. Allow the necessary time after the heat has stopped to form a good weld.

The video below shows a step-by-step process for installing HDPE pipes using electrofusion welding.

For this welding method, all parameters (temperature, heating time and precipitation) must be indicated on the part.

Back to content

How to perform butt welding?

Butt welding is popular today. This method is used not only in industry, but also in everyday life. It is used to connect homogeneous workpieces. Butt welding has a number of advantages over other technologies.

For its implementation, couplings and other elements are not needed. This allows you to save a lot of money on the purchase of additional materials. The applied technology ensures the preservation of indicators of flexibility and strength. With its help, you can connect segments of products of different lengths. At the same time, the strength at the welding point will not be lower than in other solid areas.

Butt welding of pipes refers to one-piece connection options. It can be performed using different technologies. The optimal method is selected based on the material of manufacture of the line

Butt welding of pipes refers to one-piece connection options. It can be performed using different technologies. The optimal method is selected based on the material of manufacture of the line

Butt welding can be done by flash and resistance. Each option has its own characteristics, pros and cons.

Flash welding

The essence of welding by this method lies in the fact that the pipe joints are melted under the influence of a heated tool to ductility. Then the ends are connected under pressure and held until completely cooled. The result is a sealed seam.

In order for the connection to be of high quality, it is necessary to firmly press the pieces of the product after heating. The use of modern equipment makes it possible to partially automate and simplify such work. With its help, the operation of connecting pipes by melting is carried out in the shortest possible time.

resistance welding

The essence of resistance butt welding is that the edges of the pipes are pressed against the electrodes, which are equipped with special sponges. This provides a high quality electrical contact.Material slippage between the electrodes is excluded.

Then the two pipes are pressed tightly against each other and fixed. Next, the welding current is applied. The contact areas of the material are melted and combined under pressure into one product. The resulting design has a low resistance to oxidation during operation. This significantly limits its scope.

Resistance welding is commonly used to connect thin mild steel parts (pipes, rods, wires). It also welds copper, bronze and brass elements.

Resistance welding is commonly used to connect thin mild steel parts (pipes, rods, wires). It also welds copper, bronze and brass elements.

Resistance welding is only suitable for pipes with a small cross section. Therefore, in large-scale production, for laying large highways, it is rarely used.

What to choose for polyethylene pipes?

Often, polyethylene material is used for laying the pipeline. This is due to its low price and excellent performance.

It is worth remembering that polyethylene is a dielectric. Therefore, unlike metal, it does not conduct current. To connect products from it, it is recommended to use the method of reflow. Butt welding with resistance on polyethylene will not work. You need to use equipment that heats the sections of two parts.

Fusion welding of polyethylene pipes has a number of features. First, the parts are brought to each other at low speed. Secondly, the voltage during the entire process remains unchanged. Thirdly, all microroughnesses disappear due to the uniform supply of the connected elements. Fourthly, to ensure the maximum contact area, the surface of the workpiece is melted.

Nuances of preliminary preparation for welding work

Speaking about how to weld polyethylene pipes at home, you need to take into account not only the rules of use, but also safety precautions when working with welding equipment.

The key to success is the preparatory work:

- Each assembly of welding equipment must be thoroughly cleaned and checked for defects that may affect the quality and safety of the work being carried out.

- All wiring and grounding should be checked for defective or missing insulation.

- Fuel units must be refueled, or old stagnant fuel must be removed from them and new fuel must be filled in.

- Be sure to perform a test run of the installation to make sure it works.

- The oil level in the hydraulic system of the welding machine must be checked and carried out in the same way as with fuel.

- If the welding machine is mobile, then its movement must be carried out freely so that the work is carried out without a hitch and without risk to the operator of the installation.

- The knives of the facing device must be honed to an ideal state so that the process of processing pipes and fittings takes place quickly, and as a result high-quality products are obtained.

- Each control and measuring device must be in good working order.

- When working with HDPE, it is necessary to purchase clamps and reducing inserts in the required quantity in advance, the diameter of which must correspond to the cross section of the pipes.

- Each part subjected to friction should be thoroughly lubricated. However, even when choosing a lubricant mixture, you need to pay attention to the requirements put forward by pipe manufacturers.

Outcome

By following all the rules and instructions given in the article, you can get a high-quality connection for polyethylene pipes. The method of how to weld a polyethylene pipe should be chosen according to the main criteria: ease of implementation and accessibility for the employee from the financial side of the issue. It is best to entrust the work to a specialist who will take responsibility for all stages - from the purchase of the necessary materials and equipment to the welding and commissioning of the system.

Extruder welding

It is a little more difficult to work with a hand-held hairdryer or soldering iron, because you need to additionally control not only the warm-up time, but also your own movements. If the welding is not carried out correctly, the integrity of the HDPE pipes can be violated or the seam can be spoiled.

Photo - professional inverter

Photo - professional inverter

Step-by-step instructions for welding with an inverter:

- It is necessary to cut the communication to a certain size, be sure to clean the end;

- The temperature for HDPE welding is 260 degrees, a soldering iron is installed at this level, welding nozzles are installed and heated at the same time;

-

Before starting work, the required installation depth must be measured and noted, it must be at least 2 mm;

- The most difficult part of this process is the moment when you need to center the fitting and pipe in the nozzle. A professional machine contains a special centering mechanism in its configuration, if it is not there, then just try to do everything very accurately;

- After the connection, they slide in to the mark (not to the joint) and hold for a certain time;

- At the end of the work, the device is turned off, and the pipe welding place is fixed for cooling.

It is very important not to overexpose the fastening, if the welding is too tightened, then the HDPE will become very thin or there will be an influx of polyethylene on the inner diameter. To control this moment, a special table is used:

| Outer diameter, mm | Weld seam, mm | Heating, sec | Connection, sec | Cooling, sec |

| 20 | 14 | 6 | 4 | 2 |

| 25 | 16 | 7 | 4 | 2 |

| 32 | 18 | 8 | 6 | 4 |

| 40 | 20 | 12 | 6 | 4 |

| 50 | 23 | 18 | 6 | 4 |

| 63 | 26 | 24 | 8 | 6 |

| 75 | 28 | 30 | 10 | 8 |

| 90 | 30 | 40 | 11 | 8 |

| 110 | 32 | 50 | 12 | 8 |

Video: Electrofusion welding of HDPE pipes

HDPE pipes

HDPE pipes or low pressure polyethylene pipes are very popular today.

This is largely due to the excellent technical characteristics of pipelines:

- Environmental Safety.

- It is very easy to use, especially since they are well mounted, and their cost is not too high. Unlike pipes that can withstand high pressure, HDPE melts at a temperature of 20 degrees more, due to which the range of their application is much wider.

- Due to their ability to withstand temperatures well, they can be used in the construction of both hot and cold water supply systems.

- The material is very plastic, it can be easily bent and deformed if desired - nothing will happen to the pipes.

- HDPE perfectly resist the effects of most aggressive chemical compounds. The inner layer of the pipe does not interact with those substances that pass through it, so they will retain their positive characteristics for a long period of time.

- The strength index is very high, due to which, pipelines perfectly resist various mechanical influences, are resistant to corrosion processes.

Depending on the scope of application, pipes made of low-density polyethylene can be divided into 4 main types:

- Sewer - able to withstand about 20 atmospheres. They are produced from primary raw materials, and are subsequently used for the construction of sewer systems.

- Plumbing. They have a distinctive external feature - a blue stripe along the entire length. Their production is strictly regulated by the GOST 18599-2001 standard. The key function of such pipes is to transfer drinking and domestic water to the place of direct consumption. Water is transported at a temperature of about 40 degrees and pressure up to 15 atmospheres.

- Gas. These products also have a strip, however, it is yellow. They are produced on the basis of GOST R 50838-2008. They are designed to transport gas, often even liquid, and operate under pressure from 3 to 12 atmospheres.

- Technical. They are made from recycled material. Unlike all other varieties, they are not produced to state standards, but only according to the manufacturer's specifications. Used for laying channels.

The use of welding when connecting polyethylene pipes allows you to get a high-quality connection.

Butt welding method

This method allows you to connect polyethylene pipes with a weld using special equipment for butt welding. The weld (or "joint") is equal in tensile strength to the polyethylene pipe itself. By welding with a heated tool, PE pipes with diameters from 50 mm to 1600 mm inclusive are connected. Standard technological welding modes are designed for operation at air temperature from -10°C to +30°C. If the air temperature in the street goes beyond the standard temperature intervals, then welding of polyethylene pipes must be carried out in a shelter in order to comply with technological parameters.Butt welding of pressure HDPE pipes is divided into two main stages: preparatory work and welding itself. The preparatory stage includes:

- checking the performance and preparation for operation of welding equipment,

- preparation of a place for placement of welding equipment,

- selection of the necessary parameters for welding,

- fixing PE pipes and centering in the clamps of the welding machine,

- mechanical processing of the ends of the welded surfaces of pipes or parts.

When preparing the equipment, inserts and clamps are selected that correspond to the diameter of the pipe to be welded. The working surfaces of the heater and the tool for processing PE pipes must be cleaned of dirt and dust. The operability of the equipment is checked during a visual inspection of the units and components of the welding machine, as well as during the control inclusion. At the welding machine, the smooth running of the movable clamp of the centralizer and the operation of the facer are checked. Placement of welding equipment is carried out on a pre-prepared and cleared site or pipeline route after PE pipes are stored on it. If necessary, the welding site is protected with awnings to protect it from precipitation, sand and dust. In wet weather, it is recommended to install welding equipment on wooden shields. And it is recommended to close the free end of the polyethylene pipe with inventory plugs to prevent drafts inside the pipe during welding.

The assembly of welded pressure HDPE pipes and parts, including the installation, centering and fixing of the ends to be welded, is carried out in the clamps of the centralizer of the welding machine.The clamps of the welding machine for PE pipes are tightened so as to prevent slipping of the pipes and eliminate, to the extent possible, ovality at the ends. When butt welding large-diameter PE pipes, since they have a sufficiently large dead weight, supports are placed under the free ends to align the pipe and prevent the welded end of the pipe from moving. The sequence of the welding process:

- first measure the force required to move the movable clamp with a fixed pipe,

- a heater is installed between the ends of the pipes, heated to the required temperature,

- carry out the reflow process by pressing the ends of the PE pipes to the heater, creating the necessary pressure,

- the ends are squeezed for some time (according to the welding technology for this polyethylene pipe) until the appearance of a primary burr with a height of 0.5 to 2.0 mm,

- after the appearance of the primary burr, the pressure is reduced and maintained for the time necessary to warm up the ends of the pipes,

- after the end of the warm-up process, the movable clamp of the centralizer is retracted 5-6 cm back and the heater is removed from the welding zone,

- after removing the heater, bring the ends of the polyethylene pipes to contact, creating the pressure necessary for precipitation,

- the precipitation pressure is maintained for the time necessary for the joint to cool, and then a visual inspection of the resulting weld is carried out in terms of the size and configuration of the outer burr,

- then mark the resulting weld.