- How to isolate sound in the bathroom

- Mounting foam

- Features of steel baths

- Soundproofing methods

- Soundproofing foam

- Soundproofing with polyethylene foam

- Preparatory work

- Vibroplast

- Ratings

- Which is better to choose a water heated towel rail: manufacturer rating

- Rating of the best wired headphones of 2020

- Rating of the best mobile phones for games

- The main ways to soundproof the bath with your own hands

- Foamed polyethylene and polypropylene

- Mounting foam

- technical traffic jam

- Vibroplast, vibroizol

- liquid acrylic

- How to soundproof a bathtub with your own hands

- The main ways to soundproof the bath with your own hands

- Foamed polyethylene and polypropylene

- Mounting foam

- technical traffic jam

- Vibroplast, vibroizol

- liquid acrylic

- Bathroom soundproofing problem

- Principles of soundproofing

- materials

- under tile

- On the walls

- To the ceiling

- On the floor

- Frameless installation and its nuances

- How to fix soundproof panels?

- Varieties of soundproof materials

- How to protect the room from additional noise

How to isolate sound in the bathroom

Now let's come close to the soundproofing of the bathroom - so that extraneous sounds do not prevent you from concentrating on the secrets of life, and so that the sound of serenades (what if you want to sing?) Do not reach outside the toilet.But seriously, quite often the toilets are located in inconvenient places, for example, opposite the living room or next to the kitchen.

First, take care of a door with good sound insulation. An ordinary wooden door is not suitable here, since wood does not have the best sound absorption coefficient. In addition, the tree is not very resistant to moisture - although there is not as much of it here as in the bathroom, it is still better to take it with a margin of safety.

So plastic or metal doors will do just fine. You can buy such doors and carefully disassemble them by filling the internal voids with mineral wool, or you can ask the craftsmen who will install the door to do this. In addition to mineral wool, it does not hurt to make a layer of sound-reflecting membranes - they are very thin and at the same time enhance the effect of sound insulation in combination with other materials.

A mandatory item of the program is the soundproofing of the riser. To begin with, check for yourself how your business is - perhaps the builders were smart enough to make soundproofing when installing pipes. In this case, a piece of pipe (sleeve) should be installed in the ceilings, the diameter of which is several centimeters larger than the diameter of the riser.

If the most negative forecasts come true, do the soundproofing yourself. To do this, it is necessary to remove as much cement as possible around the pipe, at least 10 centimeters deep and as wide as it will be enough for convenient winding of the riser with sound and vibration insulating material. In this capacity, the Texound membrane is suitable.

We offer you to familiarize yourself with the self-leveling floor finishing with your own hands

It will be sufficient to insulate the walls and ceiling of the toilet with mineral wool (a layer of at least 5 cm), covering it with drywall. It is best to decorate the floor with ceramic tiles and put a soft rug - it will also participate in the process of dissipating extraneous sounds. So in the reflection room, as the bathroom is often jokingly called, really no one can interfere with the flow of your thoughts.

If we talk about the elimination of noise effects on the scale of the entire bathroom, then we can note several common points, namely:

- soundproofing of the bathroom - when the walls, partitions, floor and ceiling of the room are isolated;

- insulation of equipment, in particular bathtubs;

- isolation of sewer and water pipes.

The first task of working with walls is to eliminate those problem areas where sound can seep through. Cracks and holes are carefully sealed with plaster or sealant.

Significant sound leakage occurs through technological connectors for sockets and switches, a smart solution would be to install electrical outlets with protective covers, specially designed for indoor with high humidity.

In building markets, in a number of modern materials, there is a huge choice for any type of finish, including sound insulation

For wall decoration, it is important to remember that there is high humidity in the bathroom, so the choice of materials should be in favor of the appropriate products, taking into account this criterion.

As for the floor, the thickness of the slab with screed and tiled lining is sufficient, but if desired, an additional barrier can be installed in the form of a moisture-resistant membrane film, which will increase the resistance to the passage of noise.

A large proportion of the noise in the bathrooms comes from the sound in the risers, especially the sewers. Recently started producing replacement of sewer lines plastic pipes. The strength and durability of pipes are indisputable advantages, but the noise effects cover all the advantages of this product. Therefore, during the replacement process, the question of sound insulation involuntarily arises.

It is possible to produce high-quality sound insulation of pipes using rolled tape materials, for example, Texound membranes. Soundproofing will also prevent condensation from forming on the pipes, which will reduce the level of humidity in the room. During installation, polyethylene shells of suitable diameter can be put on the risers and the entire water supply tape during installation, which will also reduce the noise level of water in the pipes.

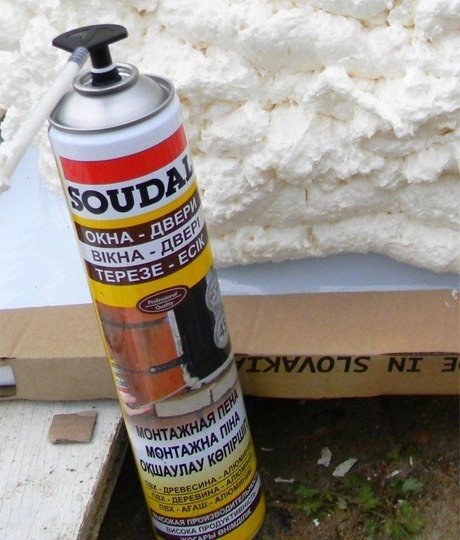

Mounting foam

Construction foam is actively used by craftsmen for the repair or construction of a new building. It is also suitable for creating noise absorption in the bathroom. You can buy it at any hardware or hardware store. Before use, protect hands, head (put on a hat or scarf), face. Read instructions.

How to use - turn the container over, degrease the surface. It is enough to treat it with an alcohol-containing composition. Then slowly cover the bath with a thick layer of this mounting foam. Gently apply in a dense, even layer, trying to avoid gaps. Act slowly, then the foam has time to harden without draining. Having finished processing the side of the bath, turn it over to the second, but after the foam has completely dried.

Polyethylene film will help to enhance the effect. Suitable polyethylene used by summer residents to create greenhouses. It is dense, inexpensive and quite elastic. After applying the foam, cover it with a piece of film prepared in advance.Pressing more tightly with your hands, form a crust resembling a shell.

Important instructions:

- foam suitable for indoor installation;

- it is better to carry out a very presentable treatment in the summer;

- to make the layer uniform, it is worth buying a special nozzle or “gun”;

- before processing, preheat the cylinder (hold it under the tap, turning on the water hotter) and shake;

- leave the place of overflow free;

- view the indicated expiration date and use the foam before it expires.

Features of steel baths

- A light weight. A steel bath weighs 3-5 times less than a cast iron bath, which makes it easy to transport and install plumbing equipment with your own hands. Steel bath

- Variety of models. Steel is more ductile than cast iron and therefore much easier to work with. Thanks to this property, the range of models, colors and sizes of steel bathtubs is more diverse.

- Enamel durability. Unlike cast iron models, steel washing containers retain the enamel coating longer, because this layer is applied under the influence of high temperature, as a result of which the enamel seems to be baked.

Soundproofing methods

A high level of noise occurs when water is poured into a steel bath, while drops fall on the surface of the thicket, and its walls reflect the resulting sound. The optimal wall thickness of products made from this alloy is 3-4 mm, if this figure is less, then the resonating ability of the product increases.

Fortunately, to reduce the noise that interferes with the use of steel wash containers, you can do it yourself. To do this, it is necessary to glue on the bottom of the bathtub 1 of the types of soundproofing materials:

- Vibroisolation. Vibroizol is called an automobile noise-insulating and vibration-insulating material based on bitumen and rubber. It is produced in the form of self-adhesive sheets. Vibrozol

- Mounting foam. By treating the outer surface of the steel bowl with mounting foam, you can also solve the problem of rapid cooling and noise. In addition, this material increases the mechanical strength of the product, protecting it from deformation. Mounting foam

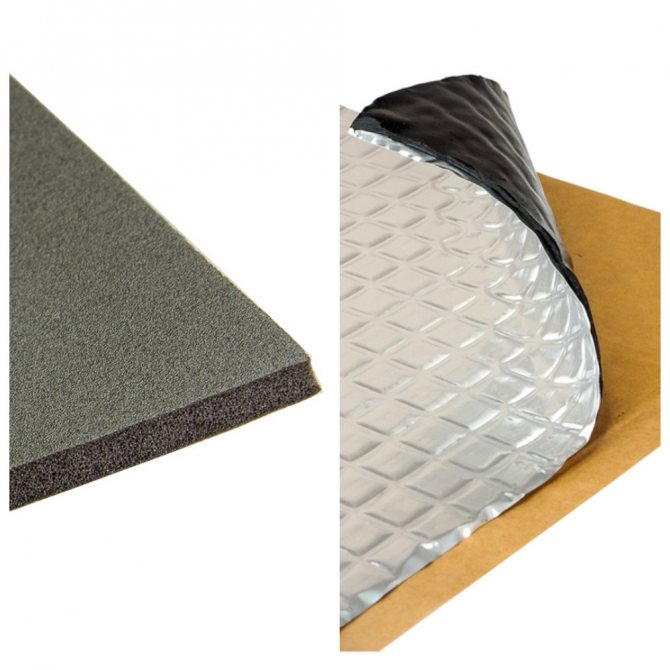

- Foamed polyethylene. The structure of polyethylene foam is a set of bubbles filled with air. This material has high soundproofing and waterproofing properties. Often, self-adhesive polyethylene mats are provided with a foil layer to better retain heat. Polyethylene foam

Soundproofing foam

The simplest and most affordable way to soundproof steel bathtubs is to treat the bottom of the bowl with mounting foam. According to experienced craftsmen, this technology helps to reduce the resonating ability of the walls, improve the thermal insulation qualities and mechanical strength of the product. The application of mounting foam is carried out in the following order:

- First, the water supply is turned off in the apartment, and then the bathtub is dismantled by disconnecting the siphon and placing the bowl on its side.

- The outer surface of the bowl is cleaned of dirt and dust, degreased. The drain and overflow hole is protected with masking tape.

- To improve the adhesion of steel with mounting foam, a thin mesh of silicone sealant is applied to the outer surface of the bath.

- Gently, slowly, apply foam to the outer part of the bowl in an even layer.

Soundproofing with polyethylene foam

Soundproofing a steel bath with polyethylene foam is also considered an effective method of reducing the resonant ability of the walls of the product with your own hands. To eliminate the excess noise that occurs when using a bowl made of steel, a conventional material is used to at the same time reduce its thermal conductivity - foil or metallized. Foamed polyethylene is produced in the form of self-adhesive mats, which are fixed on the bottom as follows:

- In the bathroom, the water supply is turned off, the siphon is disconnected, and then the plumbing bowl is carefully turned on its side.

- The outer surface of the bowl is cleaned of dirt, dust and grease.

- Carry out cutting of self-adhesive mats made of polyethylene foam.

- The protective film is removed from the adhesive layer of the mat, and then pressed firmly against the outer surface of the bath, gently smoothing and eliminating bubbles.

Preparatory work

Soundproofing an apartment in a panel house is easy to do with your own hands

It is important to follow the sequence of work exactly. At the first stage, the structure is prepared for insulation:

Remove the decorative coating of the structure. This applies to both walls and ceilings with floors. This work will allow you to assess the condition of the structure.

Sealing cracks and crevices. After the surface has been cleaned of finish, it is checked for defects. If there are cracks and crevices, then they are puttied. This stage is very important, since it is precisely such structural defects that are the main way for the spread of noise pollution.

Outlet insulation. At the next stage, the boxes of sockets and switches are dismantled.Before you make soundproofing in the wall, you must turn off the electricity in the house. After that, the installation sites of the sockets are filled with mineral wool or glass wool.

Pipe soundproofing

Particular attention should be paid to the junction of engineering systems to the structure. The free space between them is filled with a special sealant

It is better to use a substance that easily tolerates sudden changes in temperature.

All these works are carried out at the preparation stage, before soundproofing the room. Their implementation must be approached very responsibly, since the quality of the final result depends on it.

Vibroplast

Plastic material based on polymeric adhesive, covered with durable aluminum foil. Good sound and heat insulator. Shows excellent performance. It is not difficult to cover plumbing with your own hands with this tool. The bathroom is processed with vibroplast according to this method:

- a piece of the required size is cut from the material;

- With the help of a hair dryer, the part warms up well. As a result, the material will become elastic and more pliable;

- remove the protective film, apply it to a metal surface and heat it again with a hairdryer, press it well (you can use a roller or a staple).

The advantages of vibroplast include:

- does not emit harmful substances;

- small price;

- maintains temperatures in the range of -45 +100 °C;

- does not absorb moisture;

- does not react with chemical irritants.

Maybe the soundproofing of any bath is not the most important part of comfort, but its positive aspects should not be denied, especially if there are many people in the family.In this case, so that others do not experience discomfort, it is best to finish the plumbing with a good sound absorber with your own hands.

When buying a bathtub for the cottage, the choice fell on a steel bathtub. Such bathtubs are notable for their low cost, lightness, and therefore hassle-free delivery on the trunk of a personal car and installation in place. But steel bathtubs also have disadvantages - this is a “boom” when water is drawn in and a quick loss of heat. The easiest way to make a bath quiet and warm is to foam a steel bath. Apply mounting foam to a dry, clean surface. There is no need to pre-treat the surface of the bath, the foam adheres well to the steel surface. When the foam dries, install the bath in place. If in some place there is an excess of foam, then simply cut it off with a knife or cutter. For a small bathtub, 150 cm long, it took me two cylinders of polyurethane foam. Before foaming, a regular plastic bag from the store was shoved into the drain hole. This method has paid off. The noise from the water when taking a bath has become much less, the foamed bath holds the temperature well. In addition, it turned out to save money on buying an inexpensive bathtub.

If the water pouring in the bathroom is getting on your nerves, there is no need to make major repairs or change the bathtub. It is required to organize sound insulation, the specifics and installation methods of which will be discussed.

Steel baths are popular in the plumbing market. The products have a number of advantages, but the sound insulation of such containers leaves much to be desired. Modern building materials allow you to solve this problem quickly and fairly budget.

The popularity of expensive and bulky cast-iron bathtubs is gradually declining. They are replaced by more affordable options: acrylic and steel. The latter are chosen because:

- steel baths are much cheaper than both acrylic and cast iron;

- the enameled coating is resistant to deformation and lasts a long time;

- the metal heats up quickly;

- the design is stable, despite the relatively low weight;

- you can choose a bath for every taste;

- it is easy to deliver and install.

The design also has disadvantages: a steel bathroom quickly loses heat and has low sound insulation. Loud noise from running water or falling objects is often annoying, but this problem can be easily solved with the upgrade process.

Ratings

Ratings

- 15.06.2020

- 2977

Which is better to choose a water heated towel rail: manufacturer rating

Types of water heated towel rails: which one is better to choose, rating of manufacturers and overview of models. Advantages and disadvantages of towel dryers. Features and installation rules.

Ratings

- 14.05.2020

- 3219

Rating of the best wired headphones of 2020

The best wired earbuds for 2019 A brief overview of popular devices designed for a variety of purposes. Pros and cons of budget gadgets.

Ratings

- 14.08.2019

- 2582

Rating of the best mobile phones for games

Rating of the best mobile phones for games and the Internet. Features of choosing a gaming smartphone. Main technical characteristics, CPU frequency, amount of memory, graphics accelerator.

The main ways to soundproof the bath with your own hands

It is optimal to carry out soundproofing work at the stage of construction or repair, before finishing.Water under pressure hits the steel or acrylic wall of the bathtub with sufficient noise, the cast iron dampens the sound a little, and it also makes noise in the pipes. Experts recommend several different methods and materials for soundproofing. Let's compare them in terms of convenience, efficiency, price and other parameters.

Foamed polyethylene and polypropylene

Soundproofing the bathtub with polyethylene and polypropylene requires a more professional approach

The porous structure of this material perfectly dampens vibrations; varieties are produced with a foil layer on one side. You can carefully glue it to the bathtub before installation, turning it upside down. In order not to damage the edges, lay a soft substrate. Pipes are also wrapped with polyethylene foam for additional sound insulation.

Advantages of this isolator:

- low price;

- flexibility and softness.

Some modifications of polypropylene do not have an adhesive layer; glue is needed for fixing. To save money, you can paste over only the bottom and sides of the bath to the level of the poured water.

Mounting foam

Soundproofing a bathtub with mounting foam is a fairly simple way that everyone can handle.

Polyurethane foam fills all cavities and cracks, fits perfectly on any complex shape, so it is used to seal windows and doors.

Before work, it is necessary to degrease the outer surface of the bowl with an alcohol-containing composition for better adhesion of the foam, then apply a thin mesh of silicone sealant. You should work with a mounting gun, slowly and evenly, so that the composition lies in a continuous even layer, let it dry, the drain and overflow should remain open.

An additional layer of insulation with a plastic film is made by pressing it against the uncured foam.The whole structure will look unpresentable, so around the bath you will need to assemble a box or screen made of moisture-resistant drywall or plastic, and tile it.

Mounting foam can be hidden behind a cladding made of any suitable material

Mounting foam is inexpensive, the “summer” variety polymerizes and expands better, withstands higher temperatures.

Minuses:

- susceptible to moisture, fungus forms over time;

- has a limited shelf life.

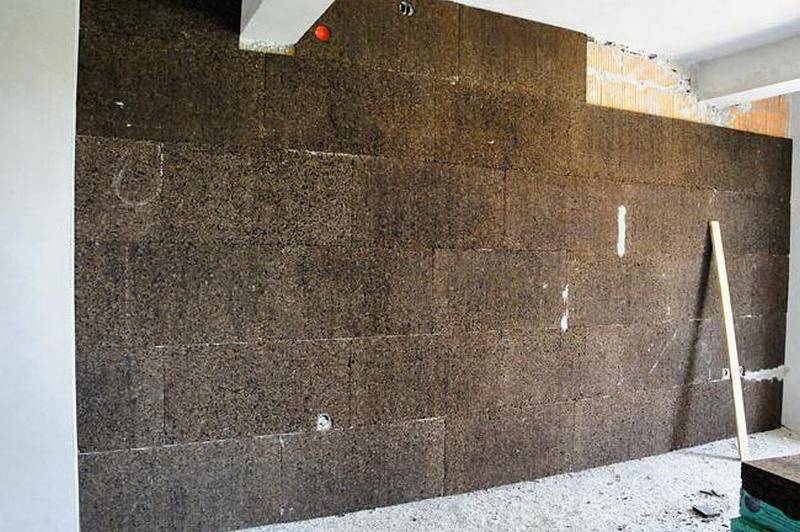

technical traffic jam

Technical cork is not the most durable and cheap option

The most environmentally friendly method of soundproofing is with natural cork. It has low thermal conductivity and a high degree of sound insulation.

The disadvantage of technical cork can be considered the highest price among all materials, the lack of flexibility, on rounded parts you will have to cut and glue pieces that fit the shape, besides, the cork crumbles easily.

Vibroplast, vibroizol

Vibroplast is a fairly durable material that does not require much effort when working.

This material is designed for soundproofing in a car, it is based on bitumen and rubber. It is very convenient to attach mats, because they have an adhesive layer protected by a film or paper. We remove the film, press it to the surface, roll it with a roller for a snug fit, the insulation is ready. You can buy it in car markets and in stores with auto parts. The material is quite flexible, so it fits snugly around the rounded surface of the bath.

Additional pluses:

- vibroisol costs more than polyurethane foam, but cheaper than technical cork;

- it does not absorb moisture;

- withstands temperatures from -45 to +100 ºС.

liquid acrylic

With the help of acrylic, you can not only make soundproofing, but also update the look of the bath.

Another easy way to soundproof a bathtub. This material is applied to the inside of the bowl, resulting in an even, thin coating and a decorative effect. To work, you need two components: a hardener and acrylic enamel. Acrylic has a rather pungent odor, so respiratory protection will be required.

Sequencing:

- Clean off the dirt and rub the inner surface with abrasive powder.

- Degrease and dry the bowl, remove the siphon.

- Pour acrylic in a circle continuously and evenly, it spreads in a layer of 6 mm thick, without bubbles and drips, completely hardens within 2 days.

Advantages of the acrylic layer:

- durability: at least 10 years;

- both white and colored enamels are sold;

- durable, smooth, wear-resistant coating.

All these methods of soundproofing a bath are quite budgetary, they will help not only reduce water noise, but also heat loss, this is especially true for steel baths, the walls of which reflect sound and conduct heat stronger than acrylic and cast iron ones.

How to soundproof a bathtub with your own hands

The bathroom is one of the private places where you can relax after a hard day's work and wash off dirt and fatigue, soak up and relax from the city noise. Water procedures are good for health and replenish the supply of human vital energy. So that extraneous sounds do not interfere with enjoying the shower and the splash of water in the bathroom does not interfere with your home, you should consider effective soundproofing of all surfaces and, of course, the bath itself.

The main ways to soundproof the bath with your own hands

It is optimal to carry out soundproofing work at the stage of construction or repair, before finishing. Water under pressure hits the steel or acrylic wall of the bathtub with sufficient noise, the cast iron dampens the sound a little, and it also makes noise in the pipes. Experts recommend several different methods and materials for soundproofing. Let's compare them in terms of convenience, efficiency, price and other parameters.

Foamed polyethylene and polypropylene

Soundproofing the bathtub with polyethylene and polypropylene requires a more professional approach

The porous structure of this material perfectly dampens vibrations; varieties are produced with a foil layer on one side. You can carefully glue it to the bathtub before installation, turning it upside down. In order not to damage the edges, lay a soft substrate. Pipes are also wrapped with polyethylene foam for additional sound insulation.

Advantages of this isolator:

- low price;

- flexibility and softness.

Some modifications of polypropylene do not have an adhesive layer; glue is needed for fixing. To save money, you can paste over only the bottom and sides of the bath to the level of the poured water.

Mounting foam

Soundproofing a bathtub with mounting foam is a fairly simple way that everyone can handle.

Polyurethane foam fills all cavities and cracks, fits perfectly on any complex shape, so it is used to seal windows and doors.

Before work, it is necessary to degrease the outer surface of the bowl with an alcohol-containing composition for better adhesion of the foam, then apply a thin mesh of silicone sealant. You should work with a mounting gun, slowly and evenly, so that the composition lies in a continuous even layer, let it dry, the drain and overflow should remain open.

An additional layer of insulation with a plastic film is made by pressing it against the uncured foam. The whole structure will look unpresentable, so around the bath you will need to assemble a box or screen made of moisture-resistant drywall or plastic, and tile it.

Mounting foam can be hidden behind a cladding made of any suitable material

Mounting foam is inexpensive, the “summer” variety polymerizes and expands better, withstands higher temperatures.

Minuses:

- susceptible to moisture, fungus forms over time;

- has a limited shelf life.

technical traffic jam

Technical cork is not the most durable and cheap option

The disadvantage of technical cork can be considered the highest price among all materials, the lack of flexibility, on rounded parts you will have to cut and glue pieces that fit the shape, besides, the cork crumbles easily.

Vibroplast, vibroizol

Vibroplast is a fairly durable material that does not require much effort when working.

This material is designed for soundproofing in a car, it is based on bitumen and rubber. It is very convenient to attach mats, because they have an adhesive layer protected by a film or paper. We remove the film, press it to the surface, roll it with a roller for a snug fit, the insulation is ready. You can buy it in car markets and in stores with auto parts. The material is quite flexible, so it fits snugly around the rounded surface of the bath.

Additional pluses:

- vibroisol costs more than polyurethane foam, but cheaper than technical cork;

- it does not absorb moisture;

- withstands temperatures from -45 to +100 ºС.

liquid acrylic

With the help of acrylic, you can not only make soundproofing, but also update the look of the bath.

Another easy way to soundproof a bathtub.This material is applied to the inside of the bowl, resulting in an even, thin coating and a decorative effect. To work, you need two components: a hardener and acrylic enamel. Acrylic has a rather pungent odor, so respiratory protection will be required.

Sequencing:

- Clean off the dirt and rub the inner surface with abrasive powder.

- Degrease and dry the bowl, remove the siphon.

- Pour acrylic in a circle continuously and evenly, it spreads in a layer of 6 mm thick, without bubbles and drips, completely hardens within 2 days.

Advantages of the acrylic layer:

- durability: at least 10 years;

- both white and colored enamels are sold;

- durable, smooth, wear-resistant coating.

Bathroom soundproofing problem

When buying an apartment, the owners pay attention to the shortcomings, including sound insulation. These are not only loud, audible sounds from the street, landing, neighbors' apartments

But also audibility in the bathroom. This can come to light later, while taking a bath, while relaxing you can hear a child playing a computer game or a neighbor watching TV. It is not uncommon to hear the noise of a descending elevator, the voices of animals, or the draining of water from neighbors above.

This does not allow you to comfortably take a bath, relax after a working day. Often drain pipes are not insulated (even in new homes). At night, you can hear the sound of running water or the sound of a cast-iron bathtub filling up.

To carry out the soundproofing process, materials, tools and knowledge of the phased work are needed. Properly made soundproofing will relieve annoying sounds at night and bring comfort and tranquility.

Principles of soundproofing

For cars, two materials are used - vibration isolation and noise isolation.The first dampens all external vibrational noise that is transmitted through the body to the passenger compartment, or vibration from acoustic basses. The second is designed to remove multiple re-reflected sound waves inside the car (echo), to improve the sound of music.

Noise isolation (Splen) and vibration isolation (Vibroplast).

For a structure such as a steel bathtub, vibration isolation is more important, because the bathtub itself is a source of sound. The metal structure vibrates from mechanical influences (jet of water, basins, buckets, etc.), generating an unpleasant sound, and these vibrations must be absorbed.

Impact noise and vibration are damped by materials with low elasticity (bitumen with foil). Noise-insulating materials like foam rubber or isolon do not make sense, since for the effect you need to paste over the inner surface of the bathroom, which is absurd. These materials can only be used outside as a heat insulator.

Cork, polyurethane foam, isolon, splen other budget materials give the effect of thermal insulation, which is also completely absent in steel bowls. They are able to reduce airborne noise, which in this case is absent.

materials

The construction market has a large selection of materials that create sound insulation and insulation. But, for such procedures, materials suitable for rooms with high humidity are needed.

- Mineral (basalt) wool. Does not decompose when exposed to moisture. It also doesn't burn. It has properties to muffle noise and warm the room. To use cotton wool, you need to choose the right waterproofing material.

- polymer membrane. This is a rolled material, up to 4 mm thick.On the one hand sticky, which facilitates installation. When using a membrane, it is worth taking care of the material that will close it.

- Noise dampening panel. Has a mineral filler. Moisture resistant, vapor permeable, which is an important factor. Mounting it is simple. After installation, the seams of the panels are sealed with tape.

- Application of soundproof plaster PalaplasteR-207. It is applied in a layer of 3 cm. It is cement-based and moisture resistant.

Before using the material, you must carefully study the technical specifications.

under tile

Tiles in the bathroom are laid on the walls, floor. Used for soundproofing walls basalt wool thicker than 5 mm, hydrobarrier. Create a metal frame for moisture-resistant drywall sheets. After that, the joints are reinforced, the GKL is puttied, primed.

A membrane, noise-absorbing panels are laid on the floor. After that, a screed is made and the tiles are laid.

On the walls

Roll waterproofing material or bitumen-based mixtures are suitable for walls. Soundproofing material should not rot from moisture. Knauf green gypsum boards.

If sound-absorbing panels are chosen, the joints should be carefully sealed with tape and joint putty.

Cement-based soundproofing plaster does not absorb moisture. Before applying, it is necessary to treat the walls with a bitumen-based mixture.

Finished tongue-and-groove panels ZIPS. This is a combination of gypsum fiber sheets and staple fiberglass.

To the ceiling

For the ceiling, a metal frame is created, into which soundproofing material is inserted. This is mineral wool.

And also a way out of a noisy situation will be the creation of a suspended acoustic ceiling.

For him choose plates of thin fiberglass, mineral fiber.

A metal frame for the ceiling is created using vibration suspensions, a damper tape.

On the floor

When performing soundproofing of the floor, it is necessary to choose a waterproofing material. Basically choose solutions of bitumen and polymers. After treatment with bitumen, the membrane is laid. Joints must be glued with adhesive tape.

For the floor, glass fiber "Shumanet-100" 3 mm is used, as well as "Shumanet-P60" - 20 mm. also lay foam, cork agglomerate, silica fiber. After that, a 6 cm screed is made and tiles are laid or a “warm floor” is created.

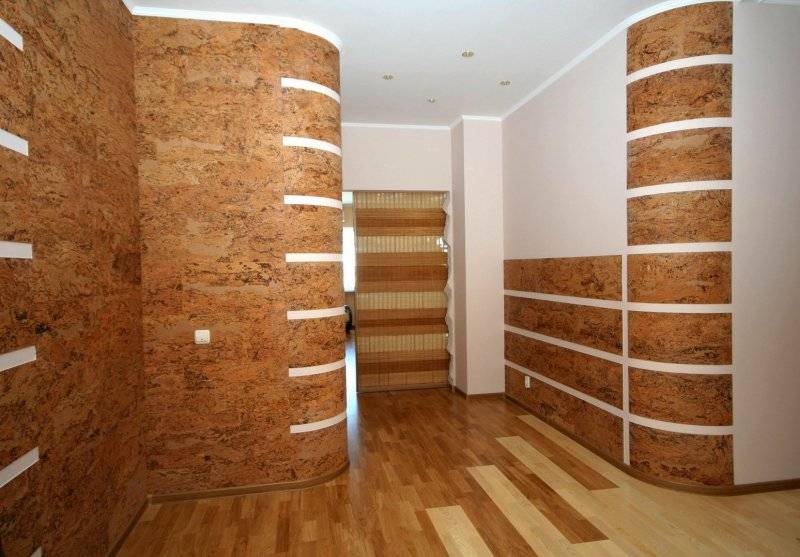

Frameless installation and its nuances

In comparison with the previous method of mounting sound insulation, frameless is utterly simple, but requires serious preparation of the base base. So, beforehand, the wall should be well leveled and treated with a primer so that any next material has excellent adhesion to the wall surface. If this does not happen, then gaps, cracks and joints will inevitably appear, through which sound waves will penetrate into your apartment.

In comparison with the previous method of mounting sound insulation, frameless is utterly simple, but requires serious preparation of the base base. So, beforehand, the wall should be well leveled and treated with a primer so that any next material has excellent adhesion to the wall surface. If this does not happen, then gaps, cracks and joints will inevitably appear, through which sound waves will penetrate into your apartment.  But the rest of you do not need to mess with the profiles. The soundproofing material is glued or fixed directly to the wall surface, and only later the finishing is done.

But the rest of you do not need to mess with the profiles. The soundproofing material is glued or fixed directly to the wall surface, and only later the finishing is done.

In some cases, such as with cork panels, additional finishing is not required.

In some cases, such as with cork panels, additional finishing is not required.

- the wall is leveled with putty and treated with a primer until a perfectly flat and smooth surface is achieved;

- fast contact adhesive is applied - a special adhesive based on polychloropropene is recommended;

- after 5 minutes, the soundproof cork sheet is pressed tightly against the wall;

- each next element is laid tightly to the previous one, the joint overlaps;

- the next row will be performed with an offset of half the sheet.

If the cork is laid in an apartment with high humidity, it is recommended to additionally cover it with varnish with hermetic protection.

If the cork is laid in an apartment with high humidity, it is recommended to additionally cover it with varnish with hermetic protection.

All stages of installation - on video.

All stages of installation - on video.

How to fix soundproof panels?

The so-called soundproof sandwich panels are not so common in modern apartments due to their high cost, but they help to achieve ideal comfort in the room and at the same time are quite easily attached to the wall. To do this, you will need dowels and screws.

- first, the bottom panels are mounted on the wall from the left corner - in the direction up and to the right;

- the bottom row is cut along the short side and the long side, depending on the area of \u200b\u200bthe wall surface of the apartment;

- holes up to 60 millimeters deep are made in the panel with a perforator, dowels are inserted into them and hammered into the wall;

- during installation, a joint of at least 25 millimeters should be observed;

- after all the panels are mounted, it is necessary to go through the joints with a slate, and then fill the seams with sealant.

Another video on the topic of frameless installation of sound insulation.

Varieties of soundproof materials

Various materials are used to soundproof walls from neighbors. Depending on the structure, the insulation can be soft or hard. In each case, a certain type of material is used. When choosing, take into account the source of the noise. This allows you to perform effective soundproofing in the apartment.

Depending on the method of propagation of sound waves, noise is classified into the following types:

- Air. Transmitted through the air. This may be noise pollution from a highway, street, etc.

- Shock.Noise is emitted during the operation of a certain type of tool, such as a jackhammer or perforator.

- Vibrating. This type includes noise from the roadway.

When choosing a material, they take into account what kind of noise the apartment needs to be protected from. So, in order to isolate housing from airborne noise, it is recommended to use the following sound insulation in an apartment from neighbors:

- Mineral wool. It is produced in the form of plates or rolls, which have a fibrous structure. The fibers are arranged randomly, which gives the material high soundproofing properties.

- Glass wool. It is made of fiberglass, located so that air voids form between them. This explains the good soundproofing properties.

- Multilayer panel. A popular modern material, which is a sandwich panel. It consists of sheets of gypsum board and gypsum fiber board with mineral board. The thickness of the panel ranges from 4-13 cm.

How to protect the room from additional noise

To protect the room from impact noise, it is recommended to use materials that can repel sound waves. The best option would be:

- Cork coating. Represents the plates made on the basis of the pressed cork crumb. It is possible to use cork roll wallpaper. The cover is very popular. The only drawback is the high cost.

- Polyethylene foam. It is presented in the form of rolls. It is glued directly to the wall. Polyethylene foam has high soundproofing properties, which allows the use of a coating of small thickness. As a result, the size of the living area practically does not change.

- Extruded polystyrene foam.Very popular and has many advantages. Plates are easy to process and install. Their thickness is 2-5 cm. Due to this, the useful area of \u200b\u200bthe room is preserved.

Sound vibrations are a fairly common problem faced by residents of houses located near busy highways. To eliminate structural noise, experts recommend soundproofing the walls. For this use:

- Fiberglass. It is presented in the form of a roll or tape of a certain width. Due to its elasticity, fiberglass absorbs vibration waves well.

- Vibroacoustic sealant. Used for sealing seams between building structures.

- elastomeric materials. Among the popular options, it is worth highlighting porous rubber and elastic plastic. With their help, they reduce the vibration pressure on the structural elements of the house.

- Silica gaskets. The rolled material is made from environmentally friendly raw materials and has high fire-fighting properties. Used at the joints of structures.

As you can see, the choice of soundproofing materials is quite extensive. To achieve the desired result and create comfortable conditions for living in an apartment, it is necessary to approach this issue correctly. So what are the best materials to use?