- Insulating materials on mineral wool

- Technology of installation of mineral wool boards

- Myths about ceiling soundproofing

- Myth 1. Stretch ceiling reduces noise

- Myth 2. Hanging drywall creates a soundproof air gap.

- Myth 3. Styrofoam and polystyrene foam can be used to soundproof the ceiling

- Sound insulation index of materials in decibels (dB)

- Mineral wool

- Shumanet BM

- noise stop

- Rules for laying mineral wool boards

- Installation of structures

- Membrane use

- Ceiling soundproofing materials

- Mineral wool

- polyurethane foam

- Self-adhesive tape

- Other materials

- Soundproof material Texound

- Mounting technology

- Soundproofing the ceiling under the stretch ceiling

- Installation instructions for ceiling soundproofing under a stretch ceiling

- Sound insulation of the ceiling under the stretch ceiling with the manufacture of the frame

Insulating materials on mineral wool

Products based on basalt mineral wool are used to insulate the ceiling, wall panels. The product shows high sound absorption characteristics, is inexpensive and at the same time has a long service life. It is better to choose not ordinary stone wool, but its more modern options, in particular:

Shumanet BM is a basalt fiber product that belongs to the premium class of sound absorption.One side has a reinforcing layer of fiberglass, which gives strength, protects the inner porous layers, prevents deformation of the sheets and debris from entering the stretched canvas. Dimensions: 1000*500 mm, 1000*600 mm, thickness 50 mm, density 45 kg/m3, 4 pcs per pack. elements, the total area of which is 2.4 m2. Packing weight up to 5.5 kg. The sound absorption coefficient is average (23-27). The material is not combustible, it is resistant to moisture, so the plates can be mounted in bathrooms and other rooms with high levels of humidity and temperature.

Noise stop C2, K2

You should pay attention to the marking, material C2 is more suitable for arranging floor sound insulation. Standard dimensions: 1200*300 mm, 1250*600 mm, thickness 20 mm, density 70-100 kg/m3, area C2 7.5 m2, K2 3.6 m2

The package weight is up to 8.8 kg, the sound absorption coefficient is average, the materials are non-combustible and resistant to moisture. Material marked K2 is made from basalt fiber and is most often used for ceiling work.

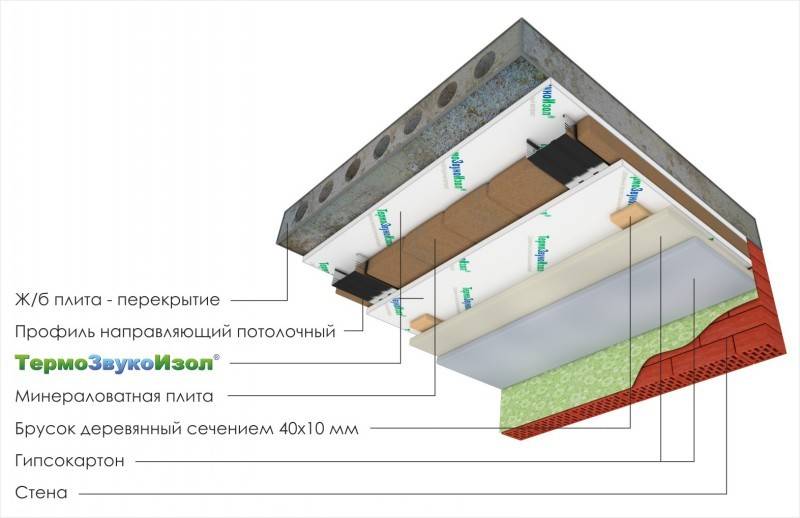

Technology of installation of mineral wool boards

The work algorithm is as follows:

- When laying out the elements between the guides of the frame, markings are first made on the ceiling. Having marked the reference points for mounting the elements, beat off the lines for fastening the frame guides. The fastening step depends on the size of the plates and is up to 550-600 mm.

- The frame can be formed from a wooden beam or a metal profile. If the crate for the insulator is made of a metal profile, it is also pasted over with a soundproof tape.

- Now the acoustic boards are being laid. They need to be pressed tightly to the ceiling. If the laying of sheets is carried out on the crate, then the entire thickness of the frame is filled, laying at a distance between the elements of the crate.

- In the absence of a crate, an adhesive mixture is used: spray, gypsum-based, cement-based mounting adhesive or liquid nails. Plates are glued to the base of the ceiling.

When using a gypsum or cement-based adhesive mixture, it is recommended to additionally fix the mats with dowels with small caps. Fastening through insulation sheets with a depth of 5-6 cm into the ceiling. 5-6 dowels are enough for each sheet.

Using a perforated stretch fabric for lining the ceiling, you should prevent the mineral wool fibers from getting on the fabric. To do this, a membrane or vapor barrier film is laid over the insulator. Mounting on dowels with a small hat. In the same way, the insulation on the crate is closed, only the fastening of the film with staples to the frame elements made of wood or double-sided tape to the metal profile. Once the glue is completely dry, you can stretch the panel.

Myths about ceiling soundproofing

Experienced finishers are often faced with the results of improperly executed noise protection, and the reason for this is common myths about the properties of various materials. Let's consider the most common of them.

Myth 1. Stretch ceiling reduces noise

Stretch ceilings made of PVC film do not in themselves have soundproofing properties. Some effect is given only by the air gap between the ceilings and the canvas of the stretch ceiling. But in some cases, if there are voids, cracks and gaps in the ceilings, the stretch ceiling can play the role of a speaker, several times amplifying the acoustic noise coming from above.

By itself, only a stretch ceiling made of acoustic fabric provides protection from extraneous sounds. It is made of high-strength PVC film, which is perforated.Sound waves are partially reflected from the canvas, and partially, passing through the perforation, change their amplitude and frequency and become imperceptible.

Such a canvas is more expensive than conventional PVC material, while it does not provide full-fledged sound insulation of the ceiling and absorbs mainly the sounds that occur inside the room. To protect against external noise, it is better to use special soundproofing materials laid between the draft and finishing ceilings.

soundproof panels

Acoustic stretch ceiling

Myth 2. Hanging drywall creates a soundproof air gap.

Another type of finish that can conduct sounds is drywall, mounted on hangers and rails without soundproofing gaskets. Such a design is often found in the installation of multi-level stretch ceilings, it has a certain rigidity and perfectly transmits impact noise. At the same time, GKL sheets and a stretch ceiling fabric amplify acoustic noise, like a speaker.

To avoid increased sound transmission, it is necessary to use suspensions with vibration damping for plasterboard structures. GKL sheets are attached to the guides using gaskets made of porous elastic material. Drywall as a sound insulator is used only in multilayer structures made up of materials of different densities.

Vibro suspension for false ceiling

Myth 3. Styrofoam and polystyrene foam can be used to soundproof the ceiling

Expanded polystyrene materials provide excellent impact sound dampening when used in a floating screed. Due to their elasticity, they do not transmit the sound of steps and falling objects. However, when used on the ceiling, they are useless and do not save from acoustic noise. It is possible to use polystyrene foam and polystyrene for sound insulation under a stretch ceiling only as part of a multilayer structure with alternating materials with different sound absorption. With a high ceiling height, it is allowed to use one foam, while its layer should be at least 15-20 cm.

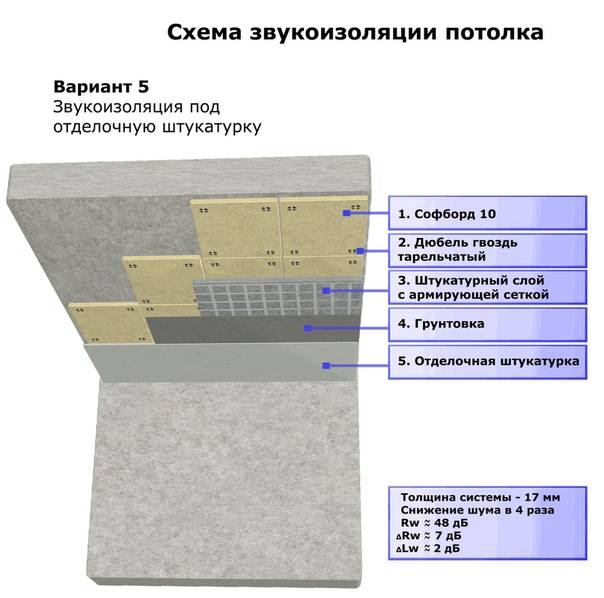

Sound insulation index of materials in decibels (dB)

| Material | Soundproofing index dB |

|---|---|

| Mineral wool | 52 dB |

| Basalt slabs | 60 dB |

| ISOVER Quiet House | 54 dB |

| MaxForte-ECOplate | 55 dB |

| Rockwool Acoustic Butts | 63 dB |

| MDVP (Isoplat) | 30 dB |

| Membrane SoundGuard | 34 dB |

| TermoZvukoIzol | 30 dB |

| MaxForte-SoundPRO | 34 dB |

| SoundGuard Quartz Panel | 37 dB |

| Gyproc AKU-Line | 54 dB |

| ZIPS panels | 12 dB |

| PVC film | 5 dB |

Conclusion

The issue of soundproofing the ceiling is not solved by using one material. In order to achieve acceptable noise reduction, it is recommended to make a soundproofing pie from several materials. Of course, this pleasure is not cheap, but it is better to take care of the silence in advance, even at the stage of repair. After all, even the most luxurious renovation will not please if the neighbors from above are haunted.

Mineral wool

Ordinary mineral wool insulation is used to insulate walls and ceilings. Today, manufacturers offer improved materials that are more practical.

Shumanet BM

The material is made on the basis of basalt fiber, with a hardened side and porous membrane filling. Strengthening is made of fiberglass, so the plates are protected from deformation, retain shape stability throughout the entire service life.

Main characteristics:

- size (cm) 100x50 or 100x60;

- thickness 5 cm;

- the area of the plates (4 pcs.) in the package is 2.4 m2;

- sound absorption coefficient up to 27 dB.

The material belongs to the category of non-combustible, according to the characteristics corresponds to SNiP.

noise stop

The plate product is produced in two types and is marked C2, K2 - the letters matter when choosing a material.

Main characteristics:

| Options | C2 | K2 |

|---|---|---|

| Production material | Hydrophobic staple fiberglass | Basalt fiber |

| Application | Insulation floor insulation | Insulation, ceiling insulation |

| Size (cm) | 125x60 | 120x30 |

| Thickness (cm) | 2 | – |

| Density (kg/m3) | 70 | 90–100 |

| The total area of the boards in the package (m2) | 7,5 | 3,6 |

| Sound absorption coefficient (dB) | 27 | 20 |

Rules for laying mineral wool boards

The soundproofing of the ceiling in the apartment under the stretch ceiling is carried out as follows:

- The base surface is equipped with a crate. The cells are formed in increments of 55 cm. The frame can be wooden or metal. The width of the guides is less than the distance from the base ceiling to the tension web.

- Laying out acoustic material slabs. Lay tightly to the base surface. Under the condition of laying out on a frameless surface, the plates are glued end-to-end. Laying in the frame is carried out with a tight fit between the details of the crate - by surprise.

- The adhesive composition is selected according to the type of ceiling. For concrete - cement, for painted surfaces - spray. After fixing the plates, additionally fix the insulation with dowels - 5 fasteners per sheet.

- Lay a membrane over the boards to reduce the risk of shedding of fibers on the tension fabric. The membrane is fixed to the crate with stapler staples or double-sided tape.

After the glue has dried, the finish is stretched.

Installation of structures

It is not so easy to make a good soundproofing of the ceiling.As a rule, in order to achieve tangible results, it is necessary to mount impressive structures, and the soundproofing material becomes the “stuffing” in them. Installation can be done with your own hands, but if your experience in repair work is not enough, then you should entrust this responsible task to a special team.

Suspension systems are a very popular and reliable way to solve the problem of extraneous sounds. Thanks to them, a cavity appears between the floor slabs and the plasterboard layer of the ceiling, and all the material for sound absorption is placed in it. For greater efficiency behind a suspended ceiling, the resulting niche is filled with a porous material that suppresses sound vibrations. Mineral wool and its derivatives can be called the leader among such materials. Usually its thickness is 50-100 mm.

The problem that arises when using mineral wool is the restriction on the choice of ceiling lights. The reason is that without good ventilation, the space under the ceiling becomes unsuitable for the removal of heat energy. As a result, the lamps emitting it can easily burn out, and if the wiring melts, the situation will become completely fire hazardous. We will have to abandon the recessed fixtures, instead of them it is recommended to install simple chandeliers and overhead fixtures. If you plan to decorate the ceiling with a scattering of spotlights, then take another noise absorber.

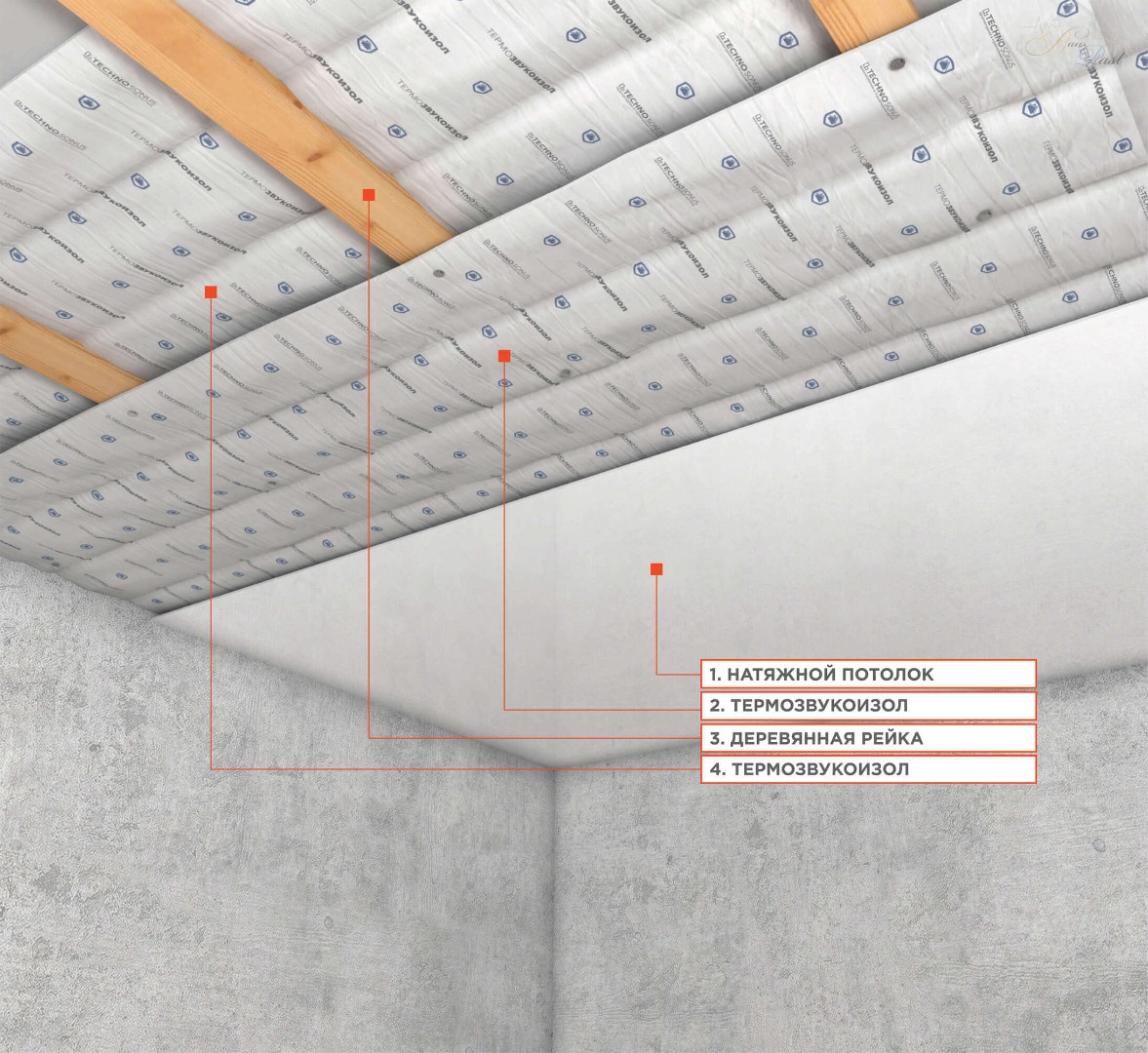

Another method involves mounting the sound absorber on the ceiling and installing it on top of the stretch ceiling structure. Care must be taken to ensure that the cotton particles do not crumble. To do this, use a vapor barrier. Together with cotton wool, it is fixed to an additional frame made of rails or metal.

If you do not want to mount complex structures, then you can try installing an acoustic stretch ceiling. High-quality products of this class are able to neutralize noise from neighbors by 90% of sounds. These designs include three layers. These are special basalt mini-slabs, canvas with micro-holes and membrane properties and baguettes. The installation of an acoustic ceiling begins with the fastening of the minplates, and then proceeds according to the usual scheme - a baguette is installed, and then the decorative canvas itself is distributed using a gas gun.

Membrane use

The canvas of this modern material has a thickness of only 3-5 mm, while it is able to absorb 20-25 dB of sound. The membrane is especially good for dampening low frequencies, and can be combined with any other materials. Its installation looks specific, so we will talk about it separately. Note that it will not be easy to mount this coating alone, since it has a fairly large weight.

- A crate made of timber 20x30mm is attached to the ceilings with self-tapping screws.

- In order not to hold the membrane with your hands, it is fixed under the ceiling with hooks and thin tubes.

- Now it can be attached with self-tapping screws to the crate with the second row of a wooden beam.

- Seams between sheets and technological cutouts are glued with a special tape.

Ceiling soundproofing materials

Deciding how to soundproof ceiling, you must first decide on the material. There are several methods to isolate your ceiling from extraneous sounds, and for each of them there is an optimal solution in terms of material.

First of all, materials for soundproofing the ceiling must, obviously, effectively absorb sound. In addition, they must protect the ceiling from the oscillating effects of the sound wave.

In other words, the material should be chosen:

- soundproof - that is, having sufficient mass to reflect sound without creating vibrations and secondary noise;

- sound-absorbing - that is, having a porous structure that “slows down” sound due to friction.

Soundproofing panels with sound-absorbing “stuffing”, finished with massive material on the outside, are best suited for soundproofing the ceiling.

In addition, you should pay attention to such properties of the material for soundproofing the ceiling in the apartment, such as:

- thickness;

- the weight;

- combustibility;

- environmental friendliness, that is, the absence of harmful substances in the composition.

The modern materials most commonly used in urban apartments for do-it-yourself ceiling soundproofing should be considered in detail.

Mineral wool

As before, when equipping ceilings in an apartment, perhaps the most popular material for soundproofing can be called mineral wool, which, however, can only be used in a room with a high ceiling, because. significantly (up to twenty centimeters) reduces the ceiling line.

At the same time, cotton wool effectively absorbs sound, has good fire-retardant properties, does not shrink, and is convenient for installation. However, the large thickness is not its only drawback. The main disadvantage is the negative impact on human health, which necessitates the use of high-quality insulating material. Therefore, soundproofing ceilings with its help is not the best option.

Mineral wool

polyurethane foam

The next widely used soundproofing for the ceiling is polyurethane foam. It is distinguished by its high density and good sound-absorbing ability, thanks to which it will not only protect the residents of the apartment from neighboring noise, but also provide the opposite effect. However, PPU has a serious drawback - when ignited, it forms highly toxic smoke.

polyurethane foam

Self-adhesive tape

A good option would be soundproofing on the ceiling with self-adhesive sealing tape. In addition to protecting the ceiling of the apartment from noise from above, it also has thermal insulation functions. In addition, the material made from environmentally friendly raw materials does not pose a health hazard.

Sealing self-adhesive tape

Other materials

Highly environmentally friendly methods of soundproofing the ceiling include the use of materials such as:

- cork and other natural raw materials (vegetable fiber, peat);

- soundproof wood fiber ceiling panels.

Regarding cork insulation, we can say the following: with all the consumer love for this natural material and with all its undoubted aesthetics, the soundproofing qualities of cork are low. So, it will not save you from noise of a non-percussive nature (loud music, talking in raised tones, etc.)

In addition, when applying it, it is important to consider what type of flooring the neighbors have on the floor from above - only concrete screed and laminate are suitable here.

Finally, the soundproofing of the ceiling in the apartment can be equipped with foam glass, reed tiles, etc.

Soundproof material Texound

This is a new product that is not yet particularly known to the buyer, but if you see it, be sure to pay attention - the material has a lot of useful qualities and has numerous advantages in a number of similar products. The main plus is a small thickness, which means that the sheets can be mounted in small rooms with low ceilings.

At the same time, the product has high density indicators, scatters and absorbs sounds, and even waves of high intensity. The coating protects from sound from the outside and does not let internal noise out, that is, you yourself can listen to loud music and at the same time not disturb your neighbors. The material is produced in rolls, sheets, polyethylene packaging.

Main characteristics:

- density up to 1900 kg/m3;

- sound absorption coefficient 25-30;

- flammability G2;

- ultimate elongation at stretching not more than 300%.

In the manufacture of plasticizers, spunbond, aragonite, polyolefins are used.

Product advantages:

- Resistant to temperature changes. The material does not change its quality indicators at -20C.

- Structural elasticity. Visually, the material resembles dense rubber.

- Resistance to water and fungi, mold, parasites makes the product indispensable in conditions of high humidity.

- The duration of operation is unlimited.

- The size range is wide, products are complemented by a foil layer, self-adhesive surface or felt. It all depends on the type of product.

Products are combined with any insulating materials, increasing and supplementing their useful properties. Installation of all types of products on Homakoll adhesive, which is sold in 8 l canisters.

Mounting technology

Soundproofing is installed under a stretch ceiling on any base - concrete, wood, brick, metal, plastic, plasterboard

It is important to carefully prepare the ceiling for fixing Teksaund: level, prime and you can fix the sheets as the only insulator or in combination with other materials

The first mounting option is the choice of Texound as the only insulator.

Installation is carried out on the adhesive composition:

- apply glue to the surface of the insulator and the ceiling;

- let the composition grab for about 15-20 minutes;

- press the canvas to the base;

- installation with an overlap of 4-5 cm;

- after installation at the junction, make an even cut, align the edges and weld them with a gas burner or a building hair dryer;

- it is allowed to glue the canvas with liquid nails or sealant;

- self-adhesive sheets are applied to the base with the adhesive side, from which the protective layer is removed;

- after gluing, the sheets are additionally pressed with dowels with small caps through to the ceiling, the fastening step is 3.5-5 cm.

To facilitate the process, sheet and roll elements are cut into small pieces, large pieces are difficult to lift to the ceiling. The second installation option is the formation of insulation on a false ceiling. It is used in rooms with a high height, carried out before the stage of placing the guides for the panel.

Work algorithm:

- Form the frame of the crate. The stages of work are described above.

- Glue Texound on the GKL sheets. It is better to do this on a large table or on the floor.

- Fix the plasterboard with the insulator on the frame with self-tapping screws. Fastener pitch 10-12 cm.

- Seal the joints between the pieces of canvas with sealant or weld with a building hair dryer.

- Now you can install guides for arranging the stretch fabric.

There is a third option, when Texound is also glued to the ceiling, then fastened with dowels. The next stage is the formation of a frame from a profile of a metal or wooden beam. And then sheets of mineral wool are laid on the crate (Shumanet, Shumostop). Sew up the frame on top of the plasterboard, then make a stretch ceiling. Such turnkey ceiling soundproofing will eliminate any sounds both from the outside and will not let them through outside the apartment.

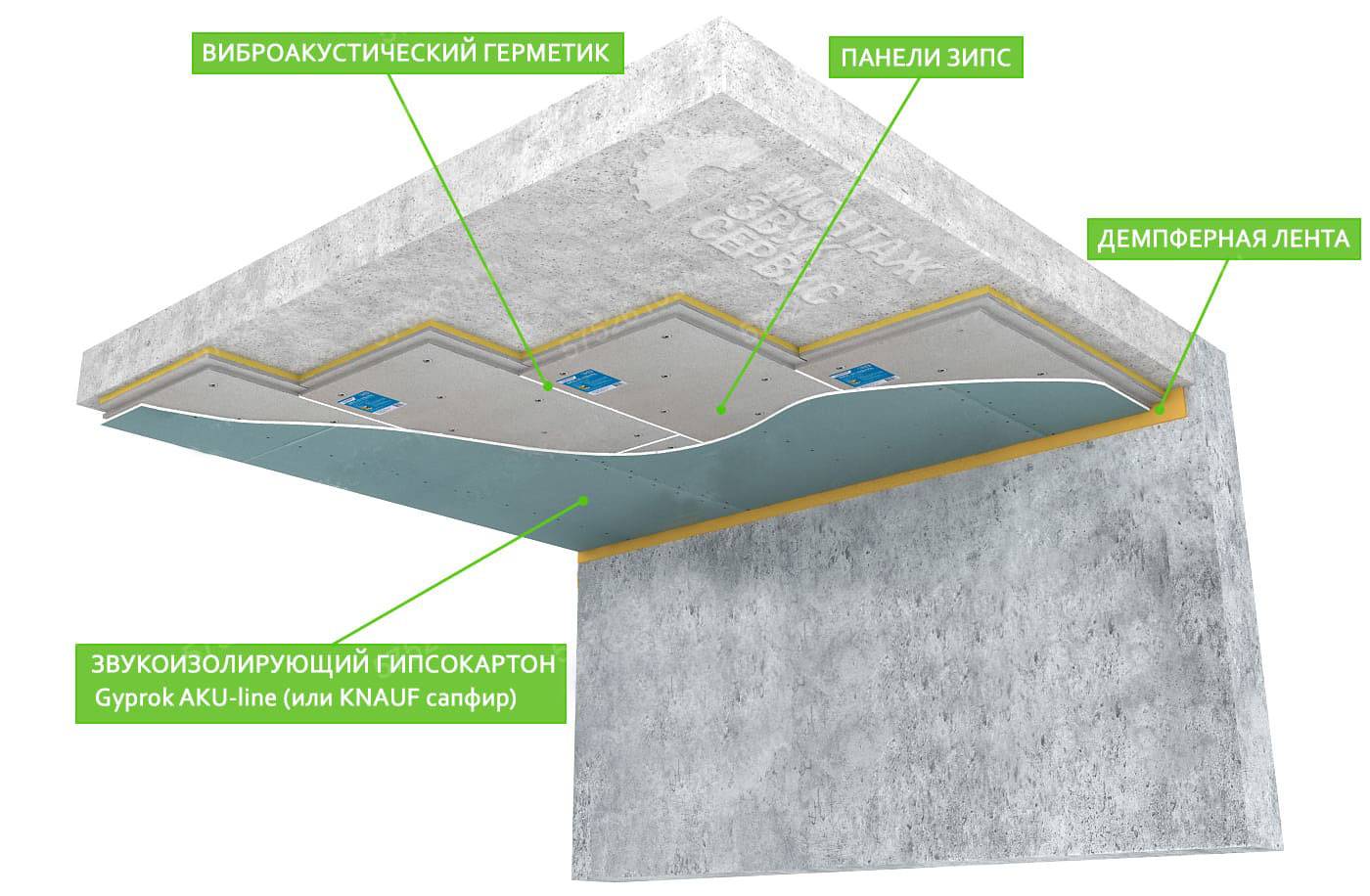

Soundproofing the ceiling under the stretch ceiling

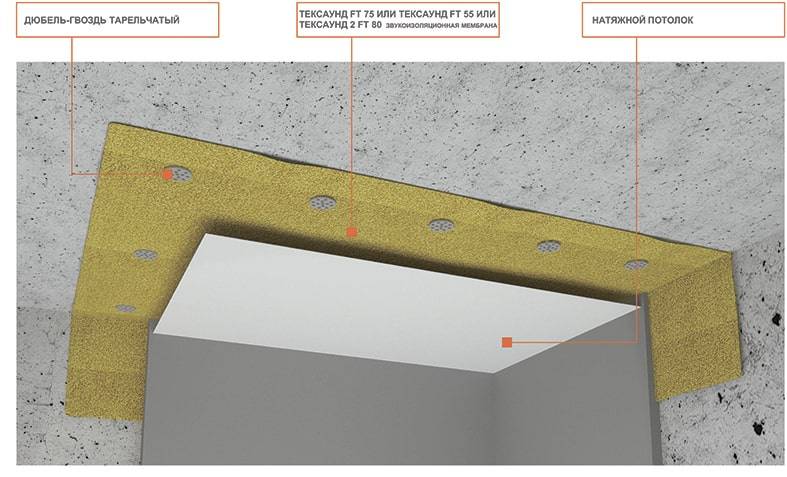

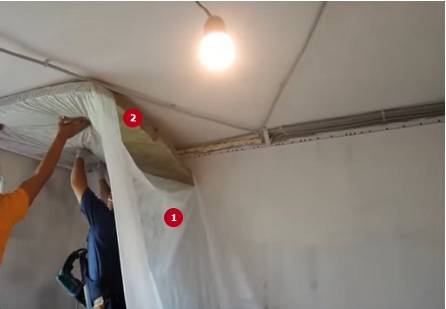

The problem of noisy neighbors cannot always be solved with acoustic tension systems. The best solution is the soundproofing of the ceiling under the stretch ceiling. This will provide protection against impact noise. Additional soundproofing of the stretch ceiling in the apartment is carried out by installing soundproof mats mounted directly to the base of the ceiling. The picture shows the fastening of the soundproofing of the stretch ceiling in the apartment. CLIPSO ACOUSTIC speaker system selected.

The kit includes: (1) - acoustic sheet, (2) acoustic mats covered with a vapor barrier film, (4) - fixing plastic dowel umbrellas, (3) - wall profile.

Installation instructions for ceiling soundproofing under a stretch ceiling

Before fixing soundproof mats to a concrete slab, work is done to clean up the old lining, lay communications (electrics, ventilation ducts).

Before mounting the wall profiles, mark the slots (1) so as not to damage the wiring. Seal the gaps between the ceiling and the wall with mounting foam, this will create a damping soundproof layer.

Installation of profiles is carried out with the application of glue on the side adjacent to the wall.

After installing the profiles around the perimeter of the room, they begin to install the sound insulation of the stretch ceiling with acoustic mats with vapor barrier. In addition to vapor barrier functions, the film protects the ingress of small particles on the canvas.

Fasten the acoustic panel with 4-5 plastic dowels with wide caps. This is what the room looks like after installing the soundproofing of the ceiling in the apartment under the stretch ceiling with soundproof panels.

It remains to stretch the acoustic canvas. This is what the ceiling looks like after installing sound insulation under the stretch ceiling in the apartment.

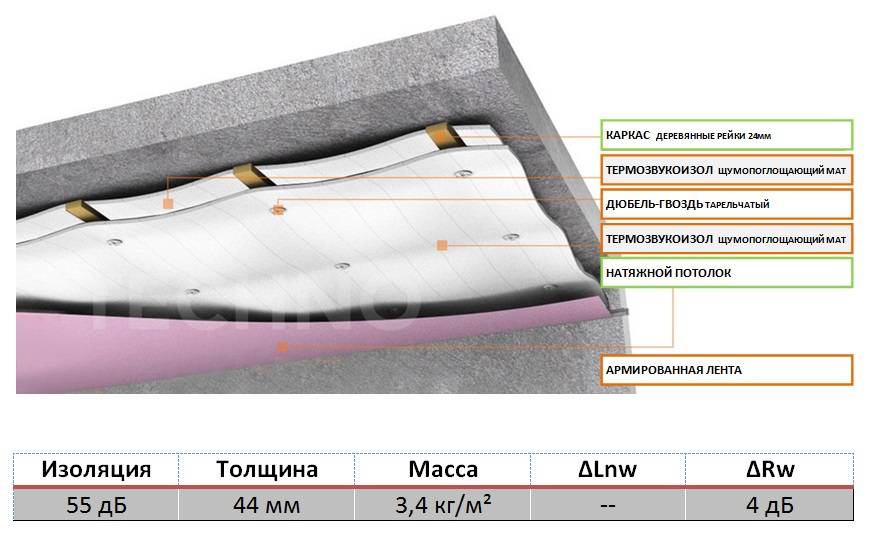

This method of soundproofing is called frameless. Consider another method that is suitable for both soundproofing stretch ceilings and soundproofing suspended ceilings - this is a frame method. This method performs sound insulation and thermal insulation at the same time.

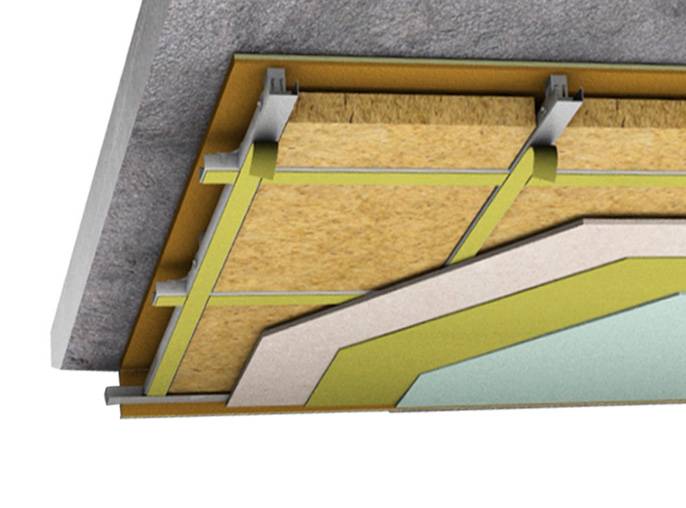

Sound insulation of the ceiling under the stretch ceiling with the manufacture of the frame

The method is based on the installation of a frame, inside which a soundproof material is laid. Before mounting the frame, the floor is prepared: the old finish is cleaned, irregularities and cracks are puttied. Then a damping soundproof tape is glued along the perimeter of the wall.

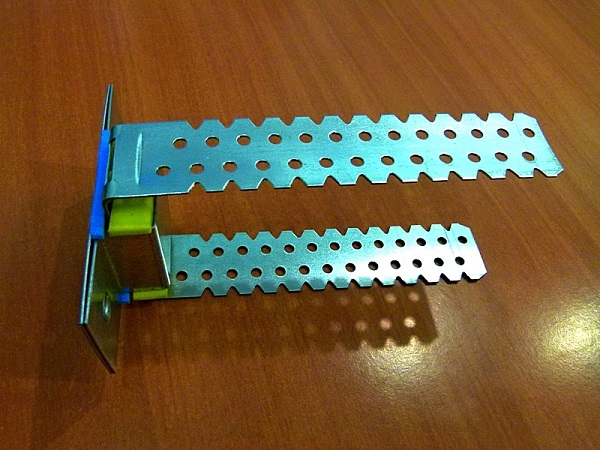

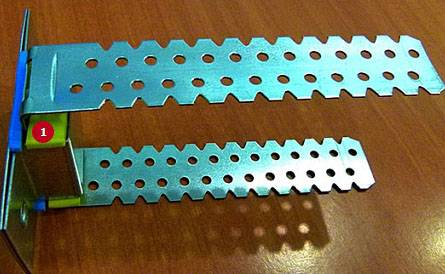

Glue "Vibrosil", on which the soundproofing tape is glued, together form a damping layer separating the ceiling panels and the wall. The damper (anti-vibration) suspension, shown in the picture, dampens floor vibrations. Hangers are attached to a concrete slab to the width of the soundproof panels.

After mounting the damper suspensions (1), profiles are screwed to them, between which sound insulation materials are laid.

Here (1) is the anti-vibration suspension. (2) - ceiling metal profile. (3) - damper tape.After installing the profiles, soundproof sheets "SCHUMANET" are laid between them. GCR is attached to the profiles with self-tapping screws.

GKL - (1), soundproofing - (2), trimming the visible part of the soundproofing tape - (3). The installation height of the profiles is horizontally adjustable. The height of the ceiling with this installation will be shortened by 8-15 mm. Next comes the finishing work, priming, leveling the seams, putty, painting or wallpapering. If the height allows, then the finish is not performed. GCR is decorated with a stretch ceiling.

In a private house, the soundproofing of the ceiling in an apartment under a stretch ceiling is carried out by mounting a frame of 50x50 mm bars between the floor beams or directly on the old ceiling. For better insulation of the sleeping area, a single wooden frame is made, as shown in the picture.

Vertical wooden posts (1) - board 50 x 100 mm, (2) - horizontal beam, (3) - ceiling lathing. The wooden fibrous structure of the beam dampens impact noise. There are several options for soundproofing:

- Laying in the crate of sound insulation with subsequent sheathing of the frame with GKVL sheets;

- Sheathing with GKVL sheets only walls, followed by the installation of a stretch ceiling;

- Sheathing the frame only with GKVL sheets, without installing sound-proofing materials, since gypsum board sheets with a fibrous structure are themselves excellent sound-proofing materials.

Instead of the traditional GKVL, soundproofing sheathing for a stretch ceiling is made with fiberboard sheets, PVC panels, wooden siding, eurolining ...

Advice. Do not forget that sound insulation, like thermal insulation, lose their technical characteristics if the material gets wet.When soundproofing a stretch ceiling in an apartment with high humidity, take care of vapor barrier.