- Buy or do it yourself?

- What capabilities are attributed to the hydroseparator

- What is a hydraulic arrow for heating?

- The principle of operation of the hydraulic separator

- Operating modes

- Additional features of the hydraulic gun

- Why do you need a hydraulic arrow in the heating system?

- On what principle does a hydraulic gun work?

- Why reduce the vertical speed in a hydraulic gun?

- How to find out that you need a hydraulic gun?

- Benefits of using hydraulic guns.

- How to choose?

- Schemes for self-manufacturing of hydraulic arrows

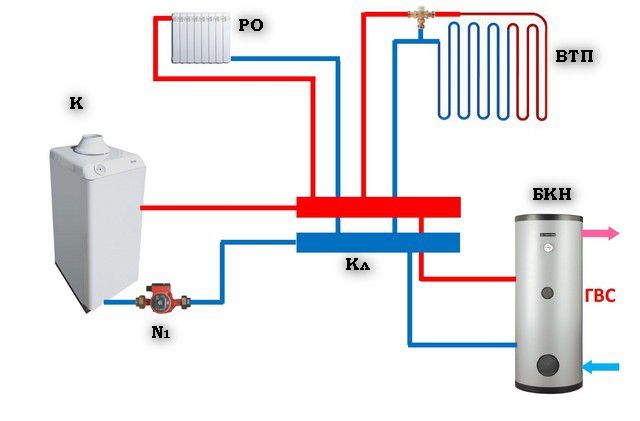

- How is the collector combined with a hydraulic arrow?

- The purpose of the water gun - what is it for

Buy or do it yourself?

Ready as they say hydraulic arrow for heating costs a lot - $ 200-300, depending on the manufacturer. To reduce costs, there is a natural desire to do it yourself. If you know how to cook, no problem - you bought the materials and did it. However, the following points must be taken into account:

- The carving on the sleds should be well cut and symmetrical.

- The walls of the outlets are of the same thickness.

The quality of a homemade product may be “not very”

Like obvious things. But you will be surprised how difficult it is to find four normal spurs with a normally made carving. Further, all welds must be of high quality - the system will work under pressure.The shanks are welded strictly perpendicular to the surface, at the right distance. In general, this is not such an easy task.

If you yourself do not know how to use a welding machine, you will have to look for a contractor. Finding him is not at all easy: either they ask for expensive services, or the quality of work, to put it mildly, is “not very good”. In general, many people decide to buy a water gun, despite the considerable cost. Moreover, recently, domestic manufacturers do not worse, but much cheaper.

What capabilities are attributed to the hydroseparator

Among heating engineers, there are diametrically opposed opinions about the need to install hydraulic arrows in heating systems. Fuels are added to the fire by the statements of hydraulic equipment manufacturers, promising an increase in the flexibility of setting operating modes, an increase in efficiency and heat transfer efficiency. To separate the wheat from the chaff, let's first look at the absolutely groundless claims about the "outstanding" abilities of hydraulic separators.

The efficiency of the boiler installation does not depend in any way on the devices installed after the boiler connecting pipes. The useful effect of the boiler is entirely contained in the conversion capacity, that is, in the percentage of heat released by the generator to the heat absorbed by the coolant. No special strapping methods can increase the efficiency, it depends only on the surface area of the heat exchanger and the correct choice of the coolant circulation rate.

The multi-mode, which is allegedly provided by the installation of a hydraulic gun, is also an absolute myth.

The essence of the promises boils down to the fact that in the presence of a hydraulic switch, three options for the ratio of consumption in the generator and consumer parts can be implemented.

The first is absolute flow equalization, which in practice is just possible only if there is no shunting and there is only one circuit in the system. The second option, in which the flow in the circuits is greater than through the boiler, supposedly provides increased savings, however, in this mode, the supercooled coolant inevitably enters the heat exchanger, which gives rise to a number of negative effects: fogging of the internal surfaces of the combustion chamber or temperature shock.

There are also a number of arguments, each of which represents an incoherent set of terms, but in essence does not reflect anything specific. These include improving hydrodynamic stability, increasing the service life of equipment, controlling temperature distribution, and others like them.

You can also find the statement that the hydraulic separator allows you to stabilize the balancing of the hydraulic system, which in practice turns out to be the exact opposite. If, in the absence of a hydraulic arrow, the reaction of the system to a change in the flow in any part of it is inevitable, then in the presence of a separator, it is also absolutely unpredictable.

Real scope

Nevertheless, the thermohydraulic separator is far from being a useless device. This is a hydraulic device and the principle of its operation is described in sufficient detail in the special literature. The water gun has a well-defined, albeit rather narrow, scope.

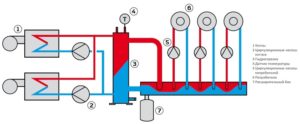

The most important benefit of a hydraulic separator is the ability to coordinate the operation of several circulation pumps in the generator and consumer parts of the system. It often happens that the circuits connected to a common collector node are supplied with pumps whose performance differs by 2 or more times.

The most powerful pump at the same time creates a pressure difference so high that the coolant intake by the other circulation devices is impossible. Several decades ago, this problem was solved by the so-called washer - artificially lowering the flow in consumer circuits by welding metal plates with different hole diameters into the pipe.

The hydraulic arrow shunts the supply and return lines, due to which the vacuum and excess pressure in them are leveled.

The second particular case is the excessive boiler capacity in relation to the consumption of distribution circuits. This situation is typical for systems in which a number of consumers do not work on a permanent basis. For example, an indirect heating boiler, pool heat exchanger and heating circuits of buildings that are heated only occasionally can be linked to the general hydraulics.

Installing a hydraulic arrow in such systems allows you to maintain the nominal power of the boiler and the circulation rate all the time, while the excess of the heated coolant flows back into the boiler. When an additional consumer is turned on, the difference in costs decreases and the excess is no longer directed to the heat exchanger, but to an open circuit.

The hydraulic arrow can also serve as a collector of the generator part when coordinating the operation of two boilers, especially if their power differs significantly.

An additional effect from the operation of the hydraulic arrow can be called the protection of the boiler from temperature shock, but for this, the flow in the generator part must exceed the flow in the consumer network by at least 20%. The latter is achieved by installing pumps of appropriate capacity.

What is a hydraulic arrow for heating?

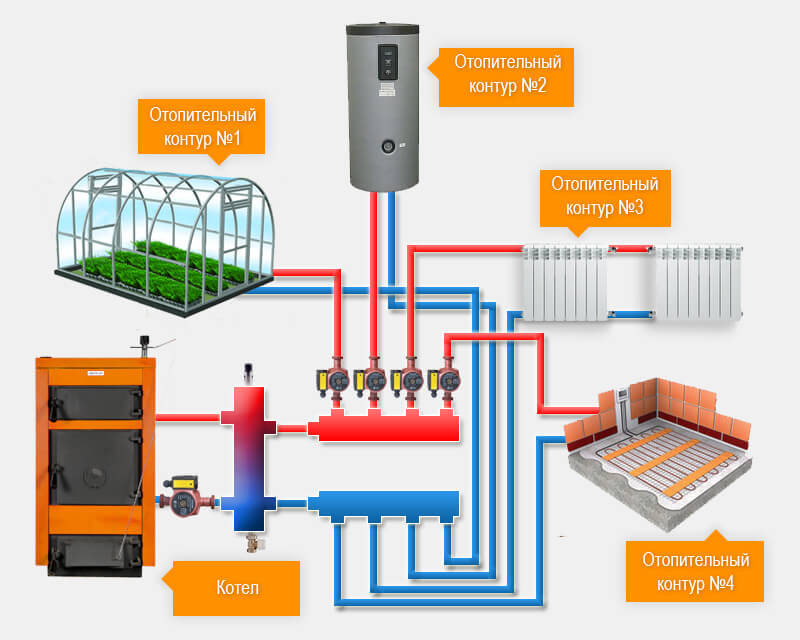

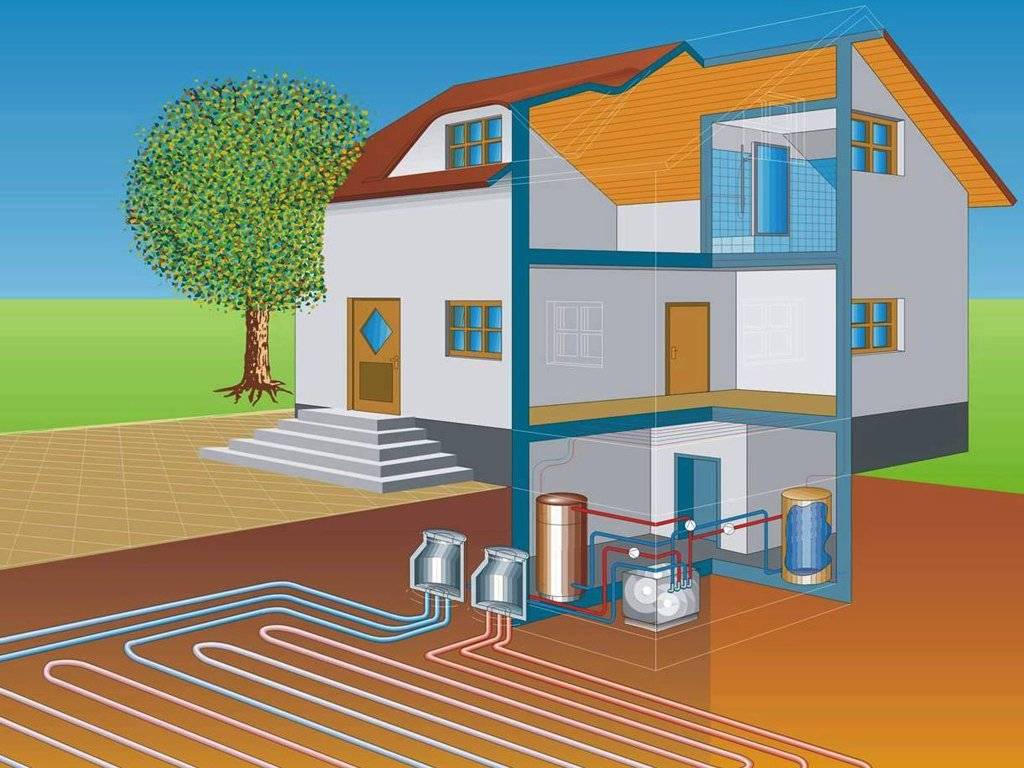

In complex branched heating systems, even oversized pumps will not be able to match the different parameters and operating conditions of the system. This will negatively affect the functioning of the boiler and the service life of expensive equipment. In addition, each of the connected circuits has its own pressure and performance. This leads to the fact that the entire system cannot work simultaneously.

Even if each circuit is provided with its own circulation pump, which will meet the parameters of a given line, the problem will only get worse. The whole system will become unbalanced, because the parameters of each circuit will differ significantly.

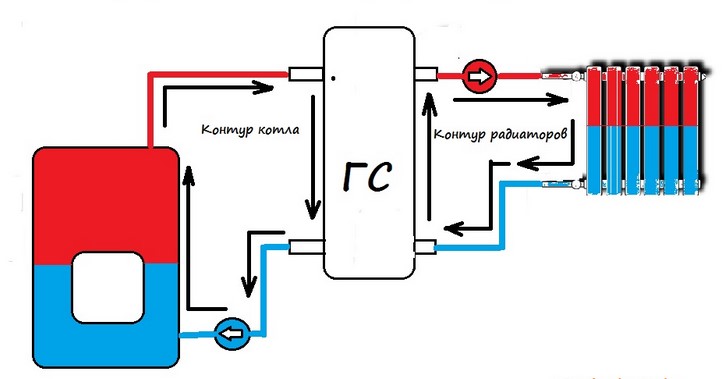

To solve the problem, the boiler must produce the required volume of coolant, and each circuit must take exactly as much as it needs from the collector. In this case, the collector performs the functions of a hydraulic system separator. It is in order to isolate the “small boiler” flow from the general circuit that a hydraulic separator is needed. Its second name is a hydraulic arrow (GS) or a hydraulic arrow.

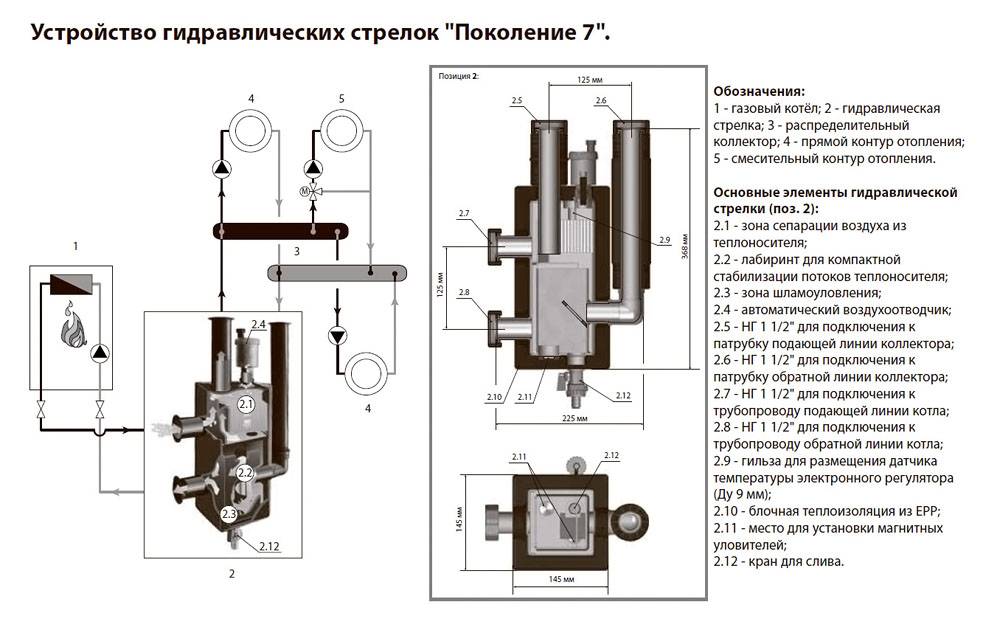

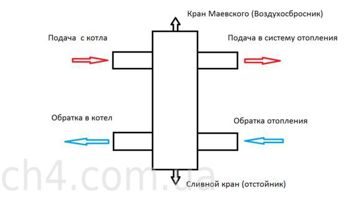

The device received this name because, just like a railway switch, it can separate the coolant flows and direct them to the desired circuit.This is a rectangular or round tank with end caps. It connects to the boiler and manifold and has several embedded pipes.

The principle of operation of the hydraulic separator

The coolant flow passes through the hydraulic separator for heating at a speed of 0.1-0.2 meters per second, and the boiler pump accelerates the water to 0.7-0.9 meters. The speed of the water flow is damped by changing the direction of movement and the volume of the passing fluid. In this case, heat loss in the system will be minimal.

The principle of operation of the hydraulic arrow is that the laminar movement of the water flow practically does not cause hydraulic resistance inside the body. This helps to maintain the flow rate and reduce heat loss. Such a buffer zone separates the consumer chain and the boiler. This contributes to the autonomous operation of each pump without disturbing the hydraulic balance.

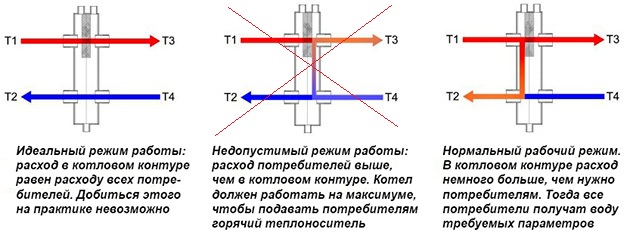

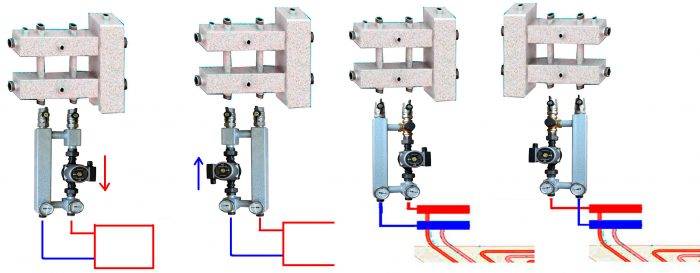

Operating modes

The hydraulic arrow for heating systems has 3 modes of operation:

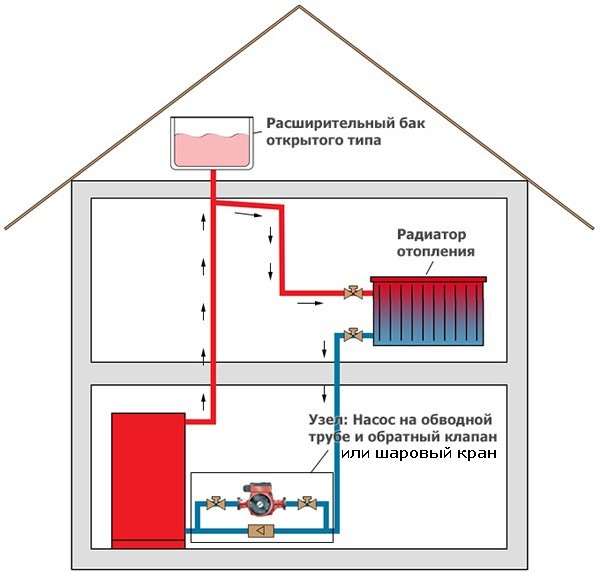

- In the first mode, the hydraulic separator in the heating system creates equilibrium conditions. That is, the flow rate of the boiler circuit does not differ from the total flow rate of all circuits that are connected to the hydraulic arrow and the collector. In this case, the coolant does not linger in the device and moves through it horizontally. The temperature of the heat carrier at the inlet and outlet pipes is the same. This is a rather rare mode of operation in which the hydraulic gun does not affect the operation of the system.

- Sometimes there is a situation when the flow rate on all circuits exceeds the performance of the boiler. This happens at maximum fluid flow by all circuits at once. That is, the demand for heat carrier exceeded the capacity of the boiler circuit.This will not stop or unbalance the system, because a vertical upward flow will form in the hydraulic arrow, which will ensure the admixture of hot coolant from the small circuit.

- In the third mode, the thermometer for heating works most often. In this case, the flow rate of the heated liquid in the small circuit is higher than the total flow rate in the collector. That is, demand in all circuits is lower than supply. This will also not unbalance the system, because a vertical downward flow is formed in the device, which will ensure that excess liquid is discharged into the return.

Additional features of the hydraulic gun

The principle of operation of the hydraulic separator in the heating system described above allows the device to realize other possibilities:

After entering the separator body, the flow rate decreases, which leads to the settling of insoluble impurities contained in the coolant. To drain the accumulated sediment, a crane is installed in the lower part of the hydraulic gun.

By reducing the speed of the ceiling, gas bubbles are released from the liquid, which are removed from the device through an automatic air vent installed in the upper part. In fact, it performs the functions of an additional separator in the system

It is especially important to remove gas at the outlet of the boiler, because when the liquid is heated to high temperatures, gas formation increases.

The hydraulic separator is very important in systems with cast iron boilers. If such a boiler is connected directly to the collector, then the ingress of cold water into the heat exchanger will lead to the formation of cracks and failure of the equipment.

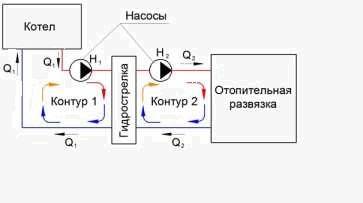

Why do you need a hydraulic arrow in the heating system?

In a heating system, a hydraulic arrow is a link between two separate heat transfer circuits and it completely neutralizes the dynamic influence between the circuits. She has two purposes:

- firstly, it eliminates the hydrodynamic influence, when turning off and on some circuits in the heating system, on the entire hydrodynamic balance. For example, when using radiator heating, underfloor heating and boiler heating, it makes sense to separate each flow into a separate circuit in order to exclude influence on each other. (see )

- the second - with a small flow rate of the coolant - it should receive a large flow rate for the second, artificially created circuit. For example, when using a boiler with a flow rate of 40 l / min, the heating system turns out to be 2-3 times more in flow (consumes 120 l / min). In this case, it is advisable to install the first circuit as the boiler circuit and install the heating decoupling system as the second circuit. In general, it is not economically feasible to accelerate the boiler more than it is provided by the boiler manufacturer, in this case, the hydraulic resistance also increases, it either does not provide the required flow rate, or increases the fluid movement load, which leads to increased pump power consumption.

On what principle does a hydraulic gun work?

The circulation of the coolant in the primary circuit is created using the first pump. The second pump creates circulation through the hydraulic arrow in the second circuit. Thus, the coolant is mixed in the hydraulic arrow. If the flow rate in both circuits is the same for us, then the coolant freely penetrates from circuit to circuit, creating, as it were, a single, common circuit.In this case, no vertical movement is created in the hydraulic gun, or this movement is close to zero. If the flow rate in the second circuit is greater than in the first circuit, then the coolant moves from bottom to top in the hydraulic arrow and, with an increased flow rate in the first circuit, from top to bottom.

Calculating and adjusting the hydraulic arrow, you need to achieve a minimum vertical movement. Economic calculation shows that this movement should not exceed 0.1 m/s.

Why reduce the vertical speed in a hydraulic gun?

The hydraulic arrow also serves as a sump for debris in the system; at low vertical speeds, the garbage gradually settles in the hydraulic arrow, being removed from the heating system.

Creation of natural convection of the coolant in the hydraulic arrow, so the cold coolant goes down, and the hot one rushes up. Thus, the necessary temperature difference is created. When using a warm floor, it is possible to obtain a lower temperature of the coolant in the secondary circuit, and a higher temperature for the boiler, ensuring rapid heating of the water.

Reducing the hydraulic resistance in the hydraulic arrow,

Separation of microscopic air bubbles from the coolant, thereby removing it from the heating system through the air vent.

How to find out that you need a hydraulic gun?

As a rule, a hydraulic arrow is installed in houses with an area of \u200b\u200bmore than 200 sq.m. in those houses where the heating system is complex. Where the distribution of the coolant into several circuits is used. It is desirable to make such circuits independent of others in the general heating system.The hydraulic arrow allows you to create a perfectly stable heating system and distribute heat throughout the house in the right proportions. When using such a system, the distribution of heat along the contours becomes accurate and deviations from the set parameters are excluded.

Benefits of using hydraulic guns.

Protection of cast iron heat exchangers eliminating thermal shock. In a conventional system, without the use of a hydraulic arrow, a sharp increase in temperature is created when some branches are turned off and the subsequent arrival of an already cold coolant. The hydraulic arrow gives a constant boiler flow, reducing the temperature difference between supply and return.

Increases the durability and reliability of boiler equipment due to stable operation without temperature fluctuations.

Lack of imbalance and creation of hydraulic stability of the heating system. It is the hydraulic arrow that allows you to increase the additional flow rate of the coolant, which is very difficult to achieve by installing additional pumps.

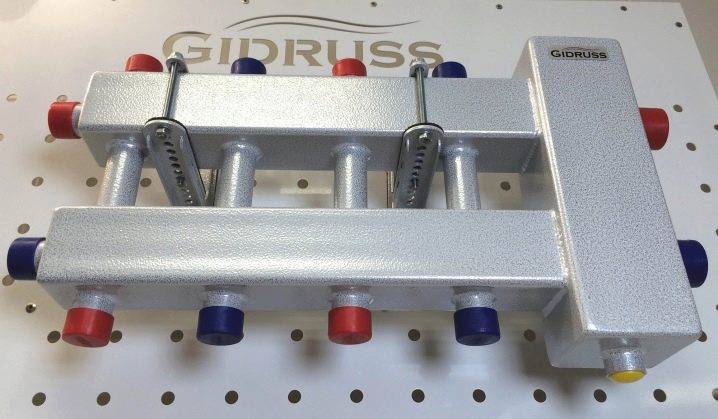

How to choose?

To select a hydraulic separator, you need to know what types they are and what are the parameters in your heating system.

Hydroseparators are classified according to the following criteria:

- the cross section is round or square;

- according to the method of supply / removal of the heat carrier;

- by the number of nozzles;

- by volume.

The country of manufacture of the device is also important. It can be Russia, the CIS countries and neighboring countries. However, all products have a similar scheme.

For example, we will give the marking of hydraulic arrows of the Hydruss trademark:

- GR-40-20 - purpose - for boilers with a capacity of up to 40 kilowatts with a connecting pipe size of three quarters;

- GR-60-25 - for boilers with a boiler power of up to 60 kilowatts with a connecting pipe size of one inch"

- TGR-40-20×2 - for boilers with a capacity of up to 40 kilowatts with a connecting pipe size of three quarters;

- TGR-60-25×2 - for boilers with a capacity of up to 60 kilowatts for two consumers with a connecting pipe size of one inch.

In the last two markings of the circuits in the heating system, there may be not two, but more. Note that hydraulic separators have different capacity, and this parameter also directly depends on the power of the boiler.

The more coolant passes through it, the wider the passage in the hydraulic arrow and the larger its volume.

The material of manufacture is also important.

Structural steel devices are also characterized by good performance parameters. But polypropylene products are not suitable for all boilers, as we indicated above.

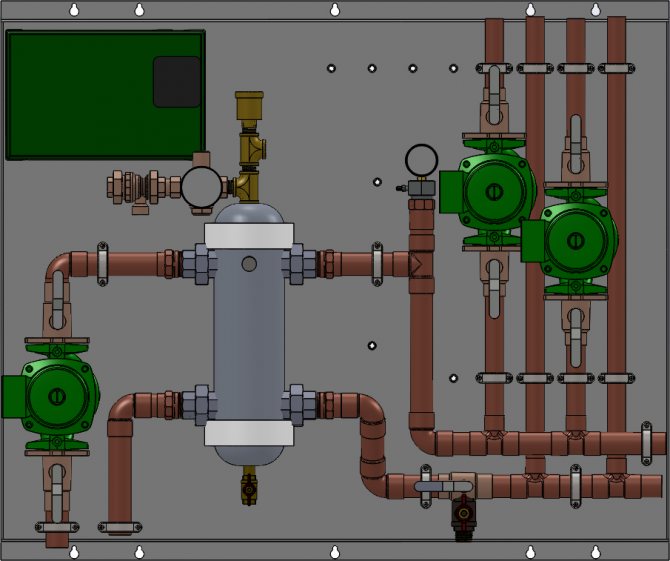

Schemes for self-manufacturing of hydraulic arrows

When assembling a hydraulic gun with your own hands, the main thing is to correctly make calculations and have the skills to work with a welded machine.

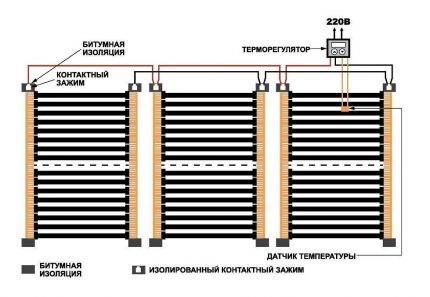

First of all, it is necessary to find the optimal dimensions of the hydraulic separator:

- inner diameter: divide the sum of all heating boiler capacities in kW by the temperature difference between supply and return, take the square root of the resulting parameter, and then multiply the last value by 49;

- height: multiply the inner diameter by six.

- nozzle spacing: multiply the inside diameter by two.

Based on the parameters obtained, you need to draw up a drawing or use one of the diagrams of the future hydraulic distributor presented by the Plumber Portal resource.After that, you need to prepare a steel tube of round or square section, which corresponds to the calculated indicators, and weld into it the required number of pipes with threaded connections.

Despite the simplicity of the device, the characteristics of the hydraulic arrow must still correspond to specific conditions. Also, with self-assembly, you need to understand what to build on.

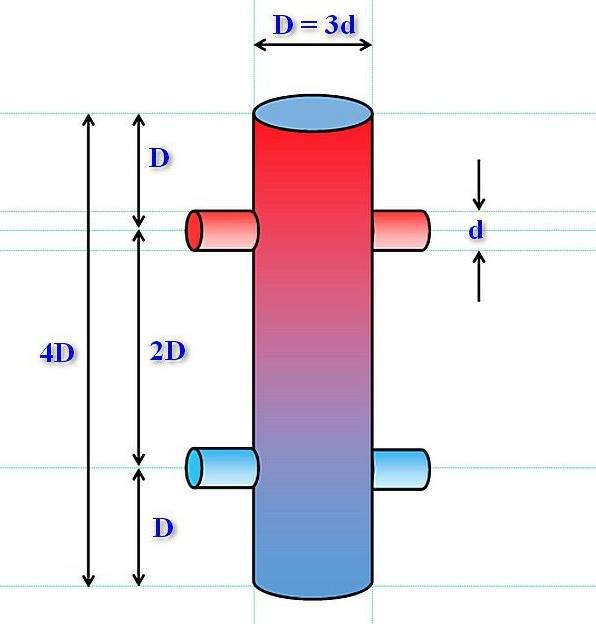

The classic assembly of a typical hydraulic switch is based on the "rule of three diameters". That is, the diameter of the nozzles is three times less than the diameter of the main cylinder of the separator. The nozzles are diametrically opposed, and their location in height is also tied to the main diameter.

The classic scheme of the hydraulic separator:

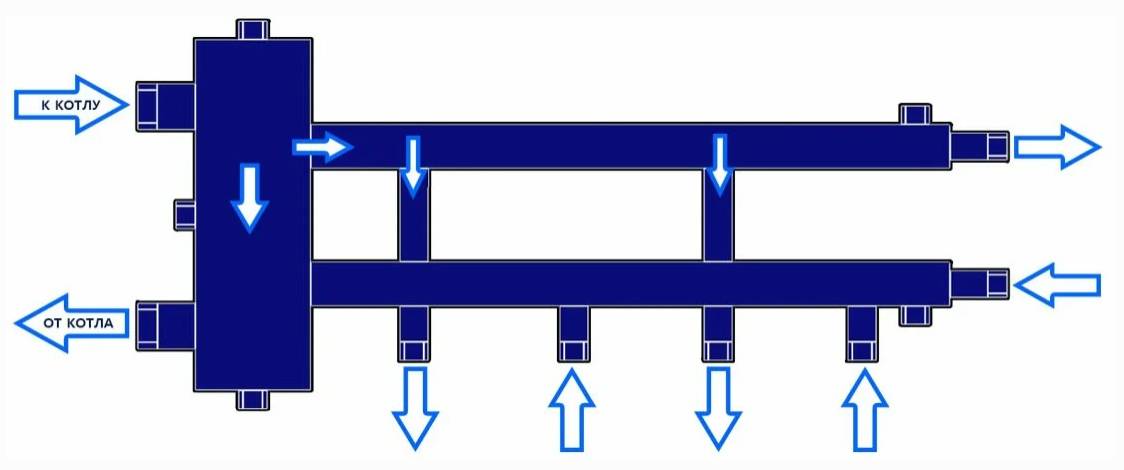

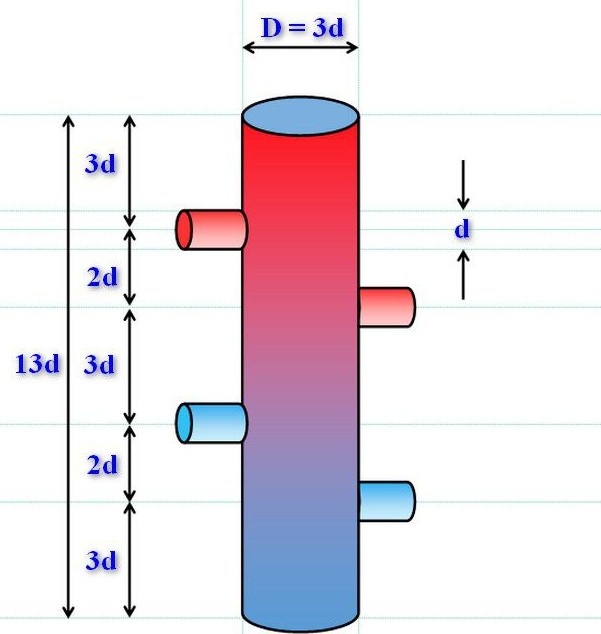

Some change in the position of the nozzles is also used - a kind of "ladder". This modification is mainly focused on more efficient removal of gas and insoluble suspensions. When circulating through the supply pipe, a slight change in the direction of the liquid flow in a zigzag downward direction contributes to the best elimination of gas bubbles.

On the reverse flow, on the contrary, the step is up, and this simplifies the removal of solid sediment. In addition, this placement contributes to optimal mixing of flows. The ratios of proportions are chosen in such a way as to create conditions for a vertical flow velocity in the range from 0.1 to 0.2 meters per second.

Exceeding this limit is prohibited. The slower the vertical flow, the more efficient the air and sludge separation will be. The slower the movement, the better the mixing of flows with different temperatures is performed.As a result, a temperature gradient is formed along the height of the device.

Scheme of a hydraulic arrow with a stepped arrangement of nozzles:

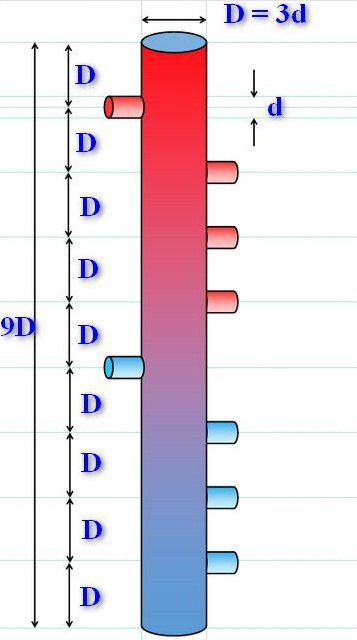

If the heating system contains circuits with different temperature conditions, then it is worth using a hydraulic distributor that acts as a collector, and different pairs of pipes will have their own temperature pressure. This will significantly reduce the load on thermostatic devices, make the entire system more manageable, efficient and economical.

The closer the pair of nozzles to the middle, the lower the temperature pressure in the supply pipe, and the smaller the temperature difference in the supply and return. For example, for batteries, the best mode is 75 degrees in supply with a difference of Δt = 20 ºС, and for a warm floor system, 40÷45 with Δt = 5 ºС is enough.

Scheme of a hydraulic separator with three outlets to the heating circuits:

Horizontal placement. In such variations, of course, there is no longer any talk of removing sediment and air. The placement of the fittings varies significantly - for the effective movement of fluid, schemes are often used even in the opposite direction of the flows of the "small" and heating circuits.

Such a hydraulic arrow is made in order, for example, to more compactly place equipment in a boiler room, since the opposite direction of flow allows you to slightly reduce the diameter of the tubes. However, the design must meet certain requirements:

- between the nozzles of one circuit, a gap of at least 4d must be maintained;

- if the inlet pipes have a diameter of less than 50 mm, then the distance between them should not be less than 200 mm.

Variants of horizontal hydraulic separator schemes:

There are also completely "outlandish" designs. For example, one craftsman was able to build a hydraulic gun from two sections of a conventional cast-iron radiator. With hydraulic separation, this device copes without problems. However, this method requires very reliable thermal insulation of the device, otherwise, thanks to it, absolutely unproductive heat losses will occur.

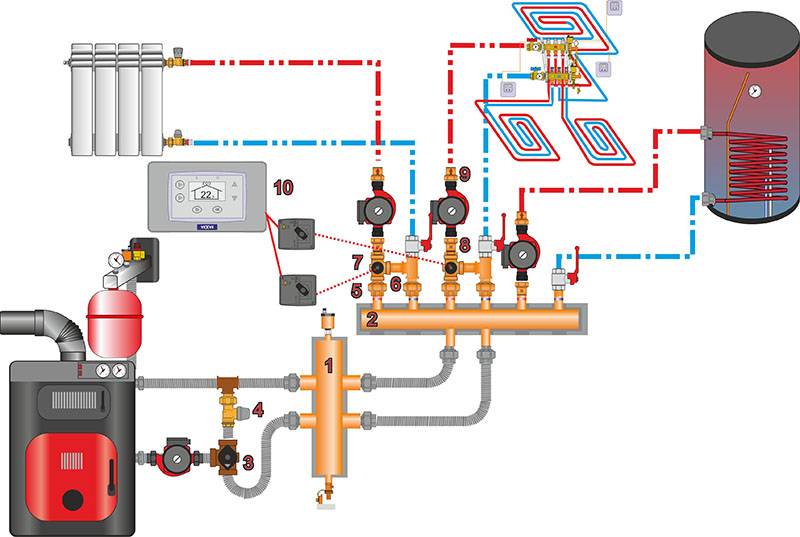

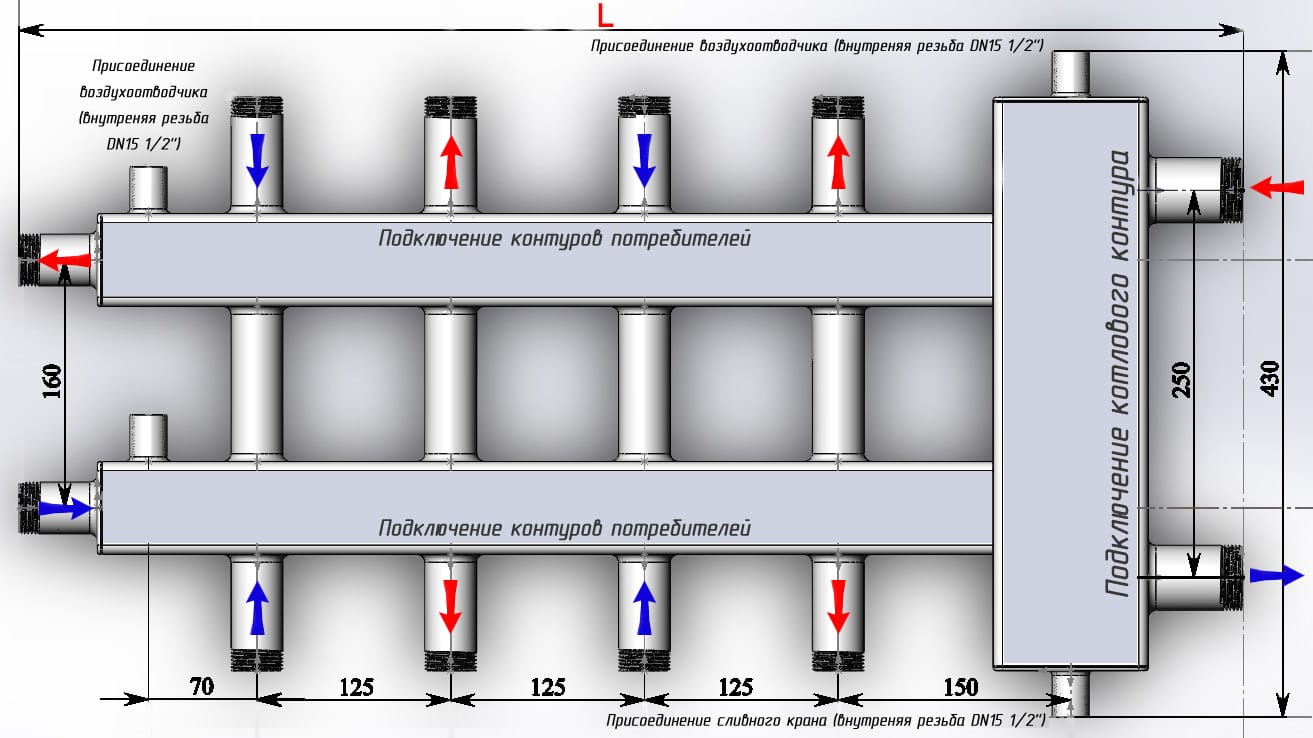

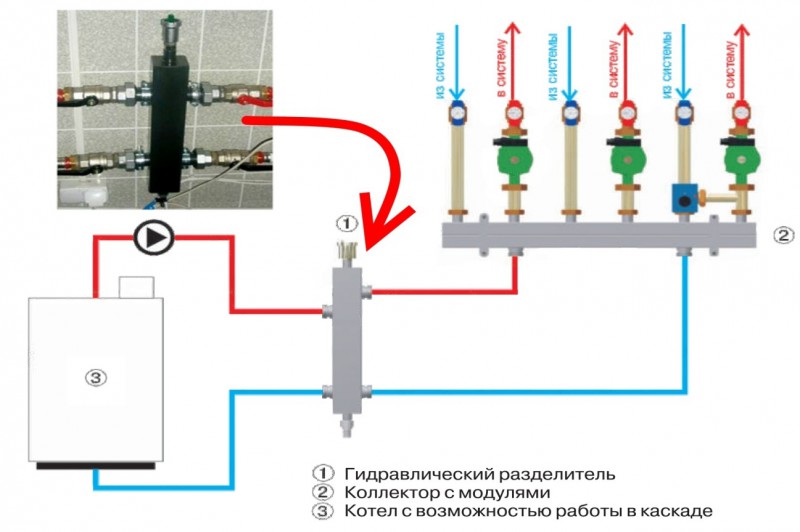

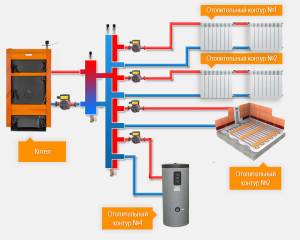

How is the collector combined with a hydraulic arrow?

For the installation of a heating system for a small private house, heating equipment with a built-in pump is used. If secondary circuits are connected to the boiler unit, then it is required to install a hydraulic arrow in the heating system. To connect the heating circuits of buildings with an area exceeding 150 m², special combs are used, and not a conventional hydraulic separator, which in this case will turn out to be very cumbersome.

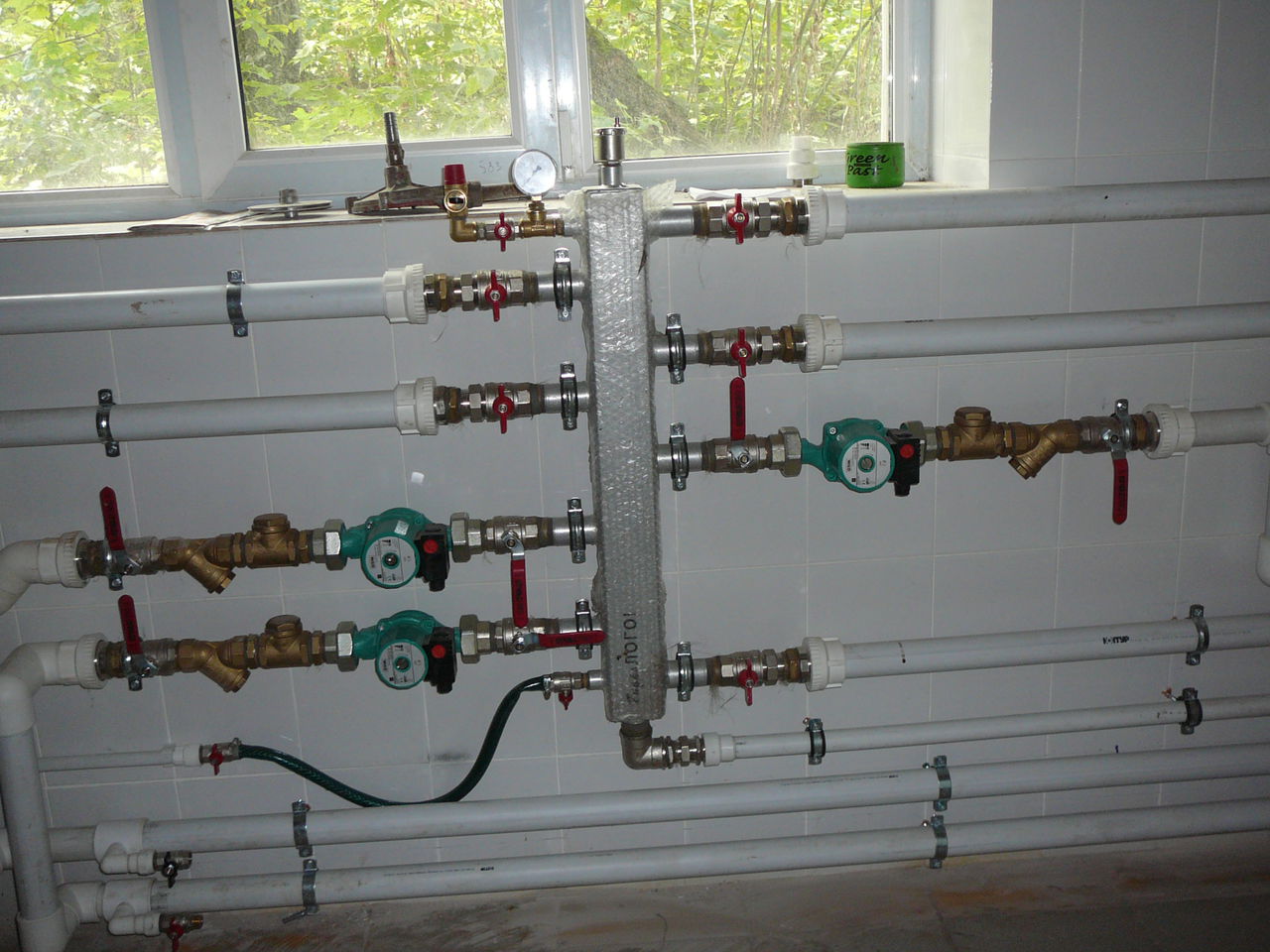

When installing a heating main, first connect the hydraulic arrow, and then the distribution manifold. This device consists of two separate parts connected by jumpers. The number of paired nozzles will be the same as the number of circuits, that is, a pair of nozzles will be needed for each circuit.

Thanks to the distribution comb, the repair and operation of heating networks are simplified. It is also convenient that the shut-off and control valves are located in one place. The collector has an increased diameter, which contributes to a uniform distribution of the coolant along the contours.

The hydraulic module consists of a manifold and a hydraulic separator

Such a compact design does not take up much space, which is very important in a small boiler room.

For the strapping device, several mounting releases are used:

- at the very top there are outlets for the high-pressure radiator circuit;

- in the lower part there are branch pipes for connecting a low-pressure floor heating circuit;

- on one side (opposite the hydraulic arrow) a heat exchanger is installed.

A balancing valve is mounted between the supply and return manifolds. Due to the presence of control valves, it is possible to set the desired coolant pressure on the farthest circuit and adjust the flow. Balancing valves allow a more even distribution of coolant flows to meet the demand of each circuit.

Before constructing a hydraulic separator on their own, they carry out the necessary calculations, make drawings and diagrams. Such work can only be done by a master who is versed in heat engineering and has the necessary installation skills.

The purpose of the water gun - what is it for

The hydraulic arrow in heating systems performs the following functions:

- One of the main functions of the hydraulic separator is hydrodynamic balancing in the heating circuit. The device in question cuts into the system as an additional element and provides protection for the cast-iron heat exchanger located in the boiler from thermal shock. That is why hydraulic separators are mandatory for installation when using boilers with cast iron heat exchangers. In addition, the hydraulic switch provides protection for heating from damage in the event of a spontaneous shutdown of one of its elements (for example, hot water supply or underfloor heating).

- When arranging multi-circuit heating, a hydraulic separator is simply necessary.The thing is that the contours during operation can conflict and interfere with each other - and the installed separator will prevent their pairing, due to which the system can function normally.

- If the heating system has been designed correctly, then the hydraulic arrow can be used as a sump that retains various solid mechanical impurities contained in the coolant.

- The hydraulic separator located in the heating system allows you to remove air from the circuit, eliminating the need to use other methods of bleeding air and preventing oxidation of the internal surfaces of the elements of the heating system.

Knowing what a hydraulic arrow is for in a heating system will allow you to choose and install such a device correctly.