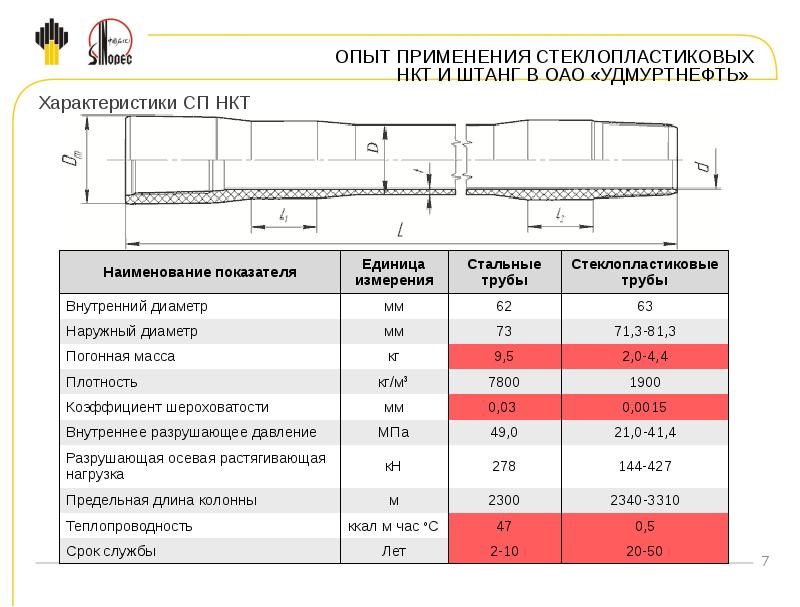

- Technical characteristics of pipes reinforced with fiberglass

- How to buy fiberglass reinforced pipes

- Fiberglass reinforced pipes wholesale

- Marking

- Scope of fiberglass pipes

- Installation of fiberglass pipes

- Application area

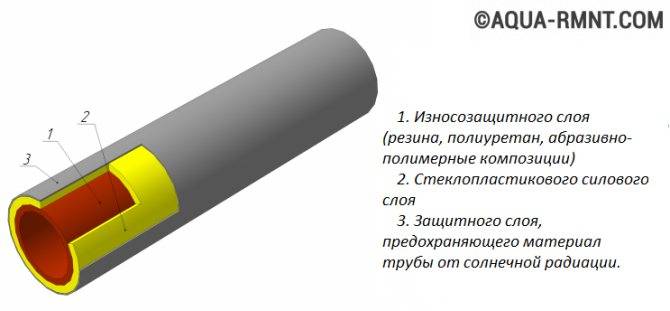

- Features of the appearance of fiberglass pipes

- Varieties of pipes depending on the type of resin

- Types of fiberglass pipes

- Benefits of using fiberglass pipes for heating and plumbing

- Production technologies

- Winding (coiling)

- Casting (centrifugal molding)

- Broaching (pultrusion)

- Extrusion (extrusion)

- Types of fiberglass pipes

- Kinds

- Where are they used?

- Story

- Varieties

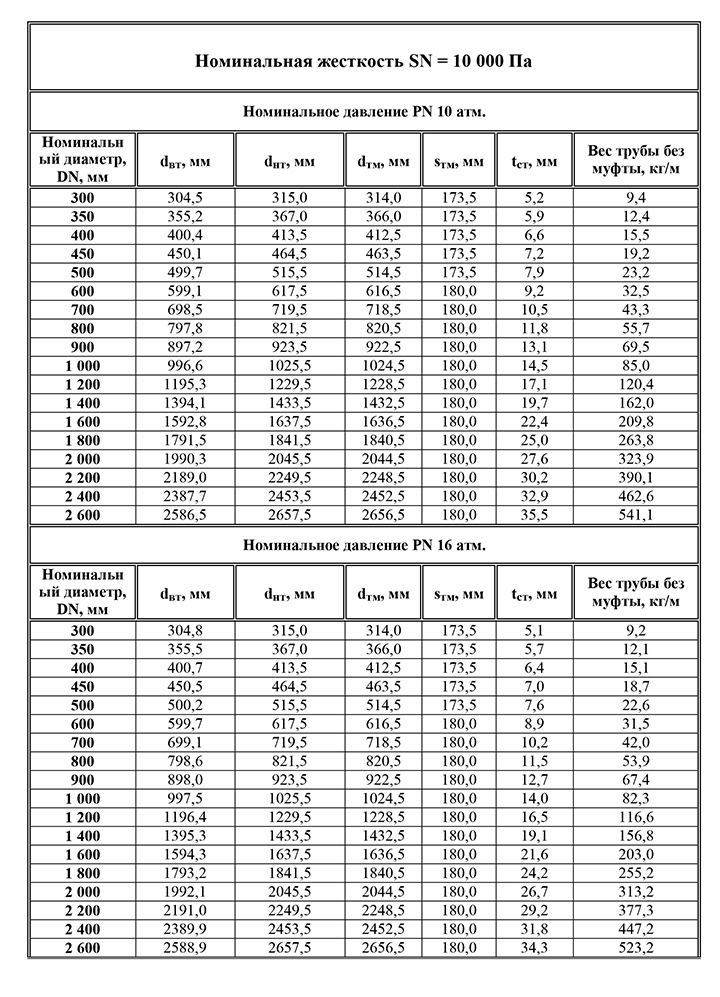

Technical characteristics of pipes reinforced with fiberglass

Supra Therm fiberglass pipes differ in nominal bore diameter and nominal pressure. The manufacturer offers the following pipe sizes according to the cross-sectional diameter: 20, 25, 32, 40, 50, 63, 75, 90, 110 and 125 mm. Nominal pressure for which they are designed fiberglass reinforced pipes

, maybe 16 and 20 bar. We also note that these products have increased rigidity and in all respects comply with the international standard ISO EN 21003.

How to buy fiberglass reinforced pipes

An order can be placed in several ways:

- using a special form on the site - order through the catalog;

- by writing an email to the specified address.

In addition, we are always happy to answer any questions about the pipeline fittings offered by our company. Our specialists are also ready to give recommendations on the use of this or that equipment and can prepare a project for any industrial pipeline system, selecting the appropriate equipment and materials.

Fiberglass reinforced pipes wholesale

Despite the fact that the main direction of our activity is wholesale sales, we are also ready to offer you fiberglass reinforced pipes

from Supra Therm and other pipeline fittings and small wholesale at the best prices. That is why more and more customers choose us as a supplier of various pipeline fittings.

Marking

Depending on the coating and purpose, each pipe has a specific marking. It is not difficult to understand these notations. Products intended for laying water pipes, supplying drinking and domestic water are designated with the letter "P". The marking indicates that fiberglass pipes can be used for any water supply systems, including drinking water supply.

The letter "G" - pipes are allowed to be used in hot water supply systems, provided that the temperature of the water or other energy carrier does not exceed seventy-five degrees.

"X" - the designation of this letter indicates that pipes can be laid for the transportation of gases and other chemically active substances.

If abrasive inclusions are present in the composition of the liquid, then such substances can be pumped through pipes marked "A".

Universal pipes made of fiberglass are marked with the marking "C", in addition, the products are acid resistant.

Due to the combination of the positive characteristics of glass and polymers, fiberglass pipes have received almost unlimited prospects for application - from the arrangement of ventilation ducts to the laying of petrochemical routes.

In this article, we will consider the main characteristics of fiberglass pipes, marking, manufacturing technology of the polymer composite and the composition of the binder components that determine the scope of the composite.

We will also give important selection criteria, paying attention to the best manufacturers, because an important role in the quality of products is assigned to the technical capacities and reputation of the manufacturer. Fiberglass is a plastic material that contains glass fiber components and a binder filler (thermoplastic and thermosetting polymers)

Along with a relatively low density, fiberglass products are distinguished by good strength properties.

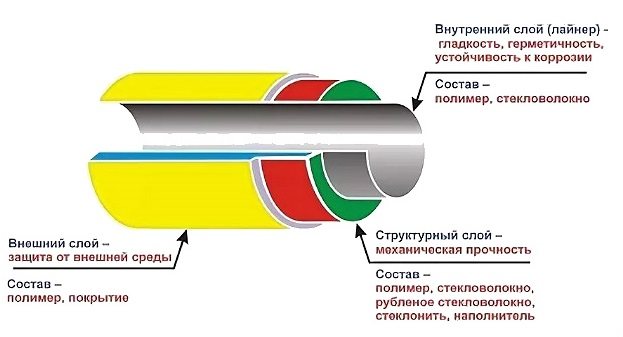

Fiberglass is a plastic material that contains glass fiber components and a binder filler (thermoplastic and thermosetting polymers). Along with a relatively low density, fiberglass products are distinguished by good strength properties.

Over the past 30-40 years, fiberglass has been widely used for the manufacture of pipelines for various purposes.

The polymer composite is a worthy alternative to glass, ceramics, metal and concrete in the manufacture of structures designed for operation in extreme conditions (petrochemistry, aviation, gas production, shipbuilding, etc.)

Highways combine the qualities of glass and polymers:

- Light weight.

The average weight of fiberglass is 1.1 g/cc. For comparison, the same parameter for steel and copper is much higher - 7.8 and 8.9, respectively. Due to its lightness, installation work and material transportation are facilitated. - Corrosion resistance.

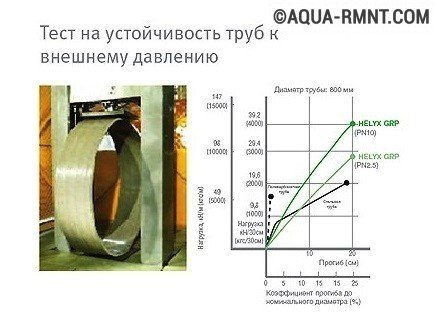

The components of the composite have a low reactivity, therefore they are not subject to electrochemical corrosion and bacterial decomposition. This quality is a decisive argument in favor of fiberglass for underground engineering networks. - High mechanical properties.

The absolute tensile strength of the composite is inferior to that of steel, but the specific strength parameter significantly exceeds thermoplastic polymers (PVC, HDPE). - weather resistance.

Boundary temperature range (-60 °С..+80 °С), treatment of pipes with a protective layer of gelcoat provides immunity to UV rays. In addition, the material is resistant to wind (limit - 300 km / h). Some manufacturers claim seismic resistance of pipe fittings. - Fire resistance.

Fireproof glass is the main component of fiberglass, so the material is difficult to ignite. When burning, the poisonous gas dioxin is not released.

Fiberglass has a low thermal conductivity, which explains its thermal insulation qualities.

Disadvantages of composite pipes: susceptibility to abrasive wear, generation of carcinogenic dust due to machining and high cost compared to plastic

As the inner walls wear out, the fibers are exposed and break off - particles can get into the transported medium.

Image gallery

Fiberglass pipes have been used quite recently. They gained their popularity because, previously used metal pipes were often corroded. To solve this problem, other materials were searched for that would be suitable for the manufacture of pipes.

Fiberglass pipes are made of a composite material, which contains different types of resin, is reinforced in different ways and uses some types of reinforcement. Pipes can be manufactured using various technologies.

Scope of fiberglass pipes

If initially fiberglass products were used in industry, now they are increasingly used for household needs. The scope of application is not limited to one industry, and depending on the type of construction, there are:

-

Fiberglass pipes for water supply and plumbing are the most common area of use in domestic needs. Products are suitable for laying pipelines for hot and cold water supply.

-

Fiberglass pipes for sewerage - are also used often, but compared to pipes for water supply the cost is a little higher. Pipes have proven themselves on the positive side due to high wear resistance;

-

Fiberglass pipes for heating are good in that heat transfer is minimal, additional insulation of pipelines is not required, for example, in winter;

-

Fiberglass pipes for wells - the advantage of the application is that the product is resistant to corrosion.Even if you have to transport water with a significant amount of impurities, this will not affect the service life;

-

Fiberglass pipes for microtunneling - are used in various areas where laying without digging trenches is necessary.

On the scale of large companies, fiberglass pipes are used for the oil and gas industry. They are subject to special safety requirements, because a chemical leak is not just an accident, but an emergency. Therefore, such products have additional protection that increases strength and durability.

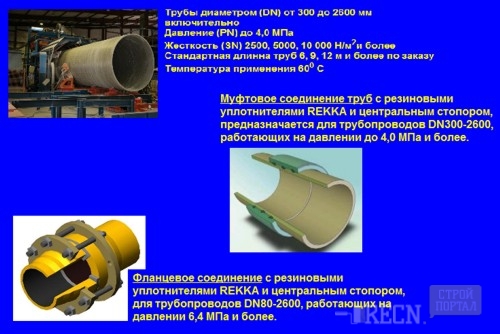

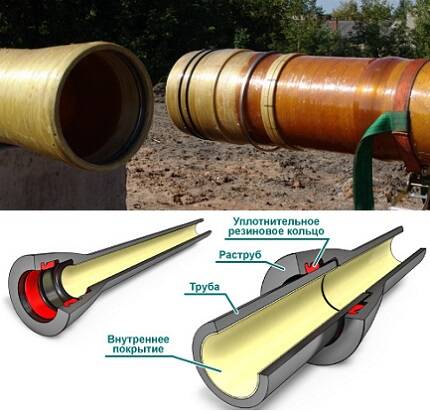

Installation of fiberglass pipes

Fiberglass pipes can be installed in a variety of ways.

Consider the most affordable and effective:

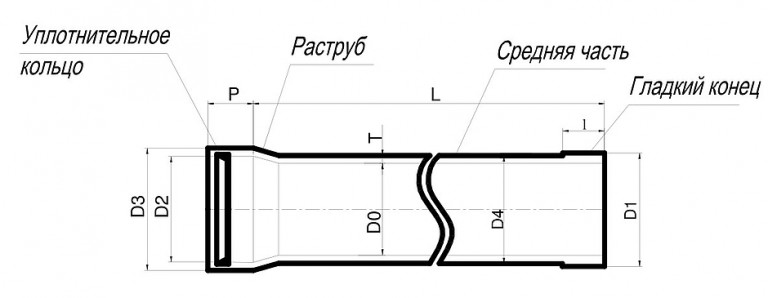

- Standard socket type pipe can be easily installed. The installation technology does not differ from the laying of PVC sewer pipes. During installation, a certain sequence should be followed - insert one pipe into the expansion (bell) next.

- Connection of pipes by a flange method. Each pipe at the end is equipped with a special flange (ring) with holes for fasteners.

- Couplings - used for pipes of any kind. You can additionally install removable connections or structures without subsequent disassembly (use of adhesive materials).

- Connection type "yoke", a type of coupling installation. This is a special device with which you can easily dock pipes, and then connect them to fasteners (for example, bolts).

- In some cases, the use of screw and threaded connections of plastic pipes is allowed.

Application area

A popular manufacturer of fiberglass pipes, Amiantit, produced a trial batch of pipes in the late sixties of the last century. For decades, the manufacturer has managed to reach the world level and now fiberglass pipes (GRP) deserve attention due to their quality and reliability. This is due to the fact that the pipes are made by a special method - continuous spiral winding. As a result, they are not affected by corrosion and are highly resistant to acids and media. In addition, unlike standard metal pipes, fiberglass pipes are easy to handle - the weight of products is many times less than heavy metal pipes. Therefore, if there are doubts about which pipes to buy - fiberglass or traditional metal, most companies choose durable and practical materials for laying fiberglass highways.

In just forty to fifty years, the eponymous leading company in the production of fiberglass pipes managed to take not only a leading position, but also become one step up.

The scope of fiberglass pipes is quite wide, they can be used for laying sewerage and drainage systems, as well as used for fire fighting, transporting drinking and industrial water. It is possible to lay pipes at power plants and when removing any kind of waste.

In addition, fiberglass pipes are widely used for laying almost any type of communications:

- main lines;

- sewer networks for any purpose;

- plumbing;

- laying gas and oil pipelines.

The popular factories of Amiantit take into account the interests of each consumer in the production of their products - you can purchase fiberglass pipes of different diameters, lengths and designs, as well as additional components and fittings. In addition, the production process is adjusted in such a way as to satisfy the requirements of any customer and produce pipes according to individual orders.

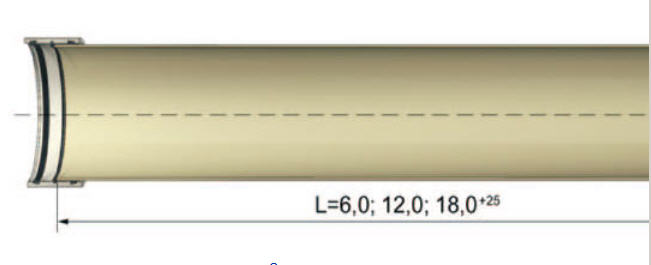

The diameter of a standard fiberglass pipe ranges from one hundred to three thousand seven hundred millimeters, and the length can reach eighteen meters. It is allowed to use such pipes in six pressure classes and in three strength classes. Thanks to these indicators, it can be noted with confidence that fiberglass pipes are not only efficient. Also noted is the high durability of products.

Features of the appearance of fiberglass pipes

The manufacture of this kind of pipes arose back in the 50s of the last century, since it was then that the production of epoxy resins gained an industrial scale. This technology, like any other novelty, was not very popular at first: people had no experience with fiberglass, moreover, traditional materials (such as aluminum or steel) were relatively inexpensive.

However, in 10-15 years the situation changed dramatically. For what reason?

- First of all, this is due to the fact that the cost of steel and non-ferrous metals has increased markedly.

- Fiberglass tubing had an advantage over steel - they weighed a little and differed in corrosion resistance (the pipes did not suffer from prolonged contact with salt water, which cannot be said about their “competitors”).

- Another reason, which is largely related to the previous one, is that the commercial development of gas / oil fields has begun to develop.

- And, finally, the production technology itself has changed - now fiberglass pipes were cheaper and became more and more durable.

It is quite obvious that the results did not have to wait long - by the end of the sixties, the United States broke into the building materials market with high-quality high-pressure fiberglass pipes. At first, the company's products conquered North America, and therefore moved to the Middle East market. Already in the eighties, European countries entered the game, and some time later, the Soviet Union.

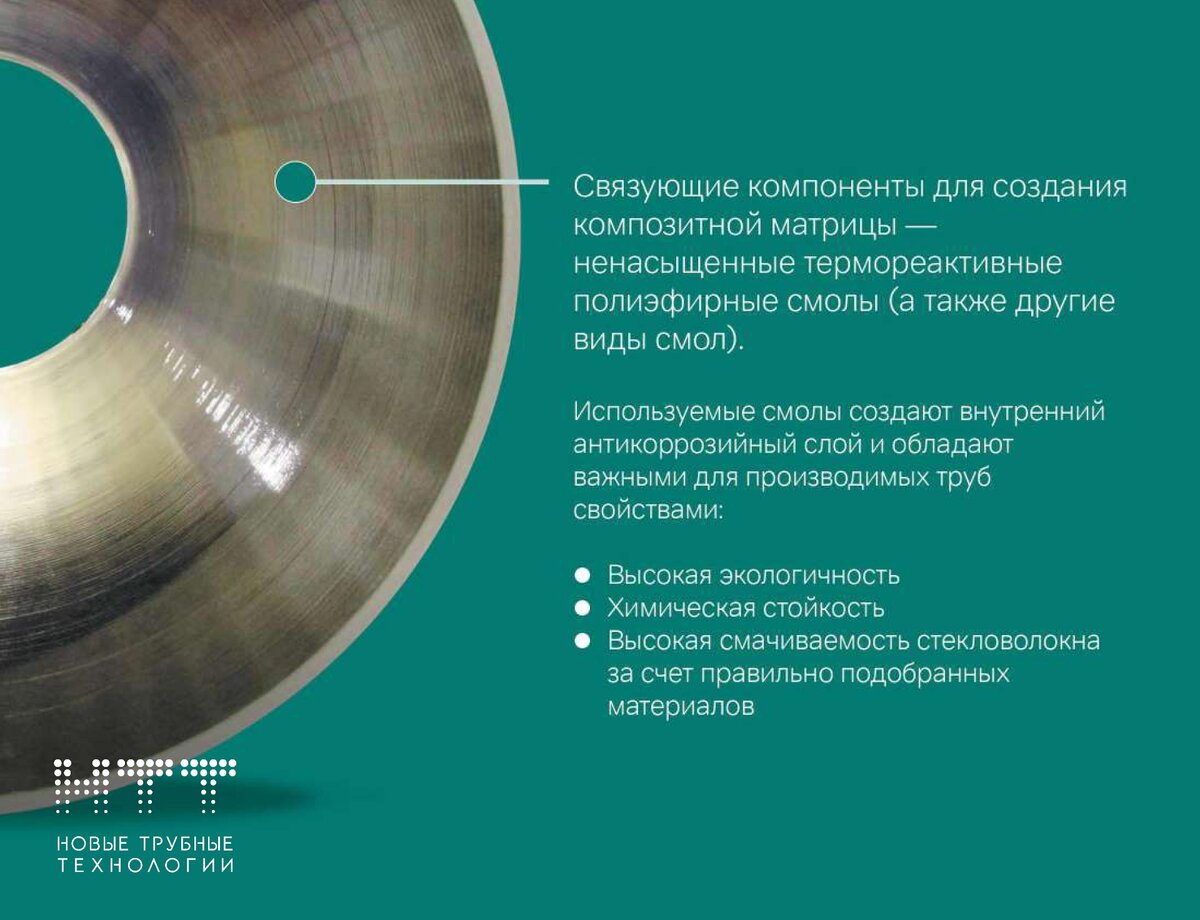

Varieties of pipes depending on the type of resin

The operational properties of the pipes described in the article may vary depending on what resins they are made of. It is for this reason that at the time of purchase it is imperative to specify what kind of fiberglass you are selling. From this point of view, products are divided into two categories, let's get acquainted with the features of each of them.

- Fiberglass, made on the basis of polyester resins. This material is characterized by chemical neutrality, resistance to the influence of various kinds of substances; material is a very important element in the laying of pipelines for the oil refining industry. However, you should be aware that such pipes are unsuitable for operation at high temperatures (above +95 degrees) or high pressure (maximum - 32 atmospheres).

- Fiberglass, made on the basis of epoxy resins.Thanks to the epoxy binder used in the manufacturing process, the finished product is much more durable. Pipes made using this technology and having a larger diameter are able to withstand very high pressure (maximum - 240 atmospheres) and temperatures of no more than +130 degrees. Another advantage of this material is its relatively low thermal conductivity, and therefore there is no need for additional thermal insulation (the products practically do not give off thermal energy). The cost of such pipes is somewhat more expensive when compared with the same indicator of polyester fiberglass.

Types of fiberglass pipes

The classification of culverts and products for the oil industry is carried out on the basis of the materials used in production. According to the type of polymer binder, fiberglass pipes are:

-

polyester;

-

Epoxy.

Another classification involves the separation into separate types of pipelines with different connection elements:

-

Coupling;

-

adhesive;

-

Mechanical.

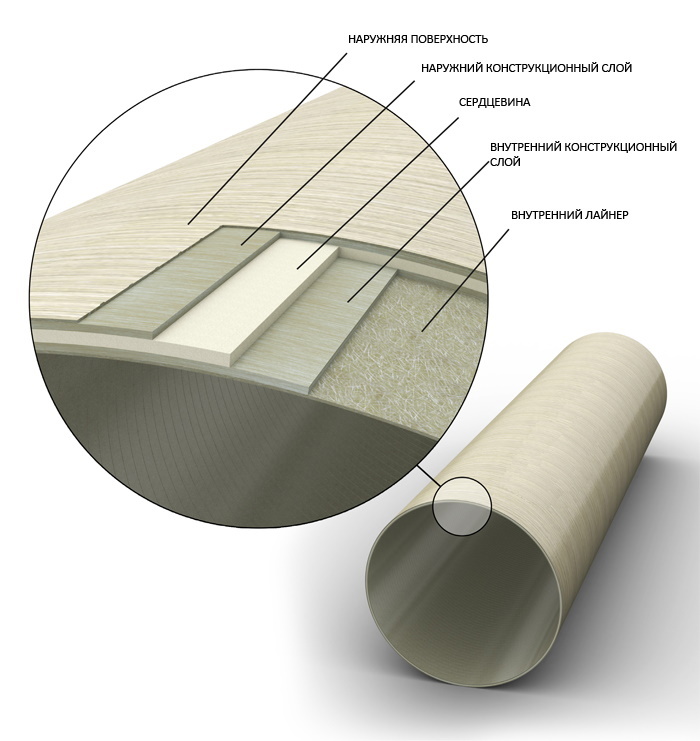

The first type is the most modern, installation can be carried out in any conditions, even in cold weather. There are several more types of pipes according to their design features:

-

lined;

-

Without lining - designed for transportation of non-aggressive media, since they do not have a protective layer;

-

Multilayer - the most reliable products.

Fiberglass products should be chosen based on the intended purpose, for example, pipes for an airfield or oil pumping stations should be distinguished by an increased level of safety. But filter pipes for sewage treatment plants are usually chosen from the most affordable options.

Benefits of using fiberglass pipes for heating and plumbing

It is difficult to evaluate all the advantages of using fiberglass pipes, because these designs - the achievement of the chemical industry and science - are in demand due to several reasons:

-

Lighter weight - several times lighter than steel, which simplifies transportation and laying of the pipeline, the involvement of special large equipment is usually not required, and a team of workers can handle the work;

-

Unpretentious installation - when laying fiberglass pipes, you do not need to use welding equipment, you can work in any climatic and weather conditions;

-

Resistance to corrosion and chemical attack - products easily tolerate high temperature, pressure and the negative effects of the transported substance;

-

Zero deposits on the inner surface, which is caused by low flow resistance - pipes can be used without cleaning;

-

The service life is up to 50 years without accidents, expensive repairs are not required.

The use of fiberglass composite pipes, which, at first glance, are of high cost, is a worthy way to save: on the subsequent replacement, repair and elimination of the consequences of an accident. Durable products will last for a long period, regardless of the scope: whether it is domestic needs and transporting water, or industrial scale and pumping oil products.

Production technologies

The modern industry successfully implements 4 fundamentally different technologies that allow the production of fiberglass tubular products in various price segments:

We recommend that you read: Is it possible to pour polypropylene pipes into the screed?

Winding (coiling)

Simple to implement and very productive technology. It is simple and continuous. It implies the use of various polymeric components: thermoplastic (polypropylene, polyamide, polyethylene, etc.) or thermosetting (polyesters, epoxy resins, phenol-formaldehydes, etc.).

Fiberglass can be installed in a variety of ways. At large manufacturing enterprises, 4 options are implemented:

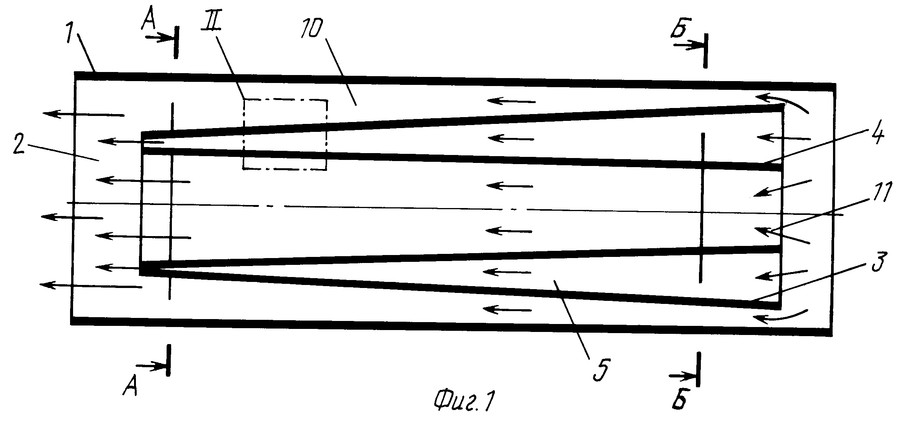

- Spiral-ring. The laying mechanism moves progressively along the rotating workpiece, winding a layer of fibers around it. Depending on the number of runs, the required wall thickness is achieved. It is used in the manufacture of high-pressure fiberglass products used in critical areas of work: in power lines, rocket science, etc. The production process is complex and expensive, it is not used for overall products.

- Longitudinally transverse. The machine stacks the longitudinal and transverse fibers of the material independently of each other.

- Spiral tape. A simplified version that makes it possible to produce inexpensive and practical products at the cost of some reduction in strength. Products are in demand in the installation of low and medium pressure networks.

- Longitudinal-transverse oblique. Innovative technology developed specifically for the military-industrial complex.

Casting (centrifugal molding)

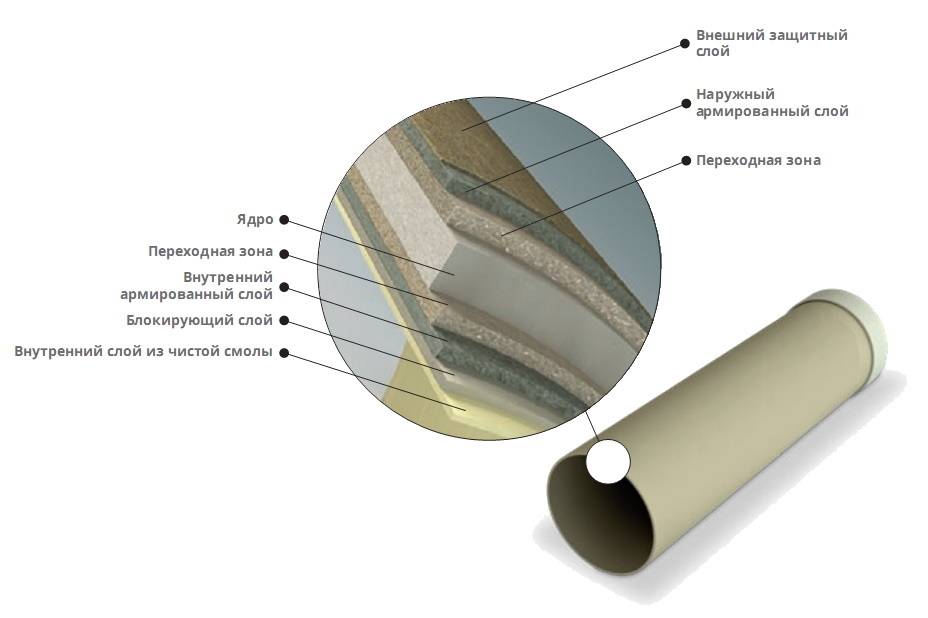

The technology involves the manufacture of the pipe in the reverse order - from the outer wall to the inner. This method makes it possible to increase the wall thickness almost without restrictions. The pipes have high ring stiffness and can easily withstand large axial loads.

Broaching (pultrusion)

Threads of glass fiber impregnated with a mixture of resins pass through the shaping machine, where, due to the pulling action, they are given the necessary configuration. It is best suited for the production of products used in the construction of water supply, heating, sewerage systems.

Extrusion (extrusion)

The cheapest technology. The viscous pasty billet is continuously forced through the forming machine. The mixing of fiberglass and resin occurs chaotically, so the products do not have continuous reinforcement. This negatively affects performance.

Types of fiberglass pipes

The use of fiberglass and composite pipes, along with structures that include organic materials or basalt, is possible in many industries. Features of operation directly depend on the type of pipe. Fiberglass products are divided into:

-

By type of joint connection - mechanical or adhesive;

-

By design features - multilayer, without lining and with a lined film layer;

-

By type of binder - epoxy and polyester.

The properties of the composite pipe and the conditions of use depend on the type of product. The marking also plays a role, forming another type of classification of fiberglass structures. The marking must necessarily correspond to the purpose for which the product will be used.

Kinds

Fiberglass pipes can be manufactured in various configurations and sizes. Their diameters can vary from 100 to 3800 millimeters.Based on the diameter of the pipe, the appropriate accessories and additional parts are selected.

And the length can be selected up to 18 meters. But if it is necessary to lay a pipeline longer than 18 meters, then they are connected using special parts, the junction is strong, reliable and durable.

According to the pressure class, you can choose pipes from 6 classes, and strengths up to class 3.

In order for the structure to gain additional strength, manufacturers use reinforcement in its composition. Reinforcement is necessary for the greatest strength of the connection of fiberglass pipes.

In some cases, it is necessary to use more reliable slot wedges on the cut; for this, the side face is reinforced. Pipes with similar reinforcement can be used for rotary wedges.

Cross section classification:

- The section is solid. The shape of the section can be in the form of a circle, semicircle, trapezoid, segment, rectangle;

- Section "ring". Fiberglass pipes with such a section must be ordered in advance, as they are made individually for each object. When developing an individual order, it is necessary to study all the features and transfer them to the design project.

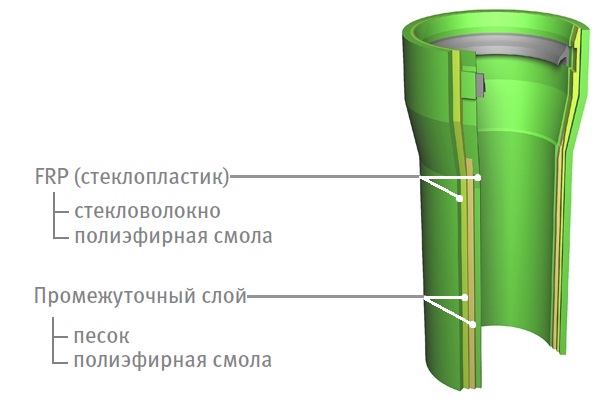

Also, fiberglass pipes can be divided into single-layer and multi-layer structures.

Single-layer structures consist only of composite material, and production is carried out using wet winding technology. The composition of the composite includes a binder and epoxy resin. Fiberglass is used as a binding material.

Multilayer structures are made of the same materials as single-layer structures, but they also use an additional shell, which is made of polyethylene.Polyethylene has increased strength, and there can be one or more shells. Several separate layers must be bound together, so polymerization is used. Polymerization is carried out at high temperatures. This technology helps to obtain fiberglass pipes, which have increased resistance to various adverse effects.

Where are they used?

Fiberglass pipes are widely used. They are often used for wiring drainage and sewerage systems, they are environmentally friendly and can be used in such structures. They are also used in the transportation of drinking or technical water. They are used in firefighting.

Even at power plants, fiberglass pipes began to be used so that they would efficiently and durablely remove any industrial waste.

They can be used for laying oil or gas pipelines. It is only necessary to choose the required pipe size and its design. In addition, custom dimensions and configurations can be ordered for special individual piping designs. In this case, the structure will include all the necessary additional fittings and components.

Story

From the mid to late 1980s of the 20th century, the production and use of large diameter underground composite pipes began to grow. Technological advances in the filament winding process, corrosion resistance and strong market factors have contributed to the popularity of fiberglass pipe. Definitions of what constitutes a large diameter pipe can vary, but in general sizes range from 12 to 14 inches.

Composite or fiberglass pipe is used in a wide range of industries such as power generation, petrochemicals, and seawater desalination. Fiberglass pipe is corrosion resistant, has a long life cycle that often exceeds 30 years, and is the best alternative to steel and other metal alloys, ductile iron and concrete. According to statistics, more than 60,000 km of large diameter pipes are in operation worldwide.

Varieties

For the implementation of various engineering projects, there are several varieties of fiberglass products. They differ in strength, durability, scope and, as a result, the final cost.

We recommend that you read: How to properly install and adjust the thermostatic valve

First of all, the strength characteristics of the pipe are affected by the type and concentration of resins added to the mixture during the production process. The technology allows the use of isophthalic, orthophthalic, biphenolic resins. This increases the resistance to salts, acids and alkaline compounds.

Also, the strength characteristics of the pipe are increased by increasing the number of layers:

- Single layer pipe. Produced by winding from a pure composite material. Differs in low cost and rather low operational characteristics.

- Double layer pipe. It has an additional outer shell that protects the product from mechanical damage, the damaging effects of ultraviolet radiation, and other aggressive environments.

- Three-layer pipe. Each layer of polymer is covered with a protective sheath made of polyethylene. The layers are joined together by high-temperature polymerization. The layer located in the center is the power layer.Its task is to increase the strength of the product.

When choosing fiberglass pipes for the implementation of a project, it is worth focusing on some important points:

- The pipe material must be free from foreign elements.

- The surface should be perfectly even and smooth, without dents and blisters.

- The edge of each product should not have delaminations and cracks - this is a clear sign of marriage.