- How to make a snail pipe bender?

- Necessary materials and tools

- The assembly process of the snail pipe bender

- Types of roll forming machines and their devices

- Drive type

- According to the way of bending

- According to the location of the movable shaft

- With pinch roller

- You may like

- VK comments:

- Types of machines

- How is a pipe bender arranged?

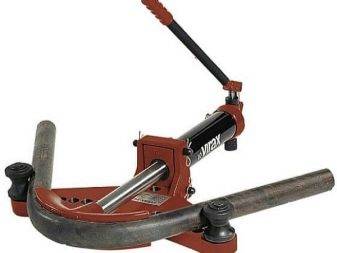

- Hydraulic Pipe Bender

- Why is it worth it

- Basic structural elements

- Movement manufacturing process

- Manufacturing nuances

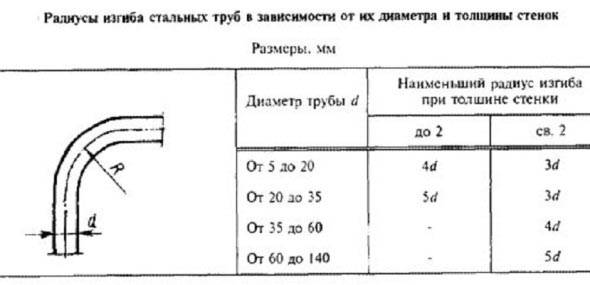

- Note to craftsmen

How to make a snail pipe bender?

Self-manufacturing a snail pipe bender may seem difficult. In fact, this device is no more difficult to assemble than a roller pipe bender. The process differs only in the parts used and assembly time.

The snail pipe bender allows you to bend the profile along the entire length at once, and not just in one place. For this property, he gained popularity among installers.

Necessary materials and tools

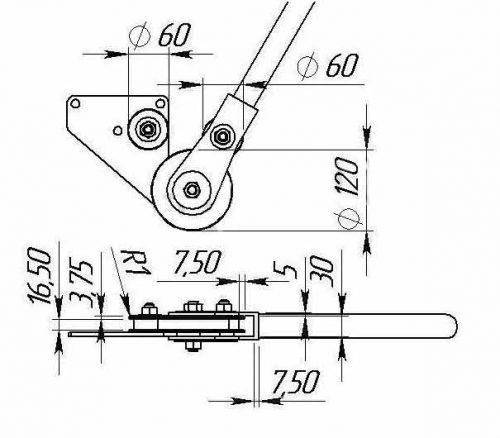

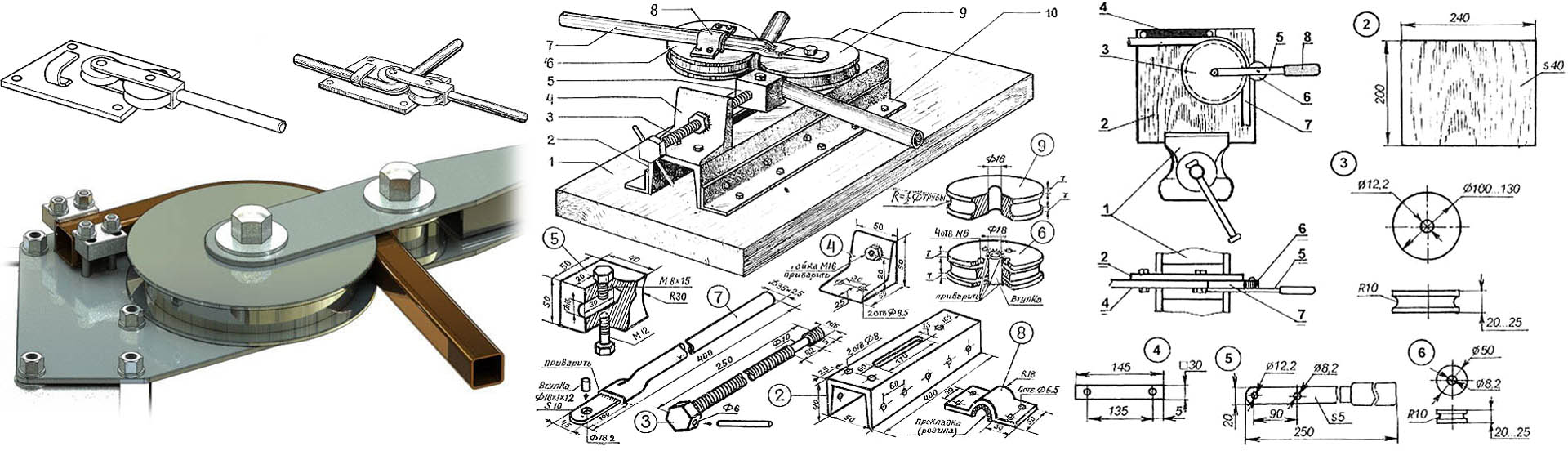

Since the described roller pipe bender does not have a specific working diameter and can be made from any available materials, the proposed materials will not contain specific sizes of parts. The thickness of all metal structural elements should be 4, and preferably 5 mm.

For the manufacture of a pipe bender will need:

- Channel - 1 meter.

- Sheet iron.

- Three shafts.

- Two stars.

- Metal chain.

- Six bearings.

- Metal 0.5-inch pipe for the manufacture of gates - 2 meters.

- Sleeve with internal thread.

- Clamp screw.

Particular attention is paid to the dimensions of sprockets, shafts and bearings, which must match each other. Asterisks can be taken from old bicycles, but they must be exactly the same size

Steel plates and profiles for the manufacture of a pipe bender should not be with deep rust, because they will have high loads during operation

Before choosing and purchasing all materials, you need to draw a drawing with a schematic representation of all structural elements so as not to buy them in pipe bender manufacturing process.

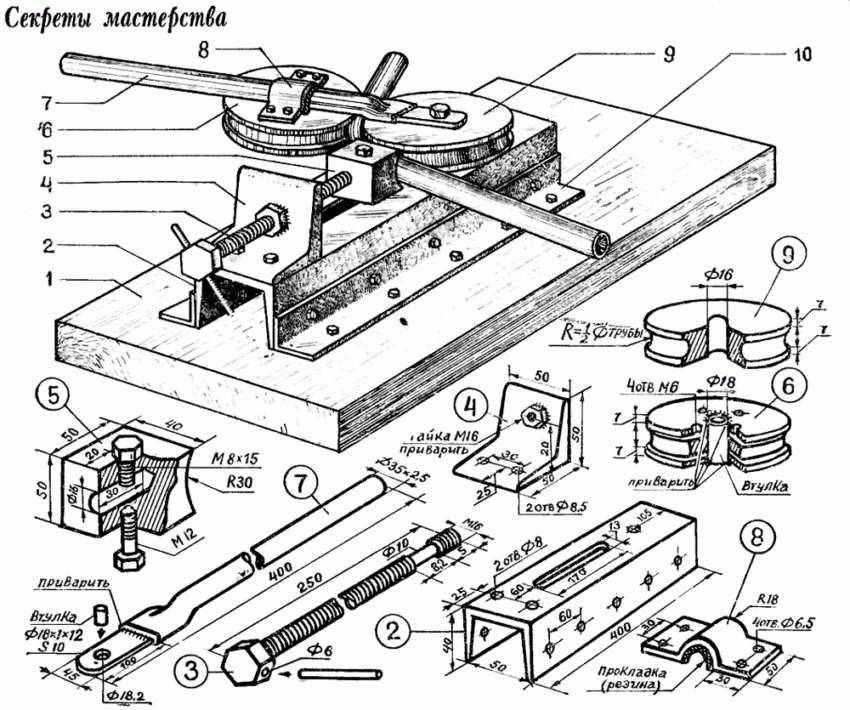

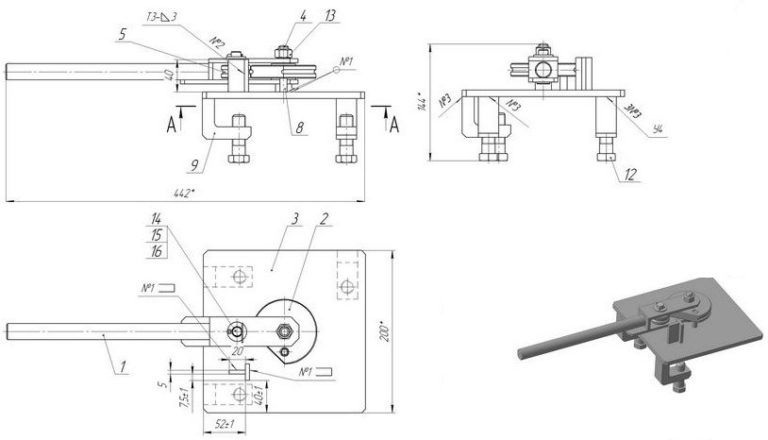

The assembly process of the snail pipe bender

The assembly of any equipment begins with the drawing up of a drawing diagram.

After that, you can proceed to the main workflows, which are shown in the photo instructions:

- Weld the base of the tool from two parallel channels. If desired, you can use just a metal plate 5 mm thick or one wide channel.

- Put bearings on the shafts and weld two such structures to the base. It is desirable to limit the shafts with metal strips or place them in the inner cavity of the channels.

- Put on the sprockets and weld them, after stretching the chain between them.

- Cut and weld to the base the side guides of the clamping mechanism.

- Put the bearings on the pressure shaft and assemble the press structure with side stops from strips or channels.

- Make a base for the bushing and weld it to the plate. Screw in the clamping screw.

- Weld to the upper edge of the clamping screw and to the driving shaft of the pipe gate.

- Lubricate the bearings with engine oil.

Some useful tips:

After assembling the pipe bender and testing it, you can paint the structure with anti-corrosion paint to better preserve the welds. To increase the convenience of work, a spring is additionally attached to the guides to return the press to the upper position.

Types of roll forming machines and their devices

Profile pipes have different wall thicknesses and diameters, so different pipe benders are required. Mechanisms for bending professional pipes have structural differences from standard pipe benders for round pipes. After all, profiles are highly resistant to bending, and their bending radius is usually larger.

Profile pipe bending machine

Profile pipe bending machine

The main types of pipe benders for a profile product:

- by type of drive;

- by the bending method;

- at the location of the movable roller.

Drive type

The choice of a bending machine depends on the bending angle, as well as the material of the corrugated pipe and the required accuracy, which are:

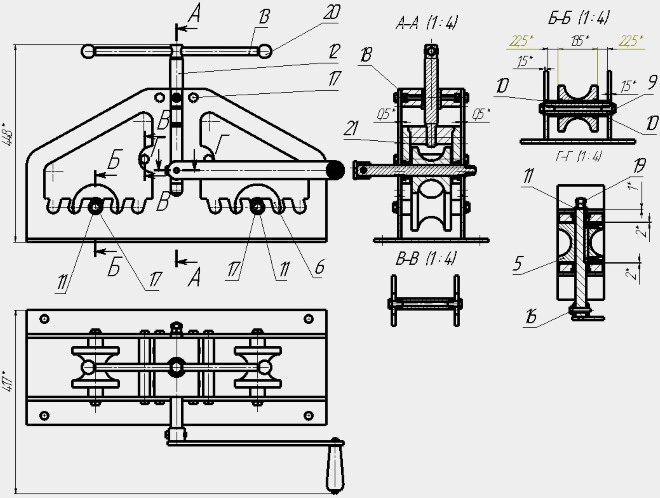

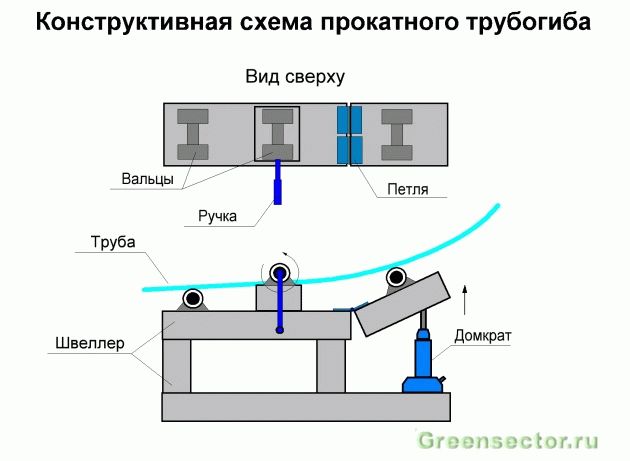

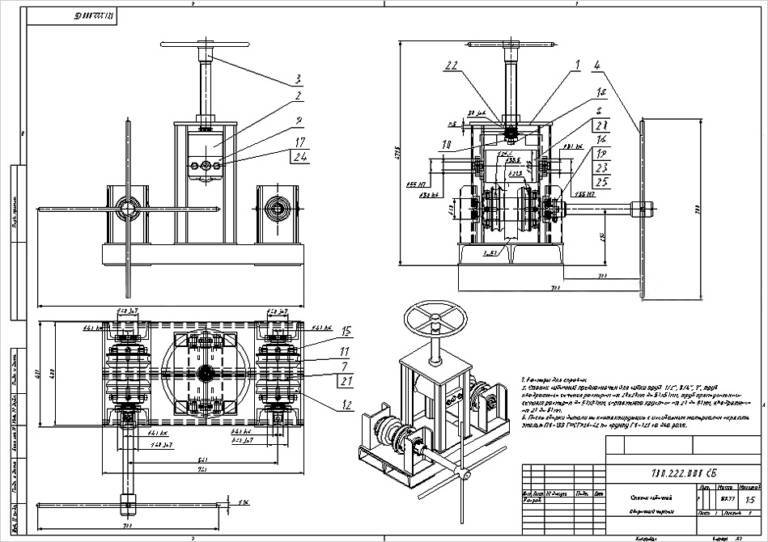

- Hydraulic - designed to bend three-inch elements. They have a high level of performance, accuracy and speed. There are manual and automatic types. This is the most powerful profile bender capable of bending any pipe. It includes - a channel (wide and narrow sections, three of each type), a loop lock, rollers - 3 pcs. (placed on bearing units), transmission handle with bushing, machine jack.

- Electric - recommended for bending large diameter profile pipes. They are used more often for main pipelines. The device consists of:

- frames from channels;

- rolling shafts made of metal - 2 pcs;

- three gears;

- metal chain;

- reducer, electric motor with mechanical drive.

- Manual - they work due to the physical strength of a person. Designed for small diameter profiles. The tool works like a rolling machine. The main parts are mostly metal:

- track roller;

- rollers;

- chassis elements;

- adjustment screw;

- feeding handle.

According to the way of bending

One and the same part can be bent in different ways, using pipe benders of various types:

- segmental - their popularity is that the part may be dragged through to obtain several turning fragments;

- crossbow - the essence of the work is to stretch the metal and bend it in one place;

- spring - designed for plastic products.

According to the location of the movable shaft

The movable roller can be located in the middle, or on the sides (right or left):

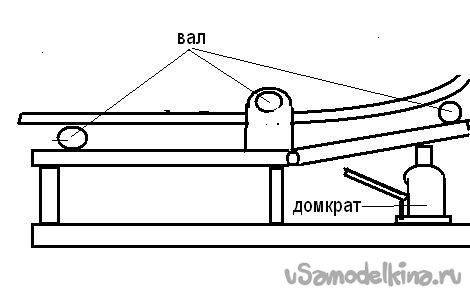

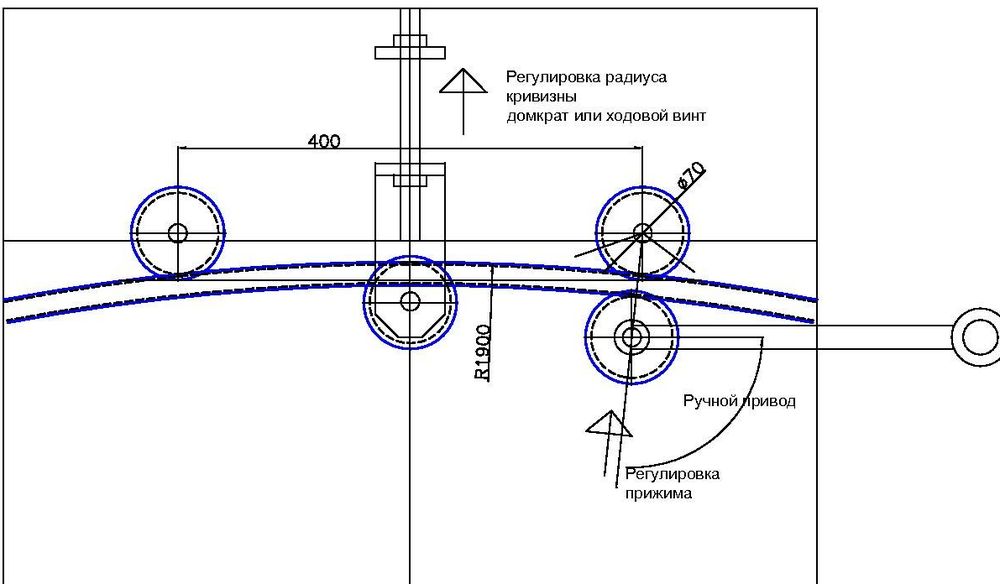

- A design in which the movable roller is in the middle, and the outer rollers are fixed to its body. They are slightly raised above the base. The middle roller is installed on a specially mounted U-shaped pedestal, in the middle of which a large clamping screw is attached. From the bottom edge, a pressure roller is welded to the screw. During the rotation of this screw, the profile is lowered or raised, which leads to its bending. A handle should be welded to one fixed roller, with its help the profile moves around the machine. To facilitate the rolling process, the fixed shafts are connected by a chain.

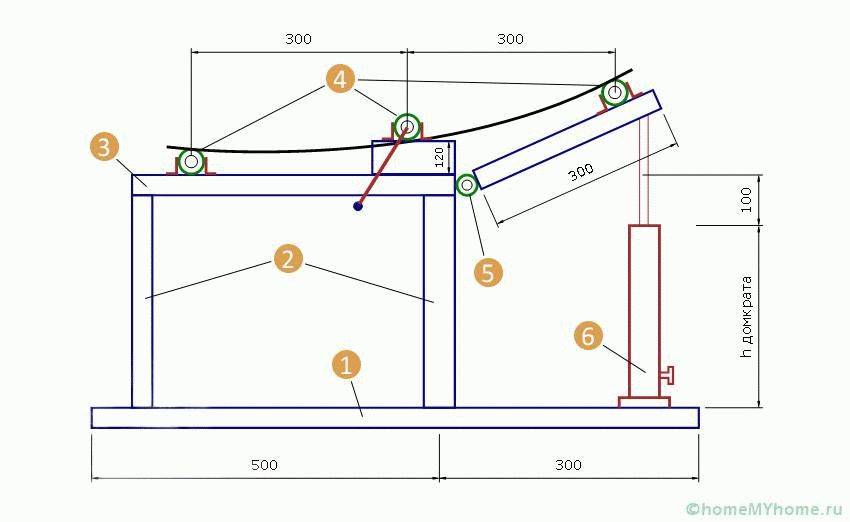

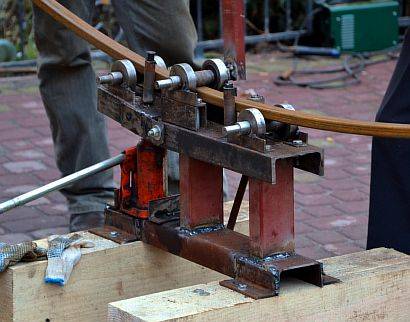

- With a movable shaft on the edge - it is placed on the right or left. It rotates together with a part of the base, which is connected to the bed with metal loops.The angle of the bend is affected by the level of the table, the height of which is changed by the jack. The design rotates due to the central roller, to which the handle is welded. To reduce the applied forces, the device can be equipped with a chain.

Summing up, let's say that the most suitable type of pipe bender, for giving the desired bend to a profile pipe, when installing a greenhouse or some structure in a house adjoining area, is with a manual drive. After all, the size of the profile blank and the amount of work are small.

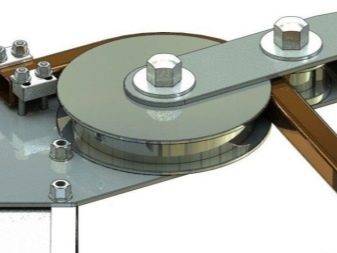

With pinch roller

This type of pipe bender will be more structurally complex, but you can also work on it with thicker-walled pipes.

The main elements of such a pipe bender are the rollers between which bending occurs. The first is attached to the desktop, and a professional pipe bends around it. The second is movable, it presses the pipe against the first, for bending.

The rollers for such a machine are made of metal or wood. Metal rollers are used to bend steel pipes. Wooden rollers are used to bend pipes made of copper or aluminum to avoid deformation.

For self-assembly of such a machine you will need:

- solid base - wooden or plywood;

- two rollers - metal or wooden;

- U-shaped holder for rollers;

- reliable handle.

The holder must be made of metal, as it will experience heavy loads. The rollers are attached to the holder on both sides. Further, this entire structure is attached to the base, through the center of the first roller

It is important to ensure that the holder rotates around the first roller. A handle is attached to the other side of the holder. The length and thickness of the handle is selected based on which pipes are to be bent

She can be under a lot of pressure.

The length and thickness of the handle is selected based on which pipes are to be bent. She can be overburdened.

You may like

VK comments:

Name *

Comment

Types of machines

According to the requirements of operation, there are fixed (stationary) and manual machines. Stationary structures are used to a greater extent in factories. A hand-made hand-held device is more suitable for work at home.

Depending on the drive, there are several types of pipe bending devices:

- Hydraulic (using a hydraulic jack). They are stationary and manual. Bends pipes up to 3 inches in diameter. Such machines are used in special industries and can carry out an impressive amount of work.

- Mechanical. Pressure is generated manually using the main screw or lever.

- Electrical. Bending occurs due to the electric motor), suitable for bending any pipes - both with thin and thick walls. Thanks to electronics, accurate calculations of the bending angle are made. Such pipes do not have deformations.

- Electrohydraulic. The hydraulic cylinder is powered by an electric motor.

It is possible to bend the pipe in different ways.

In this regard, pipe benders are divided into:

- Segment. They are equipped with a special device that simultaneously pulls and bends the workpiece at the desired angle around the segment.

- Crossbow machine. It is equipped with a special mechanism consisting of a bending component.

- Spring devices. Supplied with springs. On such machines it is possible to process metal-plastic parts.

- Soddy.It consists of a guide, which is placed inside the pipe before starting work. Such an element with a mandrel protects the part from deformation and flattening. This machine is used in the manufacture of automobile pipes and for bending aluminum pipes.

- Lint-free. Bending is performed by winding the part on a bending roller.

From the length of the workpiece to be bent, two types of devices are used:

- lever machines;

- rental devices.

Lever type devices are considered the most common in use. There are also turf and crossbow pipe benders in industrial production. The principle of operation of such machines consists in two guide rollers and a pressure template (mandrel). Such a mechanism makes it possible to carry out cold processing of round metal pipes in small areas. Due to its small dimensions, the crossbow pipe bender is considered a more common device among professional installers of technical communications. The device got its name due to the fact that the design is similar to a crossbow.

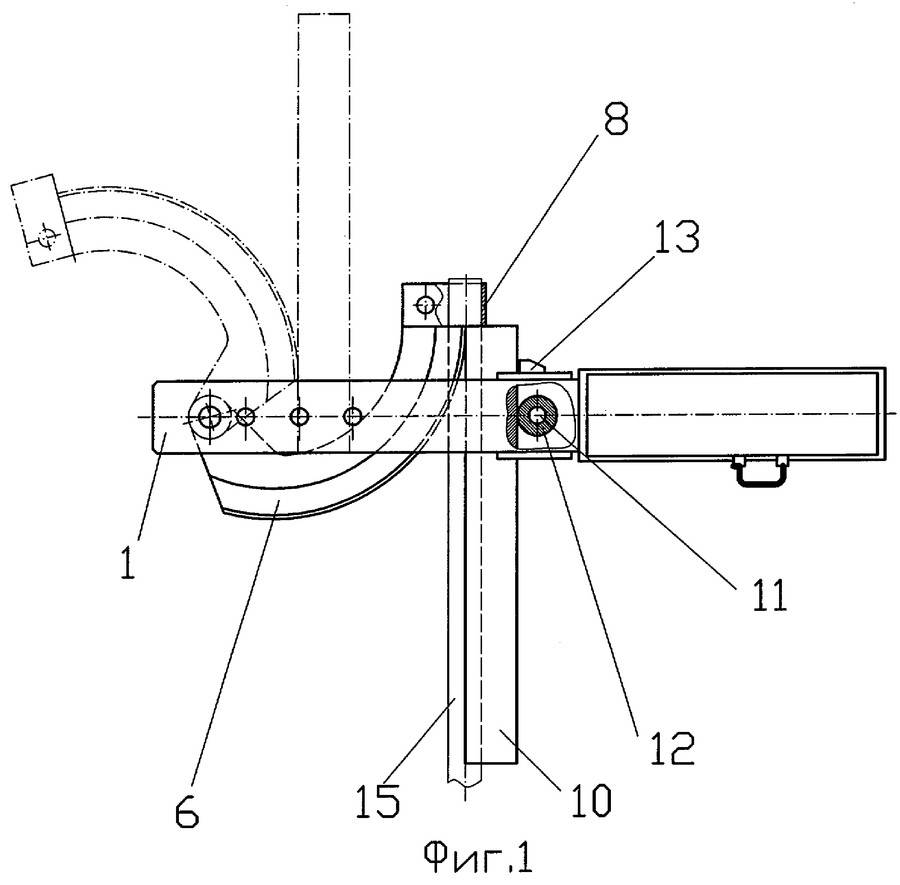

For the production of a significant number of monotype parts with a small bending radius, it is possible to use a snail pipe bender. This device consists of two pulleys (wheels) of different diameters, fixed on the shafts. Having fixed one end of the pipe on the wheel, the roller of the smallest diameter (the main wheel) exerts pressure on the workpiece, at the same time rolling the roller over the workpiece area. Because of this, the pipe bends along the surface of the large pulley, acquiring its shape. The only disadvantage of this method is the impossibility of extracting roundings of a larger radius.

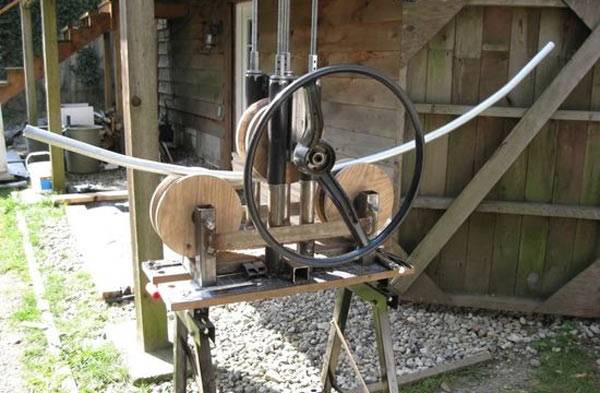

Do-it-yourself rolling (bending) machines are considered practical and versatile in work, in which it is possible to adjust the deformation angle of a metal pipe. The simplest rolling machine system consists of a base and a drive shaft fixed on it, located at a certain distance from each other. The pressure on the pipe is exerted by a movable roller, and its pulling is performed due to the rotation of the main shafts. When creating small radius bends, you will need to make 50-100 runs. To avoid deformation, the product should be rolled at the same speed. Assemble the rolling mechanism yourself at home it will be difficult, as turning and welding work will be required.

How is a pipe bender arranged?

The specific design of the device depends, first of all, on its purpose, however, without fail, the pipe bender includes:

- frame;

- a pair of pipe stops;

- hydraulic cylinder;

- straps (upper/lower).

Note also that the frame can be either open or closed. As for the hydraulic cylinder, it is the main part of the device that performs the power function.

Also in the do-it-yourself pipe bender circuit there is an injection device, which is located on the back of the case; in the same place is the bypass valve screw, the handle. But on top of the cylinder there is a plug through which oil is poured inside and its level is checked. The unit bar located at the bottom is screwed onto the thread located in front of the housing, and then pressed with a special fixing nut. Additionally, the bar is fastened with a lock and a pair of screws.

For manual reinforcement, a retractable rod is used, which returns back thanks to a spring located in the cylinder. The pipe bender bars are made as a welded structure. On the transverse plates there are holes through which the stops are installed. In the lower part of the body there are also threaded holes for mounting bolts, adjustable in height.

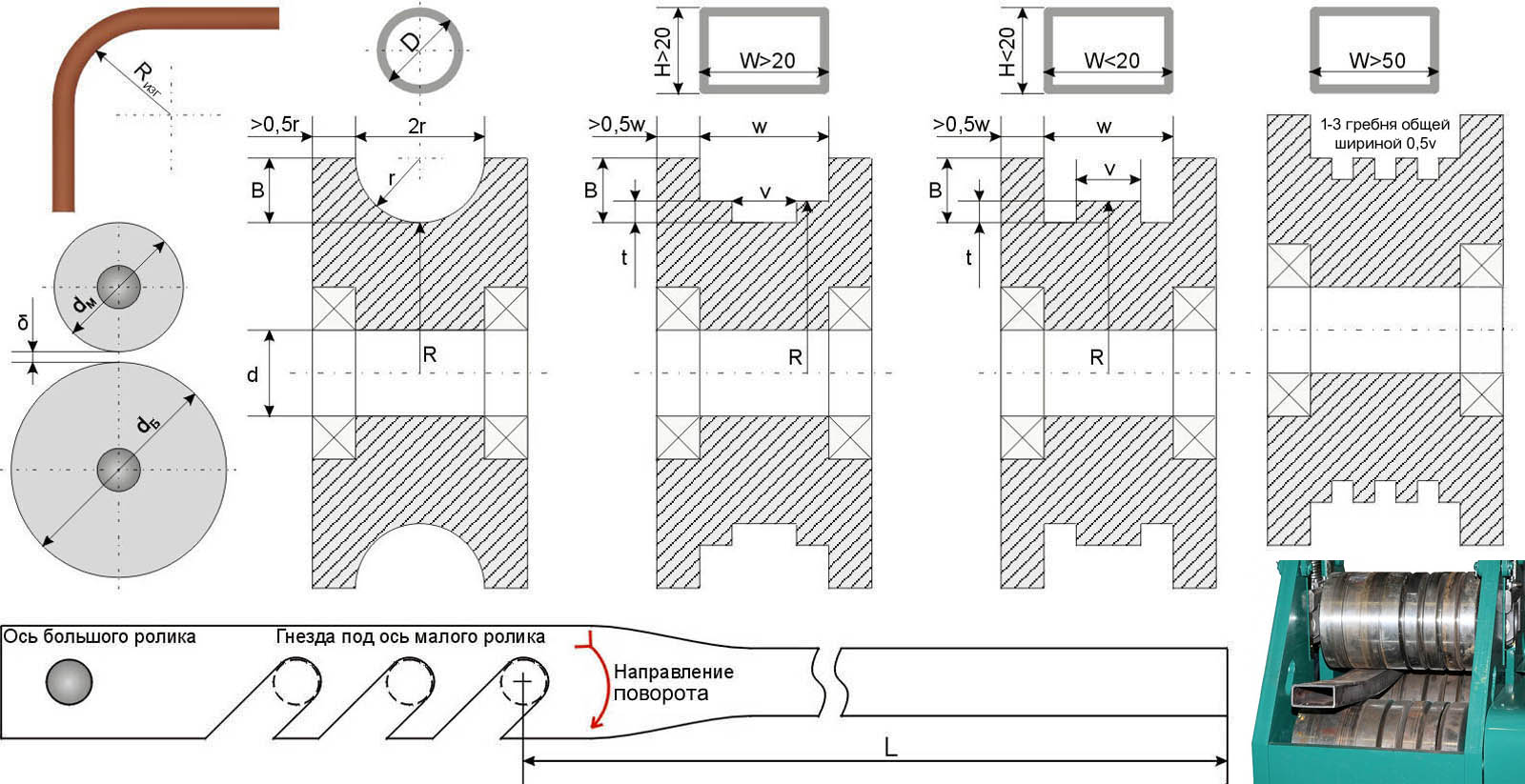

Considering a do-it-yourself pipe bender, one cannot fail to note the fact that thin-walled profile pipes have become increasingly popular in recent years, moreover, they make it possible to create durable and attractive structures, as well as save on construction work. It is from such pipes that greenhouses and various sheds are made today. What is the difference between a profile pipe and an ordinary one? First of all, the cross section, which in this case is not round, but oval, rectangular or square. This is precisely what explains the design features of the pipe bender for this type of pipe - the rollers must be of the same cross section as the products being bent, otherwise the cross section of the latter may be deformed.

Hydraulic Pipe Bender

When making a pipe bending machine with your own hands, you should decide what kind of drive will be. In most cases, home-made versions have a manual drive, as it is easy to manufacture and is cheap. However, such a design cannot work with workpieces that are made using hard metals. The hydraulic pipe bender allows you to work with workpieces of large diameter and with a significant wall thickness, however, the design is quite complex in execution and has many features.

Manual hydraulic pipe bender device

When making a machine for a round pipe with a hydraulic drive, the following points should be considered:

- The transmission of force is carried out through the working fluid, which is oil or water. All lines must have a high degree of tightness, and also be designed for a certain pressure.

- A compressor can be used to create pressure.

- The pressure is transmitted to the working body through a hydraulic cylinder.

A do-it-yourself hydraulically driven pipe bender for metal-plastic pipes can have a very different design. An important element in this case is the drive, which allows you to automate the bending process and increase the scope of the device.

Why is it worth it

All three ways to make a simple do-it-yourself pipe bender are effective and accessible to anyone who has locksmith skills, knows how to work with electric welding and read technical drawings. In the conditions of a small metalworking workshop or a metalworking workshop, it is all the more easy to build a home-made pipe bender - if there are specialists of different profiles, you can make a tool in one day.

Why a home-made pipe bender is relevant for industrial enterprises will be understood by everyone when they see the prices for factory-made machines. With self-assembly of a pipe bending machine, even if you have to buy all the parts on the market or in a store, it will cost several times cheaper than when buying. Moreover, a do-it-yourself pipe bender can be adapted to your needs as much as possible by making changes to the basic drawings, according to the specifics of its future use.

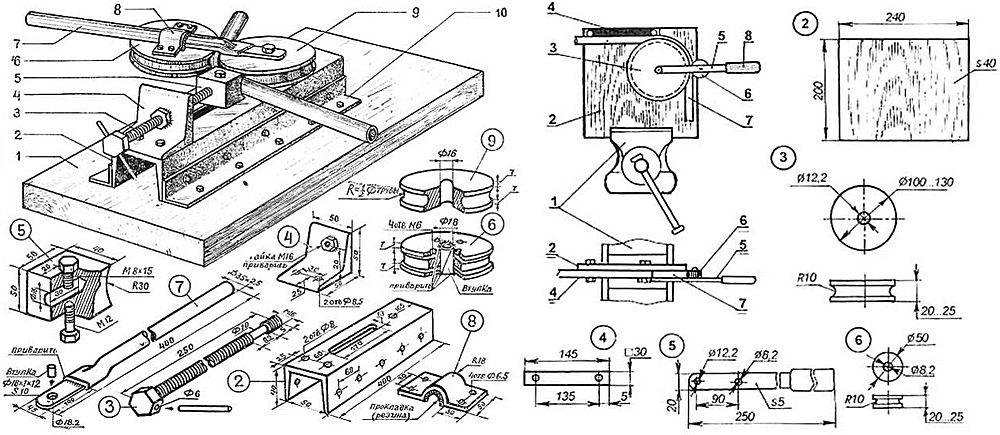

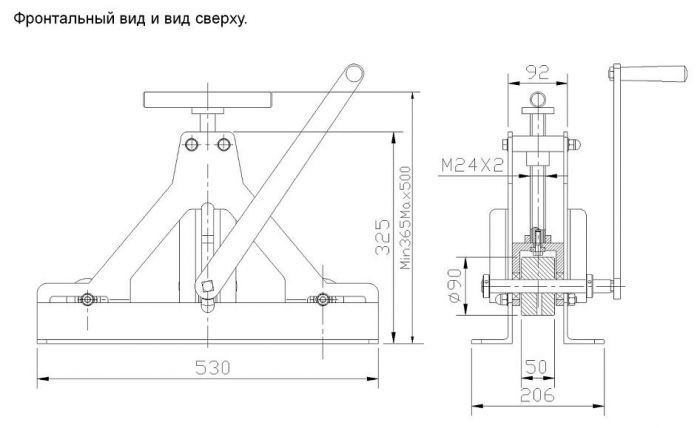

Basic structural elements

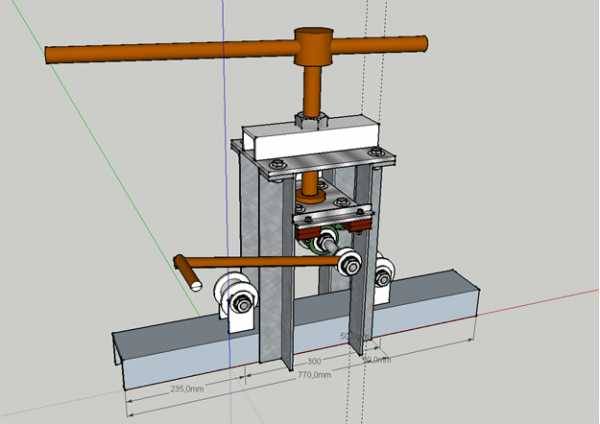

Principle of operation

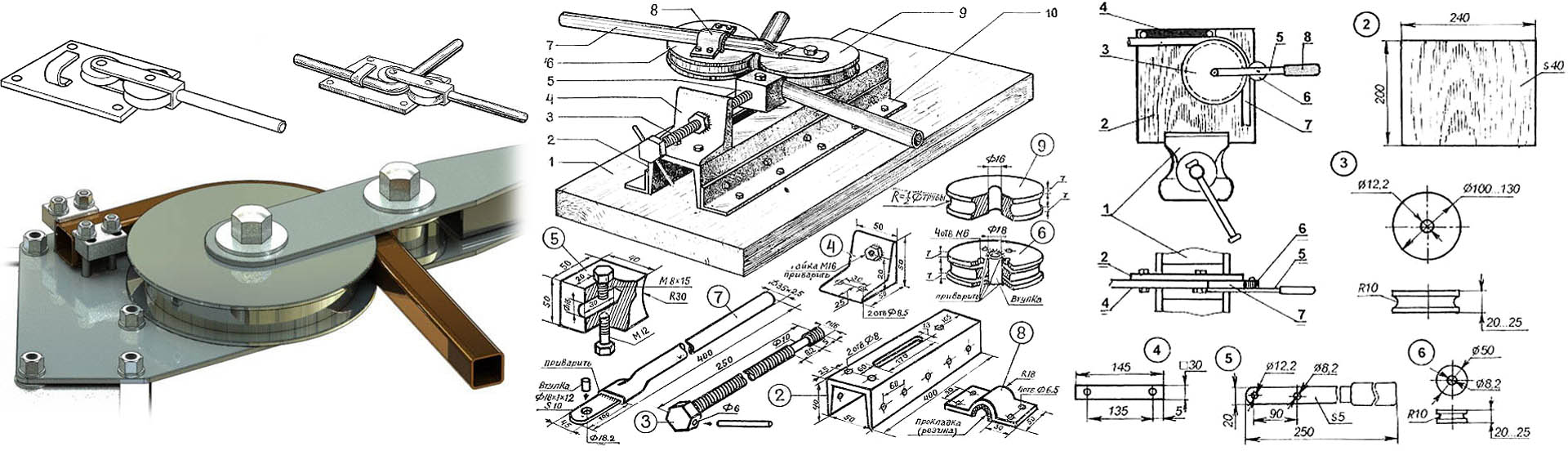

For the manufacture of a particular machine design, you should look at several diagrams to determine the set of parts. The fact is that, if necessary, all the components of the nodes can be purchased for money, but you can also use the materials that are on your farm and do not pay anything for it. In most cases, home craftsmen stop at frontal structures, and for this you should have available:

- three metal rollers (rollers);

- drive chain;

- axes of rotation;

- drive mechanism;

- metal profiles (channels) for the frame.

Sometimes, in the absence of metal rollers, they are replaced with wooden or polyurethane ones, but ... Such a rolling mechanism will not withstand a long load, that is, the machine will serve its purpose, but not for long. Is there any point in wasting your labor for a short-term benefit if, with effort or even paying a certain amount, you can find steel rollers?

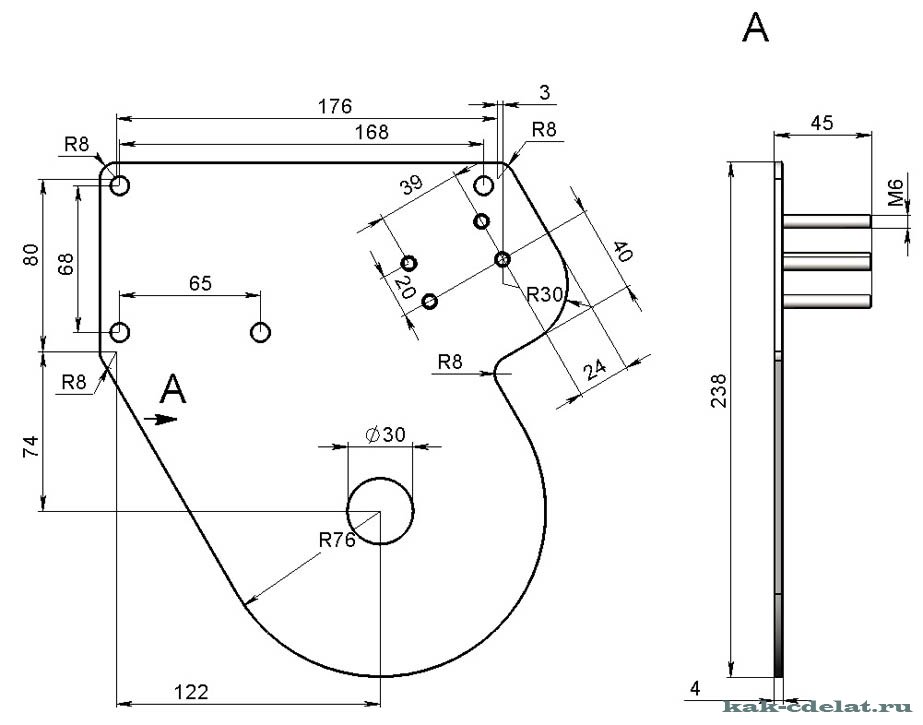

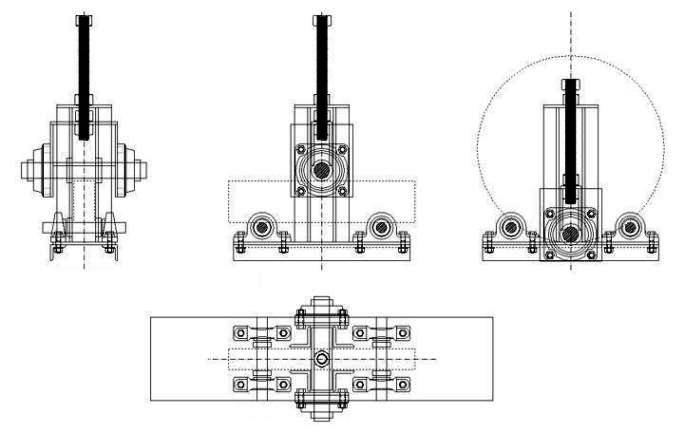

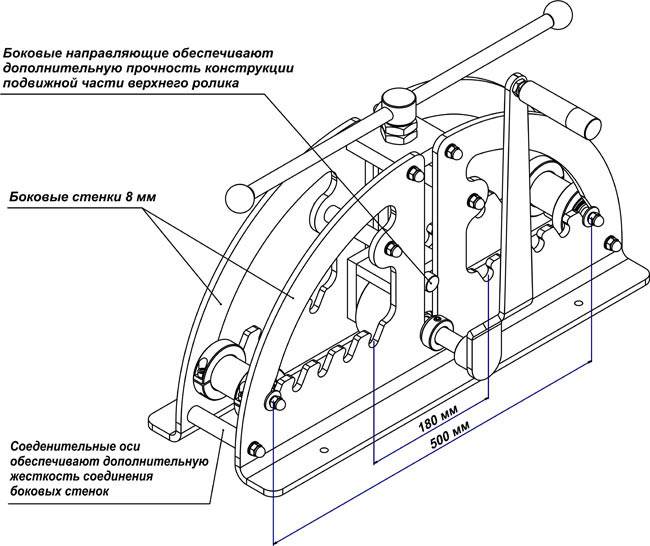

Scheme of a simple pipe bender with dimensions in mm

As you understand, the process of profile deformation occurs with the help of rolling, that is, the pipe is rolled over rollers (rollers), which eliminates fracture and cracking. For rolling (bending) the profile is inserted into the rolling line (between the rollers) and pressed from above with a screw fixture or jack to the desired bending radius. Then, when the feed knob is rotated, the pipe moves and the bend runs along its entire length. It turns out that this is a manual drive, which is set in motion by muscular strength, but at home such a mechanism is very convenient.

The profile is clamped with a jack

To assemble a simple do-it-yourself pipe bender in question, you will need:

- jack (preferably rack type);

- metal profiles with a shelf for a horizontal and vertical frame;

- alloy steel springs (they are distinguished by high strength);

- three steel shafts with bearings;

- chain for drive (can be from a bicycle or moped);

- gears (leading and driven);

- thick fittings for axles and drive handle.

Video: pipe bending process

As you can see, it is easier to make a profile bender with your own hands according to the available drawings, and photo and video materials only help in this. The profile bender shown in the picture is driven by a handle that rotates a shaft with a drive gear. With the help of a chain, rotation is transmitted to the shaft with the driven gear, and the third shaft presses the profile from above to the required bending angle. Everything is very simple.

Movement manufacturing process

Bending device drawings

If you are interested in how to make a profile bender, then you will have to perform a series of actions that will ensure this reliability of the mechanism, and this:

- production of a powerful frame assembled by welding and bolt ties;

- according to the terms of the drawing (technical assignment), make and install the axis of rotation for the rollers. There are three of them - two rolling and one clamping;

- for the rotation of the rolling rollers, it is necessary to provide a chain transmission, that is, to weld (exactly) the driving and driven gears;

- weld a handle on the drive gear for rotation.

Manufacturing nuances

Ready pipe bender

If you have all the necessary parts available, then it is not difficult to make a mechanism for profile bending.First of all, you need to take into account that all rollers must rotate on bearings - the accuracy of rotation will ensure the correct rolling, without failures and kinks. The driving and driven gears must be correctly centered - a failure from the center by at least 0.5 mm will lead to incorrect deformation (the bend will turn out to be uneven).

The pressure roller must also be centered - the accuracy of the bending angle depends on this. Best of all, when the dimensions of all three shafts are the same - the rolled product is the most clear. The accuracy of rolling also depends on the rigidity of the clamp, so the shaft must be well fixed.

Note to craftsmen

Useful advice from the masters are always popular and in demand. Based on the experience of the master, you can avoid various mistakes when carrying out the relevant work:

- In manual devices, it is not at all necessary to resort to installing a chain transmission, since the design will function when only one shaft moves.

- To prevent the pipe from slipping off the template, according to which it is bent, it is necessary to use appropriate metal hooks.

- If you need to get a pipe bend of a large radius, then three rollers are used.

- When designing a manual machine, care should be taken in advance to be able to adjust the bending radius.

The video shows another version of the manufacture of a manual pipe bender with two stars. A useful thing that does not require large economic and physical waste.

If you have a pipe bender at your disposal, then you can even earn money on it. Indeed, with its help, you can not only bend a profile pipe, but also reinforcement, obtaining the necessary patterns.Curved fittings are used for the manufacture of decorative elements for entrance gates, visors, awnings, etc.