- Features and technical characteristics of water and gas pipes

- Standards and dimensions of steel pipes

- Parameters for straight seam weldments

- Regulations for electric-welded spiral-seam pipes

- Requirements for seamless hot-formed products

- Standards for cold-formed seamless pipes

- Features and characteristics of water and gas products

- Scheme of ductile iron pipes

- Specifications

- Why choose metal for heating systems

- Types of pipes by production method

- Seamless hot-formed steel pipes GOST 8732

- Pipes steel seamless cold deformed in accordance with GOST 8734

- Electric-welded steel pipes according to GOST 10704

- Pros and cons of metal pipes

- What are the GOSTs for steel pipes

- Production of steel pipes: basic methods

- How are electrically welded straight seam products made?

- Production of electric welded spiral seam types

- Production of hot-formed seamless products

- Features of the production of cold-formed pipes

- Overview of products from leading manufacturers

- Manufacturer #1 - HOBAS brand

- Manufacturer # 2 - Glass Composite Company

- Manufacturer #3 - brand Amiantit

- Manufacturer #4 - Poliek company

- Rectangular pipe

Features and technical characteristics of water and gas pipes

VGP pipes are products that have a welded seam.Their production is much cheaper than the production of solid-rolled pipes. Rigid standards make it possible to produce welded pipes that are not inferior in strength to solid-rolled pipes. For protection, a zinc coating is applied both inside the pipe and on its outer side.

Galvanized VGP pipelines are distinguished by:

- resistance to corrosion;

- long trouble-free operation;

- versatility of use;

- relatively low price.

Electric welded pipes distinguish between black (without anti-corrosion coating) VGP pipes and galvanized pipes. The official requirements for these materials are set out in GOST 3262-75. Round VGP pipes from production are produced smooth, with a thread or a coupling. The thread differs in location (external or internal) and in the method of application (knurled, cut).

The rolling thread must not reduce the inside diameter of the pipe by more than 10%. There are no strict requirements for the size of the thread - it can be either long or short.

Common for shaped and welded round steel pipes is their use in urban infrastructure, not related to transport communications. This is the design of billboards, the improvement of urban street space, adjacent territories, the construction of playgrounds. "Non-core" use of galvanized pipes reaches a significant scale.

We recommend that you read: Which heating is better and how to install it in a private house

A significant characteristic of the VGP of pipe material is the wall thickness. The longest-lived pipes are thick-walled galvanized pipes.

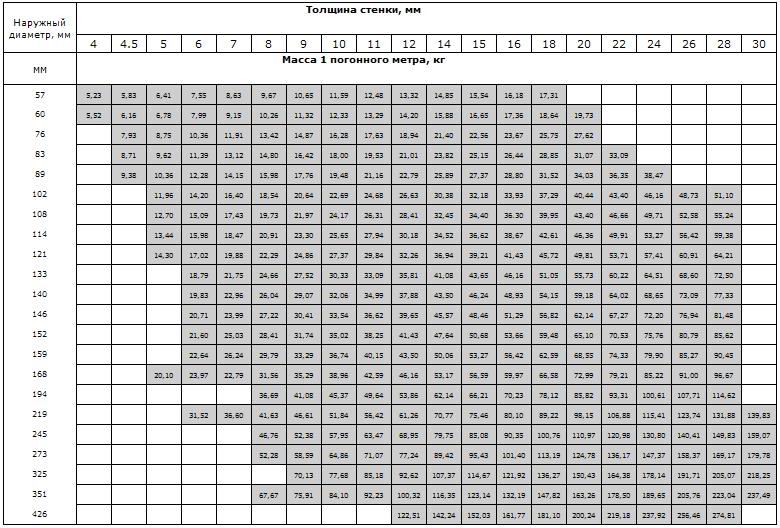

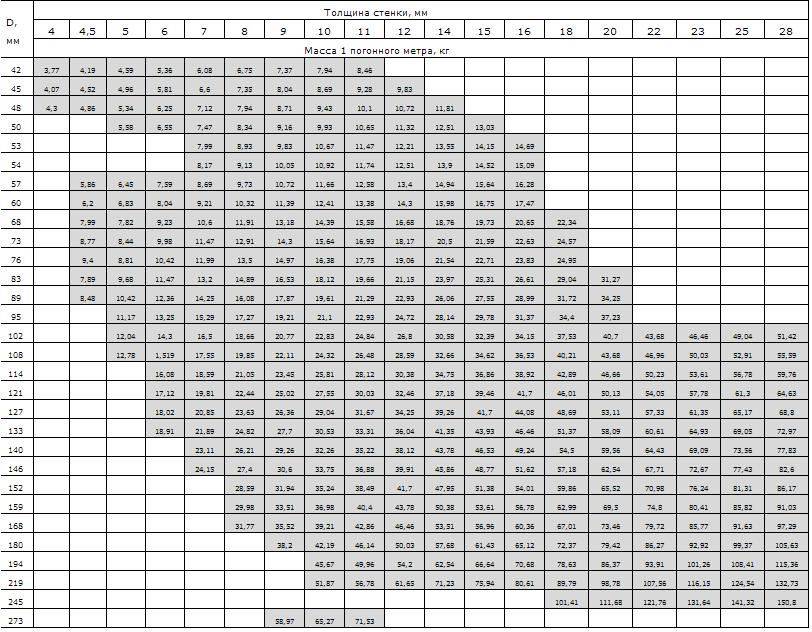

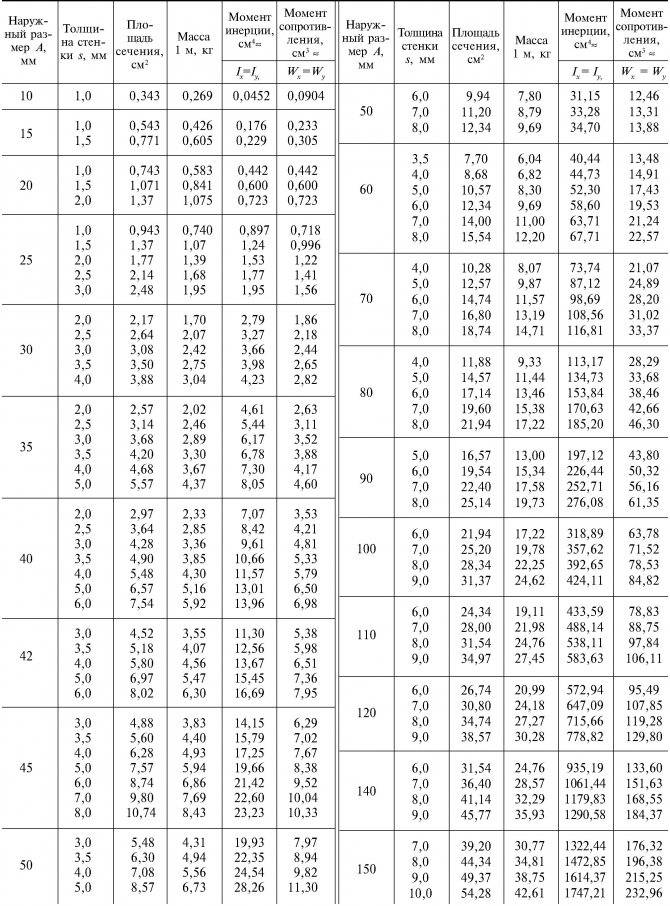

It should be borne in mind that the thickness of the pipe wall affects its diameter and weight. The outer dimension of the galvanized steel VGP pipe remains unchanged, regardless of the wall thickness.Thus, the best throughput, ceteris paribus, will be demonstrated by a thin-walled pipe. Pipes are manufactured according to the dimensions and weight given in the table, the dimensions are indicated in mm.

With working pressure inverse relationship. A thin-walled pipe can withstand up to 25 atm., Thick-walled - up to 35 atm.

Pipes with an average wall thickness are called ordinary. The purchase of pipe products of this type is carried out by weight, i.e. the consumer does not pay per linear meter, but the price is tied to the weight of the product.

Standards and dimensions of steel pipes

For pipes made of rolled steel, there are special standards and GOSTs. These parameters describe the method of manufacturing the product, its basic dimensions, cross section and wall thickness. Focusing on this information, the area of \u200b\u200buse of a particular part is determined.

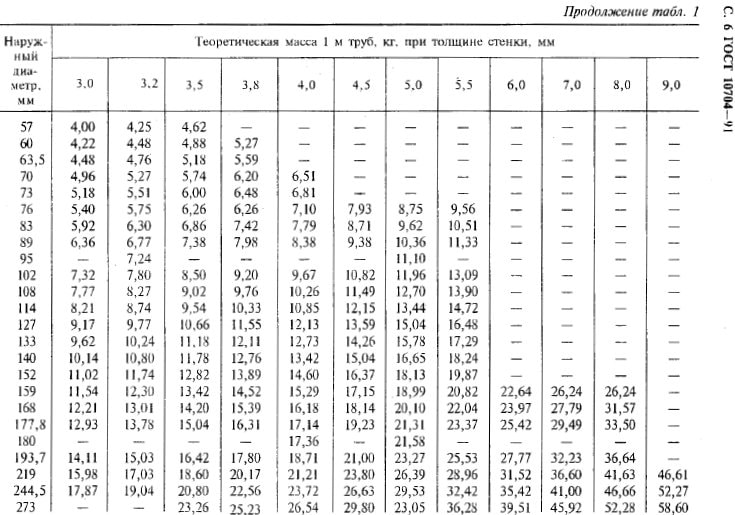

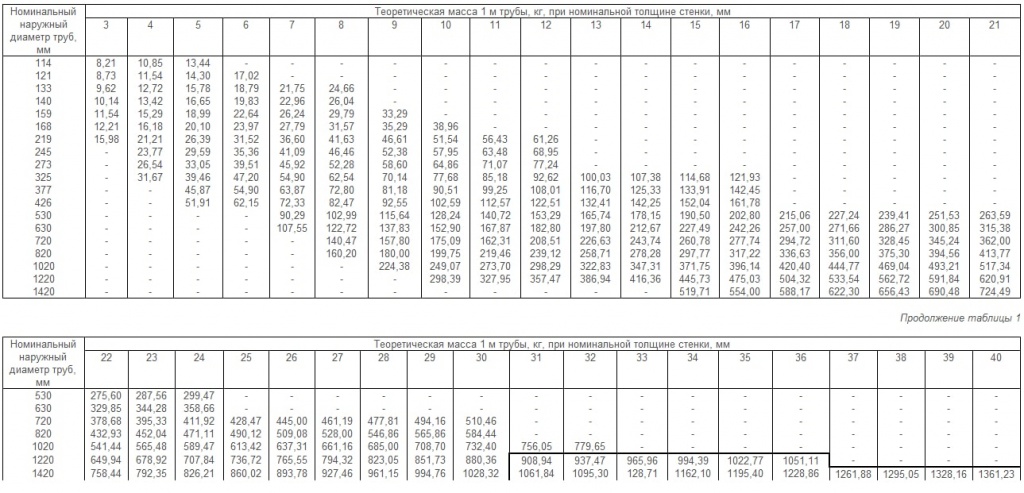

Parameters for straight seam weldments

The production of electric-welded pipes with a straight seam is regulated by GOST 10704-91. According to him, the outer diameter of the product is 10-1420 millimeters, and the wall thickness varies from 1 to 32 millimeters.

Reinforcement, not exceeding 426 millimeters in diameter, has a measured and unmeasured length. In special cases, pipes are made with a stronger, reinforced seam, but for them there is a separate special standard - GOST 10706.

Steel electric welded pipes with a straight seam are a versatile material with a wide range of applications. Decent quality and low price make their use relevant both in large-scale facilities and in everyday life.

Pipes of this type are most often used for laying technological communication systems with moderate pressure and creating practical, convenient and lightweight metal structures for various purposes.

Regulations for electric-welded spiral-seam pipes

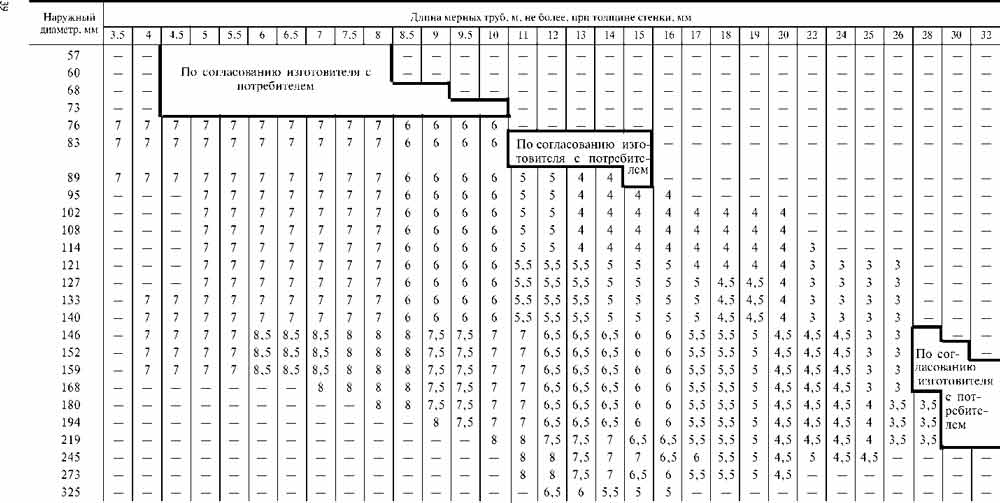

The production of electric-welded pipes with a spiral seam is carried out in accordance with GOST 8696-74. The outer diameter of such products is 159-2520 millimeters, the wall thickness ranges from 3.5 to 25 millimeters, and the length is 10-12 meters.

Electric welded pipes with a spiral seam are more expensive than their longitudinal counterparts. However, the costs are well justified, especially if the system requires a flawlessly accurate, perfect connection.

Pipes made in this way are more durable and have the ability to withstand high pressure. The standard allows them to be used both for domestic and industrial purposes, to create reliable, sealed and operationally stable communication systems.

Requirements for seamless hot-formed products

Standards for seamless hot-formed pipes are described in GOST 8732-78. The thickness of their walls is 2.5-75 millimeters, and the diameter varies from 20 to 550 millimeters. In length, both measured and unmeasured, the size ranges from 4 to 12.5 meters.

Seamless pipes made by hot deformation are practically not used in everyday life. Most often they are used for industrial systems with increased requirements for reliability and tightness.

Pipes of this type are used to transport highly toxic substances for chemical industries. The absence of a seam guarantees the impossibility of leakage and ingress of harmful substances into the ground or atmosphere.

The ability to easily withstand constant high pressure makes seamless pipes relevant to the oil and gas industry.

Standards for cold-formed seamless pipes

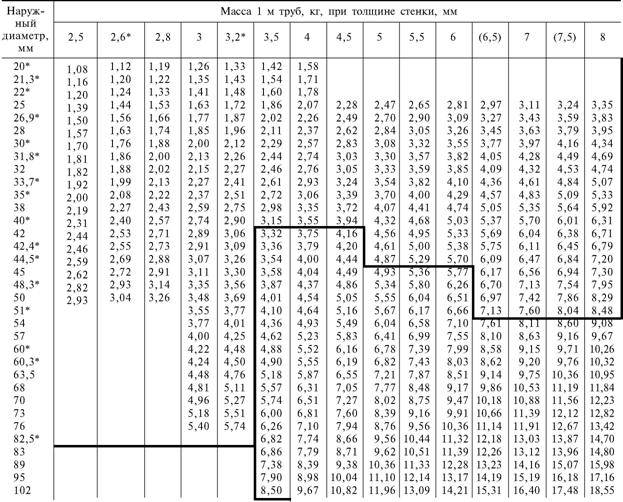

Steel cold-rolled pipes are manufactured in accordance with GOST 8734-75. The outer diameter of the reinforcement varies from 5 to 250 millimeters, and the wall thickness is 0.3-24 millimeters. Products are produced in random lengths from 1.5 to 11.5 meters and measured lengths from 4.5 to 9 meters.

Thick-walled seamless cold-rolled steel pipes are used in the same way as hot-worked pipes. And thin-walled ones are most often used where a combination of impeccable strength and low weight is needed (aerospace industry, shipbuilding, etc.)

Seamless steel pipes produced by cold forming demonstrate high strength, operational stability and reliability throughout the entire period of use.

Features and characteristics of water and gas products

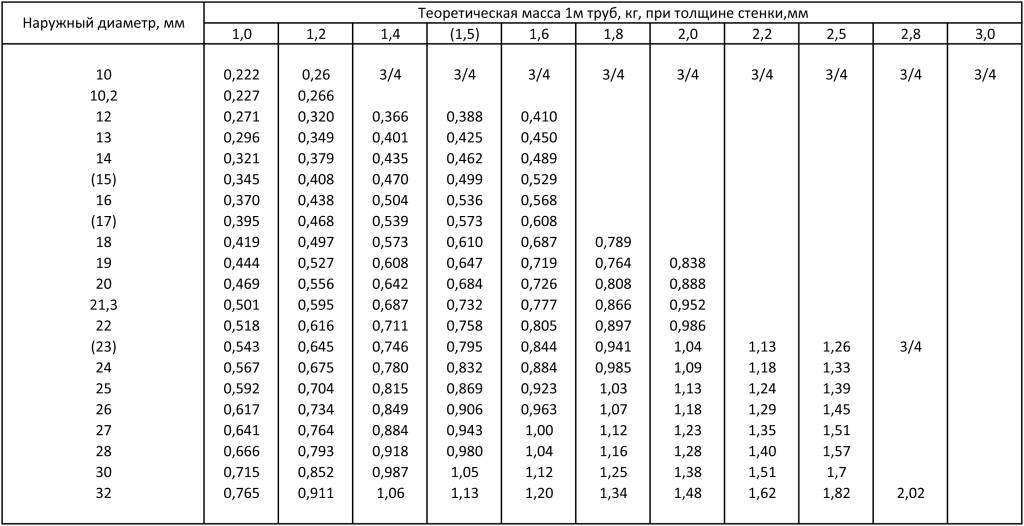

Gas and water pipes are produced according to the regulations of GOST 3262-75. In a separate standard, this type of rolled metal is distinguished only because of a narrower scope.

The outer diameter of the product is 10.2-165 millimeters, and the wall thickness ranges from 1.8-5.5 millimeters. The size range for random and measured lengths is the same - from 4 to 12 meters.

Water and gas pipes are mainly used for their intended purpose: for the organization of water supply and gas communication systems. Sometimes they are used to create lightweight structures or are used in the furniture industry to make stylish interior decor items.

The standard provides for the production of not only conventional, but also galvanized water and gas pipes.

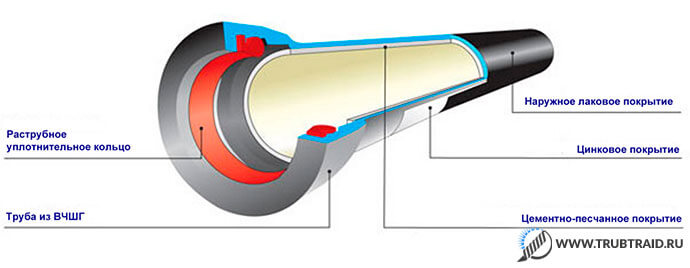

Scheme of ductile iron pipes

Visual drawing of high-strength cast iron pipes with a spherical decanter

Visual drawing of high-strength cast iron pipes with a spherical decanter

As it becomes clear, the design consists of some external and internal elements:

- Sealing ring: this protective layer is needed to enhance the strength of the structure. It also serves as a fuse in case the pipe breaks or deforms.

- Zinc coating: necessary to significantly reduce the effect of corrosion on the outer surface of the structure.

- Cement-sand coating: serves as a kind of grounding against the effect of electricity on the surface of the pipe. In the event of an accident with an electric current, it is this protective layer that will take the brunt of the blow.

- VChShG: actually the main material from which the structure is made.

- The final layer: it contains the least impurities and alloys, since it has the least load.

This scheme presents the physical and mathematical quantities, on the basis of which calculations are carried out and the dimensions of structures are set.

Description:

- Bell, D: a physical quantity that characterizes the fundamental parameter at the start of production - the zero cycle. It is the basis for the construction of pipe structures.

- Nominal passage, DN: nominal value characterizing the passability of the transport substance through the internal channels of the pipe.

- Average Diameter, DE: A conditional parameter used to calculate the space between the inner, outer and middle diameters.

- Pipe wall area, S: fundamental parameter in calculating the main parts of the pipe.

- L and L1: the length of individual sections of the structure.

Specifications

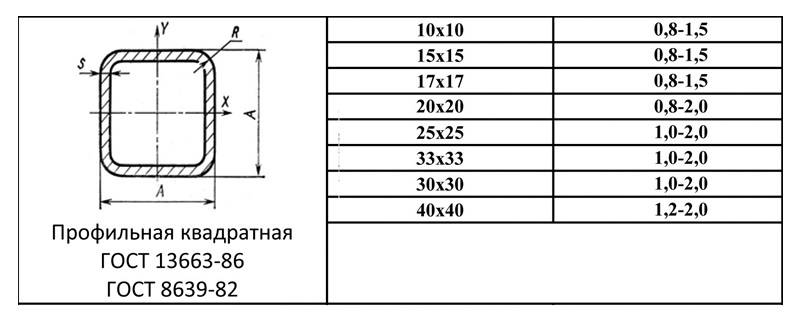

Consider the main technical characteristics of a profile steel pipe:

- Profile view. Its main types are square, rectangular and oval.This criterion determines the division of the pipe profile in the general assortment.

- geometric dimensions. For rectangular views, these are the width and height. As well as the length of each segment.

- Wall thickness. Quite a significant detail, because it is it that determines the scope of further use.

- Weight. An equally significant assessment that determines the quality level of goods. Through weight and geometric dimensions, you can find out the wall thickness. This becomes very useful in situations where the ability to access measurements is not available.

Describing steel professional pipes, it should be noted that their range is determined by GOST 8639-82. In this document, three main types of profile are distinguished:

- Cold-formed.

- Hot rolled.

- Electrowelded.

The first two are seamless, and the third is produced from sheet material using welded technologies.

The first two are seamless, and the third is produced from sheet material using welded technologies.

It should be noted that any characteristic of a pipe is dependent on a number of its other indicators. For these reasons, we can conclude that the presence of a table of the corresponding calculated values of GOST makes it easy to find out how high the level of quality is from one or another manufacturer.

Why choose metal for heating systems

For more than twenty years, there was practically no alternative to steel pipes - carbon (colloquially black metal), galvanized, stainless steel. At that time, they did not hear about the use of copper for heating; plastic pipes were not even mentioned in progressive scientific journals. Now the situation has changed radically: several types of inexpensive high-tech plastics have strongly pushed metal out of heating systems.

Nevertheless, metal pipes are still indispensable in many situations: when systems operate at very high operating pressures, in hot shops, when high strength is required from pipelines.

Types of pipes by production method

There are the following methods of pipeline production: hot-formed, cold-formed, electric-welded. Dimensions and maximum deviations of products, materials of manufacture are regulated by assortments for round steel pipes, different assortments for each production method:

Seamless hot-formed steel pipes GOST 8732

The production of pipes takes place in three stages. At the beginning, in a round billet heated to 900-1200 degrees, a hole is pierced on special machines, as a result, a sleeve is obtained. Next, the sleeve is rolled into a draft pipe, and the last stage is sizing, rolling with final dimensions in terms of thickness and diameter.

The dimensions of the products obtained by this method of production can be: outer diameter 16-630 mm, wall thickness 1.5-50 mm. The blanks of products are divided into several groups, depending on the material used for manufacturing:

- A - the mechanical properties of the product are normalized.

- B - the chemical composition is regulated during manufacture.

- B - mechanical properties and chemical composition are simultaneously regulated;

- D - the chemical composition is normalized and the mechanical properties are checked on prototypes;

- D - the value of the test pressure during verification is regulated.

Production of hot-formed pipes

Pipes steel seamless cold deformed in accordance with GOST 8734

For rolling, round steel billets are used.The workpiece is heated in special furnaces to the temperature of the beginning of crystallization to obtain the necessary plasticity. Then it is stitched and enters the rolling mill, where the rough dimensions of the product are formed with the help of rollers. The last operation is sizing and cutting to a certain length.

Unlike a hot-formed pipe, a cold-formed pipe receives additional heat treatment during calibration, which makes such products stable and durable.

Cold-formed products are divided into the following categories, where the main criterion is the ratio of the diameter D to the wall size S:

- Particularly thin-walled, with a D / S ratio greater than 40. If the dimension D = 20 mm or less, the dimension S = 0.5 mm or less.

- Thin-walled, with a D / S ratio of 12.5 and less than 40. In addition, pipes with D \u003d 20 mm. and less, at S=1.5 mm, and less.

- Thick-walled, with a D / S ratio of 6 to 12.5.

- Particularly thick-walled with a D / S ratio of less than 6.

Thin-walled and extra-thin-walled pipes are used in various hydraulic systems, automotive engines, industrial refrigeration systems, as well as in the medical and food industries. The main application of thick-walled pipes is in the oil and gas industry.

Thin-walled cold-rolled products

Electric-welded steel pipes according to GOST 10704

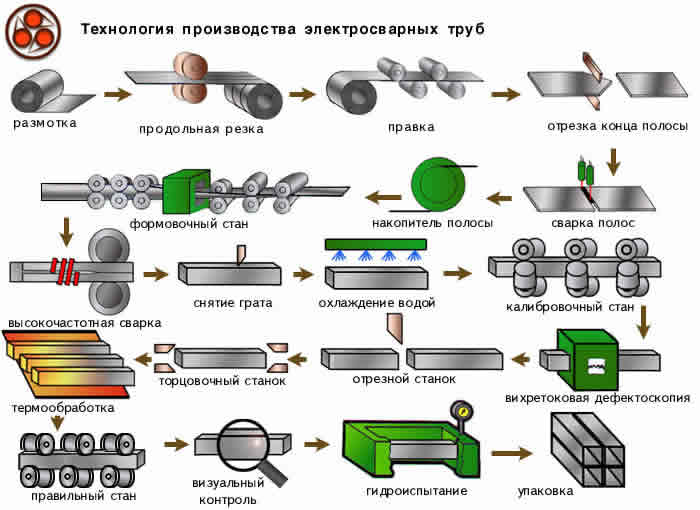

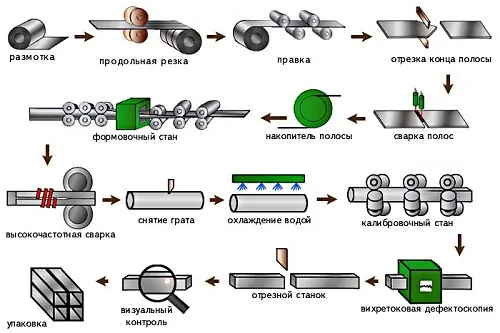

The manufacturing technology includes several stages, which are combined into one continuous process:

- Sheet cutting. It is performed on high-precision machines and allows you to get blanks of the same size.

- To obtain an endless tape, the strips are welded together, previously passed through a system of rollers to eliminate surface defects.

- The resulting workpiece is passed through a system of horizontal and vertical rollers, with which the product is formed.

- Edge welding is performed using high-frequency welding. The edges of the workpiece are heated by an inductor to the melting temperature, and then squeezed by crimping rollers. Another way, when the edges are heated with a high-frequency generator, current is applied to the edges using contacts.

- Calibration and deburring. The workpiece is cooled, and then passed through the calibration rollers to eliminate ovality and ensure the required dimensions.

- Product cutting. The blanks are cut to the required size.

- Quality control of manufactured products is carried out in three ways: weld inspection, high water pressure test and flattening. To control the weld, the ultrasonic method is mainly used. The flaw detector is located directly on the line after the welding operation. 100% of products are subject to control. 15% of the products from the batch are subjected to hydrotesting. And two products from the batch pass the flattening test.

Scheme for the manufacture of electric-welded pipes

Scheme for the manufacture of electric-welded pipes

Electrowelded pipelines are widely used in the laying of engineering networks that can withstand heavy loads and pressures. Products with a diameter of 1200 mm. used in the installation of almost all main gas pipelines and oil pipelines.

Pros and cons of metal pipes

Advantages of metal products:

- strength. Steel, copper and cast iron are able to withstand much more pressure than plastic and are much more resistant to water hammer;

- strength as a guarantee of non-destruction of pipes when working in shops - often in production conditions there is a possibility of damage to them during the operation of lifting mechanisms, equipment, emergency situations in hot shops. When heating is laid open between buildings, sufficient structural strength is also required - the metal changes its geometry less when heated, the metal is more resistant to vandalism;

- fire resistance;

- resistance to temperature fluctuations;

- harmlessness to humans;

- resistance to ultraviolet radiation;

- a welded system is in any case more airtight than prefabricated structures, and when installing gas systems this can be decisive;

- low thermal expansion - the metal does not sag and does not change its configuration when heated, like plastic;

- long service life.

- thermal conductivity. The metal heating system serves as an additional source of heat in the room; when laying pipes around the perimeter of the building, you can warm up the corners of the rooms a little, increase the movement of air in them and protect them from dampness, fungus and mold.

General disadvantages of metal pipes:

- for steel and cast iron - a tendency to corrosion;

- big weight;

- for steel and cast iron - overgrowing with calcium and magnesium salts of the inner surface;

- complex installation by welding or threaded fittings.

What are the GOSTs for steel pipes

The list of technical indicators of any type of steel pipe directly depends on which manufacturing method was used. All this is determined with the help of GOSTs, knowledge of which, at least, will make it possible to take into account recommendations for the operation of a certain type of pipe.

Currently, the following regulatory documents for the production of steel pipes are most often used:

GOST 30732-2006. It was adopted in 2006: its provisions relate to pipes and fittings made of steel coated with a heat-insulating layer.

Steel products, where polyurethane foam thermal insulation and a polyethylene sheath are used, or a protective steel coating, are used in cases where it is necessary to lay underground heating networks. The coolant temperature should not exceed 140 degrees (increase to 150 degrees is allowed only for a short time). In this case, the pressure in the system should not exceed 1.6 MPa. GOST 2591-2006 (88).

GOST, designed for hot-rolled steel, was adopted in 2006, although some sources allow the use of the old GOST - 2591-81. The document contains information regarding square steel products, for the manufacture of which the "hot" method was used. This GOST applies to all products with side sizes from 6 to 200 mm.

Larger square pipes are produced if the manufacturer and the customer draw up a separate contract. GOST 9567-75. It stipulates precision pipes made of steel, for which high precision manufacturing. A distinction is made between cold-formed and hot-rolled galvanized or chrome-plated precision tubes.

The machine-building industry especially needs the products of this increased GOST. GOST 52079-2003. This document specifies the standards for longitudinally welded and spiral welded pipes made of steel with a diameter of 114 - 1420 mm. From such overall products, main gas pipelines, pipelines through which oil and oil products are transported are equipped.

GOST 52079-2003 indicates that only products that do not have corrosive activity can be transferred through these pipes. With the help of steel pipes with large diameters, it is possible to transport substances with a pressure of up to 9.8 MPa. For the environment, a temperature minimum of -60 degrees is set.

At the same time, it is important to know that officially GOST 52079-2003 is no longer valid: from January 1, 2015, a new GOST 31447-2012.GOST 12336-66 is in effect. Its provisions relate to closed products of the profile type, with a section in the form of a square or rectangle. Starting from January 1, 1981, the powers of GOST 12336-66 were transferred to TU 14-2-361-79, but the relevance of its provisions has not been lost to this day. GOST 10705-91 (80)

Starting from January 1, 1981, the powers of GOST 12336-66 were transferred to TU 14-2-361-79, but the relevance of its provisions has not been lost to this day. GOST 10705-91 (80).

Contains a list of technical conditions under which steel electric-welded pipes of longitudinal type with a diameter of 10 to 630 mm are produced. For the production of pipes according to this GOST, carbon or low-alloy steel is used. These products are used in many areas, but the priority is the pipeline for pumping water.

The provisions of the standard do not apply to steel pipes from which electric heaters are made. GOST 10706 76 (91). Concerns electric-welded steel pipes of longitudinal type, which have a general purpose. As follows from this document, the diameter of this product is in the range from 426 to 1620 mm. GOST 10707 80.

Here are the standards according to which electric-welded cold-formed pipes are produced, having a different degree of accuracy: ordinary, increased and precision.The diameter of the products targeted for this document can be from 5 to 110 mm: in this case, unalloyed carbon steel is used. Sometimes electric-welded longitudinally welded products have references to GOST 10707 80 in the accompanying documentation: this is due to the fact that in 1991 it was decided to extend the validity of this document.

Production of steel pipes: basic methods

Steel pipes are made in several ways.

The most common manufacturing options are:

- electrowelded with a direct seam;

- electric welded with a spiral seam;

- hot-worked without a seam;

- cold rolled without a seam.

The choice of a suitable metal processing method depends on the quality of raw materials and equipment available from the manufacturer.

A separate standard regulates water and gas pipes. However, this does not happen because there is a special manufacturing method for this material, but only based on the field of application.

In fact, pipes of this type are a universal electric welded product with a straight seam. Typically, this type is used in communication systems with moderate pressure.

How are electrically welded straight seam products made?

A steel sheet (strip) rolled into a tight roll is unwound and cut into longitudinal strips of the desired length and width. The resulting fragments are welded into an endless belt, thus ensuring continuity in production.

Then the tape is deformed in rollers and the workpiece is turned into a round section product with open edges. The connecting seam is welded by the arc method, induction currents, plasma, laser or electron beams.

The seam on a steel pipe, made in an inert gas environment with a tungsten electrode (the active element of electric arc welding), is quite strong and durable. However, processing takes a long time. Pipe welding with high-frequency induction currents is carried out almost 20 times faster, therefore the price of such products is always much lower

After all the manipulations, the round steel pipe is calibrated in the rollers and a delicate non-destructive control of the strength and integrity of the seam is carried out by ultrasound or eddy currents. If no errors are found during the testing process, the workpiece is cut into fragments of the planned length and sent to the warehouse.

Production of electric welded spiral seam types

The production of steel spiral-seam pipes follows the same principle as straight-seam pipes, only simpler mechanisms are used for the manufacture of products. The main difference is that the cut steel strip is rolled up with the help of rollers not as a tube, but as a spiral. This ensures high connection accuracy at all stages.

On pipes with a spiral seam, in the event of an emergency, a main longitudinal crack does not form, which is recognized by experts as the most dangerous deformation of any communication system

The spiral seam is considered more reliable and gives the pipe increased tensile strength. The disadvantages include the increased length of the seam, requiring additional costs for welding consumables and more time for connection.

Production of hot-formed seamless products

As a blank for creating a seamless (solid-drawn) steel pipe by hot deformation, a monolithic cylindrical billet is used.

It is heated at high temperature in an industrial furnace and driven through a piercing press. The unit turns the product into a sleeve (hollow cylinder), and subsequent processing with several rollers gives the element the desired wall thickness and a suitable diameter.

The wall thickness of the pipe material made of steel produced by hot deformation reaches 75 mm. Pipes of this quality are used in difficult operating conditions and in communication systems where strength and reliability are the main priority.

At the last stage, the hot steel pipe is cooled, cut according to the specified parameters and transferred to the finished product warehouse.

Features of the production of cold-formed pipes

The initial stage of the process of manufacturing seamless steel pipes by cold deformation is identical to the "hot" version. However, after running through the piercing mill, the sleeve is immediately cooled and all other operations are carried out in a cold environment.

When the pipe is fully formed, it must be annealed, first heating it to the steel recrystallization temperature, and then cooling it again. After such measures, the viscosity of the structure increases, and the internal stresses that inevitably arise during cold deformation leave the metal itself.

Cold-formed steel pipes can be used to lay a highly reliable communication system, in which the risk of leakage is minimized.

Now on the market are seamless cold-rolled pipes with a wall thickness of 0.3 to 24 mm and a diameter of 5 - 250 mm.Their advantages include a high level of tightness and the ability to withstand high pressure.

Overview of products from leading manufacturers

Among the variety of products presented, there are reputable brands with a long-term positive reputation. These include products from companies: Hobas (Switzerland), Glass Composite (Russia), Amiantit (a concern from Saudi Arabia with production facilities in Germany, Spain, Poland), Ameron International (USA).

Young and promising manufacturers of composite fiberglass pipes: Poliek (Russia), Arpipe (Russia) and Plant of fiberglass pipes (Russia).

Manufacturer #1 - HOBAS brand

The brand's factories are located in the USA and many European countries. The products of the Hobas group have earned worldwide recognition for their excellent quality. Polyester-bonded GRT pipes are spin-cast from fiberglass and unsaturated polyester resins.

Hobas pipe systems are widely used in sewerage, drainage and water systems, industrial pipelines and hydroelectric power plants. Surface laying, microtunneling and drag placement are acceptable

Characteristics of Hobas composite pipes:

- diameter - 150-2900 mm;

- class SN-rigidity - 630-10 000;

- PN-pressure level - 1-25 (PN1 - non-pressure pipeline);

- the presence of an internal lining anti-corrosion coating;

- acid resistance over a wide pH range.

The production of fittings has been launched: elbows, adapters, flanged pipes and tees.

Manufacturer # 2 - Glass Composite Company

The Steklokompozit company has set up a line for the production of Flowtech fiberglass pipes, the production technique is continuous winding.

Involved equipment with a double supply of resinous substances.High-tech resins are applied to the laying of the inner layer, and cheaper composition - to the structural layer. The technique allows to rationalize the consumption of material and reduce the cost of products.

The range of Flowtech pipes is 300-3000 mm, class PN is 1-32. Standard footage - 6, 12 m. Under the order, production is possible within 0.3-21 m

Manufacturer #3 - brand Amiantit

The main components of Amiantit's Flowtite pipes are fiberglass, polyester resin, and sand. The technique used is continuous winding, which ensures the creation of a multilayer pipeline.

The fiberglass structure includes six layers:

- external winding of non-woven tape;

- power layer - chopped fiberglass + resin;

- middle layer - fiberglass + sand + polyester resin;

- repeated power layer;

- lining of glass threads and resin;

- protective coating made of non-woven glass fiber.

The conducted studies showed high abrasive resistance - for 100 thousand cycles of gravel treatment, the loss of the protective coating amounted to 0.34 mm.

The strength class of Flowtite products is 2500 - 10000, it is possible to manufacture SN-30000 pipes on request. Operating pressure - 1-32 atmospheres, maximum flow rate - 3 m / s (for clean water - 4 m / s)

Manufacturer #4 - Poliek company

Poliek LLC produces various modifications of fiberglass Fpipes pipe products. The manufacturing technique (continuous oblique longitudinal-transverse winding) allows you to create three-layer pipes up to 130 cm in diameter.

Polymer composite materials are involved in the creation of casing pipes, sections of water-lifting columns, water supply pipelines and heating systems.

The range of sewer fiberglass pipes - 62.5-300 mm, high-pressure products - 62.5-200 mm, ventilation ducts - 200-300 mm, well casing - 70-200 mm

The range of sewer fiberglass pipes - 62.5-300 mm, high-pressure products - 62.5-200 mm, ventilation ducts - 200-300 mm, well casing - 70-200 mm

Except fiberglass pipes there are many products on the market made of other materials - steel, copper, polypropylene, metal-plastic, polyethylene, etc. Which, due to their more affordable price, are actively used in various areas of domestic use - installation of heating systems, water supply, sewerage, ventilation, etc.

You can get acquainted with the characteristics of pipes made of various materials in our following articles:

- Metal-plastic pipes: types, technical characteristics, installation features

- Polypropylene pipes and fittings: types of PP products for pipeline assembly and connection methods

- Plastic ventilation pipes for exhaust: types, their characteristics, application

- Copper pipes and fittings: types, marking, features of the arrangement of a copper pipeline

- Steel pipes: types, assortment, overview of technical characteristics and installation nuances

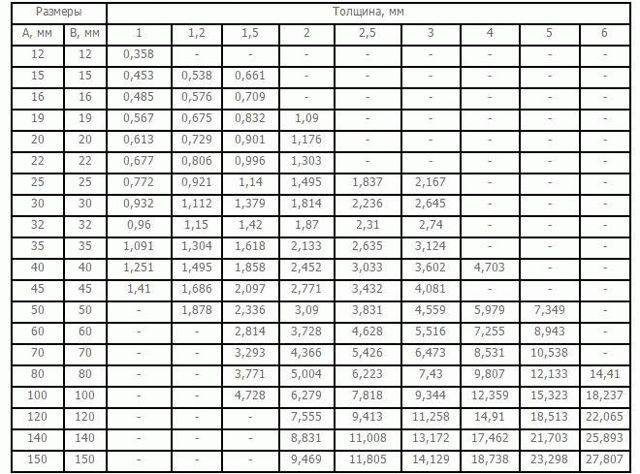

Rectangular pipe

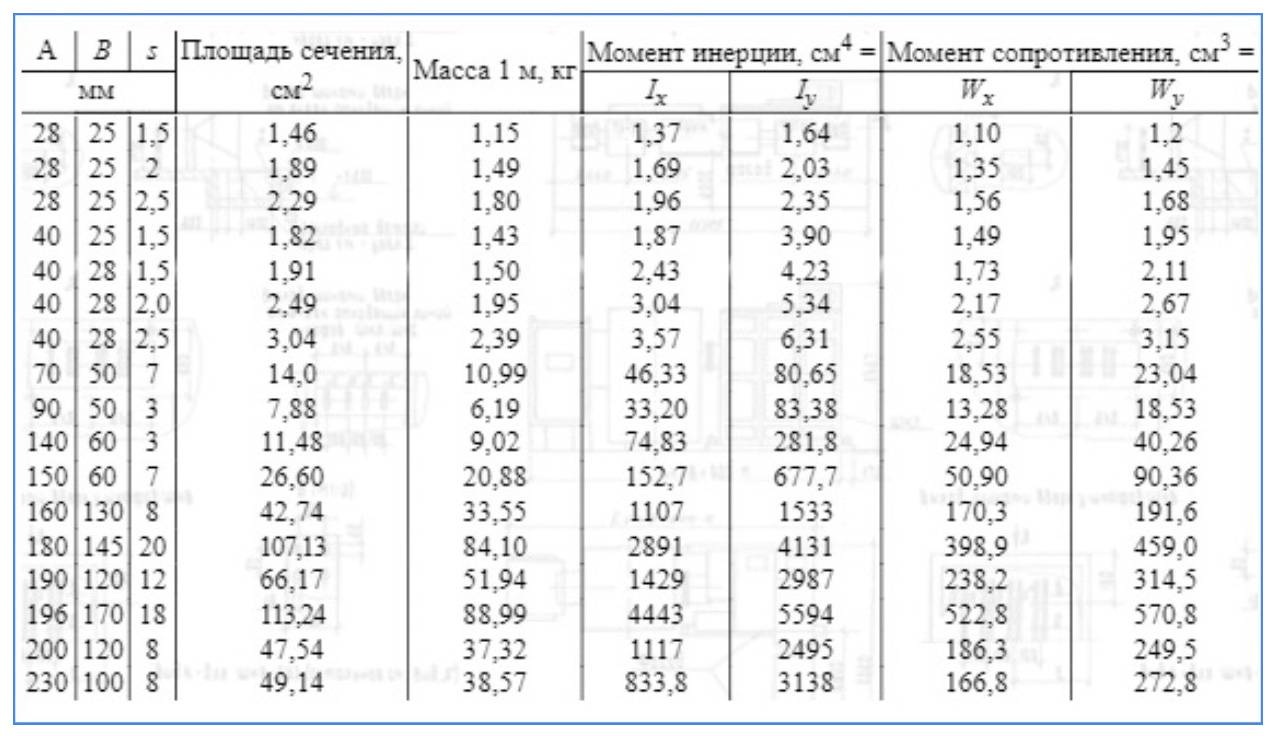

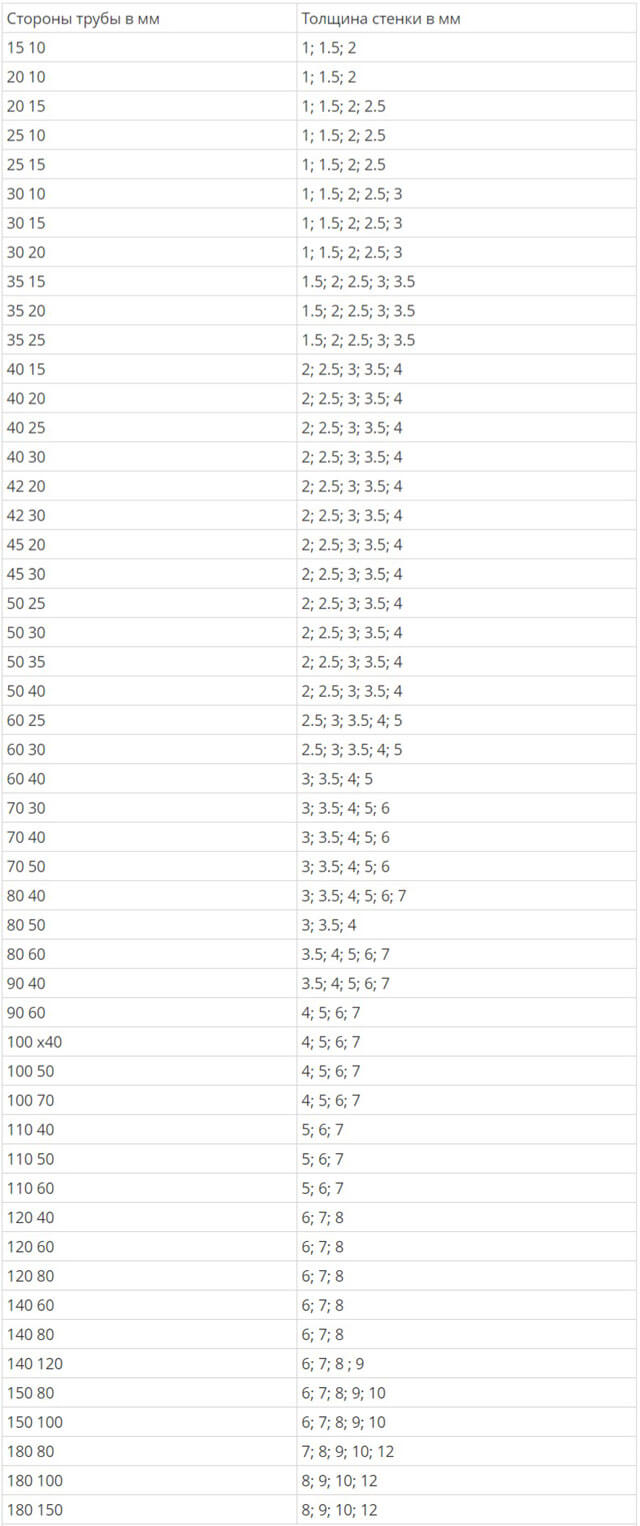

Most rectangular steel pipes are produced by direct seam electric welding. The assortment of this type of material is indicated in GOST 8645-82, according to which the maximum wall thickness for pipes of a certain size is determined. For example, for a product with sides of 15 and 10 millimeters, wall thicknesses of 1 mm, 1.5 mm and 2 mm are allowed.

For a pipe with a size of 80 * 60 mm, the walls can have a thickness of 3.5 mm, 4 mm, 5 mm, 6 mm and 7 mm. The maximum dimensions of a standard rectangular pipe can be 180*150mm. With these parameters, it is allowed to produce products with a wall thickness of 8 mm, 9 mm, 10 mm, 12 mm.

GOST 8645-82 allows the manufacture of steel pipes of non-standard sizes, for example, 28 * 25 mm or 196 * 170 mm. The wall thickness of such products also has deviations, respectively 1.5 mm and 18 mm.

Supplemental document 8645-68 contains information on a different list of rectangular steel pipes. There are no special differences between the regulatory documents. However, the second standard specifies special parameters. They allow the production of steel products of rectangular section, having parameters of 230 * 100 millimeters.

Conclusion

Detailed descriptions of the assortment of st pipes and documents regulating their production will help you make the right choice of material for construction and select the right dimensions. Happy building!