- Advantages and disadvantages of panel-type radiators

- Chinese

- Manufacturers of steel appliances

- Classification by prestige class

- More about the features of panel radiators

- Advantages and disadvantages of steel panel radiators

- Installing a panel radiator

- Manufacturers

- Design features and variety of steel heating radiators

- Panel Type Radiators

- Tubular type radiators

- Connection

- TOP-4 steel heating radiators

- Axis Classic 22 500×1000

- Buderus Logatrend K-Profil 22 500×1000

- Kermi FKO 22 500×1000

- Arbonia 2180 1800 270

- Characteristics of tubular radiators

- Steel plate radiators - general information

- How to calculate the required number of battery sections

- Steel Panel Batteries

- Manufacturing

Advantages and disadvantages of panel-type radiators

Steel panel radiators have a lot of positive qualities, among which the following are worth noting:

- Ease of installation. Since the steel panel heating radiator is a one-piece product, its installation is reduced to very simple operations - first you need to hang the device on the brackets, and then connect it to the heating pipeline.True, the inability to disassemble the radiator can also be attributed to the disadvantages - in case of damage to the device, it will have to be changed completely, while sectional batteries can be changed in parts.

- High heat dissipation. The panels have a rather large area, due to which the thermal energy is transferred to the room in full. The presence of convectors, which allows you to direct warm air in the right direction, also greatly increases the efficiency of steel batteries.

- Profitability. A relatively small volume of coolant passes through the internal cavities, so relatively little energy is required for heating. Compared to conventional cast iron batteries, panel devices produce about a third more heat.

- Low injury risk. There are no sharp corners in the design of steel panel radiators, which can cause injury. This item is especially relevant for families with small children - the smooth metal surface of the radiator reduces the likelihood of serious injury to a minimum.

- Good visual qualities. Panel radiators initially have a fairly neat and pleasant appearance, so after installing them you do not have to think about various options for protective or decorative elements.

Panel devices also have disadvantages, of which the following stand out:

Weak resistance to pressure drops. In the manufacture of panel batteries, welding is used - and the resulting welds do not withstand water hammer very well. However, this disadvantage can be leveled with the help of gearboxes, which take the effect of pressure drops on themselves.

Dependence on the quality of the coolant.If there is a high concentration of impurities in the water poured into the heating system, then the radiators will very quickly become unusable. In centralized systems, the quality of the coolant is usually not very good, so the inner surface of the radiators becomes covered with a thick layer of scale and begins to rust.

Low mechanical strength

The components of panel radiators are not very durable, so care must be taken when transporting and operating them - even a slight impact can lead to damage to the products.

Chinese

The most budget model of a metal tubular radiator can be called Chinese-made Oasis batteries. Despite the low cost, the device is distinguished by good strength, resistance to aggressive influences and the absence of operational restrictions. A number of models are manufactured taking into account the specifics of domestic heating networks. Tubular heating batteries Oasis have the most positive reviews. The company also specializes in the manufacture of standard bimetallic heating radiators, which are distinguished by excellent thermal performance and affordable cost.

Manufacturers of steel appliances

In the heating equipment market, steel radiators are represented by models from many manufacturers, but at the same time, the manufacturing technology practically does not differ, and the cost may vary slightly.

Steel tubular radiators are assembled from stamped sections welded together by spot welding

The price of a product is determined by its size, brand, design. It is often possible to purchase a high-quality domestic device that is not inferior in its characteristics to a world-famous brand.

Among the domestic companies, whose products are in stable demand in our market, are the following:

- Lideya;

- Prado;

- Konrad.

Lideya devices are manufactured in Belarus. They are supplied with 1-2-3 panels, the volume of coolant in which is in the range of 0.9-6.55 liters and depends on the size. Radiator power with one panel - 2.1 kW, with two panels - 3.9 kW, with three panels - 5.6 kW. Steel thickness 1.2 mm, operating pressure 8.9 bar.

Prado heating equipment is produced in Izhevsk. It is equipped with 1-2 panels, the volume of coolant varies between 0.8-5.7 liters. As for power, a radiator with one panel has 1.4 kW, with two panels - 2.3 kW. Steel thickness 1.4 mm, operating pressure 8.8 bar.

Batteries Konrad are produced in St. Petersburg. They are equipped with 1-2 panels, the volume of coolant in which is 0.85-5.2 liters and depends on the size. The power of the device with one panel is 1.35 kW, with two panels - 2.3 kW. Steel thickness 1.4 mm, operating pressure 10 bar.

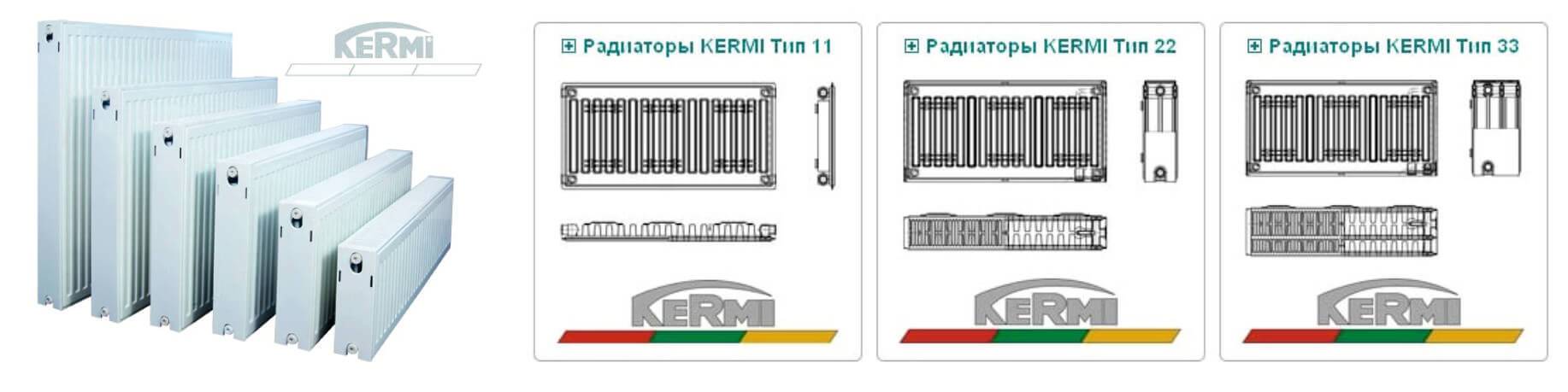

Among European manufacturers of tubular steel batteries, German and Italian companies have proven themselves well: Charlston, Kermi, Arbonia, Israp Tesi.

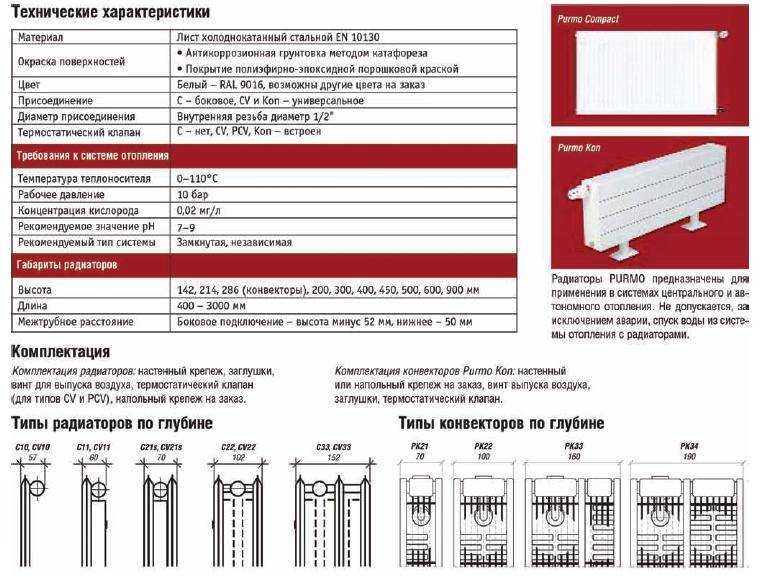

Also, panel heating batteries of the German production Kermi and Buderus, the Finnish company PURMO, are the most popular. Almost in no way inferior to them in quality and popularity are Delonghi radiators from Italy, as well as Korado devices of Czech origin.

Models of panel and tubular radiators of European production have different dimensions and power. Technical characteristics are presented in the passport of each model.

A well-known brand will cost an order of magnitude more than equipment from less popular companies.But buying a branded device gives a guarantee of purchasing a device of proper European quality.

Steel radiators are among the most popular heating devices. Due to their presentable appearance, affordable price and high heat dissipation, they are widely used in offices, houses and apartments. The maximum service life of steel radiators is achieved in autonomous heating systems.

Classification by prestige class

This division is based on the summation of the indicators of different classifications, mainly based on the structure of the batteries and the materials from which they are made. Allocate:

- economy class radiators, which include panel, steel and cast iron

- mid-range batteries made of aluminum and biometal, sectional structure

- premium-class heating appliances, i.e. tubular and artistic cast iron

Artistic cast iron casting is always an individual order. These models are not commercially available. Tubular radiators are sold, but rarely. Demand is low due to high cost. Tubes, by the way, can be located not only vertically, but also horizontally.

More about the features of panel radiators

Panel heaters in terms of efficiency may be slightly inferior to the best representatives of conventional radiators (for example, bimetallic ones). But it fully pays off with an excellent appearance, and the difference is not so significant. In addition, there are a number of other features, the knowledge of which will definitely not be superfluous.

Advantages and disadvantages of steel panel radiators

Panel radiators have an impressive list of advantages:

- due to the combination of direct heat transfer and convection, the efficiency of the devices exceeds 75%, and the heat is distributed more evenly throughout the room;

- such devices are characterized by a reduced need for a coolant, compared with a heating system that uses cast-iron batteries, the need for water is more than halved;

There are, of course, a couple of disadvantages, you can highlight:

steel is subject to corrosion and, in general, increased requirements are imposed on the quality of the coolant. In particular, it is necessary to maintain acidity at a normal level (pH should not exceed 9.5);

pH should not exceed 9.5

- It is recommended not to leave panel radiators without water for a long time. The fact is that steel will rust when exposed to air;

- such heating devices are suitable only for systems with normal pressure and coolant temperature not higher than 110ᵒС;

- they do not tolerate water hammer.

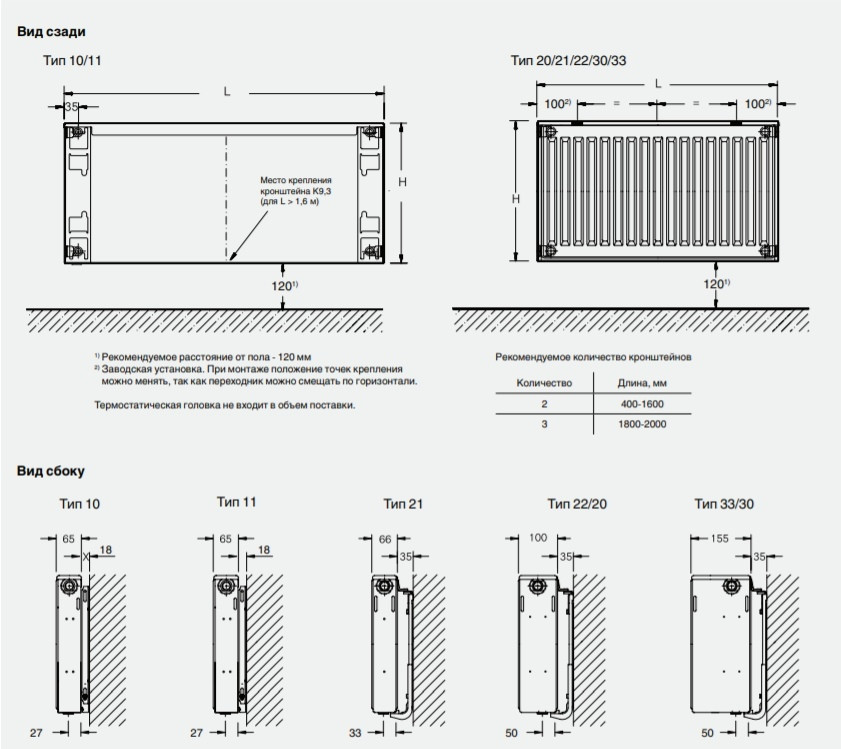

Installing a panel radiator

The process itself is slightly different from installing a conventional battery.

The instruction consists of the following items:

first you need to check if the window sill is too close to the upper convection grate. If the distance is less than 7 cm, then the radiator will heat the room worse;

Convection will be disturbed when close to the windowsill

- then brackets are placed on the wall, they come with a radiator;

- further, the radiator is placed on brackets fixed in the wall. At the same time, the packaging from the heater has not yet been completely removed, but only in places where the supply and discharge pipelines will be connected;

- if the connection is done by hand, then the next step is to install a Mayevsky crane at the top of the screen and a thermostat (also comes with a radiator);

Installing a thermostat

plugs are installed.

Finally, the packaging from the heating device is removed only after the finishing work in the room is finally completed. Thanks to this, you do not have to clean it from dust, and the risk of scratching the steel surface is lower.

The most common installation errors are:

- deviation from the horizontal during installation. As a result, the thermal power of the device becomes lower than declared by the manufacturer;

- if the gap between the floor and the bottom of the panel radiator is too large, there will be too cool air in the lower part of the room, this will create discomfort;

- it is strictly forbidden to paint the heater with metal-like paints (this will worsen the heat transfer of the device), and the outlet of the device for air release is also quite often painted over.

As for the selection of thermal power, you can simply calculate the volume of the room in cubic meters and multiply by 41. The resulting number will indicate the required power in watts to heat the room. The technical characteristics of panel heating radiators necessarily include this parameter, so it can be taken from the documentation for the heater.

Characteristics of popular panel radiators

Manufacturers

Among the many brands, the following brands have proven themselves well:

Lideya (Russia). This manufacturer has received a lot of positive feedback, as all its products are of high quality finishes.Radiator panels are covered with a unique two-layer varnish, and the devices can work in one-pipe and two-pipe heating systems.

- Biasi S.p. A. (Italy). The radiators of this company are created using the latest technologies, so their heat transfer is high, and the premises are heated instantly. The devices can also operate at low temperatures, their operating pressure limit is 9 bar.

- Korado (Czech Republic). Batteries have both one and two or three panels. The main feature of the products is their wide range of colors, small volume of coolant, convenient brackets. The pressure limit reaches 8.7 bar, and the water is heated to +110 C.

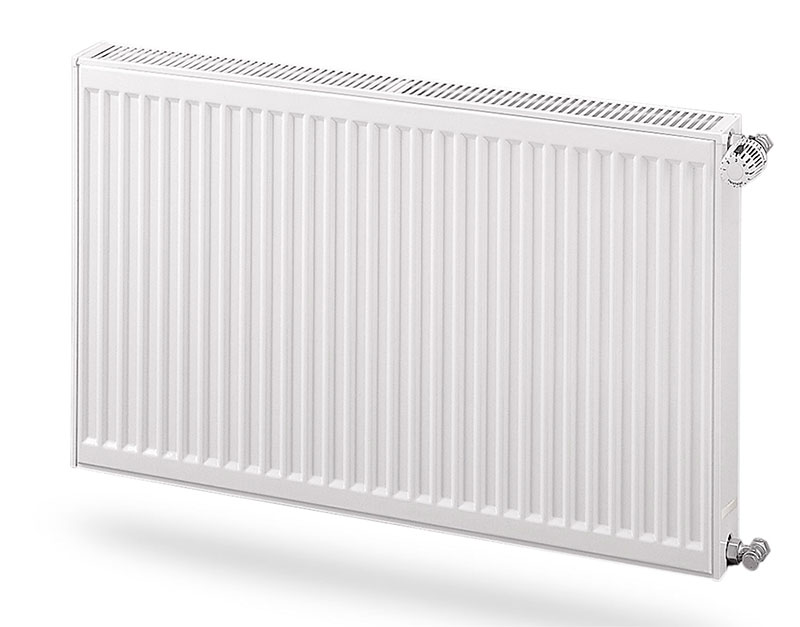

Design features and variety of steel heating radiators

The high manufacturability of steel does not require proof. This plastic, strong, flexible and malleable material lends itself well to welding, and also conducts heat remarkably. So steel is suitable for radiators in many ways.

Two types of steel radiators are produced:

- panel;

- tubular.

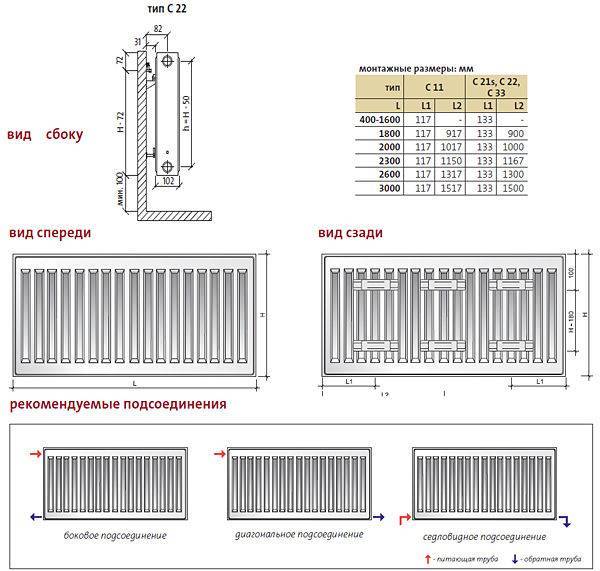

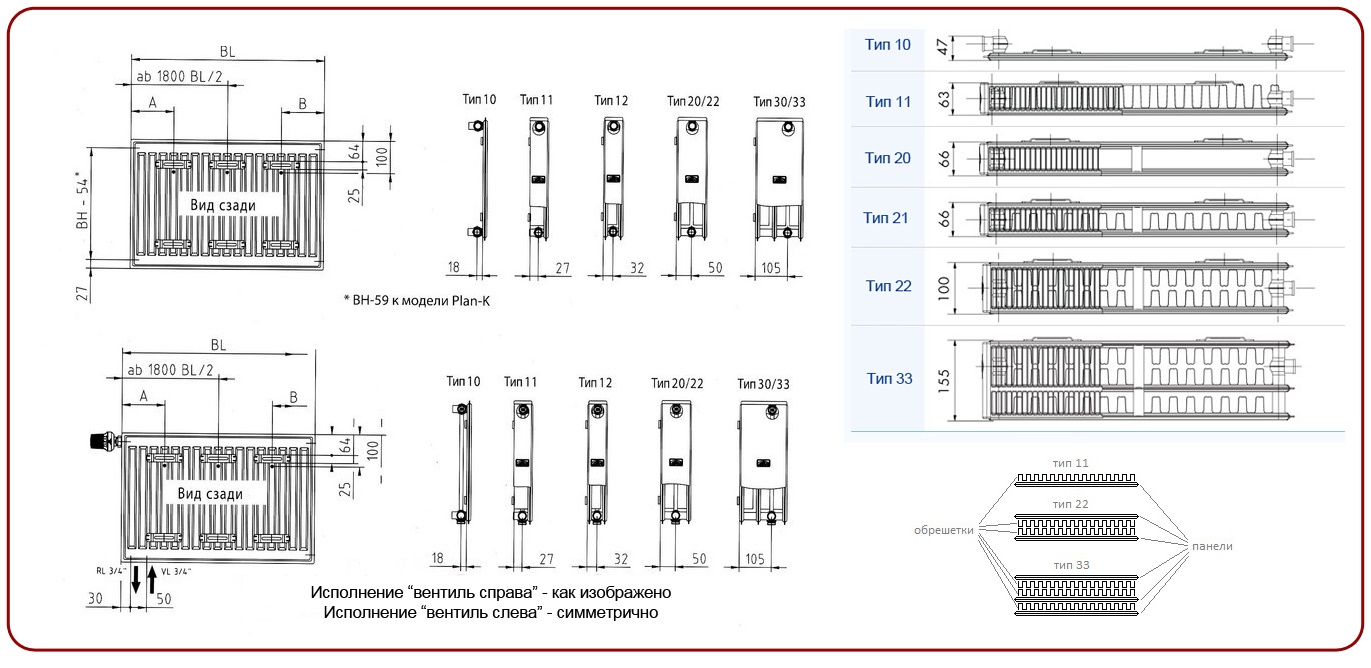

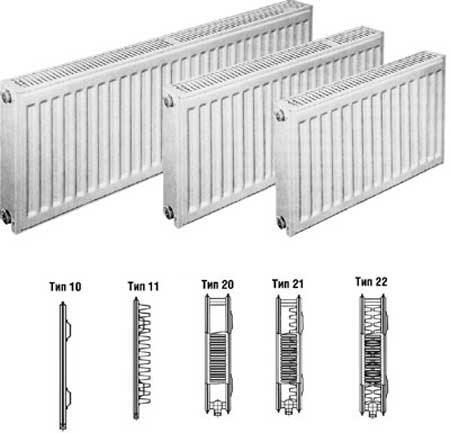

Panel Type Radiators

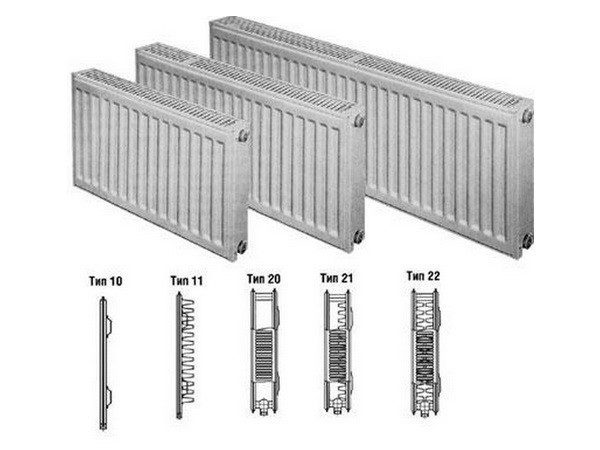

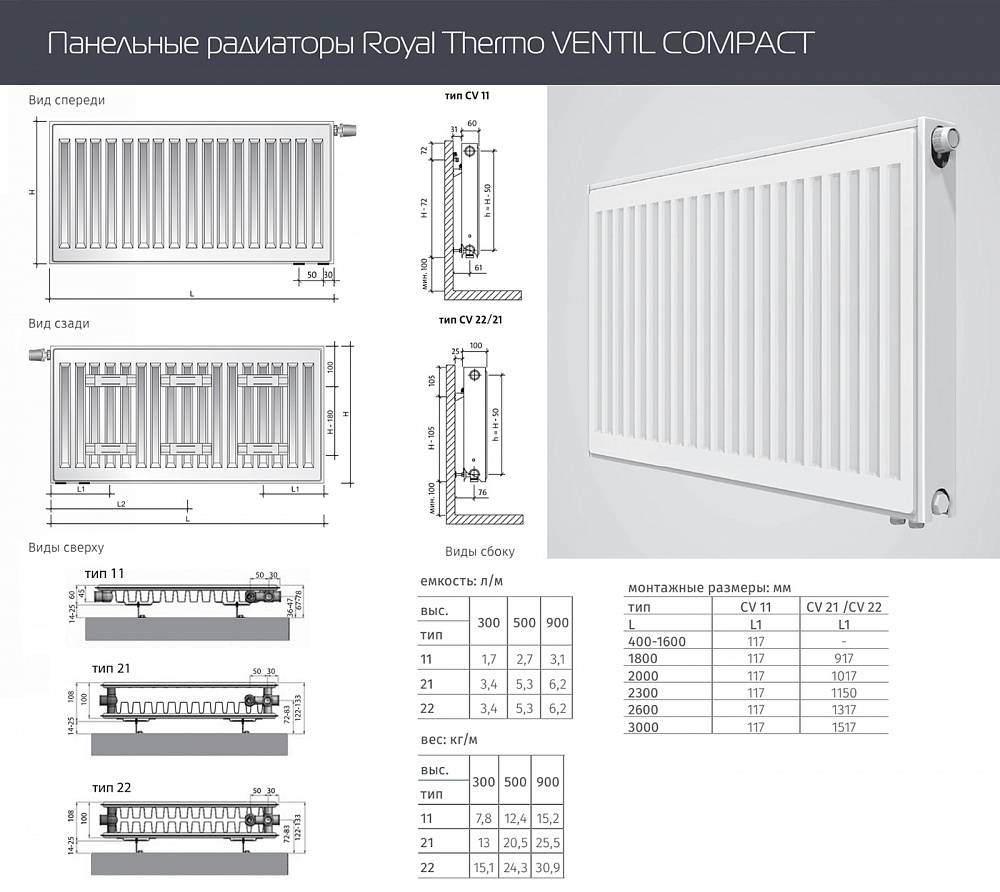

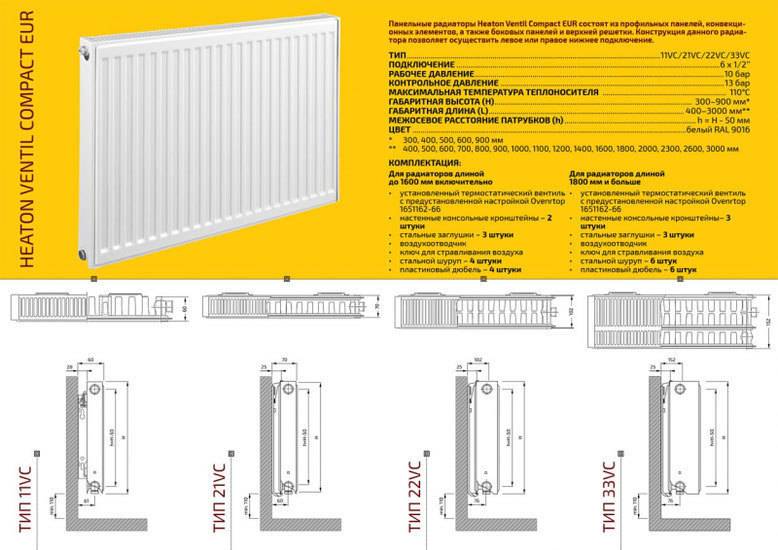

In the middle of this device are one, two or three panels. Each of them consists of two steel flat profiles, welded along the contour for connection. The plates are stamped, after which oval vertical channels are formed on them - paths for the coolant. The production of these radiators is simple - roller welding connects blanks that have been stamped. After that, the finished parts are fastened in two pieces using nozzles.

The device of a steel convector radiator.

To increase heat transfer, manufacturers often equip panels from the inside with U-shaped ribs. For their manufacture, thinner sheets of steel are taken than for panels.The fins help increase convection. If several panels are connected in a row, then they are covered with casings on both sides. Depending on the number of heating and convector panels located inside the radiators, there are the following types.

Type 10 is a single-row radiator without convector and without cladding.

Type 11 is a single-row radiator with one convector, without a top grate.

Type 20 is a two-row radiator without a convector, with an air outlet grille.

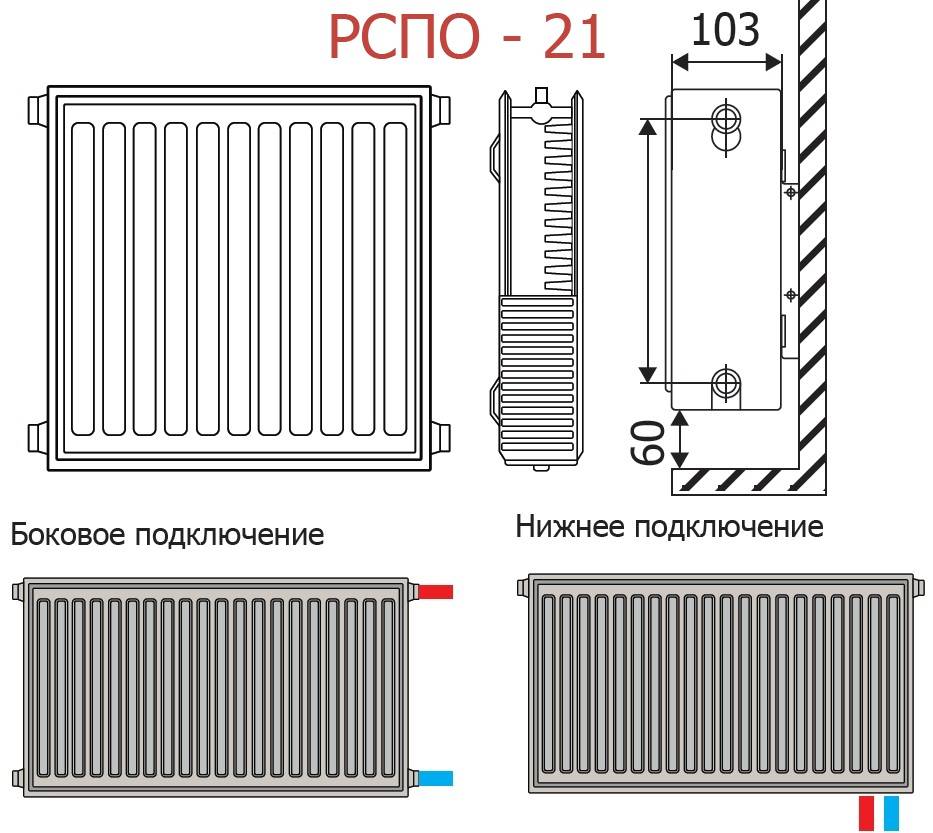

Type 21 is a two-row radiator with one convector fin, enclosed by a casing.

Type 22 is a two-row radiator with two convector fins, enclosed by a casing.

Type 30 - three-row, without convector fins, closed with a grill on top.

Type 33 - a three-row radiator with three convector fins, closed by a casing.

The finished radiator is quite narrow, which is very convenient for installation. The price of such products is very affordable, so the owners of their own homes prefer to install them.

Tubular type radiators

Steel pipes welded together make up the core of this heater. However, it also serves as a body. It is not as easy to make such a radiator as the previous one, but it undoubtedly has much more model variations. The most common classic option is a radiator similar to cast iron, but having many more channels for the movement of the coolant.

The number of channels that a tube radiator can have.

Such a device is quite expensive, and it can not be called a budget option. This is rather an option for a designer who is not constrained by means.

All possible colors of pipe radiators.

His imagination, coupled with bright colors, original shapes and the whole range of sizes, makes such radiators a real highlight of a stylish and beautiful interior.

Connection

Due to the connection scheme, heat transfer may deteriorate, losses sometimes reach up to 25%. Connection is possible in several ways.

- Lateral - the extreme sections will be colder than the central ones. The more segments are installed, the worse the extreme ones are heated.

- Diagonal. If the water supply is carried out from below and goes into the upper pipe, then the radiator does not warm up completely. The correct method would be in which the liquid is supplied from above and goes down, such a scheme is recommended for long samples (more than 15 segments).

- Lower - the distribution of heat occurs evenly. In addition, this variety has the most aesthetic appearance, since the feed elements are almost invisible.

You can fix the situation with unheated areas without running additional pipes around the battery by installing plugs in place of the radiator plug in front of the last section at the top or bottom (depending on which connection is used). Then we get a diagonal scheme with effective heat transfer.

To learn more about different connection methods and compare them, as well as how to increase the efficiency of the radiator, watch the video.

TOP-4 steel heating radiators

Steel radiators are distinguished by reliability, high heat transfer. Of the minuses, it is worth highlighting the instability to water hammer, susceptibility to corrosion. Some manufacturers use special coatings to protect against it.Most steel radiators have a panel view, i.e. it is impossible to dial the required number of sections, as in aluminum and bimetallic ones. The exception is tubular steel radiators.

Axis Classic 22 500×1000

The steel radiator consists of two water-conducting panels and two convection rows. The outer grille is removable: you can clean the internal parts. It differs from the standard dimensions characteristic of all models of the rating (50 × 100 × 10 cm) by a slightly larger thickness - 11 cm. Almost all radiators weigh about 28 kg. The capacity of water is 5.63 liters. Steel radiators differ from bimetallic radiators with a lower working pressure - 9 bar (13.5 - during pressure testing). Side connection ½ inch. The center distance is non-standard - 449 mm. Designed for coolant temperatures up to 120 °C. The model has increased power - 2188 watts.

Advantages:

- Nice view. Simple design.

- Quality build. Russian production on Italian equipment.

- The kit includes everything you need for installation.

- Heats well.

- Inexpensive.

Flaw

- Non-standard center connection. There are no problems if the eyeliner is made of polypropylene pipes.

Axis Classic 22 500 1000 costs 3700 rubles. The model surpasses all types of steel radiators included in the rating in terms of power. Provides rapid heating of the room. The quality of the metal, reliability satisfied demanding users, so the vast majority of them recommend the product for purchase.

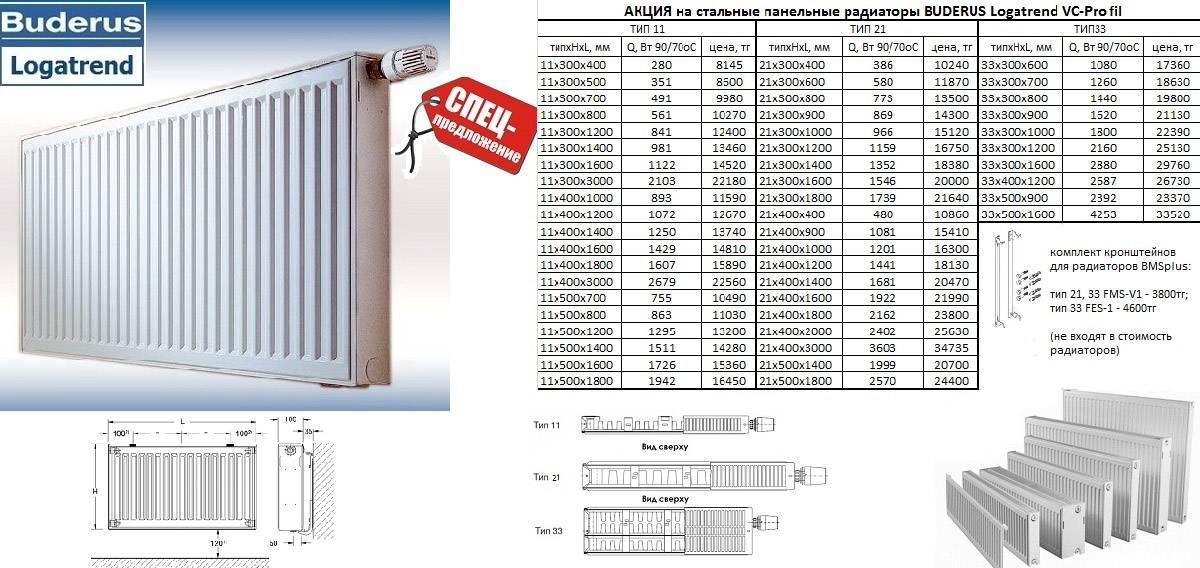

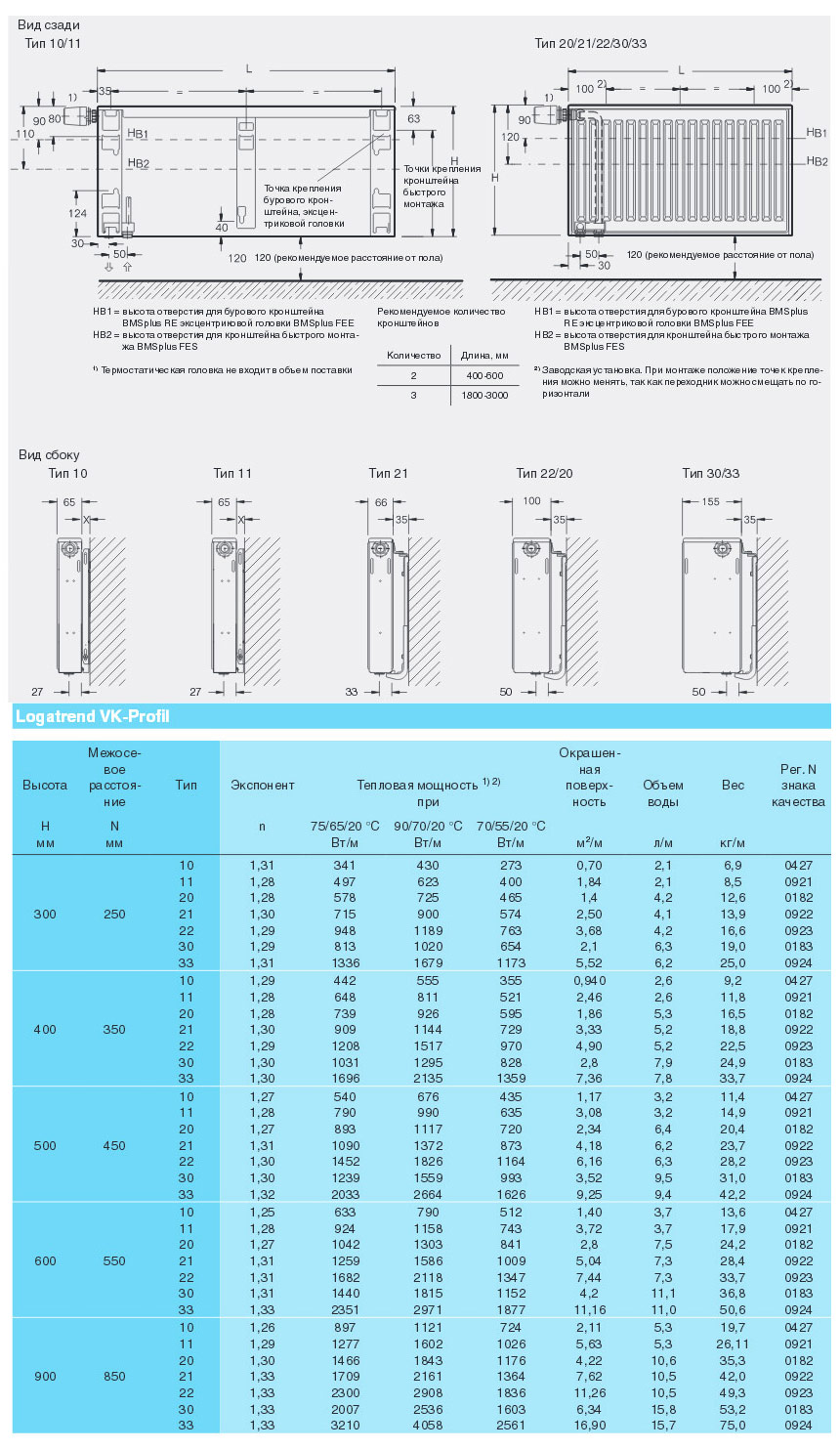

Buderus Logatrend K-Profil 22 500×1000

It features a large volume of water - 6.3 liters. The working pressure in the system is higher - up to 10 bar, but less power - 1826 watts. According to the manufacturer's calculations, one radiator is enough to heat a room of about 18 square meters. m.The model undergoes anti-corrosion treatment by phosphating and hot powder spraying. Center distance - 450 mm.

Advantages:

- Laconic design.

- Good painted. Does not turn yellow over time.

- They heat well.

- Build quality is ok.

Flaw:

- One radiator is not enough for the declared area (but it depends on the coolant temperature).

Price Buderus Logatrend K-Profil 22 500 1000 - 4270 rubles. The model is somewhat inferior to Axis Classic 22 in terms of power, but it has a better anti-corrosion coating. Customers are satisfied with the quality of workmanship and the operation of the radiator.

Kermi FKO 22 500×1000

Differs in the smallest volume - 5.4 liters. But it loses in power to the first two models - 1808 watts. Designed for system pressure up to 10 bar (13 bar - pressure test). Provides operation at a coolant temperature up to 110 °C. Center distance - 446 mm. The manufacturer has applied Therm X2 technology, which increases the energy efficiency of the equipment. The outer coating is made of two layers of powder paint, which increases the resistance to mechanical damage.

Advantages:

- Beautiful view.

- Quality made.

- Ease of care.

- Good heat dissipation.

Flaw:

There are cases of leakage after several years of use (in an apartment building where the system is drained for the summer).

Kermi FKO 22 500 1000 for 6200 rubles provide a normal level of heat. Due to the small volume of coolant, the heating of the radiator and the room is faster. Recommended for installation in a closed system without draining the coolant for a long period.

Arbonia 2180 1800 270

The only representative of tubular steel radiators in the review. It differs from panel models in non-standard dimensions.This is a narrow model (65 mm) with a very high height (1800 mm). The width of one section (tube) is 45 mm. Center distance - 1730 mm. One section weighs 2.61 kg, but it includes a much larger volume than aluminum and bimetallic radiators - 1.56 liters. In terms of heat transfer, the six-section Arbonia is expectedly inferior to other models in the rating - 1730 W. Power - 990 watts.

Advantages:

- Interesting view.

- Normal heat dissipation. Heats up well.

- Quality build.

Flaw:

- It is necessary to take into account the place for installation, the possibility of piping. If there are windows in the room, they will blow (you cannot place such a radiator under them).

The price of Arbonia 2180 1800 270 is 9950 rubles. You can choose the number of sections, unlike other steel samples. Non-standard sizes significantly increase heat transfer due to the larger radiator area. Can become part of the interior. Customers have no complaints about the quality.

Characteristics of tubular radiators

The material for the manufacture of tubular radiators is most often steel, which gives them special strength and reliability.

Main technical parameters of tubular steel radiator:

- Height. It can be from 30 to 300 cm.

- Number of pipes. There are no restrictions here: there are models with one tube, and there are also with a much larger number of jumpers.

- Depth. Approximately 225 mm. One row may contain 1 - 6 elements. The formation of the cost of the device is affected by the working volume and parameters of the jumpers.

- sectional distance. There are two options: 65 and 45 mm. Radiators with a section spacing of 65 mm are mainly used in hospitals, schools and other institutions where there are very high hygiene requirements.

- Wall thickness. It can be from 1 to 2 mm.Western products are characterized by a thickness of 1-1.5 mm. For domestic devices, it is slightly larger - 2 mm.

- Section section. The standard version is a round tube shape, with a diameter of about 25 mm. Less often you can find products with a flat, rectangular, oval and triangular section.

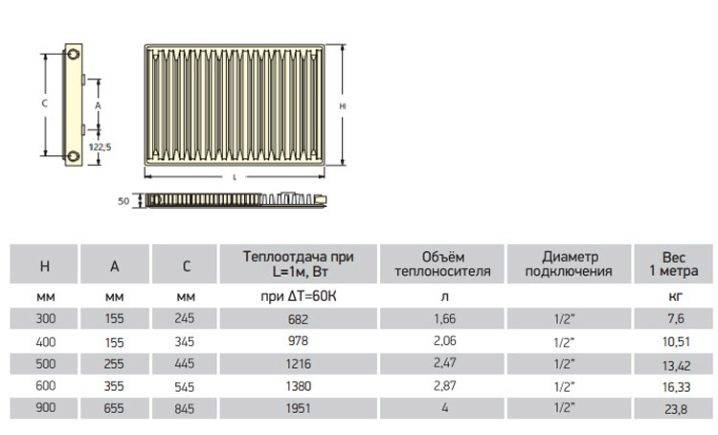

Steel plate radiators - general information

Steel plate radiators in simple speech are called "accordions". The type of accordion is created by plates strung on a pipe for a coolant.

A distinctive feature of such radiators is high reliability. There are no connections in the plate radiator, except for the inlet and outlet of the coolant. As a result, the radiator itself simply cannot leak, there is nowhere for the coolant to break through.

Due to the large number of plates and the direct movement of the coolant, the convector heats up to a high temperature. To protect against touches, the main frame of the radiator is covered with a decorative casing. Convection holes are made in the top cover of the casing.

The convectors have a low thermal inertia, which means that they can be controlled by automation, that is, thermostats can be installed in systems with plate radiators.

See also: Cellar hood correctly with two pipes

Lamellar radiators form a fairly powerful thermal curtain. This property of convectors allows them to be used in floor heating systems. True, the design of thermal convectors for installation in the floor differs from wall convectors, but the principle of heating is the same.

How to calculate the required number of battery sections

For example, let's take Russia, its middle lane and the usual panel high-rise building.We multiply the area of the room by 100 watts, and then divide this number by the amount of heat given off by one section.

If the center distance is 500 millimeters, then the calculation will be easier than easy. We divide the area of \u200b\u200bthe room in half - and that's it. For example, a room of 12 square meters. We need 6 sections with heat output from 180 to 190 watts. 10 percent will have to be thrown on the last or first floor, corner rooms with a large window (more than two square meters) or thin walls (less than 250 millimeters).

In a cottage built outside the city, you will have to tinker with the calculations. First, find out the coefficients of thermal conductivity of each material from which the house is built. These are not only walls, but also a roof and a floor. For this, it is preferable to invite a professional from a reliable company. An experienced specialist will calculate everything exactly, and will advise the battery that is suitable for your home, and will not require extra money.

Steel Panel Batteries

These heaters consist of two ribbed plates made by casting. They have a sealed circuit inside, which is filled with a coolant that provides space heating.

Due to the ribbed shape, the steel battery has an efficient heat dissipation. The thermal conductivity of steel is similar to that of cast iron. But the walls of steel units are much thinner than those of cast iron products and therefore they heat up much faster. It will take 2 times less time to warm up the cold living space. Such high performance is provided by convection.

The devices are designed for a working pressure of 10 - 11 atmospheres, which corresponds to the technical characteristics of the central heating system.Some models of modern steel apartment heating radiators are equipped with ventilation (convection) holes that create a thermal curtain for cold air coming from a window or door.

After the assembly is completed, the entire structure is covered with a special paint that protects against mechanical and various chemical damage. If there are doubts about which battery to choose from the offered assortment for an apartment, you need to carefully check the uniformity of applying the coloring composition - it is this circumstance that often affects the duration of operation of heating equipment.

The fact is that poorly covered areas can be the cause of corrosion. Panel radiators made of steel of standard models are designed to heat the working environment up to 85-90 degrees, but sometimes they are able to withstand temperatures up to 100-110 degrees. The quality of water circulating in such devices is subject to minimum requirements with an acceptable pH threshold of 3-9.5 units.

When deciding which radiators are better to install in an apartment, you need to remember that experts do not advise leaving steel products without a coolant for a long time. The reason is that when in contact with air, this metal undergoes corrosive processes.

Steel radiators have a classification system based on the number of panels and convectors. For example, type 10 corresponds to one panel. It is considered the simplest and most budget option, but the absence of a convection heat exchanger reduces heat transfer. In turn, 21 types consist of 2 panels and 1 convector between them.

Steel units also differ in size.Their length is from 400 to 3000 millimeters, and their height is from 200 to 900 millimeters. The variety of parameters allows you to choose the best heating batteries for an apartment with rooms of different sizes.

The advantages of steel panel units include:

- small thickness and weight;

- high heat transfer coefficient;

- ease of installation;

- rapid heating of the premises;

- affordable cost;

- minimum requirements for water quality;

- the ability to choose a model with a certain number of convectors.

As for the shortcomings of steel batteries, they appear in apartments equipped with autonomous heating. The fact is that the dimensions of the structures cannot accommodate a sufficient volume of water, and therefore the boiler will often have to turn on to maintain the required temperature regime.

This in turn will lead to an increase in energy consumption. If the apartment is connected to the central heating system, this feature does not matter.

Before choosing a steel radiator, you need to familiarize yourself with the quality of the coolant. When the central heating system does not have clean water, the unit will not last long, since its inner surface usually does not have a protective coating.

In a steel panel structure, thin walls do not tolerate water hammer, the presence of which is evidenced by the presence of extraneous sounds in the system in the form of clicks, murmur, crackling.

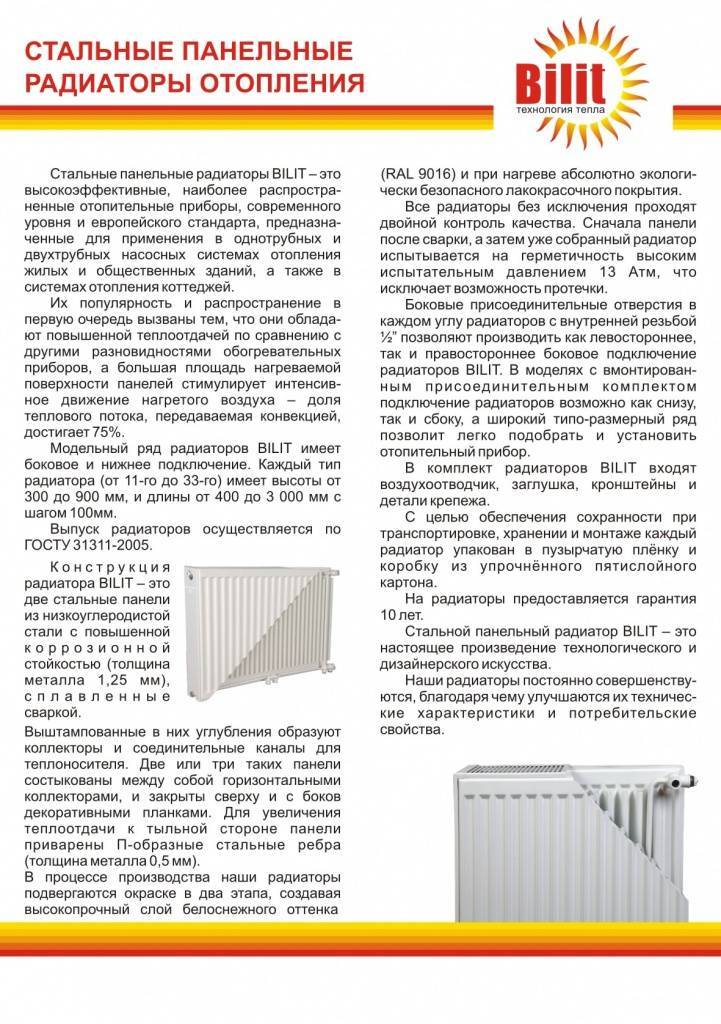

Manufacturing

For the production of panel-type radiators, special stamping machines are used to give steel blanks the required shape.

The manufacturing technology of panel products includes the following steps:

- First of all, steel sheets are processed on machines by stamping (the standard thickness of blanks is 1.25 mm);

- Two processed workpieces are adjusted in size and having a mirror configuration, are interconnected by welding;

- Further, from sheet steel with a thickness of 0.3 to 0.5 mm, convectors with U-shaped ribs are made by stamping;

- Ready-made convectors are attached to the finished panels by welding (of course, if their presence is provided for by the design of the radiator);

- When the main part of the panel radiators is assembled, pipes are welded to it, allowing the device to be integrated into the heating system;

- After welding is completed, all remaining seams are cleaned, and the finished steel stamped radiators are painted.

During the stamping process, vertical channels are squeezed out on metal sheets, which, after welding two parts, form sealed cavities, inside which the coolant will pass. As a rule, fixation of sheet blanks is carried out using roller welding, which ensures the tightness of the internal channels.