- Load value

- How to choose the power of the stabilizer

- Choosing the type of stabilizer

- Connecting a gas boiler through a stabilizer

- Choose the power of the stabilizer

- TOP 5 Double Conversion Voltage Stabilizers

- Stihl IS550

- Stihl IS1500

- Stihl IS350

- Stihl IS1000

- Stihl IS3500

- Types of stabilizers

- What kind of device is this - a stabilizer?

- When is it advisable to use a UPS instead of a stabilizer

- UPS types

- UPS architecture type

- Comparison of voltage regulators and UPS

- Stabilizer power calculation

- Calculation formula:

- Rating of the best stabilizing devices

- Conclusion: which stabilizer for a gas boiler to choose

- Mounting and connection technology

- Stabilizer Selection Criteria

- Parameters of the network to which the instrument is connected

- Load value

- Installation method

Load value

Before choosing a device, it is necessary to calculate the power of the voltage stabilizer so that it ensures the correct operation of the heating system without problems and can reliably protect it from power surges. In this case, it is necessary not to confuse the electrical and thermal power of the gas boiler

To choose a voltage stabilizer, take into account the electrical power of the equipment, which is indicated in the passport for the boiler and is indicated in watts (note that the thermal power generated by the boiler is indicated in kilowatts)

An uninterruptible switch protects equipment from short circuits

If only the boiler itself is connected to the voltage converter in order to select a stabilizer, the power of the gas equipment indicated in the instructions is increased by one third. This will be the calculated value of the converter. If a circulation pump is also connected to it, then the full load from both devices is taken into account. At the same time, the pump power is tripled, since it is not the working, but the starting power of the device that is taken into account, which is 3 times higher than the working one. Then add the boiler power and multiply by 1.3.

Consider the calculation on a simple example. If the Ariston single-circuit gas boiler, which is used only for heating, consumes a power of 80 W, then without connecting the pump, the stabilizer power must be at least 104 W. If a circulation pump with a power of 70 W is additionally connected to the device, then according to the results of the calculation we get:

(70 x 3 + 80) x 1.3 \u003d 377 watts.

If the room is installed double-circuit wall-mounted gas a boiler that provides the inhabitants of the house not only with heat, but also with hot water, therefore, has a large power (for example, 200W), the calculation will look like this:

(70 x 3 +200) x 1.3 = 533 watts.

How to choose the power of the stabilizer

The protective device must have good power in order to ensure the performance of absolutely all elements connected to the boiler unit: the unit control unit, the coolant circulation pump and the fan.

Therefore, in the very first place, it is necessary to clarify how many nodes for consuming electric current will be connected through the stabilizer.

Power data is written in the passports

In addition, it must be taken into account that current consumers, for example, such as a pump, have increased starting power characteristics. Therefore, the calculated value needs to be increased by 1.3

Choosing the type of stabilizer

Stabilizers differ in many ways. So, for example, the units can be located on the walls of the room (hinged) or on the floor (floor). The industry produces stabilizers operating on direct or alternating current, single-phase or three-phase.

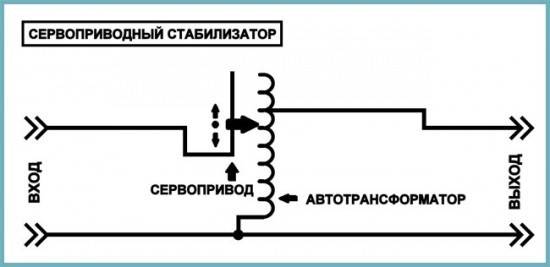

The stabilizers use several ways to switch the windings, according to this principle, the units are usually subdivided: With a servo drive (electromechanical stabilizers), - a slider moves along the windings of the unit with the help of a servo drive. This type of stabilizer is made like a car transformer. Electromechanical stabilizers function thanks to built-in devices that ensure the operation of the transformer.

Schematic: servo stabilizer

Schematic: servo stabilizer

The advantages of an electromechanical stabilizer include:

- gradual voltage regulation without the occurrence of phase disturbances and a decrease in the current sinusoid;

- small dimensions;

- high operability at various voltages, including the moments of occurrence of voltage surges from 100 to 120V.

Relay (electronic) - in this design, the windings are switched using a relay. At a low cost, such units have sufficient reliability and quality. The closed hermetic housing of the relay stabilizers prevents the penetration of dust and moisture into the structure.

Relay Voltage Stabilizer

Relay Voltage Stabilizer

The advantages of relay stabilizers are:

- relay stabilizers do not require maintenance;

- speed of reaction;

- high switching speed when the input signal changes;

- cost-effectiveness - the units have a low cost.

Attention! A significant disadvantage of electronic units is the stepwise regulation of the output voltage, which significantly reduces their use.

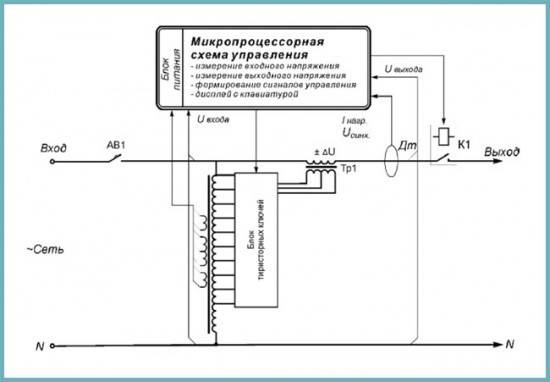

In the design of a triac voltage stabilizer, relays and triacs are used together. The advantages of this type of stabilizers are:

Triac voltage stabilizer

- triac voltage stabilizers do not contain parts in the design of the unit that wear out during mechanical operation, which distinguishes them from relay and electromechanical stabilizers;

- these units are highly durable and reliable;

- triac units are available in floor and wall versions;

- complete noiselessness of the unit;

- during short-term power outages, overloads, the triac stabilizer guarantees the uninterrupted operation of household appliances, including a gas boiler;

Scheme: operation of a triac voltage regulator

Scheme: operation of a triac voltage regulator

- the system is equipped with a built-in multi-level automatic protection, which provides load disconnection in case of overcurrent, protection against short circuits, protection against excessively high and low voltage;

- the service life of the device, set by the manufacturers, is up to 10 years.

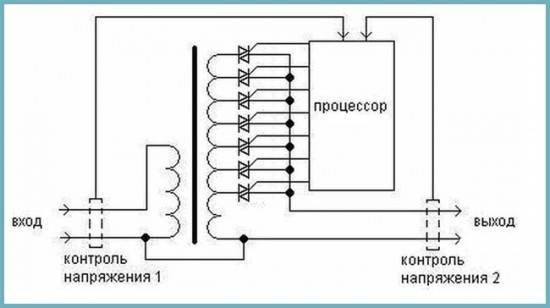

Thyristor. Stabilizers of this design have thyristor switches, which, when turned on or off, can affect the sinusoidal shape of the current, causing it to be distorted. The algorithm for measuring the voltage by several tens of times and determining the moment when the thyristors are turned on is determined taking into account the algorithm for changing the voltage in a matter of fractions of a second. Turning the thyristors on or off is controlled by a processor built into the circuit.

Tristor voltage regulator

Tristor voltage regulator

Thyristor stabilizers are not threatened with overload in case of emergency situations that have arisen on the power supply networks - the microcontroller immediately sends a command to turn off the stabilizer.

The advantages of thyristor stabilizers are:

- noiselessness during the operation of the current conversion unit;

- durability - the thyristor can work more than 1 billion times;

- during the operation of thyristors, an arc discharge is not formed;

- economy in energy consumption;

- small overall dimensions;

Schama: tristor voltage regulator

Schama: tristor voltage regulator

- lightning-fast speed and accuracy in leveling and normalizing voltage;

- operating range at voltage levels from 120 to 300 volts.

With an extensive list of advantages of a thyristor stabilizer, the unit is not without some disadvantages:

- stepwise current stabilization method;

- high cost - this is the most expensive stabilizer of all existing on the market today.

Connecting a gas boiler through a stabilizer

- Like other electrical appliances, the stabilizer must be located in a dry room. High humidity is contraindicated for him.

- The housing must not be located near flammable, combustible substances.

- A constant supply of fresh air is a must.

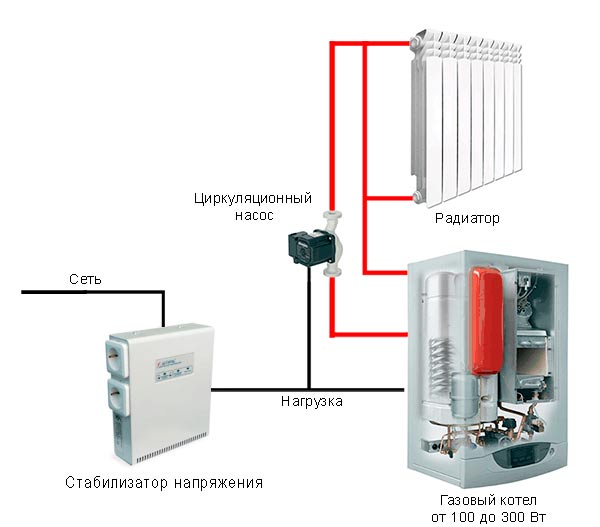

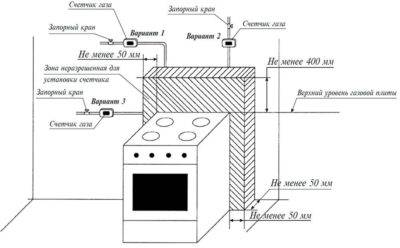

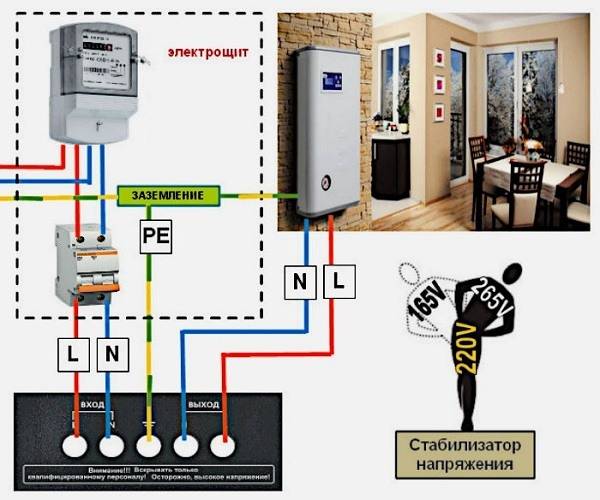

The device is connected to the mains through a socket with grounding. Wall models are mounted in the immediate vicinity of the gas boiler. The device is connected to it with sockets on the body stabilizer. The following diagram will help you understand the connection:

Gas boiler connection through a stabilizer - an operation that will protect expensive equipment from power surges, give it the opportunity for uninterrupted operation, and help it last for many years without breakdowns. However, when choosing a model, all important parameters must be taken into account. Otherwise, you can buy an unsuitable or unreliable device that will not become a worthy protection for the system.

To complete the topic of stabilizers, you can watch a video dedicated to these devices:

Choose the power of the stabilizer

Before purchasing a stabilizer, it is necessary to correctly calculate the power of the unit.

When choosing a protective device, it is necessary to take into account the amount of power consumed (the one consumed by the boiler and the pump at the same time). It must be borne in mind that when starting the pump, the current consumed can exceed the nominal value by almost three times.

Types of voltage stabilizers

Types of voltage stabilizers

In any case, the starting points for choosing a suitable stabilizer for a gas boiler will be the technical characteristics of the equipment, as reflected in the unit's passport, including.

- Response time to voltage changes. This indicator determines the voltage drop, which is stabilized by the unit in 1 second.

- Input voltage range (measurements are carried out in fact in the home network).

Gas boiler with connected voltage stabilizer

Gas boiler with connected voltage stabilizer

Accuracy and compliance of output voltage indicators. The highest accuracy is provided by triac and thyristor voltage stabilizers, but these devices should not always be purchased, since it is enough for the uninterrupted operation of the heater of an average value of 5%, which is provided by relay and electromechanical counterparts.

The choice of stabilizer always raises the question for the buyer: Whose stabilizers are more reliable? Russian or imported? As the practice of operating Russian-made stabilizers has shown, they are considered quite reliable.

TOP 5 Double Conversion Voltage Stabilizers

The most high-quality and reliable types of stabilizers include devices with double conversion. Consider the most notable models:

Stihl IS550

Low power voltage stabilizer (400 W), designed to work with one consumer. Compact, lightweight  device. It is intended for hinged installation. The output is single-phase voltage, the error is only 2%.

device. It is intended for hinged installation. The output is single-phase voltage, the error is only 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- high stabilization accuracy, sh

- wide input voltage range,

- compactness and low weight.

Flaws:

- low power,

- too high price.

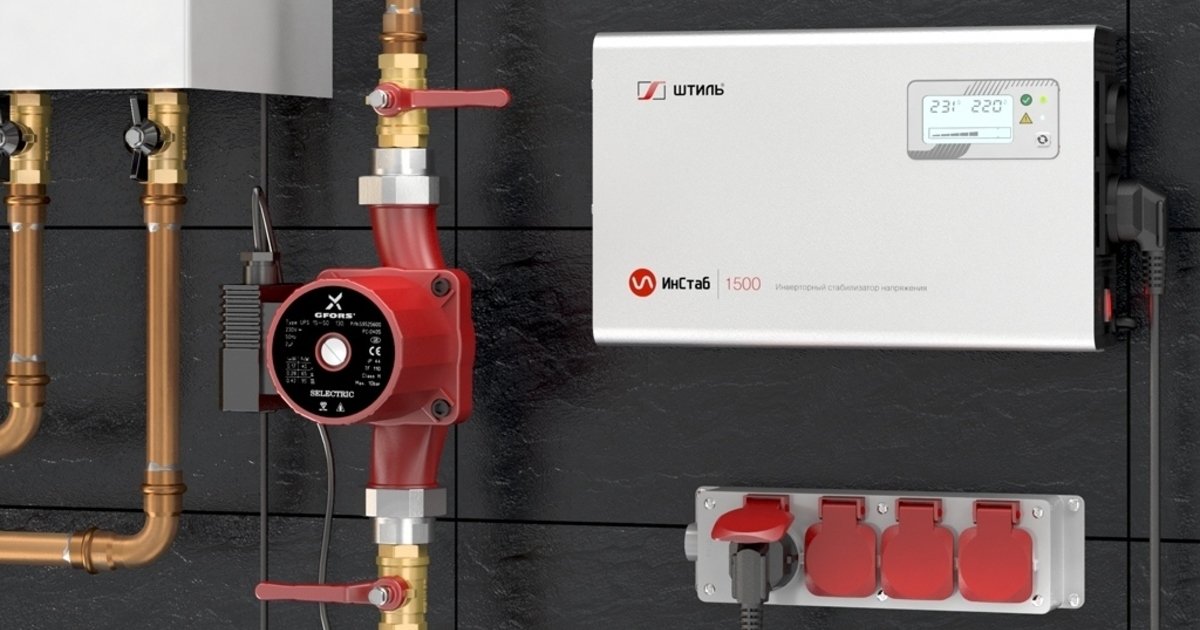

Stihl IS1500

Household voltage stabilizer with double conversion. Power is 1.12 kW. Designed for single-phase current  frequency 43-57 Hz.

frequency 43-57 Hz.

Main parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 96%;

- dimensions - 313x186x89 mm;

- weight - 3 kg.

Advantages:

- compactness,

- attractive appearance,

- light weight.

Flaws:

noise from a running fan, for which there is no data on the service life in the passport.

Stihl IS350

300 watt dual voltage stabilizer. Is different high stabilization accuracy — 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- compactness,

- small weight of the device,

- able to work with different sources,

- has high accuracy.

Flaws:

- low power,

- too high price of the device.

Stihl IS1000

Stabilizer with a power of 1 kW. Device with double voltage conversion, designed for wall mounting. Is different  compactness, low weight of the device does not create an unnecessary load on the supporting structures.

compactness, low weight of the device does not create an unnecessary load on the supporting structures.

Stabilizer Specifications:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 300x180x96 mm;

- weight - 3 kg.

Advantages:

- high speed,

- reliability,

- the input voltage range is very large, which gives no reason to worry about household appliances and electrical appliances.

Flaws:

- short power cord length

- little fan noise

- inconvenient location of plugs for consumers.

Stihl IS3500

2.75 kW double conversion stabilizer. Designed for surface mounting, has a high accuracy of work (total  2% error).

2% error).

Main parameters of the device:

- input voltage - 110-290 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 370x205x103 mm;

- weight - 5 kg.

Advantages:

- high accuracy,

- reliability,

- wide input voltage range.

Flaws:

- excessive noise from cooling,

- relatively high cost.

Types of stabilizers

Three types of devices are most widely used:

- Relay. They are also called digital.

- Electronic - the second name is "thyristor".

- Electromechanical.

At the heart of any stabilizer is an autotransformer. In relay and electronic devices, it has several windings - from 4 to 20. By connecting / disconnecting them, the input voltage is equalized. It is clear that the stabilization accuracy depends on the number of windings: the more there are, the smaller the adjustment step, that is, the voltage is maintained with smaller deviations.

Thyristors control the connection of transformer windings in electronic stabilizers

The difference between relay and electronic models is the type of switches used. As the names suggest, these are relays and thyristors. Their construction scheme is similar, but due to the difference in the response time of the elements (thyristors are much faster), electronic models have better performance. The high speed of switching elements (thyristors) allows you to control a large number of windings. As a result, the output voltage has a smaller run-up - a higher stabilization accuracy:

- relay stabilizers provide an accuracy of 5-8% (voltage run-up 203V - 237V);

- electronic - accuracy 2-3% (run-up 214V - 226V).

Since gas boilers require high voltage stability, the choice between these two types is unambiguous: only electronic ones. A pleasant surprise is the low level of noise they produce, but an unpleasant surprise is their high price.

Electromechanical ones have a different principle of operation: a roller or a carbon brush moves along the transformer winding - removable devices. The voltage at the output of the stabilizer depends on their position. Such a device produces a smoother voltage change, but their disadvantage is low speed. In order for them to work normally, the range of network jumps must be in the range from 190V to 250V. If the voltage in the network in your area is within these limits, then electromechanical stabilizers can be used. You can check the takeoff with a tester. The minimum value is usually observed in the period from 19 to 23 hours. The maximum is unpredictable.

In electromagnetic stabilizers, a brush or wheel “runs” along the winding

Electromechanical stabilizers are more expensive than relay ones, but cheaper than electronic ones. But it is worth considering that in addition to their main drawback - the inability to quickly smooth out sharp jumps - they have one more thing: brushes and rollers wear out and become dirty, can spark and require periodic replacement. Also, due to the possibility of a spark in the same room with gas appliances, they cannot be installed.

Comparative analysis of the characteristics of different types of stabilizers (click to enlarge the image)

From all of the above, we can conclude that it is better to use an electronic stabilizer for a gas boiler, even if it costs more. If you already have a relay one, it should be installed on another device or supplemented with an on-line type uninterruptible power supply.

What kind of device is this - a stabilizer?

The service life of almost any device that runs on electricity, including a standard gas boiler, depends on the stability of the voltage in the network.But at the same time, not every power grid can boast of constant performance. Many devices fail solely because they received a little more or less than the prescribed 220V. If the device was inexpensive, it is easier to repair it or replace it with a new one. But such a device as a gas boiler can be classified as expensive, and its repair is also very expensive.

Voltage drops sharply negatively affect the operation of automation and the control board of the device. It starts to work intermittently, and later just fails. To avoid this, you need a voltage stabilizer. The device corrects the voltage and frequency of the current, which makes it possible for all systems to function without overloads and prevents their possible burnout. In addition, boilers that are connected through a stabilizer operate in the most economical mode of energy consumption, and this reduces electricity costs.

A voltage stabilizer connected to the gas boiler corrects the voltage and frequency of the current, allowing the equipment to work without overloads and protecting it from burnout

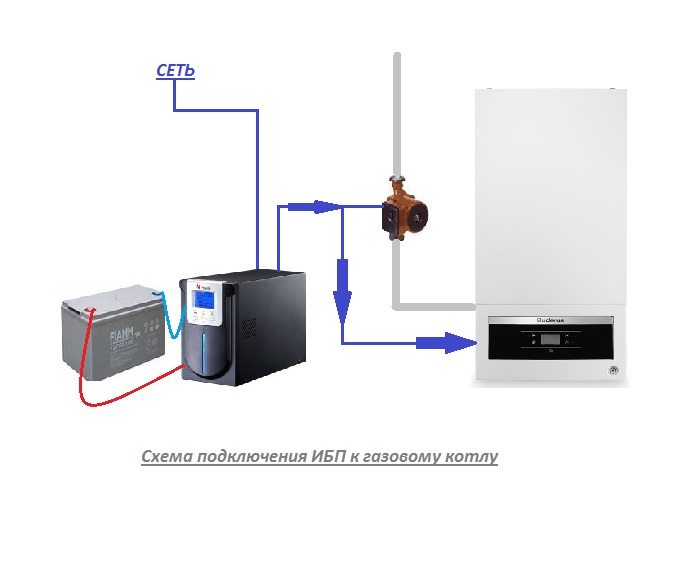

When is it advisable to use a UPS instead of a stabilizer

In addition to voltage stabilizers, there are also uninterruptible power supplies (IPS), which give out a constant volt value and can provide boiler equipment with voltage. Their difference lies in the presence of batteries that provide backup current even when the electricity in the house is completely cut off. Feed duration power depends on battery capacity, and the latter is directly related to the size of the equipment and cost.

IPB is not advisable to buy when there are no long blackouts. If voltage sometimes disappears in an apartment building or village (breaks in the line, drops below 100 V from user loads), the stabilizer will turn off the boiler and wait for the power to be restored. Since the heating has a large reserve of temperature, the system will not freeze for 5-6 hours of inactivity even in the most severe frosts. As soon as the voltage level is restored to the minimum allowable stabilizer according to the passport, it will skip it and the boiler automation will start working again.

But if power outages occur for a long time (the light disappeared in the evening and appeared only the next day at lunch), and this happens once a month, then you should think about purchasing an IPB. Due to the batteries, the device will be able to provide power to the boiler and pump, which will not allow the coolant to cool.

Its principle of operation is to store energy in batteries while there is voltage in the network, and to transfer current to consumers in the event of a general outage. The transition from external voltage to its own occurs instantly, so the equipment continues to work. The disadvantages of the UPS include more complex maintenance, increased case size, and high cost.

UPS types

Uninterruptible power supplies are structurally divided into two types:

UPS with built-in battery. They have a small margin due to the low battery capacity. Designed to maintain the functionality of the boiler electronics, and possibly equipment alarms (low-voltage networks).

UPS connected to external batteries. This is a more advanced type of equipment that is able to power the boiler, pumps, ensure the operation of solenoid valves and other actuators.With their help, you can survive long blackouts without any consequences for the indoor climate.

UPS architecture type

Equipment with batteries is divided into three types according to the execution architecture:

- Offline. They function without a built-in stabilizer, so as soon as the network performance becomes unacceptable, they switch to battery operation. If the input current parameters are changed frequently, the battery will be regularly used and quickly discharged.

- Online. It has an increased number of batteries and produces a double current conversion. The battery is constantly recharged and the boiler is powered by the battery, converting 36V DC to 220V AC. Ideal for boiler equipment, but expensive.

- Line interactive. At the same time, the battery is recharged and the voltage is supplied to the boiler with the leveling of the indicator up to 220 V. It is distinguished by sufficient accuracy of the output voltage and an average price.

Comparison of voltage regulators and UPS

| Stabilizer | UPS | |

| In which case is it appropriate to use . | With short-term power surges and rare power outages. | With frequent power outages for long periods. |

| Principle of operation. | Eliminates short-term power surges and stabilizes the voltage. | As long as there is electricity, the batteries are charged, and when there is a power outage, the batteries are a source of electricity. |

| Service. | Simple. | More difficult due to the presence of batteries. |

| Device size. | The device is compact. | The dimensions of the device are large. |

| Price. | Lower than UPS. | High. |

Summing up, we can highlight the main points: a voltage stabilizer is essential for gas boiler protection; it is important to calculate its power with a margin according to the formula, choose a speed of 5-10 ms. Protection and restart functions are important

For long blackouts, it is better to choose a UPS with an online architecture.

Stabilizer power calculation

When buying equipment, special attention should be paid to its power. First you need to find out exactly what indicator is indicated in the passport

Boilers have several meanings:

- Thermal power, which varies from 6000 to 24000 kW.

- Power consumption - 100-200 W or 0.1-0.2 kW.

Volt-amps (VA) indicate the required power of the stabilizer. The parameter is not similar to W or kW in that it indicates full power. Others are extremely useful

This means that if the device indicates a power of 500 VA, then the final figure will be 350 watts.

It is important to note that the power of the device must exceed the data of the heat generator itself, but also of the connected equipment. We are talking primarily about the circulation pump, it has its own parameters

To select a high-quality protective mechanism for personal use, you will have to take into account the increasing starting currents. At the same time, the stabilizer itself must necessarily have a kind of power reserve, which exceeds the performance of all devices by 30%.

Calculation formula:

(Power of the boiler selected and installed in the house in W + pump power W * 3) * 1.3 = final power of the stabilizer in VA.

For example, if the boiler has a power of 150 W, the pump has 70 W, then the following formula is obtained: (150 W + 70 W * 3) * 1.3 = 468 VA.

But we must not forget about the current drawdown. If the input voltage drops, then the indicated indicators of the stabilizer will also decrease.If the outlet is 170 V, then the performance will drop by about 80% of the nominal value. Therefore, the power that is indicated in the passport must be multiplied by the percentage drop and divided by 100.

Only in this case it is possible to obtain optimal performance indicators.

Rating of the best stabilizing devices

We bring to your attention our own TOP 7 of the best 220V stabilizers, which we compiled after studying numerous ratings of electrical appliance stores and customer reviews. Sorted model data in descending order of quality.

- Powerman AVS 1000D. Toroidal unit with high quality standards: low noise level, high efficiency, small dimensions and weight. The power of this model is 700W, the operating temperature is within 0...40°C, and the input voltage ranges from 140...260V. It has six adjustment levels and two outputs, and the reaction time is only 7 ms.

- Energy Ultra. One of the best electronic models for the buderus, baxi, viessman gas boiler. It has high technical parameters: load power 5000-20,000W, range 60V-265V, temporary overload up to 180%, accuracy within 3%, frost resistance from -30 to +40 °С, wall mounting type, absolute noiselessness of operation.

- Rucelf Boiler-600. An excellent device in a high-quality metal case, inside of which there is a well-insulated autotransformer. It has high technical parameters: power 600W, range 150V-250V, operation within 0 ... 45 ° C, four steps of adjustment, and the response time is 20 ms. There is one euro socket, which is located below. Wall mounting type.

- Resanta ACH-500/1-Ts. Relay-type device with a power of 500 W and an input voltage of 160 ... 240 V.Products brand Resanta have two variations. The response time is 7 ms, it has four adjustment levels and built-in protection against overheating, short circuit, high voltage. Connects to a grounded outlet.

- Sven AVR Slim-500. Despite the Chinese origin, the relay device has decent mounting quality and technical characteristics: power 400W, four adjustment levels, input voltage in the range of 140 ... 260 V. Sven is able to operate at temperatures from 0 to 40 ° C. Equipped with a toroidal autotransformer with an overheating sensor. The response time is only 10ms.

- Calm R600ST. The only electronic stabilizer designed specifically for gas stakes. Thanks to triac switches, the operating voltage ranges from 150 to 275V. Device power - 480W, temperature range - 1 ... 40 ° C, four-stage adjustment, response time is 40 ms. There is a separate circuit for each of the two Euro sockets. Completely silent operation.

- Bastion Teplocom ST-555. Another model of the relay type, but whose power is an order of magnitude lower - 280 W, and the input voltage is 145 ... 260 V. Also, unlike the Resant brand, Bastion's reaction time is 20 ms, and the number of steps is only three. In addition, the device heats up during operation and there is no automatic fuse in it.

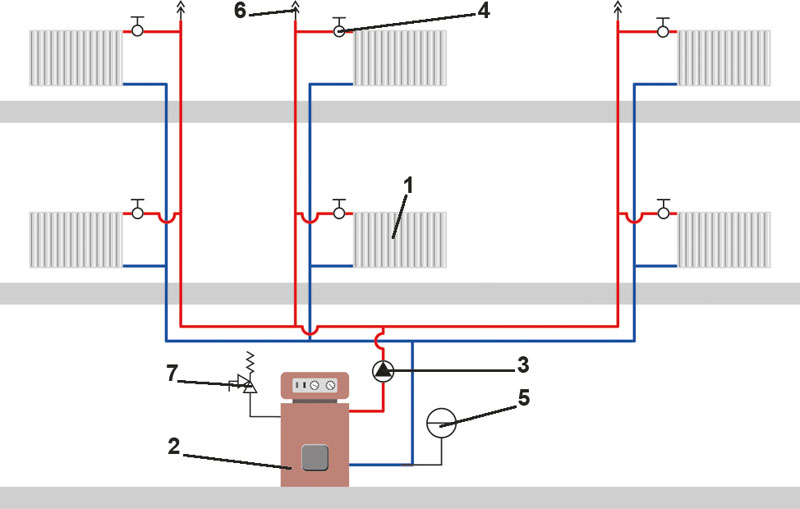

How to connect the device to the boiler?

Now you need to study the correct connection diagram of the stabilizing device.

First of all, in order to protect your gas boiler, you need a surge protector directly in front of it, and immediately after the incoming automation, a voltage control relay.

As a rule, in places where heating boilers are used, the power supply is transmitted using a two-wire overhead line that is equipped with a TT earthing system. In such a situation, it is necessary to add an RCD with a setting current of up to 30 mA.

This results in the following diagram:

Attention! Both the stabilizer and the gas boiler must be equipped with grounding!

In order to ground the boiler (as well as other electrical appliances), in the TT system it is required to equip a separate ground loop, which is completely isolated from the zero working conductor, as well as from the rest of the network. The resistance of the ground loop is calculated in accordance with the regulations of the Electrical Installation Rules.

Conclusion: which stabilizer for a gas boiler to choose

From all of the above, we can summarize which stabilizing device is best suited for a gas boiler:

- single-phase;

- with a power of 400 W or 30-40% more than the boiler power;

- any type, except for electromechanical, or install an electromechanical device in another room.

For consumers, the main criterion for choosing voltage stabilizers is the price of the product. One at the same cost, you can buy a device that is not suitable for gas equipment at all, or you can purchase a reliable model that will provide decent protection. Therefore, when choosing a stabilizing device, it is necessary to take into account the listed parameters, and not just the price.

Mounting and connection technology

Before connecting the stabilizer, you need to find a suitable place for it.You need to understand that the electrician does not like dampness very much, so the room where the device will be installed must be dry, without excessive humidity in the air. Most often, the permissible parameters are indicated in the instructions for the device. If they are not, you can focus on your own feelings. If there is excessive humidity in the room, for example, in the basement, it is better not to install the equipment here.

The garage will also not be the best place to place the stabilizer. According to the instructions, the device should not be in close proximity to chemically active, combustible and flammable substances. The attic doesn't work either. In the warm season, the temperature here often rises very high, which will adversely affect the operation of the device. Another inappropriate place is a niche in the wall or a closed closet. Lack of natural air circulation leads to overheating of the equipment.

Actually connecting the stabilizer is very simple. A gas boiler is connected to the equipment, and it is simply connected to the network. If you have to install several single-phase stabilizers at the same time, for example, in the case when three phases enter the room, you cannot plug them into one outlet. Then the first one, when switching, will create network interference, and force the other to switch. This process is practically endless. Thus, a socket must be prepared for each of the devices.

The location for installing the voltage stabilizer must be chosen correctly. The room should not be too humid or hot. In addition, natural air circulation must be ensured, otherwise the device is threatened with overheating.

Manufacturers of gas boilers warn that all warranty obligations that are given when purchasing equipment will be canceled if their operating requirements are not met. In the first place among them is most often the high-quality power supply of the device. The role of a voltage stabilizer in its provision cannot be underestimated, so the choice of a device should be approached very responsibly. Properly selected equipment will allow the gas boiler to work for a long time and uninterruptedly in the most economical mode, which will enable its owner to save a decent amount.

Stabilizer Selection Criteria

When choosing a voltage stabilizer for your gas boiler, you should pay attention to a few points.

Parameters of the network to which the instrument is connected

Each of the models has certain requirements for the voltage supplying the equipment. Most manufacturers indicate in the passport of a gas boiler a narrowed range of its operating voltage. For example, 210-230 V. This is due to the fact that the vast majority of such devices are single-phase devices designed for a standard voltage of 220 V. For them, only 10% deviation will be enough for the stabilizer to fail.

Be sure to take into account the fluctuation of the actual voltage that occurs in the network during the day. It is very good to find out the lower and higher limits of fluctuations, because if the upper limit is “broken”, the device will immediately de-energize the gas boiler. The selected model of the stabilizer must keep the voltage within strictly defined limits, taking into account the permitted tolerance.

Load value

For the correct operation of the device, it is necessary to determine whether it can cope with the expected load. A low-power model simply cannot withstand constant overloads. Buying an overly powerful device is a waste of money. First of all, you need to determine the power consumed by the gas boiler. It can be viewed in the device passport.

Here you need to be very careful not to confuse thermal and electrical power. In this case, you will need an electrical or input. It is indicated in the "Characteristics" section with numbers with the name W. Whereas in kW the thermal power is indicated. The value taken from the passport must be increased by a third. This will be the margin necessary for the correct operation of the device.

If it is planned to connect not only the boiler, but also the pump to one stabilizer, the full load from both devices must be taken into account. It should be noted that experts do not recommend such an installation, but in practice this often happens. An important nuance is to take into account the value of the starting current of the pump, which in some cases can be three times the nominal one. To determine the required power of the stabilizer, you need to perform the following steps. The pump power is multiplied by three, and the boiler power is added to it. The resulting number is multiplied by a factor of 1.3.

The voltage stabilizer for the gas boiler in the floor version is more massive. Such devices are less convenient to use, but their cost is lower.

Installation method

Depending on the mounting method, three types of stabilizers are available:

- Wall. Small devices that are fixed directly on the wall.

- Floor. Devices designed for installation on any horizontal surface.

- Universal.Can be fixed both on a vertical and, if necessary, on a horizontal surface. The most convenient models, because if necessary they can be easily reinstalled.

In general, the stabilizer for the boiler must meet the following requirements:

- Have a power reserve. Most often, a device rated for 250-600 VA will suffice.

- Have protection against overload, short circuit and overheating.

- Have a sinusoidal voltage output, otherwise the pump motor will be damaged.

- Have auto-start when power is turned on after a power outage.

- Have a safety shutdown function in case of voltage going beyond the safety limits, the so-called voltage cut-off.

- Have a ground terminal.

And a few more tips from practitioners:

In areas with intensive development and in areas served by old substations, power surges occur very often. In such conditions, the optimal choice is a thyristor stabilizer.

If the passport of the stabilizer model you like indicates that it operates in the range of about 200 V, or even more, you should be wary of such a device. Most often, the quality of the output voltage will be insufficient

Particular attention in this case should be paid to the country of assembly and the manufacturer. His reputation will be a guarantee of quality.

When choosing between floor and wall appliances, preference should be given to the second option. Such devices significantly save space, in addition, the risk of accidental mechanical damage is minimal.

Wall-mounted voltage stabilizers are very convenient. The devices are compact, resistant to mechanical damage, but their cost is slightly higher than that of floor standing ones.