Main varieties

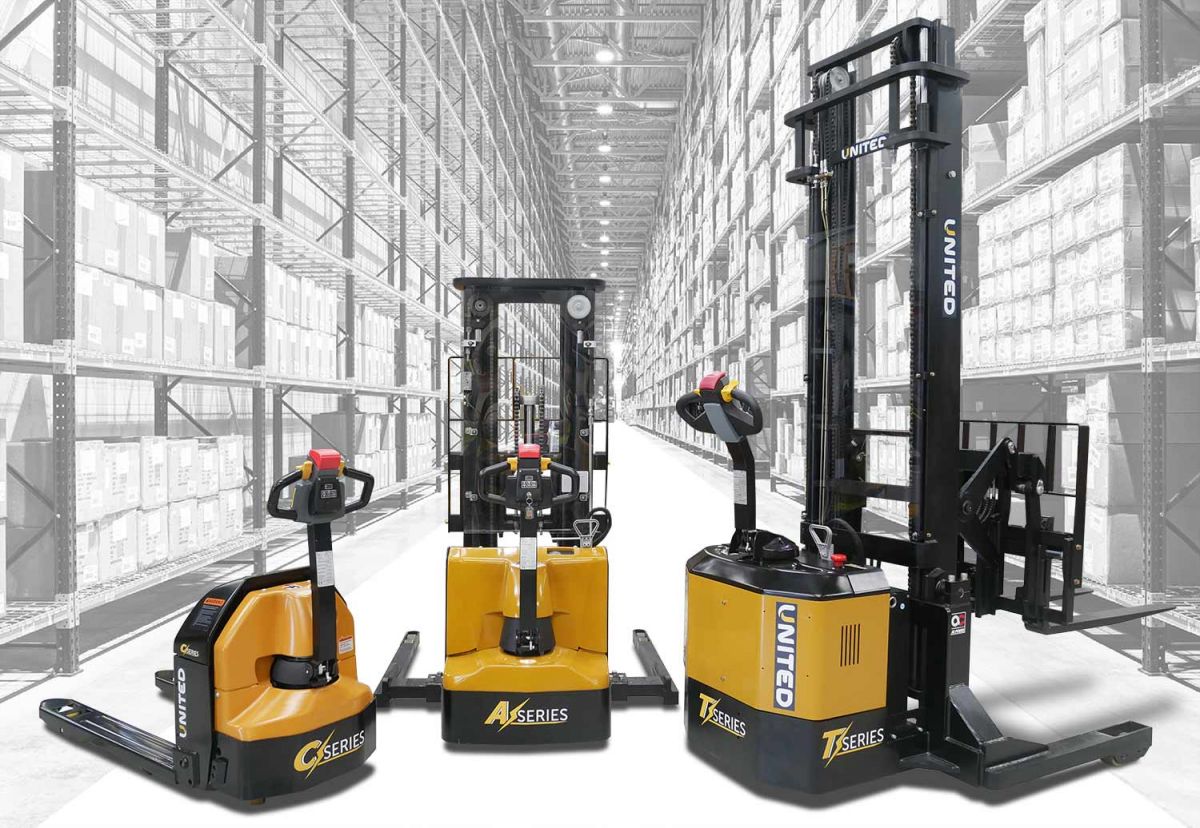

The industry produces several varieties of these special vehicles, which are lifting mechanisms mounted on a movable chassis.

They are usually divided into three main categories:

Manual, with hydraulic mechanisms driven by the muscular strength of the operators. They are suitable for small warehouses with limited handling volumes. Depending on the version, the manual stacker is able to move a load weighing from 350 to 1000 kg, lifting it to a height of up to 3000 mm.

Electric, with lifting devices equipped with electric drives. Such models are a good choice for medium-sized warehouses. Their maximum load capacity reaches 1500 kg, and the height of the forks is 3500 mm.

Reading now

Self-propelled, completely eliminating the manual labor of operators. Such equipment is necessary in large warehouses with a high intensity of cargo flows. With the help of the most powerful modifications, a load weighing up to one and a half tons can be moved vertically by 5600 mm.All of them are smaller and cheaper than forklift trucks, which often turn out to be redundant. Supervised by trained operators, they are reliable, completely safe and able to increase the efficiency of warehouses designed to store products for various purposes.

Storage equipment

Racks and other places for storing goods

Kinds:

- Racks shelf and frame, mobile;

- Pallets;

- plastic containers;

- Bins;

- Reservoirs;

- Industrial furniture;

- Packaging equipment;

- Workbenches;

- Tables on wheels, tools for packing and unpacking.

There are different models of shelving:

- Light office and warehouse models;

- Pallet racks that can be multi-storey.

This design differs in load capacity and the number of levels. It is possible to manufacture products to order, which is very convenient for the warehouse and allows you to place products in a compact and practical way, depending on the availability of a particular product.

Varieties:

- The main types of warehouse racks are shelving for storing piece goods, as well as racks for cargo pallets.

- Console racks are useful for storing long, non-standard cargo.

- Non-standard racks for storage of reels, barrels.

- There are also gravity and elevator racks.

Elevator racks

The larger the warehouse, the more diverse the means for storing products will be presented in it.

Racks should provide not only the strength and stability of the structure, but also the convenience of working with them.

In addition, it is necessary to pay attention to the safety of working with this equipment. So metal racks must have grounding.In general, the design should not have sharp corners and uneven surfaces.

Also on the shelves should be marked with the allowable load. You can not load shelves above the specified norm. This may result in structural failure or an accident. Since the racks are manufactured in accordance with GOST 14757-81, it is best to purchase finished products or order individual fixtures from a trusted company.

In general, the design should not have sharp corners and uneven surfaces. Also on the shelves should be marked with the allowable load. You can not load shelves above the specified norm. This may result in structural failure or an accident. Since the racks are manufactured in accordance with GOST 14757-81, it is best to purchase finished products or order individual fixtures from a trusted company.

The pursuit of excellence

A modern stacker is a perfect and well-thought-out mechanism, for the manufacture of which high-quality materials and innovative technologies are used. Compared with previously produced modifications, the capabilities of the new models are significantly expanded due to the use in the design of:

- Compact high-capacity lithium-ion batteries that quickly restore their potential when recharging.

- Electronic components that make the control process simple and comfortable.

- Original design solutions.

Experienced rigging specialists have been able to appreciate stackers for a long time.They do not spend much time and effort moving heavy loads from place to place, lifting them to the upper tiers of racks or lowering them to the ground, loading or unloading a vehicle.

Do you want to purchase warehouse equipment that meets the highest requirements? Become a client of HYPERLINK Stabeler-SPB. In its catalog you will find models that differ in design and performance. The equipment adapted to Russian operating conditions fully complies with European standards. Warranty and post-warranty service is provided.

Types of stackers:

Manual hydraulic models

Differences:

- movement is carried out manually

- the hydraulic system is equipped with a manual and (or) foot drive

Pros:

- Moderate prices

- light weight

- work in cramped conditions (turning radius usually does not exceed 1.2-1.3 m)

- minimum requirements for Maintenance (MS)

- small amount of required consumables

Minuses:

- poor performance

- high physical costs for the operator

- low moving weight (up to 1500 kg)

- low lifting height (up to 3m)

Go to catalog

Electric Lift Models (Electric Stackers)

Differences:

- lifting the load with an electric pump

- the hydraulic system is equipped with a manual and (or) foot drive

Pros:

- higher performance

- low price

Minuses:

- operator's physical costs

- low moving weight (up to 1500 kg)

- low lifting height (up to 3.5m)

Differences:

- lifting and moving by electric motor

- high lift height

Pros:

- high performance

- safety when working with cargo

- low physical costs for the operator

- large selection of models

Minuses:

- flat floor required

- indoor work

Other types of equipment

When receiving cargo in boxes or bundles, it is placed in pallets, and they, in turn, are placed on racks.

Pallets are convenient because they do not allow damage to the goods during transportation from place to place and they can be easily transported with a forklift. Also, the standard dimensions of this design allow for more compact storage of products. With mechanized loading of products, standard pallets speed up the processing time of the goods.

What pallets are distinguished:

- Flat. They can place goods in boxes, boxes, bags;

- Rack-mounted. On these pallets, you can stack goods in several rows;

- Box. The rigid framework allows to store and move freights. which can be easily damaged. These pallets have removable and non-removable walls;

- Metal pallets. They are used for transportation of barrels and other products of oversized volume and heavy weight.

Since wooden pallets do not last long, it is better to use metal products.

Additional suggestions for work optimization

To store small volumes of products, you can use not only racks, but also industrial furniture. It will allow you to systematize cargo and keep a strict record of various units of goods.

Packing equipment is required for fast and high-quality transportation of goods. It allows not only to store goods in coils, but also to transport them without violating the integrity of the package, without losing small goods.

How to choose equipment for a warehouse and what to look for

If the turnover of goods is large, then it is best to use forklifts.They can not only transport large goods, but also travel outside the warehouse. If, in addition to the loader, a car drives in, then an overpass with adjustable height is needed. It is also possible to move the goods with the help of hydraulic trolleys. When loading is done infrequently, in this case it is easier to purchase a stacker. It will cost less. If you still purchased a loader, then you can pay for it by leasing it to neighboring warehouses.

The purchase of equipment for intra-warehouse work will depend on:

- Strength of the floor and coating;

- The size of the passages between the racks;

- Weight, height and dimensions of the cargo.

You can buy a loader for internal work only if the warehouse area allows. Otherwise, it makes no sense to change the width of the aisles for it and lose usable area. In this case, stackers, reach trucks and self-propelled carts will help out.

The most convenient are hydraulic stackers. They are designed for small companies.

When choosing equipment and machinery, always proceed from the needs of the company and the volume of the warehouse, as well as the cargo turnover on it.

Specifications

To choose a stacker for a warehouse, you need to consider the following main parameters:

Stacker Cesab R216

initial load capacity. The indicator means how much weight the stacker can handle at a height of up to 2 tiers of the rack. The formula usually works - the higher you need to lift the load, the less it should weigh. This, above all, affects the safety of the stacker, as the center of gravity shifts with height. Stackers are very compact in design and can work in narrow spaces.If the distances between the racks are large enough, counterweight stackers can be used, with this design the lifting height can be increased up to 12.5 m.

Performance indicator. Productivity is a measure of the uptime of a stacker. If the stacker is electric, then this indicator means the operating time before recharging. The performance of stackers depends on many indicators: battery type, travel speed with and without load, power of the lifting mechanism, height and speed of lifting the load. Traction battery stackers are more productive and able to work a full shift without recharging. Equipment with a semi-traction engine can move up to 50 tons of cargo without recharging in one go.

The distance between the racks is the main indicator when choosing a stacker. Manual stackers under the control of the operator can work productively only in aisles of at least 2 m

When purchasing stackers, you must first of all pay attention not only to the width of the working space, but also to the turning radius. It is also worth considering that the stacker will move with the load

In the characteristics, the width of the passage is indicated by Latin letters AST. This value takes into account the working width of the stacker and 10 cm on both sides. Moreover, pallets with goods can be different in length - this feature should also be taken into account when choosing a stacker.

Working surface. The main parameter is the quality of the flooring. Stackers are equipment capable of working only on a flat surface, without visible defects and pits. First of all, this is due to a small clearance, reaching a maximum of 30 mm.You should also take into account the difference in floor coverings, the angle of ascent and descent should not exceed certain characteristics. Most often, the angle of the surface drop should tend to zero, otherwise the control of the stacker becomes unsafe. Manufacturers are working in this direction, so they currently use a system with variable clearance. The disadvantage of such a system is its cost. The type of flooring also plays an important role when choosing a stacker, primarily from what material the chassis of the equipment will be made.

Fork size. Here you should consider which pallets will be used in the warehouse. Standard pallets require a fork length of at least 1 m and 140 cm from loaders. Non-standard pallets are compensated by the ability to install short or longer forks on the stacker. Also stackers can be produced with the function of changing the width between the forks. This is necessary when working with non-standard cargo.

lift height. In narrow aisles stackers are typically capable of lifting loads up to 3m, and stackers with support mechanisms are capable of lifting loads up to 12.5m, requiring wider spacing between warehouse racks.

Control. Management directly affects the performance of equipment. In manual models, the operator steps on the foot pedal and the weights are slowly raised/lowered hydraulically. For electric stackers, the load rises more quickly, and the operator lifts / lowers the load using a lever, releasing the stacker control handle. In more advanced stackers, manufacturers use lift speed control systems.Depending on the force of pressing the lever or button, the movement of the forks changes its speed.

In most cases, when choosing a stacker, you should also take into account the climatic component of work in the warehouse. In this case, when choosing, you need to take into account: the protection of mechanisms from external influences (moisture or dust), the design of the forks (with grippers for non-standard loads), the material used to make the forks (stainless) and much more.

Conclusions:

Special equipment will help with daily work in warehouses and closed production sites, both with small and heavy traffic.

Depending on the conditions of use of stackers, the following characteristics are selected:

- stacker type

- lifting height

- load capacity

- leash (when the operator walks behind the stacker),

- with platform or cab for operator

- battery capacity

- mast type

- fork width

- frost-resistant or explosion-proof execution

- additional lifting devices

During the operation of self-propelled stackers, you can move at a speed of up to 9.2 km / h and lift a pallet weighing up to 2000 kg onto a rack at a speed of up to 145 mm/s. Depending on the model, the height of the forks from the floor level reaches 6.8 meters.

The electrical equipment is powered by rechargeable batteries, while the charge of a standard traction battery with an average intensity of operation is enough to work one work shift (about 8 hours). Usually this is done - the stacker is used all day, and put on charge at night. This allows you to work every day without days off and be sure that the battery will last for many more years. In the case of multi-shift operation, you can order a model with an additional battery (LemaZowell SR, SRB, STR series with a side battery recess).With this scheme of operation, the battery is removed from the case and charged separately.