- Classification by stitching method

- PEX A

- PEX B

- PEX C

- PEX-D

- Choosing the type of pipe for underfloor heating: which ones are better

- What to do if a floor heating pipe is broken?

- Types of pipes

- Polypropylene

- Cross-linked polyethylene

- Copper

- metal-plastic

- Soldering PP fittings

- Cross-linked pipe construction

- Filling the screed

- The right choice of polypropylene products

- Polyethylene pipes

- Choosing the best option for TP

- Features of the manufacture of cross-linked polyethylene

- Conclusions and useful video on the topic

- XLPE pipes

- How long will they serve

- Mounting Features

- Cons of cross-linked polyethylene

- Metal-plastic pipes

- How long will they serve

- Mounting Features

- Minuses

Classification by stitching method

To create additional stable bonds in polyethylene molecules, four crosslinking methods are used. They are classified by letters: A, B, C and D. Of these four methods, PEX A is considered the highest quality production method. But due to its high price, many prefer cross-linked polyethylene with the Rex B marking.

PEX A

Pipes are marked PEX A when polyethylene is cross-linked by heating with the addition of peroxides. The crosslink density here is the highest up to 75%. Products have the following positive characteristics:

- the greatest flexibility among other analogs;

- the presence of a "memory effect", after unwinding takes its correct position;

- creases, kinks are restored when heated with a building hair dryer;

PEX A also has disadvantages:

- high price due to expensive technology;

- during the operational period, some chemical elements are washed out of the pipeline, and more in quantity in comparison with other PEX groups.

PEX B

In the next PEX B method, silane crosslinking is carried out in two steps. Organic silanides are added to the raw material and a pipe is obtained that is not yet cross-linked. Then the product is hydrated, a crosslink with a density of up to 65% is obtained. It's just below the first method. The characteristics of this crosslink are as follows:

- high reliability, bond strength is higher than that of PEX A;

- affordable price;

- resistance to oxidation;

- high pressure readings.

This option also has its drawbacks:

- the products are relatively rigid, not easy to bend;

- there is no “memory effect” - it will take time to restore the form;

- in case of creases, special couplings must be used.

PEX C

When marking PEX C, radiation cross-linking is carried out. The material is affected by gamma rays or electrons. In this case, the evenness of the stitching depends entirely on the position of the electrode in relation to the pipe itself. The maximum density achieved with this method is 60%. The characteristics are as follows:

- the products have satisfactory flexibility, it is better than PEX B;

- there is molecular memory;

The disadvantages are the following:

- cracks, creases may appear on the pipeline, which are corrected, like with PEX couplings;

- in our country this category is not popular.

PEX-D

Nitrogen crosslink is labeled as PEX D. The method is based on the treatment of polyethylene itself with nitrogen compounds. The crosslinking is average up to 60%.Pipes with this marking are inferior in quality to similar products. Now this technology is practically not used.

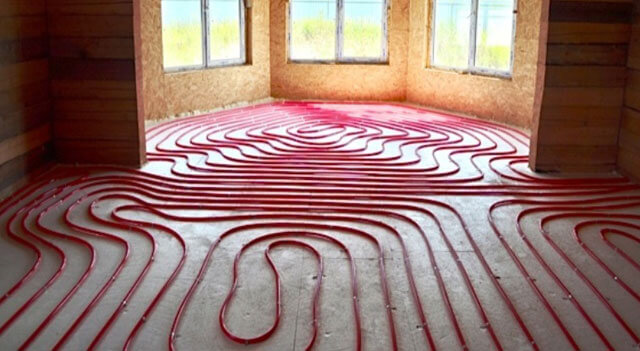

Choosing the type of pipe for underfloor heating: which ones are better

All materials have positive and negative sides in use. Below we will consider 4 types of the most popular pipes for underfloor heating, which are mainly used by professionals.

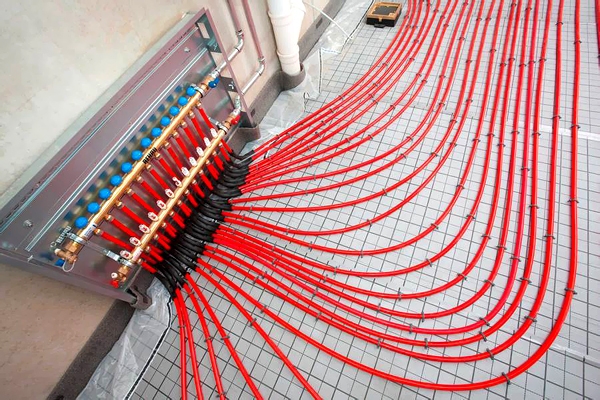

Metal-plastic pipes for floor insulation are popular.

Namely:

- Copper;

- metal-plastic;

- Polypropylene;

- PEX pipes.

The first option is expensive, copper is a universal building material, and laying the floor with copper pipes guarantees durability. Despite the fact that time does not stand still, and new materials appear, the “red” copper tube is still relevant in the flooring device. The main advantage of the material is durability.

Copper is resistant to rust, and tubes from it perfectly endure difficult temperature conditions, mechanical loads. Copper pipes for underfloor heating will not crack, melt, or burst. Due to the highest performance characteristics, building materials can be safely used in modern heating systems. If all the conditions recommended by the manufacturer are met, copper pipes will last more than 50 years. This pays off the initial investment. You can buy them at any building trade center, such as, for example, Leroy Merlin.

With all the advantages and excellent technical characteristics, copper pipes also have disadvantages. The material is susceptible to hardness, acidity of water, pipes can quickly deteriorate. Do not drain water from systems with copper pipes very often.Also, copper / steel should not be combined so that there are no negative electrochemical processes. As for mounting, the connections of copper tubes with the help of special press fittings are reliable. They are sometimes stronger than the pipes themselves. Press machines are expensive, therefore, for installation, it is necessary to invite masters, which will lead to additional financial expenses.

What to do if a floor heating pipe is broken?

In the presence of warm

water floors in a house or apartment, there are times when the floor pipeline can

be pierced. First of all, if the floor is functioning, you should disconnect it from

water supply. But more often, such damage occurs during installation or repair.

systems, when the topcoat is not laid and the screed is not poured - this is a huge

a plus.

In the presence of a concrete screed, in order to find the place of damage, you will need a puncher, a chisel and a hammer to destroy the concrete. This should be done carefully so as not to damage the entire circuit.

When punching a pipe

from metal-plastic or polyethylene, their repair is carried out by press couplings, with

using a special press.

Having calculated the place of the breakdown, the damaged area should be removed, and a whole circuit should be installed in its place. The connection is carried out using press couplings, which should be wrapped in polyethylene film to protect against cement mortar.

Types of pipes

Using the above characteristics as a guide, we can say that the choice of pipes for underfloor heating is limited. The following types are most suitable for this:

- polypropylene;

- from cross-linked polyethylene;

- copper;

- metal-plastic.

Let's take a closer look at each type.

In order for the warm floor to have a long service life and provide a comfortable temperature, it is necessary that the installation of the system be carried out with high quality and in accordance with all the rules.

Polypropylene

Like any other material, polypropylene pipes have both pluses and minuses. The positive qualities of such material include:

- Low price. It is one of the cheapest options.

- Durability. If the operating standards are observed, the service life is more than 25 years.

- Solidity. When connecting to each other or with fittings, special welding is used (pipes are soldered). The result is a completely monolithic and sealed system.

- Environmental friendliness. Throughout the entire period of operation, they are safe for human health and do not emit harmful substances even when overheated.

But with all these advantages, polypropylene products have one big disadvantage - they are difficult to install. This difficulty lies in the fact that the bending of such products without compromising performance is about 8 - 10 radii of the pipe itself.

Thus, the gaps between them are more than one meter. Another disadvantage is the low temperature resistance compared to other materials - no more than 95 degrees Celsius. Thus, their use is limited.

Cross-linked polyethylene

Unlike conventional polyethylene, cross-linked polyethylene has higher performance properties, so it is increasingly used in the manufacture of underfloor heating.

The advantages of such material include:

- resistance to elevated temperatures (up to 120 degrees Celsius);

- smaller bend radius - about 5 radii of the pipe itself;

- not afraid of mechanical influences;

- not afraid of sudden changes in temperature and pressure;

- plasticity (very flexible material);

- even if the pipe is crumpled from repeated bends, it returns to its original shape when heated;

- resistance to chemicals and bacteria;

- environmental friendliness (even when melting or burning, it does not emit harmful substances).

The only disadvantage of this material is that its installation requires a large number of fasteners, since it does not hold a given shape.

Copper

Copper pipes have been used for a long time in the installation of a warm floor. They have high performance and are able to withstand significant mechanical stress, and at the same time are neutral to the effects of microorganisms and are not subject to corrosion.

Their service life is one of the longest, and with high-quality installation and normal operation is more than 50 years. Equally important is the ability to withstand significant temperature changes (from -100 degrees Celsius to +250), without losing its performance. In addition, the bending radius when laying such pipes is quite small.

However, they also have a number of disadvantages:

- Firstly, this is the most expensive material of all considered.

- Secondly, for the reliability of the connection, special press fittings are used, the installation of which can only be carried out by specialists with the necessary equipment. Thus, there are additional installation costs.

- Thirdly, with increased acidity and hardness of water, the service life is significantly reduced.

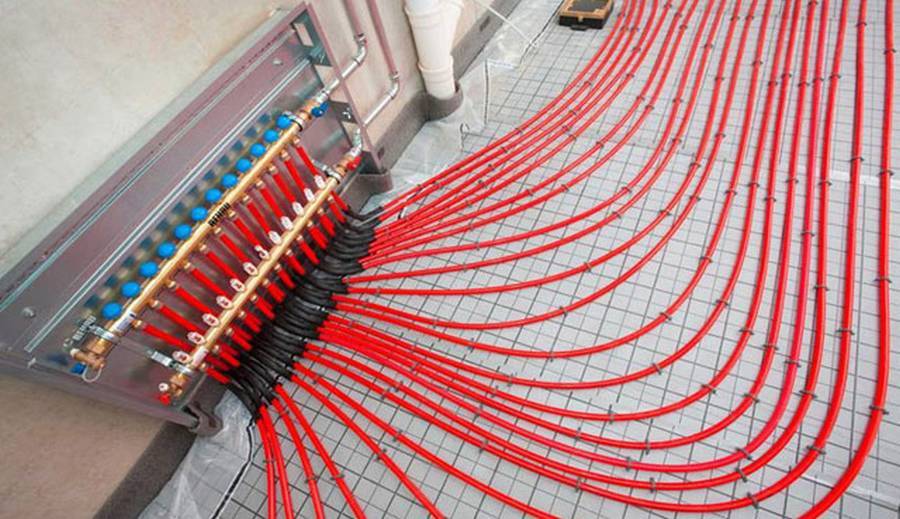

metal-plastic

Metal-plastic pipes are the most popular in the manufacture of underfloor heating. This is largely due to the operational properties similar to copper, at a lower price.

The positive qualities of such material are:

- long service life (more than 50 years under normal operation),

- have a small bending radius and keep a given shape, which allows you to additionally save on fasteners,

- high degree of sound insulation (virtually inaudible water flow),

- lighter weight than copper

- environmental friendliness.

They practically do not have negative qualities. The only negative point may be the unreliability of connecting pipes with fittings, since even with the slightest gap between the inner diameter of the connecting element and the outer diameter of the pipe, a leak can occur.

Soldering PP fittings

Before connecting two pipes with fittings, they must be fixed to the pipe. We discussed the fastening of the collet on the HDPE pipe above. Now consider the connection of a polypropylene pipe with a fitting.

Polypropylene fittings with a pipe are connected by soldering with a special soldering iron. The soldering iron with nozzles is placed on a stand and heated to 260°C. The edge of the pipe is cleaned of dirt, chamfered and degreased together with the inside of the coupling. The pipe and fitting are simultaneously put on heated nozzles. After heating, the pipe is inserted into the fitting exactly without turning and allowed to cool. This completes the soldering process.

After reading this article, you can easily connect a polypropylene pipe to a HDPE pipe. Here are all possible options for the correct connection. There are enthusiasts who claim on construction forums that these two pipes can be soldered with a coupling at different temperatures.But the thing is that polypropylene and HDPE consist of different materials, they have different melting points, so such a seam can burst or even melt. If you decide to save money and experiment, then do it at your own peril and risk.

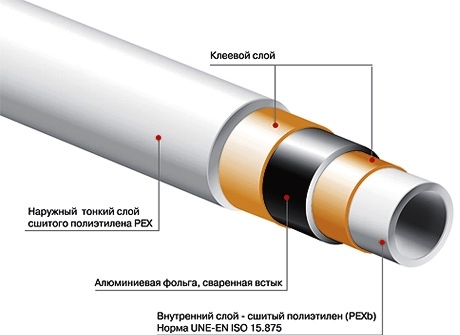

Cross-linked pipe construction

In most cases, cross-linked pipes have a complex structure. To increase the strength of the pipeline, reduce the ability to expand, they are covered with a reinforced layer, these are:

- aluminum foil.

- Perforated aluminium.;

- Polypropylene.

- Aluminum sheet.

A reinforced layer (for example, polypropylene) levels out pressure drops when using the product for heating. Reinforcement is provided on the upper side, at different depths of the product. When sewing pipes, the reinforcement layer is removed by 10 mm. Products used for heated floors almost do not reinforce. They are called "pure".

In addition to reinforcement, the manufacturer covers all the details of cross-linked polyethylene with a layer called a "diffuse barrier". This is due to the fact that oxygen molecules are able to penetrate into cross-linked polyethylene and slowly destroy it. Therefore, an oxygen protective barrier is required - it is done outside or inside.

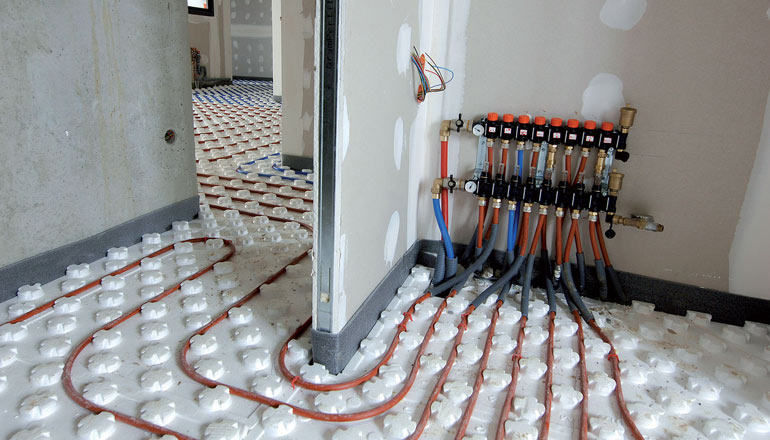

Filling the screed

When the system has been successfully checked for leaks, it is considered that the installation of pipes has been completed.

The screed is being poured: its height is not less than 3 cm on top of the pipe. Only under this condition will the screed protect the cross-linked polyethylene pipe and allow heat to be evenly distributed over the floor. A solution is poured, based on cement M300.

Masters disagree on the issue of reinforcing the screed.

If there is no experience in the correctness of the reinforcement device, then it is better to bypass this stage.Underfloor heating works without a reinforcing layer.

Reinforcement makes the screed more durable and reliable. A mesh of 100x100 mm is used. It is correct to “drown” it in the screed solution so that it is inside the screed, and does not lie on the pipes.

The floor is allowed to be put into operation one month after the screed has been poured.

For flooring, any coating is used.

The right choice of polypropylene products

It is difficult to choose something specific from the wide range provided by many manufacturers. There are criteria that must be followed when purchasing.

1. Products must be in accordance with the characteristics of the plumbing / heating system.

2. In order to assemble the system with high quality, you need to purchase all the parts from one manufacturer. This approach will create a reliable and durable design.

3

When choosing, pay attention to the quality of pipelines, fittings. Evaluate the following:

- smoothness of the inner / outer surface;

- the presence of cracks, chips, bubbles, heterogeneous structure, foreign particles;

- the correctness of the geometry;

- same wall thickness.

4. Remember that polypropylene products are designed for operation at a temperature of at least minus twenty. Ask the store how to store them in the winter. Improper storage leads to deformation of products.

5. If drinking water will flow through the water supply, ask the seller if the product meets the standards of sanitation and hygiene.

6. Buy only straight pipes, no bends. In stores, they are stored vertically, so they gradually bend, cease to be even.

Be sure to pay attention to this

7. Choose products from trusted manufacturers that have proven themselves and have all the necessary certificates. Trying to save money, you can buy a low-quality product that will not be able to serve you for the entire operational period. Therefore, it is better to pay more once than to spend money again and carry out complex repairs to the water supply / heating complex.

Polyethylene pipes

For underfloor heating, one of two types of polyethylene is used: cross-linked PEX or specialized PERT. The term "crosslinked" refers not to the sheets of material, but to the molecules of which they are composed.

As a result of structural features, the flexibility and strength of tubular products increases significantly, and the temperature of the medium being transported increases. If for ordinary polyethylene the maximum is 40 degrees, then for cross-linked - 95 degrees.

To distinguish between XLPE pipe products depending on the processing method, pay attention to the designations:

- PE-Xa - means that the heat treatment was carried out using peroxides. As a result, the crosslink strength is 75%;

- PE-Xc - after bombardment with electrons, the strength increased to 60%;

- PE-Xb - silane wet treatment carried out in the presence of a catalyst. Crosslinking is 65%;

- PE-Xd - nitrogen treatment technology is rarely used.

To equip the underfloor heating system, polyethylene is used, which has a crosslink strength of 65 - 80%. The greater the density of the material, the better, but the price of the product is higher. When choosing which pipe to use for a warm water floor, experts recommend purchasing cross-linked polyethylene PE-Xa or PE-Xc.

At the same time, PE-Xc pipes are preferable, since electron bombardment ensures uniform cross-linking, but chemical influences give strength to the upper layers of the material and the degree of processing decreases with deepening.

The only drawback of such polyethylene is a high degree of elasticity. As a result, the pipe bends easily, but it must be attached to the frame, otherwise it returns to its original position.

Many manufacturers make special mats with two functions:

- improvement of thermal insulation;

- the presence of a fixation system for pipes made of polyethylene.

Installation with their use is easier and faster. At the same time, regardless of the speed of movement of the coolant, the design operates silently. Therefore, the PEX pipe for underfloor heating is recommended by experienced craftsmen.

PE-RT (Perth) products have even better characteristics. The molecular structure of this material provides it with high flexibility and resistance to high temperature and pressure. As a result, we can conclude that when comparing pipes for underfloor heating, PE-RT products are the best choice.

Choosing the best option for TP

If you carefully study the analysis of each type of pipeline, you can draw a preliminary conclusion: copper wins in all performance indicators, but significantly loses to polymers in price. Stainless steel corrugation will also not become an alternative to polyethylene - it is twice as expensive and worse in hydraulics.

Which pipe to use for underfloor heating in the first place:

- Number 1 of our rating is metal-plastic PEX-AL-PEX, proven by many years of practice.The material is relatively inexpensive, convenient for do-it-yourself installation, durable, transfers heat well and elongates a little from heating.

- Cross-linked polyethylene PE-X - pipes for professionals who know how to make high-quality TS contours. "PEX" is easily restored after a break, but it conducts heat worse and expands greatly from an increase in temperature.

- Heat-resistant polyethylene PE-RT is a budget option for professional installation. The main disadvantages are oxygen permeability and a significant reduction in service life in case of overheating.

- The fourth place of a copper pipe is caused by the high price inaccessible to the majority of ordinary homeowners. If you do not take into account this factor, copper will be an ideal option for underfloor heating.

- Stainless corrugation is good for short sections, such as connecting pipes and hoses. Laying corrugated pipes under the screed is not a very good solution.

- Polypropylene is not used at all.

Recommendation for the correct laying and concreting of PE-X and PE-RT pipelines. To reduce the elongation of the heating threads, do not exceed the number of pipes in one circuit - 100 m, ideally - 80 m. Before pouring the solution, fill the system with water and pump up the test pressure (1.5 times higher than the working one). The TP installation technology is described in detail in a separate article.

Let's add a few arguments in favor of choosing polyethylene or metal-plastic for floor heating. First, polymers have been successfully used in European countries for a long time. Secondly, the chemical composition of the base substance is continuously improved, and the properties are improved. Thirdly, polymer pipes are very durable, the standard service life is 50 years.

Features of the manufacture of cross-linked polyethylene

Ordinary polyethylene has a linear molecular structure, which gives plasticity, but there is no strength, resistance to stress. To achieve worthy characteristics, polyethylene molecules are “crosslinked” by a chemical (physical) method.

Chemical bonds are formed between the molecules, they form into a cellular network, which is characteristic of many building materials. This process gives strength, resistance to temperatures, leaving good ductility. The material tends to recover its shape after deformation.

Polyethylene pipes differ in the way they are made

Cross-linked polyethylene is designated pex. According to the production method, the material is:

- pex a: formed when using peroxides, has good elasticity, strength;;

- pex b: obtained by treatment with water with a silane implanted catalyst. This is the cheapest way to get cross-linked polyethylene. It has low flexibility, small bending diameter;

- pex c: formed after using the physical method of exposure - electron bombardment. The material does not have sufficient plasticity, strength, which are required for the installation of a warm floor;

- pex d: produced using nitrogen technology. It is outdated and rarely used.

Products of cross-linked polyethylene PEXa are suitable for a water floor. Manufacturers cover them with protective layers that do not allow oxygen to penetrate inside, increase the resistance to chemical destruction.

Parts made from this material can withstand high temperatures (95°C), pressures of 10 atm. When choosing a model for any heating system, use a wide range of hoses.

Conclusions and useful video on the topic

The video review details the structural features, physical and operational properties of various types of pipe fittings

Attention is paid to the assessment of the quality of metal-plastic products and PEX-polymers:.

What parameters should be taken into account when choosing pipe products for the heating circuit:

Tips for choosing underfloor heating equipment:

Video on how to choose the diameter of the product:

Strength test for different types of pipes:

If the budget allows, then the ideal solution is to equip the floor with copper pipes. However, it is not necessary to overpay for the excess strength of the metal. To make a reliable, durable and efficient heating system will be obtained from metal-plastic fittings based on heat-resistant polyethylene. A worthy, more budgetary alternative is PEX pipes.

The quality of the materials and components will depend on the efficiency of the service of a water-heated floor. The right choice will allow you to equip the most economical, comfortable and aesthetic heating system in the house.

We hope our material helped you decide on the choice of pipes for underfloor heating. If you have any questions, you can ask them in the box below.

XLPE pipes

These are thermoplastic hoses, which, when produced in the CIS countries, must comply with the technical specifications of GOST 32415-2013 "Thermoplastic pressure pipes and fittings for them for water supply and heating systems."

Easily holds 95 degrees and high pressure, chemically resistant, even gas can be passed through it without leakage. They do not conduct electric current - in the country, you can safely use the remaining piece to insulate the cable.The polyethylene material is perfectly smooth, which does not allow salt deposits and dirt to linger and accumulate.

Linear expansion is average between polypropylene and metal-plastic, but closer to PPR pipes.

In terms of operational characteristics, it is the same as metal-plastic, but does not have an aluminum reinforced layer, therefore it is cheaper. Very convenient to install.

According to reviews, a very nice cool pipe: light, bends, you can heat it with a hairdryer and restore it if it is pinched or broken.

How long will they serve

We can say for sure that longer PPMS. Cross-linked polyethylene confidently holds 90 degrees for more than 50 years. Varieties of the PEX-pipe, have a "genetic memory", after the curvature restore the previous position without additional manipulation.

Mounting Features

Each customer cares that after installation the system does not leak. But pipes do not flow by themselves. Only with improper installation, if the technology is violated, or with a mechanical breakdown. Build quality is determined by the mind and ingenuity of a technician who loves his job. After all, to do “well, let it be so for now”, take the money and disappear from sight is just a scam.

Real pros are proud of their brainchildren, they ask to take a picture of the finished work for a personal portfolio. After all, this is the authority and reputation of the master.

In order to make the correct adjustment of the segments, it is necessary to use special couplings. The declared "genetic memory" will work if the hoses are connected using press technology with pressure fittings. One-piece reliable connection of segments is obtained.

Cons of cross-linked polyethylene

The first disadvantage is exposure to ultraviolet radiation.The sun's rays, both direct and oblique, destroy cross-linked polyethylene and all its advantages, so it is not used for outdoor installation.

The second is the lack of hoses with a diameter of more than 25 mm due to the very expensive chemical production.

Conclusion: XLPE pipes are ideal for heating systems in apartments and private houses. Definitely one of the best plastic pipes on the market.

Metal-plastic pipes

Metal-polymer products have taken the best of plastic and metal. The inner layer of the hose is cross-linked polyethylene, the middle layer is a reinforcing aluminum mesh, the outer layer is polyvinyl chloride - protects from ultraviolet radiation.

Teams of plumbers, having tried metal-plastic products in installation and operation, retain sincere affection for them. For 18 years of active work with this material in the Press technology, the craftsmen never had to blush.

Among the tales of plumbers, there is one that a metal-plastic professional recognizes with his eyes closed by the characteristic ringing sound that a twisted pipe bay has.

The product is heavy, but this is compensated by stability, which eliminates mechanical damage.

Holds pressure 16 bar and 95 degrees temperature. In housing and communal services, a diameter of 16-40 mm is used.

Antistatic, beautiful, silently let water through, easy to repair without special equipment.

How long will they serve

The shelf life of metal-plastic samples is 50 years. In order for everything to be in order, it is necessary to follow the installation with reliable press fittings. The weak point of these pipes is leaks at the joints.

Mounting Features

The pipe perfectly holds various manipulations performed with it: turns, flips, twists, snakes, vintage.At an object of any complexity, you can figure out how to make the necessary trick and fix it. If it is impossible to remove the damaged iron pipe, the metal-plastic one even allows you to stick yourself inside the old rusted, slightly larger diameter.

Minuses

The disadvantages include: high cost due to complex manufacturing technology and loss of strength with sharp fluctuations in operating temperature.

Conclusion: well suited for plumbing and heating in urban apartments and institutions with a constant temperature in the system. Not suitable for cottages and cottages with temporary residence.

It seems to have figured out which plastic pipe is better.